T. Subbian

Graduate Student.

D. R. Flugrad, Jr.

Four-Bar Path Generation

Synthesis by a Continuation

Method

Assistant Professor.

Mechanical Engineering Department,

Iowa State University,

Ames, IA 50011

A different approach for the synthesis of four-bar planar path generating mechanisms

is presented. A continuation method is used to solve the system of nonlinear equations

derived for the path generating problem. A brief description of the method is

providedfollowed by the development of equations representing thefour-bar linkage.

The implementation of the method for five position path generation is discussed in

detail and the solutions for two examples are presented.

Introduction

Synthesis of four-bar path generating mechanisms has been procedure that theoretically assures convergence without any

accomplished in the past by both graphical and analytical meth- initial solution estimates and that also produces the complete

ods. Lindholm (1969) applied the point position reduction solution set for the given system of nonlinear equations, protechnique to synthesize five and six position path generation vided they are cast in polynomial form. It is used here as a

linkages. Suh and Radcliffe (1983) used Newton's method in tool to solve the five position synthesis problem. The procedure

arriving at a solution. An analytical approach developed by can effectively be extended to six or more precision points

Sandor and Erdman (1984) successfully reduces the system of without difficulty. However, the computational expense inequations associated with the five position path generation creases significantly.

problem with prescribed timing to a quartic polynomial expresSimilar methods were implemented by Freudenstein and Roth

sion. Solutions for the quartic equation can then be determined (1963) for synthesis of geared five bar mechanisms and by Tsai

numerically.

and Morgan (1985) for the analysis of five and six degree of

Closed form solutions are effective up to four precision freedom manipulators. Roth and Freudenstein (1963) made

points and can be used as a tool to solve five specified points, use of a variation of the method discussed here for the synthesis

but for six points and beyond the nonlinear equations are of nine position, path generating, geared five-bar and fourdifficult to handle. Graphical methods have been applied for bar mechanisms. Nine points on the coupler path of an arsix precision points but with only limited success. Furthermore, bitrary mechanism were chosen as the starting points. A numthe solution set obtained by graphical methods is not complete. ber of subproblems were solved to move from these points

This leads to the application of numerical methods that can toward the nine prescribed positions, thereby developing the

theoretically be used to solve for a maximum of nine prescribed desired mechanism. The method to be used here starts with a

precision points. However, the practical limit has been five or simple set of equations involving the link lengths and moves

six specified positions. On the other hand, if exact precision toward the set of equations for the five prescribed precision

is not required, least square methods (Sarkisyan et al., 1973) points. In doing so, it moves from the starting solution of a

and selective precision synthesis (Kramer and Sandor, 1975; simple mathematical system to the desired result. The method

Kramer, 1979) have been used to minimize the deviation from is set up to determine all possible solutions for the system of

equations at hand while Roth and Freudenstein (1963) looked

a path described by more than nine points.

Numerical methods presently used for precision point syn- at one solution only.

thesis of path generating mechanisms exhibit two major shortThe continuation method and its application to the synthesis

comings:

of path generating mechanisms is described in detail in the

• Convergence depends on reasonably good approximations following sections. Nonlinear loop closure equations are developed and modified for efficient implementation. The nufor the solutions.

9

Current numerical methods converge to a single solution merical method is then applied to determine the solutions for

dependent on the initial estimates, and thus do not yield •two five position synthesis problems.

all designs that satisfy the constraints.

The continuation method (Morgan, 1987) is a mathematical

Continuation Method

Continuation methods constitute a family of mathematical

procedures used to solve systems of nonlinear equations. These

methods are particularly useful for dealing with sets of

Contributed by the Design Automation Committee for publication in the

JOURNAL OF MECHANICAL DESIGN. Manuscript received December 1989.

polynomial equations. To implement the approach, one starts

Journal of Mechanical Design

MARCH 1991, Vol. 113/63

Copyright © 1991 by ASME

Downloaded From: http://mechanicaldesign.asmedigitalcollection.asme.org/ on 01/20/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Similarly, for vectors Z 3 and Z 4 ,

Ziie'^J - 1) + Z 4 (e^ - 1) = 5j

(6)

Where Zk for k = 1, 2, 3, 4 are complex link lengths that can

be represented using real and imaginary terms in the form Zk

= Zkx + iZky. Upon substitution for Zk in terms of real and

imaginary quantities and expansion of the exponentials using

Euler's equation, the expressions may be written as

(Z u .+ iZly)(cos4>j - 1 + /sin0,)

• + (Z to + iZ2y)(cos7j - 1 + /sin?,) = 8jx + i8jy

(7)

and

(Zix + iZ3y)(cos\l/j - 1 + /sim/'y)

with a system of equations for which the solutions are known

and then marches along a path toward the solutions of the

original system. For simplicity, the procedure for a system of

two equations in two unknowns is described here.

Consider two polynomial equations given by,

F\(zuz2)

=0

(!)

F2{zu z2) = 0

To implement the method a simple system of two equations

in two unknowns is first considered (Morgan, 1987),

Gi = C 1 1 z 1 1 -C 1 2 = 0

(2)

2

G2 = C2lz2 -C22 = 0

The terms Cn, Cl2, C2U and C22 are randomly chosen complex

constants, and dl and d2 are the degree of functions Fx and

F2, respectively. The necessary homotopy functions are then

obtained by combining the two systems of equations (1) and

(2).

Hl(zl,z2,t)

= tFl + (\-t)Gl

=0

(3)

H2(zi,z2, t) = tF2 + {\-t)G2 = Q

Here t is called the homotopy parameter. When t = 0, the

homotopy functions reduce to the simple set of equations and

when / = 1, they represent the original system. Therefore, by

increasing t from zero to one, and by solving a number of

intermediate subproblems along the way, the solutions for the

original system are found. There are a variety of ways to move

from a t value of zero to one. In the present approach, basic

differential equations (BDE's) (Garcia and Zangwill, 1981) are

formed, and ordinary differential equations involving the variables with respect to t are determined. These differential equations are integrated numerically to determine the solution for

the given system of equations. The solution is then refined

using Newton's method. The procedure is repeated using all

the various combinations of solutions for the simple assumed

equations as starting points.

+ (Z4x + /Z4>,)(cosYy- - 1 + /sinYy) = 5jx + i8jy

(8)

To transform the equations into polynomial form, cos^y and

sin^ are treated as two independent variables, C4>j and Sfy,

respectively. In order for this to work, of course, a constraint

equation representing the relationship between sine and cosine

must be introduced. This is done for the angles ipj and T,- as

well. Upon substitution of these values into equation (7) and

separation into real and imaginary components, the following

expressions result,

Z\xC<l>j -Zlx — ZlyS(j)j + Z^CJj — Z-te — Z2yS7j = 8jx

ZlxS4>j + ZiyC<t>j -Zly

Z^J

+ Z^J

= 8j+Zi + Z2

(4)

Z 1 ( e ' ^ - l ) + Z 2 ( e ' ^ - l ) = 5y

(5)

or

+ Z2yCYj - Z2y = 8jy

zlxS\i,j+z3yapj - ziy+z4xsyj+z^cij

- z4>,= sjy

(1 o)

The constraint equations mentioned above are represented by,

Gj>] + S4>j=l

(11)

cy] + syj=i

(12)

aij+stf=i

(13)

Multiplication of the first equation (9) by Zly and the second

by Zix followed by subtraction of the two eliminates the C<t>j

terms,

(Z\x + Z\y)S4>j + Z^Z^Slj

- Z^Z^CJj

+ ZlxZ2yCjj + ZiyZ2yS7j

— Z[xZ2y + ZlyZ2x = Zlx8jy — Zly8jX

S<t>j = (Zlx8jy — Zly8jx — Z\xZ2xS7j + Z^Z^Clj

- zlyz2ysyj+zlxz27

(14)

— ZlxZ2yCYj

- Z 1 ^,Z 2A .)/(Z 1X +z ly )

(i 5)

The equation for C<$>j is obtained from equation (9) by following a similar procedure to eliminate S<j>j,

C4>j = (Zly8jy + Zlx8Jx + (Z\x + Z\y) - Z^Z^Slj

-

Z^Z^CJJ

— Z\yz2ycyj+zlxz2ysjj+zl7z2>,+Z1XZ2A.)/(Z1X+zly)

(16)

By substituting for S<j>j and C</>; in equation (11) and by rearranging the results we get,

2(.ZixZ2y - Z ^ Z ^ + Z2y8jx -

Z^j^Syj

~ 2(%2x + ^2y + Z ^ Z ^ + Z l7 Z 2y + Z^jx + Z2y8jy)Cyj

~ ^Ziy. — Z£j2y — LZ^Z-^

— LZ\yZ2y — 2Z2xoyx

-2Z2y8jy-2Zly8Jy-2Zlx8jx-8Jx-8jy

(17)

To simplify the relationship further, the following quantities

are defined,

A\j = Z lxZ2y - Z xyZ^ + Z2y8jx -

Z^jy

By = Z2x + Z2y + Z u Z 2jr + Z ^ Z ^ + Z ^ j . + Z2y8jy

D,j = 2Zlx8jx + 2Zly8jy + 8% + 8%

6 4 / V o l . 113, MARCH 1991

(9)

^ixGwj — Zix — Z}yS\//j + ZAxClj — Z 4x — Z4ySyj = 8jx

=

Development of Equations

A four-bar mechanism in two finitely separated positions

can be represented by the vectors shown in Fig. 1. Two loop

closure equations are written, one for each dyad (vector pair).

For vectors Zx and Z 2 we can establish a loop as follows,

+ Z^Jj

Similarly for equation (8) we obtain

(18)

Then equation (17) can be written as,

Transactions of the ASME

Downloaded From: http://mechanicaldesign.asmedigitalcollection.asme.org/ on 01/20/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

2Ay SVj-Wtj Clj= - 2 5 „ - A y

(19)

A parallel development is pursued using equation (10) to eliminate i/j. This yields

2AySyJ-2ByCYJ=

-2By-D2j

(20)

The degree of these equations should be at least equal to the

degree of the original system. The equations considered for

the five position synthesis problem are,

G{ = C u Z lx — C12 = 0

G2 = C2iZ[y — C22 = 0

where,

Ay = Z3xZ4y — Z}yZ4x + Z4y5jX — Z4x6jy

G3 - C3(L3x — C32 = 0

By = Z4x + Z4y + Z3^Z4x + ZfyZfy + Z4xojx + Z4y5jy

Dv = 2Z3x5JX + 2Z3y5jy + 5% + 5]y

G4 = C 4 1 Z ^ - C 4 2 = 0

where the Cyi's'and Cy2's are randomly chosen complex constants. Each equation results in four complex solutions determined as follows,

Equations (19) and (20) are then solved for 57, and CV),

SYj = (By Dy-By

Dy)/(2(Ay

CYj=l+ (Ay Dy-Ay

By-Ay

Dy)/(2(Ay

By) )

By-Ay

By) )

(22)

Substitution for ST) and C7,- in equation (12) produces the final

function, a polynomial in the complex variables Z,, Z 2 , Z 3 ,

and Z 4 ,

Fj= {By Dy-By

Dy)2 + A(Ay By-Ay

X (Ay Dy-Ay

By)

Dy) + (Ay Dy-Ay

Dy)2 = 0

(23)

In the expression above j represents the individual displacements from an initial position. Therefore, a five position path

synthesis problem yields four equations. Since four complex

Z variables are involved, the maximum number of positions

is limited to nine. In the sections to follow equation (23) is

used in conjunction with the continuation method to solve five

position synthesis problems.

The Five Position Synthesis Problem

Having developed the equations for the path generation

problem, we need to implement the continuation method to

solve them. For a five position synthesis problem a set of four

complex polynomial equations is required. Since the number

of variables is greater than the number of equations, we have

the freedom of selecting values for four of the eight complex

components. Here, the coupler link vectors, Z 2 and Z 4 , are

specified to be, e + if and g + in, respectively, with particular

numerical values assigned to e,f, g, and h. The four equations

to be solved then reduce to the following form,

Fj= (By Dy-By

Dy)2+4(Ay

X (Ay Dy-Ay

By - Ay By)

Dy) + (Ay Dy-Ay

Dy)2 = 0

(24)

where j = 1, 2, 3, 4 and

Ay=fZix-

eZly +fbjx- ebjy

By = eZlx + / Z „ + e2+f2 + e6jx +/S y >

D[j = 2bjXZU + 2bjyZXy + 8jX + 8jy

Ay = flZ3x - gZ3y + hbjX - gdjy

By =gZix + hZiy + g2 + h2 + g8jx + hbjy

Dy = 28jXZ3x + 2djyZ3y + djX + 8jy

Upon substitution and simplification, it is apparent that the

degree of each of the equations is 4.

If we rule out the possibility of an infinite number of finite

solutions as well as an infinite number of solutions at infinity,

Bezout's theorem guarantees that (Morgan, 1987) the total

number of finite solutions and solutions at infinity should add

up to 256 counting multiplicities. This number is equal to the

product of the degrees of each of the individual equations; in

this case 44 = 256. Therefore, this system of equations will

produce a maximum of 256 complex solutions, real solutions

and/or solutions at infinity.

To implement the continuation method, it is necessary to

start with a set of polynomial equations (one for each of the

four unknowns Zlx, Zly, Z3x, and Z3y) which are easy to solve.

Journal of Mechanical Design

(25)

(21)

Zix = r\M[cos(2irk/4 + a,/4) + /sin(27rA:/4 + a,/4)]

(26)

where (rlt o^) are polar coordinates of the ratio Cl2/Cn and

k = 0, 1, 2, 3. Similarly Zly, Z3x, and Z3y can be determined.

The solutions thus obtained are grouped to form 256 combinations satisfying the simplified system of equations. These

provide 256 starting points for the continuation procedure.

Homotopy functions are defined next using the original

equations, the simplified equations and the homotopy parameter t as follows,

Hj = tFj+(l-t)Gj

= 0, j= 1,2,3,4

(27)

When ? = 0 the homotopy functions reduce to the simplified

set of equations, and when t= 1 they represent the equations

to be solved to obtain a four-bar linkage passing through the

five prescribed positions. Hence, on varying the parameter t

from zero to one we move away from the simple system to the

original system of equations. To do this we need to follow the

paths of the unknowns as we increment the t variable.

For path following, we determine the first order derivatives

of the variables with respect to / using the BDE's discussed

earlier (for example dZlx/df). Knowing the derivatives we can

integrate these first order differential equations with solutions

of the simplified system as initial values to obtain the desired

four-bar mechanism.

In order to determine the derivatives we need to evaluate

the extended Jacobian matrix of the homotopy function set as

indicated below,

3Zix

dHi

dZly

dHt

3Z3x

dHi

dZ3y

dHx

dt

dH2

dZu

dH2 dH2

BZly dZix

dH2

dZ3y

dH2

dt

dH3

3Zlx

dH3

8Zly

dH3

dZ3x

dH3

dZ3y

dH3

dt

dHA

dZu

dH4

dZly

dH4

dZ3x

dH4

dZ3y

dH4

dt

Use of this Jacobian matrix allows the ordinary differential

equations to be written as,

dZiX/dt, dZiy/dt,

dZ3x/dt

and dZ3y/dt

= ((-iy'+1

det(DHu]))/Den for./ = 1,2, 3,4, respectively. The det(DHm)

represents the determinant of the Jacobian matrix, DH, with

the y'th column deleted, and Den is the determinant with the

fifth column deleted.

Each of the solutions for the simplified system is a starting

point for a path, or an initial condition for the integration of

the differential equations. As the assumed system has 256

combinations of solutions, there are 256 paths and they proceed

to all of the solutions of the original system with multiple paths

converging toward repeated solutions. If the original system

has solutions at infinity, paths will diverge toward those solutions.

Thus by integrating the first order differential equations

MARCH 1991, Vol. 1 1 3 / 6 5

Downloaded From: http://mechanicaldesign.asmedigitalcollection.asme.org/ on 01/20/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Table 1

Prescribed precision points for example 1

Precision

Point

1

2

3

4

5

X

Y

0

0

-0.4535 -0.1730

-0.8385 -0.5228

-1.0840 -0.9358

-1.1794 -1.2957

Table 2 Continuation method solutions satisfying the prescribed conditions for example 1

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Z\j.

0.0009

-5.1960

-1.1852

1.9835

0.2998

-1.9668

-1.8773

-2.0930

-0.9050

-0.8583

0.6044

0.4295

1.9769

-2.2828

-2.5162

0.1328

0.1401

1.0298

0.0467

-0.0567

-0.0121

0.3723

-0.5502

0.7951

1.3553

Z\y

Zix

0.9997

-0.6386

1.8622

0.4997

-0.1413

1.6996

5.9712 -21.9874

1.6070

-1.8717

-0.8894

2.0674

-0.9879

2.0039

-0.7404

2.1363

-0.2183

2.2164

0.2599

2.5453

-0.8544

-1.4799

1.4901

1.1392

-4.9389

2.1435

-0.5300

2.1898

-0.3240

2.2195

-2.5004

2.1082

0.8555

0.8157

-1.0562

3.5144

0.9137

0.9355

1.0265

1.0408

0.9483

0.9808

0.8183

0.6657

-1.5196

2.0264

-0.5396

-8.6096

-0.7603

4.3469

Z3y

1.8974

0.4437

0.8254

23.4323

3.0586

1.4717

1.6386

1.3139

0.7913

2.5985

4.8112

-0.1488

0.0899

1.1878

1.1085

0.0314

-0.2319

-3.7175

-0.2420

-0.2781

-0.2618

-0.2566

0.0965

12.1160

-4.6379

COMMENTS

Grashof,crank rocker

Grashof.crank rocker

Grashof,double crank

Grashof, double rocker

Non Grashof,double rocker

Non Grashof,double rocker

Non Grashof,double rocker

Non Grashof,double rocker

Grashof

Grashof

Grashof

Grashof

Grashof

Grashof

Grashof

Non Grashof

Non Grashof

Non Grashof

Non Grashof

Non Grashof

Non Grashof

Non Grashof

Non Grashof

Non Grashof

Non Grashof

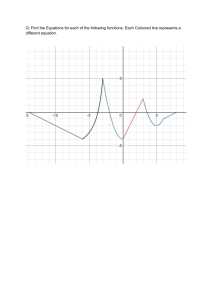

Fig. 4 Mechanism 3 in its first position with the coupler curve

(example 1)

Fig. 2 Mechanism 1 in its first position with the coupler curve

(example 1)

obtained, we can determine all the solutions (complex, real,

and those at infinity) for the original system of equations.

Among these, the real solutions turn out to be the only useful

ones.

Fig. 5 Mechanism 4 in its first position with the coupler curve

(example 1)

uation method. To synthesize the mechanism the links Z2 and

Z4 were chosen to be 1.1344 + zT.3975 and -1.7287 + /'0.5016,

respectively, and the complex link vectors Zx and Z3 were

Example 1

computed. A total of 256 real, complex and solutions at infinity

A four-bar mechanism was designed to pass through the were obtained from the 256 starting points. Of these only

five precision points listed in Table 1 by applying the contin- twenty-five solutions which are listed in Table 2 were real.

Examples

66 / V o l . 113, MARCH 1991

Transactions of the ASME

Downloaded From: http://mechanicaldesign.asmedigitalcollection.asme.org/ on 01/20/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Fig. 6 Mechanism 5 in its first position with the coupler curve

(example 1)

Fig. 8 Mechanism 7 in its first position with the coupler curve

(example 1)

Fig. 7 Mechanism 6 in its first position with the coupler curve

(example 1)

Thirty-three pairs of complex conjugate solutions were obFig. 9 Mechanism 8 in its first position with the coupler curve

tained, and the rest either diverged to infinity or resulted in

(example 1)

very large link lengths that caused the procedure to be aborted.

Of the twenty-five real solutions found, the first five did not

exhibit any branch or order defects and so these are the only from the point where it is close to position 1, it will pass through

useful solutions. Three more solutions came close to satisfying 2, 3, 4, 5 in the specified order. It should be noted, however,

the prescribed conditions, and they are discussed here as well. that when the coupler is at this new starting point the configOf the eight useful solutions only the first four satisfy Grash- uration is different from that shown in the figures. That is,

of's criteria. All eight are shown in Figs. 2 through 9. Among the configuration is not consistent with the arbitrarily specified

them, the first two solutions resulted in crank rocker mech- values for Z and Z . Even so .these three linkages might still

4

anisms and the third was a double crank mechanism. Mech- be usable to 2solve the

path generation problem.

anism 4, a double rocker mechanism, has very large link lengths.

The above designs then provide us with eight four-bar mechHowever there are situations in which such dimensions might anisms for the task. Figures 2 through 9 give the mechanisms

be feasible, and so it is listed here as a valid solution. Solution in their initial position with the coupler curve superimposed.

5 turned out to be a double rocker mechanism as well.

More mechanisms can be obtained, giving the designer more

Mechanisms 6, 7, and 8 at the outset looked like multiple options, by changing the link vectors Z and Z . For each of

2

4

solutions (repeated solutions) but on further analysis were iden- the link vectors chosen the procedure is carried

out for the 256

tified as being distinct and geometrically isolated. These so- starting points.

lutions are discussed here despite the fact that they do not

quite satisfy the specified order for the precision points. From

Example 2

Figs. 7, 8, and 9 it is clear that the coupler passes through the

specified points in the order 1, 5, 4, 3, 2 and then comes close

The procedure was also applied to design a mechanism passto passing through 1 again. If the device is driven backwards ing through five points lying on a straight line (Table 3). The

Journal of Mechanical Design

MARCH 1991, Vol. 113/67

Downloaded From: http://mechanicaldesign.asmedigitalcollection.asme.org/ on 01/20/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Table 3

Prescribed precision points for example 2

Precision

Point

1

2

3

X

0

-3

-6

Y

0

0

0

4

-9

0

5

-12

0

Table 4 Continuation method solutions satisfying the prescribed conditions for example 2

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

2i,

21.725

37.915

21.806

39.436

23.716

-44.669

35.249

42.292

17.125

11.872

-0.016

-22.630

-3.394

-0.184

-27.774

-9.345

1.433

12.722

4.627

0.148

Z\y

-29.334

-53.216

-58.840

-55.532

-64.374

50.802

-49.166

-59.879

-21.851

-12.500

4.074

23.825

3.400

4.108

30.043

-10.556

3.784

-15.122

-9.862

6.971

z„

-17.410

-51.574

2.966

-49.675

2.479

55.339

-53.763

-41.478

-12.011

-8.037

2.128

10.239

-1.106

3.298

16.779

-2.861

1.503

-7.535

2.871

1.863

Zzy

-26.083

-34.365

-17.521

-32.166

-17.364

-4.733

-38.150

-25.550

-24.651

-25.530

-9.682

-16.170

-9.701

-13.797

-14.634

-32.327

-10.734

-23.276

-18.844

-14.603

COMMENTS

Grashof,double rocker

Grashof,doubIe rocker

Grashof,double rocker

Grashof, double rocker

Grashof,double rocker

Grashof,double rocker

Grashof,double rocker

Grashof,double rocker

Non Grashof,double rocker

Non Grashof,double rocker

Non Grashof,double rocker

Non Grashof,double rocker

Non Grashof,double rocker

Non Grashof,double rocker

Non Grashof,double rocker

Non Grashof,double rocker

Non Grashof,double rocker

Non Grashof,double rocker

Non Grashof,double rocker

Non Grashof,double rocker

Fig. 11 Mechanism 9 in its first position with the coupler curve (example 2)

Fig. 10 Mechanism 1 in its first position with the coupler curve (example 2)

links Z2 and Z4 were chosen to be 9.7226 + il. 1722 and 2.572,3

+ (17.5314, respectively. Twenty usable solutions were obtained without any order or branch defects. These are listed

in Table 4. Of these twenty, eight were Grashof double rocker

mechanisms, and the rest were non-Grashof double rocker

linkages. No usable crank rocker solutions were obtained. One

of the Grashof double rocker mechanisms is shown in Fig. 10

with its coupler path and precision points. Figure 11 depicts

a non-Grashof double rocker mechanism. A couple of the

6 8 / V o l . 113, MARCH 1991

Fig. 12 Mechanism 19 in its first position with the coupler curve (example 2)

Transactions of the AS ME

Downloaded From: http://mechanicaldesign.asmedigitalcollection.asme.org/ on 01/20/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

solutions produced quite unexpected results. One of them is

displayed in Fig. 12 which shows the coupler point passing

through all five precision points in the proper order, but a full

loop is executed between the third and fourth points. For that

reason this particular design might not be acceptable.

Computations for the above examples were carried out in a

VAX/VMS (11/785) environment. The average CPU time for

each starting point was 26.65 seconds for the first example and

46.56 seconds for the second. When the solution diverged to

infinity the CPU time was 60 seconds on average for example

1 and 100 seconds for example 2. For converging solution paths

the CPU times were considerably less. The values were approximately 20 and 30 seconds for the first and second problems respectively.

Conclusions

The continuation method, as indicated by the above examples, can be used to systematically solve a five position path

generation problem. Newton's method could be applied, with

a random number generator to pick the initial guesses, but we

would not be assured of a complete solution set. Thus the

continuation method is more reliable than the mathematical

procedures currently available.

When a set of polynomial equations is solved using the

continuation method, we should obtain real solutions, complex

solutions, and solutions at infinity. As mentioned earlier, the

real solutions are the only useful ones for mechanical design

applications. The solutions at infinity and complex solutions

are of no use. If the procedure is working properly, the complex

solutions should appear with their conjugates. This was observed in solving the two example problems. Further work is

planned to perfect the technique for path generation linkage

Journal of Mechanical Design

synthesis. Extension of the continuation method to a wide

variety of other synthesis problems is also a very promising

possibility.

References

Freudenstein, F., and Roth, B., 1963, "Numerical Solution of Systems of

Nonlinear Equations," Journal of the Association of Computing Machinery,

Vol. 10, pp. 550-556.

Garcia, C. B., and Zangwill, W. I., 1981, Pathways to Solutions, Fixed Points,

and Equilibria, Prentice-Hall, Englewood Cliffs, New Jersey.

Kramer, S. N., 1975, "Selective Precision Synthesis of the Four-Bar Motion

Generator with Prescribed Input Timing," ASME JOURNAL OF MECHANICAL

DESIGN, Vol. 101, pp. 614-618.

Kramer, S. N., and Sandor, G. N., 1975, "Selective Precision Synthesis - A

General Method of Optimization for Planar Mechanisms," ASME Journal of

Engineering for Industry, pp. 689-701.

Lindholm, J. C , 1969, " A Survey of the Graphical Techniques in Designing

for Specific Input-Output Relationships of a Four-Bar Mechanism," Proceedings of the First Applied Mechanisms Conference, Oklahoma State University,

Stillwater, Oklahoma, pp. 35-1-35-6.

Morgan, A., 1987, Solving Polynomial Systems using Continuation for Engineering and Scientific Problems, Prentice-Hall, Inc., Englewood Cliffs, New

Jersey.

Morgan, A., 1981, " A Method for Computing all Solutions to Systems of

Polynomial Equations," GM Research Publication, GMR 3651.

Roth, B., and Freudenstein, F., 1963, "Synthesis of Path-Generating Mechanisms by Numerical Methods," ASME Journal of Engineering for Industry,

pp. 298-306.

Sandor, G. N., and Erdman, A. E., 1984, Advanced Mechanism Design:

Analysis and Synthesis, Prentice-Hall, Englewood Cliffs, New Jersey.

Sarkisyan, Y. L., Gupta, K. C , and Roth, B., 1973, "Kinematic Geometry

Associated with the Least-Square Approximation of a Given Motion," ASME

Journal of Engineering for Industry, Vol. 95, No. 2, pp. 503-510.

Suh, C. H., and Radcliffe, C. W., 1983, Kinematics and Mechanisms Design,

Robert E. Krieger Publishing Company, Malabar, Florida.

Tsai, L. W., and Morgan, A. P., 1985, "Solving the Kinematics of the Most

General Six- and Five-Degree-of-Freedom Manipulators by Continuation Methods,"

ASME JOURNAL OF MECHANISMS, TRANSMISSIONS, AND AUTOMATION IN

DESIGN, Vol. 107, pp. 189-200.

MARCH 1991, Vol. 113/69

Downloaded From: http://mechanicaldesign.asmedigitalcollection.asme.org/ on 01/20/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use