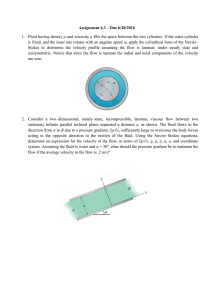

CONVECTION MODULE 3 BY: DR. TUSHAR CHOUDHARY DIMENSIONLESS NUMBERS AND THEIR PHYSICAL SIGNIFICANCE Reynolds number (Re) : It is defined as the ratio of the inertia force to the viscous force. • Reynolds number signifies the relative predominance of the inertia to the viscous forces occuring in the flow systems. • The higher the value of Re the greater will be the relative contribution of inertia effect. The smaller the value of Re, the greater will be the relative magnitude of the viscous stresses. • Reynolds number is taken as an important criterion of kinematic and dynamic similarities in forced convection heat transfer. Prandtl number (Pr) : It is the ratio of kinematic viscosity (V) to thermal diffusivity (a). • Kinematic viscosity indicates the impulse transport through molecular friction whereas • thermal diffusivity indicates the heat energy transport by conduction process. • Prandtl number provides a measure of the relative effectiveness of the momentum and energy transport by diffusion. • Prandtl number is a connecting link between the velocity field and temperature field, and its value strongly influences relative growth of velocity and thermal boundary layers. Nusselt number can be defined in several ways: (i) It is the ratio of heat flow rate by convection process under a unit temperature gradient to the heat flow rate by conduction process under a unit temperature gradient through a stationary thickness of L metres. Thus, (ii) It is the ratio of heat transfer rate, Q to the rate at which heat would be conducted within the fluid under a temperature gradient of 110/L. Thus, (iii) It is the ratio of characteristic length L to the thickness Ax of a stationary fluid layer conducting the heat at the same rate under the same temperature difference as in the case of convection process. Thus Stanton number (St) : It is the ratio of heat transfer coefficient to the flow of heat per unit temperature rise due to the velocity of the fluid. Thus, Stanton number may also be defined as the ratio of Nusselt number and the product of Reynolds number and Prandtl number. It is worth noting that Stanton number can be used only in correlating forced convection data (since the expression contains the velocity U). Peclet number (Pe) : It is the ratio of mass heat flow rate by convection to the flow rate by conduction under a unit temperature gradient and through a thickness L. The Peclet number can be written as It indicates that the Peclet number can be written as a function of Re and Pr also. Graetz number (G) : It is related only for the heat flow to the fluid flowing through circular pipe. It is defined as the ratio of heat capacity of fluid flowing through the pipe per unit length of the pipe to the conductivity of the pipe. where D and L are the diameter and length of the pipe respectively. This can be written in the other form as This shows that Graetz number is merely a product of Peclet number and a constant. Grashoff number is related with natural convection heat transfer. It is defined as the ratio of the product of inertia force and buoyancy force to the square of viscous force. Thus Grashoff number has a role in free convection similar to that played by Reynolds number in forced convection. Free convection is usually suppressed at sufficiently small Gr, begins at some critical value of Gr depending upon the arrangement and then becomes more and more effective with increasing Gr. BOUNDARY LAYER The layer adjacent to the boundary is known as boundary layer. Boundary layer is formed whenever there is relative motion between the boundary and the fluid. Since, , the fluid exerts a shear stress on the boundary and boundary exerts an equal and opposite force on fluid known as the shear resistance. According to boundary layer theory the extensive fluid medium around bodies moving in fluids can be divided into following two regions (i) A thin layer adjoining the boundary called the boundary layer where the viscous shear takes place. (ii) A region outside the boundary layer where the flow behaviour is quite like that of an ideal fluid and the potential flow theory is applicable The characteristics of a boundary layer may be summarised as follows : (viii) If Ux/v < 5 x 10^5 ... boundary layer is laminar ( velocity distribution is parabolic). If Ux/v > 5 x 10^5 .. . boundary layer is turbulent on that portion ( velocity distribution follows Log law or a power law). (ix)Critical value of Ux/v at which boundary layer changes from laminar to turbulent depends on : • turbulence in ambient flow, • surface roughness, • pressure gradient, • plate curvature, and • temperature difference between fluid and boundary. (x) Though the velocity distribution would be a parabolic curve in the laminar sub-layer zone, but in view of the very small thickness we can reasonably assume that velocity distribution is linear and so the velocity gradient can be considered constant LAMINAR FLOW OVER FLAT PLATES AND WALLS LAMINAR FLOW OVER FLAT PLATES AND WALLS LAMINAR FLOW OVER FLAT PLATES AND WALLS Air at a temperature of 10°C flows at a velocity of 6.5 m/s across a flat plate maintained at a temperature of 590°C. Calculate the amount of heat transferred per metre width from both sides of the plate over a distance of 350 mm from the leading edge. The following relation holds good in the case of large temperature difference between the plate and the fluid : where Ts and T∞ = are the absolute temperatures of the plate surface and free stream respectively and all fluid properties are evaluated at the mean film temperature. Solution. Given: T∞ = 15 + 273 = 288 K, Ts= 605 + 273 = 878 K, x = 350 mm= 0.35 m. The thermo-physical properties, at 300°C are p = O.682kg/m3; μ= 32.46 x 10^-6Ns/m2; cp= 0.997kJ/kgK Pr= 0.673 k = 0.04803 W/mK; LAMINAR FLOW OVER FLAT PLATES AND WALLS = Nux The average heat transfer coefficient is given by Heat transfer from both sides of the plate, per metre width, LAMINAR FLOW INSIDE TUBES LAMINAR FLOW INSIDE TUBES This equation is valid (i) for constant wall temperature and fully developed flow, (ii) when properties are evaluated at the bulk temperature, (iii) tube length is much greater than diameter, (iv) when Re and Nu are calculated on the basis of pipe diameter as the length parameter. (v) when 0.5 <Pr< 100. TURBULENT FLOW OVER FLAT PLATE TURBULENT FLOW OVER FLAT PLATE The following correlations for fully developed turbulent flow in circular tubes have been proposed: 1. Mc Adams has proposed the following general correlation on the basis of Nu= ϕ (Re, Pr) for heating and cooling of all fluids with some limitations as given below : 2. Colburn suggested the following correlation PROBLEMS A surface condenser consists of two hundred thin walled circular tubes (each tube is 22.5 mm in diameter and 5 m long) arranged in parallel, through which water flows. If the mass flow rate of water through the tube bank is 160 kg/sand its inlet and outlet temperatures are known to be 21°C and 29°C respectively, calculate the average heat transfer coefficient associated with flow of water. Solution. Given: D = 22.5 mm= 0.0225 m, L = 5 m, ti= 21 °C, t0 = 29°C. ഥ Average heat transfer coefficient, 𝒉: The mean bulk temperature, The thermo-physical properties of water at 25°C are : Page 30 p = 996.65 kg/m3; μ = 0.862 x 10-3 kg/ms; k = 0.6079 W/m°C; cP = 4.178 kJ/kg°C =52518.26 PROBLEMS 7562.27 W/m2°C PROBLEMS 0.06 kg/s of hot air flows through an uninsulated sheet metal duct of 180 mm diameter. The air enters the duct at a temperature of ll0°C and after a distance of 4.5 m gets cooled to a temperature of 70°C. If the heat transfer coefficient between the outer surface of the duct and cold ambient air at 5°C is 6.5 W/m2°C, calculate the following : (i) The heat loss from the duct over its 4.5 m length, (ii) The heat flux and the duct surface temperature at a length of 4.5 m. Solution. Given: m = 0.06 kg/s, D = 180 mm= 0.18 m, h0 = 6.5 W/m2°C The mean bulk temperature The thermo-physical properties of air at 90°C are Reynolds number, =19169.5 As Re>> 2500 the flow is turbulent. (i) The heat loss from the duct over its 4.5 m length, Q : =2421.6W (ii) The heat flux and duct surface temperature at a length of 4.5 m : The heat flux at x = 4.5 m is calculated from the relation : = 54.22 where, h0 = 6.5W/m2°C hi (inside convection coefficient) is calculated from the correlation = 9.42 W/m°C Hence, heat flux = 250 W/m2 t = 43.46°C