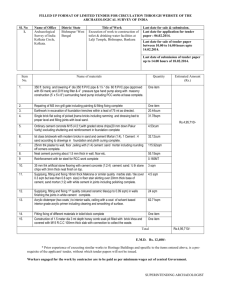

PWD SCHEDULE OF RATES 2018 FOR CIVIL WORKS FIFTEENTH EDITION PUBLIC WORKS DEPARTMENT GOVERNMENT OF THE PEOPLE’S REPUBLIC OF BANGLADESH EFFECTIVE FROM 01 MAY 2018 © Public Works Department Published by: Public Works Department Purta Bhaban, Segun Bagicha Dhaka-1000. Fifteenth Edition 01 May 2018 Price: Tk. 5000.00 Written suggestions on PWD Schedule of Rates 2018 for Civil Works may please be addressed to Chief Engineer Public Works Department Purta Bhaban, Segun Bagicha Dhaka- 1000 Fax: +88-02-9562913 Email: ce@pwd.gov.bd AUTHENTICATION The Fifteenth Edition of PWD Schedule of Rates 2018 for Civil Works that has been recommended by the committee formed vide memo. no. 5 sh-12/14-1551, dated 14-09-2017 is hereby authenticated and endorsed by the undersigned for official use in Public Works Department (PWD), Bangladesh with effect from 01 May 2018. Mohammad Rafiqul Islam Chief Engineer Public Works Department FOREWORD Public Works Department (PWD) under Ministry of Housing and Public Works is pleased to publish the PWD Schedule of Rates 2018 for Civil Works. With the advent of modern construction technologies and emergence of new construction materials, the diversity and complexity of construction of buildings have increased manifold. Bangladesh is now holding the status of developing country. Timely completion of construction projects is utmost important to hold that milestone and to accelerate achieving further goal, hope and aspiration of the nation. Unlike past, construction of high-rise buildings has become a necessity for optimum use of scarce land in a very populous country like Bangladesh. Building services and environmental issues are getting importance along the passage of time. As per the direction of the government, projects are now being planned keeping provisions for onsite waste management system. Use of environment friendly building materials are also being encouraged by the government. These have made a paradigm shift in the nature of construction of buildings in public sector. Moreover, price of existing building materials also changed over time. These called for a revision of the existing PWD Schedule of Rates. The current edition has been substantially enhanced to keep it aligned with the modern construction practices and current market price of construction materials. Many new items pertaining to civil works have been included. Efforts have been made to incorporate as many items as possible which are being used in the construction sector of the country. However, due to high diversity in type and class of construction materials available in the market, only the most commonly used materials listed in BSTI approved brands have been incorporated with their average market rates. Some amendments of the earlier version of PWD SoR have also been made in this edition. Rates of all the items of work prescribed in this PWD Schedule of Rates 2018 for Civil Works should be read and understood in conjunction with the document Analysis of PWD Schedule of Rates 2018 for Civil Works. Rates are based on study of price of various input such as material, labour, machine etc. of Dhaka, other metropolitan cities and district towns collected during the period of September 2017 to April 2018. These rates have been used in analyzing and developing built-up item rates. This document can be used as a guiding tool for rate analysis for different item for which built-up item rates could not be included. Useful information for such analysis have been included in the document. Preparation of such document within a short span of time is a daunting task. In spite of every effort to make this document flawless, there might have inadvertent errors in various parts of the document. Notifying any such mistakes by the users would be highly appreciated. Moreover, PWD welcomes comments, suggestions and feedback from the users to improve this document in future. Manufacturers and dealers are also welcome to send details of materials approved by BSTI to be incorporated in the next version. The department expresses its gratitude to all who contributed directly or indirectly in preparing and publishing this new edition. Purta Bhaban Segun Bagicha, Dhaka Mohammad Rafiqul Islam Chief Engineer Public Works Department PREFACE 1.0 PWD Schedule of Rates 2018 for Civil Works is the revised edition of PWD Schedule of Rates 2014 for Civil Works. 2.0 This PWD Schedule of Rates 2018 for Civil Works incorporates most of the items with all corrections and will replace PWD Schedule of Rates 2014 for Civil Works. The nomenclature of many items has been improved by making it more generic and comprehensive. Items of PWD Schedule of Rates 2014 for Civil Works, which have become obsolete over a period of time or are not in use, have been dropped. 3.0 Items of some new and imported materials are included for better quality works with the demand of time. 4.0 This PWD Schedule of Rates 2018 for Civil Works is based on the study of current market rates of materials at Dhaka and other metropolitan cities, district towns collected during the period of September 2017 to April 2018 and labour rates are the current market rates. 5.0 The following are the salient features of PWD Schedule of Rates 2018 for Civil Works. 6.0 5.1 The description of items of works of this PWD Schedule of Rates 2018 for Civil Works bears the adherence to PWD Book of Specification and Bangladesh National Building Code (BNBC). 5.2 Basic rates of relevant materials are provided for convenience of the user. 5.3 Generally, the basic rates of materials, incorporated in the schedule, are pertaining to materials conforming to Bangladesh Standards (BDS) and other international standards available in the market. A lot of effort has gone into the preparation of this PWD Schedule of Rates 2018 for Civil Works. I convey my deep appreciation and sincere thanks to all the members and their associates involved in producing this PWD Schedule of Rates 2018 for Civil Works. Purta Bhaban Segun Bagicha, Dhaka Md. Aminul Islam Khan Convenor PWD Schedule of Rates Committee & Additional Chief Engineer (P&SP) Public Works Department PWD SCHEDULE OF RATES PREPARATION COMMITTEE Formed vide memo. no. 5 sh-12/14-1551, dated 14-09-2017 Sl. No. Name Designation and Office Status 1. Md. Aminul Islam Khan Additional Chief Engineer (P&SP), PWD, Dhaka Convenor 2. Md. Shahadat Hossain Additional Chief Engineer (Establishment & Co-ord.), PWD, Dhaka Member 3 Md. Abdul Hye Additional Chief Engineer, Dhaka Zone, PWD, Dhaka Member 4. Md. Salim Khan Additional Chief Engineer (Health Wing), PWD, Dhaka Member 5. Mohammad Abdul Majid Additional Chief Engineer, E/M Zone, PWD, Dhaka Member 6. Shahadat Hossain Deputy Chief Architect (Co-ord), Department of Architecture, Dhaka Member 7. Zafar Ahmed Superintending Engineer, E/M Circle-1, PWD, Dhaka Member 8. Md. Nurul Islam Superintending Engineer, E/M P&D Circle, PWD, Dhaka Member 9. Md. Nazibar Rahman Superintending Engineer, Savar Circle, PWD, Dhaka Member 10. S.M Zulkernine Superintending Engineer (Development), PWD, Dhaka Member 11. Md. Sohel Rahman Superintending Engineer, Design Circle-1, PWD, Dhaka Member 12. Md. Rafiqul Islam Superintending Engineer, Project Circle-2, PWD, Dhaka Member 13. Md. Jamilur Rahman Superintending Engineer, Project Circle-1, PWD, Dhaka Member 14. Kazi Md. Firoze Hassan Superintending Engineer, PECU Circle, PWD, Dhaka Member 15. Md. Syied Mahbub Morshed Superintending Engineer, Monitoring & Audit Circle, PWD, Dhaka Member 16. Abdur Razzaque Khan Executive Engineer, E/M P&D Division-2, PWD, Dhaka Member 17. Md. Shakhawat Hossain Executive Engineer, Design Division-5, PWD, Dhaka Member 18. SK. Md. Kudrot-E-Khuda Chief Arboriculturist, Arboriculture PWD Division, Dhaka Member 19. Rafia Begum Executive Engineer, E/M P&D Division-1, PWD, Dhaka Member 20. Md. Shamsul Islam Executive Engineer, Design Division-1, PWD, Dhaka Member 21. Nur-E-Kawonine Executive Engineer, Design Division-4, PWD, Dhaka Member 22. Zahid Hasan Khan Executive Engineer, PWD, Dhaka Member 23. Md. Maminul Haque Bhuiyan Chief Accounts Officer, PWD, Dhaka Member 24. Md. Emdadul Huq Executive Engineer, Design Division-2, PWD, Dhaka Associates Mohammad Ferdous-Uz-Zaman, Sub-Divisional Engineer, Design Division-2, PWD, Dhaka Md. Raquibul Hasan, Sub-Divisional Engineer, Design Division-2, PWD, Dhaka Md. Fateh Azam Khan, Assistant Engineer, Design Division-4, PWD, Dhaka Rajib Kanti Biswas, Assistant Engineer, Design Division-2, PWD, Dhaka Tariq Mahmud, Assistant Engineer, Design Division-1, PWD, Dhaka Member Secretary SPECIAL NOTE Utmost care has been taken to overcome mistakes and confusion etc. in description of items, units, rates although there may always be chances of unwilling printing mistakes. However, if confusion arises in the interpretation in any item/items, unit, rates etc. and if situation so demands, then the procuring entity must clarify and resolve the issue and approval is to be obtained in this regard from the competent authority (HOPE or his authorized representative). Hence the decision given by the competent authority will be treated as final. TABLE OF CONTENTS Sl. No 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 Contents Conversion Table Unit weight of different engineering materials and weight of different steel sections Cross sectional area and mass of round bar Wire and sheet metal gauge in decimals of an inch Distance matrix (District HQ to District HQ) Miscellaneous measurement relations Rates of man, materials and mark-ups Carriage of materials Division 1: General and site facilities Division 2: Excavation, filling & site development and palisading Division 3: Brick soling, CC, DPC etc. Division 4: Brick works, patent stone in floor and fancy screen block works Division 5: Mosaic works Division 6: Tiles, marble stone and granite stone works Division 7: Reinforced cement concrete (RCC) works Division 8: M. S. fabrication and construction joint in RCC works Division 9: Pile works and pile test Division 10: Structural steel works, sheet roofing and safety canopy Division 11: Wood works in door and window frame, roof truss and railings Division 12: Door-window shutter & fly proof wire-net shutter Division 13: Window grill, verandah grill & netting Division 14: Aluminium door, window frame and glass works Division 15: Cement plaster, fair-face plaster and pointing works Division 16: Painting and polishing Division 17: Lime terracing, roof top water proofing for garden and swimming pool Division 18: False ceiling, wall paneling Division 19: Collapsible gate, M.S. gate, rolling shutter etc. Division 20: Stair & verandah railing and stair nosing Division 21: Grill fencing and barbed wire fencing Division 22: Miscellaneous items Division 23: Ferrocement works Division 24: Road and pavement works Division 25: Arboriculture works Division 26: Sanitary & water supply works Division 27: Deep tube-well Division 28: Gas connection works Division 29: Termite treatment works Division 30: Concrete hollow block, facings and paving stone, non fire block Division 31: Sub-soil investigation works Division 32: Repair works Division 33: Laboratory tests of Engineering Materials* Annexure –A: Plinth Area Rates Annexure –B: Guideline for Preparation of Rough Estimate Annexure –C: Finishing Schedule Annexure –D: Material Brand as User Guide * Every tender shall bear related items from this division Page i-iii iv-v vi vii viii-ix x 1-66 66-67 68-71 72-75 76-77 78-83 84-87 88-94 95-102 103-104 105-111 112-114 115-116 117-123 124-125 126-134 135-137 138-141 142-143 144-146 147-150 151-153 154-155 156-160 161-164 165-170 171-172 173-193 194-213 214-216 217-218 219-227 228-230 231-240 241-276 277-287 288-294 295-298 299-305 CONVERSION TABLE PWD SoR 2018 for Civil Works i CONVERSION TABLE FPS AND METRIC SYSTEM (TABLE – 1 TO 3) TABLE – 1 FPS METRIC METRIC FPS 1 inch 25.40 mm = 2.54 cm 1 mm 0.03937 inch 1 feet 30.48 cm = 0.3048 m 1 meter 3.281 ft. 1 mile 1.609 km 1 km 0.6214 mile 1 gallon (UK) 4.546 liter 1 liter 0.22 gallon (UK) 1 pound 0. 4536 kg 1 kg. 2.205 lb 1 seer 0.9331 kg 1 kg 1.072 seer 1 maund 37.324 kg 1 kg 85.74 tolas 1 ton 1.016 tonne 1 tonne 0.984 ton = 1000 kg. 1 cwt. (UK) 0.508 quintal 1 quintal 1.969 cwt (UK) 1 in2 6.452 cm2 1 cm2 0.155 in2 1 ft2 0.093 m2 1 m2 10.764 ft2 PWD SoR 2018 for Civil Works ii TABLE – 2 CONVERSION FACTOR CONVERSION FACTOR Remarks British (FPS) Metric SI SI Metric British (FPS) Length 1 in 1 ft. 1 yd 1 mile 1 nautical mile 25.4 mm 0.3048 m 0.9144 m 1.609 km 1.852 km 25.4 mm 0.3048 m 0.9144 m 1.609 km 1.852 km 1 mm 1 cm 1m 1 km 1 km 1 mm 1 cm 1m 1 km 1 km 0.03937 in 0.3937 in 3.281 ft. 0.6214 mi 0.5399 nautical mile 1 in = 2.54 cm Area 1 in2 1 ft2 1 yd2 1 mi2 acre 6.452 cm2 0.0929 m2 0.8361 m2 2.59 km2 0.4047 ha 6.452 cm2 0.0929 m2 0.8361 m2 2.59 km2 0.4047 ha 1 cm2 1 m2 1 m2 1 km2 1 ha 1 cm2 1 m2 1 m2 1 km 1 ha 0.155 in2 10.764 ft2 1.196 yd2 0.3861 mi2 2.471 acre 1 in2 = 645.2 mm2 1 acre = 43560 ft2 = 4047m2 1 km2= 247.105 acres 1 hectre = 10000 m2 1 in3 1 ft3 1 yd3 1 gal (UK) 1 gal (US) 16.387 cm3 0.02832 m3 0.7648 m3 4.546 liters 3.7854 liters 16.387 cm3 0.02832 m3 0.7648 m3 4.546 liters 3.7854 liters 1 cm3 1 m3 1 m3 1 liter 1 liter 1 cm3 1 m3 1 m3 1 liter 1 liter 0.061 in3 35.315 ft3 1.308 yd3 0.22 gal (UK) 0.264 gal (US) 1 ft3 = 6.23901 gal = 28.316 liters 1 bushel (imperial) = 36.37 liters 1 in4 1 ft4 41.623 cm4 0.008631 m4 41.623 cm4 0.008631 m4 1 cm4 1 m4 1 cm4 1 m4 0.024 in4 115.86 ft4 1 hp 1 btu 0.7457 kw 1.055 kilo joules 0.7457 kw 1.055 kilo joules 1 kw 1 kj 1 kcl 1 kw 1 kj 1 kcl 1.341 hp 0.9478 btu 3.9651 btu Volume Moment of Inertia Power, Work, Energy, Quantity of heat Miscellaneous Units: 1 great gross = 12 gross = 144 dozen 1 quire=24 sheets 1 gross=12 dozen = 144 units 1 ream = 20 quires = 480 sheets 1 dozen=12 units 1 ream printing paper = 500 sheets 1 score=20 units 1 J = 1 Nm 1 hp = 1.01387 metric hp = 550 ft-lb/sec 1 W = 1 J/sec PWD SoR 2018 for Civil Works iii TABLE – 3 CONVERSION FACTOR British (FPS) 1 gr 1 oz (avoir) 1 lb (avoir) CONVERSION FACTOR Remarks Metric SI SI Metric British (FPS) 0.0648 gm 28.349 gm 0.4536 kg 0.0648 gm 28.349 gm 0.4536 kg 1 gm 1 gm 1 kg 1 gm 1 gm 1 kg 15.432 gr 0.0353 oz 2.205 lbs 4.4482 N 4.4482 kN 9.964 kN 1 cwt 0.4536 kg 453.6 kg 1.016 tonne (1016 kg) 50.80 kg 1N 1 kN 1 kN 0.102 kg 101.96 kg 101.96 kg 0.2248 lb 224.81 lb 2.007 cwt Linear loads (load per unit length) 1 lb/in 1 lb/ft. 1 kip/ft. 1 ton/ft 0.01786 kg/mm 1.488 kg/m 1488.19 kg/m 3.333 tonne/m 0.17512 N/mm 0.0146 kN/m 14.5939 kN/m 32.69 kN/m 1 N/mm 1 kN/m 1 kN/m 0.102 kg/mm 101.96 kg/m 0.102 tonne/m 5.71 lb/in 68.52lb/ft. 0.031 ton/ft Surface loads (load per unit area) 1 lb/in2 1 lb/ft2 1 kip/ft2 1 ton/ft2 0.0703 kg/cm2 4.883 kg/m2 4883 kg/m2 10.937 tonne /m2 6.895 kN/m2 0.04788 kN/m2 47.8803 kN/m2 107.14 kN/m2 1 MN/m2 145.038 lb/in2 1 lb/in3 0.0000277 kg/mm3 16.02 kg/m3 35.88 tonne/m3 0.00027N/mm3 101972.6 kg/m2 101.97 kg/m2 0.102 tonne/ m2 0.1021 kg/mm3 101.92 kg/m3 0.102 tonne/m3 Mass Conc. load/force, mass, weight Density (unit weight) Stress, modulus of elasticity, pressure Moment/ Torque Velocity/ Speed Accelerati on Temperatu re (Celsius) 1 lb 1 kip 1 ton 1 lb/ft3 1 ton/ft3 0.4982 kN 0.1572 kN/m3 352.08 kN/m3 1 lb/in2 1 kip/in2 1 lb/ft2 0.0703 kg/cm2 70.3078 kg/cm2 4.883 kg/m2 6.895 kPa 6.895 mPa 47.8802 Pa 1 lb-in 1 lb-ft 1 kip-ft 1 ton-ft 1 ft/sec 1 mile/sec 1 mile/hr 11.5214 kg-mm 0.1383 kg-m 138.3 kg-m 0.31 tonne-m 0.3048 m/sec 1.609 km/sec 0.4470 m/sec 112.98 N-mm 1.3558 N-m 1.3558 kN-m 3.037 kN-m 0.3048 m/sec 1.609 km/sec 0.4470 m/sec 1 ft/sec2 0.3048 m/sec2 0.3048 m/sec2 kN/m2 1 1 kN/m2 1 N/mm3 1 kN/m3 1 kN/m3 lb/ft2 20.885 0.00933 ton/ft2 3703.70 lb/in3 6.361 lb/ft3 0.0028 ton/ft3 1 mPa 1 kPa 10.19 kg/cm2 101.97 kg/m2 145.038 lb/in2 20.885 lb/ft2 1 N-mm 1 N-m 1 kN-m 0.102 kg-mm 0.102 kg-m 0.102 tonnem 0.0088lb-in 0.738 lb-ft 0.3293 ton-ft 1 m/sec 1 km/sec 1 m/sec 1 km/sec 3.281 ft/sec 2236.94 mi/hr 1 m/sec2 1 m/sec2 3.281 ft/sec2 1 degree Fahrenheit (0F) = (t0-32)/1.8 degree Celsius (0C) 1 lb = 0.486 seer 1 kg = 1.072 seer = 85.74 tolas 1 kg = 2.2046 lb = 9.807 N 1 tonne = 10 quintal = 1000 kg = 26.7923 maund 1 kg = 0.01968 cwt 1 ton = 2200 lb =907.2 kg. 1 kg/m = 9.80 N/m = 0.672 lb/ft. 1 kg /cm2 = 2048.16lb/ft2 1 kg/cm2 = 0.968 atom 1 kg/m2 = 0.205 lb/ft2 1 kg/m3 = 0.0624 Ib/ft3 MPa = MN/m2 = N/mm2 = 1000 kN/m2 1 Pa = 1N/m2 1 kN = 224.809 lbs 1 kg/cm2 = 14.223 lb/in2 1 ft. of water = 2.989 kPa PWD SoR 2018 for Civil Works iv UNIT WEIGHT OF DIFFERENT ENGINEERING MATERIALS AND WEIGHT OF DIFFERENT STEEL SECTIONS (TABLE – 4 TO 8) TABLE – 4 UNIT WEIGHT OF ENGINEERING MATERIALS Unit Weight of Different Materials Unit weight Materials lb/cft kg/cum Asphalt 66 1057 Aluminium 165 2643 Bamboo 25 400 Bitumen 65 1040 Brass 534 8552 Bricks 69 1110 Brick ballast 60-70 960-1120 Brick chips 80-110 1280-1760 Brick work 120 1922 Cast iron 450 7207 Cement 90 1440 Cement concrete 140 2240 Clay ( dry to wet) 115-130 1840-2080 Coal (loose) 50 800 Copper 556 8905 Earth (compacted & damp) 100 1600 Earth (dry & loose) 90 1440 Garjan timber 45-50 720-800 Gravel 90 1440 Lead 710 11371 Lime concrete 120 1920 Lime (slaked to fresh) 40-60 640-960 Lime stone 150 2400 Macadam (tar) 140 2242 Marble 169 2707 Mild steel 490 7850 Pebbles 90 1440 Plain concrete 144 2300 Reinforced cement concrete 150 2400 Sal wood 60-65 960-1040 Sand (dry to wet) 100-120 1600-1920 Shingles 90 1440 Silver 656 10506 Stone ballast 100 1600 Sundari wood 55-65 880-1040 Surki 80 1280 Surki mortar 85-120 1360-1920 Tar 90 1440 Teak wood 45-55 720-880 Water at 40 C 62.45 1000 Wrought iron 480 7688 Unit Weight of M.S. Flat Bars** Size Weight inch mm* lb/rft kg/meter ¾ x 1/8 20 x 3 0.32 0.471 ¾ x 3/16 20 x 5 0.48 0.785 ¾x¼ 20 x 6 0.64 0.942 1 x 1/8 25 x 3 0.43 0.589 1 x 3/16 25 x 5 0.64 0.981 1x¼ 25 x 6 0.85 1.178 1 ¼ x 1/8 30 x 3 0.53 0.707 1 ¼ x 3/16 30 x 5 0.80 1.178 1¼x¼ 30 x 6 1.06 1.413 1 ½ x 1/8 40 x 3 0.64 0.942 1 ½ x 3/16 40 x 5 0.96 1.570 1½x¼ 40 x 6 1.28 1.884 2 x 3/3/16 50 x 5 1.28 1.9625 2x¼ 50 x 6 1.70 2.335 UNIT WEIGHT OF M.S. SOLID SQUARE BARS Size Weight inch mm* lb/rft kg/meter ½x½ 12 x 12 0.851 1.130 ¾x¾ 20 x 20 1.914 3.140 1x1 25 x 25 3.403 4.906 UNIT WEIGHT OF M.S. Z-SECTION Size Weight inch mm* lb/rft kg/meter ¾ x ¾ x ¾ x 1/8 20 x 20 x 20 x 3 0.851 1.272 ¾ x ¾ x ¾ x 3/16 20 x 20 x 5 1.196 1.963 1 x 1 x 1/8 25 x 25 x 3 1.170 1.625 1 x 1 x 3/16 25 x 25 x 5 1.675 2.551 UNIT WEIGHT OF M.S. ANGLE Size Weight inch mm* lb/rft kg/meter ¾ x ¾ x 1/8 20 x 20 x 3 0.585 0.871 ¾ x ¾ x 3/16 20 x 20 x 5 0.837 1.374 ¾x¾x¼ 20 x 20 x 6 1.063 1.601 1 x 1 x 1/8 25 x 25 x 3 0.798 1.107 1 x 1 x 3/16 25 x 25 x 5 1.156 1.766 1x1x¼ 25 x 25 x 6 1.489 2.072 1 ½ x 1 ½ x 1/8 40 x 40 x 3 1.223 1.813 1 ½ x 1 ½ x 3/16 40 x 40 x 5 1.794 2.944 1½x1½x¼ 40 x 40 x 6 2.339 3.485 2 x 2 x 3/16 50 x 50 x 5 2.432 3.729 2x2x¼ 20 x 20 x 6 3.190 4.427 2½x2½x¼ 65 x 65 x 6 4.041 5.840 3x3x¼ 75 x 75 x 6 4.891 6.782 3 x 3 x 5/16 75 x 75 x 8 6.048 8.918 ** Unit weight with respect to FPS measurements of materials * Measurements in soft conversion PWD SoR 2018 for Civil Works v TABLE – 5 WEIGHT OF M.S. TEES PER RFT Size in inch Weight in lbs. Size in inch Weight in lbs. Size in inch Weight in lbs. Size in inch Weight in lbs. 1 x 1 x 1/8 0.81 1½x1½x¼ 2.35 2¼x2¼x¼ 3.64 3 x 3 x 3/8 7.20 1x1x¼ 1.54 1¾x1¾x¼ 2.79 2½x2½x¼ 4.07 3x3x½ 9.38 1 ¼ x 1 ¼ x 3/16 1.50 1 ¾ x 1 ¾ x 3/16 2.11 2 ½ x 2 ½ x 5/16 5.00 3 ½ x 3 ½ x 3/8 8.49 1¼x1¼x¼ 1.88 2x2x¼ 3.21 2 ½ x 2 ½ x 3/8 5.92 3½x3½x½ 11.08 1 ½ x 1 ½ x 3/16 1.81 2 x 2 x 3/8 4.64 3x3x¼ 4.91 TABLE – 6 WEIGHT OF M.S SHEET/PLATE PER SFT. Thickness in Weight in Thickness in Weight in Thickness in Weight in Thickness BWG lbs. inch lbs. inch lbs. in inch 24 1.01 1/16 2.55 5/16 12.75 5/8 25.50 22 1.27 1/8 5.10 3/8 15.30 3/4 30.60 20 1.59 3/16 7.65 7/16 17.85 7/8 35.70 18 2.04 1/4 10.20 1/2 20.40 1 40.80 Weight in lbs. PWD SoR 2018 for Civil Works vi TABLE – 7 CROSS-SECTIONAL AREA AND MASS OF ROUND BAR Nominal Size (dia in mm) Cross-sectional area in mm2 Perimeter in mm Mass per running meter in kg Length per 100 kg in meter 4 12.6 12.7 0.099 1010.10 5 19.6 15.71 0.154 644.35 28.3 18.85 0.222 450.45 7 38.5 21.99 0.302 331.12 8 50.3 25.13 0.395 253.16 6 2 10 3 78.5 31.42 0.616 162.34 12 4 113.0 37.70 0.888 112.61 16 5 201.0 50.27 1.579 63.33 20 6 314.0 62.83 2.466 40.55 22 7 380.0 69.11 2.980 33.56 25 8 491.0 78.54 3.854 25.95 28 9 616.0 87.96 4.830 20.70 32 10 804.0 100.53 6.313 15.8 1257.0 125.66 9.864 10.14 40 1BDS Bar No. 1 1313: 1991 PWD SoR 2018 for Civil Works vii TABLE – 8 WIRE AND SHEET METAL GAUGES IN DECIMALS OF AN INCH Name of Gauge United States Standard Gauge Principle Use Uncoated Steel Sheets and Light Plates Gauge No. Weight oz. per sq. ft. Approximate thickness in inch United States Steel American or Brown New British Imperial or Birmingham or Stubs Wire Gauge & Sharpe Wire Birmingham English Legal Iron Wire Gauge Gauge Standard Sheet Standard Wire Gauge (BWG) & Hoop Gauge (SWG) Steel Wire except Non-Ferrous Iron and Steel Wire Strips, Bands, Hoops Music Wire Sheets and Wire Sheets and and Wire Hoops Thickness in inch 7/0's 0.4960 . 0.6666 0.5 6/0's 0.4615 0.5800 0.625 0.464 5/0's 0.4305 0.5165 0.5883 0.432 0.5 4/0's 0.3938 0.4600 0.5416 0.4 0.454 3/0's 0.3625 0.4096 0.5 0.372 0.425 2/0's 0.3310 0.3648 0.4452 0.348 0.38 0 0.3065 0.3249 0.3964 0.324 0.34 1 0.2830 0.2893 0.3532 0.3 0.3 2 0.2625 0.2576 0.3147 0.276 0.284 3 160 0.2391 0.2437 0.2294 0.2804 0.252 0.259 4 150 0.2242 0.2253 0.2043 0.25 0.232 0.238 5 140 0.2092 0.2070 0.1819 0.2225 0.212 0.22 6 130 0.1943 0.1920 0.1620 0.1981 0.192 0.203 7 120 0.1793 0.1770 0.1443 0.1764 0.176 0.18 8 110 0.1644 0.1620 0.1285 0.157 0.16 0.165 9 100 0.1495 0.1483 0.1144 0.1398 0.144 0.148 10 90 0.1345 0.1350 0.1019 0.125 0.128 0.134 11 80 0.1196 0.1205 0.0907 0.113 0.116 0.12 12 70 0.1046 0.1055 0.0808 0.0991 0.104 0.109 13 60 0.0897 0.0915 0.072 0.0882 0.092 0.095 14 50 0.0747 0.0800 0.0641 0.0785 0.08 0.083 15 45 0.0673 0.0720 0.0571 0.0699 0.072 0.072 16 40 0.0598 0.0625 0.0508 0.0626 0.064 0.065 17 36 0.0538 0.0540 0.0453 0.0556 0.056 0.058 18 32 0.0478 0.0475 0.0403 0.0495 0.048 0.049 19 28 0.0418 0.0410 0.0359 0.044 0.04 0.042 20 24 0.0359 0.0348 0.032 0.0392 0.036 0.035 21 22 0.0329 0.0318 0.0285 0.0349 0.032 0.032 22 20 0.0299 0.0286 0.0253 0.0313 0.028 0.028 23 18 0.0269 0.0258 0.0226 0.0278 0.024 0.025 24 16 0.0239 0.0230 0.0201 0.0248 0.022 0.022 25 14 0.0209 0.0204 0.0179 0.022 0.020 0.020 26 12 0.0179 0.0181 0.0159 0.0196 0.018 0.018 27 11 0.0164 0.0173 0.0142 0.0175 0.0164 0.016 28 10 0.0149 0.0162 0.0126 0.0156 0.048 0.014 29 9 0.0135 0.0150 0.0113 0.0139 0.036 0.013 30 8 0.0120 0.0140 0.01 0.0123 0.024 0.012 31 7 0.0105 0.0132 0.0089 0.011 0.0116 0.01 32 6.5 0.0097 0.0128 0.008 0.0098 0.0108 0.009 33 6 0.0090 0.0118 0.0071 0.0087 0.01 0.008 34 5.5 0.0082 0.0104 0.0063 0.0077 0.0092 0.007 35 5 0.0075 0.0095 0.0056 0.0069 0.0084 0.005 36 4.5 0.0067 0.0090 0.005 0.0061 0.0076 0.004 37 4.25 0.0064 0.0085 0.0045 0.0054 0.0068 38 4 0.0060 0.0080 0.004 0.0058 0.006 39 0.0075 0.0035 0.0043 0.0052 40 0.0070 0.0031 0.0039 0.0048 U.S. Standard Gauge is officially a weight Gauge, in oz. Per sq. ft as tabulated. The approximate thickness shown is the "Manufacturers' Standard" of the American Iron and Steel Institute, based on steel as weighing 501.81 Ib. per cu. ft. (489.6 true weight plus 2.5% for average over-run in area and thickness). PWD SoR 2018 for Civil Works Distance Matrix (District HQ to District HQ)**, Length in kilometer URL: www.rhd.gov.bd viii PWD SoR 2018 for Civil Works ix **Note: This is a indicative distance chart. Users are requested to verify the distances before using. District headquarters have been consider on the nearest RHD roads. Shortest route have been considered for measuring the distance. For the same destination, if alternate route is used, then distance will vary. PWD SoR 2018 for Civil Works x MISCELLANEOUS MEASUREMENT RELATIONS Dry volume of concrete, mortar etc. = 1.5 x wet volume(approx.) 100 maunds of slaked lime or sand or Surki = 225 cft. (2.25 cft. = 1 maund) 100 cft. of khoa or brick chips required 850 Nos. bricks of size 9.5" x 4.5" x 2.75" Standard Bricks(9.5" x 4.5" x 2.75")1000 Nos. = approx. 72 cft. = 2.039 cum = 3172 to 4000 kg. 1 bag of cement (British) = 1.25 cft. = 50 kg. (BDS EN 197 CEM-I) 1 Ton of C.I. Sheet (24 B.W.G.) = 10 bundles 1 bundle = Size of C.I. sheet No of C.I. sheet Size of C.I. sheet No of C.I. sheet 6' – 0" long 12 nos 8' – 0" long 9 nos 7' – 0" long 10 nos 9' – 0" long 8 nos 10' – 0" long 7 nos Width of C.I. Sheet = 32 inch 950 rft of barbed wire (12 B.W.G.) = 1 cwt 200 Nos. of 2.5" long nails = 1 seer 1 gallon of plastic emulsion paint / synthetic enamel paint covers 300 sft of new surface (approx.) 1 gallon of distemper covers 250 sft of new surface (approx.) 1 drum (40 kg) of snowcem covers 2070 square meters (approx.) 100 cft masonry brick work requires 1100 nos standard bricks (size 9.5" x 4.5" x 2.75") with 0.25” thickness of mortar Brick Soling: Single brick flat soling requires : 300 Nos. bricks per % sft. (Brick size 9.5" x 4.5" x 2.75") Double brick flat soling requires : 600 Nos. bricks per % sft. (Brick size 9.5" x 4.5" x 2.75") Herringbone bond (HBB) brick soling requires : 500 Nos. bricks pre % sft. (Brick size 9.5" x 4.5" x 2.75") Brick on end edging requires : 250 Nos. bricks per % rft. (Brick size 9.5" x 4.5" x 2.75") RATES OF MAN, MATERIAL AND MARK-UPS PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate Unit 1 MARK-UPS 1 Contractor's Profit 2 Contractor's Overhead Expenses 3.50% 3 VAT 6.00% 4 Additional Incidental Expenses for Gas Line Installation Works C1 10.00% 10.00% LABOUR & MAN-POWER: PER DAY 1 Head mason / Mosaic head mistry Tk. 600.00 per day 2 Mason Tk. 500.00 per day 3 Skilled labour Tk. 390.00 per day 4 Ordinary labour Tk. 320.00 per day 5 Field Engineer (minimum BSc in Eng. with 3yrs exp or Diploma in Eng. with 8yrs exp) Tk. 1,800.00 per day 6 Skilled technician Tk. 1,000.00 per day 7 Semi skilled technician Tk. 600.00 per day 8 Foreman/Supervisor Tk. 800.00 per day 9 Electrician Tk. 600.00 per day 10 Assistant Electrician Tk. 500.00 per day 11 Rod binder Tk. 500.00 per day 12 Mosaic mistry Tk. 500.00 per day 13 Plumber Tk. 600.00 per day 14 Painter Tk. 600.00 per day 15 Carpenter Tk. 600.00 per day 16 Welder Tk. 600.00 per day 17 Polish mistry Tk. 600.00 per day 18 Helper to carpenter/painter/plumber/rod binder/electrician/polish mistry/rig operator Tk. 390.00 per day 19 Machine operator Tk. 600.00 per day 20 Pile rig operator Tk. 600.00 per day 21 Diesel hammer mounted rig operator Tk. 800.00 per day 1 PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate Unit 22 Helper to diesel hammer mounted rig operator Tk. 390.00 per day 23 Rig operator including site allowances for soil exploration Tk. 600.00 per day 24 Assistant laboratory technician Tk. 800.00 per day 25 Laboratory technician (Diploma in engg in relevant field having minimum 3yrs exp) Tk. 1,400.00 per day 26 Laboratory engineer (minimum BSc in relevant field with minimum 3yrs exp) Tk. 1,800.00 per day 27 Ghorami Tk. 500.00 per day 28 Sweeper for ODD JOB Tk. 800.00 per use 29 Tube-well mistry Tk. 500.00 per day 30 Tube-well head mistry Tk. 600.00 per day 31 Surveyor (10yrs Exp / diploma Engineer trained in survey) Tk. 1,400.00 per day 32 Helper to surveyor Tk. 800.00 per day C2 EQUIPMENT, TOOLS & PLANTS, VEHICLE, SCAFFOLDING ETC. 33 Scaffolding Tk. 9.00 per sft 34 Carrying charge of earth by 5-ton capacity truck in Dhaka city Tk. 1,700.00 per trip 35 Carrying charge of earth by 5-ton capacity truck in Narayanganj / Chittagong / Sylhet city Tk. 1,200.00 per trip 36 Carrying charge of earth by 5-ton capacity truck in Rajshahi / Barisal / Khulna metropolitan area Tk. 950.00 per trip 37 Carrying charge of earth by 5-ton capacity truck in all district except Dhaka/ Chittagong/ Rajshahi / Barisal / Khulna and Narayangonj city Tk. 800.00 per trip 38 Carriage of earth by any means for site development in Dhaka city Tk. 7.50 cft 39 Carriage of earth by any means for site development in Narayanganj / Chittagong / Sylhet city Tk. 6.00 cft 40 Carriage of earth by any means for site development in Rajshahi / Barisal / Khulna city Tk. 5.50 cft 41 Carriage of earth by any means for site development in in all district except Dhaka, Chittagong, and Narayangonj city Tk. 4.50 cft 42 5-ton capacity truck-fare in Dhaka city including loading & unloading Tk. 1,700.00 per trip 43 Hire charge of concrete mixer machine Tk. 1,200.00 per day 44 Hire charge of concrete vibrator Tk. 600.00 per day 45 Hire charge of water pump for concreting or similar purposes Tk. 500.00 per day 46 Hire charge of diesel operated 1/4 cusec capacity water pump Tk. 600.00 per day 2 PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate Unit 47 Hire charge of electricity operated 1 cusec capacity water pump Tk. 800.00 per day 48 Hire charge of 1 cusec capacity diesel operated water pump Tk. 1,200.00 per day 49 Fuel & lubricant for mixer machine, vibrator, pump etc. Tk. 1,200.00 per day 50 Hire charge of mosaic cutting machine Tk. 400.00 per day 51 Hire charge of marble cutting and shaping machine including cutting disc. Tk. 400.00 per day 52 Hire charge of marble polishing machine including polishing stone Tk. 550.00 per day 53 Hire charge of marble cutting disk Tk. 400.00 per day 54 Hire charge of electric grinding machine Tk. 260.00 per day 55 Hire charge of cast in situ pile boring complete rig set including operational expenses Tk. 6,000.00 per day 56 Hire charge of pre-cast pile driving complete rig set including operational expenses Tk. 5,500.00 per day 57 Hire charge of pre-cast micro pile driving complete rig set including operational expenses Tk. 4,000.00 per day 58 Hire charge of load testing devices including hydraulic fluid: up to 200 ton capacity Tk. 6,000.00 per test 59 Hire charge of pile load testing devices including hydraulic fluid: up to 400 ton capacity Tk. 8,000.00 per test 60 Hire charge of diesel hammer mounted completed rig set. Tk. 24,000.00 per day 61 Hire charge of auger boring complete rig set including operational expenses Tk. 75,000.00 per day 62 Hire charge of crane for auger boring Tk. 50,000.00 per day 63 Hire charge of air compressor for auger boring Tk. 5,000.00 per day 64 Hire charge of concreting equipment for auger boring Tk. 5,000.00 per day 65 Hire charge of generator for auger boring Tk. 5,000.00 per day 66 Hire charge of excavator for auger boring Tk. 10,000.00 per day 67 Hire charge of desander for auger boring Tk. 6,000.00 per day 68 Hire charge of mud silo for auger boring Tk. 1,000.00 per day 69 Hire charge of water bowser for auger boring Tk. 5,000.00 per day 70 Hire charge of hydraulic static pile driver complete rig set Tk. 75,000.00 per day 71 Generator, fuel, lubricant for hydraulic static pile driver Tk. 20,000.00 per day 72 Hire charge of 3HP mud pump Tk. 600.00 per day 73 Hire charge of MS steel tank (6'-6" x 10'-0" x 4'-0") Tk. 350.00 per trip 74 Truck fare for carrying diesel hammer mounted rig Tk. 15,000.00 per trip 3 PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate Unit 75 Hire charge of 8 - 12 ton road roller Tk. 5,500.00 per day 76 Hire charge of vibratory (ride on) roller with 2 steel drum compactor (3-5 tons) Tk. 5,000.00 per day 77 Hire charge of pneumatic multiple tired roller (7 tires, 8-10 tons) Tk. 5,000.00 per day 78 Hire charge of asphalt plant Tk. 15,000.00 per day 79 Hire charge of AC paver Tk. 6,000.00 per day 80 Hire charge of dump truck/ tripping trucks Tk. 5,000.00 per day 81 Hire charge of distributor Tk. 5,500.00 per day 82 Hire charge of water tanker (truck mounted) Tk. 3,000.00 per day 83 Hire-charge of chain dozer Tk. 7,500.00 per day 84 Fuel & lubricants, spares, maintenance, driver etc. for 8-12 ton road roller Tk. 1,300.00 per day 85 Hire charge of paint spray machine Tk. 650.00 per day 86 Hire charge of machine for cutting terrazzo tiles Tk. 500.00 per % sft 87 Chisel for heavy duty power hammer (100 sft capacity) Tk. 1,700.00 88 Hire charge of heavy duty chisel machine Tk. 650.00 per day 89 Shuttering including prop for partial dismantling of R.C.C. Tk. 27.00 per sft 90 Hire charge of welding machine Tk. 700.00 per day 91 Hire charge of survey instrument (Level / Theodolite etc.) Tk. 950.00 per day C3 WORK RATE EXCLUDING COST OF MATERIALS 92 Breaking of 50 mm down brick chips Tk. 850.00 per % cft 93 Breaking of 20 mm down brick chips Tk. 950.00 per % cft 94 Breaking of 12 mm (1/2") down brick chips Tk. 1,200.00 per % cft 95 Breaking of 20 mm down stone chips Tk. 2,000.00 per % cft 96 Breaking of 12 mm down stone chips Tk. 2,200.00 per % cft 97 Placing and removing of shutter for formwork Tk. 15.00 per sft 98 Making steel shutter for formwork Tk. 75.00 per sft 99 Making steel door-window frame and shutter Tk. 65.00 per sft 100 Making fixed steel glazed frame Tk. 55.00 per sft 101 Making steel grill Tk. 45.00 per sft each 4 PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 5 Unit 102 Filling and stitching gunny bags Tk. 10.00 per bag 103 Load testing result sheet preparation Tk. 6,000.00 per test 104 Carrying cost of timber Tk. 40.00 per cft 105 Seasoning of timber in plant Tk. 150.00 per cft 106 Carrying cost of steel door and window Tk. 70.00 each 107 Fabrication and erection of mild steel truss Tk. 2,100.00 per 50 kg 108 Fabrication of light section steel Tk. 300.00 per 50 kg C4 WORK RATE INCLUDING COST OF MATERIALS 109 Point welding Tk. 2.50 per point 110 Line welding (at field) Tk. 6.00 per inch 111 Bitumenous coating (for damp proof course (D.P.C)) Tk. 800.00 per % sft 112 Coal-tar (over timber surface) Tk. 7.00 per sft 113 Glass pan fitting including putty Tk. 16.00 per sft 114 Jute hessian (for making formwork water-tight) Tk. 2.50 per sft C5 BRICKS AND SCREEN BLOCKS 115 1st class/Picked jhama standard bricks Tk. 8,700.00 per % 0 nos 116 Automatic machine made 1st class standard bricks Tk. 9,000.00 per % 0 nos 117 1st class 10 holes machine made 9.5" x 4.5" x 2.75" / 237.5 mm x 112.5 mm x 68.75 mm size ceramic bricks Tk. 18,900.00 per % 0 nos 118 9.5" x 4.5" x 2.75"/ 237.5 mm x 112.5 mm x 68.75 mm size machine made solid klinker facing bricks Tk. 13,500.00 per % 0 nos 119 9.5" x 4.5" x 2.75" / 237.5 mm x 112.5 mm x 68.75 mm size 10 hole machine made rockface/textured klinker facing bricks Tk. 13,500.00 per % 0 nos 120 9.5" x 4.5" x 2.75"/ 237.5 mm x 112.5 mm x 68.75 mm size 3 hole machine made reinforcing facing bricks Tk. 21,500.00 per % 0 nos 121 8" x 4" x 2"/ 200 x 100 x 50 mm machine made hard pressed klinker facing bricks Tk. 19,000.00 per % 0 nos 122 8" x 2" x 2"/ 200 x 50 x 50 mm machine made klinker facing red or maroon strips Tk. 16,000.00 per % 0 nos 123 200 mm x 62 mm x 16.51 mm machine made clay wall tile red strips Tk. 18,500.00 per % 0 nos 124 200 mm x 62 mm x 12.7 mm machine made clay wall tile beige strips Tk. 21,000.00 per % 0 nos 125 200 mm x 62 mm x 8.9 mm machine made clay wall tile red strips Tk. 16,400.00 per % 0 nos PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 6 Unit 126 241 mm x 70 mm x 12.7 mm machine made clay wall tile red strips Tk. 28,000.00 per % 0 nos 127 242 mm x 70 mm x 12.7 mm machine made clay wall tile matt glazed textured strips Tk. 34,000.00 per % 0 nos 128 4.5'' x 4.5'' x 4.5''/ 112.5 mm x 112.5 mm x 112.5 mm fancy screen block Tk. 28,000.00 per % 0 nos 129 5.5'' x 5.5'' x 4'' / 137.5 mm x 137.5 mm x 100 mm fancy screen block Tk. 34,000.00 per % 0 nos 130 6" x 6" x 4" / 150 mm x 150 mm x 100 mm fancy screen block Tk. 37,000.00 per % 0 nos 131 8'' x 8'' x 4.25''/ 200 mm x 200 mm x 106.25 mm fancy screen block Tk. 47,000.00 per % 0 nos 132 8'' x 4.75'' x 4''/ 200 mm x 118.75 mm x 100 mm fancy screen block Tk. 47,000.00 per % 0 nos 133 6" x 6" x 6" / 150 mm x 150 mm x 150 mm fancy screen block Tk. 37,000.00 per % 0 nos 134 9.5'' x 4.5'' x 2.75''/ 237.5 mm x 112.5 mm x 68.75 mm fancy screen block Tk. 37,000.00 per % 0 nos 135 190 mm x 190 mm size glass bricks Tk. 350.00 each C6 CEMENT 136 Ordinary Portland Cement, BDS-EN - 197-1-CEM-I ,52.5N (52.5MPa) / ASTM C-150 TypeI, 50 kg bag Tk. 415.00 per bag 137 Portland Composite Cement, (CEM-II/A - M 42.5N (42.5MPa) (6-20% constituents other than clinker): 50 kg bag Tk. 395.00 per bag 138 White Cement Tk. 26.00 per kg C7 STONE / BOULDER / MOSAIC CHIPS, BITUMEN / ADMIXTURE / MEMBRANE 139 Uncrushed boulder Tk. 16,000.00 per % cft 140 19 mm (3/4") down grade crushed stone chips Tk. 19,500.00 per % cft 141 12 mm (1/2") down grade stone chips Tk. 16,500.00 per % cft 142 6 mm (1/4") down grade stone chips Tk. 14,000.00 per % cft 143 Stone shingles Tk. 12,000.00 per % cft 144 Stone dust (2.38 mm down grade) Tk. 4,248.00 per % cft 145 Pea-gravel Tk. 8,500.00 per % cft 146 Slaked lime Tk. 20.00 per kg 147 Surki from 1st class brick Tk. 70.00 per cft 148 Pakistan origin (onix) mosaic chips Tk. 20.00 per kg 149 Indian origin (deradun) mosaic chips Tk. 18.00 per kg 150 Pumice stone for finishing mosaic work Tk. 175.00 each PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 7 Unit 151 Minar stone for finishing mosaic work Tk. 420.00 each 152 Colour pigment Tk. 70.00 per lbs 153 20 mm x 50 mm glass strip Tk. 10.00 per foot 154 60/70 grade bitumen for road work Tk. 52,000.00 155 Water-proofing PVC membrane Tk. 600.00 per sqm 156 Primer for laying PVC membrane on wall Tk. 600.00 per litre 157 Water reducing admixture in concrete: Type - A Tk. 150.00 per litre 158 Retarding admixture in concrete: Type - B Tk. 130.00 per litre 159 Accelerating admixture in concrete: Type - C Tk. 115.00 per litre 160 Water reducing and retarding admixture in concrete: Type - D Tk. 220.00 per litre 161 Water reducing and accelerating admixture in concrete: Type - E Tk. 170.00 per litre 162 Water reducing high range admixture in concrete: Type - F Tk. 230.00 per litre 163 Water reducing high range retarding admixture in concrete: Type - G Tk. 160.00 per litre 164 Micro fibre for concrete Tk. 750.00 per kg 165 Shutter releasing agent / form oil Tk. 150.00 per litre 166 Polymer based curing compound Tk. 220.00 per litre 167 Epoxy bonding agent Tk. 1,800.00 per litre 168 Salt guard coating Tk. per litre C8 EARTH/SAND 169 Royalty of earth Tk. 1,715.00 per % 0 cft 170 Royalty of sand Tk. 6,000.00 per % 0 cft 171 Royalty of turf Tk. 15.00 per % sft 172 Sand (F.M. 0.8) Tk. 900.00 per % cft 173 Sand (F.M. 1.2) Tk. 1,400.00 per % cft 174 Sand (F.M. 2.2) Tk. 4,500.00 per % cft C9 TIMBER / BOARD / TIMBER PRODUCT 175 Garjan/Jam/local Sal Tk. 2,000.00 per cft 176 Mehgani Tk. 1,800.00 per cft 700.00 per M. ton PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 8 Unit 177 Silkarai/Chikrashi Tk. 2,490.00 per cft 178 Teak Chambal Tk. 3,400.00 per cft 179 Chittagong teak Tk. 4,390.00 per cft 180 Kathal Tk. 2,250.00 per cft 181 Gamari Tk. 1,700.00 per cft 182 Chapalish Tk. 2,390.00 per cft 183 Timber for formwork Tk. 500.00 per cft 184 Bamboo Tk. 15.00 per foot 185 Shal ballah (avg. dia 6") for driving Tk. 70.00 per foot 186 Burma teak veneered flush door shutter Tk. 335.00 per sft 187 Champ veneered flush door shutter Tk. 240.00 per sft 188 Chapalish veneered flush door shutter Tk. 240.00 per sft 189 Garjan veneered flush door shutter Tk. 250.00 per sft 190 12 mm thick Plain Particle board : 550kg/m3 Tk. 38.00 per sft 191 Melamine board (12 mm thick): 8' -0" x 4'-0" size, 700kg/m3 Tk. 2,150.00 per pc 192 9 mm thick gypsum board Tk. 33.00 per sft 193 9 mm thick perforated gypsum board Tk. 39.00 per sft 194 12 mm thick laminated vinyl board : 550 kg/m3 Tk. 65.00 per sft 195 12 mm thick Burma Teak veneered board : 550kg/m3 Tk. 86.00 per sft 196 Burma teak Tk. 6,500.00 per cft 197 50 mm thick glass wool Tk. 210.00 per sft 198 Rubber gum Tk. 650.00 per kg C10 STEEL 199 Grade 300(300Mpa / 300N/mm2 ≈ 43500psi/40 Grade): BDS- 6935-2006 - B300 and Ratio fy to fu =>1.25 Tk. 58,000.00 per M. ton 200 Grade 400(400Mpa / 400N/mm2 ≈ 60900psi/ 60 Grade), BDS-6935-2006, B400: and ratio fy to fu => 1.25 Tk. 60,500.00 per M. ton 201 M.S sheet Tk. 60,500.00 per M. ton 202 M.S. angle, T and Z-section, Channel etc. Tk. 55,000.00 per M. ton PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 9 Unit 203 M.S. plain bar and F.I. bar (non-structural use) Tk. 55,000.00 per M. ton 204 Solid square bar Tk. 55,000.00 per M. ton 205 0.45 mm thick C.I. sheet: Tk. 79,500.00 per M. ton 206 0.45 mm thick coloured C.I. sheet: Tk. 81,000.00 per M. ton 207 0.27 mm thick 6'-0" x 18" ridging: Tk. 350.00 per pc 208 0.27 mm thick 6'-0" x 18" coloured ridging: Tk. 400.00 per pc 209 Anchor bolt fiting charge Tk. 25.00 per Kg 210 Galvanized anchor bolt of varying dia Tk.120,000.00 per M.Ton 211 MS plate of grade 345 Mpa Tk. 75,000.00 per M.Ton 212 MS plate of grade 275 Mpa Tk. 70,000.00 per M.Ton 213 Hot rolled W, I, S, T shape sections of grade 275 MPa Tk. 80,000.00 per M.Ton 214 MS tube / angle Tk. 70,000.00 per M.Ton 215 Fabrication charge for column, beam, rafter using MS plates including the cost of electricity, LP gas, machinares etc. Tk. 20,000.00 per M.Ton 216 Fabrication charge for column, beam, rafter using Hot Rolled sections including the cost of electricity, LP gas, machinares etc. Tk. 12,000.00 per M.Ton 217 MS sheet for purlin of any thickness Tk. 75,000.00 per M.Ton 218 GP sheet for purlin of any thickness Tk. 98,000.00 per M.Ton 219 0.70 mm thick GP decking sheet of Grade 345 Mpa Tk.125,000.00 per M.Ton 220 0.47mm colour profile sheet Tk.155,000.00 per M.Ton 221 Fastner / roof, wall screw Tk. 4.00 per pcs 222 Decking screw Tk. 8.00 per pcs 223 Galvanized nut bolt of varying dia ASTM 325 Tk. 250.00 per Kg 224 Galvanized nut bolt of varying dia ASTM 307 Tk. 205.00 per Kg 225 Fabrication charge for roof / wall sheet Tk. 7,500.00 226 8 mm thick double bubble insulation Tk. 227 Fabrication charge for decking panel Tk. 9,000.00 per M.Ton 228 Fabrication charge for Purlin Tk. 7,000.00 per M.Ton 229 Erection charge for built-up or hot rolled sections Tk. 8,000.00 per M.Ton 175.00 per M.Ton per sqm PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 10 Unit 230 Erection charge for decking panel Tk. 8.00 per Kg 231 Erection charge for purlin Tk. 4.00 per Kg 232 Erection charge for roof/wall sheet including flashing and trims Tk. 10.00 per Kg 233 Fitting and fxing of dubble bubble insulation on roof and wall Tk. 50.00 sqm 234 Anti corrosive epoxy paint Tk. 950.00 per litre 235 Anti corrosive red oxide paint Tk. 180.00 per litre 236 Thinner for anti corrosive red oxide paint Tk. 120.00 per litre 237 Labour charge for redoxide painting Tk. 600.00 per M.Ton 238 Labour charge for enamel painting Tk. 3,500.00 per M.Ton 239 Labour charge for application of non-shrink grout including the cost of making shutter Tk. 50.00 per cft 240 16 mm steel wire Tk. 120.00 per meter 241 16 mm I bolt with heal side washer and clamp Tk. 175.00 per set 242 12 mm I bolt with heal side washer and clamp Tk. 150.00 per set 243 Shear stud of variable dia of grade 275 Mpa Tk. 120.00 per Kg 244 Making thread for sag rod Tk. 12.00 per Kg 245 Nut with washer for 12 mm dia sag rod Tk. 150.00 per Kg 246 cost of non-shrink grout per bag (25 kg ) Tk. 1,500.00 per bag 247 Labour charge for wire bracing Tk. per foot 248 Local carriage, load-unload Tk. 1,500.00 C11 TILES / MARBLE STONE / GRANITE STONE 249 18 mm thick marble stone, Indian standard quality (Bansowara/ Indian grey/ Indian pink or equivalent) Tk. 450.00 per sft 250 16 mm thick marble stone, Indian standard quality (Bansowara/ Indian grey/ Indian pink or equivalent) Tk. 400.00 per sft 251 12 mm thick marble stone, Indian standard quality (Bansowara/ Indian grey/ Indian pink or equivalent) Tk. 370.00 per sft 252 12 mm thick marble stone, Indian superior quality Tk. 400.00 per sft 253 18 mm thick marble stone, Indian superior quality Tk. 500.00 per sft 254 16 mm thick marble stone, Indian superior quality Tk. 420.00 per sft 10.00 per M.Ton PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 11 Unit 255 18 mm thick marble stone, Italian or equivalent Tk. 650.00 per sft 256 12 mm thick marble stone, Italian or equivalent Tk. 600.00 per sft 257 Country made wall tiles less than , equal or equivalent to 250mmx330mm in sizes Tk. 40.00 per sft 258 Country made wall tiles more than 250 mm x 330 mm & less than 310 mm x 510 mm in sizes or equaivalent Tk. 62.00 per sft 259 Country made wall tiles more than 310 mm X 510 mm in sizes or equivalent Tk. 80.00 per sft 260 Country made decor tiles Tk. 100.00 per sft 261 Country made border Tiles Tk. 270.00 per sft 262 Country made rustic wall tiles less than or equal to 300 mm x 600 mm Tk. 90.00 per sft 263 GP (glazed/unglazed homogeneous) 300 mm x 300 mm floor tiles country made Tk. 60.00 per sft 264 GP (glazed/unglazed Homogeneous) 400 mm x 400 mm floor tiles country made Tk. 70.00 per sft 265 GP (mirror polished) 300 mm x 300 mm floor tiles country made Tk. 65.00 per sft 266 GP (mirror polished) 400 mm x 400 mm floor tiles country made Tk. 80.00 per sft 267 GP (mirror polished) 600 mm x 600 mm floor tiles country made Tk. 100.00 per sft 268 GP (mirror polished) 500 mm x 500 mm floor tiles country made Tk. 90.00 per sft 269 GP (mirror polished) 800 mm x 800 mm floor tiles country made Tk. 110.00 per sft 270 GP (mirror polished) 600 mm x 900 mm country made Tk. 132.00 per sft 271 GP (mirror polished) 600 mm x 1200 mm country made Tk. 165.00 per sft 272 Matt or rustic floor tiles of size 400 mm x 400 mm and min. thick 8.4 mm (country made) Tk. 87.00 per sft 273 Matt or rustic floor tiles of size 600 mm x 600 mm and min. thick 9.8 mm (country made ) Tk. 103.00 per sft 274 GP 300 mm x 300 mm stair tiles (country made) Tk. 62.00 per sft 275 GP 300 mm x 600 mm stair tiles (country made ) Tk. 95.00 per sft 276 Stair tiles size 300 mm x 600 mm foreign (China/equivalent) made Tk. 100.00 per sft 277 Rustic stair tiles country made Tk. 90.00 per sft 278 Rustic stair tiles foreign (China/equivalent) made Tk. 95.00 per sft 279 Mirror polish 600 mm x 600 mm floor tiles foreign(China/equivalent) made Tk. 125.00 per sft 280 Mirror polish 800 mm x 800 mm floor tiles foreign(China/equivalent) made Tk. 150.00 per sft 281 Mirror polish 600 mm x 1200 mm floor tiles foreign(China/equivalent) made Tk. 300.00 per sft 282 Mirror polish 1000 mm x1000 mm floor tiles foreign(China/equivalent) made Tk. 400.00 per sft PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 12 Unit 283 Mirror polish 1200 mm x 1200 mm floor tiles foreign (China/equivalent) made Tk. 500.00 per sft 284 Matt or rustic floor tiles of size 600 mm x 600 mm and minimum thickness 9.8 mm foreign (China/equivalent) made Tk. 170.00 per sft 285 foreign (China/ equivalent) glazed wall tiles of size 300 mm x 600 mm with mathcing floor tiles, décor and border (if any) Tk. 150.00 per sft 286 foreign (China/equivalent) rustic wall tiles of size 300 mm x 600 mm with mathcing floor tiles, décor and border (if any) Tk. 150.00 per sft 287 20 mm to 25 mm thick machine made cement pavement tiles(country made) Tk. 130.00 per sft 288 Roof tiles of size 100 mm x 200 mm or equivalent (Red colour) (country made) Tk. 14,000.00 per % sft 289 Roof tiles of size 125 mm x170 mm to 200 mm x 200 mm or equivalent (red colour) (country made) Tk. 17,575.00 per % sft 290 Roof tiles of size 160 mm x 268 mm or equivalent (red colour) (country made) Tk. 15,600.00 per % sft 291 Roof tiles of size 225 mm x 300 mm or larger (red colour) (country made) Tk. 16,200.00 per % sft 292 Flower shaped roof tiles of size 175 mm x 175 mm or equivalent (red colour)(country made) Tk. 22,420.00 per % sft 293 Roof tiles of size 100 mm x 200 mmor equivalent (beige colour) (country made) Tk. 14,500.00 per % sft 294 Roof tiles of size 125 mm x 170 mm to 200 mm x 200 mm or equivalent (beige colour) (country made) Tk. 18,500.00 per % sft 295 Roof tiles of size 225 mm x 300 mm or larger (beige colour) Tk. 18,000.00 per % sft 296 Flower shaped roof tiles of size 175 mm x 175 mm or equivalent (beige colour)(country made) Tk. 23,600.00 per % sft 297 Flower shaped roof tiles of size 175 mm x 175 mm or equivalent (grey or black colour) (country made) Tk. 26,200.00 per % sft 298 Pasting tiles adhesive Tk. 21.00 per kg 299 Tiles grout / joint filler Tk. 81.00 per kg 300 18 mm thick granite stone (Indian/equivalent) Tk. 550.00 per sft 301 18 mm thick granite stone (Italian/equivalent) Tk. 650.00 per sft 302 12 mm thick granite stone(Indian/equivalent) Tk. 400.00 per sft 303 12 mm thick granite stone(Italian/equivalent) Tk. 500.00 per sft 304 Acid stone Tk. 450.00 each 305 Water Proofing Paper (12 Size) Tk. 22.00 each 306 Water Proofing Paper (320 Size) Tk. 24.00 each PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 13 Unit C12 PROPS / PIPES / I-SECTION/BOX CHANNEL FOR CONCRETING WORK 307 Bamboo prop including top supports Tk. 120.00 each 308 Salballah prop including top supports Tk. 1,000.00 each 309 50 mm/2" dia M.S. pipe Tk. 140.00 per foot 310 38 mm/1.5" dia M.S. pipe Tk. 115.00 per foot 311 50 mm/2" dia G.I. pipe Tk. 180.00 per foot 312 38 mm/1.5" dia G.I. pipe Tk. 148.00 per foot 313 19 mm/3/4" dia G.I. pipe Tk. 70.00 per foot 314 13 mm/1/2" dia G.I. pipe Tk. 52.00 per foot 315 Adjustable mechanism including top and bottom plate Tk. 600.00 per set 316 I-section joist to support inclined prop Tk. 400.00 per foot 317 4" x 2" M.S. box channel with 1/8" thick M.S. sheet Tk. 350.00 per foot 318 Steel prop with adjustable mechanism including top and bottom plate Tk. 1,650.00 per set 319 Turn-buckle including tie rod Tk. 450.00 per set C13 PAINT / POLISHING 320 Standard exterior emulsion paint Tk. 279.00 per litre 321 Premium exterior emulsion paint Tk. 397.00 per litre 322 Sealer for exterior emulsion paint Tk. 174.00 per litre 323 Silicon based paint/coating Tk. 280.00 per litre 324 Ready-mix putty ( exterior) Tk. 50.00 per litre 325 Ready-mix putty ( interior) Tk. 52.00 per kg 326 Thinner for oil-based paint (turpentine) for general purpose Tk. 120.00 per kg 327 Synthetic polyvinyl (S.P.) distemper Tk. 80.00 per litre 328 Synthetic polyvinyl (S.P.) distemper primer /sealer Tk. 149.00 per litre 329 Acrylic plastic emulsion paint (plastic/matt finish) Tk. 202.00 per litre 330 Acrylic plastic emulsion paint (silky finish) Tk. 391.00 per litre 331 Acrylic plastic emulsion paint (odorless) Tk. 500.00 per litre 332 Sealer for acrylic plastic emulsion paint Tk. 149.00 per litre PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 14 Unit 333 Standard synthetic enamel paint Tk. 200.00 per litre 334 Premium synthetic enamel paint Tk. 270.00 per litre 335 Oil based anticorrosive primer Tk. 175.00 per litre 336 Thinner for oil-based paint (turpentine) for general purpose Tk. 120.00 per litre 337 Chlorinated rubber paint Tk. 588.00 per litre 338 Chlorinated rubber sealer Tk. 523.00 per litre 339 Chlorinated rubber paint thinner Tk. 212.00 per litre 340 Epoxy enamel primer including base, curing agent & thinner Tk. 500.00 per litre 341 Epoxy enamel paint including base, curing agent & thinner Tk. 523.00 per litre 342 Textured coating including sealer, texture coat & top coat Tk. 250.00 per litre 343 Wood varnishing: Yacht ( alkyd based) Tk. 250.00 per litre 344 Wood varnishing: Egg-shell ( alkyd based) Tk. 250.00 per litre 345 Wood varnishing: Matt ( alkyd based) Tk. 250.00 per litre 346 Thinner for alkyd based wood varnishing Tk. 130.00 per litre 347 Self leveling epoxy coating (4 mm thickness) Tk. 150.00 per sft 348 Oxalic acid Tk. 95.00 per litre 349 Wax for polishing Tk. 299.00 per kg 350 Design Paint including base coat , design coat & protection coat Tk. 390.00 per litre French-Polishing 351 French powder Tk. 46.00 per kg 352 Spirit Tk. 130.00 per Ib 353 Gala Tk. 780.00 per kg 354 Karpa Tk. 550.00 per kg 355 Sand paper Tk. 14.00 each 356 Putty Tk. 90.00 per kg 357 Markin cloth Tk. 10.00 per yard 358 Cotton Tk. 90.00 per lbs PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL C14 Items Rate ALUMINIUM : 15 Unit Powder coated Anodized coated I. Aluminium Channel / Sections: Rate per foot Bronze Silver S.S colour Any colour Unit 359 101.60 mm, 44.45 mm wall frame of 1.2 mm thick Tk. 118.00 Tk.115.00 Tk.122.00 Tk.125.00 per foot 360 54 mm, 46 mm wall frame of 1.8 mm shutter side 2.3 mm thick Tk. 130.00 Tk.125.00 Tk.133.00 Tk.135.00 per foot 361 16.54 mm, 15.49 mm Door glass bit of 0.99 mm thick Tk. 16.00 Tk. 15.00 Tk. 16.00 Tk. 18.00 per foot 362 101.54 mm, 42.93 mm closure system of 1.8 mm thick Tk. 131.00 Tk.126.00 Tk.134.00 Tk.141.00 per foot 363 101.60 mm closure cover of 1.2 mm thick Tk. 45.00 Tk. 44.00 Tk. 47.00 Tk. 54.00 per foot 364 101.60 mm, 12.70 mm floor bottom of 4 mm thick Tk. 133.00 Tk.123.00 Tk.131.00 Tk.131.00 per foot 365 82.60 mm, 43.99 mm door shutter bottom of 1.8 mm thick Tk. 173.00 Tk.168.00 Tk.178.00 Tk.186.00 per foot 366 51 mm, 43.99 mm door shutter top of 1.8 mm thick Tk. 142.00 Tk.138.00 Tk.146.00 Tk.153.00 per foot 367 101.60 mm, 38.10 mm, 25.4 mm door handle (short) of 2.3 mm, 2.3 mm, 4.01 mm thick Tk. 183.00 Tk.177.00 Tk.188.00 Tk.197.00 per foot 368 101.60 mm, 44.45 mm top & side 1.8 mm thick Tk. 176.00 Tk.171.00 Tk.182.00 Tk.187.00 per foot 369 101.35 mm, 44.45 mm bottom of 1.2 mm thick Tk. 90.00 Tk. 88.00 Tk. 93.00 Tk. 96.00 per foot 370 44.32 mm, 19.61 mm fixed bottom cover of 1.2 mm thick Tk. 52.00 Tk. 51.00 Tk. 54.00 Tk. 55.00 per foot 371 83.21mm, 16.00 mm fixed grouve cover of 1.2 mm thick Tk. 79.00 Tk. 76.00 Tk. 81.00 Tk. 83.00 per foot 372 39.09mm, 14.81mm fixed glass protector of 1.0 mm thick Tk. 25.00 Tk. 24.00 Tk. 26.00 Tk. 27.00 per foot 373 15.75 mm, 14.81mm fixed glass protector bit of 0.99 mm thick Tk. 18.00 Tk. 17.00 Tk. 19.00 Tk. 21.00 per foot 374 75.50 mm, 17.79 mm outer low bottom 0f 1.2 mm thick Tk. 82.00 Tk. 81.00 Tk. 85.00 Tk. 96.00 per foot 375 75.5 mm, 26.8 mm outer top of 1.2 mm thick Tk. 92.00 Tk. 89.00 Tk. 95.00 Tk.107.00 per foot 376 33 mm, 26.80 mm, 22 mm shutter top of 1.2 mm thick Tk. 62.00 Tk. 60.00 Tk. 64.00 Tk. 66.00 per foot 377 60 mm, 24 mm shutter bottom of 1.2 mm thick Tk. 87.00 Tk. 84.00 Tk. 89.00 Tk. 92.00 per foot 378 75.50 mm, 19.90 mm outer side of 1.2 mm thick Tk. 77.00 Tk. 74.00 Tk. 79.00 Tk. 81.00 per foot 379 49.20 mm, 26.20 mm shutter lock of 1.2 mm thick Tk. 80.00 Tk. 78.00 Tk. 82.00 Tk. 85.00 per foot 380 34.40 mm, 32.10 mm, 25.40 shutter inter lock of 1.2 mm thick Tk. 83.00 Tk. 81.00 Tk. 86.00 Tk. 88.00 per foot 381 31.75 mm shutter divider of 1.2 mm thick Tk. 66.00 Tk. 64.00 Tk. 68.00 Tk. 71.00 per foot PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 16 Unit 382 31.00 mm, 26.00 mm sliding fixed side of Tk. 46.00 Tk. 44.00 Tk. 47.00 Tk. 50.00 per foot 383 7.14 mm spandrel of 1.4mm to 1.2mm thick Tk. 88.00 Tk. 85.00 Tk. 90.00 Tk. 92.00 per foot 384 75.50 mm, 32 mm outer bottom (high) of 1.2 mm thick Tk. 90.00 Tk. 88.00 Tk. 93.00 Tk. 96.00 per foot 385 75.5 mm, 26.80 mm outer top of 1.2 mm thick Tk. 92.00 Tk. 89.00 Tk. 95.00 Tk. 98.00 per foot 386 37.78 mm, 31.78 mm bottom cover of 1.2 mm thick Tk. 39.00 Tk. 38.00 Tk. 40.00 Tk. 42.00 per foot 387 76.20 mm, 38.10 mm grouve cover of 1.2 mm thick Tk. 88.00 Tk. 85.00 Tk. 90.00 Tk. 92.00 per foot 388 57.15 mm, 15.80 mm grouve cover of 1.2 mm thick Tk. 59.00 Tk. 57.00 Tk. 60.00 Tk. 62.00 per foot 389 76.20 mm, 38.10 mm, 57.15 mm fixed top & side of 1.2 mm thick Tk. 115.00 Tk.112.00 Tk.118.00 Tk.123.00 per foot 390 38.88 mm, 36.63 mm casement outer 1.2 mm thick Tk. 52.00 Tk. 50.00 Tk. 53.00 Tk. 56.00 per foot 391 47.62 mm, 28.57 mm, 40.82 mm casement shutter of 1.9 mm thick Tk. 90.00 Tk. 88.00 Tk. 93.00 Tk. 97.00 per foot 392 15.87 mm, 27.00 mm casement shutter top of 1.245 mm thick Tk. 25.00 Tk. 24.00 Tk. 26.00 Tk. 29.00 per foot 393 57.15 mm, 15.80 mm grouve cover of 1.2 mm thick Tk. 59.00 Tk. 57.00 Tk. 60.00 Tk. 62.00 per foot 394 17.40 mm, 31.78 mm bottom cover of 1.2 mm thick Tk. 39.00 Tk. 38.00 Tk. 40.00 Tk. 42.00 per foot 395 76.20 mm, 38.10 mm fixed bottom cover of 1.2 mm thick Tk. 115.00 Tk.112.00 Tk.118.00 Tk.120.00 per foot 396 57.15 mm, 38.10 mm top & side of 1.2 mm thick Tk. 128.00 Tk.125.00 Tk.132.00 Tk.135.00 per foot 397 76.00 mm, 38.10 mm wall frame of 1.2 mm thick Tk. 90.00 Tk. 88.00 Tk. 93.00 Tk. 99.00 per foot 398 55.02 mm, 37.39 mm louver Z-section of 1.2 mm thick Tk. 30.00 Tk. 30.00 Tk. 31.00 Tk. 34.00 per foot 399 39.67 mm, 15.06 mm louver U-section of 1.2 mm thick Tk. 35.00 Tk. 34.00 Tk. 37.00 Tk. 40.00 per foot 400 95.00 mm, 38.00 mm outer bottom of 1.2 mm thick Tk. 113.00 Tk.110.00 Tk.117.00 Tk.124.00 per foot 401 95.00 mm, 28.50 mm outer top of 1.2 mm thick Tk. 113.00 Tk.110.00 Tk.117.00 Tk.122.00 per foot 402 95.00 mm, 19.50 mm outer side of 1.2 mm thick Tk. 90.00 Tk. 88.00 Tk. 93.00 Tk. 97.00 per foot 403 42.2 mm, 13.2 mm net section of 1.2 mm thickness Tk. 55.00 Tk. 53.00 Tk. 57.00 Tk. 59.00 per foot 404 1" x 1" square pipe Tk. 38.00 Tk. 37.00 Tk. 39.00 Tk. 41.00 per foot 405 7.14 mm span drel of 1.2 mm thick (0.70 kg/m) Tk. 90.00 Tk. 88.00 Tk. 92.00 Tk. 94.00 per foot 406 Mosquito net (fiber net) (per sft) Tk. 17.00 Tk. 15.00 Tk. 19.00 Tk. 21.00 per foot 407 T-section (main T) for false ceiling Tk. 25.00 Tk. 24.00 Tk. 26.00 Tk. 29.00 per foot PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 17 Unit 408 T-section (cross T) for false ceiling Tk. 22.00 Tk. 21.00 Tk. 22.00 Tk. 27.00 per foot 409 L-section for wall and ceiling Tk. 21.00 Tk. 20.00 Tk. 22.00 Tk. 26.00 per foot 410 Aluminium curtain rail including hard-wares and fittings Tk. 27.00 Tk. 26.00 Tk. 28.00 Tk. 30.00 per foot 411 44 mm, 44 mm, 1.20 box Tk. 79.00 Tk. 76.00 Tk. 81.00 Tk. 84.00 per foot 412 25 mm, 25 mm, 1.20 angle Tk. 23.00 Tk. 22.00 Tk. 24.00 Tk. 25.00 per foot 413 25 mm, 25 mm, 1.20 fitting angle Tk. 48.00 Tk. 47.00 Tk. 50.00 Tk. 52.00 per foot 414 Alluminium composite Panel Tk. 250.00 Tk.248.00 Tk.252.00 Tk.255.00 per foot 415 Curtain wall sub mullium (100mm X 50 mm X 2.00 mm) Tk. 294.00 Tk.286.00 Tk.303.00 Tk.313.00 per foot 416 Curtain wall sub mullium (50mm X 50 mm X 1.50 mm) Tk. 177.00 Tk.173.00 Tk.184.00 Tk.191.00 per foot 417 Casement outer frame (29mm X 20 mm X 1.20 mm) Tk. 39.00 Tk. 38.00 Tk. 40.00 Tk. 44.00 per foot 418 Casement outer section (52mm X 22 mm X 40mm X 1.5 mm) Tk. 152.00 Tk.147.00 Tk.156.00 Tk.163.00 per foot 419 Aluminium angle (50mm X 50 mm X 6mm) Tk. 235.00 Tk.230.00 Tk.240.00 Tk.245.00 per foot 420 Aluminium cover (50mm X 6 mm X 1.5mm) Tk. 74.00 Tk. 72.00 Tk. 76.00 Tk. 78.00 per foot 421 50mm X 6 mm X 1.5mm angle for casement shutter Tk. 78.00 Tk. 75.00 Tk. 80.00 Tk. 82.00 per foot 422 38mm x 38mm Aluminium frame (Wall box) of 1.5 mm Tk. 75.00 Tk. 72.00 Tk. 77.00 Tk. 80.00 per foot 423 38mm x 12mm and 1.5 mm thick Aluminium frame of Netting shutter top, bottom & side Tk. 67.00 Tk. 65.00 Tk. 69.00 Tk. 72.00 per foot 424 20 mm Aluminium pipe Tk. 93.00 Tk. 91.00 Tk. 95.00 Tk. 98.00 per foot PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate Unit II. Accessories for aluminium door-window works 425 Swing door clouser Tk. 2,700.00 set 426 Swing door lock Tk. 625.00 set 427 Swing door Mohiar Tk. 5.00 foot 428 Fixed Neoprene Tk. 2.60 foot 429 Flush bolt Tk. 320.00 set 430 Sliding door lock Tk. 200.00 set 431 Sliding door /window wheel Tk. 70.00 no 432 Sliding door /window Mohiar Tk. 1.30 foot 433 Sliding Neoprene Tk. 2.70 foot 434 Sealant Tk. 3.00 gm 435 Sliding window key lock Tk. 80.00 set 436 Bolts and Screws including sealants Tk. 70.00 LS 437 4-bar hinge Tk. 700.00 no 438 Casement handle Tk. 260.00 no 439 Rivet Tk. 5.00 no 440 S.S. screw Tk. 2.50 no 441 Screws Tk. 1.00 no 442 5 mm tinted glass Tk. 82.00 sft 443 5 mm clear glass Tk. 66.00 sft 444 Rubber gasket Tk. 1.90 sft 445 Aluminium sheet Tk. 382.00 Kg. 446 Protector bit (Single) Tk. 19.33 foot 447 Protector bit (Double) Tk. 26.76 foot 448 Silicon (1 piece 300 mm) Tk. 300.00 each 449 Steel rowel bolt Tk. 40.00 each 450 Rivets (Big) Tk. 2.00 each 451 Norton Tap Tk. 27.00 each 18 PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 19 Unit 452 Masking tape Tk. 25.00 each 453 Structural sealant Tk. 12.00 each 454 Casement 4-bar huge Tk. 500.00 each 455 Casement handle Tk. 245.00 each 456 Sealant Gum Tk. 365.00 each 457 Arm lock Tk. 400.00 each 458 M.S. angle Tk. 108.00 each 459 Curtain wall jointer Tk. 313.00 each 460 Dow coling silicon gum Tk. 620.00 pcs 461 Fin connector Tk. 4,000.00 each 462 Fin hanger Tk. 5,000.00 each 463 SS U Channel Tk. 200.00 foot 464 SS Spider Set Tk. 9,000.00 each 465 6 mm thick PVC board of size 600x600 mm Tk. 40.00 per sft 466 0.6 mm thick plain aluminium board of size 600x600 mm Tk. 95.00 per sft 467 0.6 mm thick perforated aluminium board of size 600x600 mm Tk. 75.00 per sft 468 6 mm thick Fiber cement board Tk. 80.00 per sft 469 38x12.5x0.5 mm U bar/ Furring channel Tk. 20.00 per foot 470 19 mm x 0.5 mm G.I. angle Tk. 22.00 per foot 471 12 mm thick solid PVC board Tk. 100.00 per sft 472 Wall paper Tk. 60.00 per sft III. Vertical Venetian Blinds 473 Head rail, Aluminium Tk. 9.00 per foot 474 Rod tilt / Hexagon Aluminium Rod Tk. 8.50 per foot 475 End cap set / End closure set Tk. 75.00 per set 476 Weight plate / Weight bar Tk. 11.00 each 477 Link Chain / Weight Chain Tk. 11.00 per foot 478 Ball Chain / Plastic Chain Tk. 10.00 per foot PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 20 Unit 479 Plastic Washer / Fabric upper clip Tk. 2.75 each 480 Spacer (Link) / Plastic Runner Spring Tk. 9.00 each 481 Handling Cord /Nylon Cord Tk. 3.00 per foot 482 Thread bar Tk. 10.00 each 483 Angle Clip Tk. 8.00 each 484 Plastic Runner Tk. 4.00 each 485 Glass fiber Fabrics (special quality, foreign made) Tk. 100.00 per sft 486 Angle Tk. 5.00 each 487 Fitting-fixing charge Tk. 4.00 per sft IV. Horizontal Venetian Blind/Horizontal Zebra Blind 488 Head rail Tk. 8.50 per foot 489 Bottom rail Tk. 5.00 per foot 490 Aluminium Strips (special quality, foreign made) Tk. 80.00 per foot 491 synthetic net Tk. 60.00 per foot 492 polyester fabrics Tk. 70.00 per foot 493 vinyl or PVC coated strip Tk. 90.00 per foot 494 Rod till / hexagon aluminium Rod Tk. 7.00 per foot 495 Gear box /tilter Tk. 10.00 each 496 Support and cord drum Tk. 6.00 each 497 Cord lock Tk. 6.00 each 498 Stop ring Tk. 8.00 each 499 Tassel Tk. 5.00 ach 500 Ladder cord Tk. 4.00 per foot 501 Stick / tilt wand Tk. 8.00 each 502 Bracket/metal intermediate bracket Tk. 7.50 each 503 Bottom cap / end cap for head rail Tk. 10.00 each 504 Tape holder Tk. 6.00 each 505 Steel washer Tk. 8.00 each PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 21 Unit 506 Head cap set Tk. 12.00 each 507 Handling cord Tk. 5.00 per foot 508 Labour cost Tk. 3.50 per sft V. Blackout/ Translucent roller Blind 509 Head control tube, 38mm aluminium tube with wall thickness 1mm Tk. 20.00 per foot 510 one idler aluminium rod Tk. 15.00 per foot 511 End cap set/end closure set Tk. 50.00 Per set 512 Weight plate/weight bar Tk. 11.00 each 513 Link chain/weight chain Tk. 11.00 per foot 514 Ball chain/plastic chain Tk. 10.00 per foot 515 Plastic washer/fabricupper clip Tk. 2.75 each 516 mounting brackets cover Tk. 12.00 per foot 517 Handling cord/nylon cord Tk. 3.00 per foot 518 Thread bar Tk. 10.00 each 519 Angle clip Tk. 8.00 each 520 Plastic runner Tk. 4.00 each 521 PVC/ vinyl laminated fiberglass fabrics Tk. 90.00 per sft 522 Angle Tk. 5.00 each 523 clip in brackets with cover Tk. 10.00 per set 524 38mm clutch Tk. 20.00 each 525 piano wire flat springs Tk. 15.00 per foot 526 elastic spindle Tk. 25.00 each 527 38mm thick rope chain bead clutch Tk. 70.00 per set 528 bead chain Tk. 20.00 per foot 529 25mm thick bottom aluminum tube with 1mm wall thickness Tk. 15.00 per foot 530 lifting plastic kit Tk. 10.00 rach 531 clutch connectors Tk. 80.00 each 532 mounting profile for outside mount of roller tube Tk. 30.00 per foot PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 22 Unit 533 bottom bar end cap Tk. 15.00 each 534 pull with tassel Tk. 50.00 each 535 Fitting-fixing charge Tk. 4.00 per sft C15 PVC I. uPVC Pipe for Electric Conduit 536 Wall grade 3/4" / 19 mm dia pipe, 1.2 mm thick Tk. 5.00 per foot 537 Wall grade 1"/ 25 mm dia pipe, 1.2 mm thick Tk. 7.00 per foot 538 Roof grade 3/4"/19 mm dia pipe, 1.5 mm thick Tk. 5.50 per foot 539 Roof grade 1"/ 25 mm dia pipe, 1.5 mm thick Tk. 8.50 per foot 540 Roof grade 1.25"/ 32 mm dia pipe, 1.5 mm thick Tk. 11.00 per foot II. Fittings for uPVC Pipe for Electric Conduit 541 3/4"/19 mm Socket Tk. 45.00 per dzn 542 1" / 25 mm Socket Tk. 60.00 per dzn 543 1.25"/ 32 mm Socket Tk. 65.00 per dzn 544 3/4" / 19 mm Plain bend Tk. 75.00 per dzn 545 1"/ 25 mm Plain bend Tk. 80.00 per dzn 546 1.25"/ 32 mm Plain bend Tk. 120.00 per dzn 547 3/4"/ 19 mm Circular box single Tk. 96.00 per dzn 548 3/4" / 19 mm Circular box double Tk. 96.00 per dzn 549 1"/ 25 mm Circular box single Tk. 108.00 per dzn 550 1"/ 25 mm Circular box double Tk. 108.00 per dzn 551 Solvent cement for jointing Tk. 2.00 per grm III. Plastic Door, Windows & Partition 552 PVC door frame thickness min 2.5 mm Tk. 107.00 per meter 553 G.I inner joint (76.2 mm x 38.1 mm) clamp Tk. 12.00 each 554 G.I inner joint (72.2 mm x 76.2 mm) clamp Tk. 13.00 each 555 G.I outer clamp Tk. 12.00 each 556 G.I. wall clamp (216 x 19 mm) Tk. 14.00 each PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 23 Unit 557 Rivet ø 3.17 ø 3 x ↔12.17 mm Tk. 1.50 each 558 Garjan wood 25.4 x 22.22 mm Tk. 27.00 per meter 559 uPVC hollow section wall thickness 2.5 mm Tk. 880.00 per meter 560 uPVC side clip 2.5 mm Tk. 26.00 per meter 561 Screw 25.5 mm Tk. 3.00 each 562 Tower bolt Ø 9.38 x 152.4 mm Tk. 56.00 each 563 Plastic handle 146 mm long Tk. 53.00 each 564 Hinges 76.2 x 57.15 mm Tk. 48.00 each 565 Hasp bolt Ø 25 x ↔ 254 mm Tk. 190.00 each 566 Round lock normal (China/Korea/Taiwan) Tk. 550.00 each 567 Rod Ø 9.52 mm x 3 pcs Tk. 40.00 each 568 Nut with washer 6 pcs Tk. 12.00 each 569 Rowel plug Tk. 1.00 each 570 T-frame Tk. 130.00 per meter 571 L-frame Tk. 130.00 per meter 572 Hollow bit Tk. 60.00 per meter 573 Screw for hollow partition Tk. 2.00 each 574 T-inner joint clamp Tk. 9.00 each 575 L-inner joint clamp Tk. 14.00 each 576 Glass bit Tk. 60.00 per meter 577 Round rubber bit Tk. 20.00 per meter 578 Rubber bit Tk. 10.00 per meter 579 Adhesive Tk. 200.00 per kg 580 10mm glass for partition wall Tk. 300.00 per sqm IV. Plastic Door, Windows & Partition 581 8 mm thick PVC sheet Tk. 1,550.00 per pc 582 Partition frame (Profile) Tk. 60.00 per foot 583 4" New sash (Profile) Tk. 140.00 per foot PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 24 Unit 584 Sliding glass bead (Profile) Tk. 20.00 per foot 585 Partition frame (Reinforcement) Tk. 28.00 per foot 586 Rubber Tk. 7.00 per foot 587 Screw Tk. 4.00 per pc 588 Hinge Tk. 47.00 per pc 589 Sitkani Tk. 65.00 each 590 Handle Tk. 50.00 each 591 Steel clamp (8") Tk. 10.00 each 592 Partition glass bit Tk. 10.00 per foot 593 Sliding frame Tk. 35.00 per foot 594 Sliding sash Tk. 40.00 per foot 595 Sliding interlock Tk. 13.00 per foot 596 Brush Tk. 10.00 per foot 597 Lock (2") Tk. 35.00 each 598 Sliding frame: reinforcement Tk. 28.00 per foot 599 Sliding sash: reinforcement Tk. 28.00 per foot 600 5 mm clear glass Tk. 70.00 per sft 601 3 mm thick plastic wood Tk. 650.00 per pc 602 2" Screw Tk. 110.00 per pack 603 Wall bit (9/64) Tk. 40.00 per pc 604 Super bit Tk. 160.00 per pc 605 Sun-star Glue Tk. 110.00 per litre 606 Tarpin Tk. 250.00 per gallon 607 Super Glue Tk. 30.00 per pc 608 6 mm thick plastic wood Tk. 1,300.00 per pc 609 12 mm thick plastic wood Tk. 2,740.00 per pc 610 2" Magnet Tk. 40.00 each 611 Chain Hinge (kabja) Tk. 120.00 each PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 25 Unit 612 Metal Handle Tk. 185.00 each 613 Cloth Tk. 10.00 per yrds 614 Rowl plug (10 Nos. per pack) Tk. 20.00 per pack 615 1" Aluminium main tee Tk. 27.00 per foot 616 1" Aluminium cross tee Tk. 23.00 per foot 617 1" Aluminium L-section Tk. 23.00 per foot C16 GAS CONNECTION WORK I. 50 PSI API 5L, Grade-B ERW M.S. Pipe 618 75 mm ND (88.90 mm OD) Tk. 312.94 per foot 619 50 mm ND (60.30 mm OD) Tk. 205.00 per foot 620 25 mm ND (33.40 mm OD) Tk. 100.00 per foot 621 20 mm ND (26.70 mm OD) Tk. 65.00 per foot II. Consumable 622 4" x 400' Black tape Tk. 6,159.23 per roll 623 2" x 200' Black tape Tk. 1,168.55 per roll 624 Primer Tk. 315.00 per litre III. Butt welded joints 625 75 mm ND (88.90 mm OD) Tk. 149.75 each 626 50 mm ND (60.30 mm OD) Tk. 127.26 each 627 25 mm ND (33.40 mm OD) Tk. 99.73 each 628 20 mm ND (26.70 mm OD) Tk. 85.32 each IV. Fittings & accessories 629 50 x 50 x 50 mm N.D. Tee CD40 Tk. 231.55 each 630 50 x 50 x 25 mm N.D. Tee CD40 Tk. 258.30 each 631 25 x 25 x 25 mm N.D. Tee CD40 Tk. 146.76 each 632 50 mm x 90o Elbow Tk. 172.43 each 633 25 mm x 90o Elbow Tk. 52.77 each 634 50 mm x 45o Elbow Tk. 74.36 each PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 26 Unit 635 50 x 25 mm reducer Tk. 82.44 each 636 20 mm plug/socket Tk. 260.00 each 637 50 x 20 mm saddle Tk. 199.17 each 638 50 mm dia end cap Tk. 64.26 each 639 25 mm dia end cap Tk. 40.39 each 640 50 x 50 mm equal tee Tk. 16,191.07 each 641 25 x 25 x 25 mm service tee Tk. 1,728.83 each 642 50 x 25 mm service tee Tk. 3,240.01 each 643 50 mm insulating kits Tk. 1,914.93 each 644 50 mm flange W/N 150 R/F Tk. 786.95 each 645 5/8" x 3" long nut bolt including washer Tk. 74.18 each 646 Valve Pit (Titas Gas T&D Co. Ltd. design & plan.) (for 2" dia above) Tk. 18,342.50 each 647 M.S. sheet cover supplied by Titas Gas T & D Co. Ltd.(for 2" dia above) Tk. 15,516.23 each 648 Testing & purging Tk. 649 50 mm ND dia ball valve class 150 R.F. Tk. 7,318.60 each 650 25 mm ND dia plug valve class 150 R.F. Tk. 5,221.92 each 651 25 mm dia flange W/N 150 R.F. Tk. 385.83 each 652 50 mm dia flange W/N 150 R.F. Tk. 786.95 each 653 50 mm dia gasket Tk. 279.28 each 654 25 mm dia gasket (asbestos) Tk. 45.62 each 655 1/2" x 2.5" nut-bolt Tk. 33.75 each 656 3/4" / 19 mm dia G.I. pipe (NTL or eqv.) Tk. 41.70 per foot 657 1/2" / 12 mm dia G.I. pipe (NTL or eqv.) Tk. 32.00 per foot 658 12 x 6 mm gas stop cock Tk. 193.00 each 659 20 x 20 mm gas stop cock Tk. 308.56 each C17 TERMITE TREATMENT 660 DURS BAN 20 EC Tk. 920.00 per litre 661 NEOCIDOL-60 Tk. 140.00 per % ml 21.82 per meter PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items 662 Kerosene / Diesel C18 CONCRETE HOLLOW BLOCKS & PAVING STONE WORKS 663 Rate 27 Unit Tk. 68.00 per litre 70 mm non load bearing concrete hollow block Tk. 24.00 each 664 Transportation 70 mm block Tk. 3.66 each 665 Mortar mix Tk. 281.08 per litre 666 90 mm non load bearing concrete hollow block Tk. 36.00 each 667 Transportation 90 mm block Tk. 3.00 each 668 140 mm non load bearing concrete hollow block Tk. 53.00 each 669 Transportation 140/190 mm block Tk. 7.87 each 670 140 mm load bearing concrete hollow block Tk. 56.06 each 671 190 mm load bearing concrete hollow block Tk. 60.00 each 672 150 mm concrete ceiling block Tk. 64.87 each 673 Transportation 150/200 mm ceiling block Tk. 8.74 each 674 200 mm concrete ceiling block Tk. 94.01 each 675 External plaster mix Tk. 286.57 per litre 676 60 mm grey uniblock: 15 N/mm2 Tk. 14.00 each 677 60 mm coloured uniblock: 15 N/mm2 Tk. 18.00 each 678 Transportation 60/80 mm uniblock/Rec-block Tk. 2.06 each 679 60 mm grey uniblock: 49 N/mm2 Tk. 17.00 each 680 60 mm coloured uniblock: 49 N/mm2 Tk. 20.00 each 681 80 mm grey uniblock: 49 N/mm2 Tk. 22.00 each 682 80 mm coloured uniblock: 49 N/mm2 Tk. 28.00 each 683 Rectangular grey block Tk. 15.00 each 684 Rectangular coloured block Tk. 18.00 each 685 250 x 250 mm grey engraved CC tiles Tk. 46.66 per sft 686 250 x 250 mm coloured engraved CC tiles Tk. 56.51 per sft 687 Transportation of 250 mm x 250 mm tiles Tk. 1.90 per sft 688 Roof Engraved Tile Tk. 36.63 per sft PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate Unit 689 Solid block (215 x 100 x 65) mm Tk. 14.00 each 690 Transportation Solid block (215 x 100 x 65) mm Tk. 1.64 each 691 200 mm x 92 mm x 37.5 mm grey solid cladding block Tk. 13.00 each 692 Transportation solid cladding block Tk. 2.31 each 693 200 mm x 92 mm x 37.5 mm coloured solid cladding block Tk. 15.00 each 694 400 mm x 92 mm x 50 mm grey split cladding Tk. 16.61 each 695 Transportation split cladding Tk. 2.00 each 696 400 mm x 92 mm x 50 mm coloured split cladding Tk. 21.45 each 697 420 mm x 330 mm x 15 mm coloured facial cladding Tk. 35.21 each 698 418 mm x 330 mm x 17 mm red colour roof tiles Tk. 150.00 each 699 Transportation roof tiles Tk. 3.45 each 700 J-hook with nut and washer Tk. 10.35 each 701 418 mm x 330 mm x 17 mm oriental colour roof tiles Tk. 42.56 each 702 418 mm x 330 mm x 17 mm antique red colour roof tiles Tk. 49.05 each 703 418 mm x 330 mm x 17 mm green colour roof tiles Tk. 53.36 each 704 600 mm x 300 mm x 100 mm kerb stone Tk. 150.00 each 705 Transportation of kerb stone Tk. 31.19 each 706 100 mm non-load bearing concrete hollow block Tk. 30.68 each 707 Transportation of 100 mm hollow block Tk. 3.75 each 708 250 mm concrete ceiling block Tk. 94.45 each 709 Transportation 250 mm ceiling block Tk. 8.75 each 710 300 mm concrete ceiling block Tk. 114.76 each 711 Transportation of 300 mm ceiling block Tk. 13.23 each 712 100 mm concrete ceiling block Tk. 37.32 each 713 Transportation of 100 mm ceiling block Tk. 5.36 each 714 418 mm x 330 mm x 17 mm brown colour roof tiles Tk. 49.45 each 715 418 mm x 330 mm x 17 mm Navy blue roof tiles Tk. 52.87 each 716 418 mm x 330 mm x 17 mm Mahogany colour roof tiles Tk. 56.00 each 28 PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 29 Unit 717 418 mm x 330 mm x 17 mm Rust Gold colour roof tiles Tk. 56.00 each 718 All type concrete ridge: red colour Tk. 150.00 each 719 60 mm gray trihex Tk. 20.00 each 720 60 mm colour trihex Tk. 30.00 each 721 400 mm x 200 mm x100 mm sand cement hollow block (SCHB) Tk. 28.00 each 722 250 mm x 115 mm x 115 mm sand cement solid block Tk. 10.00 each 723 300 mm x 115 m x 115 mm size thermal block Tk. 22.00 each 724 240 mm x 115 mm x 70 mm size compressed stabilized earth block(CSEB) Tk. 7.00 each 725 300 mm x 115 mm x 70 mm size sand cement solid block (SCSB) Tk. 11.00 each C19 SANITARY AND WATER SUPPLY WORK I. Misc. items 726 Water sealed heavy type 18" dia C.I. M.H. cover having locking arrangement Tk. 900.00 each 727 Water sealed heavy type 24" dia C.I. M.H. cover having locking arrangement Tk. 1,390.00 each 728 RCC tees Tk. 425.00 each 729 CI brackets Tk. 115.00 per pair 730 Heavy type CI brackets Tk. 158.00 per pair 731 Nuts with washer Tk. 26.00 each 732 Clamp Tk. 50.00 each 733 50 mm screw & rowel plug Tk. 9.00 each 734 75 mm Screw, Rowel plug & Washer Tk. 13.00 each 735 Plastic clip Tk. 10.00 each 736 Solvent cement Tk. 0.70 per ml 737 Hem Tk. 30.00 per sqm 738 Scaffolding Tk. 3.00 per foot 739 Teflon Tk. 16.00 per pcs 740 Nipples with jum-nuts Tk. 60.00 each 741 PVC connection pipe Tk. 30.00 each II. Fixtures & Accessories PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate Unit 742 White 465 x 340 x 415 mm commode Tk. 1,450.00 each 743 Coloured commode: 465 x 340 x 415 mm Tk. 1,530.00 each 744 Special coloured commode: 465 x 340 x 415 mm Tk. 1,670.00 each 745 Seat cover: 465 x 340 x 415 mm Tk. 510.00 each 746 White 490 x 190 x 350 mm low-down Tk. 1,250.00 each 747 Coloured low-down: 490 x 190 x 350 mm Tk. 1,400.00 each 748 Special coloured low-down: 490 x 190 x 350 mm Tk. 1,600.00 each 749 32 mm dia plastic pipe for low-down connection Tk. 75.00 each 750 Light colour combicloset , Size 670 x 365 x 755 mm, 31kg Tk. 6,040.00 each 751 Coloured combicloset (Marbel shaded) :670 x 365 x 755mm, 31kg Tk. 7,850.00 each 752 Special coloured combicloset: (Deep colour) 670 x 365 x 755 mm, 31kg Tk. 9,060.00 each 753 Light colour (Ivory, Alpine White, Grey, Pink, Blue, Aqua Verde), 700 x 370 x 795 mm, 32.5kg Tk. 7,130.00 each 754 Coloured (Marble shade) 700 x 370 x 795 mm, 32.5kg Tk. 9,270.00 each 755 Special coloured (Deep Blue, Ruby, Rain Forest, Green), 700 x 370 x 795 mm, 32.5kg Tk. 10,695.00 each 756 Light colour (Ivory, Alpine White, Grey, Pink, Blue, Aqua Verde), 700 x 360 x 785 mm, 38 kg Tk. 9,950.00 each 757 Coloured (Marble Shade) 700 x 360 x 785 mm, 38 kg Tk. 13,935.00 each 758 Special coloured (Deep Blue, Ruby, Rain Forest, Green) 700 x 360 x 785 mm, 38 kg Tk. 14,925.00 each 759 White / Ivory colour 440 x 730 x 785 mm, 36.75 kg Tk. 11,825.00 each 760 White and Ivory colour 440 x 730 x 785 mm, 36.75 kg Tk. 11,825.00 each 761 White combicloset, 725 x 360 x 840 mm, 42.7kg Tk. 12,640.00 each 762 Coloured (Marble Shade) , 725 x 360 x 840 mm size, approx. 42.7 kg Tk. 16,430.00 each 763 Special coloured (Deep Blue, Ruby, Rain Forest, Green), 725 x 360 x 840 mm size, approx. 42.7 kg Tk. 18,950.00 each 764 White colour, 370 x 760 x 800 mm size, approx. 44.69 kg Tk. 13,990.00 each 765 White / Ivory colour glazed vitreous W/H wash basin excluding pedastal, 560 x 410 x 205 mm, 7.90kg Tk. 3,150.00 each 766 Supplying, glazed vitreous W/H Wash Basin including pedastal approx (size 600 x 500 x 855 mm, 26.92kg ) Tk. 4,650.00 each 767 Flushing equipment: Tk. each 750.00 30 PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items 768 Light Colour Bangladesh pattern, long pan with foot-rest , Size 530 x 430 x 210 mm, 12.5 kg Tk. 887.00 each 769 Coloured ( Marbel Shaded) long pan 530 x 430 x 210 mm, 12.5 kg Tk. 1,153.00 each 770 Special coloured (Deep colour) Bangladesh pattern, long pan with foot-rest, Size 530x430x210 mm 12.5 kg Tk. 1,330.00 each 771 White colour, long pan with foot-rest, approx. 530 x 450 x 290 mm 14.5 kg Tk. 1,315.00 each 772 Coloured, long pan with foot-rest, approx. 530 x 450 x 290 mm 14.5 kg Tk. 1,643.00 each 773 Special, long pan with foot-rest, coloured approx. 530 x 450 x 290 mm 14.5 kg Tk. 1,972.00 each 774 White/coloured foot-rest, Size 280 x 140 x 30 mm size glazed porcelain foot rest, 1.5 kg Tk. 200.00 per pair 775 Light colour long pan (Bangladeshi) approx. 525 x 295 x 285 mm, 5.7kg or equivalent Tk. 550.00 each 776 White colour , 600x465x225 mm,14kg Tk. 1,280.00 each 777 Coloured 600x465x225 mm,14kg Tk. 1,480.00 each 778 Special coloured 600x465x225 mm,14kg Tk. 1,580.00 each 779 White,595x430x190 mm,10kg Tk. 966.00 each 780 Coloured 595x430x190 mm,10kg Tk. 1,167.00 each 781 Special coloured 595x430x190 mm,10kg Tk. 1,400.00 each 782 White,510x450x203 mm, 9.5kg Tk. 937.00 each 783 Coloured 510x450x203 mm , 9.5kg Tk. 984.00 each 784 Special coloured 510x450x203 mm, 9.5kg Tk. 1,089.00 each 785 White, 450x405x180 mm, 7kg Tk. 665.00 each 786 Coloured 450x405x180 mm, 7kg Tk. 698.00 each 787 Special coloured 450x405x180 mm, 7kg Tk. 733.00 each 788 White 465x340x180 mm, 6kg Tk. 604.00 each 789 Coloured 465x340x180 mm, 6kg Tk. 635.00 each 790 Special coloured 465x340x180 mm, 6kg Tk. 665.00 each 791 White 535x465x210 mm, 10.5kg Tk. 966.00 each 792 Coloured 535x465x210 mm, 10.5kg Tk. 1,014.00 each 793 Special coloured 535x465x210 mm, 10.5kg Tk. 1,064.00 each Cabinet Basin Rate 31 Unit PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate Unit 794 Light colour (Ivory, Alpine White, Grey, Pink, Blue, Aqua Verde), 500x450x180 mm , 9 kg Tk. 2,613.00 each 795 Coloured ( Marble Shade) 500x450x180 mm, 9 kg Tk. 3,396.90 each 796 Special coloured (Deep Blue, Ruby, Rain Forest, Green) 500x450x180 mm, 9 kg Tk. 3,919.50 each Corner Basin 797 Light colour (Ivory, Alpine White, Grey, Pink, Blue, Aqua Verde) 440x360x195 m, 7.0kg Tk. 788.00 each 798 Coloured ( Marble Shade) 440x360x195 mm, 7.0kg Tk. 1,024.40 each 799 Special coloured ( Deep Blue, Ruby, Rain Forest, Green), 440x360x195 mm, 7.0kg Tk. 1,182.00 each 800 Light colour W-basin including pedastal, , approx. size 660 x 545 x 850 mm, 29kg Tk. 3,295.00 each 801 Coloured ( Marble Shade), approx. size 660 x 545 x 850 mm, 29kg Tk. 4,280.00 each 802 Special coloured W-basin:( Deep Colour ),including pedasta, approx. size 660 x 545 x 850 mm, 29kg Tk. 4,940.00 each 803 Light colour W-basin including pedastal : approx. 665 x 490 x 840 mm, 29.5 kg Tk. 4,760.00 each 804 Coloured ( Marble Shade) W-basin:approx. 665 x 490 x 840 mm, 29.5 kg Tk. 6,185.00 each 805 Special coloured ( Deep Colour ) W-basin: approx. 665 x 490 x 840 mm, 29.5 kg Tk. 7,135.00 each 806 Grating with brass coupling Tk. 300.00 each 807 125 mm dia Convex Cast Iron Grating Tk. 400.00 each 808 32 mm dia PVC waste pipe for W-Basin connection Tk. 150.00 each 809 CP chain with rubber plug Tk. 80.00 each Pedestal 810 White colour: approx. 670 x 186 x 170 mm, 6.5kg Tk. 1,345.00 each 811 Coloured (Marble shaded) approx. 670 x 186 x 170 mm, 6.5kg Tk. 1,750.00 each 812 Special coloured (Deep colour ): approx. 670 x 186 x 170 mm, 6.5kg Tk. 2,020.00 each 813 Light colour (Ivory, Alpine White, Grey, Pink, Blue, Aqua Verde) : approx. 670 x 186 x 170 mm Tk. 1,840.00 each 814 Coloured (Marble Shaded) approx. 670 x 186 x 170 mm, 6.5kg Tk. 2,392.00 each 815 Special coloured (Deep Blue, Ruby, Rain Forest, Green) approx. 670 x 186 x 170 mm Tk. 2,760.00 each 816 Light colour (Ivory, Alpine White, Grey, Pink, Blue, Aqua Verde) : approx. 670 x 186 x 170 mm Tk. 1,980.00 each 817 Coloured (Marble Shaded) approx. 670 x 186 x 170 mm Tk. 2,574.00 each 818 Special coloured (Deep Blue, Ruby, Rain Forest, Green ) approx. 670 x 186 x 170 mm Tk. 2,970.00 each 32 PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 33 Unit 819 Light colour : approx 445 x 355 x 330 mm, 11.5kg Tk. 1,115.00 each 820 Coloured (Marble shaded) approx 445 x 355 x 330 mm, 11.5kg Tk. 1,450.00 each 821 Special coloured (Deep colour ) approx 445 x 355 x 330 mm, 11.5kg Tk. 1,670.00 each 822 Light colour :approx 445 x 355 x 330 mm, 10kg (partition Type) Tk. 1,650.00 each 823 Coloured (Marble shade approx 445 x 355 x 330 mm, 10kg (partition Type) Tk. 2,171.00 each 824 Special coloured (Deep colour ) approx 445 x 355 x 330 mm, 10kg (partition Type) Tk. 2,505.00 each 825 White colour flat/squatting bowl urinal: 510 x 380 x 85mm in size, approx. 9.5 kg Tk. 950.00 each 826 Coloured flat/squatting bowl urinal: 510 x 380 x 85mm in size, approx. 9.5 kg Tk. 1,000.00 each 827 Special coloured flat/squatting bowl urinal: 510 x 380 x 85 mm in size, approx. 9.5 kg Tk. 1,100.00 each 828 White porcelain sink, size (mm) 635 x 480 x 195 mm, 19.5kg Tk. 1,500.00 each 829 Coloured porcelain sink: 635 x 480 x 195 mm, 19.5kg Tk. 1,800.00 each 830 Stainless steel, single bowl sink: Singapore/M'Asia, size 450 mm x 1050 mm Tk. 2,500.00 each 831 Stainless steel, double bowl Sink: Singapore/M'Asia, Tk. 4,500.00 each 832 450 x 600 x 5 mm mirror Tk. 550.00 each 833 450 x 350 x 4 mm mirror Tk. 350.00 each 834 Super quality steel frame with brackets for 600 x 125 x 5 mm size glass shelf Tk. 600.00 each 835 Super quality coloured glass for 600 x 125 x 5 mm size glass shelf Tk. 400.00 each 836 Medium quality CP iron frame with brackets for 600 x 125 x 5 mm size glass shelf. Tk. 350.00 each 837 Medium quality glass for 600 x 125 x 5 mm size glass shelf Tk. 300.00 each 838 Super quality 600 x 20 mm dia size CP towel rail. Tk. 450.00 each 839 Medium quality CP Towel Rail 600 x 20 mm dia size Tk. 375.00 each 840 White porcelain toilet paper holder, size (mm) 150 x 150 x 126 Tk. 250.00 each 841 Coloured porcelain toilet paper holder, Size (mm) 150 x 150 x 126 Tk. 325.00 each 842 White special porcelain toilet paper holder Size (mm) 150 x 150 x 126 Tk. 320.00 each 843 Coloured special porcelain toilet paper holder Size (mm) 150 x 150 x 126 Tk. 420.00 each 844 Standard size stainless steel toilet paper holder with cover Tk. 400.00 each 845 Standard size CP toilet paper holder with pastic holder rod Tk. 245.00 per set 846 125 mm dia atainless-steel floor-grating Tk. 150.00 per set PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 34 Unit 847 150 x 150 mm size stainless steel floor grating Tk. 740.00 each 848 75 x 75 mm size stainless steel floor grating Tk. 195.00 each 849 62mm dia stainless steel floor grating Tk. 95.00 each 850 150 x 150mm size plastic-grating with hinged cover Tk. 75.00 each 851 Plastic low down complete set including internal and external fittings Tk. 900.00 per set 852 Internal and external fittings for plastic low down Tk. 540.00 per set 853 CP soap tray Tk. 130.00 each 854 Porcelain soap tray: white Tk. 230.00 each 855 Porcelain soap tray: coloured Tk. 275.00 each 856 Stainless steel soap tray Tk. 230.00 each 857 Surface mounted automatic liquid soap dispenser Tk. 5,500.00 each 858 Automatic wall-mounted liquid soap dispenser Tk. 6,000.00 each 859 Liquid soap dispenser (push-up type) Tk. 500.00 each 167.00 per foot III. Pipes & Accessories (a) HDPE Pipe 860 110 mm dia HDPE pipe Tk. 861 110 mm HDPE plain tee/T-Y Tk. 1,408.00 each 862 110 mm HDPE plain bend Tk. 885.00 each 863 160 mm dia HDPE pipe Tk. 307.00 per foot 864 160 mm HDPE plain tee/T-Y Tk. 1,925.00 each 865 160 mm HDPE plain bend Tk. 1,358.00 each 866 200 mm dia HDPE pipe Tk. 867 200 mm HDPE plain tee/T-Y Tk. 2,275.00 each 868 200 mm HDPE plain bend Tk. 2,500.00 each 869 250 mm dia HDPE pipe Tk. 870 250 mm HDPE plain tee/T-Y Tk. 6,333.00 each 871 250 mm HDPE plain bend Tk. 4,166.00 each 872 Electro fusion welding joint(upto 110 mm) Tk. each 552.00 860.00 400.00 per foot per foot PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 35 Unit 873 Electro fusion welding joint(over 110 mm) Tk. 500.00 each 874 110 mm dia HDPE pipe for under-ground Tk. 167.00 per foot 875 110 mm HDPE plain Tee/T-Y for under-ground Tk. 646.00 each 876 110 mm HDPE plain Bend for under-ground Tk. 465.00 each 877 160 mm dia HDPE pipe for under-ground Tk. 307.00 per foot 878 160 mm HDPE plain Tee/T-Y for under-ground Tk. 916.00 each 879 160 mm HDPE plain bend for under-ground Tk. 802.00 each 880 200 mm dia HDPE pipe for under-ground Tk. 552.00 per foot 881 200 mm HDPE plain tee/T-Y for under-ground Tk. 2,274.00 each 882 200 mm HDPE plain bend for under-ground Tk. 1,527.00 each 883 250 mm dia HDPE pipe for under-ground Tk. 884 250 mm HDPE plain tee/T-Y for under-ground Tk. 4,541.00 each 885 250 mm HDPE plain bend for under-ground Tk. 3,054.00 each 886 280 mm dia HDPE pipe for under-ground Tk. 1,072.00 per foot 887 280 mm HDPE plain tee/T-Y for under-ground Tk. 5,465.00 each 888 280 mm HDPE plain bend for under-ground Tk. 3,960.00 each 889 315 mm dia HDPE pipe for under-ground Tk. 1,367.00 per foot 890 315 mm HDPE plain tee/T-Y for under-ground Tk. 7,320.00 each 891 315 mm HDPE plain bend for under-ground Tk. 5,402.00 each 892 400 mm dia HDPE pipe for under-ground Tk. 2,190.00 per foot 893 400 mm HDPE plain tee/T-Y for under-ground Tk. 14,057.00 each 894 400 mm HDPE plain bend for under-ground Tk. 10,780.00 each 895 630 mm dia HDPE pipe for under-ground Tk. 5,105.00 per foot 896 630 mm HDPE plain tee/T-Y for under-ground Tk. 40,555.00 each 897 630 mm HDPE plain bend for under-ground Tk. 31,042.00 each 898 710 mm dia HDPE pipe for under-ground Tk. 6,908.00 per foot 899 710 mm HDPE plain tee/T-Y for under-ground Tk. 50,689.00 each 900 710 mm HDPE plain bend for under-ground Tk. 42,570.00 each 850.00 per foot PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 36 Unit 901 900 mm dia HDPE pipe for under-ground Tk. 11,110.00 per foot 902 900 mm HDPE plain Tee/T-Y for under-ground Tk. 90,894.00 each 903 900 mm HDPE plain bend for under-ground Tk. 70,420.00 each Butt Welding Joint 904 Butt fusion welding joint(75-355 mm dia HDPE pipe) Tk. 350.00 each 905 Butt fusion welding joint(400-560 mm dia HDPE pipe) Tk. 450.00 each 906 Butt fusion welding joint(630-1000 mm dia HDPE pipe) Tk. 600.00 each (b) uPVC 907 12 mm dia uPVC pipe Tk. 6.75 per foot 908 12 mm dia uPVC plain Tee Tk. 5.50 each 909 12 mm dia uPVC plain elbow Tk. 4.50 each 910 12 mm dia uPVC faucet elbow Tk. 6.00 each 911 12 mm dia uPVC plain socket Tk. 4.00 each 912 12 mm dia uPVC thread plug Tk. 3.00 each 913 19 mm dia uPVC pipe Tk. 10.00 per foot 914 19 mm dia uPVC plain tee Tk. 8.00 each 915 19 mm dia uPVC plain elbow Tk. 7.50 each 916 19 mm dia uPVC plain socket Tk. 5.00 each 917 19mm x 12 mm dia uPVC reduced tee Tk. 20.00 each 918 19mm x 12 mm dia uPVC reduced elbow Tk. 20.00 each 919 25 mm dia uPVC pipe Tk. 13.00 per foot 920 25 mm x 19 mm dia reduced tee Tk. 22.50 each 921 32 mm dia uPVC pipe Tk. 20.00 per foot 922 32 mm dia uPVC tee Tk. 22.50 each 923 32 mm dia uPVC socket Tk. 29.00 each 924 32 mm dia elbow Tk. 17.50 each 925 32 mm plain bend 900 Tk. 17.50 each 926 37 mm dia uPVC pipe Tk. 14.50 per foot PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 37 Unit 927 37 mm dia uPVC tee Tk. 22.50 each 928 37 mm dia uPVC socket Tk. 29.00 each 929 37 mm dia uPVC elbow Tk. 21.00 each 930 50 mm dia uPVC pipe: 20 foot (6m) long Tk. 32.00 per foot 931 50 mm dia uPVC bend/offset Tk. 23.00 each 932 50 mm dia uPVC Tee/T-Y/Y (50 x 50 mm) Tk. 99.00 each 933 60 mm dia uPVC pipe Tk. 40.00 per foot 934 60 mm tee Tk. 123.00 each 935 60 mm socket Tk. 60.00 each 936 60 mm elbow Tk. 85.00 each 937 75 mm dia uPVC pipe Tk. 54.00 per foot 938 75 mm dia tee Tk. 165.00 each 939 75 mm dia socket Tk. 71.00 each 940 75 mm dia elbow Tk. 137.00 each 941 88 mm dia uPVC pipe Tk. 60.00 per foot 942 88 mm dia tee Tk. 175.00 each 943 88 mm dia socket Tk. 105.00 each 944 88 mm dia elbow Tk. 150.00 each 945 114 mm dia uPVC pipe Tk. 80.00 per foot 946 114 mm dia tee Tk. 250.00 each 947 114 mm dia socket Tk. 125.00 each 948 114 mm dia elbow Tk. 160.00 each 949 100 mm dia uPVC Pipe: 20 foot (6m) long Tk. 79.00 per foot 950 100 mm dia uPVC bend/offset Tk. 146.00 each 951 100 mm dia uPVC Tee/T-Y/Y (50 x 50 mm) Tk. 179.00 each 952 110 mm dia uPVC pipe Tk. 68.00 per foot 953 110 mm dia door tee (Back) Tk. 180.00 each 954 110 mm dia uPVC plain bend 90 Tk. 100.00 each PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 38 Unit 955 110 mm dia uPVC long trap Tk. 212.00 each 956 110 mm dia round grating Tk. 295.00 each 957 110 mm dia uPVC vent cowl Tk. 28.00 each 958 150 mm dia uPVC Pipe: 20 foot (6m) long Tk. 167.00 per foot 959 150 mm dia uPVC bend/offset/cowl Tk. 354.00 each 960 150 mm dia uPVC Tee/T-Y/Y (50 x 50 mm) Tk. 307.00 each 961 150 mm dia uPVC for under-ground Tk. 129.00 per foot 962 200 mm dia uPVC pipe for under-ground Tk. 257.00 per foot 963 250 mm dia uPVC pipe for under-ground Tk. 405.00 per foot 964 280 mm dia uPVC pipe for under-ground Tk. 540.00 per foot 965 315 mm dia uPVC pipe for under-ground Tk. 550.00 per foot (c) G.I. Pipe & fittings 966 12 mm dia GI pipe Tk. 33.00 per foot 967 12 mm dia elbow Tk. 23.00 each 968 12 mm dia tee Tk. 28.00 each 969 12 mm dia nipple Tk. 18.00 each 970 12 mm dia plug Tk. 11.00 each 971 12 mm dia socket Tk. 14.50 each 972 20 mm dia GI pipe Tk. 48.00 per foot 973 20 mm dia elbow Tk. 35.00 each 974 20 mm dia tee Tk. 44.00 each 975 20 mm dia nipple Tk. 23.00 each 976 20 mm dia plug Tk. 12.00 each 977 20 mm dia reducer Tk. 35.00 each 978 20 mm dia socket Tk. 25.00 each 979 25 mm dia GI pipe Tk. 66.00 per foot 980 25 mm dia elbow Tk. 49.00 each 981 25 mm dia tee Tk. 54.00 each PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 39 Unit 982 25 mm dia nipple Tk. 34.00 each 983 25 mm dia plug Tk. 21.00 each 984 25 mm dia reducer Tk. 38.00 each 985 25 mm dia socket Tk. 30.00 each 986 32 mm dia GI pipe Tk. 84.00 per foot 987 32 mm dia elbow Tk. 63.00 each 988 32 mm dia tee Tk. 80.00 each 989 32 mm dia nipple Tk. 45.00 each 990 32 mm dia plug Tk. 27.00 each 991 32 mm dia reducer Tk. 58.00 each 992 32 mm dia socket Tk. 45.00 each 993 40 mm dia GI pipe Tk. 104.00 per foot 994 40 mm dia elbow Tk. 82.00 each 995 40 mm dia tee Tk. 82.00 each 996 40 mm dia nipple Tk. 74.00 each 997 40 mm dia plug Tk. 37.00 each 998 40 mm dia reducer Tk. 82.00 each 999 40 mm dia socket Tk. 55.00 each 1000 50 mm dia GI pipe Tk. 125.00 per foot 1001 50 mm dia Elbow Tk. 122.00 each 1002 50 mm dia tee Tk. 98.00 each 1003 50 mm dia nipple Tk. 74.00 each 1004 50 mm dia plug Tk. 46.00 each 1005 50 mm dia reducer Tk. 88.00 each 1006 50 mm dia socket Tk. 75.00 each 1007 62 mm dia GI pipe Tk. 191.00 per foot 1008 62 mm dia elbow Tk. 222.00 each 1009 62 mm dia tee Tk. 322.00 each PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 40 Unit 1010 62 mm dia nipple Tk. 176.00 each 1011 62 mm dia plug Tk. 60.00 each 1012 62 mm dia reducer Tk. 126.00 each 1013 62 mm dia socket Tk. 148.00 each 1014 75 mm dia GI pipe Tk. 215.00 per foot 1015 75 mm dia elbow Tk. 400.00 each 1016 75 mm dia tee Tk. 322.00 each 1017 75 mm dia nipple Tk. 176.00 each 1018 75 mm dia plug Tk. 135.00 each 1019 75 mm dia reducer Tk. 153.00 each 1020 75 mm dia socket Tk. 147.00 each 1021 100 mm dia G.I. pipe Tk. 310.00 per foot 1022 100 mm dia elbow Tk. 612.00 each 1023 100 mm dia tee Tk. 785.00 each 1024 100 mm dia nipple Tk. 395.00 each 1025 100 mm dia plug Tk. 252.00 each 1026 100 mm dia reducer Tk. 342.00 each 1027 100 mm dia socket Tk. 348.00 each (d) SS Pipe & fittings 1028 62 mm dia stainless steel (2 mm thick) pipe Tk. 248.00 per foot 1029 50 mm dia stainless steel (2 mm thick) pipe Tk. 197.00 per foot 1030 40 mm dia stainless steel (2 mm thick) pipe Tk. 148.00 per foot 1031 25 mm dia stainless steel (2 mm thick) pipe Tk. 95.00 per foot 1032 20 mm dia stainless steel (2 mm thick) pipe Tk. 68.00 per foot 1033 12 mm dia stainless steel (2 mm thick) pipe Tk. 34.00 per foot 1034 6 mm dia stainless steel (1.5 mm thick) pipe Tk. 20.00 per foot 1035 25 mm x 25 mm SS square solid bar Tk. 111.00 per foot 1036 Top cap for 40 mm dia SS pipe Tk. 80.00 each PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 41 Unit 1037 Bottom cap for 40 mm dia SS pipe Tk. 60.00 each 1038 65 mm x 55 mm x 6 mm SS plate Tk. 150.00 each 1039 50 mm x 25 mm x 2 mm SS box: Tk. 60.00 per foot 1040 19 mm x 19 mm x 3 mm SS angle Tk. 80.00 per foot 1041 25 mm x 25 mm x 3 mm SS angle Tk. 110.00 per foot 1042 25 mm x 25 mm x 6 mm SS angle Tk. 190.00 per foot 1043 30 mm x 30 mm x 6 mm SS angle Tk. 210.00 per foot 1044 38 mm x 38 mm x 3 mm SS angle Tk. 180.00 per foot 1045 38 mm x 38 mm x 6 mm SS angle Tk. 270.00 per foot 1046 50 mm x 50 mm x 3 mm SS angle Tk. 220.00 per foot 1047 50 mm x 50 mm x 5 mm SS angle Tk. 250.00 per foot 1048 50 mm x 50 mm x 6 mm SS angle Tk. 350.00 per foot 1049 19 mm x 3 mm SS flat bar Tk. 45.00 per foot 1050 25 mm x 3 mm SS flat bar Tk. 55.00 per foot 1051 38 mm x 3 mm SS flat bar Tk. 90.00 per foot 1052 50 mm x 3 mm SS flat bar Tk. 110.00 per foot 1053 50 mm x 5 mm SS flat bar Tk. 150.00 per foot 1054 50 mm x 6 mm SS flat bar Tk. 200.00 per foot 1055 SS pipe post with glass holder Tk. 300.00 per foot 1056 SS base cup 38 mm Tk. 200.00 each 1057 50 x 62 x 2 mm SS pipe post with glass holder Tk. 300.00 each 1058 SS welding rod Tk. 6.00 per pcs 1059 Cutting charge of SS angle Tk. 6.13 each 1060 62 mm dia SS bend Tk. 65.00 each 1061 62 mm dia end socket Tk. 30.00 each 1062 50 mm dia SS bend Tk. 55.00 each 1063 50 mm dia end socket Tk. 20.00 each 1064 40 mm dia end socket Tk. 15.00 each PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 42 Unit 1065 25 mm dia socket Tk. 12.00 each 1066 Royal bolt Tk. 50.00 each 1067 Glass hole Tk. 25.00 each 1068 Spider knob Tk. 150.00 each (e) CPVC 1069 12 mm dia CPVC pipe Tk. 28.00 per foot 1070 12 mm dia CPVC plain tee Tk. 34.00 each 1071 12 mm dia CPVC plain elbow Tk. 26.00 each 1072 12 mm dia CPVC faucet elbow Tk. 24.00 each 1073 12 mm dia CPVC plain socket Tk. 21.00 each 1074 12 mm dia CPVC thread plug Tk. 6.00 each 1075 19 mm dia CPVC pipe Tk. 40.00 per foot 1076 19 mm dia CPVC plain tee Tk. 57.00 each 1077 19 mm dia CPVC plain elbow Tk. 54.00 each 1078 19 mm dia CPVC plain socket Tk. 17.00 each 1079 19mm x 12 mm dia CPVC reduced tee Tk. 79.00 each 1080 19mm x 12 mm dia CPVC reduced elbow Tk. 57.00 each 1081 25 mm dia CPVC pipe Tk. 57.00 per foot 1082 25 mm x 19 mm dia redeuced Tee Tk. 140.00 each 1083 32 mm dia CPVC pipe Tk. 89.00 per foot 1084 32 mm dia CPVC tee Tk. 211.00 each 1085 32 mm dia CPVC socket Tk. 64.00 each 1086 32 mm dia elbow Tk. 130.00 each 1087 37 mm dia CPVC pipe Tk. 130.00 per foot 1088 37 mm dia CPVC tee Tk. 304.00 each 1089 37 mm dia CPVC socket Tk. 98.00 each 1090 37 mm dia CPVC elbow Tk. 258.00 each 1091 50 mm dia CPVC pipe Tk. 200.00 per foot PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 43 Unit 1092 50 mm dia CPVC tee Tk. 648.00 each 1093 50 mm dia CPVC socket Tk. 360.00 each 1094 50 mm dia CPVC elbow Tk. 482.00 each (f) PP-R Pipe 1095 12 mm PP-R pipe Tk. 14.00 per foot 1096 19 mm PP-R pipe Tk. 20.50 per foot 1097 25 mm PP-R pipe Tk. 29.50 per foot 1098 32 mm PP-R pipe Tk. 49.00 per foot 1099 38 mm PP-R pipe Tk. 61.50 per foot 1100 50 mm PP-R pipe Tk. 95.00 per foot PP-R Fittings 1101 12 mm PP-R elbow Tk. 7.50 each 1102 12 mm PP-R tee Tk. 9.75 each 1103 12 mm PP-R end cap Tk. 7.00 each 1104 12 mm PP-R plug Tk. 6.00 each 1105 12 mm PP-R reducer Tk. 20.00 each 1106 12 mm PP-R socket Tk. 7.50 each 1107 19 mm PP-R elbow Tk. 10.50 each 1108 19 mm PP-R tee Tk. 13.00 each 1109 19 mm PP-R end cap Tk. 9.75 each 1110 19 mm PP-R plug Tk. 7.50 each 1111 19 mm PP-R reducer Tk. 27.00 each 1112 19 mm PP-R socket Tk. 8.00 each 1113 25 mm PP-R elbow Tk. 17.25 each 1114 25 mm PP-R tee Tk. 19.25 each 1115 25 mm PP-R end cap Tk. 16.00 each 1116 25 mm PP-R plug Tk. 14.00 each 1117 25 mm PP-R reducer Tk. 30.00 each PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate Unit 1118 25 mm PP-R socket Tk. 18.00 each 1119 32 mm PP-R elbow Tk. 58.50 each 1120 32 mm PP-R tee Tk. 61.00 each 1121 32 mm PP-R end cap Tk. 36.75 each 1122 32 mm PP-R plug Tk. 36.00 each 1123 32 mm PP-R reducer Tk. 66.00 each 1124 32 mm PP-R socket Tk. 21.75 each 1125 38 mm PP-R elbow Tk. 77.00 each 1126 38 mm PP-R tee Tk. 81.00 each 1127 38 mm PP-R end cap Tk. 93.00 each 1128 38 mm PP-R plug Tk. 18.00 each 1129 38 mm PP-R reducer Tk. 102.00 each 1130 38 mm PP-R socket Tk. 41.00 each 1131 50 mm PP-R elbow Tk. 137.00 each 1132 50 mm PP-R tee Tk. 149.00 each 1133 50 mm PP-R end cap Tk. 140.00 each 1134 50 mm PP-R plug Tk. 20.00 each 1135 50 mm PP-R reducer Tk. 131.00 each 1136 50 mm PP-R socket Tk. 61.00 each PP-R Union 1137 12 mm PP-R union Tk. 131.00 each 1138 19 mm PP-R union Tk. 153.00 each 1139 25 mm PP-R union Tk. 170.00 each 1140 32 mm PP-R union Tk. 328.00 each 1141 38 mm PP-R union Tk. 524.00 each 1142 50 mm PP-R union Tk. 688.00 each Tk. 175.00 each PP-R Gate-Valve 1143 12 mm PP-R Gate-valve 44 PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 45 Unit 1144 19 mm PP-R Gate-valve Tk. 274.00 each 1145 25 mm PP-R Gate-valve Tk. 306.00 each 1146 32 mm PP-R Gate-valve Tk. 560.00 each 1147 38 mm PP-R Gate-valve Tk. 606.00 each 1148 50 mm PP-R Gate-valve Tk. 818.00 each (g) RCC Pipes 1149 150 mm dia RCC pipe (stone-chips, 40 mm thickness. 6'-0" long) Tk. 1,017.00 each (6'-0") 1150 225 mm dia RCC pipe (stone-chips, 40 mm thickness. 6'-0" long) Tk. 1,575.00 each (6'-0") 1151 300 mm dia RCC pipe (stone-chips, 50 mm thickness. 6'-0" long) Tk. 2,743.00 each (6'-0") 1152 375 mm dia RCC pipe (stone-chips, 50 mm thickness. 6'-0" long) Tk. 3,580.00 each (6'-0") 1153 900 mm dia RCC pipe (stone-chips, 100 mm thickness. 6'-0" long) Tk. 13,190.00 each (6'-0") iv) G.I. Union 1154 12 mm dia union Tk. 35.00 each 1155 20 mm dia union Tk. 50.00 each 1156 25 mm dia union Tk. 63.00 each 1157 32 mm dia union Tk. 82.00 each 1158 40 mm dia union Tk. 127.00 each 1159 50 mm dia union Tk. 175.00 each 1160 62 mm dia union Tk. 290.00 each 1161 75 mm dia union Tk. 330.00 each 1162 100 mm dia union Tk. 465.00 each v) G.I. Gate-Valve 1163 12 mm dia gate-valve Tk. 270.00 each 1164 20 mm dia gate-valve Tk. 320.00 each 1165 25 mm dia gate-valve Tk. 440.00 each 1166 32 mm dia gate-valve Tk. 550.00 each 1167 40 mm dia gate-valve Tk. 720.00 each 1168 50 mm dia gate-valve Tk. 1,250.00 each PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate Unit 1169 62 mm dia gate-valve Tk. 2,600.00 each 1170 75 mm dia gate-valve Tk. 3,500.00 each 1171 100 mm dia gate-valve Tk. 5,800.00 each vi) G.I. Glove-Valve 1172 12 mm dia globe-valve Tk. 200.00 each 1173 20 mm dia globe-valve Tk. 250.00 each 1174 25 mm dia globe-valve Tk. 400.00 each 1175 32 mm dia globe-valve Tk. 650.00 each 1176 40 mm dia globe-valve Tk. 850.00 each 1177 50 mm dia globe-valve Tk. 1,200.00 each 1178 62 mm dia globe-valve Tk. 2,700.00 each 1179 75 mm dia globe-valve Tk. 3,700.00 each 1180 100 mm dia globe-valve Tk. 5,000.00 each vii) G.I. Check-Valve 1181 12 mm dia check-valve Tk. 180.00 each 1182 20 mm dia check-valve Tk. 280.00 each 1183 25 mm dia check-valve Tk. 400.00 each 1184 32 mm dia check-valve Tk. 570.00 each 1185 40 mm dia check-valve Tk. 680.00 each 1186 50 mm dia check-valve Tk. 1,100.00 each 1187 62 mm dia check-valve Tk. 2,100.00 each 1188 75 mm dia check-valve Tk. 2,850.00 each 1189 100 mm dia check-valve Tk. 4,700.00 each viii) Float-Valve 1190 12 mm dia float-valve Tk. 225.00 each 1191 20 mm dia float-valve Tk. 315.00 each 1192 25 mm dia float-valve Tk. 385.00 each 1193 32 mm dia float-valve Tk. 630.00 each 46 PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL 1194 Items 40 mm dia float-valve Rate Unit Tk. 700.00 each ix) Drainage Pipe Fittings: 1195 50 mm plastic Y or T-Y cleanout Tk. 380.00 each 1196 100 mm plastic "P" or "S" trap Tk. 390.00 each 1197 100 mm "Y" or "T-Y" plastic cleanout Tk. 430.00 each 1198 50 mm plastic P or S trap Tk. 350.00 each X. Faucets 1199 12 mm CP bib cock (normal) Tk. 770.00 each 1200 12 mm CP bib cock (medium) Tk. 780.00 each 1201 12 mm special quality CP bip cock Tk. 845.00 each 1202 12 mm plastic bip cock with internal brass thread Tk. 150.00 each 1203 12 mm CP medium quality Pillar cock Tk. 950.00 each 1204 12 mm CP special heavy duty Pillar cock Tk. 990.00 each CP Self closing Pillar Cock [ With Mixture ] 1205 Standard Tk. 6,500.00 each 1206 Super Tk. 20,000.00 each CP Self closing Pillar Cock [ Without Mixture ] 1207 Standard Tk. 4,500.00 each 1208 Super Tk. 15,000.00 each 1209 12 mm CP medium heavy duty Pillar cock Tk. 950.00 each 1210 12 mm CP concealed fixed Sink cock Tk. 875.00 each 1211 12 mm CP concealed moving sink cock(medium) Tk. 1,160.00 each 1212 12 mm CP concealed moving sink cock(special) Tk. 1,280.00 each 1213 CP basin mixture(medium) Tk. 2,100.00 each 1214 CP basin mixture(special) Tk. 2,290.00 each 1215 CP single handle basin mixture(medium) Tk. 2,470.00 each 1216 CP single handle basin mixture(special) Tk. 2,700.00 each 1217 CP shower mixture including shower head Tk. 3,500.00 each 47 PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate Unit 1218 CP shower mixture including shower head & faucet Tk. 4,250.00 each 1219 CP bath-tub mixture with shower head Tk. 3,700.00 each 1220 CP self closing pillar cock Tk. 840.00 each 1221 12 mm ordinary type (brass) for surface mount CP stop cock Tk. 300.00 each 1222 12 mm medium quality CP stop cock Tk. 295.00 each 1223 12 mm special quality CP stop cock Tk. 900.00 each 1224 Stop cock: concealed Tk. 900.00 each 1225 Stop cock: concealed (medium) Tk. 950.00 each 1226 Stop cock: concealed (heavy) Tk. 990.00 each 1227 Surface mounted angle stop cock Tk. 665.00 each 1228 12 mm surface special heavy type angle stop cock Tk. 685.00 each 1229 12 mm CP concealed angle stop cock Tk. 665.00 each 1230 12 mm medium quality concealed angle stop cock Tk. 715.00 each 1231 Stop cock (Medium) Tk. 715.00 each 1232 Special concealed type heavy stop cock Tk. 950.00 each 1233 12 mm CP medium quality surface & heavy type angle stop cock Tk. 625.00 each 1234 12 mm CP surface special heavy type stop cock Tk. 670.00 each 1235 100 mm dia CP fixed type cleansing shower rose Tk. 440.00 each 1236 100 mm dia CP moving type cleansing shower rose Tk. 900.00 each 1237 CP Moving hand shower Tk. 1,215.00 each 1238 CP Moving push shower Tk. 715.00 each XI. Water Tank, Water Purifier 1239 16 BWG GI 1200 x 1200 x 1200 mm size over-head water-tank Tk. 10,400.00 each 1240 18 BWG GI 1200 x 1200 x 1200 mm size over-head water-tank Tk. 10,200.00 each 1241 1000 litre food-grade Plastic over-head water-tank Tk. 7,100.00 each 1242 1500 litre food-grade Plastic over-head water-tank Tk. 10,650.00 each 1243 2000 litre food-grade Plastic over-head water-tank Tk. 14,200.00 each 1244 150 litre capacity plastic mini tank (loft tank) Tk. 1,875.00 each 48 PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate Unit 1245 300 litre capacity plastic mini tank (loft tank) Tk. 2,550.00 each 1246 500 litre capacity plastic mini tank (loft tank) Tk. 3,400.00 each 1247 500 litre capacity stainless steel water tank Tk. 7,640.00 each 1248 1000 litre food-grade stainless steel water tank Tk. 14,036.00 each 1249 2000 litre food-grade stainless steel water-tank Tk. 24,056.00 each 1250 4000 litre food-grade stainless steel water tank Tk. 49,191.00 each 1251 6000 litre food-grade stainless steel water tank Tk. 53,481.00 each 1252 400 gallon capacity Ferro-cement water tank Tk. 6,320.00 each 1253 450 mm long metal cover connection pipe Tk. 100.00 each 1254 600 mm long metal cover connection pipe Tk. 120.00 each 1255 12 mm or 19 mm dia ball cock for water tank Tk. 130.00 each 1256 19 mm dia overflow pipe with jam-nut for plastic water tank Tk. 80.00 each 1257 12 mm dia & 450 mm long plastic flexible connection pipe Tk. 40.00 each 1258 12 mm dia & 600 mm long plastic flexible connection pipe Tk. 50.00 each 1259 50 GPD reverse osmosis water purifier Tk. 10,000.00 each 1260 75 GPD reverse osmosis water purifier Tk. 15,000.00 each 1261 75 GPD reverse osmosis water purifier ( Touch type) Tk. 20,000.00 each 1262 100 GPD reverse osmosis water purifier ( with hot cold & warm option) Tk. 55,000.00 each 1263 200 GPD reverse osmosis water purifier Tk. 40,000.00 each 1264 400 GPD reverse osmosis water purifier Tk. 60,000.00 each 1265 400 gal capacity ferro-cement water tank including installation Tk. 6,500.00 each 1266 Water dispencer Tk. 3,500.00 each 1267 600 mm dia C I man hole cover Tk. 1,500.00 each Booster Water Pump Including Pressure Guage 1268 Local Made Tk. 6,200.00 each 1269 Foreign Made Tk. 15,000.00 each Tk. 1,900.00 each Water Pressure Reducing Valve 1270 12 mm dia water pressure reducing valve 49 PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 50 Unit 1271 19 mm dia water pressure reducing valve Tk. 2,600.00 each 1272 25 mm dia water pressure reducing valve Tk. 3,200.00 each 1273 32 mm dia water pressure reducing valve Tk. 6,200.00 each 1274 38 mm dia water pressure reducing valve Tk. 6,900.00 each 1275 50 mm dia water pressure reducing valve Tk. 10,000.00 each 1276 62 mm dia water pressure reducing valve Tk. 17,000.00 each 1277 75 mm dia water pressure reducing valve Tk. 24,500.00 each 1278 Automatic hand drier Tk. 4,500.00 each C20 ARBORICULTURE WORK 1279 Alluvial loamy silty soil Tk. 1,800.00 per % cft 1280 Well decomposed cow dung Tk. 2,500.00 per % cft 1281 Possible cost/royalty of lawn grass Tk. 45.00 per % sft 1282 16'-0" long muli bamboo (for split) Tk. 120.00 each 1283 25'-0" long muli bamboo (full size) Tk. 200.00 each 1284 Borrak bamboo (for post) Tk. 12.00 per foot 1285 Borrak bamboo (full size) Tk. 375.00 each 1286 200 mm size earthen tub Tk. 32.00 each 1287 250 mm size earthen tub Tk. 40.00 each 1288 300 mm size earthen tub Tk. 56.00 each 1289 350 mm size earthen tub Tk. 82.00 each 1290 400 mm size earthen tub Tk. 145.00 each 1291 300 mm size earthen plate Tk. 24.00 each 1292 Mustard oil cake Tk. 40.00 per kg 1293 Bone mele Tk. 40.00 per kg 1294 Urea fertilizer Tk. 20.00 per kg 1295 Murate of potash Tk. 20.00 per kg 1296 Triple super phosphate (TSP) Tk. 30.00 per kg 1297 Spade (kodal) Tk. 450.00 each PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 51 Unit 1298 Spray machine (plaotic), 5ltr capacity Tk. 1,800.00 each 1299 Steel funna, 450 mm size wirth wooden handle Tk. 350.00 each 1300 Hand hoe, 250 mm size Tk. 90.00 each 1301 Standard Steel hand trolly Tk. 6,000.00 each 1302 Hedge scissors Tk. 1,200.00 each 1303 10" size Secature Tk. 650.00 each 1304 22 BWG G.I. water can (2.5 gallon) Tk. 350.00 each 1305 300 mm size G.I. bucket Tk. 250.00 each 1306 19 mm dia plastic hose pipe Tk. 18.00 per foot 1307 400 mm blade Hand Lawn Mower, Model no 1403 – 16 (USA) Tk. 12,500.00 each 1308 4.5 h.p., 550 mm blade power lawn mower machine Tk. 44,500.00 each 1309 6.5 h.p., 550 mm blade power lawn mower machine Tk. 58,400.00 each 1310 22 h.p. 1150 mm cutting blade power riding lawn mower machine Tk.449,000.00 each 1311 perfekthion 1-100ml ,bottle Tk. 230.00 each 1312 Redomil gold, 500gm packet Tk. 720.00 each 1313 Ripcord 1-100 ml bottle Tk. 200.00 each 1314 Proclaim,1 box (10gm-10 pack) Tk. 600.00 each 1315 Vertimec,1-50ml bottle Tk. 120.00 each C21 DEEP TUBE-WELL I. For Test boring & design 1316 Mobilization of equipment for drilling 38 mm dia test and observation well Tk. 6,553.16 LS 1317 Boring by using 100 mm dia cutter (0 m to 50 m) Tk. 158.07 meter 1318 Best quality heavy type hand type pump no 6 Tk. 2,330.46 each 1319 2.91 mm wall thick 38 mm dia G.I. pipe Tk. 534.06 meter 1320 38 mm dia water grade PVC pipe (D-Class or eqv.) including carriage Tk. 105.41 meter 1321 36 mm dia water grade PVC Strainer (D-Class or eqv.) including carriage Tk. 124.45 meter 1322 38 mm dia socket adopter Tk. 66.52 each 1323 Best quality 38 mm dia PVC Cap. Tk. 49.30 each PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 52 Unit 1324 Complete development of the tube-well (test boring) up to 200 m depth. Tk. 5,817.24 LS 1325 Design of production well upto 200 m Tk. 7,769.73 LS 1326 Design of production well beyond 200m Tk. 12,659.00 LS 1327 Disinfections of tube-well using bleaching powder Tk. LS 1328 Maintaining and filling and sealing test bore Tk. 3,295.65 each bore LS 358.36 II. For Production well 1329 Mobilization of drilling rig for shrouded production wells of depth up to 100 m Tk. 32,491.42 1330 325 mm dia boring: up to 50 m depth. Tk. 777.65 meter 1331 350 mm dia boring: up to 50 m depth. Tk. 818.18 meter 1332 400 mm dia boring: up to 50 m depth. Tk. 854.13 meter 1333 600 mm dia boring: up to 50 m depth. Tk. 1,058.85 meter 1334 800 mm dia boring: up to 50 m depth. Tk. 1,256.94 meter 1335 50 mm dia Class C PVC pipe Tk. 113.71 meter 1336 50 mm dia Class D PVC pipe Tk. 137.76 meter 1337 50 mm dia Class E PVC pipe Tk. 190.24 meter 1338 75 mm dia Class C PVC pipe Tk. 233.33 meter 1339 75 mm dia Class D PVC pipe Tk. 308.33 meter 1340 75 mm dia Class E PVC pipe Tk. 701.22 meter 1341 100 mm dia Class C PVC pipe Tk. 386.67 meter 1342 100 mm dia Class D PVC pipe Tk. 511.67 meter 1343 100 mm dia Class E PVC pipe Tk. 645.83 meter 1344 150 mm dia Class C PVC pipe Tk. 916.67 meter 1345 150 mm dia Class D PVC pipe Tk. 1,083.20 meter 1346 150 mm dia Class E PVC pipe Tk. 1,500.00 meter 1347 50 mm dia PVC cap Tk. 62.95 each 1348 100 mm dia PVC cap Tk. 161.62 each 1349 150 mm dia PVC cap Tk. 419.52 each 1350 125 mm x 50 mm PVC reducer Tk. 546.60 each PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 53 Unit 1351 150 mm x 75 mm PVC reducer Tk. 703.72 each 1352 200 mm x 100 mm PVC reducer Tk. 786.18 each 1353 200 mm x 150 mm PVC reducer Tk. 1,000.00 each 1354 250 mm x 150 mm PVC reducer Tk. 1,200.00 each 1354 125 mm dia PVC housing pipe Class C Tk. 625.00 meter 1355 125 mm dia PVC housing pipe Class D Tk. 783.33 meter 1356 125 mm dia PVC housing pipe Class E Tk. 933.33 meter 1357 150 mm dia PVC housing pipe Class C Tk. 916.67 meter 1358 150 mm dia PVC housing pipe Class D Tk. 1,250.00 meter 1359 150 mm dia PVC housing pipe Class E Tk. 1,500.00 meter 1360 200 mm dia PVC housing pipe Class C Tk. 1,400.00 meter 1361 200 mm dia PVC housing pipe Class D Tk. 1,875.00 meter 1362 200 mm dia PVC housing pipe Class E Tk. 2,200.00 meter 1363 250 mm dia PVC housing pipe Class C Tk. 2,200.00 meter 1364 250 mm dia PVC housing pipe Class D Tk. 3,083.00 meter 1365 250 mm dia PVC housing pipe Class E Tk. 3,666.67 meter 1366 PVC Tape Tk. 101.47 each 1367 PVC Solution / gum Tk. 660.68 no 1368 Petrol Tk. 89.00 litre 1369 Diesel Tk. 68.00 litre 1370 M.S split centralizer Tk. 451.67 meter 1371 S.S split centralizer Tk. 1,427.19 meter 1372 Complete development of the tube-well up to 200 m depth (50 mm x 150 mm tube-well). Tk. 19,273.83 LS 1373 Complete development of the tube-well up to 200 m depth. (75 mm x 150 mm tube-well) Tk. 26,020.65 LS 1374 Complete development of the tube-well up to 200 m depth. (100 mm x 200 mm tube-well) Tk. 31,935.12 LS 1375 Complete development of the tube-well up to 200 m depth. (150 mm x 200 mm tube-well) Tk. 38,183.30 LS 1376 Complete development of the tube-well up to 200 m depth. (400 mm x 200 mm tube-well) Tk. 35,526.40 LS 1377 Hire charge of pump including spare and maintenance Tk. 267.26 hour PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 54 Unit 1378 Disinfections of tube-well using bleaching powder (for 50 mm x 125 mm tube-well) Tk. 1,030.37 LS 1379 150 mm dia and 4 mm thick M.S. pipe Tk. 2,326.85 meter 1380 200 mm dia and 6 mm thick M.S. pipe welded Tk. 3,305.41 meter 1381 200 mm dia and 6 mm thick M.S. pipe seamless Tk. 3,637.63 meter 1382 4 mm thick 200 mm dia plate Tk. 1,120.75 each 1383 5 mm thick 250 mm dia plate Tk. 1,277.17 each 1384 6 mm thick 150 mm dia M.S. Cap Tk. 1,102.80 each 1385 6 mm thick 200 mm dia M.S. Cap Tk. 1,421.27 each 1386 150 mm dia 4.85 mm thick G.I. pipe Tk. 2,826.21 meter 1387 200 mm dia 6 mm thick G.I. pipe Tk. 6,135.50 meter 1388 150 mm dia stainless steel strainer of continuous slot Tk. 12,977.66 meter 1389 150 mm dia 2.5 mm thick stainless steel bridge type strainer Tk. 9,527.04 meter 1390 200 mm dia stainless steel strainer of continuous slot Tk. 15,212.20 meter 1391 200 mm dia 2.5 mm thick stainless steel bridge type strainer Tk. 10,084.79 meter 1392 75 mm dia 2.5 mm thick stainless steel bridge type strainer Tk. 5,648.28 meter 1393 100 mm dia 2.5 mm thick stainless steel bridge type strainer Tk. 5,717.85 meter 1394 50 mm dia 2.5 mm thick stainless steel bridge type strainer Tk. 4,927.94 meter 1395 75 mm dia 2.5 mm thick stainless steel bridge type strainer Tk. 6,674.32 meter 1396 200 mm x 200 mm dia 6 mm thick M.S. reducer Tk. 2,300.00 each 1397 150 mm x 300 mm dia 6 mm thick M.S. reducer Tk. 2,200.00 each 1398 200 mm x 300 mm dia M.S. reducer Tk. 2,200.00 each 1399 50 mm x 150 mm dia M.S. reducer Tk. 750.00 each 1400 75 mm x 150 mm dia M.S. reducer Tk. 750.00 each 1401 100 mm x 200 mm dia M.S. reducer Tk. 1,000.00 each 1402 (i) 300 mm dia 6 mm thick M.S. housing pipe welded Tk. 5,448.65 meter 1403 (ii) 300 mm dia 6 mm thick M.S. housing pipe seamless Tk. 7,500.00 meter 1404 (iii) 400 mm dia 6 mm thick M.S. housing pipe welded Tk. 8,565.72 meter 1405 (iv) 400 mm dia 6 mm thick M.S. housing pipe seamless Tk. 10,500.00 meter PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 55 Unit 1406 150 mm dia 6 mm thick M.S.housing pipe welded Tk. 4,000.00 meter 1407 150 mm dia 6 mm thick M.S. housing pipe seamless Tk. 3,500.00 meter 1408 350 mm dia 6 mm thick M.S. cap Tk. 1,500.00 each 1409 40 mm dia "D" grade pipe Tk. 35.12 foot 1410 50 mm dia C-Class water- grade pipe Tk. 85.69 foot 1411 3 m long 40 mm dia PVC strainer Tk. 314.39 each 1412 EPI / RFL (medium) brand no 6 Pump with necessary fittings etc. Tk. 2,485.38 each 1413 50 mm x 40 mm socket (reducer) Tk. 69.84 each 1414 40 mm dia pipe nipple Tk. 109.28 each 1415 4'-0" long cylinder Tk. 185.03 each 1416 Tie foot ball Tk. 33.05 Pair 1417 Tie plunger Tk. 66.02 each 1418 3/8" dia socket Tk. 17.25 each 1419 3/8" dia nut Tk. 15.69 each 1420 Solution big size Tk. 304.76 each 1421 Tape Tk. 24.85 each III. Testing of water including arsenic, collected from the test bore in BUET Laboratory 1422 pH/Hydrogen Ion density Tk. 400.00 per test 1423 Colour (filtered) Tk. 500.00 per test 1424 Carbon dioxide (CO2) Tk. 300.00 per test 1425 Chlorine (Cl) Tk. 800.00 per test 1426 Fluorine (Fl) Tk. 600.00 per test 1427 Iron (Fe) Tk. 2,500.00 per test 1428 Manganese (Mn) Tk. 1,700.00 per test 1429 Nitrate-Nitrogen (NO3-N) Tk. 700.00 per test 1430 Total Alkalinity Tk. 500.00 per test 1431 Total hardness Tk. 1,000.00 per test 1432 Total dissolved solids (TDS) Tk. 1,000.00 per test PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 56 Unit 1433 Arsenic (As) Tk. 1,700.00 per test 1434 Turbidity Tk. 400.00 per test 1435 Sieve analysis for sand from different layer Tk. 1,200.00 per test C22 SUB-SOIL INVESTIGATION WORK I. Operational cost 1436 Truck fare within 20 km including loading & un-loading Tk. 1,700.00 per trip 1437 Temporary camp at site for soil investigation work Tk. 1,053.00 per site 1438 Field Engineer including site allowances: 1-3yrs Exp, Membersip with IEB Tk. 1,800.00 per day 1439 Foundation Engineer: 5-10yrs exp , Membership with IEB Tk. 2,500.00 per day 1440 Foreman including site allowances Tk. 800.00 per day 1441 Rig operators including site allowances Tk. 600.00 per day 1442 Helper to rig operator/c site allowances Tk. 390.00 per day 1443 Unskilled labour including site allowances Tk. 320.00 per day 1444 Asstt laboratory technician Tk. 800.00 per day 1445 Laboratory technician Tk. 1,400.00 per day 1446 Laboratory engineer Tk. 1,800.00 per day 1447 Conveyance within 25 km Tk. 80.00 per day 1448 Wooden plank (mango) Tk. 650.00 per cft 1449 Rope Tk. 60.00 per kg 1450 Small boat Tk. 700.00 per day 1451 Drum (defects free) Tk. 1,000.00 each 1452 Hire charge of boring rig Tk. 3,000.00 per day II Laboratory Charge for Sub-Soil Investigation Work 1453 Sp. gr. test Tk. 200.00 per test 1454 Hydrometer, sieve analysis & sp. gr.,& Classification according to ASTM Tk. 1,200.00 per test 1455 Linear shrinkage Tk. 700.00 per test 1456 Shrinkage limit Tk. 500.00 per test 1457 Liquid limit Tk. 300.00 per test PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 57 Unit 1458 Plastic limit Tk. 300.00 per test 1459 Unit weight (wet & dry) Tk. 250.00 per test 1460 Void ratio Tk. 1,000.00 per test 1461 Moisture content Tk. 200.00 per test 1462 Organic matter content Tk. 1,200.00 per test 1463 Consolidated quick test (direct shear test) Tk. 1,200.00 per test 1464 Unconfined compression Tk. 1,500.00 per test 1465 Ground water level location Tk. 500.00 per site 1466 Visual Inspection & Classification of soil for engineering purposes Tk. 150.00 per test C23 FITTINGS I. Fittings for Wooden Door-windows/Hard wares/Glass/CI sheet 1467 250 mm long iron tower bolt Tk. 50.00 each 1468 250 mm long brass tower bolt Tk. 400.00 each 1469 200 mm long brass tower bolt Tk. 300.00 each 1470 250 mm long SS tower bolt Tk. 150.00 each 1471 200 mm socket bolt Tk. 50.00 each 1472 200 mm long brass socket bolt Tk. 300.00 each 1473 200 mm long SS socket bolt Tk. 200.00 each 1474 Hatch bolt Tk. 300.00 each 1475 100 mm long hinges nickel plated Tk. 65.00 each 1476 100 mm longs brass hinge Tk. 150.00 each 1477 75 mm longs brass hinge Tk. 110.00 each 1478 100 mm longs SS hinge Tk. 100.00 each 1479 75 mm longs SS hinge Tk. 60.00 each 1480 Nickel plated handle Tk. 75.00 each 1481 Brass handle Tk. 100.00 each 1482 SS handle Tk. 60.00 each 1483 Iron screws Tk. 17.00 per dzn PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 58 Unit 1484 Hinged cleats. Tk. 20.00 each 1485 SS Hinged cleats. Tk. 50.00 each 1486 Screws for Hinged cleats. Tk. 12.00 each 1487 Hinged cleats and buffer block Tk. 62.00 set 1488 plastic / rubber buffer block Tk. 7.00 each 1489 Country made door viewer Tk. 150.00 each 1490 Foreign made door viewer Tk. 245.00 each 1491 Knob catchment Tk. 40.00 each 1492 Best quality round lock/ rim lock Tk. 550.00 each 1493 Best quality security lock Tk. 800.00 each 1494 62 mm dia iron rings Tk. 15.00 each 1495 250 mm long & 12 mm dia tower bolt Tk. 50.00 each 1496 150 mm Socket bolt Tk. 45.00 each 1497 75 mm long Iron hinges Tk. 10.00 each 1498 225 mm long catch hook Tk. 20.00 each 1499 150 mm long brass tower & socket bolt Tk. 250.00 each 1500 75 mm long brass hinges Tk. 110.00 each 1501 150 mm long catch hooks Tk. 15.00 each 1502 Heavy type nickel plated handle Tk. 75.00 each 1503 Brass screw/38 mm screw Tk. 20.00 per doz. 1504 5 mm thick clear glass Tk. 66.00 per sft 1505 5 mm thick reflected glass Tk. 95.00 per sft 1506 6 mm thick clear glass Tk. 85.00 per sft 1507 10 mm thick clear glass Tk. 140.00 per sft 1508 5 mm thick ambush / frosted glass Tk. 65.00 per sft 1509 5 mm thick tinted glass Tk. 82.00 per sft 1510 6 mm thick reflected glass Tk. 106.00 per sft 1511 3 mm thick clear glass Tk. 40.00 per sft PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 59 Unit 1512 1.5 mm thick corrugated fiber glass Tk. 80.00 per sft 1513 1.5 mm thick fiber glass sheet ridging Tk. 142.00 per foot Glass Door 1514 10 mm thick tempered glass Tk. 388.00 per sft 1515 10 mm thick non- tempered glass Tk. 164.00 per sft 1516 Auto closer set Tk. 6,131.00 per set 1517 Top and bottom clamping device Tk. 1,177.00 per set 1518 Locking device Tk. 2,736.00 per set 1519 Top hinge Tk. 1,203.00 per set 1520 Handle Tk. 2,646.00 per set I. Hardware for steel door-window 1521 Stopper handle Tk. 20.00 each 1522 300 mm long iron cleats Tk. 30.00 each 1523 50 mm long pin hinges Tk. 25.00 each 1524 100 mm long iron hinges Tk. 54.00 each 1525 Hand lock Tk. 50.00 each 1526 150 mm long clamp Tk. 35.00 each C24 MISCELLENEOUS ITEMS 1527 Nails and wires Tk. 65.00 per kg 1528 G.I. wire Tk. 120.00 per kg 1529 Chalk powder Tk. 40.00 per kg 1530 38 mm x 38 mm x 6 mm brass Tk. 315.00 per foot 1531 Polythene sheet Tk. 250.00 per % sft 1532 EPS sheet (62mm thick) density 15 kg per cum Tk. 90.00 per cft 1533 Perforated aluminium board Tk. 110.00 per sft 1534 Lubricants Tk. 220.00 per litre 1535 Glass fiber mesh (10mmX10mm grid and weight 110gm/sqm) Tk. 7.00 per sft PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS Rate 60 SL Items Unit 1536 Water proof, damp proof, dry & breathable cement STN-EN - 1015-11 , compressive strength 34 MPa), Max depth of water penetration into hardened plaster is < 1 mm (25 kg bag)(Only for plaster work) Tk. 1,500.00 per bag 1537 Fire rated door complying standard specification Tk. 3,435.00 per sft 1538 Installation charge of fire rated door Tk. 215.00 per sft 1539 Nut-bolts, J-hooks etc. Tk. 160.00 per kg 1540 Empty gunny bags/ Polymer bag to fill sand for load test Tk. 10.00 each 1541 Salballah for driving Tk. 70.00 per foot 1542 Counter-sunk rivets for shoe-plate Tk. 50.00 each 1543 20 mesh 24 BWG wire mesh Tk. 25.00 per sft 1544 18 BWG galvanized wire mesh (2 mesh per 25mm) Tk. 20.00 per sft 1545 225 mm dia RCC pipe Tk. 262.50 per foot 1546 300 mm dia RCC pipe Tk. 457.17 per foot 1547 12 BWG barbed wire Tk.120,000.00 1548 Rivet, washer, wire nails etc. Tk. 90.00 per kg 1549 38 mm dia M.S. wheel for collapsible gate Tk. 28.00 each 1550 75 mm - 150 mm M.S. clamp Tk. 30.00 each 1551 Electrodes including electricity Tk. 10.00 each 1552 Grease/lubricant etc. Tk. 56.00 per Ib 1553 38 mm dia iron ring Tk. 20.00 each 1554 38 mm dia heavy type gate wheel Tk. 160.00 each 1555 Clamp with huskel dumney Tk. 144.00 each 1556 Heavy duty gate locking arrangement Tk. 275.00 each 1557 125 mm M.S. hinges Tk. 68.00 each 1558 High performance elastomeric cementitious waterproof coating Tk. 280.00 per kg 1559 15.62 mm socket bolt Tk. 60.00 each 1560 China made spring for rolling shutter Tk. 50.00 per foot 1561 Spring box for rolling shutter Tk. 70.00 each 1562 12 mm dia nut-bolt Tk. 12.00 each per M. ton PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 61 Unit 1563 Coal-tar Tk. 70.00 per kg 1564 150 mm long brass tower & socket bolt Tk. 250.00 each 1565 75 mm long brass hinges Tk. 110.00 each 1566 150 mm long catch hooks Tk. 15.00 each 1567 Screws Tk. 10.00 per doz. 1568 24 BWG wire-net Tk. 20.00 per sft 1569 Gum Tk. 200.00 per kg 1570 Blue Tk. 200.00 per kg 1571 Pigment for colour washing Tk. 200.00 per kg 1572 300 mm long brass hasp bolt Tk. 375.00 each 1573 Hydraulic door closer Tk. 1,250.00 each 1574 Mortice door lock Tk. 600.00 each 1575 Rim (round) door lock Tk. 550.00 each 1576 Magnetic door-shock absorber Tk. 100.00 each 1577 Used and empty Bitumen drum Tk. 200.00 each 1578 Fire-wood Tk. 200.00 per mound 1579 Bleaching powder Tk. 100.00 per kg 1580 Fly proof wire-net Tk. 100.00 per sqm 1581 25 mm expanded metal net Tk. 100.00 per sqm 1582 Bamboo darma Tk. 43.00 per sqm 1583 Single layer double bamboo tarja Tk. 130.00 per sqm 1584 Premix cement plaster Tk. 45.00 per kg 1585 Skim coat Tk. 2,000.00 per kg 1586 Cementetious pinhole filler Tk. 100.00 per kg 1587 Bentonite Tk. 20.00 per kg 1588 16 gauge thick 50 mm x 50 mm ss hollow box Tk. 278.00 per ft 1589 16 gauge thick 50 mm x 38 mm ss hollow box Tk. 240.00 per ft 1590 18 gauge thick 50 mm x 12 mm ss hollow box Tk. 175.00 per ft PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 62 Unit 1591 2 ply petroleum asphalt (Chinese) Tk. 9.00 per sft 1592 Coal Tk. 7.00 per kg 1593 2.44 m x 1.22 m size hard board Tk. 600.00 per piece 1594 PVC water stopper Tk. 160.00 per foot 1595 Sign board including material, painting,lettering etc all complete Tk. 225.00 sft 1596 Autocad operator Tk. 800.00 per day 1597 printing of drawing Tk. 18.00 sft 1598 As built work survey & report Tk. 1,800.00 per day 1599 Providing expertised Architect 5years exp with registration in respective professional body Tk. 70,000.00 per month 1600 Providing expertised engineer 10 years exp with registration in respective professional body Tk.120,000.00 per month 1601 Providing pick up (double Cabined) Tk. 70,000.00 per month 1602 photographer Tk. 1,100.00 per day 1603 photo print , post card sisez Tk. 1604 Engineer, Expertise in microsoft MS Project /Primavera and experience by min 5yrs Tk.120,000.00 permonth 1605 Engineer, min graduate in relevant field Tk. 1,800.00 per day 1606 Diploma Engineer, min 5yrs Exp Tk. 1,800.00 per day 1607 Diploma Engineer, min 1yrs Exp Tk. 1,000.00 per day 1608 Royality of Earth Tk. 1,715.00 per thousand cft 1609 Royality of Dredge material in the water body Tk. per thousand cft 1610 Calibration of pressure gauge Tk. 5,400.00 per set 1611 Calibration of hydrauic jack & pressure gauge combined Tk. 33,100.00 per set 1612 Arc welding at workshop / factory Tk. 25.00 per foot 1613 Cutting by oxy-ace of 12 mm M.S plate, top & bott plate Tk. 36.00 per foot 1614 12 mm MS Plate Grinding to V bevel top & bott Tk. 50.00 per foot 1615 25 mm dia Hole in 12 mm M.S plate Tk. 50.00 per nos 7.00 800.00 each PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS Rate 63 SL Items Unit 1616 Cutting by shearing granding and hole for steel jacket, 6 mm plate on 2U x ( top & bott) - C or U form Tk. 13.00 per foot 1617 6 mm MS Plate Grinding to V bevel on faces of U legs for top & bott Tk. 70.00 per foot 1618 Charge to bend 6 mm MS Plates Tk. 30.00 per foot 1619 50 mm dia Hole in 6 mm M.S plate Tk. 100.00 p/nos 1620 38 mm G.I / MS pipe for dowel bar Tk. 180.00 per foot 1621 Fabrication: bending of 20mm bar in U Tk. 5,600.00 per Mton 1622 Data logging engineer at hydraulic pile driver Tk. 1,800.00 per day 1623 Chief Mechanic, at hydraulic pile driver Tk. 1,400.00 per day 1624 Helper to mechanic, at hydraulic pile driver Tk. 390.00 per day 1625 Foreman, at hydraulic pile driver Tk. 800.00 per day 1626 Crane Operator, at hydraulic pile driver Tk. 800.00 per day 1627 Asst. Crane Operator, at hydraulic pile driver Tk. 600.00 per day 1628 Machine Operator, at hydraulic pile driver Tk. 600.00 per day 1629 Asst machine operator, at hydraulic pile driver Tk. 600.00 per day 1630 Helper to crane operator, at hydraulic pile driver Tk. 390.00 per day 1631 Helper to machine operator, at hydraulic pile driver Tk. 390.00 per day 1632 Generator Operator, at hydraulic pile driver Tk. 600.00 per day 1633 Surveyer to pile layout , at hydraulic pile driver Tk. 1,200.00 per day 1634 Helper to surveyer, at hydraulic pile driver Tk. 800.00 per day 1635 Skilled Labor, at hydraulic pile driver Tk. 390.00 per day 1636 ordinary labor, at hydraulic pile driver Tk. 320.00 per day 1637 Compilation of driving report, pile capacity log & submission to PE on signing it on hydraulic pile driver Tk. 10,000.00 per day 1638 PIT : mobilization,demobilization, accomodation +12pile PIT Tk. 20,000.00 per 100km within Dhaka 1639 Pile Integrity Test (PIT) Tk. 1,000.00 per pile after 1st 12 pile 1640 PIT expert engineer graduated in civil engg. And in geotech. engg. by profession , 10 yrs experience Tk.160,000.00 per month PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL 1641 Items Asst to PIT expert engineer: civil engr / geotech engineer by profession, 5yrs experience Rate 64 Unit Tk.100,000.00 per month GLASS: Float / Anealed 1642 Float / annealed glass thickness :2.5mm Tk. 35.00 sft 1643 Float / annealed glass thickness :3.0mm Tk. 35.00 sft 1644 Float / annealed glass thickness :3.5mm Tk. 42.00 sft 1645 Float / annealed glass thickness :4.0mm Tk. 48.00 sft 1646 Float / annealed glass thickness :5.0mm Tk. 65.00 sft 1647 Float / annealed glass thickness :6.0mm Tk. 85.00 sft 1648 Float / annealed glass thickness :8.0mm Tk. 125.00 sft 1649 Float / annealed glass thickness :10.0mm Tk. 140.00 sft 1650 Float / annealed glass thickness :12.0mm Tk. 180.00 sft GLASS: Tempered Glass 1651 Tempered glass thickness 5.0mm Tk. 160.00 sft 1652 Tempered glass thickness 6.0mm Tk. 190.00 sft 1653 Tempered glass thickness 8.0mm Tk. 250.00 sft 1654 Tempered glass thickness 10.0mm Tk. 280.00 sft 1655 Tempered glass thickness 12.0mm Tk. 390.00 sft 1656 Tempered glass thickness 15.0mm Tk. 1,000.00 sft 1657 Tempered glass thickness 19.0mm Tk. 1,300.00 sft 1658 12 mm two in one bib cock Tk. 1,800.00 each 1659 Fibre mesh Tk. 1,210.00 per kg 1660 3 mm thick frosted glass Tk. 45.00 sft 1661 Synthetic fly proof net. Tk. 140.00 sqm 1662 100 mm x 38 mm x 6 mm size clamp Tk. 14.00 each 1663 Stone lime Tk. 16.00 kg 1664 Surki Tk. 1,250.00 1665 25 mm mesh expanded metal for using under patent stone Tk. 15.00 sft 1666 25 mm iron screw Tk. 8.00 dz cum PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate Unit 1667 50 mm iron screw Tk. 15.00 dz 1668 25 mm brass screw Tk. 14.00 dz 1669 38 mm iron hinge Tk. 4.00 each 1670 38 mm brass hinge Tk. 6.00 each 1671 75 mm long cath hook Tk. 4.00 each 1672 100 mm long catch hook Tk. 6.00 each 1673 150 mm long catch hook Tk. 8.00 each 1674 200 mm long catch hook Tk. 10.00 each 1675 225 mm long catch hook Tk. 15.00 each 1676 50 mm dia 100 mm long socket bolt Tk. 8.00 each 1677 50 mm dia 100 mm long socket bolt (SS) Tk. 35.00 each 1678 50 mm dia 150 mm long socket bolt Tk. 11.00 each 1679 50 mm dia 150 mm long socket bolt(SS) Tk. 55.00 each 1680 50 mm dia 200 mm long socket bolt Tk. 20.00 each 1681 50mm dia 200 mm long socket bolt(SS) Tk. 70.00 each 1682 50 mm dia 150 mm long brass socket bolt Tk. 110.00 each 1683 50 mm dia 200 mm long brass socket bolt Tk. 140.00 each 1684 50 mm dia 250 mm long brass socket bolt Tk. 180.00 each 1685 75 mm long hinge Tk. 25.00 each 1686 100 mm long hinge Tk. 50.00 each 1687 75 mm long brass hinge Tk. 110.00 each 1688 100 mm long brass hinge Tk. 150.00 each 1689 50 mm dia iron ring Tk. 15.00 each 1690 50 mm dia brass ring Tk. 40.00 each 1691 Colouring materials Tk. 180.00 kg 1692 Laqure spray polishing Tk. 500.00 litre 1693 Materials for french polishing: 3 coats on new surface Tk. 800.00 % sft 1694 Earthoil Tk. 50.00 kg 65 PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items Rate 66 Unit 1695 40 mm dia G.I. Socket Tk. 105.00 each 1696 3 gal capacity C. I. Cistern (Not available in market) Tk. 1,260.00 each 1697 300 long clamp: Iron Tk. 22.00 each 1698 150 long clamp: Iron Tk. 12.00 each 1699 Aluminium paint Tk. 1,364.00 gallon (U.K.) 1700 Plastic low-down cistern Tk. 800.00 each 1701 Siphon set for plastic low-down Tk. 360.00 set 1702 Jarul Tk. 1,800.00 per cft 1703 Loha/Pyiankado Tk. 2,600.00 per cft 1704 8 BWG welding electrodes Tk. 6.00 per piece 1705 25mm dia G.I. Pipe for structural work Tk. 75.00 foot 1706 China made spring for rolling shutter Tk. 15.00 foot 1707 Spring box for rolling shutter Tk. 120.00 each 1708 Scaffolding including safety provision Tk. 11.00 per sft 1709 Tar boiler Tk. 1,000.00 per day 1710 Vibrating roller Pedestrain (0.5 - 1 ton) Tk. 3,000.00 per day 1711 Cart fare within 5 km Tk. 500.00 per trip 1712 2 mm geo-textile Tk. 8.00 per sft C25 CARRIAGE OF MATERIALS 1713 Carriage of materials except bricks and bats by motor trucks bullock carts or any other means, including loading, unloading at both ends and stacking properly at site as per direction of the Engineer. (a) Up to 1.5 kilometer Tk. 190.00 per M. ton (b) Up to 3.0 kilometer Tk. 260.00 per M. ton (c) Up to 5.0 kilometer Tk. 340.00 per M. ton (d) For each additional km beyond 5.0 kilometer and up to 30.0 kilometer Tk. 18.00 per M. ton (e) For each additional km beyond 30.0 kilometer and up to 80.0 kilometer Tk. 13.00 per M. ton (f) Beyond 80.0 kilometer Tk. 9.00 per M. ton Weighing at both ends for items of steel materials only Tk. 105.00 per M. ton 1714 PWD SoR 2018 for Civil Works RATES OF MAN, MATERIAL AND MARK-UPS SL Items 1715 Carriage of bricks or bats by motor truck, bullock carts or any other means including loading, unloading at both ends and stacking properly at site as per direction of the Engineer. Rate 67 Unit (a) Up to 1.5 kilometer Tk. 300.00 per % 0 nos (b) Up to 3.0 kilometer Tk. 400.00 per % 0 nos (c) Up to 5.0 kilometer Tk. 525.00 per % 0 nos (d) For each additional km beyond 5.0 kilometer and up to 30.0 kilometer Tk. 28.00 per % 0 nos (e) For each additional km beyond 30.0 kilometer and up to 80.0 kilometer Tk. 18.00 per % 0 nos (f) Beyond 80.0 kilometer Tk. 6.00 per % 0 nos SCHEDULE OF RATES FOR CIVIL WORKS PWD SoR 2018 for Civil Works GENERAL AND SITE FACILITIES 68 SCHEDULE OF RATES FOR CIVIL WORKS FIFTEENTH EDITION: 2018 DIVISION 01: GENERAL AND SITE FACILITIES Item No. 01.1 Description of Item Unit Unit Rate Erection and maintenance of site office and removal of the same after completion of work in accordance with the conditions of contract. In addition to the office required for his own use, the contractor shall provide and maintain furnished field office for the use of the Engineer-in-charge and his staff. The field office is to have a concrete floor, adequate foundation, brick walls, false ceiling of hard board with seasoned Garjan wood frame and painted, and all windows are to be glazed and provided with steel grill. Outside and inside wall surface are to be painted on plaster acceptable to the Engineer-in-charge. The field office shall be maintained in a secure and watertight condition by the contractor until the completion of the contract and shall be provided with electricity, running water and sewerage. All doors shall be fitted with approved locks and windows shall be provided with screen/blinds. Before construction the contractor shall submit plans and drawings showing proposed details and location for the field office, including foundations, access roads, shades, layout of electrical and water supply and hard standings thereto for the approval of the Engineer-in-charge. The Engineer-in-charge may require revision of the plans prior to giving approval for construction. The contractor shall also submit details proposed furniture, fittings and other items of equipment and plant to the Engineer-in-charge for approval. These items shall be of the standard quality suitable for site. The office, complete with furnishings, fittings, access roads and hard standings shall be ready for occupation by the Engineer-in-charge within 28 days of the date when the contractor first occupies the site. The contractor will provide day and night guards and a tea boy for the field office. At the end of the project all materials, equipment and plant, furniture, fittings recovered from dismantling the office and removing access road will be the property of the contractor. No interim payment shall be certified unless engineer‟s office with required facilities are constructed and accepted by the Engineer-in-charge. (This is a time related item; proportionate payment for this item shall be made distributing in each bill on the basis of percentage progress of the whole works under contract) 01.1.1 Engineer‟s site office of minimum 15 sqm plinth area with providing furniture, first aid-box, safety helmet, level / theodolite, consumables, stationeries etc. LS Tk. 144,894.00 01.1.2 Engineer‟s site office of minimum 38 sqm plinth area with providing security fencing, 5 KVA stand-bye generator, furniture, first aid-box, safety helmet, level / theodolite, consumables, stationeries etc. LS Tk. 440,718.00 01.1.3 Engineer‟s site office of minimum 38 sqm plinth area with providing security fencing, 5 KVA stand-bye generator, IBM compatible PC with monitor, uninterruptible power supply (UPS), laserjet printer (minimum 25 ppm), furniture, first aid-box, safety helmet, level/theodolite/EDM, consumables, stationeries etc. LS Tk. 561,463.00 01.1.4 Engineer‟s site office of minimum 38 sqm plinth area with providing security fencing, 5 KVA stand-bye generator, IBM compatible PC with monitor, uninterruptible power supply (UPS), laserjet printer (minimum 25 ppm), photocopier, 6 cft. Freeze, furniture, first aidbox, safety helmet, level/theodolite/EDM, consumables, stationeries etc. LS Tk. 602,999.00 01.1.5 Engineer‟s site office of minimum 10 sqm plinth area with providing furniture, first aid-box, safety helmet, consumables, stationeries etc for low value simple work of short duration (not more than six months). LS Tk. 27,168.00 PWD SoR 2018 for Civil Works GENERAL AND SITE FACILITIES Item No. 69 Description of Item Unit Unit Rate 01.1.6 Providing and maintenance one project profile signboards of the size not exceeding 1 m x 2 m, to be placed at a suitable place of the site including submission of proposals for the materials of the signboards and text layout to the Engineer-in-charge for approval which will be positioned as directed by the Engineer-in-charge and removing the same on completion of the works or as instructed by the Engineer-in-charge. sqm 01.2.1 Providing 3 sets as-built drawings subject to Engineer‟s approval produced in AutoCAD software in 584.5 mm x 413.5 mm (A-2 size) standard drawing paper, and operating and maintenance manual of the equipment and plant incorporated in the works, if any, in original by the date stated in the particular conditions of contract (PCC). If the contractor does not supply the as-built drawings and operating and maintenance manuals by the date stated in the particular conditions of contract (PCC), or they do not receive the Engineerin-charge‟s approval, the Engineer-in-charge shall withhold the amount stated in the PCC from the payments due to the contractor. per tender Tk. 24,423.00 Tk. 2,670.00 The as-built drawings must show the permanent works as actually constructed and reflect the revision of Tender drawings and drawings supplied to the contractor during the Contract as well as revisions of drawings supplied to the contractor during the contract. (One set of as-built drawings shall be considered for measurement and payment) 01.2.2 Providing additional copy of as-built drawing produced in AutoCAD software in 584.5 mm x 413.5 mm (A-2) standard drawing paper accepted by the Engineer-in-charge. sqm of drawing sheet Tk. 293.00 01.2.3 Providing minimum ten (10) copies coloured post-card size progress photograph of „works under contract‟ taken by professional photographer which record the progress of the Works. per month Tk. 1,413.00 01.2.4 Preparation & submission of implementation schedule to the Engineer-in-charge for approval prior ground breaking showing the events (works) and successive sub-events of works including all the management & control parameters like Earliest Start Time (EST), Earliest Finish Time (EFT), float events on critical path, resource allocation etc. with description of general method of works, in orderly manner all in the form network diagram prepared in computer software like MS project/ Primavera and presenting in displayable hard and soft copy minimum 3 (three) sets. (This is a time related item. Proportionate payment for this item shall be made distributing in each bill on the basis of percentage progress of the whole works under contract) per tender Tk. 35,158.00 01.2.5 Updating the Implementation Schedule and submission to the Engineer-in-charge at intervals no longer than 28 days showing actual physical and financial progress achieved, on each activity and the effect of the progress on the timing of the remaining work, including any changes to the sequence of the activities. However, Engineer‟s approval of the programme shall not alter the contractor‟s obligations. The contractor may revise the programme and submit it to the Engineer-in-charge again at any time. A revised programme shall show the variations and events related to change of contract price. Month wise documentation shall be the basis of payments on this item. per month Tk. 14,752.00 01.2.6 Providing all necessary logistic support to frame ‘monthly progress meeting’ between contractor/contractor‟s representatives and employer / employer‟s representatives at the Engineer-in-charge's office at site. Month wise documentation shall be the basis of payments on this item. per month Tk. 2,475.00 PWD SoR 2018 for Civil Works GENERAL AND SITE FACILITIES Item No. 70 Description of Item Unit Unit Rate 01.3 Providing layout and carry over PWD bench-mark (BM) at site from nearby BM pillar, property lines, existing ground level (EGL), formation ground level (FGL), highest flood levels (HFL), plinth levels (PL), mean sea level (MSL), setting and marking all pillars, marker, pegs etc. showing and maintaining reduced levels (RL‟s) including locating, establishing, protecting all public utilities within the premise of work and finally all to be presented in black and white. sqm Tk. 24.00 01.4 Mobilization and cleaning site before commencing actual physical work and during contract period and demobilization after completion of the works under contract to be accepted by the Engineer-in-charge. This work shall also covers clayey cleaning and clearing, cutting or filling, dressing the project area on and in the ground to an extent that all the events of works of the project can be executed smoothly in a working environment with a particular attention on safety and security in all respects, and to stockpile the end outcome to a place for disposal agreed by the Engineer-in-charge, where, payments are to be based on ground area determined by the Engineer-in-charge and be proportionate to the percentage progress of work under contract as a whole in all respects and approved by the Engineer-in-charge. sqm Tk. 169.00 01.5 Providing expertised architect having relevant experience (s) more than 5 years for detail documentation of architectural themes, drawings, workingout shop drawings, communication with theme architect & getting approval, specifying architectural needs according to approved master architectural themes & plan, certifying as built drawing for the approval etc. and any relevant jobs assigned by the HOPE or his official at site (max man month not greater than 1/4th of project duration & payment for the item subject to submission of CV & approved by HOPE or his authorized officer. per month Tk. 70,000.00 01.6 Providing expertised engineer having relevant experience (s) more than 10 years, for the project documentation, progress study & adjustment, preparation of project material schedule and testing schdule for approval etc. & jobs assigned by the HOPE or his official, at site (max man month not greater than 1/4th of Project duration & payment for the item subject to submission of CV & approved by HOPE or his authorized officer. per month Tk. 120,000.00 01.7 Pick-up (double cab) for transport of test samples, work samples & emergency services etc. including cost of fuel etc. (Total usage not more than 1/6th of project duration.) per month Tk. 70,000.00 01.8 Supplying, fitting, fixing, operating and maintenance of the costruction supervision lift (1000Kg capacity) for supervision of building construction work during the entire construction period including all necessary components like, steel frame, car, guide rails. push button, driving motor, gear box, car door, travelling cable, RCC base for steel frame, necessary connections with the building, electric supply & electricity bill and dismantling the same after completion of the building construction etc. all complete complying all safety factors and accepted by the Engineer-in-charge. (The construction supervision lift shall be the contractor property after completion of work). Number of month shall be calculated as 1/2 (half) of the project period for new construction and full project period for vertical extension work. The contractor must submit detail structural drawing of supporting frame with foundation and lift specification prior to supply on site. 01.8.1 6th to 10th floor, hoisting speed 40 m/min per month Tk. 28,287.00 01.8.2 11th to 15th floor, hoisting speed 40 m/min per month Tk. 37,661.00 01.8.3 16th to 20th floor, hoisting speed 50 m/min per month Tk. 44,911.00 PWD SoR 2018 for Civil Works GENERAL AND SITE FACILITIES Item No. Description of Item Unit Unit Rate 71 01.8.4 21th to 25th floor, hoisting speed 60 m/min per month Tk. 49,426.00 01.8.5 26th to 30th floor, hoisting speed 60 m/min per month Tk. 55,589.00 ………………….. END OF DIVISION ONE ………………….. EXCAVATION, FILLING & SITE DEVELOPMENT AND PALISADING PWD SoR 2018 for Civil Works 72 DIVISION 02: EXCAVATION, FILLING & SITE DEVELOPMENT AND PALISADING Item No. Description of Item Unit Unit Rate 02.1 Earth work in excavation in all kinds of soil for foundation trenches including layout, providing center lines, local bench-mark pillars, levelling, ramming and preparing the base, fixing bamboo spikes and marking layout with chalk powder, providing necessary tools and plants, protecting and maintaining the trench dry etc., stacking, cleaning the excavated earth at a safe distance out of the area enclosed by the layout etc. all complete and accepted by the Engineer-in-charge, subject to submit method statement of carrying out excavation work to the Engineer-in-charge for approval. However, engineer‟s approval shall not relieve the contractor of his responsibilities and obligations under the contract. 02.1.1 Layout and marking for earthwork in excavation in foundation accepted by the Engineer-in-charge. [Plinth area of the structure shall be considered for measurement] sqm Tk. 15.00 02.1.2 Earthwork in excavation in foundation trenches up to 1.5 m depth and maximum 10 m lead: in soft clayey soil / loose sand / silt cum Tk. 88.00 02.1.3 Earthwork in excavation in foundation trenches up to 1.5 m depth and maximum 10 m lead: in medium stiff clayey soil. cum Tk. 126.00 02.1.4 Earthwork in excavation in foundation trenches up to 1.5 m depth and maximum 10 m lead: in very stiff (hard) clayey soil/ rubbish etc. cum Tk. 189.00 02.1.5 Earthwork in excavation in foundation trenches up to 1.5 m depth and maximum 10 m lead: in very soft / saturated / organic clayey soil / soil of semi-liquid state. cum Tk. 217.00 02.1.6 Extra rate for each additional 0.5 meter depth exceeding 1.5 meter. cum Tk. 20.00 02.1.7 Extra rate for each 1 m additional lead beyond 10 m. cum Tk. 3.00 02.2 Bailing out of trapped water caused by inundation or rain, by pump from foundation trenches. hour Tk. 424.00 02.3 Supplying of straight and strong borrak bamboo posts of having minimum 75 mm diameter althrough and driving the same vertically in the ground up to required depth by any means shaping the top of the post, all complete and accepted by the Engineer-incharge. meter Tk. 80.00 02.4 Supplying of wooden ballah having an average diameter not less than 150 mm (without barks) at one third distance from larger end with a minimum end diameter of 100 mm for retaining purpose and driving to a depth as per design and drawing by any method including all arrangement for staging, hoisting, carrying etc. complete and accepted by the Engineer-in-charge. meter Tk. 592.00 02.5 Palisading work by supplying of bitumen drum sheet walling tied with 20 BWG G.I. wire fixing the same with already driven borrak bamboo posts with half split borrak bamboo runners @ 450mm c/c horizontally with iron nails, G.I wire etc. all complete and accepted by the Engineer-in-charge. (Rate is excluding the cost of bamboo post). sqm Tk. 520.00 02.6 Supplying and fitting-fixing horizontal bracing in palisading with half split wooden ballah having an average diameter not less than 150 mm with a minimum end diameter of 100 mm @ 450 mm including supply of iron nails, gazals etc. complete approved and accepted by the Engineer-in-charge. meter Tk. 180.00 EXCAVATION, FILLING & SITE DEVELOPMENT AND PALISADING Item No. PWD SoR 2018 for Civil Works 73 Description of Item Unit Unit Rate 02.7.1 Shore protection work during excavation in foundation trenches up to 1.5 m depth to protect loss due to damage of property by palisading accepted by the Engineer-in-charge. [The rate is including the cost of vertical post] sqm Tk. 609.00 02.7.2 Shore protection work during excavation in foundation trenches beyond 1.5 m depth to protect loss due to damage of property by palisading accepted by the Engineer-in-charge, [The rate is including the cost of vertical post] sqm Tk. 877.00 02.8 Supply of 2 mm thick best quality geo-textile from approved manufacturer/origin and laying as per manufacturer‟s instructions approved and accepted by the Engineer-incharge. Before commencement of laying of geo-textile, the contractor must submit the method statement for carrying out this work including sample with evidence of origin and compliance certificate from independent testing laboratory for approval. sqm Tk. 143.00 02.9 Removing sludge or semi-liquid clay/substances etc not suitable for pumping out or carrying by head load from the bottom of any marshy land, lake, ditch, pond by mixing fine local sand of F.M. 0.8 or less to a proportion such that it can be carried to an intermediate point of disposal and cutting the same including stacking and spreading properly on a suitable place to dry in the sun for a certain days and dispose the dried sludge or clay to a safe distance etc. complete and accepted by Engineer-in-charge subject to submit method statement to the engineer in charge for carrying out the works including ultimate disposal of the sludge under this item for approval. However, engineer‟s approval shall not relieve the Contractor of his responsibilities and obligations under the contract. cum Tk. 879.00 02.10.1 Sand filling in foundation trenches and plinth with sand having F.M. 0.5 to 0.8 in 150 mm layers including leveling, watering and compaction to achieve minimum dry density of 95% with optimum moisture content (Modified proctor test) by ramming each layer up to finished level as per design supplied by the design office only, all complete and accepted by the Engineer-in-charge. cum Tk. 635.00 02.10.2 Sand filling in foundation trenches and plinth with sand having minimum F.M. 1.2 in 150 mm in layers including leveling, watering and compaction to achieve minimum dry density of 95% with optimum moisture content (Modified proctor test) by ramming each layer up to finished level as per design supplied by the design office only, all complete and accepted by the Engineer-in-charge. cum Tk. 913.00 02.10.3 Sand filling in foundation trenches and plinth with sand having minimum F.M. 2.2 in 150 mm layers including leveling, watering and compaction to achieve minimum dry density of 95% with optimum moisture content (Modified proctor test) by ramming each layer up to finished level as per design supplied by the design office only, all complete and accepted by the Engineer-in-charge. cum Tk. 2,631.00 02.11 50 mm down graded picked jhama khoa consolidation in foundation trenches by mixing the same with best quality local sand (F.M. 1.2) in 2:1 (khoa: sand) proportion to achieve minimum dry density of 95% with optimum moisture content (Modified proctor test) including breaking and screening chips, laying and spreading in 150 mm layers uniformly and compacting etc. all complete and accepted by the Engineer-in-charge. cum Tk. 4,239.00 02.12 50 mm down graded picked jhama khoa consolidation in foundation trenches by mixing in mixer machine with best quality local sand (F.M. 1.2) and cement in 1:6:12 (cement: sand: khoa) proportion to achieve minimum dry density of 95% with optimum moisture content (Modified proctor test) including breaking and screening chips, laying and spreading in 150 mm layers uniformly and compacting etc. all complete and accepted by Engineer-in-charge. cum Tk. 4,931.00 EXCAVATION, FILLING & SITE DEVELOPMENT AND PALISADING Item No. PWD SoR 2018 for Civil Works 74 Description of Item Unit Unit Rate 02.13 Earth filling in foundation trenches and plinth in 150 mm layer with earth available within 90 m of the building site to achive minimum dry density of 95% with optimum moisture content (Modified proctor test) including carrying, watering, leveling, dressing and compacting to a specified percentage each layer up to finished level etc. all complete and accepted by Engineer-in-charge. cum Tk. 149.00 02.14 Cleaning and disposing of excavated earth from the construction site by truck or by any other means to a place within 30 km radius of the city or town area including loading & unloading at both ends, leveling and dressing the carried earth etc. complete and accepted by the Engineer-in-charge. cum Tk. 539.00 02.15 Earth filling in foundation trenches and plinth in 150 mm layers with carted earth carried by truck or by any other means including loading and unloading at both ends, leveling, watering and compacting to achive minimum dry density of 95% with optimum moisture content (modified proctor test) including local carriage each layer up to finished level including cost of water and test (carried from beyond 300 m) etc. all complete and accepted by the Engineer-in-charge 02.15.1 For Dhaka metropolitan area. cum Tk. 622.00 02.15.2 For Chittagong / Sylhet metropolitan area and Narayanganj district. cum Tk. 497.00 02.15.3 For Rajshahi / Barisal / Khulna metropolitan area. cum Tk. 432.00 02.15.4 For other than Dhaka, Chittagong, Sylhet, Rajshahi, Barisal, Khulna metropolitan area and Narayanganj district. cum Tk. 393.00 02.16 Site development/Improvement by carted earth or dredged sand, sandy silt (free from any organic, foreign, environmental hazardous substances) carried by head or by truck or by any other means including cost of cutting or by dredging of sand, sandy silt, all; including local carrying, placing the earth/sand, sandy silt in the designated area, maintaining slopes, breaking lumps, levelling and dressing in layers up to finished level etc. all complete as per direction and accepted by the engineer in charge. 02.16.1 For Dhaka metropolitan area. 02.16.1.1 By other method/means than dredgeing. cum Tk. 481.00 02.16.1.2 By dredging including necessary systems thereof. cum Tk. 299.00 02.16.2 For Chittagong / Sylhet metropolitan area and Narayanganj district. 02.16.2.1 By other method/means than dredgeing. cum Tk. 377.00 02.16.2.2 By dredging including necessary systems thereof. cum Tk. 247.00 02.16.3 For Rajshahi / Barisal / Khulna metropolitan area. 02.16.3.1 By other method/means than dredgeing. cum Tk. 352.00 02.16.3.2 By dredging including necessary systems thereof. cum Tk. 230.00 02.16.4 For other than Dhaka, Chittagong, Sylhet, Rajshahi, Barisal, Khulna metropolitan area and Narayanganj district. EXCAVATION, FILLING & SITE DEVELOPMENT AND PALISADING Item No. Description of Item PWD SoR 2018 for Civil Works Unit 75 Unit Rate 02.16.4.1 By other method/means than dredgeing. cum Tk. 302.00 02.16.4.2 By dredging including necessary systems thereof. cum Tk. 195.00 02.17 Mechanical compaction of earth beyond plinth area, required for pre-approved specific engineering purpose in 150 mm layers including levelling, watering and consolidation each layer with chain dozer, grader, roller etc. to achieve minimum dry density of 95% with optimum moisture content (modified proctor test) up to finished level all complete and accepted by the engineer-in-charge subjected to submission of the method statement. cum Tk. 418.00 02.18 Earthwork in excavation of tank of any dimension in all kinds of soil including cutting up to required depth including bailing out water and throwing on the embankment, breaking clods, ramming and leveling, dressing in 225 mm layer with maintaining the side slopes and level of both tank and the embankment as per design and accepted by the Engineerin-charge. 02.18.1 For initial lead of 30 m and lift of 1.5 m cum Tk. 185.00 02.18.2 For each additional lift of 0.3 m beyond 1.5 m and up to 3 m cum Tk. 7.00 02.18.3 For each additional lift of 0.3 m beyond 3 m and up to 4.5 m cum Tk. 10.00 02.18.4 For each additional lift of 0.3 m beyond 4.5 m and up to 6 m cum Tk. 14.00 02.18.5 Extra each additional lead of 0.3 m or part thereof beyond initial lead 30 meter cum Tk. 27.00 02.19.1 Bailing out water by 1 cusec diesel operated pump including hire charge of pump, fuel, operator, spares and maintenance etc. all complete and accepted by by the Engineer-incharge. per hour Tk. 538.00 02.19.2 Bailing out water by 1 cusec electricity operated pump including hire charge of pump, fuel, operator, spares and maintenance etc. all complete and accepted by the Engineer-incharge. per hour Tk. 433.00 ………………….. END OF DIVISION TWO ………………….. PWD SoR 2018 for Civil Works BRICK SOLING, CC, DPC ETC. 76 DIVISION 03: BRICK SOLING, CC, DPC ETC. Item No. Description of Item Unit Unit Rate 03.1 One layer brick flat soling in foundation or in floor with first class/picked jhama bricks including preparation of bed and filling the interstices with local sand, leveling etc. complete and accepted by the Engineer-in-charge sqm Tk. 420.00 03.2 One layer Herringbone bond (HBB) brick soling in foundation or in floor with first class/picked jhama bricks including preparation of bed and filling the interstices with local sand, leveling including supply of water, other charges, costs of tools and plants etc. all complete and accepted by the Engineer-in-charge sqm Tk. 662.00 03.3 Brick on end edging including preparation of bed and filling the interstices with local sand, leveling, maintaining alignment and grid etc. all complete and accepted by the Engineer-in-charge meter Tk. 104.00 03.4 Mass concrete (1:3:6) in foundation or in floor with cement, sand (F.M. 1.2) and picked jhama brick chips including breaking of chips, screening, mixing, laying, compacting to required level and curing for at least 7 days including the supply of water, electricity, costs of tools & plants and other charges etc. all complete and accepted by the Engineer-incharge.(Cement: CEM-II/A-M) 03.4.1 Mass concrete in foundation (1:3:6) with cement, brick chips and sand of F.M. 1.2 cum Tk. 6,647.00 03.4.2 Mass concrete in floor (1:3:6) with cement, brick chips and sand of F.M. 1.2 cum Tk. 6,579.00 03.5 Mass concrete (1:2:4) in foundation or in floor with cement, sand (F.M. 1.2) and picked jhama brick chips including breaking of chips, screening, mixing, laying, compacting to required level and curing for at least 7 days including the supply of water, electricity, costs of tools & plants and other charges etc. all complete and accepted by Engineer-in-charge. (Cement: CEM-II/A-M) 03.5.1 Mass concrete in foundation (1:2:4) with brick chips and local sand of F.M. 1.2. cum Tk. 7,643.00 03.5.2 Mass concrete in floor (1:2:4) with brick chips and local sand of F.M. 1.2. cum Tk. 7,575.00 03.6 Damp proof course (DPC) (1:1.5:3) of cement concrete with cement, sand and picked jhama brick chips or stone chips including breaking of chips, screening, centering, shuttering, casting, curing and finishing with a coat of bitumen including the supply of water, electricity, costs of tools & plants and other charges etc. all complete and accepted by Engineer-in-charge. (Cement: CEM-II/A-M) 03.6.1 75 mm thick damp proof course (1:1.5:3) with cement, 50% Sylhet sand (F.M. 2.2) & 50% local sand (F.M. 1.2) and picked jhama brick chips. sqm Tk. 1,095.00 03.6.2 75 mm thick damp proof course (1:1.5:3) with cement, Sylhet sand (F.M. 2.2) and stone chips. sqm Tk. 1,330.00 03.6.3 150 mm thick damp proof course (1:1.5:3) with cement, Sylhet sand (F.M. 2.2), stone chips and water-proofing admixture/agent approved by Engineer-in-charge. cum Tk. 14,413.00 03.7 Supplying and laying of single layer polythene sheet weighing one kilogram per 6.5 square meter in floor or any where below cement concrete complete in all respect and accepted by Engineer-in-charge. sqm Tk. 03.8 Extra rate for mass concrete work in additional floor: 42.00 PWD SoR 2018 for Civil Works BRICK SOLING, CC, DPC ETC. Item No. Description of Item Unit 77 Unit Rate 03.8.1 Add for each additional floor up to 5th floor cum Tk. 102.00 03.8.2 Add for each additional floor for 6th floor to 9th floor cum Tk. 136.00 03.8.3 Add for each additional floor for 10th floor & above cum Tk. 171.00 ………………….. END OF DIVISION THREE ………………….. BRICK WORKS, PATENT STONE IN FLOOR AND FANCY SCREEN BLOCK WORKS PWD SoR 2018 for Civil Works 78 DIVISION 04: BRICK WORKS, PATENT STONE IN FLOOR AND FANCY SCREEN BLOCK WORKS Item No. Description of Item Unit Unit Rate 04.1 Brick works with first class bricks with cement sand (F.M. 1.2) mortar (1:6) in foundation and plinth, filling the joints/interstices fully with mortar, racking out the joints, cleaning and soaking the bricks at least for 24 hours before use and curing at least for 7 days etc. all complete including cost of water, electricity and other charges and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) cum Tk. 6,040.00 04.2 Brick works of width one brick or one and a half brick length of first class bricks with cement sand (F.M. 1.2) mortar (1:6) in superstructure including raking out joints, filling the interstices with mortar, cleaning and soaking the bricks at least for 24 hours before use and washing of sand, necessary scaffolding, curing at least for 7 days etc. all complete (measurement to given as 250 mm width for one brick length and 375 mm for one brick and a half brick length) and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor cum Tk. 6,443.00 04.3 Brick works with first class bricks with cement sand (F.M. 1.2) mortar (1:4) in exterior walls including filling the interstices with mortar, raking out joints, cleaning and socking the bricks at least for 24 hours before use and washing of sand, necessary scaffolding, curing at least for 7 days etc. all complete including cost of water, electricity and other charges (measurement to given as 250 mm width for one brick length and 375 mm for one brick and a half brick length) accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor cum Tk. 6,769.00 04.4 Exposed brick works (for exterior wall without outside plaster) with special quality sorted out first class bricks, very carefully laid in cement sand (F.M. 1.2) mortar (1:4) in superstructure with uniform width and depth of joints, true to vertical and horizontal lines including raking out joints, scaffolding, soaking the bricks at least for 24 hours before use, washing and screening of sand, curing at least for 7 days and high class flush pointing with cement sand (F.M. 1.2) mortar (1:1) including cost of water, electricity and other charges etc all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor cum Tk. 7,894.00 04.5 Exposed brick works (for exterior wall without outside plaster) with automatic machine made first class bricks, very carefully laid in cement sand (F.M. 1.2) mortar (1:4) in superstructure with uniform width and depth of joints, true to vertical and horizontal lines including raking out joints, scaffolding, soaking the bricks at least for 24 hours before use, washing and screening of sand, curing at least for 7 days and high class flush pointing with cement sand (F.M. 1.2) mortar (1:1) including cost of water, electricity and other charges etc all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor cum Tk. 7,218.00 04.6 Brick works with 10 holes machine made bricks of approved size (241 mm x 114 mm x 70 mm) having uniform colour carefully laid in cement sand (F.M. 1.2) mortar (1:4) in superstructure with uniform width and depth of joints, true to vertical and horizontal lines including raking out joints, filling the interstices with mortar, cleaning and soaking bricks at least for 24 hours before use and washing and screening of sand, necessary scaffolding, curing at least for 7 days and pointing with cement sand (F.M. 1.2) mortar (1:2) including cost of water, electricity and other charges etc. complete and accepted by the Engineer-incharge. (Cement: CEM-II/A-M) In ground floor cum Tk. 11,862.00 BRICK WORKS, PATENT STONE IN FLOOR AND FANCY SCREEN BLOCK WORKS Item No. PWD SoR 2018 for Civil Works 79 Description of Item Unit Unit Rate 04.7 Brick work with 241 mm x 114 mm x 70 mm size machine made solid klinker facing bricks having uniform colour carefully laid in cement sand (F.M. 1.2) mortar (1:4) in superstructure with uniform width and depth of joints, true to vertical and horizontal lines including raking out joints, filling the interstices with mortar, cleaning and soaking bricks at least for 24 hours before use and washing and screening of sand, necessary scaffolding, curing at least for 7 days and pointing with cement sand (F.M. 1.2) mortar (1:2) including cost of water, electricity and other charges etc. complete and accepted by the Engineer-incharge. (Cement: CEM-II/A-M) In ground floor cum Tk. 9,286.00 04.8 Brick works with 241 mm x 114 mm x 70 mm size 10 hole machine made rock-face or textured klinker facing bricks having uniform colour carefully laid in cement sand (F.M. 1.2) mortar (1:4) in superstructure with uniform width and depth of joints, true to vertical and horizontal lines including raking out joints, filling the interstices with mortar, cleaning and soaking bricks at least for 24 hours before use and washing and screening of sand, necessary scaffolding, curing at least for 7 days and pointing with cement sand (F.M. 1.2) mortar (1:2) including cost of water, electricity and other charges etc. all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor cum Tk. 9,167.00 04.9 Brick works with 241 mm x 114 mm x 70 mm size 3 hole machine made reinforced klinker facing bricks having uniform colour carefully laid in cement sand (F.M.1.2) mortar (1:4) in superstructure with uniform width and depth of joints, true to vertical and horizontal lines including raking out joints, filling the interstices with mortar, cleaning and soaking bricks at least for 24 hours before use and washing and screening of sand, necessary scaffolding, curing at least for 7 days and pointing with cement sand (F.M. 1.2) mortar (1:2) including cost of water, electricity and other charges etc. all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor cum Tk. 13,380.00 04.10 Extra cost shall be incorporated in the estimate for each additional floor for brick works (item No.- 4.2 to 4.9) 04.10.1 Add for each additional floor up to 5th floor cum Tk. 171.00 04.10.2 Add for each additional floor from 6th floor to 9th floor cum Tk. 239.00 04.10.3 Add for each additional floor for 10th floor and above cum Tk. 273.00 04.11 Extra cost for brick-work for each additional meter (or part of meter) free height of brick wall beyond 4 m from the respective floor in auditorium, go-down, overhead water tank etc. as description of the item No. 4.2 to 4.9 including cost of water, electricity and other charges etc. all complete and accepted by the Engineer-in-charge. (Extra cost shall be incorporated in the estimate only when both sides of wall is uninterruptedly free beyond 4.0 meter) cum Tk. 174.00 04.12 Providing brick works for 200 mm x 100 mm facing in superstructure with 200 mm x 100 mm x 50 mm machine made klinker hard pressed facing bricks of approved quality with cement sand (F.M. 1.2) mortar (1:4), including racking out joints, cutting the bricks to required size wherever necessary including high class recessed pointing, cleaning and soaking the bricks at least for 24 hours before use and washing and screening of sand, necessary scaffolding, curing at least for 7 days for all floors up to 4th floor including cost of water, electricity and other charges etc. all complete and accepted by the Engineer-in-charge. (100x200 mm face should be placed for facing). (Cement: CEM-II/A-M) In ground floor sqm Tk. 1,703.00 BRICK WORKS, PATENT STONE IN FLOOR AND FANCY SCREEN BLOCK WORKS Item No. PWD SoR 2018 for Civil Works 80 Description of Item Unit Unit Rate 04.13 Providing brick works for 200 mm x 50 mm facing in superstructure with 200 mm x 50 mm x 50 mm machine made hard pressed klinker facing red or maroon strips of approved quality with 20 mm thick cement sand (F.M.1.2) mortar (1:4), 10 mm thick cement mortar in adjacent sides including racking out joints and cutting the bricks to required sizes wherever necessary with high class recessed pointing, cleaning and soaking the bricks for at least 24 hours before use and washing of sand, necessary scaffolding, curing at least for 7 days for all floors up to 4th floor including cost of water, electricity and other charges etc. all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor sqm Tk. 2,401.00 04.14 Providing clay wall tile facing strips (water absorption ratio below 4.5%) in superstructure with machine made hard pressed klinker facing strips of approved quality with 20 mm thick cement sand (F.M.1.2) mortar (1:3) in adjacent side wall, column, drop wall etc. and racking out joints, cutting to required sizes wherever necessary with high class recessed pointing, cleaning and soaking at least for 24 hours before use washing and screening of sand and necessary scaffoldings, curing at least 7 days including cost of water, electricity and other charges etc. all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor. 04.14.1 With 200 mm x 62 mm x 16.51 mm red strip sqm Tk. 2,313.00 04.14.2 With 200 mm x 62 mm x 12.7 mm beige strip sqm Tk. 2,542.00 04.14.3 With 200 mm x 62 mm x 8.9 mm red strip sqm Tk. 2,121.00 04.14.4 With 241 mm x 70 mm x 12.7 mm red strip sqm Tk. 2,585.00 04.14.5 With 241 mm x 70 mm x 12.7 mm matt glazed textured strip sqm Tk. 3,006.00 04.15 125 mm brick work with first class bricks with cement sand (F.M. 1.2) mortar (1:6) and making bond with connected walls including necessary scaffolding, raking out joints, cleaning and soaking the bricks for at least 24 hours before use and washing of sand, curing at least for 7 days in all floors including cost of water, electricity and other charges etc. all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor sqm Tk. 917.00 04.16 125 mm brick works with first class bricks with cement sand (F.M. 1.2) mortar (1:4) and making bond with connected walls including necessary scaffolding, raking out joints, cleaning and soaking the bricks for at least 24 hours before use and washing of sand, curing at least for 7 days in all floors including cost of water, electricity and other charges etc. all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor sqm Tk. 948.00 04.17 Exposed 125 mm thick pointing ornamental brick work with sorted out first class bricks with cement sand (F.M. 1.2) mortar (1:4) and making bond with connected walls including necessary scaffolding, raking out joints, cleaning and soaking the bricks for at least 24 hours before use and washing of sand, curing at least for 7 days in all floors including cost of water, electricity and other charges etc. all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor sqm Tk. 1,155.00 04.18 Exposed 125 mm thick pointing ornamental brick work with automatic machine made first class bricks with cement sand (F.M. 1.2) mortar (1:4) and making bond with connected walls including necessary scaffolding, raking out joints, cleaning and soaking the bricks for at least 24 hours before use and washing of sand, curing at least for 7 days in all floors including cost of water, electricity and other charges etc. all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor sqm Tk. 1,082.00 BRICK WORKS, PATENT STONE IN FLOOR AND FANCY SCREEN BLOCK WORKS Item No. PWD SoR 2018 for Civil Works 81 Description of Item Unit Unit Rate 04.19 Providing 125 mm thick brick work in superstructure (partition walls) with cement sand (F.M. 1.2) mortar (1:4) with 10 hole machine made ceramic bricks of approved size having uniform colour, carefully laid in cement mortar of uniform width & depth of joints, true to vertical and horizontal lines including racking out joints, filling the interstices with same mortar, making bond with connected walls, cleaning, soaking brick at least 24 hours and washing of sand, curing 7 days in all floors, including cost of water, electricity and other charges accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor sqm Tk. 1,634.00 04.20 Fancy screen work with different size hollow machine made design blocks of uniform colour, carefully laid in cement sand (F.M. 1.2) mortar (1:3) in all floors in wall with uniform mortar joints, true to vertical and horizontal line including racking out joints, cleaning and soaking the blocks for minimum 24 hours before use including washing and screening of sand, scaffolding, curing etc. complete in all respect including supply of all necessary materials, cost of water, electricity and other charges accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) 04.20.1 With design block size: 114 mm x 114 mm x 114 mm or equivalent volume & design. sqm Tk. 4,079.00 sqm Tk. 2,873.00 sqm Tk. 2,639.00 sqm Tk. 1,953.00 sqm Tk. 2,167.00 sqm Tk. 2,639.00 sqm Tk. 2,062.00 In ground floor 04.20.2 With design block size: 140 mm x 140 mm x 102 mm or equivalent volume & design. In ground floor 04.20.3 With design block size: 152 mm x 152 mm x 102 mm or 152 mm x 152 mm x 114 mm or equivalent volume and design. In ground floor 04.20.4 With design block size: 203 mm x 203 mm x 108 mm or equivalent volume and design. In ground floor 04.20.5 With design block size: 203 mm x 121 mm x 102 mm or equivalent volume and design. In ground floor 04.20.6 With design block size: 152 mm x 152 mm x 152 mm or equivalent volume and design. In ground floor 04.20.7 With design block size: 241 mm x 114 mm x 70 mm or equivalent volume and design. In ground floor 04.21 Extra cost shall be incorporated in the estimate for each additional floor for brick and screen block works (item No.- 4.12 to 4.20) 04.21.1 Add for each additional floor up to 5th floor sqm Tk. 31.00 04.21.2 Add for each additional floor from 6th floor to 9th floor sqm Tk. 42.00 04.21.3 Add for each additional floor for 10th floor and above sqm Tk. 52.00 BRICK WORKS, PATENT STONE IN FLOOR AND FANCY SCREEN BLOCK WORKS Item No. Description of Item PWD SoR 2018 for Civil Works Unit 82 Unit Rate 04.22 Klinker paving brick works in floor or pavement with machine made pressed bricks of approved quality with cement sand (F.M. 1.2) mortar (1:4) on minimum 12 mm thick cement sand (F.M. 1.2) mortar (1:4) including raking out joints, cutting the bricks to required size, soaking the same for 24 hours before use wherever necessary including high class flush pointing in cement mortar (1:2), cleaning, curing at least for 7 days etc. including washing and screening of sand, cost of water, electricity and other charges complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) 04.22.1 100 mm thick flat brick pavement with 200 mm x 100 mm x 50 mm size klinker facing bricks. sqm Tk. 2,740.00 04.22.2 50 mm thick brick on edge pavement with 200 mm x 100 mm x 50 mm klinker paving bricks in 1:4 cement sand mortar having 200 mm x 100 mm face at top. sqm Tk. 1,620.00 04.22.3 50 mm thick brick pavement with 200 mm x 50 mm x 50 mm klinker facing bricks. sqm Tk. 2,315.00 04.23 125 mm thick brick pavement or flooring with first class brick on edge with cement sand (F.M. 1.2) mortar (1:4) on minimum 12 mm thick cement sand (F.M. 1.2) mortar (1:4) including cutting the bricks as per requirement, cleaning and racking out joints, finishing with flush pointing with cement sand (F.M. 1.2) mortar (1:2) and curing for at least 7 days etc. including cost of water, washing and screening of sand (F.M. 1.2), electricity and other charges complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) sqm Tk. 1,079.00 04.24 125 mm thick brick pavement/flooring with 10 hole machine made ceramic bricks with cement sand (F.M. 1.2) mortar (1:4) on minimum 12 mm thick cement sand (F.M. 1.2) mortar (1:4) including cutting the bricks as per requirement, cleaning and racking out joints, finishing with flush pointing with cement sand (F.M. 1.2) mortar (1:2) and curing for at least 7 days etc. including cost of water, washing and screening of sand (F.M. 1.2), electricity and other charges etc. all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) sqm Tk. 1,728.00 04.25 75 mm thick cement concrete (1:3:6) flooring with cement, best quality coarse sand and 19 mm down graded picked jhama brick chips including breaking of chips, screening, mixing, laying, compacting, washing and screening of sand (F.M 1.2) and curing at least for 7 days etc. including cost of water, electricity and other charges etc. all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) sqm Tk. 507.00 04.26 25 mm thick artificial patent stone (1:2:4) flooring with cement, best quality coarse sand (50% quantity of Sylhet sand or coarse sand of equivalent F.M. 2.2 and 50% best quality local sand of FM 1.2) and 12 mm down well graded brick chips including breaking chips, screening, laying the concrete in alternate panels, compacting and finishing the top with neat cement and curing at least for 7 days in all floors including cost of water, electricity and other charges etc. all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor sqm Tk. 372.00 04.27 38 mm thick artificial patent stone (1:2:4) flooring with cement, best quality coarse sand (50% quantity of Sylhet sand or coarse sand of equivalent F.M. 2.2 and 50% best quality local sand of FM 1.2) and 12 mm down well graded brick chips including breaking chips, screening, laying the concrete in alternate panels, compacting and finishing the top with neat cement and curing at least for 7 days in all floors including cost of water, electricity and other charges etc. all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor sqm Tk. 468.00 BRICK WORKS, PATENT STONE IN FLOOR AND FANCY SCREEN BLOCK WORKS Item No. PWD SoR 2018 for Civil Works 83 Description of Item Unit 04.28 25 mm thick artificial patent stone (1:2:4) flooring with cement, best quality coarse sand (50% quantity of Sylhet sand or coarse sand of equivalent F.M. 2.2 and 50% best quality local sand of FM 1.2) and 12 mm down well graded stone chips, laying the concrete in alternate panels, compacting and finishing the top with neat cement and curing at least for 7 days in all floors including cost of water, electricity and other charges etc. all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor sqm Tk. 450.00 04.29 38 mm thick artificial patent stone (1:2:4) flooring with cement, best quality coarse sand (50% quantity of Sylhet sand or coarse sand of equivalent F.M. 2.2 and 50% best quality local sand of FM 1.2) and 12 mm down well graded stone chips, laying the concrete in alternate panels, compacting and finishing the top with neat cement and curing at least for 7 days in all floors including cost of water, electricity and other charges etc. all complete and accepted by the Engineer-in-charge. Cement: (CEM-II/A-M) In ground floor sqm Tk. 583.00 04.30 25 mm thick artificial patent stone (1:1.5:3) flooring with cement, best quality coarse sand (50% quantity of Sylhet sand or coarse sand of equivalent F.M. 2.2 and 50% best quality local sand of FM 1.2) and 12 mm down well graded stone chips, laying the concrete in alternate panels, compacting and finishing the top with neat cement and curing at least for 7 days in all floors including cost of water, electricity and other charges etc. all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor sqm Tk. 467.00 04.31 38 mm thick artificial patent stone (1:1.5:3) flooring with cement, best quality coarse sand (50% quantity of Sylhet sand or coarse sand of equivalent F.M. 2.2 and 50% best quality local sand of FM 1.2) and 12 mm down well graded stone chips, laying the concrete in alternate panels, compacting and finishing the top with neat cement and curing at least for 7 days in all floors including cost of water, electricity and other charges etc. all complete and accepted by the Engineer-in-charge.(Cement: CEM-II/A-M) In ground floor sqm Tk. 609.00 04.32 Extra cost shall be incorporated in the estimate for each additional floor for patent stone works. 04.32.1 Add for each additional floor up to 5th floor sqm Tk. 31.00 04.32.2 Add for each additional floor from 6th floor to 9th floor sqm Tk. 42.00 04.32.3 Add for each additional floor for 10th floor and above sqm Tk. 52.00 ………………….. END OF DIVISION FOUR ………………….. Unit Rate PWD SoR 2018 for Civil Works MOSAIC WORKS 84 DIVISION 05 : MOSAIC WORKS Item No. Description of Item Unit Unit Rate 05.1 10 mm thick finished and 12.5 mm laying thickness cast in situ mosaic work on floor with one part of 10 mm machine crushed well graded dust free and properly washed marble chips and one part of mixture containing white cement / grey cement including preparation of mix. and laying the same over minimum 25 mm thick artificial patent stone flooring with brick chips (1:2:4) including making suitable panel, compacting, curing at least for 7 days, cutting with pumice stone (No. 40, No. 80, No.120) /cutting with mosaic cutting machine and finishing with minar stone and spreading oxalic acid including breaking of brick chips, screening, washing mosaic chips and supply of all necessary materials and water, electricity and other charges in all respect and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) 05.1.1 With Indian chips and glass strip using 100% white cement In ground floor sqm Tk. 1,770.00 05.1.2 With Indian chips and glass strip using 100% grey cement In ground floor sqm Tk. 1,470.00 05.1.3 With Pakistani chips and glass strip using 100% white cement In ground floor sqm Tk. 1,802.00 05.1.4 With Pakistani chips without glass strip using 100% grey cement In ground floor sqm Tk. 1,272.00 05.1.5 With Indian chips without glass strip using 100% grey cement In ground floor sqm Tk. 1,315.00 05.1.6 With Pakistani chips without glass strip using 100% white cement In ground floor sqm Tk. 1,566.00 05.2 12 mm thick finished and laying thickness 14.5 mm cast in situ mosaic work on floor with one part of 10 mm machine crushed well graded dust free and properly washed marble chips and one part of mixture containing 100% white cement including preparation of mix and laying the same over minimum 25 mm thick artificial patent stone flooring with brick-chips (1:2:4) including making suitable panel, compacting, curing at least for 7 days, cutting with pumice stone (No. 40, No. 80, No. 120)/ cutting with mosaic cutting machine and finishing with minar stone including breaking of brick chips, screening, spreading oxalic acid, washing of mosaic chips and supply of all necessary materials and water, electricity and other charges in all respect and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) 05.2.1 With Indian chips and glass strip In ground floor sqm Tk. 1,855.00 05.2.2 With Pakistani chips and glass strip In ground floor sqm Tk. 1,892.00 05.2.3 With Indian chips without glass strip In ground floor sqm Tk. 1,620.00 05.2.4 With Pakistani chips without glass strip In ground floor sqm Tk. 1,656.00 PWD SoR 2018 for Civil Works MOSAIC WORKS Item No. Description of Item Unit 85 Unit Rate 05.3 10 mm thick finished and laying thickness 12.5 mm silver grey cast in situ mosaic work on floor with one part of 10 mm machine crushed well graded, dust free and properly washed marble chips and one part of mixture containing white cement and grey cement in proportion (1:1) including preparation of mix and laying the same over minimum 25 mm thick artificial patent stone flooring with brick-chips (1:2:4) including making suitable panel, compacting, curing at least for 7 days, cutting with pumice stone (No. 40, No. 80, No. 120) and finishing with minar stone including breaking of brick chips, screening, washing of mosaic chips and supply of all necessary materials including water, electricity and other charges in all respect and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) 05.3.1 With Indian chips and glass strip In ground floor sqm Tk. 1,623.00 05.3.2 With Pakistani chips and glass strip In ground floor sqm Tk. 1,655.00 05.3.3 With Indian chips without glass strip In ground floor sqm Tk. 1,387.00 05.3.4 With Pakistani chips without glass strip In ground floor sqm Tk. 1,419.00 05.4 12 mm thick finished and laying thickness 14.5 mm silver grey cast in situ mosaic work on floor with one part of 10 mm machine crushed well graded dust free and properly washed marble chips and one part of mixture containing white cement and grey cement in proportion (1:1) including preparation of mix and laying the same over minimum 25 mm thick artificial patent stone flooring with brick-chips (1:2:4) including making suitable panels, compacting, curing at least for 7 days, cutting with pumice stone (No. 40. No. 80, No. 120) and finishing with minar stone including breaking of brick chips, screening, washing of mosaic chips and supply of all necessary materials and water, electricity and other charges in all respect and accepted by the Engineer-in-charge. (Cement: CEM-II/AM) 05.4.1 With Indian chips and glass strip In ground floor sqm Tk. 1,691.00 05.4.2 With Pakistani chips and glass strip In ground floor sqm Tk. 1,727.00 05.4.3 With Indian chips without glass strip In ground floor sqm Tk. 1,455.00 05.4.4 With Pakistani chips without glass strip In ground floor sqm Tk. 1,491.00 05.5 10 mm thick finished and laying thickness 12.5 mm cast in situ mosaic work in wall with one part of 10 mm machine crushed well graded dust free and properly washed marble chips and one part of mixture containing 100% white cement including preparation of mix and laying the same on 12 mm thick cement plaster (1:4) to wall including compacting, curing at least for 7 days, cutting with pumice stone (No. 40, No. 80, No. 120), finishing the corners and edges and also finishing with minar stone and supplying all necessary materials including water, electricity and other charges in all respect and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) 05.5.1 With Indian chips In ground floor sqm Tk. 1,724.00 PWD SoR 2018 for Civil Works MOSAIC WORKS Item No. Description of Item 05.5.2 With Pakistani chips In ground floor 05.6 10 mm thick finished and laying thickness 12.5 mm silver grey cast in situ mosaic work in wall with one part of 10 mm machine crushed well graded, dust free and properly washed marble chips and one part of mixture containing white cement and grey cement in proportion (1:1) including preparation of mix. and laying the same on 12 mm thick cement plaster (1:4) to wall including compacting, curing at least for 7 days, cutting with pumice stone (No. 40, No. 80, No 120) including finishing the corners and edges and also finishing with minar stone and supplying all necessary materials and water, electricity and other charges in all respect and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) 05.6.1 Unit 86 Unit Rate sqm Tk. 1,757.00 With Indian chips In ground floor sqm Tk. 1,577.00 05.6.2 With Pakistani chips In ground floor sqm Tk. 1,610.00 05.6.3 With Indian chips using 100% grey cement In ground floor sqm Tk. 1,430.00 05.7 10 mm thick finished and laying thickness 12.5 mm coloured cast in situ mosaic work in floor with one part of 10 mm machine crushed well graded, dust free and properly washed marble chips and one part of mixture containing white and grey cement in proportion (9:1) and necessary quantity of approved colouring materials including preparation of mix and laying the same over min 25 mm thick artificial patent stone flooring with brick-chips (1:2:4) including making suitable panel, compacting, curing at least for 7 days, cutting with pumice stone (No. 40, No. 80, No. 120) and finishing with Minar stone including breaking of brick chips, screening, washing of mosaic chips and supply of all necessary materials and water, electricity and other charges in all respect and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) 05.7.1 With Indian chips and glass strip In ground floor sqm Tk. 1,842.00 05.7.2 With Pakistani chips and glass strip In ground floor sqm Tk. 1,875.00 05.7.3 With Indian chips without glass strip In ground floor sqm Tk. 1,387.00 05.7.4 With Pakistani chips without glass strip In ground floor sqm Tk. 1,492.00 05.8 12 mm thick finished and laying thickness 14 mm coloured cast in situ mosaic work on floor with one part of 10 mm machine crushed well graded, dust free and properly washed marble chips and one part of mixture containing white cement and grey cement in proportion (9:1) and necessary quantity of approved colouring materials including preparation of mix and laying the same over minimum 25 mm thick artificial patent stone flooring with brick-chips (1:2:4) including making suitable panel, compacting, curing at least for 7 days, cutting with pumice stone (No. 40, No. 80, No. 120) and finishing with minar stone including breaking of brick chips, screening, washing of mosaic chips and supply of all necessary materials and water, electricity and other charges in all respect and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) PWD SoR 2018 for Civil Works MOSAIC WORKS Item No. Description of Item Unit 87 Unit Rate 05.8.1 With Indian chips and glass stripIn ground floor sqm Tk. 1,928.00 05.8.2 With Pakistani chips and glass strip In ground floor sqm Tk. 1,965.00 05.8.3 With Indian chips without glass strip In ground floor sqm Tk. 1,692.00 05.8.4 With Pakistani chips without glass strip In ground floor sqm Tk. 1,729.00 05.9 10 mm thick finished and laying thickness 12.5 mm coloured cast in situ mosaic work in walls with one part of 10 mm machine crushed well graded, dust free and properly washed marble chips and one part of mixture containing white cement and grey cement in proportion (9:1) and necessary quantity of approved colouring materials including preparation of mix and laying the same on 12 mm thick cement sand (F.M. 1.2) plaster (1:4) to walks including compacting, curing at least for 7 days, cutting with pumice stone (No. 40, No. 80, No. 120) including finishing the corners and edges and also finishing with minar stone and supply of all necessary materials etc. and water, electricity and other charges complete in all respect and accepted by the Engineer-in-charge. (Cement: CEMII/A-M) 05.9.1 With Indian chips In ground floor sqm Tk. 1,797.00 05.9.2 With Pakistani chips In ground floor sqm Tk. 1,829.00 05.10 200 mm x 200 mm x 20 mm mosaic terrazzo tiles flooring having 10 mm thick finished mosaic top with one part of 10 mm machine crushed well graded dust free and properly washed marble chips and one part of mixture containing white cement and grey cement in 9:1 proportion pressed on 12 mm thick cement sand (F.M. 1.2 and 2.5 by 50% each) mortar (1:2) base including preparing the base; finally, setting the tiles on 40 mm thick cement sand (F.M.1.2 and 2.5 by 50% each) mortar (1:3) including compacting, cutting with pumice stone (No. 40, No. 80, No. 120) and finishing the corners and edges and also finishing with minar stone including screening, washing mosaic chips and supply of all necessary materials etc. and water, electricity and other charges complete in all respect and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) 05.10.1 200 mm x 200 mm x 20 mm (finished) mosaic terrazzo tiles flooring with Indian chips In ground floor sqm Tk. 1,653.00 05.10.2 200 mm x 200 mm x 20 mm (finished) mosaic terrazzo tiles flooring with Pakistani chips In ground floor sqm Tk. 1,684.00 05.11 Extra cost shall be incorporated in the estimate for mosaic and terrazzo tiles work above ground floor (item no.- 5.1 to 5.10). 05.11.1 Add for each additional floor up to 5 th floor sqm Tk. 10.00 05.11.2 Add for each additional floor for 6th to 9th floor sqm Tk. 21.00 05.11.3 Add for each additional floor for 10th floor and above sqm Tk. 31.00 ………………….. END OF DIVISION FIVE ………………….. PWD SoR 2018 for Civil Works TILES, MARBLE STONE AND GRANITE STONE WORKS 88 DIVISION 06: TILES, MARBLE STONE AND GRANITE STONE WORKS Item No. Description of Item Unit Unit Rate 06.1 Supplying, fitting and fixing country made GP(Gress Porcellanto) - glazed or unglazed homogeneous floor tiles complying BDS ISO 13006: 2015, water absorbtion ≤ 0.5%, modulus of rupture (MOR) ≥ 27 N/mm2, irrespective of color &/or design, with cement sand (F.M. 1.2) mortar (1:4) base and raking out the joints with white cement including cutting and laying the tiles in proper way and finishing with care etc. all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M). In ground floor 06.1.1 GP (homogeneous) 300 mm x 300 mm floor tiles sqm Tk. 1,526.00 06.1.2 GP (homogeneous) 400 mm x 400 mm floor tiles sqm Tk. 1,663.00 06.2 Supplying, fitting and fixing country made mirror polished homogeneous floor tiles complying BDS ISO 13006: 2015, water absorbtion ≤ 0.5%, modulus of rupture (MOR) ≥ 27 N/mm2, irrespective of color &/or design, with cement sand (F.M. 1.2) mortar (1:4) base and raking out the joints with white cement including cutting and laying the tiles in proper way and finishing with care etc. all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor 06.2.1 GP (mirror polished) 400 mm x 400 mm floor tiles sqm Tk. 1,799.00 06.2.2 GP (mirror polished) 500 mm x 500 mm floor tiles sqm Tk. 1,935.00 06.2.3 GP (mirror polished) 600 mm x 600 mm floor tiles sqm Tk. 2,072.00 06.2.4 GP (mirror polished) 800 mm x 800 mm floor tiles sqm Tk. 2,208.00 06.2.5 GP (mirror polished) 600 mm x 900 mm floor tiles sqm Tk. 2,509.00 06.2.6 GP (mirror polished) 600 mm x 1200 mm floor tiles sqm Tk. 2,959.00 06.3 Supplying, fitting and fixing country made homogeneous matt finished/ rustic floor tiles complying BDS ISO 13006: 2015, water absorbtion ≤ 0.5%, modulus of rupture (MOR) ≥ 27 N/mm2, irrespective of color &/or design, with cement sand (F.M. 1.2) mortar (1:4) base and raking out the joints with white cement including cutting and laying the tiles in proper way and finishing with care etc. all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor 06.3.1 Matt or rustic floor tiles of size 400 mm x 400 mm and below sqm Tk. 1,894.00 06.3.2 Matt or rustic floor tiles of size 600 mm x 600 mm and below sqm Tk. 2,113.00 06.4 Supplying, fitting and fixing foreign (China or equivalent) made polished pocelain/ mirror polished homogeneous floor tiles complying BDS ISO 13006: 2015, water absorbtion ≤ 0.5%, modulus of rupture (MOR) ≥ 35 N/mm 2, irrespective of color &/or design, with cement sand (F.M. 1.2) mortar (1:4) base and raking out the joints with white cement including cutting and laying the tiles in proper way and finishing with care etc. all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor 06.4.1 Polish pocelain/ mirror polished 600 mm x 600 mm floor tiles sqm Tk. 2,413.00 06.4.2 Polished pocelain/ mirror polished 800 mm x 800 mm floor tiles sqm Tk. 2,754.00 PWD SoR 2018 for Civil Works TILES, MARBLE STONE AND GRANITE STONE WORKS Item No. Description of Item Unit 89 Unit Rate 06.4.3 Polished pocelain/ mirror polished 600 mm x 1200 mm floor tiles sqm Tk. 4,801.00 06.4.4 Polished pocelain/ mirror polished 1000 mm x 1000 mm floor tiles sqm Tk. 6,166.00 06.4.5 Polished pocelain/ mirror polished 1200 mm x 1200 mm floor tiles sqm Tk. 7,531.00 06.5 Supplying, fitting and fixing foreign (China or equivalent) made homogeneous matt finished/ rustic floor tiles complying BDS ISO 13006: 2015, water absorbtion ≤ 0.5%, modulus of rupture (MOR) ≥ 27 N/mm2, irrespective of color &/or design, with cement sand (F.M. 1.2) mortar (1:4) base and raking out the joints with white cement including cutting and laying the tiles in proper way and finishing with care etc. all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor 06.5.1 Matt or rustic floor tiles of size 600 mm x 600 mm sqm Tk. 3,027.00 06.6 Supplying, fitting and fixing country made glazed wall tiles complying BDS ISO 13006: 2015, irrespective of color &/or design, with 20 mm thick cement sand (F.M. 1.2) mortar (1:3) base and raking out the joints with white cement including cutting, laying and hire charge of machine and finishing with care etc. including cost of water, electricity and other charges complete in all respect and accepted by the Engineer-in-charge. (Cement: CEMII/A-M). In ground floor 06.6.1 Wall tiles less than, equal or equivalent to 250 mm x 330 mm in sizes sqm Tk. 1,271.00 06.6.2 Wall tiles more than 250 mm x 330 mm & less than or equal to 250 mm x 400 mm in sizes sqm Tk. 1,571.00 06.6.3 Wall tiles more than 250 mm x 400 mm & less than or equal to 300 mm x 600 mm in sizes sqm Tk. 1,817.00 06.6.4 Decor wall tiles of any size sqm Tk. 2,090.00 06.6.5 Border wall tiles of any size sqm Tk. 4,410.00 06.7 Supplying, fitting and fixing country made rustic or matt finished wall tiles complying BDS ISO 13006: 2015, irrespective of color &/or design, with 20 mm thick cement sand (F.M. 1.2) mortar (1:3) base and raking out the joints with white cement including cutting, laying and hire charge of machine and finishing with care etc. including water, electricity and other charges complete in all respect and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M). In ground floor 06.7.1 Matt or rustic wall tiles less than or equal to 300 mm x 600 mm size sqm Tk. 1,954.00 06.8 Supplying, fitting and fixing foreign (China or equivalent) made glazed wall tiles complying BDS ISO 13006: 2015, irrespective of color &/or design, with 20 mm thick cement sand (F.M. 1.2) mortar (1:3) base and raking out the joints with white cement including cutting, laying and hire charge of machine and finishing with care etc. including water, electricity and other charges complete in all respect and accepted by the Engineerin-charge. (Cement: CEM-II/A-M). In ground floor 06.8.1 Glazed wall tiles 300 mm x 600 mm in sizes along with maching floor tiles, decor and border (if any) sqm Tk. 2,772.00 PWD SoR 2018 for Civil Works TILES, MARBLE STONE AND GRANITE STONE WORKS Item No. Description of Item 06.9 Supplying, fitting and fixing foreign (China or equivalent) made rustic or matt finished wall tiles complying BDS ISO 13006: 2015, irrespective of color &/or design, with 20 mm thick cement sand (F.M. 1.2) mortar (1:3) base and raking out the joints with white cement including cutting, laying and hire charge of machine and finishing with care etc. including water, electricity and other charges complete in all respect and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M). In ground floor 06.9.1 Matt or rustic wall tiles 300 mm x 600 mm in sizes along with matching floor tiles, decor and border titles (if any) 06.10 Supplying, fitting and fixing country made GP homogeneous stair tiles having non skidding offsets, complying BDS ISO 13006: 2015, water absorbtion ≤ 0.5%, modulus of rupture (MOR) ≥ 27 N/mm2, irrespective of color &/or design, with cement sand (F.M. 1.2) mortar (1:4) base and raking out the joints with white cement including cutting and laying the tiles in proper way and finishing with care etc. all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor 06.10.1 Unit 90 Unit Rate sqm Tk. 2,772.00 Glazed stair tiles having size of width 250 mm to 300 mm and length 300 mm sqm Tk. 1,553.00 06.10.2 Glazed stair tiles having size of width 250 mm to 300 mm and length 325 mm to 600 mm sqm Tk. 2,004.00 06.11 Supplying, fitting and fixing country made rustic or matt finished stair tiles complying BDS ISO 13006: 2015, water absorbtion ≤ 0.5%, modulus of rupture (MOR) ≥ 27 N/mm2, irrespective of color &/or design, with 20 mm thick cement sand (F.M. 1.2) mortar (1:3) base and raking out the joints with white cement including cutting, laying and hire charge of machine and finishing with care etc. including water, electricity and other charges complete in all respect and accepted by the Engineer-in-charge. (Cement: CEMII/A-M). In ground floor 06.11.1 Rustic stair tiles of size 300 mm x 600 mm sqm Tk. 1,935.00 06.12 Supplying, fitting and fixing foreign (China or equivalent) made GP homogeneous stair tiles having non skidding offsets, complying BDS ISO 13006: 2015, water absorbtion ≤ 0.5%, modulus of rupture (MOR) ≥ 27 N/mm 2, irrespective of color &/or design, with cement sand (F.M. 1.2) mortar (1:4) base and raking out the joints with white cement including cutting and laying the tiles in proper way and finishing with care etc. all complete and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor 06.12.1 Glazed stair tiles of size 300 mm x 600 mm sqm Tk. 2,072.00 06.13 Supplying, fitting and fixing foreign (China or equivalent) made rustic or matt finished stair tiles complying BDS ISO 13006: 2015, water absorbtion ≤ 0.5%, modulus of rupture (MOR) ≥ 27 N/mm2, irrespective of color &/or design, with 20 mm thick cement sand (F.M. 1.2) mortar (1:3) base and raking out the joints with white cement including cutting, laying and hire charge of machine and finishing with care etc. including water, electricity and other charges complete in all respect and accepted by the Engineer-incharge. (Cement: CEM-II/A-M). In ground floor 06.13.1 Rustic stair tiles of size 300 mm x 600 mm sqm Tk. 2,004.00 06.14 Supplying, fitting and fixing country made floor tiles complying BDS ISO 13006: 2015, water absorbtion ≤ 0.5%, modulus of rupture (MOR) ≥ 27 N/mm 2, irrespective of color &/or design, with adhesives in full thickness of tiles, filler/tiles grout including cutting, shaping, placing in proper level etc. all complete and accepted by the Engineer-in-charge. In ground floor PWD SoR 2018 for Civil Works TILES, MARBLE STONE AND GRANITE STONE WORKS Item No. Description of Item Unit 91 Unit Rate 06.14.1 GP glazed / unglazed homogenous floor tiles (400 mm x 400 mm) sqm Tk. 1,864.00 06.14.2 GP glazed / unglazed homogenous floor tiles (300 mm x 300 mm) sqm Tk. 1,273.00 06.14.3 GP mirror polished floor tiles (300 mm x 300 mm) sqm Tk. 1,341.00 06.14.4 GP mirror polished floor tiles (400 mm x 400 mm) sqm Tk. 1,546.00 06.14.5 GP mirror polished floor tiles (600 mm x 600 mm) sqm Tk. 1,819.00 06.14.6 GP mirror polished floor tiles (800 mm x 800 mm) sqm Tk. 1,956.00 06.14.7 GP mirror polished floor tiles (600 mm x 900 mm) sqm Tk. 2,256.00 06.15 Supplying, fitting and fixing foreign made (China or equivalent) floor tiles complying BDS ISO 13006: 2015, water absorbtion ≤ 0.5%, modulus of rupture (MOR) ≥ 27 N/mm 2, irrespective of color &/or design, with adhesives in full thickness of tiles, filler/tiles grout including cutting, shaping, placing in proper level etc. all complete as direction of the Engineer-in-charge. In ground floor 06.15.1 GP mirror polished floor tiles (600 mm x 600 mm) sqm Tk. 2,160.00 06.15.2 GP mirror polished floor tiles (800 mm x 800 mm) sqm Tk. 2,501.00 06.15.3 GP mirror polished floor tiles (600 mm x 1200 mm) sqm Tk. 4,548.00 06.16 Supplying, fitting and fixing 20mm to 25mm thick mchine made cement pavement tiles having minimum compressive strength of 27 MPa, irrespective of color &/or design, with 20 mm thick cement sand (F.M. 1.2) mortar (1:4) base and making the joints carefully in true staight line including cutting, laying and hire charge of machine and finishing with care etc. including water, electricity and other charges complete in all respect and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M). In ground floor 06.16.1 Pavement tiles of size 300 mm x 300 mm sqm Tk. 2,481.00 06.17 Supplying, fitting and fixing mchine made clay roof tiles with ridge tiles on RCC inclined slab, irrespective of color &/or design, water absorbtion capacity <6% with 20 mm thick cement sand (F.M. 1.2) mortar (1:3) base and making the joints carefully in true staight line including cutting, laying and hire charge of machine and finishing with care etc. including water, electricity and other charges complete in all respect and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M). In ground floor 06.17.1 Roof tiles of size 100 mm x 200 mm or equivalent (red colour) sqm Tk. 2,683.00 06.17.2 Roof tiles of size 125 mm x 170 mm to 200 mm x 200 mm or equivalent (red colour) sqm Tk. 3,171.00 06.17.3 Roof tiles of size 160 mm x 268 mm or equivalent (red colour) sqm Tk. 2,901.00 06.17.4 Roof tiles of size 225 mm x 300 mm or larger (red colour) sqm Tk. 2,983.00 06.17.5 Flower shaped roof tiles of size 175 mm x 175 mm or equivalent (red colour) sqm Tk. 3,832.00 06.17.6 Roof tiles of size 100 mm x 200 mm or equivalent (beige colour) sqm Tk. 2,751.00 06.17.7 Roof tiles of size 125 mm x170 mm to 200 mm x 200 mm or equivalent (beige colour) sqm Tk. 3,297.00 PWD SoR 2018 for Civil Works TILES, MARBLE STONE AND GRANITE STONE WORKS Item No. Description of Item Unit 92 Unit Rate 06.17.8 Roof tiles of size 225 mm x 300 mm or larger (beige colour) sqm Tk. 3,229.00 06.17.9 Flower shaped roof tiles of size 175 mm x 175 mm or equivalent (beige colour) sqm Tk. 3,993.00 06.17.10 Roof tiles of size 125 mm x 170 mm to 200 mm x 200 mm or equivalent (grey or black colour) sqm Tk. 3,297.00 06.17.11 Flower shaped roof tiles of size 175 mm x 175 mm or equivalent (grey or black colour) sqm Tk. 4,348.00 06.18 Marble stone flooring with Indian standard quality (Bansowara/ Indian grey/ Indian pink or equivalent) marble stone of approved quality, texture and size with 25 mm thick cement sand (F.M. 1.2) mortar (1:2) including placing cement slurry below the stone, cutting the marble stone to desired size, grinding and finishing the edges, setting in position in proper level, filling the gaps with white cement and colouring pigments including supplying all necessary equipments/materials and finishing the top by pumice stone and necessary auxiliary materials and water, electricity and other charges complete in all respect and accepted by the Engineer in charge. (Cement: CEM-II/A-M). 06.18.1 18 mm thick marble stone flooring In ground floor sqm Tk. 7,325.00 06.18.2 16 mm thick marble stone flooring In ground floor sqm Tk. 6,675.00 06.19 Marble stone flooring with Indian superior quality marble stone of approved quality, texture and size with 25 mm thick cement sand (F.M. 1.2) mortar (1:2) including placing cement slurry below the stone, cutting the marble stone to desired size, grinding and finishing the edges, setting in position in proper level, filling the gaps with white cement and colouring pigments including supplying all necessary equipments/materials and finishing the top by pumice stone and necessary auxiliary materials and water, electricity and other charges complete in all respect and accepted by the Engineer in charge. (Cement: CEM-II/A-M) 06.19.1 18 mm thick marble stone flooring In ground floor sqm Tk. 7,975.00 06.19.2 16 mm thick marble stone flooring In ground floor sqm Tk. 6,935.00 06.20.1 Supplying and setting 12 mm thick Indian standard quality (Bansowara/ Indian grey/ Indian pink or equivalent) marble stone of approved quality, texture and size on wall with 12 mm thick cement sand (F.M. 1.2) mortar (1:2) including cutting and grinding the marble stone slab/tile, setting in position keeping horizontal and vertical alignment correct, filling the joints with white cement, cutting and grinding the top surface, finishing etc including water, electricity and other charges complete in all respect and accepted by the Engineerin-charge. (Cement: CEM-II/A-M) In ground floor sqm Tk. 6,286.00 06.20.2 Supplying and setting 12 mm thick Indian superior quality marble stone of approved quality, texture and size on wall with 12 mm thick cement sand (F.M. 1.2) mortar (1:2) including cutting and grinding the marble stone slab/tile, setting in position keeping horizontal and vertical alignment correct, filling the joints with white cement, cutting and grinding the top surface, finishing etc including water, electricity and other charges complete in all respect and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor sqm Tk. 6,676.00 PWD SoR 2018 for Civil Works TILES, MARBLE STONE AND GRANITE STONE WORKS Item No. 93 Description of Item Unit Unit Rate 06.21.1 Marble stone flooring with 18mm thick Italian or equivalent marble stone of approved quality, texture and size over 25 mm thick cement sand (F.M. 1.2) mortar (1:2) including. placing cement slurry below the stone, cutting the marble stone to desired size, grinding and finishing the edges, setting in position in proper level, filling the gaps with white cement and colouring pigments including supplying all necessary equipments/materials and finishing the top by pumice stone and necessary auxiliary materials and water, electricity and other charges complete in all respect and accepted by the Engineer-incharge. (Cement: CEM-II/A-M). In ground floor. sqm Tk. 9,924.00 06.21.2 Supplying and setting 12 mm thick Italian or equivalent quality marble stone on wall of approved quality, texture and size on wall with 12 mm thick cement sand (F.M. 1.2) mortar (1:2) including cutting and grinding the marble stone slab/tile, setting in position keeping horizontal and vertical alignment correct, filling the joints with white cement, cutting and grinding the top surface, finishing etc including water, electricity and other charges complete in all respect and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor Sqm Tk. 9,276.00 06.22 Labour cost for making moulding in marble stone as per architectural drawing including cutting, grinding, finishing, supplying necessary equipment etc. complete in all respect and accepted by the Engineer in Charge. (Cement: CEM-II/A-M). 06.22.1 18 mm thick marble stone meter Tk. 387.00 06.22.2 16 mm thick marble stone meter Tk. 382.00 06.22.3 12 mm thick marble stone meter Tk. 331.00 06.23 Granite stone flooring with 18 mm thick Indian or equivalent granite stone of approved quality, texture and size over 25 mm thick cement sand (F.M. 1.2) mortar (1:2) including placing cement slurry below the stone, cutting the granite stone to desired size, grinding and finishing the edges, setting in position in proper level. filling the gaps with white cement and colouring pigments including supplying all necessary equipments/materials and finishing the top by pumice stone and necessary auxiliary materials and water, electricity and other charges complete in all respect and accepted by the Engineer-incharge. (Cement: CEM-II/A-M) In ground floor sqm Tk. 8,624.00 06.24 Granite stone flooring with 18 mm thick Italian or equivalent origin granite stone of approved quality, texture and size over 25 mm thick cement sand (F.M. 1.2) mortar (1:2) including. placing cement slurry below the stone, cutting the granite stone to desired size, grinding and finishing the edges, setting in position in proper level, filling the gaps with white cement and colouring pigments including supplying all necessary equipments/materials and finishing the top by pumice stone and necessary auxiliary materials and water, electricity and other charges complete in all respect and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor sqm Tk. 9,924.00 06.25 Supplying and setting 12 mm thick Indian or equivalent granite stone of approved quality, texture and size on wall with 12 mm thick cement sand (F.M. 1.2) mortar (1:2) including cutting and grinding the granite stone slab, setting in position keeping horizontal and vertical alignment correct, filling the joints with white cement, cutting and grinding the top surface, finishing etc including water, electricity and other charges complete in all respect and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor sqm Tk. 6,676.00 PWD SoR 2018 for Civil Works TILES, MARBLE STONE AND GRANITE STONE WORKS Item No. 94 Description of Item Unit 06.26 Supplying and setting 12 mm thick Italian or equivalent granite stone of approved quality, texture and size on wall with 12 mm thick cement sand (F.M. 1.2) mortar (1:2) including cutting and grinding the granite stone slab, setting in position keeping horizontal and vertical alignment correct, filling the joints with white cement, cutting and grinding the top surface, finishing etc including water, electricity and other charges complete in all respect and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) In ground floor sqm Tk. 7,976.00 06.27 Extra rate for each additional floor for tiles works 06.27.1 Add for each additional floor up to 5th floor sqm Tk. 10.00 06.27.2 Add for each additional floor for 6th floor to 9th floor sqm Tk. 21.00 06.27.3 Add for each additional floor for 10th floor and above sqm Tk. 31.00 06.28 Extra rate for each additional floor for marble and granite stone works 06.28.1 Add for each additional floor up to 5th floor sqm Tk. 15.00 06.28.2 Add for each additional floor for 6th floor to 9th floor sqm Tk. 27.00 06.28.3 Add for each additional floor for 10th floor and above sqm Tk. 35.00 ………………….. END OF DIVISION SIX ………………….. Unit Rate PWD SoR 2018 for Civil Works REINFORCED CEMENT CONCRETE (RCC) WORKS 95 DIVISION 07: REINFORCED CEMENT CONCRETE (RCC) WORKS Item No. Description of Item Unit Unit Rate RCC WORKS: 1:2:4 (measured on gross concrete section) (f'c = 19 MPa, minimum f'cr = 24 MPa in nominal mix 1:2:4), with brick-chips (Sand of F.M. 1.2 and F.M. 2.2 in equal proportion) 07.1 Reinforced cement concrete works with minimum cement content relates to mix ratio 1:2:4 having minimum f'cr = 24 MPa, satisfying a specified compressive strength f'c= 19 MPa at 28 days on standard cylinders as per standard practice of Code ACI/BNBC/ASTM, cement conforming to BDS EN-197-1-CEM-I, 52.5N (52.5 MPa) / ASTM-C 150 Type – I, best quality sand [50% quantity of best local sand (F.M. 1.2) and 50% quantity of Sylhet sand or coarse sand of equivalent F.M. 2.2] and 20 mm down well graded picked jhama brick chips conforming to ASTM C-33 including breaking chips and screening, making and placing shutter in position maintaining true to plumb, making shutter water-tight properly, placing reinforcement in position; mixing in standard mixer machine with hopper fed by standard measuring boxes or mixing in batching plant, casting in forms, compacting by vibrator machine and curing at least for 28 days, removing centering-shuttering after specified time approved; including cost of water, electricity, testing charges of materials and cylinders as required, other charges etc. all complete, approved and accepted by the Engineer-in-charge. (Rate is excluding the cost of reinforcement and its fabrication, placing, binding etc. and the cost of shuttering & centering) 07.1.1 Individual & combined footing, pile cap, raft/mat, floor slab and foundation beam up to plinth level cum Tk. 7,517.00 07.1.2 Pedestal, column, column capital, lift wall and wall up to ground floor cum Tk. 7,730.00 07.1.3 Floor / roof slab, T-beam, L-beam and rectangular beam, tie beam, lintel, stair case slab and step etc. up to ground floor cum Tk. 7,602.00 07.1.4 Cornice, railing, drop wall, louver, fins, sunshade, false ceiling, waffle and ribbed floor slab etc. up to ground floor cum Tk. 7,944.00 cum Tk. 11,817.00 RCC WORKS: 1:2:4 (measured on gross concrete section) (f 'c = 22 MPa, minimum f 'cr = 27 MPa in nominal mix 1:2:4), with stone chips (100% sand of F.M. 2.2 ) 07.2 Reinforced cement concrete works with minimum cement content relates to mix ratio 1:2:4 having minimum f'cr = 27 MPa, satisfying a specified compressive strength f'c = 22 MPa at 28 days on standard cylinders as per standard practice of Code ACI/BNBC/ASTM, cement conforming to BDS EN-197-1-CEM-I, 52.5N (52.5 MPa) / ASTM-C 150 Type – I, best quality Sylhet sand or coarse sand of equivalent F.M. 2.2 and 20 mm down well graded stone chips conforming to ASTM C-33, making and placing shutter in position maintaining true to plumb, making shutter water-tight properly, placing reinforcement in position; mixing in standard mixer machine with hopper fed by standard measuring boxes or mixing in batching plant, casting in forms, compacting by vibrator machine and curing at least for 28 days, removing centering-shuttering after specified time approved; including cost of water, electricity, testing charges of materials and cylinders as required, other charges etc. all complete, approved and accepted by the Engineer-in-charge. (Rate is excluding the cost of reinforcement and its fabrication, placing, binding etc. and the cost of shuttering & centering) 07.2.1 Individual & combined footing, pile cap, raft/mat, floor slab and foundation beam up to plinth level PWD SoR 2018 for Civil Works REINFORCED CEMENT CONCRETE (RCC) WORKS Item No. Description of Item Unit Unit Rate 96 07.2.2 Pedestals, column, column capital, lift wall and RCC wall up to ground floor cum Tk. 12,031.00 07.2.3 Floor / roof slab, T-beam, L-beam and rectangular beam, tie beam, lintel, stair case slab and steps etc. up to ground floor cum Tk. 11,903.00 07.2.4 Cornice, railing, drop wall, louver, fins, sunshade, false ceiling, waffle and ribbed floor slab etc. up to ground floor cum Tk. 12,243.00 RCC WORKS: 1:1.5:3 (measured on gross concrete section) (f'c = 25MPa, minimum f'cr = 30 MPa in nominal mix 1 : 1.5 : 3), with stone chips (100% sand of F.M. 2.2) 07.3 Reinforced cement concrete works with minimum cement content relates to mix ratio 1:1.5:3 having minimum f'cr = 30 MPa, satisfying a specified compressive strength f‟c = 25 MPa at 28 days on standard cylinders as per standard practice of Code ACI/BNBC/ASTM, Cement conforming to BDS EN-197-1-CEM-I, 52.5N (52.5 MPa) / ASTM-C 150 Type – I, best quality Sylhet sand or coarse sand of equivalent F.M. 2.2 and 20 mm down well graded stone chips conforming to ASTM C-33, making and placing shutter in position and maintaining true to plumb, making shutter water-tight properly, placing reinforcement in position; mixing with standard mixer machine with hopper, fed by standard measuring boxes or mixing in batching plant, casting in forms, compacting by vibrator machine and curing at least for 28 days, removing centering-shuttering after specified time approved; including cost of water, electricity, testing charges of materials and cylinders as required, other charges etc. all complete, approved and accepted by the Engineer-in-charge. (Rate is excluding the cost of reinforcement and its fabrication, placing, binding etc. and the cost of shuttering & centering) 07.3.1 Individual & combined footing, pile cap, raft/mat, floor slab and foundation beam up to plinth level cum Tk. 12,154.00 07.3.2 Pedestals, column, column capital, lift wall and RCC wall up to ground floor cum Tk. 12,367.00 07.3.3 Floor / roof slab, T-beam, L-beam and rectangular beam, tie beam, lintel, stair case slab and steps etc. upto ground floor cum Tk. 12,240.00 07.3.4 Cornice, railing, drop wall, louver, fins, sunshade, false ceiling, waffle and ribbed floor slab etc. up to ground floor cum Tk. 12,580.00 RCC WORKS : 1:1.25:2.5 (measured on gross concrete section) (f'c = 32 MPa, minimum f'cr = 40 MPa in nominal mix 1 : 1.25 : 2.5) with stone chips and admixture(high strength concrete) (100% sand of F.M. 2.2) PWD SoR 2018 for Civil Works REINFORCED CEMENT CONCRETE (RCC) WORKS Item No. Description of Item Unit Unit Rate 97 07.4 Reinforced cement concrete works with minimum cement content relates to mix ratio 1:1.25:2.5 having minimum f'cr = 40 MPa, satisfying a specified compressive strength f‟c = 32 MPa at 28 days on standard cylinders as per standard practice of Code ACI/BNBC/ASTM, Cement conforming to BDS EN-197-1-CEM-I, 52.5N (52.5 MPa)/ ASTM-C 150 Type – I, and adding approved high range water reducing admixture of complying specific type (generally be Type-G) under ASTM-C 494, best quality coarse sand [Sylhet sand or coarse sand of equivalent F.M. 2.2], 20 mm down well graded crushed stone chips conforming to ASTM C-33, including screening sand through proper sieves, making and placing shutter in position and maintaining true to plumb, making shutter water-tight properly, placing reinforcement in position; mixing with standard mixer machine with hopper and fed by standard measuring boxes or mixing in batching plant, casting in forms, compacting by vibrator machine and curing at least for 28 days, removing centering-shuttering after specified time approved; including cost of water, electricity, testing charges of materials and cylinders as required, other charges etc. all complete, approved and accepted by the Engineer-in-charge. (Doses of admixture to be fixed in consultation with design office) (Rate is excluding the cost of reinforcement and its fabrication, placing, binding etc, admixture and the cost of shuttering & centering) 07.4.1 Individual & combined footing, pile cap, raft/mat, floor slab and foundation beam up to plinth level cum Tk. 12,451.00 07.4.2 Padestal, column, column capital, lift wall and RCC wall up to ground floor cum Tk. 12,664.00 07.4.3 Floor / roof slab, T-beam, L-beam and rectangular beam, tie beam, lintel, stair case slab and steps etc. up to ground floor cum Tk. 12,536.00 07.4.4 Cornice, railing, drop wall, louver, fins, sunshade, false ceiling, waffle and ribbed floor slab etc. up to ground floor cum Tk. 12,877.00 RCC WORKS: 1:1:2 (measured on gross concrete section) (f'c = 40 MPa, minimum f'cr = 49 MPa in nominal mix 1 : 1 : 2) with stone chips and admixture (high strength concrete) (100% sand of F.M. 2.2) 07.5 Reinforced cement concrete works with minimum cement content relates to mix ratio 1:1:2 having minimum f'cr = 49 Mpa, satisfying a specified compressive strength f‟c = 40 MPa at 28 days on standard cylinders as per standard practice of Code ACI/BNBC/ASTM, Cement conforming to BDS EN-197-1-CEM-I, 52.5N (52.5 MPa) / ASTM-C 150 Type – I, and adding approved high range water reducing admixture of complying specific type (generally be Type-G) under ASTM-C 494, best quality coarse sand [Sylhet sand or coarse sand of equivalent F.M. 2.2], 20 mm down well graded crushed stone chips conforming to ASTM C-33, making and placing shutter in position and maintaining true to plumb, making shutter water-tight properly, placing reinforcement in position; mixing with standard mixer machine with hopper and fed by standard measuring boxes or mixing in batching plant, casting in forms, compacting by vibrator machine and curing at least for 28 days, removing centering-shuttering after specified time approved; including cost of water, electricity, testing charges of materials and cylinders required by engineer, other charges etc. all complete approved and accepted by the Engineer-in-charge. (Doses of admixture to be fixed in consultation with design office) (Rate is excluding the cost of reinforcement and its fabrication, placing, binding etc, admixture and the cost of shuttering & centering) 07.5.1 Individual & combined footing, pile cap, raft/mat, floor slab and foundation beam up to plinth level cum Tk. 12,920.00 07.5.2 Pedestal, column, column capital, lift wall and RCC wall upto ground floor cum Tk. 13,134.00 PWD SoR 2018 for Civil Works REINFORCED CEMENT CONCRETE (RCC) WORKS Item No. Description of Item Unit Unit Rate 98 Fair-faced RCC WORKS: 1:1.5:3 (measured on gross concrete section) (f'c = 25 MPa, minimum f'cr = 30 MPa in nominal mix 1:1.5:3) (100% sand of F.M. 2.2) 07.6 Cast-in-place fair-faced concrete works with f'cr=30 Mpa and f'c=25 Mpa at 28 days on standard cylinders by using 75% of OPC and 25% of white cement conforming to BDS EN-197-1-CEM-I, 52.5N (52.5 MPa) / ASTM-C 150 Type – I, best quality Sylhet sand or coarse sand of equivalent F.M. 2.2, 20 mm down and well graded stone chips conforming to ASTM C-33 at mix ratio of 1:1.5:3, adding coloring pigment as per architectural design, conforming to the standard practice of code ACI/BNBC/ASTM including screening sand and chips through proper sieves, washing, making and placing shutter in position maintaining true to plumb, making shutter water tight properly, placing reinforcement in position, including pouring of concrete in form, compacting by vibrator machine and curing at least for 28 days, removing centering-shuttering after specified time approved; including cost of water, electricity, testing charges of materials and cylinders as required, other charges etc. all complete, approved and accepted by the Engineer-in-charge. (Rate is excluding the cost of reinforcement and its fabrication, placing, binding etc, and the cost of shuttering & centering) 07.6.1 For column, wall, beam, slab, drop wall, cornice etc. up to ground floor cum Tk. 15,185.00 07.7 Extra rate for RCC works/fair-faced concrete works (materials, consumables and laying/placing concrete) in column, column capital, lift wall & wall, T- beam, L-beam, rectangular beams, floor / roof slab, cantilever slab, waffle slab and drop panels where the free height of the structure exceeds 4 meter (rate is considered for each additional meter height) cum Tk. 251.00 07.8 Extra rate for RCC work/fair-faced work in additional floor: concrete 07.8.1 Add for each additional floor up to 5th floor cum Tk. 108.00 07.8.2 Add for each additional floor for 6th floor to 9th floor cum Tk. 145.00 07.8.3 Add for each additional floor for 10th floor & above cum Tk. 181.00 FORM WORK (Steel) 07.9 Centering and shuttering, including strutting, propping etc. (The formwork must be rigid enough both in and out of plane, to make the concrete surface true to the designed shape and size by using necessary MS sheets of minimum 16 BWG, angles of minimum size 40 mm x 40 mm x 5 mm, flat bars etc.) and removal of form for: 07.9.1 Individual and combined footing sqm Tk. 438.00 07.9.2 In raft/mat/floor slab up to plinth level sqm Tk. 434.00 07.9.3 Foundation beam sqm Tk. 380.00 07.9.4 Pedestal, column, column capital, lift wall and wall up to ground floor sqm Tk. 408.00 07.9.5 Tie beam and lintel: ground floor sqm Tk. 419.00 07.9.6 T-beam, L-beam and rectangular beam etc up to ground floor sqm Tk. 455.00 07.9.7 Floor and roof slab up to ground floor sqm Tk. 532.00 PWD SoR 2018 for Civil Works REINFORCED CEMENT CONCRETE (RCC) WORKS Item No. 99 Description of Item Unit Unit Rate 07.9.8 Cornice, railing, drop walls, louver, fins etc.: ground floor sqm Tk. 387.00 07.9.9 Sunshade, false ceiling: ground floor sqm Tk. 438.00 07.9.10 Stair case slab and steps up to ground floor sqm Tk. 437.00 07.9.11 Waffle or ribbed floor upto ground floor sqm Tk. 578.00 07.9.12.1 Arches, domes, vaults up to 8m span (for single use) sqm Tk. 1,830.00 07.9.12.2 Arches, domes, vaults up to 8 m span (for 2-times use) sqm Tk. 1,281.00 07.9.12.3 Arches, domes, vaults up to 8 m span (for 3-times use) sqm Tk. 915.00 07.9.12.4 Arches, domes, vaults up to 8 m span (for more than 3-times use) sqm Tk. 641.00 07.10 Extra rate for arches, domes, vaults exceeding 8 m span sqm Tk. 458.00 07.11 Extra rate for shuttering in circular work sqm Tk. 91.00 07.12 Extra rate for additional height in centering, shuttering where ever required with adequate bracing, propping etc. over a height of 4.0 m, for every additional height of 1 metre or part thereof. sqm Tk. 45.00 07.13 Extra rate for formwork/shuttering in additional floor 07.13.1 Add for each addl. floor up to 5th floor sqm Tk. 41.00 07.13.2 Add for each addl. floor for 6th floor to 9th floor sqm Tk. 61.00 07.13.3 Add for each addl. floor for 10th floor & above sqm Tk. 82.00 07.14 Extra rate of formwork for making ‘fair-faced’ surface of the concrete as per design, drawing and direction of Engineer-in-charge. (The formwork must be rigid enough both in and out of plane, to make the concrete surface true to the designed shape and size by using necessary MS sheets of minimum 10 BWG, angles of minimum size 50 mm x 50 mm x 6 mm, flat bars, formwork releasing agent etc.) sqm Tk. 382.00 FORMWORK (Wooden) for boundary wall, gate, centry post etc. 07.15 Centering and shuttering, including strutting, propping etc. and removal of form for: 07.15.1 Individual and combined footings sqm Tk. 399.00 07.15.2 Foundation beam sqm Tk. 381.00 07.15.3 Padestals, column, wall sqm Tk. 429.00 07.15.4 Tie beam & lintels sqm Tk. 417.00 07.15.5 T-beam, L-beam and rectangular beam sqm Tk. 414.00 07.15.6 Floor & roof slab sqm Tk. 456.00 07.15.7 Cornice, railing, drop wall, louver, fins etc. sqm Tk. 370.00 PWD SoR 2018 for Civil Works REINFORCED CEMENT CONCRETE (RCC) WORKS Item No. Description of Item Unit 100 Unit Rate 07.15.8 Sunshade, false ceiling sqm Tk. 399.00 07.15.9 Stair case slab and steps upto ground floor sqm Tk. 387.00 07.16 Supply and use of specified type chemical admixture delivered from an authorized local agent or manufacturer, complying with the ASTM C-494 requirements; conforming the current compliance of the admixture to specification requirements like physical properties, uniformity and equivalence in composition etc.; performance (water content, fresh concrete setting time and compressive strength) requirements, delivered in sealed watertight containers confirming plainly marked product name & type under this specification, net weight and /or volume, manufacturing and expiry date, non aggressiveness to environment, aggregates and metals in concrete etc. and mixing the admixture in non prestressed cement concrete mixture in the field in accordance with manufacturers recommendation and instruction; providing safety provisions in all respects etc. all complete as per instruction and approved by the Engineer-in-charge. Dose (quantity in mililitres per 50 kg bag cement) and brand/origin/ manufacturer with respect to particular brand of cement and particular stock of aggregates and method of use to be determined by mix design / trial mix at the cost of contractor and approved by the Engineer. (Use of admixture is subjected to prior approval of design office) 07.16.1 Supply and use of water reducing chemical admixture in concrete, complying ASTM C494 Type - A of approved brand / origin / manufacturer and supplied by only manufacturer's authorised dealer with certificate of origin. The admixture is to reduce quantity of mixing water required for normal workability and to maintain low water-cement (W/C) ratio, for improved concrete quality ensuarance. liter Tk. 193.00 07.16.2 Supply and use of retarding chemical admixture in concrete, complying ASTM C-494 Type - B of approved brand/origin/manufacturer and supplied by only manufacturer‟s authorised dealer with certificate of origin. The admixture for retarding setting time of concrete, there by reducing shrinkage in concrete specially for concrete laid in thick layers and intended delayed construction for improved construction joints, re-concreting etc. liter Tk. 169.00 07.16.3 Supply and use of accelerating chemical admixture in concrete, complying ASTM C-494 Type - C of approved brand/origin/manufacturer and supplied by only manufacturer's authorised dealer with certificate of origin. An admixture that is to accelerate the setting time and early strength gain of concrete. liter Tk. 151.00 07.16.4 Supply and use of water-reducing and retarding chemical admixture in concrete, complying ASTM C-494 Type - D of approved brand/origin/manufacturer and supplied by only manufacturer's authorised dealer with certificate of origin. The admixture to reduce the quantity of mixing water required to produce concrete of given consistency, i.e. low water-cement (W/C) ratio and intend to retard setting time of concrete, specially for layered, thick laid concrete etc. liter Tk. 278.00 07.16.5 Supply and use of water-reducing and accelerating chemical admixture in concrete, complying ASTM C-494 Type - E of approved brand/origin/manufacturer and supplied by only manufacturer's authorised dealer with certificate of origin. The admixture to reduce the quantity of mixing water required to produce concrete of given consistency, i.e. low water-cement (W/C) ratio and intend to accelerate setting time of concrete, and early strength gain in concrete etc. liter Tk. 217.00 07.16.6 Supply and use of water-reducing high range chemical admixture in concrete, complying ASTM C-494 Type - F of approved brand/origin/manufacturer and supplied by only manufacturer's authorised dealer with certificate of origin. The admixture required to produce concrete of consistency by 12% or greater (flowing concrete) and for higher strength of concrete. liter Tk. 290.00 PWD SoR 2018 for Civil Works REINFORCED CEMENT CONCRETE (RCC) WORKS Item No. 101 Description of Item Unit Unit Rate 07.16.7 Supply and use of water-reducing high range and retarding chemical admixture in concrete, complying ASTM C-494 Type - G of approved brand/origin/manufacturer and supplied by only manufacturer's authorised dealer with certificate of origin. The admixture required to produce concrete of consistency by 12% or greater (flowing concrete) and for higher strength of concrete and intend to retard setting time of concrete. liter Tk. 205.00 07.17 Supply and use of best quality pliable, cold applied pre-formed self adhesive rubberized/ bituminous water proofing membrane of approved brand / origin / manufacturer from an authorized local agent or manufacturer having minimum thickness 1.5 mm, lined with 2 ply cross laminated high density polyethylene film performances and properties all conforming to ASTM standards and laying, placing, fixing on made up firm and dry surfaces free from hollows, sharp protrusions, contaminates etc. laid over-lap by at least 75 mm along the edges and 125 mm at ends ensuring good initial bond with the surfaces all complete under the strict accordance with the manufacturer recommendations and instructions providing all safety provisions in all respects and accepted by the Engineer. (supplied by only manufacturer's authorised dealer with certificate of origin) under following specification: Backing(HDPE) thickness minimum 0.10mm Membrane thickness minimum 1.40mm Total thickness minimum 1.50mm Cold flexibility greater than (-)200C: ASTM D146 Pliability: "No crack" tested in ASTM D146 Tensile strength (film only) min 3.50 MPa( 35000 kN/m2) testing in ASTM D882 Tensile strength (composite) at least 2.40 MPa or N/mm2 Elongation (composite) min 300% Cycling over crack at (-) 320C No effect 100 cycles ASTM C836-89a Puncture resistance greater than 240N ASTM E 154-88 Resistance to hydrostatic head at least 50m ASTM D5385 Tear resistance min 4.0 MPa (N/mm2) Adhesion to primed concrete min 4.0N/mm : ASTM D1000 Water vapor transmission less than 0.10g/m2 per hour : ASTM E96 Water absorption in 24 hour less than 0.33% ASTM D570 Heat stability (+) 900C environmental complience to conform: ASTM D543 07.17.1 Water-proofing membrane on external surface of primed vertical or inclined wall /on plastered and primed back-wall and concrete cast against membrane. (Excluding cost of back fill/brick wall on back/plaster when membrane laid on back-wall and concrete cast against membrane which to be paid as per corresponding items in this schedule) sqm Tk. 999.00 07.17.2 Water-proofing membrane on made up surface below the floor or below the horizontal surfaces with temporary protective cover using polysterene/38 mm thick sand-cement mortar in 4:1 /or by equally effective alternative. (Rate is excluding the cost of protective cover which to be paid as per corresponding items in this schedule) sqm Tk. 871.00 07.17.3 Water-proofing membrane on the floor or on the horizontal surfaces with permanent protective cover & wearing coarse. (Rate is excluding the cost of protective cover and wearing coarse which to be paid as per corresponding items in this schedule) sqm Tk. 908.00 PWD SoR 2018 for Civil Works REINFORCED CEMENT CONCRETE (RCC) WORKS Item No. 102 Description of Item Unit 07.18 Supply of polymer based curing compound as per ASTM C 309 or BS 7542-1992 standard and apply by stirring & spraying with motorized sprayers over the surface of fresh concrete free from surface water and avoiding bleeding of concrete maintaining the spray nozzle approximately 450 mm away from the concrete surface with passed back and forth to ensure complete coverage confirming the pump pressure for fine spray and keeping the concrete surface undisturbed until it has sufficient strength to bear surface loads [The suitability of motorized sprayer should be ensured by an application trial] ensuring adequate ventilation to avoid inhalation of vapors and contact with skin and eyes all complete and accepted by Engineer-in-charge. sqm Tk. 156.00 07.19 Supply of epoxy bonding agent following ASTM C881 / C881M - 14 or any international acceptable standard and apply over the old concrete surface after making free of standing water, removal of dust, laitance, grease, curing compounds, impregnations, waxes and any other contaminants to achieve optimum bonding in between fresh and old concrete and accepted by the Engineer-in-charge. sqm Tk. 978.00 07.20 Supply of best quality salt guard coating on concrete surface following ASTM B117 delivered from authorized local agent of the manufacturer in a sealed container and apply by a firm experienced in applying salt guard coating or workers trained and approved by manufacturer to wall and ceiling in 2 coats elapsing specified time for drying/ recoating including cleaning and sand papering making the surface free from loose and efflorescence, flaky materials, dirt, grease, wax, polish, scraping all chalked and scaled materials, applying the paint by brush/spray following manufacturer's written instructions and necessary scaffolding etc. all complete and accepted by the Engineer-in-charge sqm Tk. 36.00 ………………….. END OF DIVISION SEVEN …………………. Unit Rate M.S. FABRICATION AND CONSTRUCTION JOINT IN RCC WORKS PWD SoR 2018 for Civil Works 103 DIVISION 08: M.S. FABRICATION AND CONSTRUCTION JOINT IN RCC WORKS Item No. Description of Item Unit Unit Rate 08.1 Supplying, fabrication and fixing to detail as per design : ribbed or deformed bar reinforcement for Reinforced cement concrete, produced and marked in accordance with BDS ISO 6935 - 2: 2006 (or standard subsequentley released from BSTI) including straightening and cleaning rust, if any, bending and binding in position with supply of G.I. wires, necessary laboratory tests (excluding splices or laps) etc. complete in all respect and accepted by the Engineer-in-charge (Measurement shall be recorded only on standard mass per unit length of bars, while dia of bars exceeds its standard) 08.1.1 Grade 300 (RB 300 /RB 300W: complying BDS ISO 6935-2:2006) ribbed or deformed bar produced and marked according to Bangladesh sandard, with minimum yield strength, fy (ReH)= 300 MPa but fy not exceeding 330 MPa and whatever is the yield strength within allowable limit as per BNBC/ ACI 318, the ratio of ultimate tensile strength fu to yield strength fy, shall be at least 1.25 and minimum elongation after fracture and minimum total elongation at maximum force is 16% and 8% respectively : up to ground floor kg Tk. 79.00 08.1.2 Grade 400 (RB 400 /RB 400W: complying BDS ISO 6935-2:2006) ribbed or deformed bar produced and marked according to Bangladesh standard, with minimum yield strength, fy (ReH)= 400 MPa but fy not exceeding 450 MPa and whatever is the yield strength within allowable limit as per BNBC/ ACI 318, the ratio of ultimate tensile strength fu to yield strength fy, shall be at least 1.25 and minimum elongation after fracture and minimum total elongation at maximum force is 16% and 8% respectively : up to ground floor. kg Tk. 82.00 08.2 Extra rate for M.S. Fabrication work in additional floor shall be incorporated in the estimate 08.2.1 Add for each additional floor up to 5th floor kg Tk. 0.48 08.2.2 Add for each additional floor for 6th floor to 9th floor kg Tk. 0.97 08.2.3 Add for each additional floor for 10th floor and above kg Tk. 1.45 08.3 Mild steel, grade 250 with minimum fy = 250 MPa, work in roof truss: supplying and fabrication of mild steel sections as per design, hoisting, fitting and fixing in position with bolt and nuts or rivets or welds and providing two coats of anti-corrosive paint over a prime coat of red oxide paint etc. complete and accepted by the Engineer-incharge.(Measurement to be given for truss member only). kg Tk. 138.00 08.4 Supplying fan hook 300-grade (RB 300) of 16 mm diameter M.S. rod (one meter straight length) having rounded hook at the middle of bar in proper size so as to be concealed within fan cup including fabrication, fitting and fixing in all floor accepted by the Engineerin-charge. each Tk. 113.00 08.5 Installtation of water stopper at movable and immovable RCC green joints as per following specification. 08.5.1 Supplying, fitting and fixing ribbed PVC water stopper with non centre bulb of width approx. 250 mm and approx 9 mm thick for immovable (non working) RCC joints, having minimum tensile strength of 8.27 MPa (approx. 1200 psi) min ultimate elongation 350%, approximate hardness 50, minimum tear resistance 0.0175 kN/mm (100 lbs/inch) at RCC construction green joints in basements, approved and in consultation with design office, providing 38 mm x 62 mm wooden batten at the top and bottom of water stopper, holding in position and keeping the water stopper in true horizontal or vertical by appropriate means as where necessary etc; all complete and accepted by the Engineer-in-charge. meter Tk. 1,017.00 M.S. FABRICATION AND CONSTRUCTION JOINT IN RCC WORKS Item No. PWD SoR 2018 for Civil Works 104 Description of Item Unit 08.5.2 Supplying, fitting and fixing ribbed PVC water stopper with centre bulb of width approx. 250 mm and approx 9 mm thick for immovable (non working) RCC joints, having minimum tensile of strength 8.27 MPa (approx. 1200 psi) minimum ultimate elongation 350%, approximate hardness 50, minimum tear resistance 0.0175 kN/mm (100 lbs/inch) at RCC construction green joints in basements, approved and in consultation with design office, providing 38 mm x 62 mm wooden batten at the top and bottom of water stopper, holding in position and keeping the water stopper in true horizontal or vertical by appropriate means as where necessary etc; all complete and accepted by the Engineer-in-charge. meter Tk. 1,017.00 08.6 Supplying, fitting and fixing 250 mm wide 16 SWG aluminium sheet water stopper in RCC construction joint holding in position and keeping the water stopper in true horizontal or vertical by appropriate means as where necessary etc; all complete and accepted by the Engineer-in-charge. meter Tk. 331.00 08.7 Providing bearing joints fixed or free with 250 mm x 375 mm x 10 mm M.S. (Grade - A36) shoe plate fitted in the truss angles with 16 mm diameter M.S. rod counter sunk rivets, welded and anchored to 250 x 375 x 10 mm. M.S shoe plate by two Nos. 19 mm dia M.S. “U” rod embedded in the bed of the lintel around the reinforcement, cleaning and greasing the joints for all floors etc. all complete and accepted by the Engineer-in-charge each Tk. 2,298.00 ………………….. END OF DIVISION EIGHT ………………….. Unit Rate PWD SoR 2018 for Civil Works PILE WORKS AND PILE TEST 105 DIVISION 09: PILE WORKS AND PILE TEST Item No. Description of Item Unit Unit Rate 09.1 Boring/drilling by wash or percussion method for cast in situ pile up to the required depth and diameter with minimum 6 m long temporary steel casing, true to vertical, providing bentonite slurry and maintaining water level in the hole, washing the hole for at least 30 minutes, cleaning the bore hole and making the bore hole ready for placing steel cage and concreting including hire charge of rig set with winch machine, tripod stand, tremie pipe, cost of fuel, lubricant, mobilization, demobilization, maintenance, spares, stand-byes, insurance coverage, water, electricity and other charges all compete, approved and accepted by the Engineer-in-charge. Before commencing boring operation, contractor shall submit the method statement of cast-in-situ pile work including sequence of boring and casting, disposal of spoils, test result of materials to the Engineer-in-charge for approval. However, Engineer‟s approval shall not relieve the contractor of his responsibilities and obligations under contract. 09.1.1 400 mm dia meter Tk. 502.00 09.1.2 450 mm dia meter Tk. 661.00 09.1.3 500 mm dia meter Tk. 794.00 09.1.4 550 mm dia meter Tk. 980.00 09.1.5 600 mm dia meter Tk. 1,167.00 09.2 Auger Boring/ Rotary Drilling for cast in situ pile up to the required depth and diameter with minimum 6 m long temporary steel casing, true to vertical, providing bentonite slurry and maintaining water level in the hole, washing the hole for at least 30 minutes, cleaning the bore-hole and making the bore- hole ready for placing steel cage and concreting including hire charge of rig set, trimie pipe, cost of fuel, lubricant, mobilization, demobilization, maintenance, spares, stand-byes, insurance coverage, bentonite, water, electricity and other charges all compete approved and accepted by the Engineer-incharge. Before commencing boring operation, contractor shall submit the method statement of cast-in-situ pile work including sequence of boring and casting, disposal of spoils, test result of materials to the Engineer-in-charge for approval. However, Engineer‟s approval shall not relieve the contractor of his responsibilities and obligations under contract. 09.2.1 600 mm dia meter Tk. 3,388.00 09.2.2 750 mm dia meter Tk. 4,065.00 09.2.3 1000 mm dia meter Tk. 5,646.00 09.3 Removing of spoils / mud accumulated during boring for cast in situ pile by wash boring from working site to a safe distance by contractor‟s own arrangement i.e. with container set in truck or on cart including loading, unloading everything complete as per standard practice and accepted by the Engineer-in-charge. (Quantity should be given three times of solid volume of boring) cum Tk. 557.00 PWD SoR 2018 for Civil Works PILE WORKS AND PILE TEST Item No. 106 Description of Item Unit Unit Rate 09.4 Cast in situ pile with reinforced cement concrete works of high slump by adding high range water reducing admixture (ASTM C494 Type A or F) with minimum cement content relates to mix ratio 1 : 1.5 : 3 having minimum f'cr = 26 Mpa, and satisfying a specified compressive strength f‟c = 21 Mpa at 28 days on standard cylinders as per standard practice of Code ACI/BNBC/ASTM & cement conforming to BDS EN-197-1- CEM -1,52.5 N / ASTM-C 150 Type – I, best quality coarse sand [Sylhet sand or coarse sand of equivalent F.M.2.2], 20 mm down well graded crushed stone chips conforming to ASTM C-33, including breaking chips, screening through proper sieves, making, placing re-bar cage in position, placing and removing tri-pod as per requirement, pouring the concrete in bore-hole with the help of a tremie pipe, maintaining the tremie pipe immersed in concrete by at least 1 meter throughout the period of concreting, maintaining required slump, etc. mixing the aggregates with standard mixer machine with hopper, casting in forms, all complete including water, electricity, testing of materials and concrete etc and other charges as per design, drawing etc all complete approved and accepted by the Engineerin-charge. (Rate is excluding the cost of reinforcement and its fabrication, binding, welding, placing and admixture (approx doses 150 to 250 ml per bag of cement which is to be fixed upon consultation with design office)) cum Tk. 13,463.00 09.5 Providing and making point welding at contact point of the spiral binders at reasonable intervals with the main reinforcements by electric arc welding for construction of cast in situ bored pile carefully with highly oxidized electrodes, making the points prominent and accepted by the Engineer-in-charge (Rate is inclusive of all materials labour, tools and plants, electricity and all equipment). point Tk. 3.00 09.6 Providing and making welded splice over two sides of contact by welding of minimum 300 mm length at the lap of main reinforcement in re-bar cage to be placed in bore-hole where necessary by electric arc welding with highly oxidized electrodes making the joint prominent all complete and accepted by the Engineer-in-charge. (Rate is inclusive of all materials labour, tools and plants, electricity and all equipment). meter of weld Tk. 570.00 09.7 Labour for breaking head of hardened cast in situ bored pile/pre-cast pile up to a required length by any means but without damaging the rest and removing the dismantled materials such as concrete to a safe distance including scraps and cleaning concrete from steel/M.S. rods, straightening and bending of pile bars, preparation and making platform where necessary, carrying, all sorts of handling, stacking the same properly after clearing, leveling and dressing the situ and clearing the bed etc. complete in all respect and accepted by the Engineer-in-charge. (Measurement will be given for the actual pile head volume to be broken) cum Tk. 4,673.00 09.8 Conducting static load test as per ASTM D1143 or equivalent standard for the cast-insitu/pre-cast pile providing required scaffolding, bracing, jacks, pressure test gauge, loading unloading, Kentledge and other plants and equipment including staging, mobilization, demobilization, hire charge, gunny bags, sand and filling sacs/gunny bags for loading, record readings and preparation of results in standard forms and other incidental charges as per standard practice and procedures including submission of load test report, furnishing all graph and chart etc. complete in all respect approved and accepted by the Engineer-in-charge (Minimum two cyclic loading; one at service load and another cycle at double the service load then to continue loading till failure of the pile). Before commencing load test, contractor shall submit method statement for conducting load test to the Engineer-in-charge for approval. However, Engineer‟s approval shall not relieve the Contractor of his responsibilities and obligations under Contract. Load test and report shall be conducted under the supervision of a professional Geotechnical Engineer registered in BPERB or Geotechnical firm registerd in PWD. Boring and pouring logs / driving logs of piles and method statement shall be the part of load test report. PWD SoR 2018 for Civil Works PILE WORKS AND PILE TEST Item No. Description of Item Unit 107 Unit Rate 09.8.1 Mobilization & de-mobilization of testing equipment per set per site Tk. 4,105.00 09.8.2 Calibration of pressure gauge per set per site Tk. 6,520.00 09.8.3 For 50 tonne load for 1 no of test per test Tk. 73,338.00 09.8.4 For 100 tonne load for 1 no of test per test Tk. 123,177.00 09.8.5 For 150 tonne load for 1 no of test per test Tk. 173,017.00 09.8.6 For 200 tonne load for 1 no of test per test Tk. 224,571.00 09.8.7 For 250 tonne load for 1 no of test per test Tk. 276,053.00 09.8.8 For 300 tonne load for 1 no of test per test Tk. 325,121.00 09.8.9 For 350 tonne load for 1 no of test per test Tk. 374,188.00 09.8.10 For 400 tonne load for 1 no of test per test Tk. 423,255.00 09.9 Rate for incremental loading 09.9.1 For intermediate loading from 50 tonne to 100 tonne for each additional tonne per tonne Tk. 1,349.00 09.9.2 For intermediate loading from 100 tonne to 150 tonne for each additional tonne. per tonne Tk. 1,193.00 09.9.3 For intermediate loading from 150 tonne to 200 tonne for each additional tonne. per tonne Tk. 1,138.00 09.9.4 For intermediate loading from 200 tonne to 250 tonne for each additional tonne. per tonne Tk. 1,114.00 09.9.5 For intermediate loading from 250 tonne to 300 tonne for each additional tonne. per tonne Tk. 1,094.00 09.9.6 For intermediate loading from 300 tonne to 350 tonne for each additional tonne. per tonne Tk. 1,077.00 09.9.7 For intermediate loading from 350 tonne to 400 tonne for each additional tonne. per tonne Tk. 1,064.00 PWD SoR 2018 for Civil Works PILE WORKS AND PILE TEST Item No. Description of Item Unit 108 Unit Rate 09.10 Pre-cast pile made in reinforced cement concrete with minimum cement content relates to mix ratio 1:1.25:2.5 having minimum f'cr = 35 Mpa, and satisfying specified compressive strength f‟c = 30 Mpa at 28 days on standard cylinders as per standard practice of Code ACI/BNBC/ASTM & cement conforming to BDS EN-197-1- CEM-I (52.5 N) / ASTM-C 150 Type – I, best quality coarse sand (F.M.2.2), 20 mm down well graded crushed stone chips conforming to ASTM C-33, mixing in standard mixture machine and fed by standard measuring boxes, including all related works like screening through proper sieves, cleaning and washing, centering and shuttering with M.S sheet, M.S angle, F.I bar, nuts and bolts, champering edges if so, preparation of casting beds, laying polythene there in, placing reinforcement cages in position, casting, compacting by vibrators and tapered rods as where necessary, curing for 28 days etc. cost of water, electricity and other charges, providing fitting and fixing pile shoe in position, tools, plants & equipments, mobilization, demobilization, labour, test of materials and concrete etc. all complete as per design, drawing and accepted by the Engineer-in-charge. (Rate is excluding the cost of reinforcement and its fabrication, binding, welding and placing) 09.10.1 250 mm x 250 mm size pre-cast pile (1:1.25:2.5) with stone chips meter Tk. 965.00 09.10.2 300 mm x 300 mm size pre-cast pile (1:1.25:2.5) with stone chips meter Tk. 1,347.00 09.10.3 350 mm x 350 mm size pre-cast pile (1:1.25:2.5) with stone chips meter Tk. 1,777.00 09.10.4 400 mm x 400 mm size pre-cast pile (1:1.25:2.5) with stone chips meter Tk. 2,294.00 09.10.5 450 mm x 450 mm size pre-cast pile (1:1.25:2.5) with stone chips meter Tk. 2,866.00 09.11 Pre-cast pile shoe making & supplying pre-fabricated frustum of square cone having four sides and a toe made of 6 mm thick ASTM A36 complied MS steel plate jointed by line welding, 4 nos 12 mm dia deformed MS bar jointed by line welding with MS plate along the four edges of shoe aligning the corner main bar of the pile and 1 no 12 mm dia bar to fix with and perpendicular to shoe toe plate aligning centre of pile, including cutting, shaping, sizing of MS plate and bar, all complete as per design & drawing and accepted by the Engineer-in-charge each Tk. 2,725.00 09.12 Mobilization and demobilization of drop hammer type pre-cast pile driving rig. per set per site Tk. 8,597.00 09.13 Driving 250 mm x 250 mm size pre-cast pile with drop hammer type rig, and maintaining driving log in prescibed format Before commencing driving operation, contractor shall submit method statement for carrying out the driving operation including sequence of driving to the Engineer-in-charge for approval. However, Engineer‟s approval shall not relieve the contractor of his responsibilities and obligations under contract. meter Tk. 404.00 09.14 Driving 300 mm x 300 mm size pre-cast pile with drop hammer type rig, and maintaining driving log in prescibed format Before commencing driving operation, contractor shall submit method statement for carrying out the driving operation including sequence of driving to the Engineer-in-charge for approval. However, Engineer‟s approval shall not relieve the contractor of his responsibilities and obligations under contract. meter Tk. 531.00 09.15 Driving 350 mm x 350 mm size pre-cast pile with drop hammer type rig, and maintaining driving log in prescibed format. Before commencing driving operation, contractor shall submit method statement for carrying out the driving operation including sequence of driving to the Engineer-in-charge for approval. However, engineer‟s approval shall not relieve the contractor of his responsibilities and obligations under contract. meter Tk. 708.00 PWD SoR 2018 for Civil Works PILE WORKS AND PILE TEST Item No. 109 Description of Item Unit Unit Rate 09.16 Mobilization and demobilzation of automatic diesel hammer mounted complete rig set. per set per site Tk. 181,117.00 09.17 Driving 250 mm x 250 mm size pre-cast pile by rig fitted with automatic diesel operated hammer. Before commencing driving operation by rig fitted with automatic diesel operated hammer, contractor shall submit method statement for carrying out the operation including sequence of driving to the Engineer-in-charge for approval. However, engineer‟s approval shall not relieve the contractor of his responsibilities and obligations under contract. meter Tk. 628.00 09.18 Driving 300 mm x 300 mm size pre-cast pile by rig fitted with automatic diesel operated hammer. Before commencing driving operation by rig fitted with automatic diesel operated hammer, contractor shall submit method statement for carrying out the operation including sequence of driving to the Engineer-in-charge for approval. However, engineer‟s approval shall not relieve the contractor of his responsibilities and obligations under contract. meter Tk. 812.00 09.19 Driving 350 mm x 350 mm size pre-cast pile by rig fitted with automatic diesel operated hammer. Before commencing driving operation by rig fitted with automatic diesel operated hammer, contractor shall submit method statement for carrying out the operation including sequence of driving to the Engineer-in-charge for approval. However, engineer‟s approval shall not relieve the contractor of his responsibilities and obligations under contract. meter Tk. 863.00 09.20 Driving 400 mm x 400 mm size pre-cast pile by rig fitted with automatic diesel operated hammer. Before commencing driving operation by rig fitted with automatic diesel operated hammer, contractor shall submit method statement for carrying out the operation including sequence of driving to the Engineer-in-charge for approval. However, engineer‟s approval shall not relieve the contractor of his responsibilities and obligations under contract. meter Tk. 920.00 09.21 Driving 450 mm x 450 mm size pre-cast pile by rig fitted with automatic diesel operated hammer. Before commencing driving operation by rig fitted with automatic diesel operated hammer, contractor shall submit method statement for carrying out the operation including sequence of driving to the Engineer-in-charge for approval. However, engineer‟s approval shall not relieve the contractor of his responsibilities and obligations under contract. meter Tk. 986.00 09.22 Pre-cast driven micro-pile with reinforced cement concrete works with minimum cement content relates to mix ratio 1:1.25:2.5 having minimum f'cr = 35 MPa, and satisfying a specified compressive strength f‟c = 30 MPa at 28 days on standard cylinders as per standard practice of Code ACI/BNBC/ASTM & cement conforming to BDS EN-197-1CEM-I (32.5 to 52.5 N) / ASTM-C 150 Type – I, best quality coarse sand (F.M.2.5) and 20 mm down well-graded crushed stone chips conforming to ASTM C-33, mixing in standard mixture machine with hopper and fed by standard measuring boxes, including cost of breaking chips, screening through proper sieves, cleaning and washing, centering and shuttering with M.S sheet, M.S angle, F.I bar, nuts and bolts, preparation of bed, laying polythene, placing of reinforcement cage, casting, compacting by vibrators and tapered rods, curing for 28 days etc. including cost of water, electricity and other charges, providing pile shoe as per design and drawing, driving the pile up to the design depth as per standard practice or specified method providing head cushion, all equipments including mobilization, demobilization and hire charge of driving set, champering, test of materials and concrete etc. including carrying all complete approved and accepted by the Engineer-in-charge. (Rate is excluding the cost of reinforcement and its fabrication, binding, welding and placing) 09.22.1 Casting of 180 mm x 180 mm x 7.6 m Pile with reinforced cement concrete (1:1.25:2.5) with stone chips meter Tk. 506.00 09.22.2 Casting of 205 mm x 205 mm x 7.6 m Pile with reinforced cement concrete (1:1.25:2.5) with stone chips meter Tk. 634.00 PWD SoR 2018 for Civil Works PILE WORKS AND PILE TEST Item No. Description of Item Unit 110 Unit Rate 09.22.3 Driving of 180 mm x 180 mm x 7.6 m pre-cast pile meter Tk. 159.00 09.22.4 Driving of 205 mm x 205 mm x 7.6 m pre-cast pile meter Tk. 189.00 09.22.5 Supply of Cold-Drawn Wire Pre-stressed Concrete (CWPC) micro-pile which is made by using cold drawn wire minimum cement content relates to mix ratio 1:1.5:3 cement conforming to BDS EN-197-1-CEM-1, 52.5N (52.5MPa) / ASTM-C 150 type - 1, having minimum f'cr = 35 MPa and satisfying specified compressive strength f'c= 30 MPa at 28 days best quality coarse sand (F.M. 2.2), 20 mm down well graded stone chips conforming to ASTM C-33, mixing in standard mixture machine and fed by standard measuring boxes, including cost of all kind of reinforcement BDS ISO 6935-2:2006 including strengthening and cleaning rust if any bending and binding in position with supply of GI wires (24 BWG), centering and shuttering with M.S. sheet, M.S. angle, F.I. bar, nuts and bolts, preparation of bed, supplying & tensioning of cold drawn wire, laying polythene, placing of reinforcement cage in position, casting, compacting by vibrator and tapered rods, curing at least 28 days etc. including cost of water, electricity and other charges, proving pile shoe making with 20 BWG plane sheet, as per design and drawing including an equipments mobilization, demobilization champering edges if so including the cost of water electricity and other charges all complete as per design, drawing and accepted by the Engineer-incharge. (Excluding the cost of carrying and driving of pile). Maximum length: Up to 7620mm (fixed size x-section: 180 mm x 180 mm) meter Tk. 1,003.00 09.23 PIT (Pile integrity test) : Conducting low strain dynamic testing of pile as per ASTM D5882-The standard method for low-strain integrity testing of pile by a qualified and approved PIT expert, preparing pile heads and providing all relevant materials, equipment, experts, labour, mobilization, demobilization, data acquisition and analysis, preparation of results in standard forms and compiling final report with recommendations on the tests etc. complete in all respect approved and accepted by the Engineer-in-charge. (Report shall contain driving log / boring and pouring logs, graphs & statement on "Callibration Pile" (pile that tested for its capacity and PIT done eralier on it, at a place of known soil profiles), soil investigation report. (Caliberation pile shall be made and tested first). Method statement for conducting PIT shall be submitted to the Engineer for approval, and shall be the part of PIT report, However, Engineer's approval shall not relieve the contractor of his responsibilities and obligations under contract 09.23.1 Mobilization and demobilization to site and PIT on12 (twelve) piles or less upto 1st 12 piles Tk. 24,149.00 09.23.2 For PIT test of each additional pile after 12 (Twelve) pile tested at same site per pile Tk. 1,207.00 09.24 Pre-cast spliced pile jointing by supplying, fitting, fixing prefabricated square shaped two steel caps made up by 6 mm thick ASTM A36 complied M.S plate, sides formed by bent in channel shape to have only two line of joinery on faces, having min 50 mm dia hole on its web; capping by min 12 mm thick ASTM A36 complied M.S plate shaping the edges in 45°, having min 40 mm dia hole at centre to pass 25 mm M.S bar 433 mm in length; jointed at channels root by welding; caps fitted with 2 nos BDS ISO 6935-2009: B400 DWR complied d20 U-bar 1244mm in length by welding, equidistant from centre holes of cap and shall have min 75 mm clear from pile faces; and finally, the system to be fitted in correct alignments on pile head positions waiting for concreting; both the pile heads fitted with the steel caps to be welded together through v-notches in field, while one of the companion segment of piles drived in ground and other one placed over it maintaining true verticality; all complete as per direction and stepwise approval leading to final approval of Engineer-in- charge. 09.24.1 X-sec of pre cast pile segments :300 mm x 300 mm each Tk. 9,286.00 PWD SoR 2018 for Civil Works PILE WORKS AND PILE TEST Item No. Description of Item 111 Unit Unit Rate 09.24.2 X-sec of pre cast pile segments :350 mm x 350 mm each Tk. 10,610.00 09.24.3 X-sec of pre cast pile segments :400 mm x 400 mm each Tk. 12,076.00 09.24.4 X-sec of pre cast pile segments :450 mm x 450 mm each Tk. 12,611.00 09.25 Pile Driving by Hydraulic Static Pile Driver 09.25.1 Mobilization and demobilzation of hydraulic static pile driver(Upto 500 metric ton capacity) per set per site Tk. 652,021.00 09.25.2.1 Driving pre-cast pile of 300 mm x 300 mm X-section made with shoe/ without shoe by Hydraulic static pile driver of approx. 500 tonne (metric ton) capacity; arranged with necessary cranes, power source, maintaining driving log and record of pressure exerted on piles driven in to desired RL or capacity level ; complete in all respect including handling of piles, dressing & leveling of site, way making, surveying, layout setting etc ended with the submission of pile driving report in three copies duly signed by professional engineer and approved by the Engineer-in-charge. meter Tk. 808.00 09.25.2.2 Driving pre-cast pile of 350 mm x 350 mm X-section made with shoe/ without shoe by Hydraulic static pile driver of approx. 500 tonne (metric ton) capacity; arranged with necessary cranes, power source, maintaining driving log and record of pressure exerted on piles driven in to desired RL or capacity level ; complete in all respect including handling of piles, dressing & leveling of site, way making, surveying, layout setting etc ended with the submission of pile driving report in three copies duly signed by professional engineer and approved by the Engineer-in-charge. meter Tk. 870.00 09.25.2.3 Driving pre-cast pile of 400 mm x 400 mm X-section made with shoe/ without shoe by hydraulic static pile driver of approx. 500 tonne (metric ton) capacity; arranged with necessary cranes, power source, maintaining driving log and record of pressure exerted on piles driven in to desired RL or capacity level ; complete in all respect including handling of piles, dressing & leveling of site, way making, surveying, layout setting etc ended with the submission of pile driving report in three copies duly signed by professional engineer and approved by the Engineer-in-charge. meter Tk. 943.00 09.25.2.4 Driving pre-cast pile of 450 mm x 450 mm X-section made with shoe/ without shoe by hydraulic static pile driver of approx. 500 tonne (metric ton) capacity; arranged with necessary cranes, power source, maintaining driving log and record of pressure exerted on piles driven in to desired RL or capacity level ; complete in all respect including handling of piles, dressing & leveling of site, way making, surveying, layout setting etc ended with the submission of pile driving report in three copies duly signed by professional engineer and approved by the Engineer-in-charge. meter Tk. 984.00 ………………….. END OF DIVISION NINE ………………….. STRUCTURAL STEEL WORKS, SHEET ROOFING AND SAFETY CANOPY PWD SoR 2018 for Civil Works 112 DIVISION 10: STRUCTURAL STEEL WORKS, SHEET ROOFING AND SAFETY CANOPY Item No. Description of Item Unit Unit Rate 10.1 Supply and fixing of galvanized anchor bolts of variable dia for rigid frame conforming to ASTM F1554 Grade 55, Galvanized to A153, Class C or equivalent with minimum yield strength of 380 MPa, manual of steel construction by American Institute of Steel Construction (AISC) etc. including the cost of washer & bolts, material testing etc. all complete as per drawing, specification and direction of the Engineer-in-charge. kg Tk. 180.00 10.2 Supply, fabrication and installation of built-up sections i.e. columns, beams, rafters, bracings etc. from steel plates conforming to ASTM A572, with a minimum yield strength of 345 MPa, including the cost of testing of plates, applicaton of red/grey-oxide primer etc. all complete as per drawing, specification and direction of Engineer-in-charge. kg Tk. 135.00 10.3 Supply, fabrication and installation of built-up sections i.e. columns, beams, rafters, bracings etc from steel plates conforming to ASTM A36, with a minimum yield strength of 250 MPa, including the cost of testing of plates, application of red/grey-oxide primer etc. all complete as per drawing, specification and direction of Engineer-in-charge. kg Tk. 129.00 10.4 Supply, fabrication and installation of hot-rolled sections (W, H, I-shape, Channel, angle, tube etc.) for columns, beams, rafters, bracings etc. conforming to ASTM A36, with a minimum yield strength of 250 MPa, including the cost of testing of plates, application of red/grey-oxide primer etc. all complete as per drawing, specification and direction of Engineer-in-charge. kg Tk. 132.00 10.5 Supply and fixing of connection bolts of variable diameter with nut and washer according to "ASTM A325 Type 1 or equivalent” with Fu =720 Mpa, including the cost of testing of bolts, all complete as per drawing, specification and direction of Engineer-In-Charge. kg Tk. 314.00 10.6 Supply and fixing of connection bolts of variable diameter with nut and washer according to "ASTM A307 Type A or equivalent” with Fu =414 Mpa, including the cost of testing of bolts, all complete as per drawing, specification and direction of Engineer-In-Charge. kg Tk. 259.00 10.7 Supply and installation of GI purlin & girt of any size conforming to "ASTM A653" grade 45, with a minimum yield strength of 310 MPa, including the cost of testing of materials, all complete as per drawing, specification and direction of Engineer-in-charge. kg Tk. 137.00 10.8 Supply and fixing of sag rod conforming to grade 40, with a minimum yield strength of 275 MPa, including the cost of making threads, nuts and washers, red oxide primer etc. all complete as per drawing, specification and direction of Engineer-in-charge. kg Tk. 127.00 10.9 Supply and fixing of cable/wire bracing conforming to "ASTM A475" with a minimum yield strength of 119.3 MPa, with I-bolt and hill side washer, all complete as per drawing, specification and direction of Engineer-in-charge. meter Tk. 214.00 10.10 Supplying and fixing of shear stud of variable dia conforming to ASTM A108 or equivalent with minimum yield strength of 275 MPa, including the cost testing, welding etc. all complete as per drawing, specification and direction of Engineer-in-charge. kg Tk. 157.00 10.11 Supply and installation of 0.70 mm thick galvanized decking panel according to ASTM A653, with minimum yield strength of 345 MPa, including all necessry accessories (sheeting screws with washers, sealants etc.), testing of materials etc. all complete as per drawing, specification and direction of Engineer-in-charge. kg Tk. 181.00 STRUCTURAL STEEL WORKS, SHEET ROOFING AND SAFETY CANOPY Item No. PWD SoR 2018 for Civil Works 113 Description of Item Unit Unit Rate 10.12 Supply and installation of 0.47 mm thick zinc alum color coated profile sheet for roof, wall, caping, flashing, trimming, gutter etc. conforming to ASTM A792, Grade: 80, AZ150 gm/m2, including the cost of necessary accessories (sheeting screws with washers, silicon sealant etc.), testing of materials etc. all complete as per drawing specification and direction of Engineer-in-charge. kg Tk. 211.00 10.13 Supply and installation of 0.457 mm thick corrugated galvanized iron sheet (Bangladesh made) having min weight 63-65 kg per bundle (2'-6" width, 70 – 72 rft long) fitted and fixed on M.S. sections with 'J' hook or wooden purlin with screws, limpet washers and putty etc. all complete and accepted by the Engineer-in-charge. sqm Tk. 555.00 10.14 Supply and installation of 2.0 mm thick fiber glass sheet (transparent sheet) for roof, wall etc. on M.S. purlin, angle etc. with 'J' hook or screws with washer and putty, all complete as per drawing, specification and direction of Engineer-in-charge. sqm Tk. 1,315.00 10.15 Supply and installation of double bubble foil insulation at wall and roof of nominal thickness of 8 mm conforming to Class A in accordance with the ASTM-E84-09 fire test standard, including the cost of lapping, costape, adhesive and necessary accessories, all complete as per drawing, specification and direction of Engineer-in-charge. sqm Tk. 283.00 10.16 Premium Synthetic Enamel paint of approved best quality and colour delivered from authorized local agent of the manufacturer(Berger robbialac supergloss synthetic enamel/Elite lucky seven/ Asian apcolipe premium paint or equivalent brand) in a sealed container, having highly water resistant, high bondibilty, flexiblity property; using specified brand thinner applying to metallic surface by spray in two coats over single coat anticorrosive coating including cleaning drying, making free from dirt, grease, wax, removing all chalked and scaled materials, all complete in all floors accepted by the Engineer-incharge. (payment shall be made on strucutral steel weight basis) kg Tk. 9.00 10.17 Supply and application of corrosion protection paint to the surface of the structural steel members conforming to SA 2.5; Steel members to be shot blasted inside the enclosed shot blasting chamber, final coat paint must be applied on site after installation, including the cost of primer, testing and necessaey accessories, all complete as per drawing, specification and direction of Engineer-in-charge. kg Tk. 26.00 10.18 Supply and pouring of non-shrink grout to steel column bases conforming to ASTM C 109 having compressive strength not less than 45 MPa, including the cost of shutter and necessary accessories, all complete as per drawing, specification and direction of Engineer-in-charge. cum Tk. 145,213.00 10.19 0.27 mm thick galvanized iron plain sheet ridging with 300 mm lap on either side fitted and fixed with galvanized bolts and nuts etc. all complete and accepted by the Engineerin-charge. 10.19.1 Galvanized meter Tk. 422.00 10.19.2 Colored meter Tk. 464.00 10.20 1.5 mm thick plain fiber glass sheet ridging with 300 mm lap on either side fitted and fixed with galvanized bolts and nuts etc. all complete and accepted by the Engineer-incharge. meter Tk. 769.00 STRUCTURAL STEEL WORKS, SHEET ROOFING AND SAFETY CANOPY Item No. PWD SoR 2018 for Civil Works 114 Description of Item Unit 10.21 Saftey Canopy: Supplying temporary safety canopy around construction work place where public safety is likely to be endangered due to construction activities; which shall be made of truss system of steel sections (main frame) at 1800 mm c/c with purlins @ 750 mm c/c, making flooring system by corrugated galvanized iron sheets of thickness 0.45 mm, laying wire mesh net on iron sheets, providing continuous gutter along the edges of the building with downpipe @ 6000 mm c/c, including fitting and fixing in position providing necessary anchors, cables, wires, ties etc. by standard anchoring and welding, nut-bolts etc, all complete and accepted by the Engineer-in-charge sqm Tk. 1,923.00 10.22 Saftey net: Supplying temporary safety net (hessian cloth) around construction work place (along the height of the building) where public safety is likely to be endangered due to construction activities; which shall be supported using scaffolding around the building for brick work/ plaster; including fitting and fixing in position providing necessary anchors, wires, ties etc. all complete and accepted by the Engineer-in-charge. (Rate is excluding the cost of scaffolding) sqm Tk. 42.00 ………………….. END OF DIVISION TEN ………………….. Unit Rate WOOD WORKS IN DOOR AND WINDOW FRAME, ROOF TRUSS AND RAILINGS PWD SoR 2018 for Civil Works 115 DIVISION 11 : WOOD WORKS IN DOOR AND WINDOW FRAME, ROOF TRUSS AND RAILINGS Item No. Description of Item Unit Unit Rate 11.1 Supplying and making door and window frames (Chowkat) for all floors with matured seasoned wood of required size. Painting two coats of coal tar to the surface in contact with wall. Fitting and fixing in position etc. all complete and accepted by the Engineer-incharge. (All sizes of wood are finished). 11.1.1 Mehgoni cum Tk. 120,461.00 11.1.2 Garjan/ Jam/ Local sal cum Tk. 130,410.00 11.1.3 Silkarai cum Tk. 154,787.00 11.1.4 Teak Chambal /Jarul cum Tk. 200,057.00 11.1.5 Chittagong Teak cum Tk. 249,308.00 11.1.6 Burma Teak cum Tk. 354,275.00 11.2 Supplying, fitting and fixing M.S. flat bar clamp of 225 mm x 38 mm x 6 mm size having bifurcated ends to door and window frames with necessary screws including cutting grooves in chowkat if necessary and encasing inside the wall with cement concrete (1:2:4) etc, all complete and accepted by the Engineer-in-charge. each Tk. 97.00 11.3 Supplying, fitting and fixing M.S. flat bar clamp of 150 mm x 38 mm x 6 mm size having bifurcated ends to door and window frames with necessary rowel plug, screws etc. including cutting grooves in chowkat if necessary etc. all complete and accepted by the Engineer-in-charge. each Tk. 97.00 11.4 Supplying, fitting and fixing double leaf door frame for all floors made with 38mm x 38 mm x 6 mm M.S. angle fitted with 150 mm long 6 nos. iron clamps of same size M.S. angle (with one end bifurcated) with the vertical members of the frame, fixing the frame in wall with cement concrete (1:2:4), mending good the damages, fixing 6 Nos. of 100 mm long iron hinges with the vertical members of the frame all complete including making holes in walls, cutting, sizing, welding, fabricating, carrying from work-shop to site and local carriage, curing etc. all complete as per plan and drawing and accepted by the Engineer-in-charge. meter Tk. 611.00 11.5 Supplying, fitting and fixing single leaf door frame for all floors made with 38 mm x 38 mm x 6 mm M.S. angle, fixing 125 mm long 6 nos. iron clamps of same size (with one end bifurcated) with the vertical members of the frame, fixing the frame in wall with cement concrete (1:2:4), mending good the damages, fixing 4 nos. 100 mm size iron hinges with the vertical members of the frame, all complete including making holes in walls, cutting, sizing, welding, fabricating, carriage from workshop to site including local carriage, curing etc. as per plan and drawing etc. all complete and accepted by the Engineer-in–charge. meter Tk. 597.00 11.6 Supplying matured seasoned wood and making roof truss of any size with wall plates as per design including supplying, fabricating and hoisting, scaffolding, fitting and fixing in position with bolts, nuts, painting two coats of coal tar etc. all complete and accepted by the Engineer-in–charge. (All sizes of wood are finished). 11.6.1 Garjan / Jam/ Local Sal wood cum Tk. 111,101.00 WOOD WORKS IN DOOR AND WINDOW FRAME, ROOF TRUSS AND RAILINGS Item No. PWD SoR 2018 for Civil Works Description of Item 116 Unit Unit Rate 11.6.2 Mehgoni cum Tk. 102,147.00 11.6.3 Silkarai /Chickrashi cum Tk. 133,040.00 11.7 Supplying and making hand rail for stair case with matured seasoned wood including necessary moulding with proper corner, finishing as per design, fitting and fixing in position in all floors etc. all complete and accepted by the Engineer-in-charge. 11.7.1 Mehgoni cum Tk. 123,458.00 11.7.2 Local Sal cum Tk. 132,413.00 11.7.3 Silkarai / Chikrashi cum Tk. 154,351.00 11.7.4 Teak Chambal wood cum Tk. 195,095.00 11.7.5 Chittagong Teak wood cum Tk. 239,420.00 11.7.6 Burma Teak wood cum Tk. 333,891.00 ………………….. END OF DIVISION ELEVEN ………………….. DOOR-WINDOW SHUTTER & FLY PROOF WIRE-NET SHUTTER PWD SoR 2018 for Civil Works 117 DIVISION 12 : DOOR-WINDOW SHUTTER & FLY PROOF WIRE-NET SHUTTER Item No. Description of Item Unit Unit Rate 12.1 Supplying, fitting and fixing 38 mm thick well matured seasoned (minimum 250 mm wide plank) solid wood single leaf door shutter having top rail style of sections 100 mm x 38 mm, lock rail 125 mm x 38 mm and bottom rail 225 mm x 38 mm. Closed joints with 25 mm x 12 mm size wooden peg and provided with best quality 4 nos 100 mm iron hinges, 2 (two) nos best quality 12 mm dia 250 mm and 200 mm long iron tower and socket bolts, 2 (two) nos heavy type nickel plated handle,1 (one) no best quality hasp bolt, hinged cleats, buffer blocks and finished by sand papering etc. all complete in all floors and accepted by the Engineer-in-charge. (All sizes of wood are finished) 12.1.1 Kathal sqm Tk. 7,492.00 12.1.2 Gamari sqm Tk. 6,390.00 12.1.3 Teak Chambal sqm Tk. 9,796.00 12.1.4 Chittagong Teak sqm Tk. 11,779.00 12.1.5 Chapalish sqm Tk. 12.1.6 Burma Teak sqm Tk. 16,007.00 12.2 Supplying, fitting and fixing 38 mm thick well matured seasoned (minimum 250 mm wide plank) solid wood single leaf flush door shutter having a frame of top, lock and bottom rail of sections 100 mm x 12 mm styles 100 mm x 38 mm covered with 100 mm x 12 mm plank, screwed to each face and provided with best quality 4 nos 100 mm iron hinges, 2 (two) nos best quality 12 mm dia 250 mm and 200 mm long iron tower and socket bolts, 1 (one) no best quality hasp bolt, 2 (two) nos heavy type nickel plated handles, hinged cleats, buffer blocks and finished by sand papering etc. all complete in all floors and accepted by the Engineer-in-charge. (All sizes of wood are finished) 12.2.1 Kathal sqm Tk. 6,366.00 12.2.2 Gamari sqm Tk. 5,386.00 12.2.3 Teak Chambal sqm Tk. 8,416.00 12.2.4 Chittagong Teak sqm Tk. 10,180.00 12.2.5 Chapalish sqm Tk. 12.1.6 Burma Teak sqm Tk. 13,941.00 12.3 Supplying, fitting and fixing 38 mm thick finished well matured seasoned (minimum 250 mm wide plank) wooden ornamental special design (equivalent hatil) (both sides) single panel flush door shutter with top and middle rail 150 mm x 38 mm bottom rail 225 mm x 38 mm and style 125 mm x 38 mm, having vertical panels 175 mm x 38 mm including minimum 12 mm lap to each panel providing 4 nos, best quality 100 mm long brass hinges, 12 mm dia best quality 200 mm & 250 mm long brass socket and tower bolts, 1 (one) no best quality hasp bolt, 2 (two) nos heavy type best quality brass handle, hinges cleats, buffer blocks including supply of necessary nails and screws, making design by machine, finished etc. all complete in all floors and accepted by the Engineer-in-charge (Chittagong teak wood). (All sizes of wood are finished) sqm Tk. 15,393.00 7,772.00 6,616.00 DOOR-WINDOW SHUTTER & FLY PROOF WIRE-NET SHUTTER Item No. PWD SoR 2018 for Civil Works Description of Item Unit 118 Unit Rate 12.4 Supplying, fitting and fixing 38 mm thick well matured seasoned (minimum 250 mm wide plank) wooden double leaf panel door shutters. Top rail and styles of sections 100 mm x 38 mm, lock rail 125 mm x 38 mm and bottom rail 225 mm x 38 mm, paneling 38 mm thick both sides raised, provided with best quality 8 nos 100 mm long iron hinges, 2 (two) nos best quality 12 mm dia 250 mm and 200 mm long iron tower and socket bolts, 2 (two) nos heavy type nickel plated handle, 1 no hasp-bolt, hinged cleats, buffer blocks and finished by sand papering, necessary screws etc. all complete in all floors and accepted by the Engineer-in-charge. (All sizes of wood are finished) 12.4.1 Kathal sqm Tk. 8,930.00 12.4.2 Gamari sqm Tk. 7,553.00 12.4.3 Teak Chambal sqm Tk. 11,808.00 12.4.4 Chittagong Teak sqm Tk. 14,285.00 12.4.5 Chapalish sqm Tk. 12.4.6 Burma Teak sqm Tk. 19,566.00 12.5 Supplying, fitting and fixing 38 mm thick well matured seasoned (minimum 250 mm wide plank) wooden double leaf panel door shutters. Top rail and styles of sections 100 mm x 38 mm. lock rail 125 mm x 38 mm and bottom rail 225 mm x 38 mm. paneling 25 mm thick one side raised, provided with best quality 6 nos. 100 mm long iron hinges, 2 (two) nos best quality 12 mm dia 250 mm and 200 mm long iron tower and socket bolts, 1 (one) no best quality hasp bolt, 2 (two) nos heavy type nickel plated handles, 1 (one) no best quality hasp bolt, hinged cleats, buffer blocks and finished by sand papering, necessary screws etc. all complete in all floors and accepted by the Engineer-in-charge.(All sizes of wood are finished) 12.5.1 Kathal sqm Tk. 7,784.00 12.5.2 Gamari sqm Tk. 6,611.00 12.5.3 Teak Chambal sqm Tk. 10,238.00 12.5.4 Chittagong Teak sqm Tk. 12,350.00 12.5.5 Chapalish sqm Tk. 12.5.6 Burma Teak sqm Tk. 16,851.00 12.6 Supplying, fitting and fixing 38 mm thick finished well matured seasoned (minimum 250 mm wide plank) wooden grooved single panel flush door shutters with top and middle rail 100 mm x 38 mm, bottom rail 225 mm x 38 mm and style 100 mm x 38 mm, having vertical panels 100 mm x 38 mm including keeping 6 mm x 12 mm even groove all around and minimum 12 mm grooved lap to each panel. Providing 4 nos best quality 100 mm long iron hinges, 12 mm dia best quality 200 mm and 250 mm long iron socket and tower bolts, 2 (two) nos heavy type best quality nickel plated handle, 1 (one) no best quality hasp bolt, hinged cleats, wooden buffer blocks including supply of necessary nails and screws, finished by sand papering etc. complete in all floors as per drawing and accepted by the Engineer-in-charge. (All sizes of wood are finished). 12.6.1 Kathal sqm Tk. 9,280.00 8,083.00 8,673.00 DOOR-WINDOW SHUTTER & FLY PROOF WIRE-NET SHUTTER Item No. PWD SoR 2018 for Civil Works Description of Item Unit 119 Unit Rate 12.6.2 Gamari sqm Tk. 7,373.00 12.6.3 Chittagong Teak sqm Tk. 13,731.00 12.6.4 Chapalish sqm Tk. 12.6.5 Burma Teak sqm Tk. 18,718.00 12.7 Supplying, fitting and fixing 36 mm thick and having density 400 kg/cum solid particle board single leaf flush door for all floors for internal use made of well matured mechanical seasoned Rubber (Malaysian timber) or other approved wooden frame having finished size 35 mm x 50 mm around upon which 1.2 mm thick veneer (total two nos of veneers one of 0.7 mm horizontally made of garjon and another of 0.5 mm vertically made of Burma Teak or Champa or Chapalish or Garjan wood) are pested on each side by mechanized process and provided with best quality 4 nos 100 mm long iron hinges, 2 nos best quality 12 mm dia 250 mm and 200 mm long iron tower and socket bolts, 2 (two) nos heavy type nickel plated handles, hinged cleats, buffer blocks, necessary screws etc. all complete and accepted by the Engineer-in-charge 12.7.1 Burma Teak veneered sqm Tk. 4,989.00 12.7.2 Champ veneered sqm Tk. 3,754.00 12.7.3 Chapalish veneered sqm Tk. 3,754.00 12.7.4 Garjan veneered sqm Tk. 3,885.00 12.8 Manufacturing and supplying, fitting, fixing well matured seasoned (minimum 250 mm wide plank) wooden fixed louver shutters having 62 mm x 125 mm frame and inner horizontal wooden louver 150 mm x 25 mm size spaced @ 50 mm c/c fixed with frame in grooves including cost of screws, nails, 12 mm x 12 mm size wooden bit, preparing the surface by sand papering etc. all complete as per drawing and accepted by the Engineer-in-charge. (All sizes of wood are finished). 12.8.1 Gamari sqm Tk. 8,930.00 12.8.2 Chittagong Teak sqm Tk. 20,624.00 12.8.3 Chapalish sqm Tk. 11,930.00 12.8.4 Burma Teak sqm Tk. 29,796.00 12.9 Supplying, fitting and fixing well matured seasoned (minimum 250 mm wide plank) wooden glazed ventilator louver shutters for all floors having wooden outer frame of section 62 mm x 125 mm with 62 mm x 125 mm size vertical divider with inner 50 mm x 38 mm shutter and with 3 nos horizontal 38 mm x 38 mm sash bar in each part and inner horizontal glazed louver of size 150 mm x 6 mm fixed in frame @ 154 mm c/c by cutting grooves in the frame including cost of screws, wooden bit, pivots, sand papering, 5 mm thick glass, cutting glass to required size etc. all complete as per design, drawing and accepted by the Engineer-in-charge.(All sizes of wood are finished). 12.9.1 Gamari sqm Tk. 12.9.2 Teak Chambal sqm Tk. 10,533.00 12.9.3 Chittagong Teak sqm Tk. 13,065.00 9,004.00 6,185.00 DOOR-WINDOW SHUTTER & FLY PROOF WIRE-NET SHUTTER Item No. PWD SoR 2018 for Civil Works Description of Item Unit 120 Unit Rate 12.9.4 Chapalish sqm Tk. 7,950.00 12.9.5 Burma Teak sqm Tk. 18,462.00 12.10 Supplying fitting and fixing 38 mm thick well matured seasoned (minimum 250 mm wide plank) wooden door shutters for all floors having styles and rails of section 150 mm x 38 mm and 5 mm glass panes fitted and fixed with wooden batten, putty and nails including supplying and fitting and fixing 50 mm dia best quality round door lock, 12 mm dia, 2 nos 250 mm long iron tower bolt and 8 nos 100 mm long iron hinges to each shutters, 2 nos nickel plated handle, 5 mm thick glass, glass cutting, hinged cleats, buffer blocks, screws, finished with necessary sand papering and putty works etc. all complete and accepted by the Engineer-in-charge. 12.10.1 Chittagong Teak sqm Tk. 8,476.00 12.10.2 Silkarai sqm Tk. 6,336.00 12.10.3 Burma Teak sqm Tk. 10,852.00 12.11 Supplying, fitting and fixing 25 mm thick well matured seasoned (minimum 250 mm wide plank) Kathal wood door and window shutters for all floors having 75 mm x 25 mm „Z‟ battens, provided with best quality 6 nos 100 mm long iron hinges, 2 nos 62 mm dia iron ring fitted with nuts, 2 nos best quality 12 mm dia, 250 mm and 200 mm long iron tower and socket bolts, hinged cleats, buffer blocks, screws and finished with sand papering in all floors etc. all complete and accepted by the Engineer-in-charge. (All sizes of wood are finished). sqm Tk. 5,897.00 12.12 Supplying, fitting and fixing 38 mm thick well matured seasoned (minimum 250 mm wide plank) wood glazed window shutters for all floors having horizontal and vertical sections of 87 mm x 38 mm and sash bar 38 mm x 38 mm fitted with 3 mm glass panes with putty and nails and provided with best quality 4 nos 75 mm long iron hinges, 2 (two) nos best quality 12 mm dia 250 mm and 150 mm long iron tower and socket bolts, 01 no. nickel plated handles, 02 nos 225 mm long catch hooks or hinged cleats, buffer blocks, necessary screws and finished with sand papering in all floors etc. all complete and accepted by the Engineer-in-charge. (All sizes of wood are finished). 12.12.1 Kathal sqm Tk. 5,981.00 12.12.2 Gamari sqm Tk. 5,166.00 12.12.3 Teak Chambal sqm Tk. 7,684.00 12.12.4 Chittagong Teak sqm Tk. 9,150.00 12.12.5 Chapalish sqm Tk. 6,188.00 12.12.6 Burma Teak sqm Tk. 12,276.00 DOOR-WINDOW SHUTTER & FLY PROOF WIRE-NET SHUTTER Item No. PWD SoR 2018 for Civil Works Description of Item Unit 121 Unit Rate 12.13 Supplying, fitting and fixing 38 mm thick well matured seasoned (minimum 250 mm wide plank) wooden window shutter one third glazed and two third raised paneling on both sides for all floors having horizontal and vertical sections of 87 mm x 38 mm and sash bars 38 mm x 38 mm fitted with 3 mm glass panes with putty and nails and provided with best quality 4 nos 75 mm long iron hinges. 2 (two) nos. best quality 12 mm dia 250 mm and 150 mm long iron tower and socket bolts, nickel plated handles, 3 mm glass, 02 nos 225 mm long catch hooks, or hinged cleats, buffer blocks and finished by sand papering in all floors etc. all complete and accepted by the Engineer-in-charge. (All sizes of wood are finished). 12.13.1 Kathal sqm Tk. 8,582.00 12.13.2 Gamari sqm Tk. 7,120.00 12.13.3 Teak Chambal sqm Tk. 11,640.00 12.13.4 Chittagong Teak sqm Tk. 14,273.00 12.13.5 Chapalish sqm Tk. 12.13.6 Burma Teak sqm Tk. 19,884.00 12.14 Seasoning of timber in a recognized mechanical timber seasoning plant up to 12% - 16% moisture content by weight as measured by an electric moisture meter or any other moisture measuring device etc. all complete including loading, unloading, carriage at both ends and accepted by the Engineer-in-charge. cum Tk. 9,125.00 12.15.1 Supplying, fitting and fixing steel glazed window shutter for all floors with frames as per design having 25 mm x 25 mm x 5 mm angle section for Chowkat and shutters and 50 mm x 25 mm x 5 mm T- section used for vertical member and 25 mm x 5 mm F.I. bar for making box (combining with angle) and 25 mm x 19 mm x 5 mm T-section used for glass divider etc. including all charges for welding, riveting etc. including cost of supplying all essential fittings like iron hinges, plate handle, pin-stopper, adjustable cleat and clamps including supplying, fitting, fixing 3 mm glass panes by pucca putty, for fittig and fixing the frame, making necessary holes in brick walls and R.C.C works and fitting with C.C. (1:2:4) and mending good the damages including all cost of carriage, workshop charges, electricity, and labour for fittings, fixing, curing etc. all complete and accepted by the Engineer-in-charge. (Rate is excluding the costs of painting). sqm Tk. 5,397.00 12.15.2 Supplying, fitting and fixing M.S. door shutter made with 38 mm x 38 mm x 6 mm angle outer frame, inner member 25 mm x 6 mm F.I. bar, cladding with 16 BWG M.S. sheet, 04 nos. 75 mm long hinge, 02 nos locking arrangement with 50 mm x 50 mm x 6 mm M.S. angle chowkat including all charges for welding, riveting etc. including cost of supplying all essential fittings like iron hinges, socket bolts, clamps, for fittig and fixing the frame, making necessary holes in brick walls and R.C.C works and fitting with C.C. (1:2:4) and mending good the damages including all cost of carriage, workshop charges, electricity, and labour for fittings, fixing, curing etc. all complete and accepted by the Engineer-incharge. (Rate is excluding the costs of painting). sqm Tk. 5,870.00 8,955.00 DOOR-WINDOW SHUTTER & FLY PROOF WIRE-NET SHUTTER Item No. PWD SoR 2018 for Civil Works Description of Item Unit 122 Unit Rate 12.16 Supplying, fitting and fixing steel glazed window shutter for all floors with frames as per design having 19 mm x 19 mm x 19 mm x 3 mm Z-section in frame and 19 mm x 3 mm F.I. bar for making T-section for horizontal dividers of shutters and 25 mm x 3 mm F.I. bar for middle vertical members of frame including all cost of charges for fabrication and manufacture by welding, riveting etc. Supplying all essential fittings like 2 nos stopper handle, 300 mm long 3 or 2 nos adjustable iron cleats, 6 or 4 nos 50 mm long iron pin hinges, 150 mm long 4 nos clamps including supplying, fitting, fixing 3 mm glass panes by pucca putty, for fitting and fixing frame making necessary holes in brick and R.C.C. wall or member as necessary filling with C.C. (1:2:4) and mending good the damages including all cost of carriage, electricity, workshop charges and labour for fitting, fixing etc. all complete as per drawing and design and accepted by the Engineer-in-charge. (Rate is excluding the costs of painting) 12.16.1 With provision for fan-light by providing necessary additional materials, 03 nos adjustable 300 mm long iron cleats and 6 nos 50 mm long iron pin hinges (total wt of grill without glass panes is min 28.13 kg for 15 sft) sqm Tk. 3,557.00 12.16.2 Without provision for fan-light by providing 02 nos adjustable 300 mm long iron cleats and 4 nos 50 mm long iron pin hinges (total wt of grill without glass panes is min 24.84 kg for 15 sft) sqm Tk. 3,324.00 12.17 Manufacturing, supplying fitting and fixing of fixed glazed frame for all floors with outer member of 19 mm x 19 mm x 19 mm x 3 mm Z-section and vertical and horizontal dividers of 19 mm x 19 mm x 3 mm T-section including all cost of fabrication and welding, supplying and fixing of 19 mm x 19 mm x 3 mm angle clamps of 150 mm long (with one end bifurcated) of required nos with the frame, fixing the frame in wall with (1:2:4) cement concrete in the hole for clamp after making necessary grooves, supplying and fixing of 3 mm glass panes with pucca putty, mending good all damages, painting iron face with two coats of synthetic enamel paint over a coat of anti-corrosive priming of approved colour and quality etc. cost of electricity, workshop charges, carriage etc. all complete as per drawing and accepted by the Engineer-in-charge. [Rate is excluding the cost of painting] sqm Tk. 3,282.00 (Scope of work of this item is in staircase and over partition wall etc.) 12.18 Supplying, fitting and fixing 25 mm thick wooden double leaf fly proof wire mesh window shutter for all floors with 75 mm x 25 mm vertical and horizontal style and sash bar of 38 mm x 25 mm section provided with 24 B.W.G. G.I wire mesh netting of 20 mm mesh fitted and fixed with shutter by 12 mm x 12 mm wooden bit, brass screws, nails etc. including supply of all necessary fittings such as 2 nos 150 mm long brass tower and socket bolt of best quality 4 nos 75mm long brass hinges, heavy type 2 nos 150 mm long catch hook and 2 nos 100 mm long brass handle including fitting and fixing the same in position with frame with supply of necessary screws and nails etc. complete and accepted by the Engineer-in-charge. (All sizes of wood are finished) 12.18.1 Kathal sqm Tk. 5,136.00 12.18.2 Teak Chambal sqm Tk. 6,228.00 12.18.3 Chittagong Teak sqm Tk. 7,168.00 12.18.4 Burma Teak sqm Tk. 9,171.00 12.19 Supplying, fitting and fixing of well matured seasoned wooden louver shutter (Chittagong Teak) having 75.50 mm x 38 mm size all around frame and inner horizontal wooden louver blade 65 mm x 20 mm spaced @ 38 mm c/c, fixed with frame in grooves including cost of nails, handle, tower bolt, screws (brass fitting) etc. all complete as per drawing and accepted by the Engineer-in-charge. sqm Tk. 15,058.00 DOOR-WINDOW SHUTTER & FLY PROOF WIRE-NET SHUTTER Item No. PWD SoR 2018 for Civil Works 123 Description of Item Unit 12.20 Supplying, fitting and fixing 75 mm X 19 mm well matured seasoned Chittagong Teak wood moulding bit as per design etc. all complete approved and accepted by the Engineer-in-charge. meter Tk. 1,333.00 12.21 Extra cost for using brass/ SS fittings in place of iron fittings in doors & windows for all floors (super quality local). 12.21.1 Brass fittings of door sqm Tk. 638.00 12.21.2 SS fittings of door sqm Tk. 329.00 12.21.3 Brass fittings of windows sqm Tk. 842.00 12.21.4 SS fittings of windows sqm Tk. 459.00 12.22 Supplying, fitting and fixing hydraulic door closer (big size) of approved quality including all necessary tools and accessories etc. all complete and accepted by the Engineer-in-charge. each Tk. 1,808.00 12.23.1 Supplying, fitting and fixing mortice door lock of approved quality including all necessary tools and accessories etc. all complete approved and accepted by the Engineer-in-charge. each Tk. 1,023.00 12.23.2 Supplying, fitting and fixing rim/round door lock of approved quality including all necessary tools and accessories etc. all complete and accepted by the Engineer-incharge. each Tk. 963.00 12.24 Supplying, fitting and fixing of best quality magnetic door shock absorber of approved quality including all necessary tools and accessories etc. all complete and accepted by the Engineer-in-charge. each Tk. 420.00 12.25 Supplying, fitting and fixing best quality heavy type 19 mm dia and 300 mm long brass hasp bolt including cutting grooves in door shutter and frames, screws etc. all complete approved and accepted by the Engineer-in-charge. each Tk. 525.00 12.26 Supplying, fitting and fixing approved best quality foreign made stainless steel/brass door viewer/eye viewer from 12 mm to 20 mm diameter with adjustable thickness suitable for fitting from 37 mm to 50 mm thick door shutter including all necessary work as per direction and accepted by the Engineer-in-charge. each Tk. 595.00 ………………….. END OF DIVISION TWELVE ………………….. Unit Rate PWD SoR 2018 for Civil Works WINDOW GRILL, VERANDAH GRILL & NETTING 124 DIVISION 13 : WINDOW GRILL, VERANDAH GRILL & NETTING Item No. Description of Item Unit Unit Rate 13.1 Supplying, fitting and fixing window grills made of 16 mm dia M.S. rod @ 100 mm c/c fitted with 3 (three) nos. horizontal M.S. flat bar (38 mm x 6 mm) including fabrication, welding, riveting, cost of electricity, workshop charges, carriage, fixing with pre-placed clamps in wall/RCC member for all floors etc. complete and accepted by the Engineer-incharge. (Total weight per sqm should be approx. 22.8 kg and add or deduct @ Tk. 97.00 for each kg/sqm excess or less respectively) sqm Tk. 2,206.00 13.2 Supplying, fitting and fixing window grills of any design made of 20 mm x 3 mm mild steel section with outer frame of 25 mm x 6 mm F.I. bar including fabricating, welding, cost of electricity, workshop charges, carriage, fixing with pre-placed clamps in walls or RCC member, all necessary tools and plants etc complete for all floors and accepted by the Engineer-in-charge. (Total weight per sqm should be approx 11.0 kg. and add or deduct @ Tk. 146.00 for each kg/sqm excess or less respectively) sqm Tk. 1,610.00 13.3 Supplying, fitting and fixing window grills of any design made with 20 mm x 5 mm F.I. bar as inner and outer section; including fabricating, welding, cost of electricity and tools and plants etc. complete for all floors accepted by the Engineer-in-charge. (Total weight per sqm should be min 12 kg. and add or deduct. @ Tk. 143.00 for each kg/sqm excess or less respectively) sqm Tk. 1,719.00 13.3.1 Supplying, fitting and fixing window grills of any design made with 20 mm x 5 mm F.I. bar as inner members but no outer frame; including fabricating, welding, cost of electricity and tools and plants etc. complete for all floors accepted by the Engineer-incharge. (Total weight per sqm should be approx 10 kg. and add or deduct. @ Tk. 160.00 for each kg/sqm excess or less respectively) sqm Tk. 1,596.00 13.4.1 Supplying, fitting, fixing window grills of any design made with 25 mm x 6 mm F.I. bar as both outer and inner section; including fabrication, welding, cost of electricity workshop charges, carriage, cutting grooves, mending good the damages, tools and plants etc. complete for all floors accepted by the Engineer-in-charge. (Total weight per sqm should be approx 21 kg. and add or deduct @ Tk. 111.00 for each kg/sqm excess or less respectively) sqm Tk. 2,334.00 13.4.1.1 Supplying, fitting, fixing window grills of any design made with 25 mm x 6 mm F.I. bar as inner section but no outer frame; including fabrication, welding, cost of electricity workshop charges, carriage, cutting grooves, mending good the damages, tools and plants etc. complete for all floors accepted by the Engineer-in-charge. (Total weight per sqm should be approx 18 kg. and add or deduct @ Tk. 118.00 for each kg/sqm excess or less respectively) sqm Tk. 2,115.00 13.4.2 Supplying, fitting and fixing window grill made of M.S. section 25 mm x 6mm outer frame and 20 mm x 5 mm inner member as per drawing and design approved and accepted by the Engineer-in-charge. (Total weight per sqm should be min 14 kg. and add or deduct @ Tk. 130.00 for each kg/sqm excess or less respectively) sqm Tk. 1,825.00 13.5.1 Supplying, fitting and fixing window grill made of 12 mm x 12 mm M.S. solid bar 140 mm c/c with outer frame of 38 mm x 6mm F.I. bar as per design approved and accepted by the Engineer-in-charge. sqm Tk. 2,442.00 13.5.2 Supplying, fitting and fixing window grill made of 10 mm x 10 mm M.S. solid bar 140mm c/c with outer frame of 38 mm x 6mm F.I. bar as per design approved and accepted by the Engineer-in-charge. sqm Tk. 2,473.00 PWD SoR 2018 for Civil Works WINDOW GRILL, VERANDAH GRILL & NETTING Item No. 125 Description of Item Unit 13.5.3 Supply, fitting and fixing window grill made of 12 mm x 12 mm hollow M.S. box made of minimum 16 BG M.S. sheet @ 100mm c/c with outer frame of 38 mm x 6 mm F.I. bar as per drawing approved and accepted by the Engineer-in-charge. sqm Tk. 2,002.00 13.6 Supplying, fitting and fixing window grills made of mild steel section of 25 mm x 3 mm including fabrication, welding, cost of electricity, workshop charges, carriage, fixing with pre-placed clamps in walls or RCC member, all necessary tools and plants etc complete for all floors and accepted by the Engineer-in-charge. (Total weight per sqm should be min 8.0 kg. and add or deduct @ Tk. 220.00 for each kg/sqm excess or less respectively) sqm Tk. 1,764.00 13.7 Supplying, fitting and fixing veranda grill made of 10 mm dia M.S. rods provided @ 100 mm c/c in any position both ways as per design with outside frame 25 mm x 25 mm x 6 mm M.S. angle including fabricating, welding in each point, painting 2 coats of synthetic enamel paint over a coat of anti-corrosive priming, including cost of electricity, tools and plants, workshop charges, carriage of the same including cutting groves in the R.C.C. or brick work, mending good the damages with C.C. (1:2:4) etc. complete for all floors accepted by the Engineer-in-charge. [Rate is excluding the cost of painting] (Total weight per sqm should be min 16.80 kg. and add or deduct @ Tk. 124.00 for each kg/sqm excess or less respectively) sqm Tk. 2,087.00 13.8 Supplying, fitting and fixing verandah grill made of 10 mm dia M.S. rod provided @ 75 mm c/c in any position both ways as per design with outside frame of 25 mm x 25 mm x 6 mm M.S. angle including fabricating, welding in each point , painting 2 coats of synthetic enamel paint over a coat of anti-corrosive priming including cost of electricity, tools and plants, workshop charges, carriage of the same including cutting groves in the R.C.C. or brick work, mending good the damages with C.C. (1:2:4) etc, all complete for all floors accepted by the Engineer-in-charge. [Rate is excluding the cost of painting] (Total weight per sqm should be min 21.00 kg. and add or deduct @ Tk. 112.00 for each kg/sqm excess or less respectively) sqm Tk. 2,357.00 ………………….. END OF DIVISION THIRTEEN ………………….. Unit Rate ALUMINIUM DOOR, WINDOW FRAME AND GLASS WORKS PWD SoR 2018 for Civil Works 126 DIVISION 14: ALUMINIUM DOOR, WINDOW FRAME AND GLASS WORKS Item No. Description of Item Unit Unit Rate 14.1 Supplying fitting and fixing of aluminium swing door with spandrel as per the U.S. Architectural Aluminium Manufacturer‟s Association (AAMA) standard specification and BDS 1879:2014 having 1.8 mm thick wall frame (size 101.60 mm, 44.45 mm, 83.21 mm), 2.33 mm thick shutter (size 54 mm, 46 mm), 0.99 mm thick door glass bit (size 16.54 mm, 14.49 mm, 0.115 kg/m), 2.5 mm thick clousure section (size 101.60 mm, 42.93 mm,1.2 mm), 106.60 mm clousure cover (0.45 kg/m), 4 mm thick floor bottom (size 101.60 mm, 12.70 mm, 1 kg/m), 1.8 mm thick shutter bottom (size 82.6 mm, 43.99 mm, 0.60 kg/m), 1.8 mm thick shutter top (size 51 mm, 43.99 mm, 1.88 kg/m) and 2.3 mm to 4.01 mm thick handle (size 101.60 mm, 38.10 mm, 25.40 mm short, 1.35 kg/m) section of all aluminum members will be anodized to aluminium bronze/silver/ss/black colour with a coat not less than 15 micrones in thickness or powder coated to any colour with a coat not less than 25 micrones in thickness and density of 4 mg per square cm etc. including all accessories like swing door clousure, swing door lock, swing door mohiar, labour charge, fabrication, fitting fixing in position, carriage and electricity charge keeping provision for fitting 5 mm thick glass including neoprene sealant etc. complete in all respect as per drawing and accepted by the Engineer-in-charge. (Total weight min 23 kg/m2) 14.1.1 Anodized to s.s colour/ black colour sqm Tk. 6,849.00 14.1.2 Anodized to bronze colour sqm Tk. 6,613.00 14.1.3 Anodized to silver colour sqm Tk. 6,592.00 14.1.4 Powder coated to any colour sqm Tk. 6,863.00 14.2 Supplying fitting and fixing of aluminium swing door as per the U.S. Architectural Aluminium Manufacturer‟s Association (AAMA) standard specification and BDS 1879:2014 having 1.8 mm thick wall frame (size 101.60 mm. 44.45 mm. 83.21 mm). 2.33 mm thick shutter (size 54 mm, 46 mm), 0.99 mm thick door glass bit (size 16.54 mm. 14.49 mm 0.115 kg/m), 2.5 mm thick clousure section (size 101.60 mm, 42.93 mm 1.2 mm), 106.60 mm clousure cover (0.45 kg/m), 4 mm thick floor bottom (size 101.60 mm. 12.70 mm 1 kg/m), 1.8 mm thick shutter bottom (size 82.6 mm, 43.99 mm, 0.60 kg/m), 1.8 mm thick shutter top (size 51 mm, 43.99 mm, 1.88 kg/m) and 2.3 mm to 4.01 mm thick handle (size 101.60 mm, 38.10 mm, 25.40 mm short, 1.35 kg/m) section of all aluminum members will be anodized to aluminium bronze/silver/ss/black colour with a coat not less than 15 micrones in thickness or powder coated to any colour with a coat not less than 25 micrones in thickness and density of 4 mg per square cm etc. including all accessories like swing door clousure, swing door lock, swing door mohiar, labour charge, fabrication, fitting fixing in position, carriage and electricity charge keeping provision for fitting 5 mm thick glass including neoprene sealant etc. complete in all respect as per drawing and accepted by the Engineer-in-charge. (Total weight min 23 kg/m2) 14.2.1 Anodized to s.s colour/ black colour sqm Tk. 6,379.00 14.2.2 Anodized to bronze colour sqm Tk. 6,302.00 14.2.3 Anodized to silver colour sqm Tk. 6,165.00 14.2.4 Powder coated to any colour sqm Tk. 6,516.00 ALUMINIUM DOOR, WINDOW FRAME AND GLASS WORKS Item No. PWD SoR 2018 for Civil Works Description of Item Unit 127 Unit Rate 14.3 Supplying, fitting and fixing of aluminium composite swing doors with fixed partition as per the U. S. Architectural Aluminium Manufacturer‟s Association (AAMA) standard specification and BDS 1879:2014 having 1.5 mm thick wall frame (size 101.60, 44.45 mm, 0.86 kg/m), 1.8 mm thick shutter side (size 54 mm, 46 mm, 1.2 kg/m ), 1 mm thick door glass bit (size 16.54 mm, 14. 49 mm, 0.115 kg/m), 1.8 mm thick closure section (size 101.54 mm, 42.93 mm, 1.20 kg/m), 1.5 thick closure cover (101.60 mm, 0.45 kg/m), 4 mm thick floor bottom (size 101.60 mm, 12.70 mm, 1 kg/m), 1.8 mm thick shutter bottom (size 86.60 mm, 43.99 mm , 0.60 kg/m), 1.8 mm thick shutter top (size 51 mm, 43.99 mm, 1.88 kg/m) 2.3mm to 4.01mm thick handle (short) (size 101.60 mm, 38.10 mm, 25.40 mm, 1.35 kg/m), 1.5 mm thick top and side (size 101.60 mm, 44.45 mm, 1.3 kg/m), 1.50 mm thick bottom (size 101.35 mm, 44.45 mm, 1.10 kg/m), 1.50 mm thick bottom cover (44.32 mm, 19.61mm, 0.392 kg/m), 1.50 mm thick grouve cover (size 83.21 mm, 16.00 mm, 0.57 kg/m), 0.99 mm thick fixed glass protector (size 39.09 mm, 14.81 mm, 0.188 kg/m), 0.99 mm thick fixed glass protector bit (size 15.75 mm, 14.81 mm, 0.13 kg/m) section of all aluminum members will be anodized to aluminium bronze/silver/ss/black colour with a coat not less than 15 micrones in thickness or powder coated to any colour with a coat not less than 25 micrones in thickness and density of 4 mg per square cm etc. (Total weight min 69.699 kg) keeping provision for 5 mm of glass panes with cost including all accessories like swing door clouser, swing door lock , swing door mohair, flush bolt , bolts and nuts including sealants, labour charge for fitting , fixing by angles, screws, mohiar, washer, machinery, cost of fabrication, making the grooves, mending good the damages, electricity etc. complete in all respect as per drawing and accepted by the Engineer-in-charge. 14.3.1 Anodized to s.s colour/ black colour sqm Tk. 3,416.00 14.3.2 Anodized to bronze colour sqm Tk. 3,358.00 14.3.3 Anodized to silver colour sqm Tk. 3,283.00 14.3.4 Powder coated to any colour sqm Tk. 3,494.00 14.4 Supplying, fitting and fixing of aluminium sliding doors as per the U.S. Architectural Aluminium Manufacturer‟s Association (AAMA) standard specification and BDS 1879:2014 having 1.2 mm thick outer bottom (size 75.50 mm, 17.79 mm, 0.528 kg/m), 1.2 mm thick outer top (size 75.50 mm, 26.80 mm, 0.78 kg/m) 1.2 mm thick shutter top (size 33 mm, 26.80 mm, 0.536 kg/m), 1.2 mm shutter bottom (size 60 mm, 24 mm, 0.736 kg/m), 1.2 mm thick outer side(size 75.50 mm, 19.90 mm, 0.616 kg/m) 1.5 mm thick shutter lock (size 49.20 mm, 26.20 mm, 0.661 kg/m), 1.2 mm thick inter lock (size 34.40 mm, 32.10 mm, 0.665 kg/m), 1.2 mm thick shutter divider (size 31.75 mm, 0.535 kg/m) sections all aluminum members (Total weight 14.789 kg) will be anodized to aluminium bronze/silver/ss/black colour with a coat not less than 15 micrones in thickness or powder coated to any colour with a coat not less than 25 micrones in thickness and density of 4 mg per square cm etc. including all accessories like handle, sliding door key lock , sliding door wheel, sliding door mohiar, sliding door neoprene, bolts and nuts including sealants, keeping provision for fitting 5mm thick glass including labour charge for fitting of accessories, making grooves and mending good damages, carriage, and electricity complete in all respect as per drawing and accepted by the Engineer-in-charge. Size up to: 2100 mm x 2100 mm 14.4.1 Anodized to s.s colour/ black colour sqm Tk. 2,928.00 14.4.2 Anodized to bronze colour sqm Tk. 2,841.00 14.4.3 Anodized to silver colour sqm Tk. 2,831.00 14.4.4 Powder coated to any colour sqm Tk. 3,014.00 ALUMINIUM DOOR, WINDOW FRAME AND GLASS WORKS Item No. PWD SoR 2018 for Civil Works Description of Item Unit 128 Unit Rate 14.5 Supplying, fitting and fixing of aluminium sliding doors as per the U.S. Architectural Aluminium Manufacturer‟s Association (AAMA) standard specification and BDS 1879:2014 having 1.2 m mm thick outer bottom (size 75.50 mm, 17.79 mm, 0.528 kg/m), 1.2 mm thick outer top (size 75. 50 mm, 26.80 mm 0.78 kg/m), 1.2 mm thick shutter top (size 33 mm, 26.80 mm, 0.536 kg/m), 1.2 mm thick shutter bottom (size 60 mm, 24 mm, 0.736 kg/m), 1.2 mm thick side (size 75.50 mm, 19.90 mm, 0.616 kg/m), 1.2 mm thick sliding fixed side (size 31 mm, 26 mm , 0.422 kg/m) 1.2 mm thick shutter lock (size 49.20 mm , 26. 20 mm , 0.661 kg/m), 1.2 mm thick inter lock (size 34.40 mm, 32.10 mm, 0.665 kg/m) 1.2 mm thick shutter divider (size 31.75 mm, 0.535 kg/m) and 1.4 mm to 1.5 mm thick spandrel (7.14 mm, 0.70 kg/m) sections all aluminium members (total weight 19.72 kg) will be anodized to aluminium bronze/silver/ss/black colour with a coat not less than 15 micrones in thickness or powder coated to any colour with a coat not less than 25 micrones in thickness and density of 4 mg per square cm etc. including all accessories like sliding door key lock, sliding door whee , sliding door mohiar, sliding door neoprene, bolts and nuts including sealants, keeping provision for fitting 5mm thick glass including labour charge for fitting of accessories, making grooves and mending good damages, carriage, and electricity complete in all respect as per drawing and accepted by the Engineer-in-charge. Size up to: 1800 mm x 2100 mm 14.5.1 Anodized to s.s colour/ black colour sqm Tk. 4,021.00 14.5.2 Anodized to bronze colour sqm Tk. 3,951.00 14.5.3 Anodized to silver colour sqm Tk. 3,886.00 14.5.4 Powder coated to any colour sqm Tk. 4,146.00 14.6 Supplying, fitting and fixing of aluminium sliding window as per the U.S. Architectural Aluminium Manufacturer‟s Association (AAMA) standard specification and BDS 1879:2014 having 1.2 mm thick outer bottom (size 75.50 mm, 32mm), 1.2 mm thick outer top (size 75.50 mm, 16.80 mm), 1.2 mm thick shutter top (size 33 mm.26.80, 22 mm), 1.2 mm thick shutter bottom (size 60mm, 24.40 mm), 1.2 mm thick outer side (size 75.50 mm,19.90 mm), 1.2 mm thick shutter lock (size 49.20 mm 26.20 mm) and 1.2 mm thick inter lock (size 34.40 mm, 32.10 mm) sections all aluminium members (total weight kg/sqm) will be anodized to aluminium bronze/silver/ss/black colour with a coat not less than 15 micrones in thickness or powder coated to any colour with a coat not less than 25 micrones in thickness and density of 4 mg per square cm etc. including all accessories like sliding door key lock, sliding door wheel, sliding door mohiar, sliding door neoprene, bolts and nuts including sealants, keeping provision for fitting 5 mm thick glass including labour charge for fitting of accessories, making grooves and mending good damages, carriage, and electricity complete in all respect as per drawing and accepted by the Engineer-in-charge. 14.6.1 Size up to: 1500 mm x 1400 mm. (total weight minimum 9.081 kg) 14.6.1.1 Anodized to s.s colour/ black colour sqm Tk. 3,611.00 14.6.1.2 Anodized to bronze colour sqm Tk. 3,563.00 14.6.1.3 Anodized to silver colour sqm Tk. 3,485.00 14.6.1.4 Powder coated to any colour sqm Tk. 3,720.00 14.6.2 Size up to: 900 mm x 1400 mm (total weight minimum 7.409 kg) 14.6.2.1 Anodized to s.s colour/ black colour sqm Tk. 5,042.00 ALUMINIUM DOOR, WINDOW FRAME AND GLASS WORKS Item No. PWD SoR 2018 for Civil Works Description of Item Unit 129 Unit Rate 14.6.2.2 Anodized to bronze colour sqm Tk. 4,950.00 14.6.2.3 Anodized to silver colour sqm Tk. 4,841.00 14.6.2.4 Powder coated to any colour sqm Tk. 5,198.00 14.7 Supplying, fitting and fixing of aluminium sliding composite window with mosquito mesh as per the U.S. Architectural Aluminium Manufacturer‟s Association (AAMA) standard specification and BDS 1879:2014 having 1.2 mm thick outer bottom (size 95.00 mm, 38 mm, 0.870 kg/m), 1.2 mm thick outer top (size 95.00 mm, 28.50 mm, 0.97kg/m), 1.2 mm thick shutter top (size 33 mm, 26.80 mm, 22 mm, 0.536 kg/m), 1.2 mm thick shutter bottom (size 60 mm, 24.40 mm, 0.736 kg/m), 1.2 mm thick outer side (size 95.00 mm, 19.50 mm, 0.738 kg/m), 1.2 mm thick shutter lock (size 49.20 mm, 26.2 mm, 0.661 kg/m), 1.2 mm thick shutter lock (size 34.40 mm, 32.10 mm, 0.665 kg/m), 1.2 mm thick mesh section (size 42.20 mm, 13.20 mm 0.460 kg/m), all aluminium members (total weight 12.79 kg) will be anodized to aluminium bronze/silver/ss/black colour with a coat not less than 15 micrones in thickness or powder coated to any colour with a coat not less than 25 micrones in thickness and density of 4 mg per square cm etc. including all accessories like sliding door key lock, sliding door wheel, sliding door mohiar, sliding door neoprene, bolts and nuts including sealants, keeping provision for fitting fiber mesh including labour charge for fitting of accessories, making grooves and mending good damages, carriage, and electricity complete in all respect as per drawing and accepted by the Engineer-in-charge. 14.7.1 Size up to: 1524 mm x 1372 mm 14.7.1.1 Anodized to s.s colour/ black colour sqm Tk. 4,626.00 14.7.1.2 Anodized to bronze colour sqm Tk. 4,518.00 14.7.1.3 Anodized to silver colour sqm Tk. 4,423.00 14.7.1.4 Powder coated to any colour sqm Tk. 4,755.00 14.7.2 Size up to: 1280 mm x 1372 mm 14.7.2.1 Anodized to s.s colour/ black colour sqm Tk. 5,231.00 14.7.2.2 Anodized to bronze colour sqm Tk. 5,112.00 14.7.2.3 Anodized to silver colour sqm Tk. 5,009.00 14.7.2.4 Powder coated to any colour sqm Tk. 5,372.00 14.7.3 Size up to: 762 mm x 610 mm 14.7.3.1 Anodized to s.s colour/ black colour sqm Tk. 10,553.00 14.7.3.2 Anodized to bronze colour sqm Tk. 10,340.00 14.7.3.3 Anodized to silver colour sqm Tk. 10,156.00 14.7.3.4 Powder coated to any colour sqm Tk. 10,810.00 ALUMINIUM DOOR, WINDOW FRAME AND GLASS WORKS Item No. PWD SoR 2018 for Civil Works Description of Item Unit 130 Unit Rate 14.8 Supplying, fitting and fixing of aluminium fixed composite window as per the U.S. Architectural Aluminium Manufacturer‟s Association (AAMA) standard specification and BDS 1879:2014 having 1.2 mm thick outer bottom (size 75.50 mm, 32 mm, 0.695 kg/m), 1.2 mm thick outer top (size 75.50mm, 26.80 mm, 0.78 kg/m), 1.2 mm thick shutter top (size 33 mm, 26.80 mm, 0.536 kg/m), 1.25 mm thick shutter bottom (size 60 mm, 24.40 mm, 0.736 kg/m), 1.2 mm thick outer side (size 75.50 mm, 19.90 mm, 0.616 kg/m), 1.2 mm thick sliding fixed side (size 31 mm, 26 mm, 0.422 kg/m), 1.2 mm thick shutter lock (size 49.20 mm, 26.20 mm, 0.661 kg/m), 1.2 mm thick inter lock (size 34.40 mm, 32.10 mm 0.665 kg/m) 1.2 mm thick bottom cover (size 37.78 mm, 31.78 mm, 0.313 kg/m), 1.2 mm thick grouve cover (size 76.20 mm, 38.10 mm, 0.912 kg/m), 1.2 mm thick grouve cover ( size 57.15 mm, 15.80 mm, 0.452 kg/m) and 1.2 mm thick top and side (size 76.20 mm, 38.10 mm, 0.3 kg/m) sections all aluminium members (total weight 12.297 kg) will be anodized to aluminium bronze/silver/ss/black colour with a coat not less than 15 micrones in thickness or powder coated to any colour with a coat not less than 25 micrones in thickness and density of 4 mg per square cm etc.including all accessories like sliding door key lock, sliding door wheel, sliding door mohiar, sliding door neoprene, bolts and nuts including sealants, keeping provision for fitting 5 mm thick glass including labour charge for fitting of accessories, making grooves and mending good damages, carriage, and electricity complete in all respect as per drawing and accepted by the Engineer-in-charge. Size up to: 1500 mm x 2100 mm. 14.8.1 Anodized to s.s colour/ black colour sqm Tk. 3,474.00 14.8.2 Anodized to bronze colour sqm Tk. 3,409.00 14.8.3 Anodized to silver colour sqm Tk. 3,355.00 14.8.4 Powder coated to any colour sqm Tk. 3,581.00 14.9 Supplying, fitting and fixing of aluminium top hung/casement windows as per the U.S. Architectural Aluminium Manufacturer‟s Association (AAMA) standard specification and BDS 1879:2014 having 1.2 mm thick casement outer (size 38.86 mm, 36.36 mm, 0.395kg/m), 1.9 mm thick casement shutter (size 47.62 mm, 28.57 mm, 0.692 kg/m), and 1.245 mm thick shutter glass clip (size 15.87 mm, 27 mm, 0.188 kg/m) sections of all aluminium members (total weight 7.584 kg) will be anodized to aluminium bronze/silver/ss/black colour with a coat not less than 15 micrones in thickness or powder coated to any colour with a coat not less than 25 micrones in thickness and density of 4 mg per square cm etc.including all accessories 4-bar hinge, casement handle, bolts and nuts keeping provision for fitting 5 mm thick glass including labour charge for fitting of accessories, making grooves and mending good damages, carriage, and electricity complete in all respect as per drawing and accepted by the Engineer-in-charge. 14.9.1 Anodized to s.s colour/ black colour sqm Tk. 11,099.00 14.9.2 Anodized to bronze colour sqm Tk. 10,980.00 14.9.3 Anodized to silver colour sqm Tk. 10,871.00 14.9.4 Powder coated to any colour sqm Tk. 11,237.00 ALUMINIUM DOOR, WINDOW FRAME AND GLASS WORKS Item No. PWD SoR 2018 for Civil Works Description of Item Unit 131 Unit Rate 14.10 Supplying fitting and fixing of aluminium corrugated curtain wall as per the U.S. Architectural Aluminium Manufacturer‟s Association (AAMA) standard specification and BDS 1879:2014 having 1.2 mm thick bottom cover (size 37.78 mm 31.78 mm, 0.313 kg/m), 1.2 mm thick grouve cover (size 76.20 m 38.10 mm, 0.912 kg/m), 1.2 mm thick grouve cover (size 57.15 mm, 15.80 mm 0.45 kg/m), 1.2 mm thick top and side (size 76.2 mm, 57.15 mm, 0.153 kg/m) and 1.8 mm thick spandrel (7.14 mm, 0.70 kg/m) sections of will be anodized to aluminium bronze/silver/ss/black colour with a coat not less than 15 micrones in thickness or powder coated to any colour with a coat not less than 25 micrones in thickness and density of 4 mg per square cm etc. including all accessories like rivet, screws fixed neoprene etc. complete in all respect as per drawing and accepted by the Engineer-in-charge. 14.10.1 Size up to: 3000 mm x 2100 mm (Total weight 50.228 kg) 14.10.1.1 Anodized to s.s colour/ black colour sqm Tk. 5,868.00 14.10.1.2 Anodized to bronze colour sqm Tk. 5,761.00 14.10.1.3 Anodized to silver colour sqm Tk. 5,612.00 14.10.1.4 Powder coated to any colour sqm Tk. 6,001.00 14.10.2 Size up to: 3000 mm x 750 mm (Total weight 26.136 kg) 14.10.2.1 Anodized to s.s colour/ black colour sqm Tk. 7,366.00 14.10.2.2 Anodized to bronze colour sqm Tk. 7,202.00 14.10.2.3 Anodized to silver colour sqm Tk. 7,025.00 14.10.2.4 Powder coated to any colour sqm Tk. 7,513.00 14.11 Supplying fitting and fixing of aluminium fixed fan light as per the U.S. Architectural Aluminium Manufacturer‟s Association (AAMA) standard specification and BDS 1879:2014 having 1.2 mm thick bottom cover (size 76.2 mm, 38.10 mm, 0.76 kg/m) and 2.5 mm thick grouve cover section (size 57.15mm, 15.80 mm, 0.425 kg/m) and 1.2 thick top and side section (76.20 mm, 16 mm, 38.10 mm, 0.961 kg/m) fixed with above mentioned frames and all aluminium members (Total weight 5.365 kg) will be anodized to aluminium bronze/silver/ss/black colour with a coat not less than 15 micrones in thickness or powder coated to any colour with a coat not less than 25 micrones in thickness and density of 4 mg per square cm etc. including all accessories, neoprene, sealant, nut and bolt etc. complete in all respect as per drawing and accepted by the Engineer-in-charge. 14.11.1 Anodized to s.s colour/ black colour sqm Tk. 4,304.00 14.11.2 Anodized to bronze colour sqm Tk. 4,241.00 14.11.3 Anodized to silver colour sqm Tk. 3,917.00 14.11.4 Powder coated to any colour sqm Tk. 4,149.00 ALUMINIUM DOOR, WINDOW FRAME AND GLASS WORKS Item No. PWD SoR 2018 for Civil Works Description of Item Unit 132 Unit Rate 14.12 Supplying fitting and fixing of aluminium fixed louver as per the U.S. Architectural Aluminium Manufacturer‟s Association (AAMA) standard specification and BDS 1879:2014 having 1.2mm thick wall frame (size 76.20 mm, 38.10 mm, 0.707 kg/m), 5 mm thick louver section (size 55.02 mm, 37.39 mm, 0.22 kg/m) and 2.50 mm thick louver outer section (size 39.67 mm, 15.06 mm, 0.265 kg/m) and inner inclined aluminium louver section fixed with above mentioned frame and all aluminium members (total weight 7.992 kg) will be anodized to aluminium bronze/silver/ss/black colour with a coat not less than 15 micrones in thickness or powder coated to any colour with a coat not less than 25 micrones in thickness and density of 4 mg per square cm etc including all accessories, neoprene, sealant, nuts and bolts etc. complete in all respect as per drawing and accepted by the Engineer-in-charge. 14.12.1 Anodized to s.s colour/ black colour sqm Tk. 7,168.00 14.12.2 Anodized to bronze colour sqm Tk. 6,992.00 14.12.3 Anodized to silver colour sqm Tk. 6,948.00 14.12.4 Powder coated to any colour sqm Tk. 7,621.00 14.13 Supplying, fitting, fixing of aluminium sliding fly proof netting shutter as per the U.S. Architectural Aluminium Manufacturer‟s Association (AAMA) standard specification and BDS 1879:2014 having 1.2 mm thick outer frame (size 38 mm x 18 mm), 1.2 mm thick mosquito net shutter frame mesh section (size 38 mm x 12 mm). All aluminium members (total weight 12.79 kg) will be anodized to aluminium bronze/silver/ss/black colour with a coat not less than 15 micrones in thickness or powder coated to any colour with a coat not less than 25 micrones in thickness and density of 4 mg per square cm etc. including all accessories like wheel, sealent, rubber, bolts and nuts keeping provision for fitting fiber mesh including labour charge for fitting of accessories, making grooves and mending good damages, carriage, and electricity, all complete in all respect as per drawing and accepted by the Engineer-in-charge. 14.13.1 Anodized to s.s colour/ black colour sqm Tk. 3,045.00 14.13.2 Anodized to bronze colour sqm Tk. 2,961.00 14.13.3 Anodized to silver colour sqm Tk. 2,866.00 14.13.4 Powder coated to any colour sqm Tk. 3,158.00 14.14 Supplying, fitting and fixing in Aluminium door frames, windows, partitions and curtain wall distortion free glass of approved quality and shade including cost of fitting fixing all necessary accessories etc. complete in all respect as per drawing and accepted by the Engineer-in-charge. 14.14.1.1 5 mm thick clear glass sqm Tk. 1,133.00 14.14.1.2 6 mm thick clear glass sqm Tk. 1,380.00 14.14.2.1 5 mm thick tinted glass sqm Tk. 1,352.00 14.14.3.1 5 mm thick ambushed/ frosted glass sqm Tk. 1,120.00 14.14.4.1 5 mm thick reflecting glass sqm Tk. 1,350.00 ALUMINIUM DOOR, WINDOW FRAME AND GLASS WORKS Item No. PWD SoR 2018 for Civil Works Description of Item Unit 133 Unit Rate 14.14.4.2 6 mm thick reflecting glass sqm Tk. 1,493.00 14.15 Supplying, fabrication and Installation of approved colour (4 mm thick) Aluminium composite panel (Alucobond/Alcopanel/Alpolic) as per US Architectural Aluminium Manufacturer's Association (AAMA) in column, beam and wall surface providing with 44 mm x 44 mm x 1.5 mm aluminum section including supply of necessary hardwares, consumables, scaffolding etc fitted with necessary accessories like rivet, screw, rowel bolt etc. all complete in all respect as per drawing and direction of the Engineer-in-charge. sqm Tk. 6,944.00 14.16 Supplying, fitting and fixing of aluminium curtain wall with aluminium top hung/casement windows as per the US Architectural Aluminium Manufacturer's Association (AAMA) standard specification and BDS 1879:2014 having 100 mm , 50mm, 2mm curtain wall submullim outer and inner frame, 15 mm thick casement outer frame (size 38.86 mm 36.6 mm), 1.9 mm thick casement shutter (size 47.62 mm, 28.57 mm,) 1.2 mm thick shutter glass strips, all aluminium member will be powder coated with coat not less than 1.5 micron in thickness including all accessories 4 bar hinge casement handle, 50 mm x 50 mm x 6 mm aluminium angle, steel rowel bolt, screws , rivets norton tape masking tape, structural sealant, gum bracket rod etc. all complete in all respect as per drawing and direction of the Engineer-in-charge. sqm Tk. 9,240.00 14.17 Supplying, fitting and fixing of aluminium curtain wall and aluminium top hung/casement windows ad per the US Architectural Aluminium Manufacturer's Association (AAMA) standard specification and BDS 1879:2014 having 50 mm , 50 mm, 2 mm curtain wall submullim outer and inner frame, 15 mm thick casement outer frame (size 38.86 mm 36.6 mm), 1.9 mm thick casement shutter (size 47.62mm, 28.57mm,) 1.2 mm thick shutter glass strips, all aluminium member will be powder coated with coat not less than 1.5 micron in thickness including all accessories 4 bar hinge casement handle, 50 mm x 50 mm x 6 mm aluminium angle, steel rowel bolt, screws , rivets norton tape masking tape, structural sealant, gum bracket rod etc. all complete in all respect as per drawing and direction of the Engineer-in-charge. sqm Tk. 7,832.00 14.18 Supplying, fitting and fixing of aluminium curtain wall along with 10 mm thick clear tempered glass as per the US Architectural aluminium Manufacturer's Association (AAMA) Standard Specification and BDS 1879:2014 having 115 mm , 64 mm, 3 mm curtain wall sub-mullim outer and inner frame, 15 mm thick casement outer frame (size 38.86 mm 36.6mm), 1.9 mm thick casement shutter (size 47.62 mm, 28.57 mm,) 1.2 mm thick shutter glass strips, all aluminium member will be powder coated with coat not less than 1.5 micron in thickness including all accessories 4 bar hinge casement handle, 50 m x 50mm x 6m aluminium angle, steel rowel bolt, screws , rivets norton tape masking tape, structural sealant, gum bracket rod etc. all complete in all respect as per drawing and direction of the Engineer-in-charge. sqm Tk. 10,303.00 14.19 Supplying, fitting and fixing of 12 mm thick clear tempered glass wall upto 3.0 m height with vertical fin glass support of same thickness and support shall be at least 1.2 m c/c fixed properly with glass by silicon glue with supply and fittings of all required accessories such as SS u channel, nut bolts, aluminium angle, steel rowel bolt, screws , rivets norton tape masking tape, structural sealant, gum bracket rod etc. all complete in all respect as per drawing and direction of the Engineer-in- charge. sqm Tk. 19,790.00 14.20 Supplying, fitting and fixing of 12 mm thick tempered glass wall from 3.0 m to 6.0 m height with spider point fixing joint and vertical fin glass support of same thickness, support shall be at least 1.2 m c/c fixed properly with main glass by silicon glue with supply and fittings of all required accessories such as SS u chennel, nut bolts, aluminium angle, steel rowel bolt, screws , rivets norton tape masking tape, structural sealant, gum bracket rod etc. all complete in all respect as per drawing and direction of the Engineer-in-charge. sqm Tk. 19,782.00 ALUMINIUM DOOR, WINDOW FRAME AND GLASS WORKS Item No. 14.21 PWD SoR 2018 for Civil Works 134 Description of Item Unit Unit Rate Supplying, fitting and fixing of 12 mm thick clear tempered glass wall from 6.0 m to 8.2 m height with spider point fixing joint and vertical/ horizontal fin glass support of double thickness, support shall be at least 2 m c/c fixed properly with main glass by silicon glue with supply and fittings of all required accessories such as SS u chennel, nut bolts, aluminium angle, steel rowel bolt, screws , rivets norton tape masking tape, structural sealant, gum bracket rod etc. all complete in all respect as per drawing and direction of the Engineer-in-charge. sqm Tk. 20,076.00 ………………….. END OF DIVISION FOURTEEN ………………….. CEMENT PLASTER, FAIR-FACE PLASTER AND POINTING WORKS PWD SoR 2018 for Civil Works 135 DIVISION 15 : CEMENT PLASTER, FAIR-FACE PLASTER AND POINTING WORKS Item No. Description of Item Unit Unit Rate 15.1 Minimum 12 mm thick cement sand (F.M. 1.2) plaster (1:4) with fresh cement to both inner-and outer surface of wall, finishing the corner and edges including washing of sand, cleaning the surface, curing at least for 7 days, cost of water, electricity, scaffolding and other charges etc. all complete in all respect as per drawing and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) ground floor. sqm Tk. 243.00 15.2 Minimum 12 mm thick cement sand (F.M. 1.2) plaster with neat cement finishing to plinth wall with cement (1:4) up to 150 mm below ground level including washing of sand, finishing the edges and corners and curing at least for 7 days, cost of water, electricity, scaffolding and other charges etc. all complete in all respect as per drawing and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) ground floor. sqm Tk. 280.00 15.3 Minimum 12 mm thick cement sand (F.M. 1.2) plaster with neat cement finishing to dado with cement (1:4) up to 150 mm including washing of sand, finishing the edges and corners and curing at least for 7 days, cost of water, electricity, scaffolding and other charges etc. all complete in all respect as per drawing and accepted by the Engineer-incharge. (Cement: CEM-II/A-M) ground floor. sqm Tk. 295.00 15.4 Minimum 12 mm thick cement sand (F.M. 1.2) plaster (1:6) having with fresh cement to both inner and outer surface of wall, finishing the edges and corners including washing of sand, cleaning the surface, curing at least for 7 days, cost of water, electricity, scaffolding and other charges etc. all complete in all respect as per drawing and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) ground floor. sqm Tk. 228.00 15.5 Minimum 6 mm thick cement sand (F.M. 1.2) plaster (1:4) with fresh cement to ceiling, R.C.C. columns, beams, surface of stair case, sunshades, cornices, railings, drop wall, louvers, fins and finishing the corners and edges including washing of sand, cleaning the surface, curing at least for 7 days, cost of water, electricity, scaffolding and other charges etc. all complete in all respect as per drawing and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) ground floor. sqm Tk. 225.00 15.6 Minimum 6 mm thick cement sand (F.M. 1.2) plaster (1:3) with fresh cement to ceiling, R.C.C. columns, beams, surface of stair case, sunshades, cornices, railings, drop wall, louvers, fins and finishing the corners and edges including washing of sand, cleaning the surface, curing at least for 7 days, cost of water, electricity, scaffolding and other charges etc. all complete in all respect as per drawing and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) ground floor. sqm Tk. 222.00 15.7 Flush pointing to brick wall with cement sand (F.M. 1.2) mortar (1:2) with cement including raking out the joints, curing at least for 7 days, cost of water, electricity, scaffolding and other charges etc. all complete in all respect as per drawing and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) ground floor. sqm Tk. 141.00 15.8 Rule pointing to brick wall with cement sand (F.M. 1.2) mortar (1:2) with fresh cement and raking out the joints, curing at least for 7 days, cost of water, electricity, scaffolding and other charges etc. all complete in all respect as per drawing and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) ground floor. sqm Tk. 179.00 CEMENT PLASTER, FAIR-FACE PLASTER AND POINTING WORKS Item No. PWD SoR 2018 for Civil Works 136 Description of Item Unit Unit Rate 15.9 Raised or tack pointing work to brick wall with cement sand (F.M. 1.2) mortar (1:2) with fresh cement of minimum 12 mm x 20 mm in size including raking out the joints and necessary scaffolding, curing at least for 7 days, cleaning each and every brick, cutting the bricks with pumice stone where necessary etc. all complete in all floors, cost of water, electricity, scaffolding and other charges etc. all complete in all respect as per drawing and accepted by the Engineer-in-charge. (Cement: CEM-II/A-M) ground floor. sqm Tk. 441.00 15.10 Providing drip course or nosing at the edge of sunshade or cornice with cement sand (F.M. 1.2) mortar (1:2) with fresh cement, curing at least for 7 days, cost of water, electricity, scaffolding and other charges etc. all complete in all respect as per drawing and accepted by the Engineer-in-charge. meter Tk. 116.00 15.11.1 Making groove in plaster on outside wall upto 50 mm X 6 mm size including scaffolding, curing etc. complete as per drawing and accepted by the Engineer-in-charge. meter Tk. 22.00 15.11.2 Making groove in plaster on outside wall upto 38 mm X 6 mm size including scaffolding, curing etc. complete as per drawing and accepted by the Engineer-in-charge. meter Tk. 35.00 15.12 Minimum 10 mm thick fair face plaster using premix cement plaster (CP2 LGT/Stucco base premix or equivalent); initial background should be 19 mm rough cement plaster (1:4); then after passing 7 days curing time surface of newly constructed rough plaster should be throughly cleaned using a stiff brush to remove any dust, loose particles, wood pieces, mould oil etc, then the backgound needs to be throughly neutralized by applying potable water; Mixing premix cement plaster with water at water/powder ratio according to the specification of the manufacturer to form paste and apply on rough plaster surface; powder for making paste must be mixed with potable water only; apply the paste on the rough plaster surface by trowel to get smooth and shiny surface and cure the finished plaster suface for 2-3 days(3-4 times daily); finally water repellent coating to protect concrete surface; all complete with necessary scaffolding etc. accepted by the Engineerin-charge.(Rate is excluding the cost of 19 mm thick rough cement plaster and water repellent paint) ground Floor sqm Tk. 1,775.00 15.13.1 Making groove in fair face plaster on outside wall upto 50 mm X 6 mm size including scaffolding, curing etc. complete as per drawing and accepted by the Engineer-in-charge. meter Tk. 44.00 15.13.2 Making groove in fair face plaster on outside wall upto 38 mm X 6 mm size including scaffolding, curing etc. complete as per drawing and accepted by the Engineer-in-charge. meter Tk. 54.00 15.14 Minimum 1mm thick fair face coating using Master Emaco N 303 Rendroc FC/Top Crete 220 or equivalent product micro toping skim coat, a high performance single component polymer fortified, colored, cementitious micro topping that can be applied on a variety of horizontal and vertical plaster surfaces; initially background should be thoroughly cleaned using a stiff brush to remove any dust, loose particles, mould oil etc.; then the background needs to be thoroughly neutralized by applying potable water ; the ratio of fair face coating and water is 1.5:1 to 2:1 or as required for workability ; powder will be mixed with potable water in a drum by blending machine; the mixture can be spread to any horizontal and vertical plaster surface using trowel to get smooth and shiny surface; all complete with necessary scaffolding etc. accepted by the Engineer-in-charge. (Rate is excluding the cost of 19 mm thick rough cement plaster) ground floor. sqm Tk. 1,362.00 CEMENT PLASTER, FAIR-FACE PLASTER AND POINTING WORKS Item No. PWD SoR 2018 for Civil Works 137 Description of Item Unit 15.15.1 Minimum 12 mm thick cement sand (F.M-1.2) water proof, damp proof, dry and breathable plaster (1:4) with water proof Izonil Cement (STN-EN -1015-11 , Compressive Strength 34 MPa ,Max depth of water penetration into hardened plaster is <1 mm) or equivalent compound to wall surface, finishing the corner and edges including washing of sand, cleaning the surface, scaffolding and curing at least for 3 days, cost of water, electricity and other charges etc. all complete in all respect as per drawing and accepted by the Engineer–in-charge. (Izonil Cement/equivalent compound: water proof, damp proof, dry and breathable cement). sqm Tk. 504.00 15.15.2 Minimum 19 mm thick cement sand (F.M-1.2) water proof, damp proof, dry and breathable plaster (1:4) with water proof Izonil Cement (STN-EN -1015-11 , Compressive Strength 34 MPa ,Max depth of water penetration into hardened plaster is < 1 mm) /equivalent compound to wall surface, finishing the corner and edges including washing of sand, cleaning the surface, scaffolding and curing at least for 3 days, cost of water, electricity and other charges etc. all complete in all respect as per drawing and accepted by the Engineer–in-charge. (Izonil Cement/equivalent compound: water proof, damp proof, dry and breathable cement). sqm Tk. 655.00 15.16 Extra rate for plaster and all types of pointing shall be incorporated in the estimate 15.16.1 Add for each additional floor up to 5th floor. sqm Tk. 14.00 15.16.2 Add for each additional floor for 6th floor to 9th floor sqm Tk. 21.00 15.16.3 Add for each additional floor 10th floor and above sqm Tk. 28.00 15.17 Pre-cast ventilators of minimum 25 mm thick of any design with cement sand (F.M.1.2) mortar (1:4) fitted and fixed in position, finishing with cement sand (F.M. 1.2) plaster (1:6) including necessary scaffolding and curing, in all floors accepted by the Engineer-incharge. (Cement: CEM-II/A-M) sqm Tk. 2,103.00 15.18 75 mm x 75 mm cornice of brick masonry in cement sand (F.M. 1.2) mortar (1:6) having minimum 12 mm thick cement sand (F.M. 1.2) plaster (1:6) including scaffolding and curing at least for 7 days in all floors accepted by the Engineer-in-charge. (Cement: CEMII/A-M) meter Tk. 216.00 15.19 Supplying, fitting, fixing of broken and sharp glass 19 mm to 32 mm height, average 19 mm width placed at a distance approximately 25 mm center to center, embedding the same to 12 mm to 19 mm thick cement plaster with neat cement finishing including necessary scaffolding approved and accepted by the Engineer-in-charge. (Cement: CEMII/A-M) sqm Tk. 223.00 ………………….. END OF DIVISION FIFTEEN ………………….. Unit Rate PWD SoR 2018 for Civil Works PAINTING AND POLISHING 138 DIVISION 16 : PAINTING AND POLISHING Item No. Description of Item Unit Unit Rate 16.1.1 Exterior standard acrylic emulsion paint of approved best quality and color having water resisting properties and resistance properties against fungi, fading & flaking delivered from authorized local agent of the manufacturer (Berger weather coat smooth/ Elite smooth exterior/ Asian apex weather coat or equivalent brand) in a sealed container; applying to exterior surface with surface preparation including cleaning, drying, making free from dirt, grease, wax, removing all chalked and scaled materials, fungus, mending good the surface defects using sand paper and necessary scaffolding; applying 1 coat of exterior sealer of specified brand on prepared surface; then applying 1 coat of exterior putty of specified brand for levelling, spot filling, crack filling and cutting by sand paper/zero water paper; finally applying 2 coats of exterior emulsion paint spreading by brush/roller/spray & necessary scaffolding etc. upto desired finishing, elapsing specified time for drying or recoating; all complete in all floors and accepted by the Engineer-incharge. sqm Tk. 238.00 16.1.2 Exterior premium acrylic emulsion paint of approved best quality and color with high performance against dirt picking tendency and efflorosence resistence properties along with water resisting properties and resistance properties against fungi, fading and flaking from authorized local agent of the manufacturer (Berger weather coat antidirt long life/ Elite master coat/ Asian apex ultima or equivalent brand) in a sealed container; applying to exterior surface with surface preparation including cleaning drying, making free from dirt, grease, wax, removing all chalked and scaled materials, fungus, mending good the surface defects using sand paper and necessary scaffolding; applying 1 coat of exterior sealer of specified brand on prepared surface; then applying 1 coat of exterior putty of specified brand for levelling, spot filling, crack filling and cutting by sand paper/zero water paper; finally applying 2 coats of exterior emulsion paint spreading by brush/roller/spray & necessary scaffolding etc. upto desired finishing, elapsing specified time for drying or recoating; all complete in all floors and accepted by the Engineer-in-charge. sqm Tk. 261.00 16.2.1 Interior standard acrylic emulsion paint (plastic or matt finish) of approved best quality and colour delivered from authorized local agent of the manufacturer (Berger robbialac plastic emulsion/Asian apcolite plastic emulsion or equivalent brand) in a sealed container; applying to interior wall and ceiling with surface preparation including cleaning drying, making free from dirt, grease, wax, removing all chalked and scaled materials, fungus, mending good the surface defects using sand paper and necessary scaffolding; applying 1 coat of interior sealer of specified brand on prepared surface; then applying 1 coat of interior putty of specified brand for levelling, spot filling, crack filling and cutting by sand paper/zero water paper; finally applying 2 coats of interior emulsion paint spreading by brush/roller/spray & necessary scaffolding etc. upto desired finishing, elapsing specified time for drying or recoating; all complete in all floors and accepted by the Engineer-incharge. sqm Tk. 234.00 16.2.2 Interior premium acrylic emulsion painting (silky finish) of approved best quality and colour delivered from authorized local agent of the manufacturer(Berger luxury silk emulsion/Elite super aclose silky finish/Asian royal luxury silk emulsion or equivalent brand) in a sealed container; applying to interior wall and ceiling with surface preparation including cleaning drying, making free from dirt, grease, wax, removing all chalked and scaled materials, fungus, mending good the surface defects using sand paper and necessary scaffolding; applying 1 coat of interior sealer of specified brand on prepared surface; then applying 1 coat of interior putty of specified brand for levelling, spot filling, crack filling and cutting by sand paper/zero water paper; finally applying 2 coats of interior emulsion paint spreading by brush/roller/spray & necessary scaffolding etc. upto desired finishing, elapsing specified time for drying or recoating; all complete in all floors and accepted by the Engineer-in-charge. sqm Tk. 259.00 PWD SoR 2018 for Civil Works PAINTING AND POLISHING Item No. 139 Description of Item Unit Unit Rate 16.2.3 Interior super premium acrylic emulsion painting (odorless) of approved best quality and colour delivered from authorized local agent of the manufacturer(Berger breath easy or equivalent brand) in a sealed container; applying to interior wall and ceiling with surface preparation including cleaning drying, making free from dirt, grease, wax, removing all chalked and scaled materials, fungus, mending good the surface defects using sand paper and necessary scaffolding; applying 1 coat of interior sealer of specified brand on prepared surface; then applying 1 coat of interior putty of specified brand for levelling, spot filling, crack filling and cutting by sand paper/zero water paper, finally applying 2 coats of interior emulsion paint spreading by brush/roller/spray & necessary scaffolding etc. upto desired finishing, elapsing specified time for drying or recoating; all complete in all floors accepted by the Engineer-in-charge. sqm Tk. 273.00 16.3.1 Standard synthetic enamel paint of approved best quality and colour delivered from authorized local agent of the manufacturer (Berger jhilik synthetic enamel/Elite quick drying/Asian decora synthetic enamel or equivalent brand) in a sealed container, having high water resistance, high bondibility, flexibility property; using specified brand thinner applying to metallic or wooden surface by brass/roller/spray in 2 coats over single coat anti-corrosive coating including cleaning, drying, making free from dirt, grease, wax, removing all chalked and scaled materials, all complete in all floors and accepted by the Engineer-in-charge. sqm Tk. 189.00 16.3.2 Premium synthetic enamel paint of approved best quality and colour delivered from authorized local agent of the manufacturer(Berger robbialac supergloss synthetic enamel/Elite lucky seven/ Asian apcolipe premium paint or equivalent brand) in a sealed container, having high water resistance, high bondibility, flexiblity property; using specified brand thinner applying to metallic or wooden surface by brass/roller/spray in two coats over single coat anti-corrosive coating including cleaning, drying, making free from dirt, grease, wax, removing all chalked and scaled materials, all complete in all floors and accepted by the Engineer-in-charge. sqm Tk. 198.00 16.4 Interior design paint of approved best quality and colour delivered from authorized local agent of the manufacturer (Berger illusion/Elite elunima/Asian royal play or equivalent brand) in a sealed container; applying to interior wall and ceiling with surface preparation including cleaning drying, making free from dirt, grease, wax, removing all chalked and scaled materials, fungus, mending good the surface defects using sand paper and necessary scaffolding; applying 1 coat of interior sealer of specified brand on prepared surface; then applying 1 coat of interior putty of specified brand for levelling, spot filling, crack filling and cutting by sand paper/zero water paper; applying 3 coats of interior design paint; 1st coat on prepared suface , then applying 1 design coat on the 1st coat and finally applying 1 protection coat on the design coat for protecting the design spreading by brush/roller/spray & necessary scaffolding etc. upto desired finishing, elapsing specified time for drying or recoating; all complete in all floors and accepted by the Engineer-incharge. sqm Tk. 706.00 16.5 Textured paint of approved best quality and colour delivered from authorized local agent of the manufacturer in a sealed container; applying to interior wall and ceiling including surface preparation including cleaning drying, making free from dirt, grease, wax, removing all chalked and scaled materials, fungus if required must be treated with fungicidal solution, mending good the surface defects using sand paper and necessary scaffolding; applying 1 coat of interior sealer of specified brand on prepared surface; then applying 1 coat of interior putty of specified brand for levelling, spot filling, crack filling and cutting by sand paper/zero water paper; applying 3 coats of texture paint; 1st coat on prepared suface , then applying 1 texture coat on the 1st coat and finally applying 1 top coat on the texture coat upto desired finishing by brush/roller/spray etc. with necessary scaffolding ; all complete in all floors and accepted by the Engineer-in-charge. sqm Tk. 620.00 PWD SoR 2018 for Civil Works PAINTING AND POLISHING Item No. 140 Description of Item Unit Unit Rate 16.6 Chlorinated rubber paint of approved quality and colour delivered from authorized local agent of the manufacturer in a sealed container; surface preparation including cleaning, drying, making free from dirt, grease, wax, removing all chalked and scaled materials, fungus (if required must be treated with fungicidal solution) flaking paints, washing the surface with soap water/caustic soda, mending good the surface defects, smoothening the surface by putty, sand papering the surface; applying to concrete surfaces and walls in three coats by brush/roller/spray etc. upto desired finishing, elapsing specified time for drying and re-coating; with necessary scaffolding all complete in all floors and accepted by the Engineer-in-charge. sqm Tk. 329.00 16.7 Epoxy enamel paint of approved quality and colour delivered from authorized local agent of the manufacturer in a sealed container; surface preparation including cleaning, drying, making free from dirt, grease, wax, removing all chalked and scaled materials, fungus (if required must be treated with fungicidal solution) flaking paints, washing the surface with soap water/caustic soda, mending good the surface defects, smoothening the surface by putty, sand papering the surface; applying to concrete surfaces and walls in three coats by brush/roller/spray etc. upto desired finishing;elapsing specified time for drying and recoating; with necessary scaffolding all complete in all floors and accepted by the Engineerin-charge. sqm Tk. 418.00 16.8 Silicon based water repellent of approved quality delivered from authorized local agent of the manufacturer in a sealed container; surface preparation including cleaning, drying, making free from dirt, grease, wax, removing all chalked and scaled materials, fungus, mending good the surface defects using sand paper and necessary scaffolding; applying 3 coats of silicon based water repellent on exposed brick surface/fair face surface spreading by brush/roller/spray & necessary scaffolding etc. upto desired finishing, elapsing specified time for drying or recoating; all complete in all floors and accepted by the Engineer-in-charge. sqm Tk. 226.00 16.9 French polishing to door and window frames and shutter by three coats over a coat of priming including putty, cleaning, finishing and polishing with sand paper etc. all complete in all floors and accepted by the Engineer-in-charge. sqm Tk. 372.00 16.10 Wood varnishing of approved quality and colour delivered from authorized local agent of the manufacturer in a sealed container using brand specified thinner to door and window frame and shutter in three coats, applied with brush including cleaning oil, grease, dirt, making dry, sand papering, if required washing with weak detergent solution, stripping out the colour straps, finishing the surface, etc. all complete in all floors and accepted by the Engineer-in-charge. 16.10.1 Yacht sqm Tk. 188.00 16.10.2 Egg-shell sqm Tk. 189.00 16.10.3 Matt sqm Tk. 188.00 16.11 Approved best quality and colour synthetic polyvinyl distemper delivered from authorized local agent of the manufacturer in a sealed container, applying to wall and ceiling with surface preparation including cleaning drying, making free from dirt, grease, wax, removing all chalked and scaled materials, fungus, mending good the surface defects using sand paper and necessary scaffolding; applying 1 coat of interior sealer of specified brand on prepared surface; then applying 1 coat of interior putty of specified brand for levelling, spot filling, crack filling and cutting by sand paper/zero water paper; finally applying 2 coats of synthetic polyvinyl distemper spreading by brush/roller/spray & necessary scaffolding etc. upto desired finishing, elapsing specified time for drying or recoating; all complete in all floors and accepted by the Engineer-in-charge. sqm Tk. 196.00 PWD SoR 2018 for Civil Works PAINTING AND POLISHING Item No. 141 Description of Item Unit 16.12 White washing by three coats, lime mixture prepared at least 12 hours before use, slacking stone lime, supplying of gums, blue, stirring thoroughly, removing the floating materials from the mixer, surface cleaning to free from all foreign materials before application of each coat, applying one vertical and one horizontal wash for each coat and successive coat is to be applied after drying up of previous coat including hair brass, providing necessary scaffolding and cleaning plinth, floors, doors, windows, portions and ventilators by washing, rubbing, oiling if necessary after white wash for all floors including cost of water, electricity and other charges etc. complete in all respect in all floors and accepted by the Engineer-in-charge. sqm Tk. 22.00 16.13 Colour wash with yellow orchard/any other colour pigment by two coats over a prime coat of white wash, lime mixture prepared at least 12 hours before use, slacking stone lime, supplying of gums, blue, stirring thoroughly, removing the floating materials from the mixer, surface cleaning to free from all foreign materials before application of each coat, applying one vertical and one horizontal wash for each coat and successive coat is to be applied after drying up of previous coat including hair brass, providing necessary scaffolding and cleaning plinth, floors, doors, windows, portions and ventilators by washing, rubbing, oiling if necessary after white wash for all floors including cost of water, electricity and other charges etc. complete in all respect in all floors and accepted by the Engineer-in-charge. sqm Tk. 25.00 16.14 Application of 02 coats of self leveling epoxy compound (4 mm thick) as base coat & finishing coat over a single layer of screet coat (primer) for making smooth hygienic floor surface; all chemicals delivered from authorized local agent of the manufacturer in sealed container; materials having high water resistence, high bondibility, flexibility property; applying by applicator machine after being mixed by force action mixer elapsing time for drying; surface preparation including surface cleaning from dust, oil or dirt, preparing underlying surface having minimum moisture content, smoothening, finishing & polishing by grinding machine & necessary tools, repairing significant ups/downs in floor before application with sacaffolding, testing charges etc. all complete in all floors approved & accepted by the Engineer-in-charge. sqm Tk. 2,079.00 ………………….. END OF DIVISION SIXTEEN ………………….. Unit Rate LIME TERRACING, ROOF TOP WATER PROOFING FOR GARDEN AND SWIMMIMG POOL PWD SoR 2018 for Civil Works 142 DIVISION 17: LIME TERRACING, ROOF TOP WATER PROOFING FOR GARDEN AND SWIMMIMG POOL Item No. Description of Item Unit Unit Rate 17.1 Supply and application of non-toxic two components acrylic polymer modified cementitious coating (minimum 1.5 mm thickness) for water proofing of roof/ roof garden/ swimmimg pool which consists of powder and liquid acrylic emulsion; under a protective cover of plaster/ cement concrete/ tiles etc. as per standard specification and accepted by the Engineer-in-charge. (Rate is excluding the cost of protective cover) sqm Tk. 758.00 17.2 Preparation and making gravel pack for roof top gardening with supply of 25 mm down graded pea gravels including sieving, washing, compacting etc. complete as per standard specification and accepted by the Engineer-in-charge. Ground floor cum Tk. 4,392.00 17.2.1 Extra rate for gravel pack work in additional floor: 17.2.1.1 Add for each additional floor up to 5th floor cum Tk. 102.00 17.2.1.2 Add for each additional floor for 6th floor to 9th floor cum Tk. 136.00 17.2.1.3 Add for each additional floor for 10th floor and above cum Tk. 171.00 17.3 Supply and application of 19 mm thick (9.5 mm X 2 layer) water proof, damp proof, dry and breathable plaster on roof slab/ underground water reservoir/ overhead water reservoir/ basement/retaining wall with water proof, damp proof, dry and breathable Izonil cement (STN-EN -1015-11, compressive strength 34 MPa ,max depth of water penetration into hardened plaster is < 1 mm) or equivalent compound in a proportion of 1:2.4 (Izonil cement or equivalent compound 1: sand 2.4) after cement grouting on existing concrete surface including finishing the corner and edges, washing sand, cleaning the surface scaffolding and curing at least 3 days etc. all completed in all respects as per direction of Engineering-in-charge. Above mentioned plaster includes glass fiber mesh of 10 mm X 10 mm grid and weight 110 gm/sqm placed in between two layers. sqm Tk. 1,002.00 17.4 Average 100 mm thick finished lime terracing with 20 mm down graded first class brick chips (khoa), surki from 1st class bricks and minimum lime content 500 kg per 2.83 cubic meter (stone lime brought at site, not being powdered in open air and to be slaked in presence of engineer-in-charge and to be measured in volume three days after slaking for using in the mix) in the proportion 7:2:2 (brick chips : surki : lime) including preparation of the mix on the ground by making a suitable platform under proper polythene cover. Cutting the mix twice daily with limewater (1:10) at least for 7 days until the mix attain desirable consistency. Laying the mix in proper slope, beating the same with standard „koppa‟ for minimum 7 days to gain maximum consolidation, making ghoondy and neat finishing with lime Surki mortar (1:2) and curing for 21 days providing polythene cover after each day work and cleaning etc. complete in all respect accepted by the Engineer-in-charge. cum Tk. 13,165.00 1st Floor 17.4.1 Extra rate for lime terracing work in additional floor: 17.4.1.1 Add for each additional floor up to 5th floor cum Tk. 102.00 17.4.1.2 Add for each additional floor for 6th floor to 9th floor cum Tk. 136.00 17.4.1.3 Add for each additional floor for 10th floor and above cum Tk. 171.00 LIME TERRACING, ROOF TOP WATER PROOFING FOR GARDEN AND SWIMMIMG POOL Item No. PWD SoR 2018 for Civil Works 143 Description of Item Unit 17.5.1 25 mm thick ferrocement treatment work for water proofing on roof having minimum cement content relates to mix ratio 1:2 cement conforming to BDS EN-197-1-CEM-I, 52.5N (52.5MPa)/ASTM-C 150 type–1, and best quality coarse sand (F.M. 2.2) including, the supply of all materials, cutting, binding of one layer of 20 BWG galvanized wire mesh having minimum yield strength fy = 450 MPa & having 2 mesh per 25 mm in both ways, clear cover 12 mm at the middle of the ferrocement lining, with washing of sand, chipping, cleaning the surface, watering, grouting, casting, laying on proper level of roof top or floor in panels (1.25 m x 1.25 m). Compaction including leveling, curing at least for 21 days including cost of water, electricity, in all respect as per drawing, design and accepted by the Engineer-in-charge. sqm Tk. 1,265.00 17.5.2 25 mm thick ferrocement treatment work for heat and water proofing on roof having minimum cement content relates to mix ratio 1:2 cement conforming to BDS EN-197-1CEM-I, 52.5N (52.5MPa)/ASTM-C 150 type–1, and best quality coarse sand (F.M. 2.2) including, the supply of all materials, cutting, binding of one layer of 20 BWG galvanized wire mesh having minimum yield strength fy = 450 Mpa & having 2 mesh per 25mm in both ways, clear cover 12mm at the middle of the ferrocement lining, applying 62 mm thick EPS sheet having density 15 kg per cum, with washing of sand, chipping, cleaning the surface, watering, grouting, casting, laying on proper level of roof top or floor in panels (1.25 m x 1.25 m). Compaction including leveling, curing at least for 21 days including cost of water, electricity, in all respect as per drawing, design and accepted by the Engineer-incharge. sqm Tk. 1,603.00 ………………….. END OF DIVISION SEVENTEEN ………………….. Unit Rate PWD SoR 2018 for Civil Works FALSE CEILING, WALL PANELING 144 DIVISION 18 : FALSE CEILING, WALL PANELING Item No. Description of Item Unit Unit Rate 18.1.1 Supplying, fitting and fixing plain particle board ceiling (complying unit wt 499 to 550 kg/m3, bending strength 0.35 N/mm2, max swelling 8%, moisture content not more than 10%), of 12 mm thick with best quality and well seasoned Garjan wood frame of section 75 mm x 38 mm at 600 mm x 600 mm in grid suspended from ceiling or roof or beam by 12 SWG double ply G.I. wire fixed to the ceiling by rowel plug, screws, hooks, nails etc, maintaining straight lines and desired finished level at bottom face including vertical strut as required, cutting holes in slabs or beams by electric drill machine and mending good the damages, if any during execution of the work, also including cost and carriage of all materials, accessories, labour for installation, electricity charge, scaffolding, screws, nails, painting 2 coats over a coat of priming with best quality and approved colour synthetic enamel paint etc. all complete, as per drawing design and accepted by the Engineer-incharge. (All sizes of wood are finished) sqm Tk. 2,913.00 18.1.2 Supplying, fitting and fixing plain particle board as in item 18.1.1. for ceiling of 12 mm for auditorium and other type of tall structures beyond 4 m up to 8 m, which do not cover the above item [Item No. 18.1.1]. Description of item is the same as in item No. 18.1.1 above. sqm Tk. 3,147.00 18.1.3 Supplying, fitting and fixing of 12 mm thick melamine board ceiling laminated by mechanical hot press milk white PVC membrane, framing by aluminium T-bar of natural anodized finish suspended in 600 mm x 600 mm grid from ceiling by 12 SWG double ply wire, fixed to the ceiling by rowel plug, screws, hooks, nails etc., maintaining straight lines and desired finished level at bottom face including vertical wooden strut as required, making holes in slabs or beams by electric drill machine and mending good the damages, if any during execution of the work, also including cost of all materials, electricity, accessories, scaffoldings, labour for installation, screws, nails, etc. all complete as per drawing, design and accepted by the Engineer-in-charge. sqm Tk. 1,765.00 18.2.1 Supplying, fitting and fixing gypsum board ceiling of 9 mm thick board laminated by mechanical hot press with milk white PVC membrane, framing by aluminium T-bar of natural anodized finish suspended in 600 mm x 600 mm grid from ceiling by 12 SWG double ply wire, fixed to the ceiling by rowel plug, screws, hooks, nails etc., maintaining straight lines and desired finished level at bottom face including vertical wooden strut as required, making holes in slabs or beams by electric drill machine and mending good the damages, if any during execution of the work, also including cost of all materials, electricity, accessories, scaffoldings, labour for installation, screws, nails, etc. all complete as per drawing, design and accepted by the Engineer-in-charge. sqm Tk. 2,130.00 18.2.2 Supplying, fitting and fixing veneered board ceiling of 12 mm thick board laminated by mechanical hot press with a milk white PVC membrane, framing by aluminium T-bar of natural anodized finish suspended in 600 mm x 600 mm grid from ceiling by 12 SWG double ply wire, fixed to the ceiling by rowel plug, screws, hooks, nails etc., maintaining straight lines and desired finished level at bottom face including vertical wooden strut as required, making holes in slabs or beams by electric drill machine and mending good the damages, if any during execution of the work, also including cost of all materials, electricity, accessories, scaffoldings, labour for installation, screws, nails, etc. all complete as per drawing, design and accepted by the Engineer-in-charge. sqm Tk. 2,546.00 PWD SoR 2018 for Civil Works FALSE CEILING, WALL PANELING Item No. 145 Description of Item Unit Unit Rate 18.2.3 Supplying, fitting and fixing of 9 mm thick perforated gypsum board false ceiling, framing by aluminium T-bar of natural anodized finish suspended in 600 mm x 600 mm grid from ceiling by 12 SWG double ply wire, fixed to the ceiling by rowel plug, screws, hooks, nails etc., maintaining straight lines and desired finished level at bottom face including vertical wooden strut as required, making holes in slabs or beams by electric drill machine and mending good the damages, if any during execution of the work, also including cost of all materials, electricity, accessories, scaffoldings, labour for installation, screws, nails, etc. all complete as per drawing, design and accepted by the Engineer-incharge. sqm Tk. 2,208.00 18.2.4 Supplying, fitting and fixing of best quality 6 mm thick PVC board false ceiling of size 600 mm x 600 mm of approved design, minimumn PVC content of 35%, framing by aluminium T-bar of natural anodized finish suspended in 600 mm x 600 mm grid from ceiling by 12 SWG double ply wire, fixed to the ceiling by rowel plug, screws, hooks, nails etc., maintaining straight lines and desired finished level at bottom face including vertical wooden strut as required, making holes in slabs or beams by electric drill machine and mending good the damages, if any during execution of the work, also including cost of all materials, electricity, accessories, scaffoldings, labour for installation, screws, nails, etc. all complete as per drawing, design and accepted by the Engineer-in-charge. sqm Tk. 3,153.00 18.2.5 Supplying, fitting and fixing of 0.6 mm thick best quality solid aluminium metal board false ceiling of size 600 mm x 600 mm, powder coated of approved design, framing by aluminium T-bar of natural anodized finish suspended in 600 mm x 600 mm grid from ceiling by 12 SWG double ply wire, fixed to the ceiling by rowel plug, screws, hooks, nails etc., maintaining straight lines and desired finished level at bottom face including vertical wooden strut as required, making holes in slabs or beams by electric drill machine and mending good the damages, if any during execution of the work, also including cost of all materials, electricity, accessories, scaffoldings, labour for installation, screws, nails, etc. all complete as per drawing, design and accepted by the Engineer-in-charge. sqm Tk. 2,936.00 18.2.6 Supplying, fitting and fixing of 0.6 mm thick best quality perforated aluminium metal board false ceiling of size 600 mm x 600 mm, powder coated of approved design, inner side is coverd by black tissue/ fabric to protect the hole from air circulation, framing by aluminium T-bar of natural anodized finish suspended in 600 mm x 600 mm grid from ceiling by 12 SWG double ply wire, fixed to the ceiling by rowel plug, screws, hooks, nails etc., maintaining straight lines and desired finished level at bottom face including vertical wooden strut as required, making holes in slabs or beams by electric drill machine and mending good the damages, if any during execution of the work, also including cost of all materials, electricity, accessories, scaffoldings, labour for installation, screws, nails, etc. all complete as per drawing, design and accepted by the Engineer-in-charge. sqm Tk. 2,676.00 18.2.7 Supplying, fitting & fixing of designed seamless false ceiling with 6 mm thick fiber cement board, framing by furring channel/ G. I. angle suspended in 600 mm x 600 mm grid from ceiling using G.I fitting angle, locking clips etc. including plastic paint of desired colour, cost of all materials, electricity, accessories, scaffoldings, labour for installation, screws, nails etc. all complete as per drawing, design and accepted by the Engineer-incharge. sqm Tk. 2,980.00 18.3.1 Supplying, fitting and fixing 12 mm thick burma teak (BT) veneered board in walling with best quality and well seasoned garjan wood frame of section 75 mm x 38 mm at 600 x 600 mm in grid, fitted and fixed to wall by plugs, nails, screws etc. including treatment of inner surface with termite and damp proofing agent maintaining leveled and finished exposed faces including. making holes in wall and mending good the damages, if any during execution of the work, also including cost and carriage of all materials, electricity, accessories, labour for installation, scaffolding, screws, nails etc. including french polishing by 3 coats over a coat of priming etc. all complete as per design, approved sample and accepted by the Engineer-in-charge. sqm Tk. 3,317.00 PWD SoR 2018 for Civil Works FALSE CEILING, WALL PANELING Item No. 146 Description of Item Unit 18.3.2 Supplying, fitting and fixing 12 mm thick particle board in walling with best quality and well seasoned Garjan wood frame of section 75 mm x 38 mm at 600 mm x 600 mm in grid, fitted and fixed to wall by plugs, nails, screws etc. including treatment of inner surface with termite and damp proofing agent maintaining leveled and finished exposed faces including. making holes in wall and mending good the damages, if any during execution of the work, also including cost and carriage of all materials, electricity, accessories, labour for installation, scaffolding, screws, nails etc. including french polishing by 3 coats over a coat of priming etc. all complete as per design, approved sample and accepted by the Engineer-in-charge. sqm Tk. 2,661.00 18.3.3 Supplying, fitting and fixing best quality wall paper along with 12 mm thick PVC solid board in walling with furring chanel frame of section 75 mm x 38 mm at 600 mm x 600 mm in grid, fitted and fixed to wall by plugs, nails, screws etc. including treatment of inner surface with termite and damp proofing agent maintaining leveled and finished exposed faces including making holes in wall and mending good the damages, if any during execution of the work, also including cost and carriage of wall paper and other materials, electricity, accessories, labour for installation, scaffolding, screws, nails etc. all complete as per design, approved and accepted by the Engineer-in-charge. sqm Tk. 3,706.00 18.3.4 Supplying, fitting and fixing best quality wall paper on finished plaster surface including cost and carriage of wall paper and other materials, electricity, accessories, labour for installation, scaffolding, screws, nails etc. all complete as per design, approved and accepted by the Engineer-in-charge. sqm Tk. 1,048.00 ………………….. END OF DIVISION EIGHTEEN ………………….. Unit Rate COLLAPSIBLE GATE, M.S. GATE, ROLLING SHUTTER ETC. PWD SoR 2018 for Civil Works 147 DIVISION 19 : COLLAPSIBLE GATE, M.S. GATE, ROLLING SHUTTER ETC. Item No. Description of Item Unit Unit Rate 19.1.1 Manufacturing, supplying, fitting and fixing collapsible gate of any design and shape made of 25 mm x 25 mm x 3 mm S.S. angle placed @ 112 mm c/c vertically and connecting the same with each other by 25 mm x 3 mm S.S flat bar scissors 525 mm/ 600 mm long provided in 3 rows including cutting the different S.S. members to required sizes, fabricating, welding, riveting with required size rivets, providing required size wheels, pulling handles on both sides, suitable locking arrangement, electrodes, grease and finally placing the same in position in between 2 (two) nos. 50 mm x 50 mm x 6 mm S.S. tee rail made by welding 2 nos. 50 mm x 6 mm S.S. flat bar fitted and fixed at top and bottom with R.C.C. lintel/roof slab, floors and side wall with required nos. 150 mm to 225 mm long 38 mm x 6 mm S.S. flat bar clamps one end welded with the gate member and the other end bifurcated and embedded in C.C. at the respective point including cutting holes and mending good the damages by pouring concrete (1:2:4) into the holes and finishing, both end carriage, including greasing, electrodes, curing etc. complete as per drawing and design and accepted by the Engineer-in-charge . sqm Tk. 17,525.00 19.1.2 Manufacturing, supplying, fitting and fixing collapsible gate of any design and shape made of 20 mm x 20 mm x 3 mm S.S. angle placed @ 112 mm c/c vertically and connecting the same with each other by 20 mm x 3 mm S.S flat bar scissors 525 mm/ 600 mm long provided in 3 rows including cutting the different S.S. members to required sizes, fabricating, welding, riveting with required size rivets, providing required size wheels, pulling handles on both sides, suitable locking arrangement, electrodes, grease and finally placing the same in position in between 2 (two) nos. 50 mm x 50 mm x 6 mm S.S. tee rail made by welding 2 nos. 50 mm x 6 mm S.S. flat bar fitted and fixed at top and bottom with R.C.C. lintel/roof slab, floors and side wall with required Nos. 150 mm to 225 mm long 38 mm x 6 mm S.S. flat bar clamps one end welded with the gate member and the other end bifurcated and embedded in C.C. at the respective point including cutting holes and mending good the damages by pouring concrete (1:2:4) into the holes and finishing, both end carriage, including greasing, electrodes, curing etc. complete as per drawing and design and accepted by the Engineer-in-charge. sqm Tk. 14,217.00 19.1.3 Manufacturing, supplying, fitting and fixing collapsible gate of any design and shape made of 25 mm x 25 mm x 3 mm M.S. angle placed @ 112 mm c/c vertically and connecting the same with each other by 25 mm x 3 mm M.S flat bar scissors 525 mm/ 600 mm long provided in 3 rows including cutting the different M.S. members to required sizes, fabricating, welding, riveting with required size rivets, providing required size wheels, pulling handles on both sides, suitable locking arrangement, electrodes, grease and finally placing the same in position in between 2 (two) Nos. 50 mm x 50 mm x 6 mm M.S. tee rail made by welding 2 nos. 50 mm x 6 mm M.S. flat bar fitted and fixed at top and bottom with R.C.C. lintel/roof slab, floors and side wall with required nos. 150 mm to 225 mm long 38 mm x 6 mm M.S. flat bar clamps one end welded with the gate member and the other end bifurcated and embedded in C.C. at the respective point including cutting holes and mending good the damages by pouring concrete (1:2:4) into the holes and finishing, etc complete, painting 2 (two) coats with approved best quality synthetic enamel paint over a coat of anticorrosive painting, both end carriage, including greasing, electrodes, curing etc. complete as per drawing and design and accepted by the Engineer-in-charge. (Rate is excluding the cost of painting) sqm Tk. 5,299.00 COLLAPSIBLE GATE, M.S. GATE, ROLLING SHUTTER ETC. Item No. PWD SoR 2018 for Civil Works 148 Description of Item Unit Unit Rate 19.1.4 Manufacturing, supplying, fitting and fixing collapsible gate of any design and shape made of 20 mm x 20 mm x 3 mm M.S. angle placed @ 112 mm c/c vertically and connecting the same with each other by 20 mm x 3 mm M.S flat bar scissors 525 mm/ 600 mm long provided in 3 rows including cutting the different M.S. members to required sizes, fabricating, welding, riveting with required size rivets, providing required size wheels, pulling handles on both sides, suitable locking arrangement, electrodes, grease and finally placing the same in position in between 2 (two) nos. 50 mm x 50 mm x 6 mm M.S. tee rail made by welding 2 nos. 50 mm x 6 mm M.S. flat bar fitted and fixed at top and bottom with R.C.C. lintel/roof slab, floors and side wall with required Nos. 150 mm to 225 mm long 38 mm x 6 mm M.S. flat bar clamps one end welded with the gate member and the other end bifurcated and embedded in C.C. at the respective point including cutting holes and mending good the damages by pouring concrete (1:2:4) into the holes and finishing, etc complete, painting 2 (two) coats with approved best quality synthetic enamel paint over a coat of anticorrosive painting, both end carriage, including greasing, electrodes, curing etc. complete as per drawing and design and accepted by the Engineer-in-charge. (Rate is excluding the cost of paint). sqm Tk. 4,494.00 19.2.1 Supplying, fitting, fixing, and installation of ordinary type M.S. gate (double leaf) of any design and shape with 38 x 38 x 6 mm M.S. Angle outer frame having 16 mm dia M.S. rod placed vertically @ 75 mm c/c. at bottom part and top part (200 mm long arrows) and also placed horizontally at bottom for interconnection of 16 mm dia M.S. rod placed vertically as per design, the top part covered with 18 BWG M.S. sheet and fixed with 4 nos. 38 mm x 6 mm F.I. bars placed diagonally and 4 Nos. 38 mm x 6 mm F.I. bars placed horizontally and vertically all passing through the center, providing locking arrangements on 3 mm thick M.S. plate one for main gate and one for minimum 600 mm x 1025 mm pocket gate with 38 mm x 38 mm x 6 mm M.S. angle and 16 mm dia M.S. rod placed vertically @ 75 mm c/c, providing 38 mm x 38 mm x 6 mm M.S. angle clamps fitted and fixed with the outer frame of the main gate, the clamp being embedded in R.C.C. or R.C.C. core pillar with cement concrete (1:2:4) in masonry including cutting holes and mending good the damages, finishing, curing etc. including riveting, welding as and where necessary, painting two coats with approved quality of synthetic enamel paint over a coat of priming of anti-corrosive paint etc. all complete as per drawing, design and accepted by the Engineer-in-charge(Rate is excluding the cost of paint). sqm Tk. 6,036.00 19.2.2 Manufacturing, supplying and fitting-fixing security door with 25 mm dia M.S. rod and outer frame with 50 mm x 50 mm x 6 mm M.S. angle including locking arrangement as per approved design and drawing providing 38 mm x 38 mm x 6 mm M.S. angle clamps fitted and fixed with the outer frame of the main gate, the clamp being embedded in R.C.C. or R.C.C. core pillar with cement concrete (1:2:4) in masonry including cutting holes and mending good the damages, finishing, curing etc. including riveting, welding as and where necessary, painting two coats with approved quality of synthetic enamel paint over a coat of priming of anti-corrosive paint etc. all complete as per drawing, design and accepted by the Engineer-in-charge. (Rate is excluding the cost of paint). sqm Tk. 10,767.00 19.3 Supplying, fitting, fixing, and installation of ordinary type M.S. security gate of any design and shape with 50 mm x 50 mm x 6 mm M.S. angle outer frame and 02 (two) 50 mm x 50 mm x 6 mm angle placed diagonally having 22 mm dia M.S. rod placed vertically @ 115 mm c/c. and also 38 mm x 6 mm F.I placed horizontally, the bottom part covered with 3 mm thick M.S. sheet providing locking arrangements on 3 mm thick M.S. plate providing heavy type clamps fitted and fixed with the outer frame of the main gate, the clamp being embedded in R.C.C. or R.C. core pillar with cement concrete (1:2:4) in masonry including cutting holes and mending good the damages, finishing, curing etc. including fabrication, riveting, welding as and where necessary, etc. all complete as per drawing, design and accepted by the Engineer-in-charge. sqm Tk. 5,283.00 COLLAPSIBLE GATE, M.S. GATE, ROLLING SHUTTER ETC. Item No. PWD SoR 2018 for Civil Works 149 Description of Item Unit Unit Rate 19.4 Supplying, fitting, fixing and installation of ordinary type M.S. gate (double leaf) of any design and shape with 38 mm x 38 mm x 6 mm M.S. angle box (made by welding 2 nos. 38 mm x 38 mm x 6 mm angle) outer frame having 25 mm x 50 mm x 25 mm x 5 mm M.S. channel (made by welding 2 nos. of channel) placed part diagonally after cutting and shaping as per requirement, part horizontally @ 75 mm c/c, the two part of each leaf being separated by a vertical member of 38 mm x 38 mm x 6 mm M.S. box and welded the each ends of diagonal and horizontal members properly with the box frame as per architectural drawing providing full locking arrangement on 3 mm thick M.S. plates providing 38 mm x 38 mm x 6 mm M.S. angle clamps, fitting fixing with the outer frame of the gate, the clamp being embedded in R.C.C. pillars with cement concrete (1:2:4) including. cutting holes and mending good the damages, finishing, curing and where necessary painting two coats with approved quality of synthetic enamel paint over a coat of priming of anticorrosive paint etc. all complete including making and providing 50 mm x 6 mm M.S. rail and 38 mm wheel for smooth movement of the gate etc. all complete as per drawing, design and accepted by the Engineer-in-charge. [Rate is excluding the cost of painting] sqm Tk. 7,843.00 19.5 Manufacturing, supplying, fitting and fixing G.I. pipe gate of any design and shape having 38 mm dia G.I. pipe outer frame and 19 mm dia. G.I. pipe vertical member placed @ 75 mm c/c by welding at top and bottom of G.I. pipe frame, cutting the pipes in proper shape and size including making semicircular band at the corners of the outer frame without damaging the pipe, covering 50% of the gate area with 18 BWG M.S. sheet, providing also two extra horizontal 38 mm dia G.I. pipes welded with vertical post, providing 6 nos. huskle domney with R.C.C. or R.C.C core pillar with cement concrete (1:2:4) in masonry including cutting holes, mending good the damages, making provision for minimum 0.61 m x 1.4 m pocket gate having its outer frame and inner vertical members made with 19 mm dia G.I. pipe including necessary locking arrangements. Painting the gate with 2 (two) coats of synthetic enamel paint over a coat of anti-corrosive priming, welding as and where necessary including necessary locking arrangement and providing 2 Nos. 16 mm M.S. socket bolts etc. all complete as per design and drawing and accepted by the Engineer-incharge. [Rate is excluding the cost of painting] sqm Tk. 9,011.00 19.6 Supplying, fitting and fixing of rolling shutter of any design and shape made of 24 SWG G.P. sheet unit minimum 69 mm width having 10 mm and 12 mm dia circular folding at ends, rolled in machine, locked together properly to form rolling shutter, top of the shutter to be fitted with circular spring box made of 22 BWG sheet, containing best quality spring made in China, nutted with 38 mm G.I. pipe at one end and the other end nutted to shutter including fitting the G.I. pipe again with 375 mm x 300 mm x 6 mm pankha at ends with side guide channel (side channel consist of 50 mm x 100 mm x 6 mm M.S. plate with 2 mm x 19 mm x 3 mm F.I. bar, middle channel consist of 2 mm x 150 mm x 6 mm M.S. plate with 2 mm x19 mm x 6 mm fixed to wall or column with clamps embedded in R.C.C. part by cement concrete (1:2:4) including cutting holes (minimum 3 mm x 25 mm x 6 mm) mending the damages, finishing, curing, bottom end of shutter fitted to folded G.P. sheet (min 125 mm width in two layers), which is again fitted to 25 mm x 25 mm x 3 mm angle, providing handle with F.I. bar 25 mm x 6 mm and locking arrangement in both sides, painting two coats with approved colour and brand of synthetic enamel paint over a coat of priming etc. complete in all respect accepted by the Engineer-in-charge. [Rate is excluding the cost of painting] sqm Tk. 5,461.00 COLLAPSIBLE GATE, M.S. GATE, ROLLING SHUTTER ETC. Item No. 19.7 PWD SoR 2018 for Civil Works Description of Item Unit Manufacturing, supplying, fitting, fixing of ordinary type M.S. folding gate with 12mm x 12mm MS square solid bar and 25 mm x 25mm x 6 mm MS angle box frame and two nos outer side fixed box post made with 40 mm x 40 mm x 6 mm angle at both ends attached to column/wall side including locking arrangement providing 38 mm x 38 mm x 6 mm M.S. angle clamps fitted and fixed with the outer frame of the main gate, the clamp being embedded in R.C.C. or R.C.C. core pillar with cement concrete (1:2:4) in masonry including cutting holes and mending good the damages, finishing, curing etc. including riveting, welding as and where necessary, painting two coats with approved quality of synthetic enamel paint over a coat of priming of anti-corrosive paint etc. all complete as per drawing, design and accepted by the Engineer-in-charge. (Rate is excluding the cost of paint) sqm ………………….. END OF DIVISION NINETEEN ………………….. 150 Unit Rate Tk. 5,116.00 PWD SoR 2018 for Civil Works STAIR & VERANDAH RAILING AND STAIR NOSING 151 DIVISION 20 : STAIR & VERANDAH RAILING AND STAIR NOSING Item No. Description of Item Unit Unit Rate 20.1 Manufacturing, supplying, fitting and fixing of stair railing of any standard height of any design and shape with square box (2 nos.in each tread) made by thorough welding of 2 nos. 19 mm x 19 mm x 3 mm M.S. angle to provide hand-rail, engraving each box 150 mm in the concrete by 50 mm x 50 mm x 6 mm anchor plate at base, welding 38 mm x 6 mm F.I. bar inclined plain with the top of the box to fit in the grooved wooden rail by necessary screws including cutting grooves in concrete, mending good the damages with cement concrete (1:2:4), applying first class polish to hand rail, 2 (two) coats of synthetic enamel paint of approved quality over a prime coat etc. finished in all respect for all floors and accepted by the Engineer-in-charge.(Exposed area of railing will be considered for measurement, rate is excluding the cost of hand-rail and cost of painting). sqm Tk. 3,441.00 20.2 Manufacturing, supplying, fitting and fixing of stair railing of standard height of any design and shape with square box (2 nos. box in each tread) made by thorough welding of 2 nos. 25 mm x 25 mm x 5 mm M.S. angle, engraving each box 150 mm in the concrete by 50 mm x 50 mm x 6 mm anchor plate at base, welding 50 mm x 50 mm x 6 mm F.I. bar in inclined plain with the top of the box fitted in the grooved wooden rail and 2 Nos. 225 mm x 25 mm finished section of wooden strip fitted and fixed at mid height of railing at both side of M.S. angle box in inclined plain parallel to the hand rail etc. fitted and fixed by necessary screws, nails including cutting grooves in concrete, mending good the damages with cement concrete (1:2:4) applying 1st class french polish to wooden hand rail and inclined wooden strip and painting to F.I bar and square box with 2 (two) coats of synthetic enamel paint of approved quality and colour over a prime coat etc. complete in all respect for all floors and accepted by the Engineer-in-charge. sqm Tk. 6,614.00 20.3 Supplying, fitting and fixing 12 mm dia G.I pipe stair railing of any standard height of any design and shape with 50 mm x 50 mm x 6 mm M.S. plate at the base of 12 mm dia G.I. Pipe and fitted and fixed by welding. Placing the pipes vertically @ 250 mm c/c (1 nos. in each steps) 150 mm embedded into the R.C.C tread of stair case after cutting grooves and mending good the damages with C.C. and providing 38 mm x 6 mm F.I. bar on the top of G.I. pipe to provide wooden hand rail of any design including polishing, painting etc. all complete and accepted by the Engineer-in-charge. (Exposed area of railing will be considered for measurement, rate is excluding the cost of paint, wood for railing) 20.3.1 With the provision of hand rail of size: 150 mm x 62 mm (finished) sqm Tk. 2,193.00 20.3.2 With the provision of hand rail of size: 112 mm x 62 mm (finished) sqm Tk. 2,895.00 20.4 Supplying, fitting and fixing stainless steel (SS) stair railing of standard height with 2 mm thick 62 mm dia pipe for hand-rail, 2 mm thick 40 mm dia 5 nos vertical pipes in each flight, 2 mm thick 20 mm dia 5 nos horizontal pipes as per drawing, design including carrying, polishing fabricating, welding and fixing with tread by 25 mm long royal bolt etc. all complete and accepted by the Engineer-in-charge. sqm Tk. 5,361.00 20.5.1 Supplying, fitting and fixing of 12 mm dia G.I pipe stair railing of any standard height and design and shape with 50 mm x 50 mm x 6 mm M.S. plate at the base of 12 mm dia G.I. Pipe and fitting & fixing by welding. Placing the pipes vertically @ 125 mm c/c (2 nos. in each steps) 150 mm embedded into the R.C.C tread of stair case after cutting grooves and mending good the damages with C.C. and providing 38 mm x 6 mm F.I. bar on the top of G.I. pipe to provide 37 mm G.I. pipe hand rail of any design including polishing, painting etc. all complete and accepted by the Engineer-in-charge.(Exposed area of railing will be considered for measurement, rate is excluding the cost of paint, wood for railing) sqm Tk. 3,736.00 PWD SoR 2018 for Civil Works STAIR & VERANDAH RAILING AND STAIR NOSING Item No. 152 Description of Item Unit Unit Rate 20.5.2 Supplying, fitting and fixing 12 mm dia G.I pipe stair railing of any standard height of any design and shape with 50 x 50 x 6 mm M.S. plate at the base of 12 mm dia G.I. Pipe and fitting & fixing by welding. Placing the pipes vertically @ 125 mm c/c (2 nos. in each steps) 150 mm embedded into the R.C.C tread of stair case after cutting grooves and mending good the damages with C.C. and providing 38 mm x 6 mm F.I. bar on the top of G.I. pipe to provide 50 mm G.I. pipe hand rail of any design including polishing, painting etc. all complete and accepted by the Engineer-in-charge.(Exposed area of railing will be considered for measurement, rate is excluding the cost of paint, wood for railing) sqm Tk. 20.6 Supplying, fitting and fixing verandah railing with 2 mm thick 50 mm dia SS hand rail, 2 mm thick 20 mm dia 5 nos SS horizontal pipes, 2 mm thick 50 mm x 25 mm SS box vertical post @ 450 mm c/c. Among the vertical box post 5 nos box posts will be fitted with floor bed by 65 mm x 55 mm x 6 mm SS plate, remaining no SS box post will be fitted and fixed with 50 mm x 25 mm x 2 mm SS horizontal box at bottom (50 mm above from floor bottom) including all fittings, fixtures, polishing, carrying etc. all complete as per approved design and drawing and accepted by the Engineer-in-charge. sqm Tk. 10,268.00 20.7 Supplying, fitting and fixing 10 mm thick tempered glass railing in stair with 62 mm dia 2 mm thick SS pipe for hand rail, 5 nos 62 mm x 50 mm x 2 mm vertical pipe in each flight fitted and fixed with 65 mm x 55 mm x 6 mm SS base plate including welding, bending, fabricating, polishing all complete as per drawing, desing and specification etc all complete in all respect and accepted by Engineer-in-charge. sqm Tk. 20.8 Supplying, fitting and fixing 10 mm thick tempered glass railing in verandah with 62 mm dia 2 mm thick SS pipe for hand rail, 5 nos 62 mm x 50 mm x 2 mm vertical box fitted with concrete slab by 65 mm x 55 mm x 6 mm SS plate @ 600 mm c/c including all fittings, fixtures as per drawing, desing and specification etc all complete in all respect and accepted by Engineer-in-charge. sqm Tk. 11,717.00 20.9 Providing nosing to the nose of tread of stair including supplying 3 nos. of 75 mm long 12 mm x 3 mm F.I./SS bar clamps with bifurcated ends in each treads including fitting and fixing with the angle by welding and fitting and fixing the angle by cutting grooves in R.C.C, fixing and finishing and the same with C.C. (1:2:4) etc. cost of electricity and other charges all complete and accepted by the Engineer-in-charge. 20.9.1 Providing 38 mm x 38 mm x 6 mm M.S. angle to the nosing of steps of staircase meter Tk. 372.00 20.9.2 Providing nosing 32 mm x 32 mm x 6 mm M.S. angle to the nosing of steps of stair case. meter Tk. 327.00 20.9.3 Providing 25 mm x 25 mm x 6 mm size M.S. angle to the nosing of stair case. meter Tk. 283.00 20.9.4 Providing 38 mm x 38 mm x 6 mm brass angle to the nosing of steps of stair case meter Tk. 1,439.00 20.9.5 Providing 38 mm x 38 mm x 6 mm S.S. angle to the nosing of steps of staircase meter Tk. 1,252.00 20.9.6 Providing 32 mm x 32 mm x 6 mm S.S. angle to the nosing of steps of stair case.. meter Tk. 1,002.00 20.9.7 Providing 25 mmx 25 m x 6 mm size S.S. angle to the nosing of stair case. meter Tk. 919.00 20.10 Supplying, fitting & fixing of column guard made of 50 mm x 50 mm x 6 mm M.S. angle around column & 50 mm x 6 mm F.I. bar for Tie at the top including fitting and fixing with the angle by welding, fitting and fixing the angle by cutting grooves in R.C.C, fixing and finishing the same with C.C. (1:2:4) etc. cost of electricity and other charges all complete and accepted by the Engineer-in-charge. meter Tk. 504.00 4,333.00 9,787.00 PWD SoR 2018 for Civil Works STAIR & VERANDAH RAILING AND STAIR NOSING Item No. 20.11 Description of Item Unit Supplying, fitting & fixing of column guard made of 75 mm x 75 mm x 3 mm S.S. angle at corner of column including supplying 3 Nos. of 75 mm long 12 mm x 3 mm SS bar clamp with bifurcated ends, fitting and fixing with the angle by welding, fitting and fixing the angle by cutting grooves in R.C.C, fixing and finishing the same with C.C. (1:2:4) etc. cost of electricity and other charges all complete and accepted by the Engineer-in-charge. meter ………………….. END OF DIVISION TWENTY ………………….. 153 Unit Rate Tk. 1,633.00 PWD SoR 2018 for Civil Works GRILL FENCING AND BARBED WIRE FENCING 154 DIVISION 21 : GRILL FENCING AND BARBED WIRE FENCING Item No. Description of Item Unit Unit Rate 21.1 Supplying, fitting and fixing steel grill fencing of any design and shape in boundary wall with 31 mm x 6 mm F.I. bar @ 150 mm c/c placed vertically after cutting as per required measurement. Welding the said F.I. bar with 2 nos. horizontal 30 mm x 6 mm F.I. bar placed one at top and another at bottom including embedding/fixing the horizontal F.I. bar in position with cutting grooves in wall up to 150 mm depth and mending good the damages with C.C. (1:2:4), finishing with two coats of painting with synthetic enamel paint over a coat of anti-corrosive paint etc. complete as per drawing and design and accepted by the Engineer-in-charge. (Rate is excluding the cost of painting) sqm Tk. 2,173.00 21.2 Supplying, fitting and fixing steel grill fencing of any design and shape made with 19 mm x 6 mm box tube (box made with 2 nos.19 mm x 19 mm x 6 mm angle by continuous welding) placed vertically @ 150 mm c/c and welding the said vertical boxes with two Nos. horizontal 25 x 25 x 6 mm angle box (made with 2 Nos. 25 x 25 x 6 mm angle by welding), placing one at bottom and another at top and again fitting & fixing by welding the said horizontal tube box (with vertical 38 mm x 38 mm x 6 mm angle box post made with 2 nos. 38 mm x 38 mm x 6 mm angle by welding) provided @ 1800 mm c/c including embedding the tube box post in brick R.C.C. pillar or core wall up to 375 mm depth after cutting grooves in wall/pillar including mending good the damages with C.C. (1:2:4) and finishing, curing, 2 coats of approved synthetic enamel paint over a coat of anti-corrosive paint etc. all complete as per design, drawing and accepted by the Engineer-in-charge. (Rate is excluding the cost of painting) sqm Tk. 4,685.00 21.3 Manufacturing, supplying, fitting and fixing M.S. grill fencing as per design with outer frames having 38 mm x 38 mm x 6 mm M.S. angle and inner members having 6 mm dia M.S. rod placed @ 110 mm c/c diagonally on both direction, welding each cris-cross end of rod with corners of outer frame including cutting rods and size angles to required shapes and size and setting the entire fence with the previously installed box tube (box tube made with 2 nos. angle) post including thorough and full welding the frame with the angle box posts, painting 2 coats of synthetic enamel paint over a coat of anti-corrosive priming etc. all complete as per drawing and accepted by the Engineer-in-charge.(Rate is excluding the cost of angle box tube post and its installation and excluding the cost of paint) sqm Tk. 2,431.00 21.4 Manufacturing, supplying, fitting and fixing M.S. box tube (made with 2 nos angle) post (bottom end bifurcated) made by thorough welding of two Nos. 38 x 38 x 6 mm M.S. angle and vertically placing the post into C.C. or R.C.C. foundation including cutting angle to required shape and size including covering the top of the post with 6 mm thick M.S. plate etc. all complete as per drawing and accepted by the Engineer-in-charge.(Rate is excluding the cost of C.C./R.C.C. foundation and paint) sqm Tk. 934.00 21.5 Providing barbed wire fencing with R.C.C (1:2:4) pillars @ 2.43 m c/c. and of section 100 mm x 100 mm at top and 150 mm x 150 mm at bottom of 2.13 m total height (1.37 m above G.L. and 0.76 m below G.L.) including 150 mm thick, 450 mm square spread footings (pillars reinforced with 4 Nos. 10 mm dia main rod and 6 mm dia stirrups @ 150 mm c/c, footing reinforced with 5 Nos. 10 mm dia rod both ways) supplying, fitting and fixing 8 lines of barbed wire horizontally (fixed with the post through 6 mm dia rods embedded in to the post) and 2 lines diagonally from post to post with 12 BWG 2 ply barbed wire, with 4 points barbs @ at least 112 mm c/c including 6 mm thick (1:4) cement plaster up to 1500 mm length of the pillars etc. complete and accepted by the Engineerin-charge. (Rate is excluding the cost of concrete and reinforcement which is to be paid as per corresponding items in the schedule) sqm Tk. 155.00 PWD SoR 2018 for Civil Works GRILL FENCING AND BARBED WIRE FENCING Item No. 155 Description of Item Unit 21.6 Providing barbed wire fencing with average 100 mm dia best quality local ballah post of 1.98 m total height (1.37 m above G.L. and minimum 0.60 m embedded in the ground) placed at 1800 mm c/c with 9 nos. horizontal lines and 2 nos. diagonal lines of 12 BWG 2 ply barbed wire with 4 points barbs @ at least 112 mm c/c in each way of 1.8 m including embedding the post tightly in ground and providing a cement concrete base of 200 mm x 200 mm x 300 mm around ballah at E.G.L, stretching the wires and fixing with the post with the help of minimum 62 mm long G.I. nails including supply of all materials etc. all complete and accepted by the Engineer-in-charge. (Rate is excluding the cost of ballah and its driving/fixing and concrete which is to be paid as per corresponding items in the schedule) sqm Tk. 270.00 21.7 Supplying, fitting and fixing 12 BWG barbed wire (2 ply, 4 points) in fencing work @ 150 mm c/c in both horizontally and vertically, supported by 38 mm x 38 mm x 6 mm M.S. L-shape angle post (300 mm embedded in R.C.C. or in brick work with a cement concrete base of 75 mm x 75 mm x 300 mm) 600 mm vertical and 450 mm inclined or as per requirement @ 2.4 m c/c including straightening, binding the joints with 18 BWG wire, making holes in the angle etc. including supplying all necessary materials complete in all respect and accepted by the Engineer-in-charge. (Rate is excluding the cost of R.C.C or brick work or C.C. which is to be paid as per corresponding items in the schedule) sqm Tk. 831.00 21.8 Supplying, fitting and fixing 12 BWG barbed wire (2 ply, 4 points) in fencing work @ 150 mm c/c both horizontally and vertically, supported by 38 mm x 38 mm x 6 mm M.S. Y-shape angle post (300 mm embedded in R.C.C. or in brick work with a cement concrete base of 75 mm x 75 mm x 300 mm) 600 mm vertical and 450 mm inclined or as per requirement @ 2.4 m c/c including straightening, binding the joints with 18 BWG wire, making holes in the angle etc. including supplying all necessary materials complete in all respect and accepted by the Engineer-in-charge. (Rate is excluding the cost of R.C.C or brick work or C.C. which is to be paid as per corresponding items in the schedule) sqm Tk. 887.00 21.9 Supplying, fitting and fixing 12 BWG barbed wire fencing in a circular shape of 600 mm dia and 76 mm pitch fitted with MS rod casing (made by 8 nos. 10 mm dia plain bar in a circular pattern and placed at equal interval ), 38 x 38 x 6 mm M.S. angle post (300 mm embedded in R.C.C. or in brick work with a cement concrete base of 75 mm x 75 mm x 300 mm) and 600 mm vertical and 450 mm inclined placed @ 3.0 m c/c including straightening, binding the joints with 18 BWG wire, making holes in the angle etc. including supply of all necessary materials complete in all respect and accepted by the Engineer-incharge. (Rate is excluding the cost of R.C.C or brick work or C.C. which is to be paid as per corresponding items in the schedule) meter Tk. 2,427.00 ` ………………….. END OF DIVISION TWENTY ONE ………………….. Unit Rate PWD SoR 2018 for Civil Works MISCELLANEOUS ITEMS 156 DIVISION 22 : MISCELLANEOUS ITEMS Item No. Description of Item Unit Unit Rate 22.1 Supplying, fitting and fixing of wooden wedge (12 mm base x 12 mm height) instead of putty for fixing glass panes with wooden frame by nails or by any other approved method including the cost of necessary wood, painting/polishing, nails etc. and excluding the cost of wooden frame, and painting and 5 mm thick glass panes all complete and accepted by the Engineer-in-charge. meter Tk. 68.00 22.2 Supplying, fitting and fixing of 20 mm dia foreign made aluminium pipe curtain rail for door and window including cutting and fitting fixing as per required measurement and supplying necessary screws, electric drill and rowel plug including charge of electricity etc. complete and accepted by the Engineer-in-charge. meter Tk. 655.00 22.3 Supplying, fitting and fixing 10 mm thick clear tempered glass door including all accessories, 1 set floor mounted auto door closure, special quality 2 nos clamping devices, 1 set locking device, top hinge and handle etc. complete in all respect as per drawing and direction of the Engineer-in-charge. sqm Tk. 15,604.00 22.4 Supplying, fitting and fixing 10 mm thick clear glass partition with 44 mm, 44 mm, 1.5 mm aluminium box, protector bit (single), protector bit (double) including all accessories etc. all complete and as per drawing and direction of the Engineer-in-charge. sqm Tk. 2,861.00 22.5 Supplying, fitting and fixing of C.T wood strip (62 mm x 25 mm x 20 mm) for fixing of aluminium curtain rails as per design and drawing, fitting and fixing coat of priming etc. all complete and accepted by the Engineer-in-charge.(Rate is excluding the cost of polishing and painting etc.) meter Tk. 743.00 22.6 Supplying, fitting and fixing vertical venetian blinds made with glass fiber fabrics (foreign made) with supply of all materials (foreign made) such as head rail (aluminium), end capset, rod tilt, sigger (stopper), runner, spacer (link), handling cord, ball chain, link chain, cord-weight weight-plate plastic washer, glass fiber fabrics, and head cap-set etc. all complete and accepted by the Engineer-in-charge. sqm Tk. 1,896.00 22.7 Supplying, fitting and fixing horizontal venetian blinds of 25 mm width made with aluminium foils/ strips (foreign made) with supply of all materials (foreign made) such as head rail, bottom rail, rod tilt, head cap, bottom cap, gear box, stick, support and cap, cord drum and support, bracket, cord lock, cord equalizer, top holder, ladder, cord, handling cord and aluminium foils etc. all complete and accepted by the Engineer-in-charge. sqm Tk. 1,440.00 22.8 Supplying, fitting and fixing of horizontal zebra blind made with polyester fabrics, synthetic net with 3 inch vinyl/upvc coated strips (foreign made) with supply of all materials (foreign made) such as head rail, bottom rail, rod tilt, head cap, bottom cap, gear box, stick, support and cap, cord drum and support, bracket, cord lock, cord equalizer, top holder, ladder, cord, handling cord and aluminium foils etc. all complete and accepted by the Engineer-in-charge. sqm Tk. 3,260.00 22.9 Supplying, fitting and fixing of blackout/ translucent roller blind of PVC/ vinyl laminated fiberglass fabrics (foreign made) with supply of all materials (foreign made) such as head rail (aluminium), end cap-set, rod tilt, sigger (stopper), runner, spacer (link), handling cord, ball chain, link chain, cord-weight weight-plate plastic washer, glass fiber fabrics, and head cap-set etc. all complete and accepted by the Engineer-in-charge. sqm Tk. 2,594.00 PWD SoR 2018 for Civil Works MISCELLANEOUS ITEMS Item No. 157 Description of Item Unit Unit Rate 22.10 Supplying, fitting & fixing of steel iron rack made of 50 mm x 50 mm x 6.35 mm vertical and horizontal angle post, welding 63.5 mm x 6.35 mm F.I. bar placed horizontally as bracing for the posts, 38 mm x 6.35 mm cross F.I. bars welded with vertical post, 12.7 mm thick M.S plate welded as cup shape at the bottom of post, supplying and fitting rivets, charge for welding, drilling, carrying, cutting, straightening in required sizes etc in all respect as per drawing, design and accepted by the Engineer-in-charge. sqm Tk. 9,578.00 22.11 Supplying fitting & fixing of uPVC plastic door or window frame having specific gravity 1.35 - 1.45, and other physical, chemical, thermal, fire resistivity properties etc. as per BSTI approved manufacturer standards or ASTM, BS/ISO/IS standards fitted and fixed in brick wall/ R.C.C wall with 6 Nos. GI clamp, 4 nos inner joint GI clamp, 2 nos. outer GI joint clamp, 16 nos. rivet making necessary grooves and mending good the damages, finishing, curing, carriage etc complete in all respect accepted by the Engineer-in-charge. meter Tk. 278.00 22.12 Supplying, fitting, fixing of uPVC hollow or solid plastic door shutter having specific gravity of 1.35 - 1.45, thickness 1.7 mm-2.2 mm, and other physical, chemical, thermal, fire resistivity properties etc. as per BSTI approved manufacturer standards or ASTM, BS/ISO/IS standards of different sizes, fitted fixed with uPVC plastic door frame weighing 5.82 kg/m2 with at least 3 Nos. SS hinges by min 64 Nos. Ø 3.17 mm and 3.97 mm 12.7 mm long rivets, 12 nos. 25.4 mm SS screws, Ø 9.38 mm, 150 mm long SS tower bolts 2 nos., 146 mm SS handle by rivet 2 Nos., G.I inner joint, 234.95 mm x 127 mm clamp, 76.2 mm x 57.15 mm, 25 mm dia 1 no ss haspbolt, special type round lock, carrying the same to the site and local carriage etc. complete in all respect and accepted by the Engineer-incharge. 22.12.1 760 mm x 1980 mm uPVC plastic shutter (hollow). each Tk. 3,650.00 22.12.2 760 mm x 2130 mm uPVC plastic shutter (solid). each Tk. 3,762.00 22.12.3 910 mm x 2130 mm uPVC plastic shutter (hollow). each Tk. 3,955.00 22.12.4 990 mm x 2130 mm uPVC plastic shutter (solid). each Tk. 4,130.00 22.13 Supplying, fitting & fixing of uPVC plastic or glass partition in plastic frame fabricated by 70 mm x 50 mm x 2 mm T and 50 mm x 40 mm x 2 mm / 50 mm x 30 mm x 2 mm Lsections, providing partition with 156 mm x 25 mm uPVC hollow section having wall thickness of 2.5 mm / partition with 5 mm thick glass. physical, chemical, thermal, fire resistivity properties etc of the materials as per BSTI approved manufacturer standards or ASTM, BS/ISO/IS standards, fitted and fixed in brick wall or R.C.C wall with 6 nos. GI clamps, 4 nos. inner joint GI clamps, 2 nos. outer GI joint clamps, 16 nos. rivets, making necessary grooves and mending good the damages, finishing, curing, carriage etc complete in all respect and accepted by the Engineer-in-charge. 22.13.1 With partition of uPVC hollow section sqm Tk. 2,666.00 22.13.2 With 5 mm glass sqm Tk. 2,175.00 22.14 Supplying, fitting & fixing of uPVC Profile for door, window and fixed partition frames applications having specific gravity of 1.36-1.43, and other physical, chemical, thermal, fire resistivity properties etc. as per BSTI approved manufacturer standards or ASTM, BS/ISO/IS standards including all accessories, fittings with 6 nos. steel clamps complete in all respect as per drawing and accepted by the Engineer-in-charge. meter Tk. 527.00 PWD SoR 2018 for Civil Works MISCELLANEOUS ITEMS Item No. Description of Item Unit 158 Unit Rate 22.15 Supplying, fitting & fixing of swing door shutter made of low density free foam (LDFF) sheet having standard size 1200 mm x 3200 mm. Physical properties: density: 0.55-0.68 g/cm3, weighing 1.3 kg/sft, providing new sash (100 mm), sliding glass bead, rubber, screws, 75 mm hinges 4 Nos., 100 mm tower bolt 2 Nos., 150 mm handle 2 nos. etc. including all accessories complete in all respect as per drawing and accepted by the Engineer-in-charge. 22.15.1 1950 mm x 750 mm size 8 mm thick uPVC swing door shutter each Tk. 22.15.2 2100 mm x 750 mm size 8 mm thick uPVC swing door shutter each Tk. 10,109.00 22.15.3 2100 mm x 900 mm size 8 mm thick uPVC swing door shutter each Tk. 10,387.00 22.16 Supplying, fitting & fixing of plastic wall paneling with 3 mm sheet, weighing 0.188 kg/sft, fitting and mending good the damages, carriage to the site including glass bead, partition frame, rubber, 5 mm clear glass fitted and fixed with screws, steel clamp etc all complete and accepted by the Engineer-in-charge. sqm Tk. 1,268.00 22.17 Supplying, fitting & fixing of uPVC profile fixed partition with 5 mm clear glass, weighing 1.032 kg/sft, fitting and mending good the damages, carriage etc. complete in all respect and accepted by the Engineer-in-charge. sqm Tk. 3,385.00 22.18. Supplying, fitting & fixing of uPVC profile sliding window having gross weight of 14.00 kg/sqm (including 5 mm glass) fitting and mending good the damages, carries etc complete in all respect accepted by the Engineer-in-charge. 22.18.1 uPVC sliding window with 5 mm glass (1200 mm x 1200 mm size) sqm Tk. 4,667.00 22.18.2 uPVC sliding window without glass (1200 mm x 1200 mm size) sqm Tk. 3,815.00 22.19 Supplying, fitting & fixing of plastic wood paneling in false ceiling with 6 mm sheet, weighing 3.85 kg/sqm, fitting and mending good the damages, carries etc complete in all respect and accepted by the Engineer-in-charge sqm Tk. 1,332.00 22.20 Supplying, fitting and fixing of approved quality 190 mm x 190 mm size glass bricks in round stair wall including all accessories & charges, complete in all respect and accepted by the Engineer-in-charge. sqm Tk. 14,910.00 22.21 Supplying, fitting & fixing 50 mm thick rock or glass wool padding of approved quality and accepted by the Engineer-in-charge. sqm Tk. 22.22 Manufacturing supplying, fitting and fixing of single leaf louver door shutter made with 16 gauge thick 50 mm x 50 mm SS hollow box as outer frame, 16 gauge thick 50 mm x 38 mm SS hollow box as pannel frame and 18 gauge thick 50 mm x 12 mm SS hollow box as louver with 150 mm long 12 mm dia SS handle, 300 mm long 20 mm dia ss hasp bolt, 100 mm hings etc, comple in all respect and accepted by the Engineering-in charge. sqm Tk. 22,545.00 22.23.1 Supplying, laying, fitting & fixing best quality 225 mm dia (internal) machine made R.C.C. pipe over 100 mm thick cement concrete (1:3:6) at base and sides including single brick flat soling and gasket with cement mortar (1:4) joints, cutting and filling trenches up to required depth including excavation of soil etc. all complete in all respect as per type plan and accepted by the Engineer-in-charge (average depth of trench is 1050 mm). (Cement: CEM-II/A-M) meter Tk. 9,832.00 3,843.00 1,359.00 PWD SoR 2018 for Civil Works MISCELLANEOUS ITEMS Item No. 159 Description of Item Unit 22.23.2 Supplying, laying, fitting & fixing best quality 300 mm dia (internal) machine made R.C.C. pipe over 100 mm thick cement concrete (1:3:6) at base and sides including single brick flat soling and gasket with cement mortar (1:4) joints, cutting and filling trenches up to required depth including excavation of soil etc. all complete in all respect as per type plan and accepted by the Engineer-in-charge (average depth of trench is 1050 mm).(Cement: CEM-II/A-M) meter Tk. 22.23.3 Supplying, laying and fitting-fixing 900 mm dia RCC pipe of approved quality and accepted by the Engineer-in-charge. [Rate is excluding cost for excavation, back-fill, materials for back-fill and bedding] meter Tk. 10,009.00 22.24 Supplying, making, fitting & fixing of R.C.C. door/window frame of 155 mm x 65 mm which is made by using M.S. rod (fy = 400 MPa) fabrication work with 24 BWG G.I. wire, steel formworks with minimum cement concrete relates mix ratio (1:2:4) having minimum f'cr = 27 MPa & satisfying a specified compressive strength, f'c= 22 MPa at 28 days and cement conforming to BDS EN-197-1-CEM-I, 52.5N (52.5MPa)/ ASTM-C 150 type–1, best quality 50% quantity of local sand (F.M. 1.2) and 50% quantity of coarse sand (F.M. 2.2), 6 mm down well graded stone chips, screening, making, placing in position, making shutter/formworks water-tight properly, jute hassian, polythene sheet, placing of 100 mm long welded iron hinges with 6 mm dia M.S. rod clamp in position and mixing with mixer machine, casting in forms, compacting properly and curing at least for 21 days, removing shuttering and demoulding etc. all complete including the cost of water, electricity and other charges as per design, drawing and accepted by the Engineer-in-charge. (Considering cross section of the frame 153 mm x 64 mm). meter Tk. 22.25 Supply & installation of fire rated door complete & accepted by the Engineer-in-charge with the following specification: sqm Tk. 48,217.00 Standard(s) for safety : UL Certified, NFPA 80 standard ANSI / UL 10C: Positive pressure of fire tests of door assemblies. ANSI / UL 10B: Fire tests of door assemblies. UL Subject 63: Outline of investigation for fire frames. Shutter materials: Mild steel. Fire resistivity (Door & frame): Two hours. Fire resistivity (accessories): Three hours (panic bar, pul handle, ceramic fibre tape for sealing smoke, hinge, bolt and screw, mortice lock, door closer Door frame: 2 vertical fire resisting jamb and 1 fire resisting horizontal jamb made with single rabbet hollow steel chanel frame made of 2.3 mm imported cold rolled mild steel sheet. Four SS hinges (size: 112 mm x 100 mm x 3.4mm) are used on each leaf screwd with frame Door leaf: Door leaf faces consists of 1.6 mm thick imported cold rolled MS sheet attached together using interlocking mechanism and tack welding which is filled with imported 100kg/m3 rock wool cake. Stiffeners should be used inside to strengthen structure. Vision Panel: Made of UL certified 5 mm glass. It has clear vision area of 150 mm x 100 mm. Its frame is mae of 1.6 mm imported cold rolled MS sheet and SS pop rivet used for fixing. Ceramic fibre tape is used for sealing smoke. Unit Rate 2,214.00 136.00 PWD SoR 2018 for Civil Works MISCELLANEOUS ITEMS Item No. Description of Item Internal insulation: Rock wool. Surface treatment: All MS sheets are chemically treated coated with zinc phosphate before assembly in highly equipped chemical treatment plant. All chemicals are imported. Paint Finish: Epoxy powder coated paint finish and curing in temperature controlled gas oven. ………………….. END OF DIVISION TWENTY TWO ………………….. Unit 160 Unit Rate PWD SoR 2018 for Civil Works FERROCEMENT WORKS 161 DIVISION 23 : FERROCEMENT WORKS Item No. Description of Item 23.1 Supplying, fitting & fixing of pre-cast ferrocement roof panel which is made by using vibration table & steel shutter with minimum cement content relates to mix ratio 1:2 for flange having minimum compressive strength 30 MPa (28 days standard cube strength) and cement conforming to BDS EN-197-1-CEM-I, 52.5N (52.5MPa)/ASTM-C150 type- 1, best quality coarse sand of equivalent F.M. 2.2, 2 layers of 18 BWG galvanized/epoxy coated wire mesh having minimum yield strength fy= 450 MPa & having 2 meshes per 25 mm and reinforced cement concrete works for rib with minimum cement content relates to mix ratio 1:1.5:3 having minimum f‟cr = 30 MPa and satisfying a specified compressive strength f'c = 25 MPa, best quality coarse sand of equivalent F.M. 2.2 and 12 mm down well graded stone chips conforming to ASTM C-33, supplying, fabrication and fixing to details as per design, deformed bar reinforcement BDS ISO 6935-2:2006, including straightening and cleaning rust, if any, bending and binding in position with supply of 24 nos GI wires, remove the shuttering, lifting the panel to floor/roof level, keeping on proper position, filling the interstices with cement concrete (1:1.5:3), satisfying a specified compressive strength f'c = 25 MPa, stitching overlapped wire meshes with 18 BWG GI wire, filling with mortar (1:2), casting of 25 mm thick as screeding (1:1.5:3) using 6 mm down stone chips and M.S. rod (fy=400 MPa) with fabrication over F.C. panel including the cost of reinforcement & wire mesh, curing at least for 7 days including the cost of water, electricity and other charges all complete as per design, drawing and accepted by the Engineer-in-charge. 23.1.1 For ground floor, span up to 3810 mm for floor/roof slab. 23.1.2 Extra cost shall be incorporated in the estimate for each additional floor 23.1.2.1 Unit Unit Rate sqm Tk. 2,354.00 Add for each additional span length of 150 mm long direction (3810 mm<span ≤ 4800 mm) sqm Tk. 9.00 23.1.2.2 Add for each additional floor up to 5th floor sqm Tk. 35.00 23.1.2.3 Add for each additional floor from 6th floor sqm Tk. 40.00 23.2 Supplying, fitting & fixing of 20 mm thick ferrocement folded plate roof which is made by using vibration table & steel shutter with minimum cement content relates to mix ratio 1:2, having minimum compressive strength of 30 MPa (28 days standard cube strength) and cement conforming to BDS EN-197-1-CEM-I, 52.5N (52.5MPa)/ASTM-C 150 type- 1, best quality coarse sand of equivalent F.M. 2.2, 1 layer of 20 BWG galvanized/epoxy coated wire mesh having minimum yield strength fy=450 MPa & having 2 meshes per 25 mm, fabrication and fixing to details as per design, deformed bar reinforcement BDS ISO 69352:2006, including straightening and cleaning the rust, if any, bending and binding in position with supply of 24 BWG GI wires, removing the shutter, lifting, keeping on proper position, curing at least for 7 days including the cost of water, electricity and other charges all complete as per design, drawing and accepted by the Engineer-in-charge. 23.2.1 For ground floor, span up to 3810 mm sqm Tk. 1,890.00 23.2.1.1 Add for each additional span length of 150 mm long direction (3810 mm < span ≤ 4800 mm) sqm Tk. 9.00 23.2.2.1 Add for each additional floor up to 5th floor sqm Tk. 35.00 23.2.2.2 Add for each additional floor from 6th floor sqm Tk. 40.00 PWD SoR 2018 for Civil Works FERROCEMENT WORKS Item No. Description of Item 23.3 Supplying, fitting & fixing of 20 mm thick ferrocement corrugated sheet roof which is made by using vibration table & steel shutter with minimum cement content relates to mix ratio 1:2, having minimum compressive strength of 30 MPa (28 days standard cube strength) and cement conforming to BDS EN-197-1-CEM-I, 52.5N (52.5MPa)/ASTM-C 150 type-1, best quality coarse sand of equivalent F.M. 2.2, 1 layer of 20 BWG galvanized/epoxy coated wire mesh having minimum yield strength fy=450 Mpa & having 2 meshes per 25 mm and supplying, fabrication and fixing to details as per design, deformed bar reinforcement BDS ISO 6935-2:2006 including straightening and cleaning rust, if any, bending and binding in position with supply of 24 nos GI wires, removing the shutter, lifting on ground floor roof, keeping on proper position, curing at least for 28 days including the cost of water, electricity and other charges all complete as per design, drawing and accepted by the Engineer-in-charge. 23.3.1 For ground floor, span up to 3810 mm for floor/roof slab. 23.3.2 Extra cost shall be incorporated in the estimate for each additional floor 23.3.2.1 Unit 162 Unit Rate sqm Tk. 1,626.00 Add for each additional floor up to 5th floor sqm Tk. 35.00 23.3.2.2. Add for each additional floor from 6th floor sqm Tk. 40.00 23.4 Supplying, fitting & fixing of pre-cast Ferrocement L-Panel which is made by using vibration table & steel shutter with minimum cement content relates to mix ratio 1:2 for flange having minimum compressive strength of 30 MPa (28 days standard cube strength) and cement conforming to BDS EN-197-1-CEM-I, 52.5N (52.5MPa)/ASTM-C 150 type- 1, best quality coarse sand of equivalent F.M. 2.2, 2 layers of 20 BWG galvanized/epoxy coated wire mesh having minimum yield strength fy=450 Mpa & having 2 meshes per 25 mm and reinforced cement concrete works for rib with minimum cement content relates to mix ratio 1:1.5:3 having minimum f‟cr = 30 MPa and satisfying a specified compressive strength f'c = 25 MPa, best quality coarse sand of equivalent F.M. 2.2 and 12 mm down well graded stone chips conforming to ASTM C-33, supplying, fabrication and fixing to details as per design, deformed bar reinforcement BDS ISO 6935-2:2006 including straightening and cleaning rust, if any, bending and binding in position, curing at least for 28 days with supply of GI wires, remove the shuttering of ferrocement L-panel, lifting the panel to floor/roof level, keeping on proper position, the cost of water, electricity and other charges all complete as per design, drawing and accepted by the Engineer-in-charge. 23.4.1 For ground floor, span up to 3810 mm for floor/roof slab. sqm Tk. 1,375.00 23.4.2 Extra cost shall be incorporated in the estimate for each additional floor 23.4.2.1 Add for each additional floor up to 5th floor sqm Tk. 35.00 23.4.2.2 Add for each additional floor from 6th floor sqm Tk. 40.00 23.5 Supplying, making and fitting fixing of ferrocement door/window frame 155 mm x 65 mm which is made by using M.S. rod (fy = 400 MPa) fabrication work minimum cement content relates to mix ratio 1:2 cement conforming to BDS EN-197-1-CEM-I, 52.5N (52.5MPa)/ ASTM-C 150 type–1, coarse sand (F.M. 2.2), cutting, bending, binding of one layer 20 BWG galvanized / epoxy coated wire mesh having minimum yield strength fy=450 MPa & 12 mm c/c gap in both directions with 24 BWG. G.I. wire, jute hassain, polythene sheet, placing of 100 mm long welded iron hinges including 6 mm dia M.S. rod clamp fittings, fixing in position, casting with neat cement finishing demoulding and lean cement sand (1:8) cement, sand (F.M. 1:2) and curing at least for 28 days etc. all complete including the cost of water, electricity, testing and other charge as per design, drawing and accepted by the Engineer-in-charge. (Considering x- section of the frame is 153 mm x 64 mm). meter Tk. 567.00 PWD SoR 2018 for Civil Works FERROCEMENT WORKS Item No. 163 Description of Item Unit Unit Rate 23.6 25 mm thick cast-in-situ ferrocement wall with minimum cement content relates to mix ratio 1:2, cement conforming to BDS EN-197-1-CEM-I, 52.5N (52.5MPa)/ASTM-C 150 type–1, and best quality coarse sand (F.M. 2.2) M.S. rod fabrication in accordance with BDS, ISO 6935-2:2006 straighting and cleaning rust if any, bending and binding in position with supply of 8 mm dia M.S. rod 250 mm c/c vertically, 6 mm dia 250 mm c/c horizontally, 24 nos G.I. wire splices laps etc. 2 layers of 20 BWG galvanized wire mesh having minimum yield strength fy=450 Mpa & 2 mesh per 25 mm, casting and finishing the both surfaces with cement sand (F.M.-1.2) mortar (1:3) and curing at least for 21 days, including the cost of water, electricity and other charges in all complete as per drawing, design and accepted by the Engineer-in-charge. sqm Tk. 1,719.00 23.7 Supplying, fitting & fixing of 25 mm thick pre-cast ferrocement wall panel with minimum cement content relates to mix ratio 1:2, cement conforming to BDS EN-197-1-CEM-1, 52.5N (52.5MPa)/ ASTM-C 150 type–1 and best quality coarse sand (F.M. 2.2) and 2 layers of 20 BWG galvanized wire mesh having minimum yield strength fy=450 Mpa & 2 mesh per 25 mm, including cutting, binding, bending, with 24 B.W.G. G.I. wire, casting and finishing the both surfaces with cement sand (F.M.-1.2) Mortar (1:3) and curing at least for 21 days before lifting, fitting & fixing the Ferrocement plate in proper position with making rib, supply of 8 mm dia M.S. rod 250 mm c/c vertically, 6 mm dia 250 mm c/c horizontally fabrication in accordance with BDS, ISD 6935-2.2006 straighting and cleaning rust if any, bending and binding in position with supply of G.I. wire etc. the cost of water, electricity and other charges, complete in all respect and accepted by the Engineer-incharge 23.7.1 Ground Floor sqm Tk. 1,572.00 23.7.2 Add for each additional floor up to 5th floor sqm Tk. 18.00 23.7.3 Add for each additional floor for 6th floor to 9th floor sqm Tk. 28.00 23.7.4 Add for each additional floor for 10th floor and above sqm Tk. 32.00 23.8 90 mm thick partition wall with ferrocement sandwich panel wall (cast in situ) using mortar having compressive strength not less than 15.0 N/mm2 and fitting-fixing of EPS sheet size (3000 mm x 1200 mm x 63 mm),8 mm M.S. bar and its fabrication in both side with 20 BWG galvanized wire mesh having minimum yield strength fy=450 Mpa & 2 mesh per 25 mm, in compliance with ASTM C129 fairly uniform thickness and water absorption not more than 7% including necessary scaffolding, cleaning and curing at least for 7 days including cost of water, electricity and other charges etc. in all complete accepted by the Engineer-in-charge. 23.8,1 Ground Floor sqm Tk. 2,037.00 23.8.2 Add for each additional floor up to 5th floor sqm Tk. 13.00 23.8.3 Add for each additional floor for 6th floor to 9th floor sqm Tk. 18.00 23.8.4 Add for each additional floor for 10th floor and above sqm Tk. 21.00 PWD SoR 2018 for Civil Works FERROCEMENT WORKS Item No. 23.9 Description of Item Unit 40 mm ferro-cement slab on soil-cement stabilized sub-grade in ground floor etc. with minimum cement content relates to mix ratio 1:2 having minimum compressive strength of 30 MPa (28 days standard cube strength) and cement conforming to BDS EN-197-1-CEM1, best quality coarse (F.M. 2.2) sand, 2 layer of 20 BWG galvanized/epoxy coated wire mesh having minimum yield strength fy=450 Mpa & having 2 mesh per 25 mm with minimum clear cover 12 mm both top & bottom, true to desired level, placing, compacting, curing at least for 7 days in all floors including cost of water, electricity and other charges etc. all complete and accepted by the Engineer-in-charge. sqm ………………….. END OF DIVISION TWENTY THREE ………………….. 164 Unit Rate Tk. 1,247.00 PWD SoR 2018 for Civil Works ROAD AND PAVEMENT WORKS 165 DIVISION 24: ROAD AND PAVEMENT WORKS Item No. Description of Item Unit Unit Rate 24.1 Earth work in road embankment up to a lift of 1.5 m in all kinds of soil including cutting and throwing earth in layers not exceeding 150 mm in thickness, breaking clods up to 40 mm size in each layer, ramming, leveling and dressing as per required side slope and alignment with earth borrowed from the road side govt. acquired land for any leads and maintaining the embankment true to level and side slopes as per profiles for one year from the date of completion including making dug, bailing, profiling etc. complete and accepted by the Engineer-in-charge. 24.1.1 For initial lift of 1.5 m cum Tk. 145.00 24.1.2 For additional lift of 1 m beyond 1.5 m up to 2.5 m cum Tk. 165.00 24.1.3 For additional lift of 1 m beyond 2.5 m up to 3.5 m cum Tk. 186.00 24.1.4 For additional lift of 1 m beyond 3.5 m up to 4.5 m cum Tk. 206.00 24.1.5 For additional lift of 1 m beyond 4.5 m up to 5.5 m cum Tk. 227.00 24.1.6 For additional lift of 1 m beyond 5.5 m up to 6.5 m cum Tk. 247.00 24.2 Earthwork in box cutting in all types of soil. Removing soil to a safe distance, maintaining proper alignment, camber and grade including leveling, dressing and compacting the sub grade as per drawing and accepted by the Engineer-in-charge. 24.2.1 Depth up to 300 mm sqm Tk. 50.00 24.2.2 Depth up to 450 mm sqm Tk. 71.00 24.3 Creating turf on the side slopes and top of embankment with good quality turf not less than 225 mm square chunk, watering till the grass grown including all leads and lifts etc. complete and accepted by the Engineer-in-charge. sqm Tk. 17.00 24.4 Single layer brick flat soling in road work with first class or picked jhama bricks as per alignment, camber and grade including filling joints with sand (F.M. 0.80) etc. complete including cost of all materials and accepted by the Engineer-in-charge. sqm Tk. 438.00 24.5 Brick on edges pavement in herring bone bond (HBB) with first class or picked jhama bricks as per alignment, camber and grade over 12 mm thick sand cushion (F.M. 0.80) including filling the joints with the same sand including cost of all materials and accepted by the Engineer-in-charge. sqm Tk. 713.00 24.6 Double brick flat soling in roadwork with first class or picked jhama bricks as per alignment, camber and grade including filling the joints with fine sand (F.M. 0.80) and also providing 12 mm thick sand cushion in between the two layers of brick flat soling with the same quality of sand including cost of all materials and accepted by the Engineer-incharge. sqm Tk. 884.00 24.7 Brick on end edging (75 mm across the road) with first class or picked jhama bricks and filling the gaps with fine sand (F.M. 0.80) including cutting trenches, true to level and grade, removing earth, refilling and ramming the sides properly including cost of all materials and accepted by the Engineer-in-charge. meter Tk. 111.00 PWD SoR 2018 for Civil Works ROAD AND PAVEMENT WORKS Item No. Description of Item Unit 166 Unit Rate 24.8 Breaking picked jhama, first class bricks or bats including cost of bricks and bats and stacking in measurable sizes at site accepted by the Engineer-in-charge. 24.8.1 For 62 mm to 40 mm size cum Tk. 3,631.00 24.8.2 For 40 mm to 25 mm size cum Tk. 3,767.00 24.9.1 Labour charge for compacted water bound macadam base course (including the cost of sand ) with graded material of crushed well burnt, picked jhama or first class bricks and bats having compacted thickness made as per specifications including local handling and spreading uniformly to proper grade, camber and super elevation, hand packing, watering, dry rolling followed by wet rolling in layers of specified thickness with 8 to 10 ton capacity power driven road roller to attain minimum soaked CBR 80% or design CBR at minimum degree of compaction of 98% MDD (Modified Proctor), including supplying and blinding with sand (F.M. 0.80) @ 0.012 m 3 per sqm or as required etc.all complete as per direction of the Engineer-in-charge. After adequate dry rolling, spreading of sand on the surface, sprinkling of water and rolling is to be continued untill all the voids are filled. thickness of each layer should not be more than 100 mm loose and payment will be made on compacted thickness. [The rate excludes the cost of brick aggregates.] cum Tk. 544.00 24.9.2 Providing compacted water bound macadam base course with graded material of crushed well burnt, picked jhama or first class bricks and bats (50 mm downgraded brick chips having LAA value not exceeding 40%) including supplying of 12 mm downgraded chips made of same quality bricks, having compacted thickness made as per specifications including local handling and spreading uniformly to proper grade, camber and super elevation, hand packing watering,dry rolling followed by wet rolling in layers of specified thickness with 8 to 10 ton capacity power driven road roller to attain minimum soaked CBR of 80% or design CBR at minimum degree of compaction of 98% of MDD (Modified Proctor), including supplying and blinding with sand (F.M. 0.80) @ 0.012 m 3 per sqm or as required etc. all complete as per direction of of the Engineer-in-charge. After adequate dry rolling, spreading of sand on the surface, sprinkling of water and rolling is to be continued untill all the voids are filled. thickness of each layer should not be more than 100 mm loose and payment will be made on compacted thickness. cum Tk. 4,955.00 24.10 Providing compacted sub-base course with well graded material of crushed well burnt picked jhama / 1st class brick bats and sand (FM 0.8) with mixing proportion 2 : 1 having compacted thickness made as per specification including local handling, spreading uniformly to proper grade camber and super elevation, packing, rolling properly with 8 to 10 ton capacity power driven road roller and watering properly for compaction of 100% MDD (standard) blinding with sand including cost of fuel, lubricants, spares, maintenance, driver etc. all complete and accepted by the Engineer-in-charge. cum Tk. 4,041.00 PWD SoR 2018 for Civil Works ROAD AND PAVEMENT WORKS Item No. 167 Description of Item Unit Unit Rate 24.11 50 mm thick compacted pre-mixed bituminous carpeting with 20 mm down graded stone-chips (having LAA value <= 30%, water absorption not greater than 2%, flakiness index not greater than 35) of gradation as specified @ 0.68 cum of stonechips mixed with 46 kg of heated bitumen of 60/70 penetration grade heated straight run bitumen satisfying the requirements of ASTM/AASHTO. Bitumen content % by wt. of total is 4.5% to 5.50% or as determined by job mix design. The bitumen and stone-chips shall be separately heated to a temperature of 140°C – 155°C and 150°C – 170°C respectively before mixing. The mixing shall be done at temperature between 140°C – 160°C at a separate place away from the fire. The bitumen and stone-chips mixture shall be laid uniformly over 10 sqm of surface in proper camber, grade and super-elevation only on the prepared and accepted base or surface in a single appropriate layer to give the specified compacted thickness. The mixture should be rolled with appropriate steel drum roller (3-5 tons) & pneumatic multiple tire roller (8-10 tons) to full compaction. The rolling temperature shall be maintained not below 90°C including supplying of all materials, their carriage, labourers, tools and equipment etc. all complete as per direction of the Engineer-incharge. (In order to achieve the specified grading a blending of nominal maximum size of 20 mm, 12 mm crushed stone chips and stone dust is suggested and proportion will have to be determined by the laboratory analysis). sqm Tk. 846.00 24.12 38 mm thick compacted pre-mixed bituminous carpeting with 20 mm down graded stone-chips (having LAA value <= 30%, water absorption not greater than 2%, flakiness index not greater than 35) of gradation as specified @ 0.63 cum of stonechips mixed with 37 kg heated bitumen of 60/70 penetration grade heated straight run bitumen satisfying the requirements of ASTM/AASHTO. Bitumen content % by wt. of total is 4.5% to 5.50% or as determined by job mix design. The bitumen and stone-chips shall be separately heated to a temperature of 140°C – 155°C and 150°C – 170°C respectively before mixing. The mixing shall be done at temperature between 140°C – 160°C at a separate place away from the fire. The bitumen and stone-chips mixture shall be laid uniformly over 10 sqm of surface in proper camber, grade and super-elevation only on the prepared and accepted base or surface in a single appropriate layer to give the specified compacted thickness. The mixture should be rolled with appropriate steel drum roller (3-5 tons) & pneumatic multiple tire roller (8-10 tons) to full compaction. The rolling temperature shall be maintained not below 90°C including supplying of all materials, their carriage, labourers, tools and equipment etc. all complete as per direction of the Engineer-incharge. (In order to achieve the specified grading a blending of nominal maximum size of 20 mm, 12 mm crushed stone chips and stone dust is suggested and proportion will have to be determined by the laboratory analysis). sqm Tk. 687.00 24.13 25 mm thick compacted pre-mixed bituminous carpeting with 12 mm down graded stone-chips (having LAA value <= 30%, water absorption not greater than 2%, flakiness index not greater than 35) of gradation as specified @ 0.34 cum of stone chips mixed with 23 kg heated bitumen of 60/70 penetration grade heated straight run bitumen satisfying the requirements of ASTM/AASHTO. Bitumen content % by wt. of total is 4.5% to 5.50% or as determined by job mix design. The bitumen and stone-chips shall be separately heated to a temperature of 140°C – 155°C and 150°C – 170°C respectively before mixing. The mixing shall be done at temperature between 140°C – 160°C at a separate place away from the fire. The bitumen and stone-chips mixture shall be laid uniformly over 10 sqm of surface in proper camber, grade and super-elevation only on the prepared and accepted base or surface in a single appropriate layer to give the specified compacted thickness. The mixture should be rolled with appropriate steel drum roller (3-5 tons) & pneumatic multiple tire roller (8-10 tons) to full compaction. The rolling temperature shall be maintained not below 90°C including supplying of all materials, their carriage, labourers, tools and equipment etc. all complete as per direction of the Engineer-incharge. (In order to achieve the specified grading a blending of nominal maximum size of 20 mm, 12 mm crushed stone chips and stone dust is suggested and proportion will have to be determined by the laboratory analysis). sqm Tk. 437.00 PWD SoR 2018 for Civil Works ROAD AND PAVEMENT WORKS Item No. 168 Description of Item Unit Unit Rate 24.14 38 mm thick compacted pre-mixed dense bituminous carpeting with 20 mm down graded stone-chips (having LAA value <= 30%, water absorption not greater than 2%, flakiness index not greater than 35) of gradation as specified @ 0.56 cum of stone chips mixed with 45 kg heated bitumen of 60/70 penetration grade heated straight run bitumen satisfying the requirements of ASTM/ AASHTO. Bitumen content % by wt. of total is 4.5% to 5.50% or as determined by job mix design. The bitumen and stone-chips shall be separately heated to a temperature of 140°C – 155°C and 150°C – 170°C respectively before mixing. The mixing shall be done at temperature between 140°C – 160°C at a separate place away from the fire. The bitumen and stone-chips mixture shall be laid uniformly over 10 sqm of surface in proper camber, grade and super-elevation only on the prepared and accepted base or surface in a single appropriate layer to give the specified compacted thickness. The mixture should be rolled with appropriate steel drum roller (3-5 tons) & pneumatic multiple tire roller (8-10 tons) to full compaction. The rolling temperature shall be maintained not below 90°C including supplying of all materials, their carriage, labourers, tools and equipment etc. all complete as per direction of the Engineer-incharge. (In order to achieve the specified grading a blending of nominal maximum size of 20 mm, 12 mm crushed stone chips and stone dust is suggested and proportion will have to be determined by the laboratory analysis). sqm Tk. 731.00 24.15 25 mm thick compacted pre-mixed dense bituminous carpeting with 12 mm down graded stone-chips (having LAA value <= 30%, water absorption not greater than 2%, flakiness index not greater than 35) of gradation as specified, @ 0.35 cum of stonechips mixed with 29.8 kg heated bitumen of 60/70 penetration grade heated straight run bitumen satisfying the requirements of ASTM/AASHTO. Bitumen content % by wt. of total is 4.5% to 5.50% or as determined by job mix design. The bitumen and stone-chips shall be separately heated to a temperature of 140°C – 155°C and 150°C – 170°C respectively before mixing. The mixing shall be done at temperature between 140°C – 160°C at a separate place away from the fire. The bitumen and stone-chips mixture shall be laid uniformly over 10 sqm of surface in proper camber, grade and super-elevation only on the prepared and accepted base or surface in a single appropriate layer to give the specified compacted thickness. The mixture should be rolled with appropriate steel drum roller (3-5 tons) & pneumatic multiple tire roller (8-10 tons) to full compaction. The rolling temperature shall be maintained not below 90°C including supply of all materials, their carriage, labourers, tools and equipments etc. all complete as per direction of the Engineer-incharge. (In order to achieve the specified grading, a blending of nominal maximum size of 20mm, 12mm crushed stone chips and stone dust is suggested and proportion will have to be determined by the laboratory analysis). sqm Tk. 464.00 PWD SoR 2018 for Civil Works ROAD AND PAVEMENT WORKS Item No. 169 Description of Item Unit Unit Rate 24.16 Providing and laying pre-mixed dense bituminous carpeting with hot mix plant using coarse aggregate, fine aggregate, filler and bituminous binder as per design Job Mix Formula conforming Marshall Method as per specification, LAA value of aggregate should be <=30%, water absorption not >2%, flakiness index not >35 mixed with 60/70 penetration grade straight run bitumen satisfying the requirements of ASTM/AASHTO. including screening, cleaning of chips and preparing a uniform and quality mix in hot mix plant and ensuring a homogenous mix, in which all particles of the mineral aggregates are coated uniformly, carrying the hot premixed materials by means of dump/tipper truck, spreading the mixed materials at specified laying temperature with a hydrostatic paver finisher with sensor control to the required grade, level and alignment over the prepared surface, tamping and finishing the mix at specified compacted thickness, maintaining specified camber, grade, super-elevation and cross section, through rolling with appropriate steel drum roller & pneumatic multiple tire roller (8-10 tons) to full compaction, for break down, inter - mediate and finished rolling to achieve the desired density of at least 98% of that of Laboratory Marshall specimen, hand packing and pinning to give an even surface, including cost of all materials, their carriages, hire charges of hot mix plant and all other machines, equipments for construction and quality control as per specification, fuels, lubricants and wages of operational staff etc. all complete as per the direction of the Engineer-in-charge. (Carpeting work by using asphalt plant is mandatory for all divisional headquarter & capital city) cum Tk. 19,555.00 24.17 Providing tack coat @ 7.50 kg of bitumen (60/70 penetration grade) per 10 sqm including heating bitumen up to 175°C to 185°C etc. all complete (cost of bitumen included) and accepted by the Engineer-in-charge. sqm Tk. 71.00 24.18.1 Providing seal coat with 4 cft of Sylhet sand (FM 2.2) mixed with @ 7.32 kg of bitumen (60/70 penetration grade) per 10 sqm of road surface including supplying and spreading of dry sand (F.M. 0.80) @ 0.09 cum per 10 sqm, including heating bitumen upto 176°C to 190°C, and spreading, rolling at a temperature not below 90°C celsius with appropriate steel drum roller (3 -5 ton) and pneumatic multiple tire roller (8-10 tons) to the desired compaction etc. all complete (cost of bitumen included ) and accepted by the Engineer-incharge. sqm Tk. 108.00 24.18.2 Premixed bituminous seal coat with 0.12 cum of pea gravels mixed with 80 kg of bitumen (60/70 penetration grade) per cum of pea gravels and laid over 10 sqm road surface, spreading with proper camber, grade, surface blinding with dry sand (F.M. 1.2) @ 0.09 cum per 10 sqm, rolling at a temperature not below 90°C with appropriate steel drum roller (3-5 ton) and pneumatic multiple tire roller (8-10 tons) to the desired compaction etc. all complete and accepted by the Engineer-in-charge. sqm Tk. 152.00 24.19.1 Providing prime coat @ 1.2 liter/sqm with cutback bitumen to be prepared by cutting back 60/70 penetration grade bitumen in the ratio of 100 parts by volume of bitumen to 40-60 parts by volume of kerosene depending on the porosity of surface and will be decided by field trials, carefully cleaning of the surface of base material to be primed and spraying cutback bitumen at a temperature from 100 degree celcius to 120 degree celcius by appropriate hand device etc.all complete as per direction of the Engineer-in-charge. sqm Tk. 99.00 24.19.2 Providing prime coat @1.2 liter/sqm with cutback bitumen to be prepared by cutting back 60/70 penetration grade bitumen in the ratio of 100 parts by volume of bitumen to 40-60 parts by volume of kerosene depending on the porosity of surface and will be decided by field trials, carefully cleaning of the surface of base material to be primed and spraying cutback bitumen at a temperature from 100°C to 120°C by mechanical distributor etc. all complete as per direction of the Engineer-in-charge. sqm Tk. 101.00 PWD SoR 2018 for Civil Works ROAD AND PAVEMENT WORKS Item No. 170 Description of Item Unit 24.20 Providing painting at the top of the road surface as road marking in two coats with approved best quality and colour of synthetic paint from authorized local agent of the manufacturer in a sealed container having high water resistance, high bondability & flexibility, using specific brand thinner applied by brass/ roller or others over a coat of priming, providing elapsing time for drying including surface cleaning from dust, oil or dirt, smoothening, finishing necessary tools etc. all complete & approved and accepted by the Engineer-in-charge. sqm Tk. 287.00 24.21 Providing expansion joints across the R.C.C. road pavement with 20 mm gap between the adjacent panels. Supplying dowel bars of size 12 mm dia and 600 mm long M.S rod placed @ 750 mm c/c. 300 mm of the bar being fixed within one slab keeping remaining portion the bar free within the adjacent slab being inserted in 20 mm dia and 300 mm long P.V.C. pipe embedded in the slab, inside of pipe fully greased, filling the gap between the slabs (with admixture) of hot bitumen and coarse sand (F.M. 2.2) in proportion of 2:1, finishing the top with bitumen, spreading coarse sand over the joint, all complete as per plan, drawing and accepted by the Engineer-in-charge. meter Tk. 390.00 ………………….. END OF DIVISION TWENTY FOUR ………………….. Unit Rate PWD SoR 2018 for Civil Works ARBORICULTURE WORKS 171 DIVISION 25 : ARBORICULTURE WORKS Item No. Description of Item Unit Unit Rate 25.1 Labour charge for scraping lawn surface up to 38 mm depth by spade, picking up all sorts of brick bats, rubbish by suitable tools, removing the same by head load or by any other means and stacking the same to a safe distance beyond 300 m including supply of tools and plants etc. all complete and accepted by the Engineer-in-charge. sqm Tk. 9.00 25.2 Preparation of ground to make ready for plantation by spading the ground to a depth of 150 mm to 230 mm beyond 38 mm deep scrapped ground by spade, breaking earth clods to powder by hammers, picking up all sorts of rubbish, unwanted grasses by suitable tools, carrying and spreading the surplus earth into low lying area including supply of tools and plants etc. all complete and accepted by the Engineer-in-charge. sqm Tk. 20.00 25.3 Leveling and dressing of lawn area to proper slope and grade by spading the same up to 150 mm including supplying tools and plants etc. all complete and accepted by the Engineer-in-charge. sqm Tk. 6.00 25.4 Supply of best and approved quality alluvial loamy silty soil including loading, unloading at both ends, properly stacking at site including supply of tools and plants etc. all complete and accepted by the Engineer-in-charge. cum Tk. 843.00 25.5 Supply well decomposed cow dung carried by trucks or any other means including loading, unloading at both ends, stacking the same at site including supply of tools and plants etc. all complete and accepted by the Engineer-in-charge cum Tk. 1,507.00 25.6 Labour charge for spreading the alluvial loamy silty soil from the stacks at site on the lawn surface, leveling, dressing the same including supply all necessary tools and plants etc. all complete and accepted by the Engineer-in-charge. cum Tk. 152.00 25.7 Extra rate for lifting alluvial loamy silty soil/ decomposed cow dung work in additional floor: 25.7.1 Add for each additional floor up to 5th floor cum Tk. 89.00 25.7.2 Add for each additional floor from 6th floor to 9th floor cum Tk. 109.00 25.7.3 Add for each additional floor for 10th floor & above cum Tk. 136.00 25.8 Supply of lawn grass of approved quality by truck or by any other means, sorting the grass to proper size, washing the grass, dibbling the grass 6 mm to 50 mm apart, irrigation of lawn area till the grass grown at least for two months after plantation, weeding the undesirable grass, mowing the lawn grass by lawn mower up to two months after plantation, applying urea fertilizer on the lawn surface @ 1 kg per 9.29 sqm including supply of tools and plants etc. all complete and accepted by the Engineer-in-charge. sqm Tk. 54.00 25.9 Labour charge for mixing well decomposed cow dung with alluvial loamy silty soil and excavated earth, removing the excess earth to safe distance including supply of tools and plants etc. all complete and accepted by the Engineer-in-charge. cum Tk. 141.00 25.10 Supplying and providing, fitting & fixing bamboo jafry fencing by best quality muli bamboo split 20 mm in width, having 75 mm x 75 mm mesh placed horizontally and diagonally doing 25 mm framing a square shape in both ways and both sides tightened with G.I wire fitted with Borrak bamboo post of 100 mm dia and placed firmly in position at 1800 mm apart including supply of tools and plants, digging hole and filling back etc. all complete and accepted by the Engineer-in-charge. sqm Tk. 505.00 PWD SoR 2018 for Civil Works ARBORICULTURE WORKS Item No. 172 Description of Item Unit 25.11 Supplying and providing, fitting & fixing muli bamboo tree guard of 1200 mm length and 500 mm dia fixing with best quality muli bamboo split 20 mm in size having 75 mm x 75 mm a square holes with 20 mm wide bamboo splits strengthen with 4 Nos. 20 mm wide bamboo split in both sides tightened with G.I wire fitted with 3 Nos. 63 mm dia borrak bamboo post of 1800 mm long of which 600 mm will be driven into earth by digging hole followed by fill back including supply of tools and plants all complete as per direction of the Engineer-in-charge. each Tk. 647.00 25.12 Earth work in excavation to make a pit of 600 x 600 x 450 mm (depth) for plantation, applying cow dung mixing with loamy silty soil and excavated earth, planting the plants, tightened with 1800 mm long borrak bamboo post with jute rope including supply of tools and plants all complete and accepted by the Engineer-in-charge. each Tk. 137.00 25.13 Spading for preparation of flower beds in pits up to 600 mm depth, re-molding, picking up and placing and removing the spaded earth to a safe distance, mixing @ 1 cft well decomposed cow dung with 20% loamy silty soil and 6 cft excavated soil and fill back the pit including supply of tools and plants, all complete and accepted by the Engineer-incharge. sqm Tk. 465.00 25.14 Preparation of hedge beds by excavation of earth up to 300 mm depth, filling up the bed by a mixture of cow dung, loamy silty soil, cutted earth @ 1 cft cow dung manure per 6 cft of cutted earth and 20% loamy silty soil including supply of tools and plant etc. all complete and accepted by the Engineer-in-charge. sqm Tk. 234.00 25.15 Carrying of rubbish, taking up all sorts of bricks, brick-bats and rubbish gravel chips, loading and unloading at both ends including supply of tools and plants etc. all complete and accepted by the Engineer-in-charge. cum Tk. 146.00 25.16 Supply and carrying of 12.20 m long 100 mm dia borrak bamboo at site, loading and unloading at both end, stacking the same at site including supply of tools and plants etc. all complete and accepted by the Engineer-in-charge. each Tk. 476.00 25.17 Supply and carrying of 7.62 m long 50 mm to 62.5 mm dia muli bamboo at site, loading and unloading at both end, stacking the same at site including supply of tools and plants etc. all complete and accepted by the Engineer-in-charge. each Tk. 261.00 25.18 Supply and carrying of 4.5 h.p. 550 mm blade 4 stroke, finger trip 3 position height adjuster 200 mm x 38 mm star tread wheels grass cutting (power lawn mower machine): YARDMAN No. 060A each Tk. 54,335.00 25.19 Supply and carrying of 6.5 h.p. 550 mm blade 4 stroke, finger trip 3 position height adjuster 200 mm x 38 mm star tread wheels grass cutting (power lawn mower machine): YARDMAN No. 060A each Tk. 72,447.00 25.20 Supply and carrying of 22 h.p. 1150 mm cutting blade power riding lawn YARDMAN mower machine made in USA. Model No.13 BT 793G678 or equivalent. each Tk. 543,351.00 25.21 Supply and carrying of 450 mm blade hand lawn mower, Model No.1403-106(USA) each Tk. 15,093.00 ………………….. END OF DIVISION TWENTY FIVE ………………….. Unit Rate PWD SoR 2018 for Civil Works SANITARY & WATER SUPPLY WORKS 173 DIVISION 26 : SANITARY & WATER SUPPLY WORKS Item No. Description of Item Unit Unit Rate 26.1 Supplying, fitting and fixing of European type glazed porcelain commode "S" type 465 mm x 340 mm x 415 mm in size, approximately 14 kg by weight, plastic seat cover and preparing the base with cement concrete and with wire mesh or rods, if necessary, in all floors including making holes wherever required and mending good the damages, fitting, fixing, finishing etc. complete with all necessary fittings and connections approved and accepted by the Engineer- in- charge. 26.1.1 White each Tk. 3,158.00 26.1.2 Coloured each Tk. 3,255.00 26.1.3 Special colour each Tk. 3,424.00 26.2 Supplying, fitting and fixing of European type glazed porcelain low-down, capacity 10 liter, 490 mm x 190 mm x 350 mm in size, approximately 14 kg of weight, on walls by screws and F.I. bar clamps, rowel plugs, making holes wherever required and mending good the damages and fitting, fixing & finishing etc. complete with all necessary fittings and connections approved and accepted by the Engineer- in- charge. 26.2.1 White each Tk. 2,228.00 26.2.2 Coloured each Tk. 2,409.00 26.2.3 Special colour each Tk. 2,650.00 26.3 Supplying, fitting and fixing of European type glazed porcelain combi closet, including plastic seat cover, cistern system, preparing the base with cement concrete and with wire mesh or rods if necessary, in all floors including making holes wherever required and mending good the damages and fitting, fixing, finishing etc. complete with all necessary fittings and connections approved and accepted by the Engineer- in- charge. 26.3.1 670 mm x 365 mm x 755 mm, 31.0 kg 26.3.1.1 Light Colored (Ivory/ Alpine White/ Grey/ Pink/ Blue/ Aqua Verde) each Tk. 8,320.00 26.3.1.2 Coloured (Marble Shaded) each Tk. 10,505.00 26.3.1.3 Special coloured (Deep Blue/ Ruby/ Rain Forest/ Green) each Tk. 11,966.00 26.3.2 700 mm x 370 mm x 795 mm, 32.5kg 26.3.2.1 Light Colored (Ivory/ Alpine White/ Grey/ Pink/ Blue/ Aqua Verde) each Tk. 26.3.2.2 Coloured (Marble Shaded) each Tk. 12,220.00 26.3.2.3 Special coloured (Deep Blue/ Ruby/ Rain Forest/ Green) each Tk. 13,941.00 26.3.3 700 mm x 360 mm x 785 mm, 38 kg 26.3.3.1 Light Colored (Ivory/ Alpine White/ Grey/ Pink/ Blue/ Aqua Verde) each Tk. 13,041.00 26.3.3.2 Coloured (Marble Shaded) each Tk. 17,853.00 9,636.00 PWD SoR 2018 for Civil Works SANITARY & WATER SUPPLY WORKS Item No. Description of Item 174 Unit Unit Rate 26.3.3.3 Special coloured (Deep Blue/ Ruby/ Rain Forest/ Green) each Tk. 19,048.00 26.3.4 Supplying, fitting and fixing of European type glazed porcelain combi closet of white or ivory color and size of approx. 340 mm x 730 mm x 785 mm, 36.75 kg of weight including plastic seat cover with soft closing, cistern system, water consumption 6 litter, siphon jet flushing system, mending good the damages and fitting, fixing, finishing etc. complete with all necessary fittings and connection approved and accepted by the Engineer- in- charge. each Tk. 15,305.00 26.4 Supplying, fitting and fixing of European type glazed combi closet, 725 mm x 360 mm x 840 mm size, 42.7 kg of weight, including plastic seat cover, cistern system, preparing the base with cement concrete and with wire mesh or rods if necessary, in all floors including making holes wherever required and mending good the damages and fitting, fixing, finishing complete with all necessary fittings and connections approved and accepted by the Engineer- in- charge 26.4.1 725 mm x 360 mm x 840 mm size, 42.7 kg 26.4.1.1 Light Colored (Ivory/ Alpine White/ Grey/ Pink/ Blue/ Aqua Verde) each Tk. 16,289.00 26.4.1.2 Coloured (Marble Shaded) each Tk. 20,865.00 26.4.1.3 Special coloured (Deep Blue/ Ruby/ Rain Forest/ Green) each Tk. 23,908.00 26.4.2 Supplying, fitting and fixing of European type glazed combi closet, of white color , 370 mm x 760 mm x 800 mm size, 44.69 kg of weight, including plastic seat cover with soft closing ,cistern system, water consumption 6 litter, siphon wash down dual flashing system which reduce water consumption, hygienic glaze in toilet bowl ,glaze in inner waste line, round bowl, outlet range 305 mm , preparing the base with cement concrete and with wire mesh or rods if necessary, in all floors including making holes wherever required and mending good the damages and fitting, fixing, finishing, complete with all necessary fittings and connection approved and accepted by the Engineer Engineer- incharge. each Tk. 17,919.00 26.5 Supplying, fitting and fixing of Bangladesh pattern, long pan with foot-rest, made of vitreous China clay and preparing the base of pan with cement mortar (1:4) and with wire mesh or rods, if necessary in all floors including making holes wherever required and mending good the damages and fitting, fixing, finishing etc. complete with all necessary fittings and connections approved and accepted by the Engineer- in- charge. 26.5.1 530 mm x 430 mm x 210 mm size & 12.5 kg of weight 26.5.1.1 White each Tk. 1,737.00 26.5.1.2 Coloured each Tk. 2,058.00 26.5.1.3 Special coloured each Tk. 2,272.00 26.5.2 530 mm x 450 mm x 290 mm size & 14.5 kg of weight 26.5.2.1 White each Tk. 2,254.00 26.5.2.2 Coloured each Tk. 2,650.00 26.5.2.3 Special coloured each Tk. 3,047.00 PWD SoR 2018 for Civil Works SANITARY & WATER SUPPLY WORKS 175 Description of Item Unit 26.6 Supplying, fitting and fixing of Bangladesh pattern long pan, made of vitreous China light color 525 mm x 295 mm x 285 mm size, 5.7kg of weight and preparing the base of pan with cement concrete and with wire mesh or rods if necessary in all floors including making holes wherever required and mending good the damages and fitting, fixing, finishing etc. complete with all necessary fittings and connections approved and accepted by the Engineer- in- charge. each Tk. 1,330.00 26.7 Supplying, fitting and fixing plastic low-down including all fittings and accessories each Tk. 1,920.00 26.8 Supplying of 280 mm x 140 mm x 30 mm size glazed porcelain foot rest, 1.5 kg of weight including fitting, fixing in position with cement mortar (1:4) if necessary in all floors including making holes wherever required and mending good the damages and fitting, fixing, finishing etc. complete with all necessary fittings and connection approved and accepted by the Engineer- in- charge. each Tk. 328.00 26.9 Supplying, fitting and fixing of white glazed vitreous W/H wash basin excluding pedestal, fitting, fixing the same in position with heavy type C.I. Brackets. 30 mm dia PVC waste water pipe with brass coupling (not exceeding 750 mm in length), basin waste with chain plug including making holes in walls and floors and fitting with wall, screws and mending good the damages, finishing etc. all complete approved and accepted by the Engineer-in-charge. 26.9.1 600 mm x 465 mm x 225 mm in size ,14kg of weight 26.9.1.1 White each Tk. 2,687.00 26.9.1.2 Coloured each Tk. 2,929.00 26.9.1.3 Special coloured each Tk. 3,050.00 29.9.2 595 mm x 430 mm x190 mm, 10kg of weight 26.9.2.1 White each Tk. 2,308.00 26.9.2.2 Coloured each Tk. 2,551.00 26.9.2.3 Special coloured each Tk. 2,832.00 26.9.3 510 mm x 450 mm x 203 mm, 9.5kg of weight 26.9.3.1 White each Tk. 2,273.00 26.9.3.2 Coloured each Tk. 2,330.00 26.9.3.3 Special coloured each Tk. 2,457.00 26.9.4 450 mm x 405 mm x180 mm, 7kg of weight 26.9.4.1 White each Tk. 1,945.00 26.9.4.2 Coloured each Tk. 1,985.00 26.9.4.3 Special coloured each Tk. 2,027.00 26.9.5 465 mm x 340 mm x180 mm, 6kg of weight Item No. Unit Rate PWD SoR 2018 for Civil Works SANITARY & WATER SUPPLY WORKS Item No. Description of Item Unit 176 Unit Rate 26.9.5.1 White each Tk. 1,871.00 26.9.5.2 Coloured each Tk. 1,909.00 26.9.5.3 Special coloured each Tk. 1,945.00 26.9.6 535 mm x 465 mm x 210 mm, 10.5kg of weight each 26.9.6.1 White each Tk. 2,308.00 26.9.6.2 Coloured each Tk. 2,366.00 26.9.6.3 Special coloured each Tk. 2,427.00 26.9.7 White or Ivory Color, 560 mm x 410 mm x 205 mm in size, 7.90kg of weight each Tk. 4,945.00 29.9.8 Cabinet Basin 500 mm x 450 mm x180 mm, 9 kg of weight 26.9.8.1 Light Colored (Ivory/ Alpine White/ Grey/ Pink/ Blue/ Aqua Verde) each Tk. 4,297.00 26.9.8.2 Coloured (Marble Shaded) each Tk. 5,243.00 26.9.8.3 Special coloured (Deep Blue/ Ruby/ Rain Forest/ Green) each Tk. 5,874.00 26.9.9 Corner Basin 440 mm x 360 mm x 195 mm, 7.0kg of weight 26.9.9.1 Light Colored (Ivory/ Alpine White/ Grey/ Pink/ Blue/ Aqua Verde) each Tk. 2,093.00 26.9.9.2 Coloured (Marble Shaded) each Tk. 2,379.00 26.9.9.3 Special coloured (Deep Blue/ Ruby/ Rain Forest/ Green) each Tk. 2,569.00 26.10 Supplying of glazed vitreous W/H wash basin including pedastal of size 660 mm x 545 mm x 850 mm, 29kg of weight including fitting, fixing the same in position with heavy type C.I. brackets, 30 mm dia PVC waste water pipe with brass coupling (not exceeding 750 mm in length), 12mm plastic lead (connection) pipe with brass coupling, basin waste with chain plug including making holes in walls and floors and fitting with wooden blocks, screws and mending good the damages, finishing etc. all complete approved and accepted by the Engineer- in- charge. 26.10.1 660 x 545 x 850 mm in size , 29 kg of weight 26.10.1.1 Light Colored (Ivory/ Alpine White/ Grey/ Pink/ Blue/ Aqua Verde) each Tk. 5,120.00 26.10.1.2 Coloured ( Marble Shaded) each Tk. 6,310.00 26.10.1.3 Special coloured (Deep Colour) each Tk. 7,107.00 26.10.2 Supplying of glazed vitreous W/H wash basin including pedastal of approx. size 600 mm x 500 mm x 855 mm, 26.92 kg of weight including fitting, fixing the same in position with heavy type C.I. brackets, 30 mm dia PVC waste water pipe with brass coupling (not exceeding 750 mm in length) used hygienic glaze, 12mm plastic lead (connection) pipe with brass coupling, basin waste with chain plug including making holes in walls and floors and fitting with wooden blocks, screws and mending good the damages, finishing etc. all complete approved and accepted by the Engineer- in- charge. each Tk. 6,756.00 PWD SoR 2018 for Civil Works SANITARY & WATER SUPPLY WORKS Item No. Description of Item Unit 177 Unit Rate 26.11 Supplying of white glazed vitreous W/H wash basin including pedastal and fitting, fixing the same in position with heavy type C.I. brackets, 32 mm dia PVC waste water pipe with brass coupling (not exceeding 750 mm in length), 32 mm dia C.P. basin waste with chain plug, bracket including making holes in walls and floors and fitting with wooden blocks, screws and mending good the damages with cement mortar (1:4), etc. all complete approved and accepted by the Engineer- in- charge. 26.11.1 665 mm x 490 mm x 840 mm in size, 29.5 kg of weight 26.11.1.1 Light Colored (Ivory/ Alpine White/ Grey/ Pink/ Blue/ Aqua Verde) each Tk. 6,889.00 26.11.1.2 Coloured (Marble Shade) each Tk. 8,610.00 26.11.1.3 Special coloured (Deep Blue/ Ruby/ Rain Forest/ Green) each Tk. 9,757.00 26.12 Supplying, fitting and fixing basin pedestal, with rowel plug and screws etc. all complete approved and accepted by the Engineer- in- charge. 26.12.1 670 mm x 186 mm x 170 mm size 26.12.1.1 Light Colored (Ivory/ Alpine White/ Grey/ Pink/ Blue/ Aqua Verde) each Tk. 1,846.00 26.12.1.2 Coloured (Marble Shaded) each Tk. 2,335.00 26.12.1.3 Special coloured (Deep Blue/ Ruby/ Rain Forest/ Green) each Tk. 2,661.00 26.12.2 670 mm x 186 mm x 170 mm size 26.12.2.1 Light Colored (Ivory/ Alpine White/ Grey/ Pink/ Blue/ Aqua Verde) each Tk. 2,443.00 26.12.2.2 Coloured (Marble Shaded) each Tk. 3,110.00 26.12.2.3 Special coloured (Deep Blue/ Ruby/ Rain Forest/ Green) each Tk. 3,554.00 26.12.3 670 mm x186 mm x 170 mm size 26.12.3.1 Light Colored (Ivory/ Alpine White/ Grey/ Pink/ Blue/ Aqua Verde) each Tk. 2,612.00 26.12.3.2 Coloured (Marble Shaded) each Tk. 3,330.00 26.12.3.3 Special coloured (Deep Blue/ Ruby/ Rain Forest/ Green) each Tk. 3,808.00 26.13 Supplying, fitting and fixing of glazed vitreous standing bowl urinal , fitting, fixing the same in position after making holes in walls and floors, providing 32 mm dia plastic waste pipe with brass coupling up to grading below, 12 mm dia plastic connection pipe with brass coupling, 12 mm dia brass stop cock including mending good the damages with cement mortar (1:4) etc. all complete approved and accepted by the Engineer- in- charge. 26.13.1 445 mm x 355 mm x 330 mm size, 11.5kg of weight 26.13.1.1 Light Colored each Tk. 2,278.00 26.13.1.2 Coloured each Tk. 2,683.00 26.13.1.3 Special coloured (Deep Colour) each Tk. 2,949.00 PWD SoR 2018 for Civil Works SANITARY & WATER SUPPLY WORKS Item No. Description of Item Unit 178 Unit Rate 26.13.2 445 mm x 355 mm x 330 mm, 10kg of weight (partition Type) 26.13.2.1 Light Colored each Tk. 2,924.00 26.13.2.2 Coloured (Marble Shaded) each Tk. 3,554.00 26.13.2.3 Special coloured (Deep Colour) each Tk. 3,957.00 26.14 Supplying, fitting and fixing of glazed vitreous china flat or squatting urinal 510 mm x 380 mm x 85 mm in size, approx. 9.5 kg of weight with flushing inlet fitted in cement mortar (1:4) with painted cast iron body: one gallon capacity, automatic flushing cistern in each group etc. including 12 mm brass controlling valve, 32 mm dia PVC flush pipe with brass coupling, 12 mm dia plastic lead (connection) pipe including mending good the damages with 1:4 cement mortar etc. all complete approved and accepted by the Engineer- in- charge. 26.14.1 White each Tk. 1,700.00 26.14.2 Coloured each Tk. 1,760.00 26.14.3 Special coloured each Tk. 1,881.00 26.15 Supplying, fitting and fixing of porcelain sink, 635 mm x 480 mm x195 mm size, 19.5 kg of weight fitted and fixed with heavy type C.I. brackets, 12 mm dia C.P. bib cock, 40 mm dia C.P. chain plug. 40 mm dia. C.P. waste, 40 mm dia PVC waste pipe with brass coupling (750 mm length) including making holes in walls and floors and mending good the damages with cement mortar (1:4) etc. all complete approved and accepted by the Engineer- in- charge. 26.15.1 White each Tk. 2,936.00 26.15.2 Colored each Tk. 3,299.00 26.16 Supplying, fitting and fixing of single bowl stainless steel sink with sink tray (size 450 mm x 1050 mm) with heavy type CI steel brackets, 12 mm dia C.P. bib-cock, 40 mm dia C.P. chain plug, 40 mm dia C.P. waste, 40 mm dia PVC waste pipe with brass coupling (750 mm length) including making hole in walls and floors and mending good the damages, finishing with 1:4 cement mortar etc. all complete approved and accepted by the Engineer-in-charge. (Malaysia / Singapore / Thailand made or equivalent). each Tk. 4,144.00 26.17 Supplying, fitting and fixing of double bowl stainless steel sink with sink tray with heavy type CI or steel brackets, 12 mm dia C.P. chain plug, 40 mm dia C.P. waste, 40 mm dia PVC waste pipe with brass coupling (750 mm length) including making hole in walls and floors and mending good the damages, finishing etc. all complete approved and accepted by the Engineer-in-charge. (Malaysia / Singapore / Thailand made or equivalent). each Tk. 7,390.00 26.18 Supplying, fitting and fixing of 450 mm x 600 mm size and 5 mm thick unframed super quality mirror with hard boards at the back with all necessary fitting including making holes in walls and mending good the damages with cement mortar (1:4) etc. all complete approved and accepted by the Engineer-in-charge. (Made in Japan or equivalent). each Tk. 886.00 26.19 Supplying, fitting and fixing of 450 mm x 350 mm size and 5 mm thick unframed super quality mirror with hard boards at the back with all necessary fitting including making holes in walls and mending good the damages with cement mortar (1:4) etc. all complete approved and accepted by the Engineer-in-charge (Made in Japan or equivalent). each Tk. 675.00 PWD SoR 2018 for Civil Works SANITARY & WATER SUPPLY WORKS 179 Description of Item Unit 26.20 Supplying, fitting and fixing of super quality 600 mm x 125 mm coloured glass shelf having 5 mm thickness with fancy C.P. brackets, screws and frames including making holes in walls and mending good the damages with cement mortar (1:4) etc. all complete approved and accepted by the Engineer- in- charge. each Tk. 1,412.00 26.21 Supplying, fitting and fixing of super quality 600 x 125 mm white glass shelf having 5 mm thickness with fancy C.P. brackets, screws and frames including making holes in walls and mending good the damages with cement mortar (1:4) etc. all complete approved and accepted by the Engineer- in- charge. each Tk. 989.00 26.22 Supplying, fitting and fixing of super quality C.P. towel rail of 600 mm long and 20 mm in dia with C.P. holder including making drills in walls and mending good the damages with cement mortar (1:4) etc. all complete approved and accepted by the Engineer- in- charge. each Tk. 711.00 26.23 Supplying, fitting and fixing of medium quality C.P. towel rail of 600 mm long and 20 mm in dia with C.P. holder including making drills in walls and mending good the damages with cement mortar (1:4) etc. all complete approved and accepted by the Engineer- incharge. each Tk. 627.00 26.24 Supplying, fitting and fixing of standard porcelain toilet paper holder of 150 mm x 150 mm x 126 mm size including making drills in walls and mending good the damages with cement mortar (1:4) etc. all complete approved and accepted by the Engineer- in- charge. 26.24.1 Light Colored each Tk. 353.00 26.24.2 Colored each Tk. 444.00 26.25 Supplying, fitting and fixing of special toilet paper holder with cover of size (150 mm x 150 mm x 126 mm) including making drills in walls and mending good the damages with cement mortar (1:4) etc. all complete approved and accepted by the Engineer- in- charge. 26.25.1 white (porcelain) each Tk. 438.00 26.25.2 colored (porcelain) each Tk. 558.00 26.25.3 Standard size stainless steel bracket and holder rod with cover. each Tk. 592.00 26.25.4 Standard size, C.P iron bracket with plastic holder rod. each Tk. 405.00 26.26 Supplying, fitting and fixing of standard size soap tray including making holes in walls and mending good the damages with cement mortar (1:4) etc. all complete approved and accepted by the Engineer- in- charge. 26.26.1 C.P. soap tray each Tk. 242.00 26.26.2 Porcelain soap tray (white) each Tk. 363.00 26.26.3 Porcelain soap tray (coloured) each Tk. 417.00 26.26.4 Stainless steel soap tray each Tk. 363.00 Item No. Unit Rate PWD SoR 2018 for Civil Works SANITARY & WATER SUPPLY WORKS Item No. Description of Item Unit 180 Unit Rate 26.27 Supplying, fitting and fixing of Automatic liquid soap dispenser to hold and dispense up to min 600 ml of liquid and lotion soaps, synthetic detergents and antibacterial soaps. Dispenser shall be powered by batteries and shall operate automatically from IR sensor that shall activate soap dispensing when hands are placed in sensor zone. Sensor detection range shall be adjustable by owner. Dispenser shall pump a drop volume of 0.8 ml to 1.0 ml of soap during each activation. A tamper resistant soap level-viewing window shall be provided. Unit shall have a swing open body secured with side-mounted lock that is opened with special key provided, all complete and accepted by the Engineer- incharge. 26.27.1 Surface mounted automatic liquid soap dispenser each Tk. 7,097.00 26.27.2 Wall-mounted automatic liquid soap dispenser each Tk. 7,700.00 26.27.3 Supplying, fitting and fixing of Liquid soap dispenser (push-up type) to dispense 16 oz (.47 liters) of soap, detergent or lotion. Unit shall be fabricated of tamper resistant, chrome plated plastic, a translucent white polyethylene soap container, and a corrosion resistant dispensing valve which can provide no more than 5 lbs (22.2 Newtons) pressure and unit can be reloaded by unscrewing base from bracket collar, inverting unit, and unscrewing soap container in which soap will continue to feed properly until empty with a continuously visible soap level etc. all complete approved and accepted by the Engineer- in- charge. each Tk. 1,060.00 26.28 Supplying, fitting and fixing of Stainless steel floor grating of following type 26.28.1 Supplying, fitting and fixing of 125 mm dia stainless steel floor grating in traps or in drains including making holes in walls/floors and mending good the damages with cement mortar (1:4) etc. all complete approved and accepted by the Engineer- in- charge. each Tk. 257.00 26.28.2 Supplying, fitting and fixing of 150 mm X 150 mm stainless steel floor grating in traps or in drains including making holes in walls/floors and mending good the damages with cement mortar (1:4) etc. all complete approved and accepted by the Engineer- in- charge. each Tk. 1,023.00 26.28.3 Supplying, fitting and fixing of 75 mm X 75 mm stainless steel floor grating in traps or in drains including making holes in walls/floors and mending good the damages with cement mortar (1:4) etc. all complete approved and accepted by the Engineer- in- charge. each Tk. 365.00 26.28.4 Supplying, fitting and fixing of 62 mm dia stainless steel floor grating in traps or in drains including making holes in walls/floors and mending good the damages with cement mortar (1:4) etc. all complete approved and accepted by the Engineer- in- charge. each Tk. 167.00 26.29 Supplying, fitting and fixing of plastic grating with hinged cover size 150 x 150 mm in traps or in drains including making holes in walls/floors and mending good the damages with cement mortar (1:4) etc. all complete approved and accepted by the Engineer- incharge. each Tk. 220.00 RAIN WATER DOWN, SOIL WASTE AND VENTILATION PIPES 26.30 Supplying, fitting and fixing of 125 mm dia convex cast iron grating on rain water down pipe (roof top) mending good the damages with cement morter (1:4) etc., all complete approved and accepted by the Engineer- in- charge. each Tk. 531.00 26.31 Supplying, fitting and fixing of 100 mm inside diameter & wall thickness 2.7 mm - 3.4 mm best quality uPVC rain water down pipe fitting, fixed in position with head and shoes, bends, minimum20 mm width F.I. Bar clamp and nails, and including all accessories such as round grating/domed roof grating, bands, sockets approved and accepted by the Engineer- in- charge. meter Tk. 701.00 PWD SoR 2018 for Civil Works SANITARY & WATER SUPPLY WORKS Item No. Description of Item Unit 181 Unit Rate 26.32 Supplying, laying, fitting and fixing of best quality HDPE soil, waste and ventilation pipe having PE-100 (Hydrostatic Strength for PE-100 is 5.0 MPa & 12.4 Mpa at 80°c & 20°c respectively according to ISO 4427:2007(E)), PN-6 (nominal pressure for PN-6 is 0.6 MPa according to ISO 4427:2007(E) ) & SDR 26 for soil, waste and ventilation pressure pipe having density 0.940 – 0.970 gm/cm3 and other physical, chemical, thermal, fire resistivity properties etc. as per BSTI approved manufacturer standards or ASTM/BS/ISO/IS standards ,fitted and fixed in position with necessary joints and fittings with all accesories complete approved and accepted by the Engineer- in- charge. 26.32.1 For underground including earth cutting & preperation of bed 26.32.1.1 HDPE pipe of 110 mm outside dia with wall thickness 4.2 mm - 4.8 mm meter Tk. 1,102.00 26.32.1.2 HDPE pipe of 160 mm outside dia with wall thickness 6.2 mm - 7.0 mm meter Tk. 1,755.00 26.32.1.3 HDPE pipe of 200 mm outside dia with wall thickness 7.7 mm - 8.6 mm meter Tk. 2,917.00 26.32.1.4 HDPE pipe of 250 mm outside dia with wall thickness 9.6 mm -10.7 mm meter Tk. 4,822.00 26.32.1.5 HDPE pipe of 280 mm outside dia with wall thickness 10.7 mm -11.9 mm meter Tk. 5,837.00 26.32.1.6 HDPE pipe of 315 mm outside dia with wall thickness 12.1 mm -13.5 mm meter Tk. 7,241.00 26.32.1.7 HDPE pipe of 400 mm outside dia with wall thickness 15.3 mm -17.0 mm meter Tk. 11,452.00 26.32.1.8 HDPE pipe of 630 mm outside dia with wall thickness 24.2 mm - 26.7 mm meter Tk. 26,598.00 26.32.1.9 HDPE pipe of 710 mm outside dia with wall thickness 27.2 mm - 30.1 mm meter Tk. 35,415.00 26.32.1.10 HDPE pipe of 900 mm outside dia with wall thickness 34.4 mm - 38.3 mm meter Tk. 56,811.00 26.32.2 For in house system 26.32.2.1 HDPE pipe 110 mm outside dia with wall thickness 4.2 mm - 4.8 mm meter Tk. 1,530.00 26.32.2.2 HDPE pipe 160 mm outside dia with wall thickness 6.2 mm -7.0 mm meter Tk. 2,500.00 26.32.2.3 HDPE pipe 200 mm outside dia with wall thickness 7.7 mm -8.6 mm meter Tk. 3,888.00 26.32.2.4 HDPE pipe 250 mm outside dia with wall thickness 9.6 mm -10.7 mm meter Tk. 6,667.00 26.33 Supplying 50 mm inside dia best quality uPVC waste and ventilation pipe having specific gravity 1.35 - 1.45, wall thickness 2.5 mm - 3.0 mm, and other physical, chemical, themal, fire resistivity properties etc. as per BSTI approved manufacturer standards or ASTM, BS/ISO/IS standards fitting and fixing in position with sockets, bends, of uPVC Pipe with all accessories such as Round grating /domed roof grating bands, sockets etc. approved and accepted by the Engineer- in- charge. meter Tk. 407.00 26.34 Supplying 100 mm inside dia best quality uPVC soil, waste and ventilation pipe having specific gravity 1.35-1.45, wall thickness 3.4- 4.0 mm, and other physical, chemical, themal, fire resistivity properties etc. as per BSTI approved manufacturer standards or ASTM, BS/ISO/IS standards fitting and fixing in position with sockets, bends, with all accessories such as round grating/domed roof grating bands, sockets etc. approved and accepted by the Engineer- in- charge. meter Tk. 617.00 PWD SoR 2018 for Civil Works SANITARY & WATER SUPPLY WORKS 182 Description of Item Unit 26.35 Supplying 150 mm inside dia best quality uPVC soil, waste and ventilation pipe having specific gravity 1.35 - 1.45, wall thickness 4.5 mm - 5.2 mm, and other physical, chemical, thermal, fire resistivity properties etc. as per BSTI approved manufacturer standards or ASTM, BS/ISO/IS standards fitting and fixing in position with sockets, bends, with all accessories such as Round grating/domed roof grating bands, sockets etc. approved and accepted by the Engineer- in- charge. meter Tk. 1,075.00 26.36 Supplying, fitting and fixing of G.I. pipe with all special fittings, such as bends, elbows, sockets, reducing sockets, Tee, unions, jam-nuts etc. including cutting trenches where necessary and fitting the same with earth duly rammed and fixing in walls with holder bats and making hole in floors, walls and consequent mending good the damages etc. all complete in all respects approved and accepted by the Engineer- in- charge. 26.36.1 12.5 mm dia G.I. pipe with wall thickness 2.65 mm, outside diameter min 17.8 mm, weight 1.31 kg/m, can withstand min 50 kg/cm2 hydraulic pressure. meter Tk. 259.00 26.36.2 20 mm dia G.I. pipe with wall thickness 2.65 mm, outside diameter min 25.3 mm, weight 1.7 kg/m, can withstand min 50 kg/cm2 hydraulic pressure. meter Tk. 336.00 26.36.3 25 mm dia G.I. pipe with wall thickness 3.35 mm, outside diameter min 31.7 mm, weight 2.59 kg/m, can withstand min 50 kg/cm2 hydraulic pressure. meter Tk. 424.00 26.36.4 32 mm dia G.I. pipe with wall thickness 3.25 mm, outside diameter min 38.5 mm, weight 3.33 kg/m, can withstand min 50 kg/cm2 hydraulic pressure. meter Tk. 529.00 26.36.5 40 mm dia G.I. pipe with wall thickness 3.25 mm, outside diameter min 46.5 mm, weight 3.83 kg/m, can withstand min 50 kg/cm2 hydraulic pressure. meter Tk. 669.00 26.36.6 50 mm dia G.I. pipe with wall thickness 3.65 mm, outside diameter min 57.3 mm, weight 5.38 kg/m, can withstand min 50 kg/cm2 hydraulic pressure. meter Tk. 860.00 26.36.7 62-65 mm dia G.I. pipe with wall thickness 3.25 mm, outside diameter min 71.5 mm, weight 6.15 kg/m, can withstand min 50 kg/cm2 hydraulic pressure. meter Tk. 1,340.00 26.36.8 75 -80 mm dia G.I. pipe with wall thickness 3.25 mm, outside diameter min 86.5 mm, weight 7.22 kg/m, can withstand min 50 kg/cm2 hydraulic pressure. meter Tk. 1,526.00 26.36.9 100 mm dia G.I. pipe with wall thickness 3.65 mm, outside diameter min 107.3 mm, weight 10.42 kg/m, can withstand min 50 kg/cm2 hydraulic pressure. meter Tk. 2,262.00 26.37 Supplying different inside dia best quality uPVC pressure pipe for water supply having specific gravity 1.35 - 1.45, and other physical, chemical, themal, fire resistivity properties etc. as per BSTI approved manufacturer standards or ASTM, BS/ISO/IS standards fitted and fixed in position with sockets, bends, with all accessories such as Round grating/domed roof grating, bends, sockets etc. approved and accepted by the Engineerin-charge. 26.37.1 12 mm dia wall thickness 1.7 mm - 2.8 mm meter Tk. 102.00 26.37.2 19 mm dia wall thickness 1.9 mm - 2.9 mm meter Tk. 140.00 26.37.3 25 mm dia wall thickness 2.2 mm - 3.4 mm meter Tk. 164.00 26.37.4 32 mm dia wall thickness 2.7 mm - 3.6 mm meter Tk. 180.00 26.37.5 37 mm dia wall thickness 2.5 mm - 3.1 mm meter Tk. 157.00 Item No. Unit Rate PWD SoR 2018 for Civil Works SANITARY & WATER SUPPLY WORKS Item No. Description of Item Unit 183 Unit Rate 26.37.6 60 mm dia wall thickness 3.0 mm - 3.9 mm meter Tk. 360.00 26.37.7 75 mm dia wall thickness 2.9 mm - 3.5 mm meter Tk. 449.00 26.37.8 88 mm dia wall thickness 3.5 mm - 4.1 mm meter Tk. 503.00 26.37.9 114 mm dia wall thickness 4.5 mm - 5.2 mm meter Tk. 615.00 26.38 Supplying different inside dia best quality CPVC pressure pipe for water supply having specific gravity 1.35 - 1.45, and other physical, chemical, thermal, fire resistivity properties etc. as per BSTI approved manufacturer standards or ASTM, BS/ISO/IS standards fitting and fixing in position with sockets, bends, with all accessories such as round grating/domed roof grating, bends, sockets etc. approved and accepted by the Engineerin-charge (length: 6000 mm each). 26.38.1 12 mm dia wall thickness 2.8 mm - 3.3 mm meter Tk. 229.00 26.38.2 19 mm dia wall thickness 2.9 mm - 3.4 mm meter Tk. 340.00 26.38.3 25 mm dia wall thickness 3.4 mm - 4.0 mm meter Tk. 385.00 26.38.4 32 mm dia wall thickness 3.6 mm - 4.2 mm meter Tk. 586.00 26.38.5 37 mm dia wall thickness 3.7 mm - 4.3 mm meter Tk. 792.00 26.38.6 50 mm dia wall thickness 3.9 mm - 4.5 mm meter Tk. 1,374.00 26.39 Supplying, fitting and fixing of PP-R Pipe meeting the perfomance & long-tem strength requirements as per DIN 8077 /78 or ASTM F 2983 including nipple, elbow, reducers, Tee, end cap, plug, socket etc as per manufacturer instruction. all complete accepted by the Engineer- in- charge. 26.39.1 12 mm dia, minimum wall thickness 2.8 mm, sustaining minimum water pressure PN 16, standard dimension ratio (SDR) 7.4 meter Tk. 244.00 26.39.2 19 mm dia, minimum wall thickness 3.5 mm, sustaining minimum water pressure PN 16, standard dimension ratio (SDR) 7.4 meter Tk. 273.00 26.39.3 25 mm dia, minimum wall thickness 4.4 mm, sustaining minimum water pressure PN 16, standard dimension ratio (SDR) 7.4 meter Tk. 316.00 26.39.4 32 mm dia, minimum wall thickness 5.5 mm, sustaining minimum water pressure PN 16, standard dimension ratio (SDR) 7.4 meter Tk. 426.00 26.39.5 38 mm dia, minimum wall thickness 6.9 mm, sustaining minimum water pressure PN 16, standard dimension ratio (SDR) 7.4 meter Tk. 502.00 26.39.6 50 mm dia, minimum wall thickness 8.6 mm, sustaining minimum water pressure PN 16, standard dimension ratio (SDR) 7.4 meter Tk. 680.00 26.40 Supplying, fitting and fixing of PP-R Union meeting the perfomance & long-tem strength requirements of ASTM F 2389 in accordance with the manufacturer‟s specifications all complete accepted by the Engineer- in- charge. 26.40.1 12 mm PP-R Union each Tk. 270.00 PWD SoR 2018 for Civil Works SANITARY & WATER SUPPLY WORKS Item No. Description of Item Unit 184 Unit Rate 26.40.2 19 mm PP-R Union each Tk. 306.00 26.40.3 25 mm PP-R Union each Tk. 342.00 26.40.4 32 mm PP-R Union each Tk. 557.00 26.40.5 37 mm PP-R Union each Tk. 844.00 26.40.6 50 mm PP-R Union each Tk. 1,035.00 26.41 Supplying, fitting and fixing of PP-R Gate-Valve meeting the perfomance & long-tem strength requirements of ASTM F 2389 in accordance with the manufacturer‟s specifications all complete accepted by the Engineer- in- charge. 26.41.1 12 mm PP-R Gate-Valve each Tk. 333.00 26.41.2 19 mm PP-R Gate-Valve each Tk. 452.00 26.41.3 25 mm PP-R Gate-Valve each Tk. 491.00 26.41.4 32 mm PP-R Gate-Valve each Tk. 797.00 26.41.5 37 mm PP-R Gate-Valve each Tk. 853.00 26.41.6 50 mm PP-R Gate-Valve each Tk. 1,109.00 26.42 Supplying, fitting and laying up to depth of invert 100 mm inside dia best quality uPVC pressure soil pipe having specific gravity 1.3 -1.45, and other physical, chemical, thermal, fire resistivity properties etc. as per BSTI approved manufacturer standards or ASTM, BS/ISO/IS standards fitted and fixed in position with sockets, bends, with all accessories such as Round grating/domed roof grating etc. complete approved and accepted by the Engineer- in- charge. 26.42.1 uPVC soil pipe of 100 mm dia and wall thickness 2.7 mm - 3.4 mm, meter Tk. 497.00 26.42.2 uPVC soil pipe of 150 mm dia and wall thickness 4.5 mm - 6.6 mm meter Tk. 855.00 26.43 Supplying, fitting and laying of Pipes up to depth of invert dia R.C.C pipe having 1.83 meter in length made of stone chips with 40 mm cement joint including all fittings and specials like plain bend, Tees, reducing sockets, junctions, door bends cowls, anti-siphon, gasket and cement joints, making holes in walls and mending good the damages etc. all complete approved and accepted by the Engineer- in- charge. 26.43.1 R.C.C pipe of 150 mm dia with thickness 40mm meter Tk. 897.00 26.43.2 R.C.C pipe of 225 mm dia with thickness 40mm meter Tk. 1,404.00 26.43.3 R.C.C pipe of 300 mm dia with thickness 50mm meter Tk. 2,293.00 26.43.4 R.C.C pipe of 375 mm dia with thickness 50mm meter Tk. 2,940.00 26.44 Supplying of 100 mm dia with wall thickness 2.7 mm - 3.4 mm uPVC pipe for waste including fitting, fixing etc. all complete approved and accepted by the Engineer- incharge. meter Tk. 489.00 PWD SoR 2018 for Civil Works SANITARY & WATER SUPPLY WORKS Item No. Description of Item Unit 185 Unit Rate 26.45 Supplying and laying uPVC pipe for for underground including fitting, fixing etc. all complete approved and accepted by the Engineer- in- charge. 26.45.1 150 mm dia with wall thickness 4.5 mm - 6.6 mm uPVC pipe meter Tk. 913.00 26.45.2 200 mm dia with wall thickness 5.3 mm - 7.8 mm uPVC pipe meter Tk. 1,364.00 26.45.3 250 mm dia with wall thickness 6.6 mm - 7.6 mm uPVC pipe meter Tk. 1,947.00 26.45.4 280 mm dia with wall thickness 6.9 mm - 8.6 mm uPVC pipe meter Tk. 2,514.00 26.45.5 315 mm dia with wall thickness 7.8 mm - 9.0 mm uPVC pipe meter Tk. 2,553.00 26.46 Supplying, fitting and fixing of G.I. Union with sealant etc. complete in all respects approved and accepted by the Engineer- in- charge. 26.46.1 12 mm dia G.I. Union each Tk. 125.00 26.46.2 20 mm dia G.I. Union each Tk. 158.00 26.46.3 25 mm dia G.I. Union each Tk. 195.00 26.46.4 32 mm dia G.I. Union each Tk. 246.00 26.46.5 40 mm dia G.I. Union each Tk. 356.00 26.46.6 50 mm dia G.I. Union each Tk. 416.00 26.46.7 62 mm dia G.I. Union each Tk. 598.00 26.46.8 75 mm dia G.I. Union each Tk. 691.00 26.46.9 100 mm dia G.I. Union each Tk. 902.00 26.47 Supplying, fitting and fixing of best quality G.I. gate valve with sealant etc. complete approved and accepted by the Engineer- in- charge. 26.47.1 12 mm brass gate valve each Tk. 409.00 26.47.2 20 mm brass gate valve each Tk. 484.00 26.47.3 25 mm brass gate valve each Tk. 650.00 26.47.4 32 mm brass gate valve each Tk. 812.00 26.47.5 40 mm brass gate valve each Tk. 1,072.00 26.47.6 50 mm brass gate valve each Tk. 1,714.00 26.47.7 62 mm brass gate valve each Tk. 3,387.00 26.47.8 75 mm brass gate valve each Tk. 4,519.00 26.47.9 100 mm brass gate valve each Tk. 7,344.00 PWD SoR 2018 for Civil Works SANITARY & WATER SUPPLY WORKS Item No. Description of Item Unit 186 Unit Rate 26.48 Supplying, fitting and fixing of best quality G.I. globe valve, threaded joint with sealant etc. complete approved and accepted by the Engineer- in- charge. 26.48.1 12 mm dia brass globe valve each Tk. 324.00 26.48.2 20 mm dia brass globe valve each Tk. 400.00 26.48.3 25 mm dia brass globe valve each Tk. 602.00 26.48.4 32 mm dia brass globe valve each Tk. 932.00 26.48.5 40 mm dia brass globe valve each Tk. 1,229.00 26.48.6 50 mm dia brass globe valve each Tk. 1,654.00 26.48.7 62 mm dia brass globe valve each Tk. 3,508.00 26.48.8 75 mm dia brass globe valve each Tk. 4,760.00 26.48.9 100 mm dia brass globe valve each Tk. 6,378.00 26.49 Supplying, fitting and fixing of best quality G.I. check valve, threaded joint with sealant etc. complete approved and accepted by the Engineer- in- charge. 26.49.1 12 mm brass check valve each Tk. 300.00 26.49.2 20 mm brass check valve each Tk. 436.00 26.49.3 25 mm brass check valve each Tk. 602.00 26.49.4 32 mm brass check valve each Tk. 836.00 26.49.5 40 mm brass check valve each Tk. 1,024.00 26.49.6 50 mm brass check valve each Tk. 1,533.00 26.49.7 62 mm brass check valve each Tk. 2,783.00 26.49.8 75 mm brass check valve each Tk. 3,734.00 26.49.9 100 mm brass check valve each Tk. 6,016.00 26.50 Supplying, fitting and fixing of best quality G.I. float valve, threaded joint Pit valve etc. complete approved and accepted by the Engineer- in- charge. 26.50.1 12 mm brass float valve each Tk. 350.00 26.50.2 20 mm brass float valve each Tk. 468.00 26.50.3 25 mm brass float valve each Tk. 568.00 26.50.4 32 mm brass float valve each Tk. 888.00 26.50.5 40 mm brass float valve each Tk. 1,023.00 PWD SoR 2018 for Civil Works SANITARY & WATER SUPPLY WORKS Item No. Description of Item Unit 187 Unit Rate 26.51 Supplying different inside dia best quality uPVC clean out / trap having specific gravity 1.35 -1.45 and other physical, chemical, themal, fire resistivity properties etc. as per BSTI approved manufacturer standards or ASTM, BS/ISO/IS standards, fitting and fixing in position etc. complete approved and accepted by the Engineer- in- charge. 26.51.1 50 mm dia uPVC Y or T - Y Cleanout each Tk. 546.00 26.51.2 100 mm dia uPVC „P‟ or „S‟ trap each Tk. 611.00 26.51.3 100 mm dia uPVC Y or T - Y Cleanout each Tk. 679.00 26.51.4 50 mm dia uPVC Y or T - Y Cleanout each Tk. 509.00 26.52 Supplying, fitting and fixing of best quality faucets etc. complete approved and accepted by the Engineer- in- charge. 26.52.1 12 mm CP bib cock each Tk. 1,014.00 26.52.2 12 mm special quality CP bib cock each Tk. 1,104.00 26.52.3 12 mm plastic bib cock with internal brass thread each Tk. 226.00 26.53 Supplying, fitting and fixing of best quality CP pillar cock etc. complete approved and accepted by the Engineer- in- charge. 26.53.1 12 mm CP medium quality pillar cock each Tk. 1,231.00 26.53.2 12 mm CP special heavy duty pillar cock each Tk. 1,280.00 26.54 Supplying, fitting and fixing of best quality CP self closing pillar pillar cock (Sensor Type) with necessary hardware etc. complete approved and accepted by the Engineerin- charge. 26.54.1 Standard CP self closing pillar cock (without mixture) each Tk. 5,557.00 26.54.2 Exclusive CP self closing pillar cock (without mixture) each Tk. 18,235.00 26.54.3 Standard CP self closing pillar cock (with mixture) each Tk. 26.54.4 Exclusive CP self closing pillar cock (with mixture) each Tk. 24,272.00 26.55 Supplying, fitting and fixing of CP Self closing pillar cock (push type) with all necessary hardware and consumables approved and accepted by the Engineer- in- charge. each Tk. 1,137.00 26.56 Supplying, fitting and fixing of best quality concealed fixed sink cock etc. complete approved and accepted by the Engineer-in-charge. 26.56.1 12 mm CP concealed fixed cock each Tk. 1,141.00 26.56.2 12 mm CP concealed moving cock each Tk. 1,504.00 26.57 Supplying, fitting and fixing of CP basin mixture with all necessary hardware and consumables approved and accepted by the Engineer.of following type 26.57.1 CP basin mixture each Tk. 2,732.00 7,971.00 PWD SoR 2018 for Civil Works SANITARY & WATER SUPPLY WORKS Item No. Description of Item Unit 188 Unit Rate 26.57.2 CP single handle basin mixture each Tk. 3,464.00 26.58 Supplying, fitting and fixing of CP shower mixture including shower head only with all necessary hardware and consumables approved and accepted by the Engineer- incharge. each Tk. 4,529.00 26.59 Supplying, fitting and fixing of CP shower mixture including shower head and faucet with all necessary hardware and consumables approved and accepted by the Engineerin- charge. each Tk. 5,435.00 26.60 Supplying, fitting and fixing of CP bath tub mixture with shower head only including all necessary hardware and consumables approved and accepted by the Engineer- incharge. each Tk. 4,770.00 26.61 Supplying, fitting and fixing of stop cock with all necessary hardware and consumables approved and accepted by the Engineer- in- charge. 26.61.1 12 mm brass stop cock for surface mount (general quality) each Tk. 412.00 26.61.2 12 mm CP stop cock for surface mount (medium quality) each Tk. 406.00 26.61.3 12 mm CP stop cock for surface mount (special type) each Tk. 1,136.00 26.61.4 Stop cock concealed (medium) each Tk. 1,197.00 26.61.5 Stop cock concealed (heavy) each Tk. 1,245.00 26.63 Supplying, fitting and fixing of angle stop cock etc. complete approved and accepted by the Engineer- in- charge. 26.63.1 12 mm CP surface mounted angle stop cock (Heavy Type) each Tk. 853.00 26.63.2 12 mm CP medium quality surface & standard angle stop cock each Tk. 804.00 26.63.3 12 mm surface special heavy type angle stop cock each Tk. 877.00 26.63.4 12 mm CP concealed mount angle stop cock each Tk. 853.00 26.63.5 Medium concealed angle stop cock each Tk. 913.00 26.63.6 Special concealed heavy type angle stop cock each Tk. 1,197.00 26.64 Groove cutting in brick work and R.C.C work, including cost for concealing of G.I. pipe work (12 mm and 20 mm dia) in brick wall by cutting groove in wall, lintel, beam etc. by any means carefully without damaging the structure and filling the grooves with C.C (4:2:1) after laying of pipe including cost of scaffolding, finishing, curing etc. all complete approved and accepted by the Engineer- in- charge. 26.64.1 Groove size 40 mm x 40 mm (For laying 12 mm to 20 mm dia pipes) meter Tk. 65.00 26.64.2 Groove size 75 mm x 75 mm (For 25 mm to 40 mm dia pipes) meter Tk. 98.00 26.65 Supplying and fitting-fixing cleansing shower for ablution including holder etc. all complete approved and accepted by the Engineer- in- charge. PWD SoR 2018 for Civil Works SANITARY & WATER SUPPLY WORKS Item No. Description of Item Unit 189 Unit Rate 26.65.1 Fixed type 100 mm CP shower rose each Tk. 658.00 26.65.2 Moving type 100 mm CP shower rose each Tk. 1,396.00 26.66 Supplying and fitting-fixing hand / push shower for ablution including holder etc. all complete approved and accepted by the Engineer- in- charge. 26.66.1 Moving type hand shower each Tk. 1,571.00 26.66.2 Moving type push shower each Tk. 967.00 26.67 Supplying, fitting and fixing of food graded plastic overhead water reservoir tank including all necessary fittings, hardware and consumables etc. all complete approved and accepted by the Engineer- in- charge. 26.67.1 1000 liter capacity each Tk. 10,912.00 26.67.2 1500 liter capacity each Tk. 15,295.00 26.67.3 2000 liter capacity each Tk. 20,064.00 26.68 Supply and installation of food-graded plastic internal mini water tank for the use in kitchen, bathroom and toilet for emergency storage and supply of water manufactured from liner low density polyethylene (ILDPE) roto-grade (ultra violet) stabilized which complies FDA (Federal Department of Agriculture, USA) regulations 21 CFR 1277. 152, having food grade quality where no recycled material is used carrying, lifting, fitting, fixing in position including supply of necessary hardware, consumables, fittings etc. all complete approved and accepted by the Engineer- in- charge. 26.68.1 150 liter capacity each Tk. 3,365.00 26.68.2 300 liter capacity each Tk. 4,277.00 26.68.3 500 liter capacity each Tk. 6,334.00 26.69 Supply and installation of foreign made food graded stainless steel water tank including supply of hardware, consumables, fittings etc. all complete approved and accepted by the Engineer- in- Charge. 26.69.1 500 liter capacity each Tk. 11,187.00 26.69.2 1000 liter capacity each Tk. 19,520.00 26.69.3 2000 liter capacity each Tk. 32,101.00 26.69.4 4000 liter capacity each Tk. 63,030.00 26.69.5 6000 liter capacity each Tk. 68,596.00 26.70 Supply and installation of 400 gallon capacity ferro-cement water tank including necessary hardware, fittings and consumables etc. all complete approved and accepted by the Engineer- in- charge. each Tk. 8,017.00 26.71 Supplying, fitting and fixing of 12 mm dia, 450 mm long plastic flexible lead (connection) pipe approved and accepted by the Engineer- in- charge. each Tk. 57.00 PWD SoR 2018 for Civil Works SANITARY & WATER SUPPLY WORKS 190 Description of Item Unit 26.72 Supplying, fitting and fixing of 12 mm dia, 600 mm long plastic flexible lead (connection) pipe approved and accepted by the Engineer- in- charge. each Tk. 101.00 26.73 Supplying, fitting and fixing of 12 mm dia 450 mm long metal cover connection pipe approved and accepted by the Engineer- in- charge. each Tk. 162.00 26.74 Supplying, fitting and fixing of 12 mm dia 600 mm long metal cover connection pipe approved and accepted by the Engineer- in- charge. each Tk. 186.00 26.75 Supply, fitting & fixing of 600 mm dia C.I. man hole cover etc. all complete approved by the Engineer- in- charge. each Tk. 1,869.00 26.76 Supply, installation, testing and commissioning of auto control booster pump system to maintain a pressure 0.8~2.2 bar in the water pipe line in the top floor(s). The booster pump system consists of the following components - 9,551.00 Item No. Unit Rate (i) Single phase pump motor- 01 no. HP 0.5~1.0, IP: 65, RPM:2900 (ii) Easy press switch : a device which control the pressure etc. all complete approved by the Engineer- in- charge. 26.76.1 Made in or assembled in Bangladesh each Tk. 26.76.2 Made in Italy/ Spain/ India etc. each Tk. 20,176.00 26.77 Suppy, fitting and fixing of Water pressure reducing valve to reduce static and flowing pressures in water distribution systems and it shall be a diaphragm/balanced piston type with integral stainless steel strainer and a built-in bypass to relieve pressure build-up downstream of the assembly. The valve shall be spring loaded to open and shall be diaphragm actuated to close under pressure conditions. The valve shall be suitable for supply pressure up to 400 psi and water temperatures from 33º to 180ºF. The valve‟s internal parts such as the cartridge assembly, strainer, diaphragm, and spring shall be accessible for inspection, repair or replacement without disconnecting the device from the pipeline. In addition, the valve shall have a clean-out feature to allow for removal of the strainer and seat disc without disturbing the pressure setting etc. all complete accepted by the Engineer- in- charge. 26.77.1 12 mm dia water pressure reducing valve each Tk. 2,384.00 26.77.2 19 mm dia water pressure reducing valve each Tk. 3,226.00 26.77.3 25 mm dia water pressure reducing valve each Tk. 3,948.00 26.77.4 32 mm dia water pressure reducing valve each Tk. 7,557.00 26.77.5 38 mm dia water pressure reducing valve each Tk. 8,399.00 26.77.6 50 mm dia water pressure reducing valve each Tk. 12,129.00 26.77.7 62 mm dia water pressure reducing valve each Tk. 20,550.00 26.77.8 75 mm dia water pressure reducing valve each Tk. 29,574.00 26.78 Manufacturing, supplying, fitting & fixing of adjustable hanger made of 38 mm x 38 mm x 6 mm m.s. angle with 600 mm long 12 mm dia nut-bolt for having pvc pipe from ceiling as per direction of the Engineer-in-charge. meter Tk. 676.00 PWD SoR 2018 for Civil Works SANITARY & WATER SUPPLY WORKS Description of Item Unit Supplying, fitting and installation of automatic hand drier of high speed, energy efficient, rapid drying, automatic sensor, adjustable speed and sound control, adjustable heat control, electric hand dryer; surface mounted or semi‐recessed which can eliminate over 99% of airborne bacteria and particles as small as 0.3 microns with the removable Super Filter System and it shall be powered by 220v AC supply/ batteries and shall operate automatically from IR sensor that shall activate it when hands are placed in sensor zone etc. all complete accepted by the Engineer- in- charge. each Tk. 6,094.00 Item No. 26.79 191 Unit Rate INSPECTION PIT & SOAK WELL 26.80 Construction of masonry inspection pit with 250 mm thick brick work in cement mortar (1:4) including necessary earth work, side filling and one layer brick flat soling, 75 mm thick (1:3:6) base concrete for making invert channel and 12 mm thick (1:2) cement plaster with neat finishing etc. all complete up to a depth of 700 mm approved and accepted by the Engineer- in- charge. 26.80.1 Clear 450 mm x 450 mm and depth 450 mm to 600 mm, average 525 mm for single 150 mm dia R.C.C. pipes and 400 mm PVC pipe. each Tk. 3,530.00 26.80.2 Clear 525 mm x 525 mm and depth 675 mm to 825 mm, average 750 mm for single 225 mm dia R.C.C. pipes and 400 mm PVC pipe. each Tk. 5,262.00 26.80.3 Clear 600 x 600 mm and depth 750 mm to 900 mm, average 825 mm for single 300 mm dia R.C.C. pipes and 400 mm PVC pipe. each Tk. 7,321.00 26.80.4 Master-pit of Size: Clear 600 mm x 500 mm and average 750 mm depth for Septic tank. each Tk. 3,825.00 26.81 Construction and placement M.H. cover with locking/unlocking arrangement including necessary earth work, side filling, shuttering, curing, cement plaster (1:4) with neat finishing on edges and top etc. all complete approved and accepted by the Engineer- incharge. 26.81.1 900 mm x 900 mm x 75 mm R.C.C. pit cover each Tk. 1,365.00 26.81.2 1025 mm x 1025 mm x 75 mm R.C.C. pit cover each Tk. 1,575.00 26.81.3 1100 mm x 1100 mm x 75 mm R.C.C. pit cover each Tk. 1,804.00 26.82 Construction and placing of R.C.C inspection pit cover (slab) with supplying and provisions for placing, fitting, fixing 450 mm dia C.I. man-hole cover with locking/unlocking arrangement including concrete (1:2:4) with approx. 1% re-enforcement, necessary earth cutting, or cleaning, side filling, curing etc. with minimum 12 mm cement plaster (1:4) and neat cement finishing on edges and top all complete and accepted by the Engineer- in- charge. 26.82.1 950 mm x 950 mm x 75 mm R.C.C. pit cover with 450 mm dia C.I. manhole cover. each Tk. 2,280.00 26.82.2 1025 mm x 1025 mm x 75 mm R.C.C. pit cover with 450 mm dia C.I. manhole cover. each Tk. 2,443.00 26.82.3 1100 mm x 1100 mm x 75 mm R.C.C. pit cover with 450 mm dia C.I. manhole cover. each Tk. 2,672.00 PWD SoR 2018 for Civil Works SANITARY & WATER SUPPLY WORKS Item No. Description of Item Unit 192 Unit Rate 26.83 Construction of masonry inspection pits up to a depth of 700 mm with 250 mm thick brick work in cement mortar (1:4) including 100 mm thick R.C.C. top slab (1:2:4) with 1% reinforcement, man-hole cover with locking arrangement including necessary earth work, side filling and one brick flat soling. 75 mm thick (1:3:6) base concrete for making invert channel and 12 mm thick (1:2) cement plaster with neat finishing etc. all complete approved and accepted by the Engineer- in- charge. 26.83.1 Clear 450 mm x 450 mm and depth 450 mm to 600 mm, average 525 mm for single 150 mm dia R.C.C. pipes and 400 mm PVC pipe with pit cover and 450 mm dia C.I. man-hole cover. each Tk. 5,810.00 26.83.2 Clear 525 mm x 525 mm and depth 675 mm to 825 mm, average 750 mm for single 225 mm dia R.C.C. pipes and 400 mm PVC pipe with pit cover and 450 mm dia C.I. man-hole cover. each Tk. 7,705.00 26.83.3 Clear 600 mm x 600 mm and depth 750 mm to 900 mm, average 825 mm for single 300 mm dia R.C.C. pipes and 375 mm and 400 mm PVC pipe with pit cover and 450 mm dia C.I. man-hole cover. each Tk. 9,993.00 26.84 Construction of septic tank of different sizes with walls of brick work in cement mortar (1:6) having a lining of minimum 125 mm R.C.C cast against the walls as per approved type plan over a brick flat soling and 150 mm thick reinforced cement concrete flooring (1:2:4) with 125 mm thick walls in partition and 12 mm thick cement plaster (1:4) with N.C.F. to insides of walls on floor and all around outside walls by 450 mm height at top including supplying, fitting and fixing of two R.C.C. Tees and providing 450 mm dia water sealed heavy type C.I. manhole cover with locking/unlocking arrangement and 100 mm thick R.C.C (1:2:4) top slab, including centering, shuttering, fabricating, casting and curing etc. complete up to required depth including necessary earth work in excavation and shoring, bailing out water and side filling including the cost of all materials, operations and incidental charges. etc. all complete as per type plan approved and accepted by the Engineer-in-charge (Rate is including cost of reinforcement and its fabrication, binding and placing). 26.84.1 For 200 users each Tk. 233,848.00 26.84.2 For 100 users each Tk. 183,728.00 26.84.3 For 50 users each Tk. 121,120.00 26.84.4 For 30 users each Tk. 84,995.00 26.84.5 For 20 users each Tk. 80,255.00 26.84.6 For 10 users each Tk. 46,023.00 26.85 Construction of soak well of different sizes (medium and large sizes) with 250 mm thick solid brick work and 250 mm honey comb brick work with cement mortar (1:6) as per design over R.C.C. (1:2:4) well curb with 1% reinforcement up to the depth as per drawing with 450 mm dia water sealed heavy type. C.I. manhole cover with locking arrangement, filling the well up to the required depth with graded khoa and sand including supplying and fabricating M.S. rod, casting, curing including necessary earth work in excavation, side filling and bailing out water including cost of all materials etc. all complete as per drawing, design approved and accepted by the (Rate is including cost of reinforcement and its fabrication, binding and placing) Engineer- in- charge. 26.85.1 200 users each Tk. 86,069.00 PWD SoR 2018 for Civil Works SANITARY & WATER SUPPLY WORKS Item No. Description of Item 193 Unit Unit Rate 26.85.2 100 users each Tk. 76,264.00 26.85.3 50 users each Tk. 64,420.00 26.86 Construction of soak well of different sizes (small sizes) with 250 mm thick solid brick work and 250 mm honey comb brick work with cement mortar (1:6) as per design over R.C.C. (1:2:4) well curb with 1% reinforcement up to the depth as per drawing with 450 mm dia water sealed heavy type. C.I. manhole cover with locking arrangement, filling the well up to the required depth with graded khoa and sand including supplying and fabricating M.S. Rod, casting, curing including necessary earth work in excavation, side filling and bailing out water including cost of all materials etc. all complete as per drawing, design approved and accepted by the Engineer- in- charge. 26.86.1 20 to 30 users each Tk. 54,765.00 26.86.2 10 users each Tk. 37,667.00 26.87 Supplying, fitting, fixing of foreign made best quality Reverse Osmosis Water Purifier (Kent / Unilever / Vapor water purifier or equivalent brand) for purification of water by reverse osmosis system to have potable water conforming WHO standard and Bangladesh concentration parameters including installation charge, carriage, sundries etc. complete approved and accepted by the Engineer- in- charge. 26.87.1 Water purification volume: 50 gallon /day water reserve capacity each Tk. 12,920.00 26.87.2 Water purification volume: 75 gallon per day each Tk. 19,279.00 26.87.3 Water purification volume: 75 gallon per day (touch type) each Tk. 25,437.00 26.87.4 Water purification volume: 100 gallon per day (with hot, cold & warm option) each Tk. 69,418.00 26.87.5 Water purification volume: 200 gallon per day each Tk. 51,035.00 26.87.6 Water purification volume: 400 gallon per day each Tk. 75,546.00 26.88 Supply, installation and commissioning of 50 liter capacity best quality ‘Water dispenser’ with container of approved brand/origin. each Tk. 4,468.00 26.89 Punching or cutting hole of any diameter for sanitary works. each Tk. 325.00 ………………….. END OF DIVISION TWENTY SIX ………………….. PWD SoR 2018 for Civil Works DEEP TUBE-WELL 194 DIVISION 27: DEEP TUBE-WELL Item No. Description of Item Unit Unit Rate Note: Tender for test & observation well must be called before hand. Tender for main production well will then be called on the basis of required data obtained from the test well. Requirements of water must be the guiding factor for dimensioning the main well. SINKING OF 38 mm DIA TEST AND OBSERVATION WELL 27.1 Mobilization of test boring or observation well: Transportation of materials, equipments, tools and plants and boring rig to work site. Construction of derrick and dismantling the same. Cleaning the site after completion of the work accepted by the Engineer-in-charge. per set Tk. 7,913.00 27.2 Boring by using 100 mm dia cutter and 40 mm dia heavy type G.I pipe (wall thickness 2.9 mm, outside diameter min 47.8 mm, weight 3.517 kg/m, capable to withstand 50 kg/cm2 pressure) and other equipments capable of drilling up to a depth of 500 meter by water jet system through all sorts of soil strata providing protection of caving by supplying necessary casing pipe. Collection of soil samples at every 3 meter interval and at every change of soil strata and preserving them in a controlled environment for analysis and laboratory test. Finally, withdrawal of boring and casing pipes etc. complete and accepted by the Engineer-in-charge. 27.2.1 From 0.0 m to 50 m = 50 m meter Tk. 191.00 27.2.2 Above 50 m to 100 m = 50 m meter Tk. 219.00 27.2.3 Above 100 m to 152 m = 52 m meter Tk. 252.00 27.2.4 Above 152 m to 200 m = 48 m meter Tk. 290.00 27.2.5 Above 200 m to 250 m = 50 m meter Tk. 334.00 27.2.6 Beyond 250 m meter Tk. 384.00 27.3 Installation of tube-well fixture for observation well: Supplying and lowering of 40/38 mm inside dia best quality uPVC pressure tube well pipe (specific gravity 1.35 - 1.45, wall thickness 2.5 mm - 3.0 mm capable to withstand a minimum hydrostatic pressure of 170 psi for 1 hr). Fitting and fixing in position with all accessories, uPVC sand trap of length 3.00m with uPVC strainer of desired slot installing in or at mid depth of the most suitable water bearing strata, 38 mm dia, best quality G.I. pipe of length 1.52 m with M.S. welded flat bar welded on each side to prevent from rotation up to desired depth, fitting, fixing the best quality no. 6 C.I. head hand-pump etc including the cost of solvent cement, socket adapter, filling medium sand up to 18.00 m above strainer and the remaining portion with available soil from boring etc. complete as per standard specification and accepted by the Engineer-in-charge. 27.3.1 Fitting & fixing of no. 6 Hand-pump set including all necessary accessories etc per set Tk. 2,968.00 PWD SoR 2018 for Civil Works DEEP TUBE-WELL Item No. 195 Description of Item Unit Unit Rate 27.3.2 Supplying and fitting 38/40 mm dia heavy type G.I pipe conforming to standard BS-1387 & BDS-1031, having chemical composition (in%) carbon 0.17-0.25, manganese 0.95-1.20, sulphur 0.060 max, phosphorous 0.060 max, tensile properties: miminum yield strength 188 MPa, minimum tensile strength 313 MPa and marking for a) manufacturer b) material c) wall thickness d) nominal outside dia e) intended use etc. on the body of the pipe having wall thickness 2.9 mm, weight 3.517 kg/m capable to withstand 50 kg/cm 2 hydraulic pressure meter Tk. 770.00 27.3.3 38/40 mm dia water grade uPVC pipe having wall thickness 2.5 mm -3.00 mm meter Tk. 162.00 27.3.4 38/40 mm dia water grade uPVC strainer having wall thickness 2.5 mm -3.00 mm meter Tk. 204.00 27.3.5 38/40 mm dia uPVC socket adapter each Tk. 100.00 27.3.6 Best quality 38 mm dia uPVC cap each Tk. 79.00 27.3.7 Supplying, fitting & fixing observation well inside the housing pipe of the deep tube well:100'-0" depth each Tk. 19,802.00 27.3.8 Supplying, fitting & fixing tube-well log describing technical information of the tube-well each Tk. 4,105.00 27.3.9 Filling the top 0.6 meter of the bore hole around the top pipe with sanitary seal of 1:2:4 (Cement: 1.2 FM sand: 20 mm downgraded brick chips) concrete each Tk. 51.00 27.4 Complete development of the tube well to obtain sand and turbidity free water at a satisfactory yield confirmed by tests as per specification and accepted by the Engineer-incharge. Water sample must be taken from 3 separate aquifers from three tube-wells 27.4.1 Wells up to 200 meter depth 27.4.1.1 For 1 No. test tube-well LS Tk. 7,024.00 27.4.1.2 For 2 Nos. test tube-wells LS Tk. 10,536.00 27.4.1.3 For 3 Nos. test tube-wells LS Tk. 14,048.00 27.4.2 Wells beyond 200 meter depth 27.4.2.1 For 1 No. test tube-well meter Tk. 40.00 27.4.2.2 For 2 Nos. test tube-wells meter Tk. 61.00 27.4.2.3 For 3 Nos. test tube-wells meter Tk. 81.00 PWD SoR 2018 for Civil Works DEEP TUBE-WELL Item No. 27.5 Description of Item 196 Unit Unit Rate "Furnishing design of a production well by testing of water and soil samples from test bores up to 350 m depth collecting samples of water from the best suitable aquifer, filling in sterilized air-tight glass bottles having no air space inside; collecting soil (sand, solids etc) at every 3 m interval and at each change of soil strata from the bores, arranging them in the cell of a box in an orderly manner. Carrying out test of water for (1) pH, (2) CO 2 (3) Chloride, (4) Fluoride, (5) Iron, (6) Manganese, (7) Nitrate-Nitrogen, (8)Total alkalinity, (9) Total hardness, (10) Arsenic, (11) Turbidity, followed by test reports along with Bangladesh Standards of potable water and (12) sieve analysis on soils throughout a bore, leading to ascertain the best suitable sustained aquifers, depths and slot sizes of strainer, types and dia of tube well for specific yield, thickness of shrouding around strainer, fineness modulus of shrouding materials, mechanical units (pumps, compressor) for testing and operation of the tube well, maintaining test bore functional till tube well installation, testing etc. is finished, finally filling and sealing the left over test bore permanently, including carrying water and soil samples under direct responsibility of Engineer-in-charge to BRTC, BUET or other reputed laboratory, approved by the authority, submitting the report and design details all complete and accepted by the Engineer-incharge and maintaining the mobilized tools and plants at site till satisfactory test results are found (if not, next test bore may be executed with the approval of concern S.E. / Design Office) Total No. of test on water: 11 types of test x 1 test bore x one set sample (3 specimen) = 11 Nos. test (each specimen 1.5 liter of water) Sieve analysis: min 9 Nos. Sample x one test x One bore = 9 Nos. test (Samples are of 1 kg dry wt. each)” There are about 55 (fifty-five) tests for potable water quality standard according to Bangladesh Environment Conservation Rules-12 (Schedule-3), 1997, under ECA 1995 of Ministry of Environment and Forest. Therefore, additional test/ tests on water or sieve analysis of soil if required, other than the above specified 12 (twelve) tests, may be carried out for public interest as per direction of the design engineer on actual payment including profit, VAT and all other charges. 27.5.1 Furnishing design considering 1 No. test bore LS Tk. 43,227.00 27.5.2 Furnishing design considering 2 Nos. test bores LS Tk. 72,930.00 27.5.3 Furnishing design considering 3 Nos. test bores LS Tk. 109,395.00 27.6 Disinfections of the well by using minimum 3 kg of bleaching powder of 33% strength or any other disinfectant as per standard specification and accepted by the Engineer-incharge. each Tk. 433.00 PRODUCTION WELL 27.7 Mobilization: Preparation for installation of tube-well and transportation of complete boring equipments, labour and materials to the work site and remove the materials after completion of the works. Installation of drilling rig and accessories, making arrangements for electricity, water, labour shed, site office and stores, digging mud pit etc, leveling, dressing and clearing of the site as per original condition and a testing for discharge using minimum 1000 liter water tub etc. all complete as per specifications and accepted by the Engineer-in-charge. 27.7.1 For Tube-wells up to 100 meter depth per set Tk. 39,232.00 27.7.2 For Tube-wells up to 200 meter depth per set Tk. 42,034.00 PWD SoR 2018 for Civil Works DEEP TUBE-WELL Item No. Description of Item 197 Unit Unit Rate per set Tk. 44,836.00 27.7.3 For Tube-wells beyond 200 meter depth 27.8 Preparation and making gravel pack around the tube well fixtures with supply of designed graded pea gravels free from any substance harmful to pipe and health confirmed by test (Passing through #10 mesh and retained on #40 mesh) including sieving, washing etc. complete as per standard specification and accepted by the Engineer-in-charge. (The rate is inclusive of the cost of extra amount required for caving and extra depth below the tube well fixtures, shrouding should not be more than 15 m above the strainer and measurement should be allowed from bottom of the tube-well fixture to top of the gravel pack) cum Tk. 4,725.00 27.9 Making a sanitary seal up to a minimum depth of 6 meter from G.L. or as specified including the supply of approved quality of cement, sand and khoa (12 mm down graded) in a ratio of (1:1:5:3) as per standard specification and accepted by the Engineer-incharge. cum Tk. 8,293.00 INSTALLATION OF 50 mm x 125 mm DIA SHROUDED PRODUCTION WELL WITH PVC PIPE 27.10 Boring: Execution of 325 mm dia boring through all sorts of strata by reverse circulation or any other approved method (Method other than reverse circulation is to be applied only for wells deeper than 152 meter). Boring for 325 mm dia vertical hole up to designed depth and collection of soil samples at every 3 meter interval or as required and at every change in soil stratum including sinking and with drawing necessary casing pipe and all necessary arrangements complete as per specification and accepted by the Engineer-in-charge. (Measurement will be allowed from E.G.L. to bottom of the blind pipe and the rate is inclusive of the cost of extra depth or of further boring required due to caving and siltation) 27.10.1 From 0.0 m to 50 m = 50 m meter Tk. 939.00 27.10.2 From 50 m to 100 m = 50 m meter Tk. 1,080.00 27.10.3 From 100 m to 152 m = 52 m meter Tk. 1,242.00 27.10.4 From 152 m to 200 m = 48 m meter Tk. 1,428.00 27.10.5 From 200 m to 250 m = 50 m meter Tk. 1,642.00 27.10.6 Beyond 250 m meter Tk. 1,889.00 27.11 Supplying the following tube well fixtures and pipes having density 1350 kg/m 3, opacity 0.2% of visible light as per ISO 7686, minimum required strength 25 MPa conforming to BDS-1:2013, 4.4.1, 4.4.2 at working site as per standard practice and accepted by the Engineer-in-charge. Note : Pipe size (wall thickness) will be chosen as per table page no: 213) 27.11.1 Best quality 50 mm dia uPVC cap each Tk. 107.00 27.11.2.1 50 mm dia water grade (Class C) uPVC blind pipe/sand trap of wall thickness 2.5 mm to 3.00 mm meter Tk. 163.00 27.11.2.2 50 mm dia water grade (Class D) uPVC blind pipe/sand trap of wall thickness 3.1 mm to 3.7 mm meter Tk. 192.00 PWD SoR 2018 for Civil Works DEEP TUBE-WELL 198 Item No. Description of Item Unit Unit Rate 27.11.2.3 50 mm dia water grade (Class E) uPVC blind pipe/sand trap of wall thickness 3.9 mm to 4.5 mm meter Tk. 255.00 27.11.3.1 50 mm dia strainer of any slot as per design made with grade (Class C) uPVC pipe of wall thickness 2.5 mm to 3 mm meter Tk. 215.00 27.11.3.2 50 mm dia strainer of any slot as per design made with grade (Class D) uPVC pipe of wall thickness 3.1 mm to 3.7 mm meter Tk. 244.00 27.11.3.3 50 mm dia strainer of any slot as per design made with grade (Class E) uPVC pipe of wall thickness 3.9 mm to 4.5 mm meter Tk. 307.00 27.11.4 Best quality 50 mm x 125 mm dia uPVC Reducer meter Tk. 691.00 27.11.5.1 125mm dia water grade (Class C) uPVC housing pipe of wall thickness 5.5 to 6.4mm meter Tk. 786.00 27.11.5.2 125mm dia water grade (Class D) uPVC housing pipe of wall thickness 7.3 to 8.4mm meter Tk. 977.00 27.11.5.3 125mm dia water grade (Class E) uPVC housing pipe of wall thickness 9.0 to 10.4mm meter Tk. 1,158.00 27.11.6 Supplying centralizer made with 12 mm dia M.S. rod of approved design each Tk. 379.00 27.12 Complete installation of 50 mm dia uPVC tube well fixtures such as expanded top or furnishing pipe, reducer, tube well pipes, strainer, blind pipe, pipe cap etc. fitting and fixing with best quality PVC solution, iron screws and PVC tape, sockets and placing in position with proper size M.S. centralizer @ 3.0 meter c/c in strainer portion including blind pipe etc. complete as per standard practice and accepted by the Engineer-in-charge. meter Tk. 80.00 27.13 Complete development of the tube well by air compressor and pump of suitable capacity by alternate surging and pumping or any specified method until satisfactory yield is achieved in sand and turbid free water confirmed by laboratory test using necessary quantity of cologne and conducting step drawn-down test before and after the development as per specification and accepted by the Engineer-in-charge. (Development should be started within 24 hours of completion of shrouding) 27.13.1 Wells up to 200 m depth each Tk. 23,272.00 27.13.2 Wells beyond 200 m depth each Tk. 29,478.00 27.14 Pumping test of the well by designed turbine/submersible pump with supply of testing equipments for pressure/ velocity/ discharge etc. and all materials for 72 hours including yield drawn and recovery test etc. complete as per specification and accepted by the Engineer-in-charge. per hour Tk. 760.00 27.15 Disinfections of the well including supply of sufficient quantity of bleaching powder (33% strength) to obtain chlorinated water having 150 ppm free chlorine in the well complete as per standard specification and accepted by the Engineer-in-charge. each Tk. 1,244.00 27.16 Filling of the borehole around the tube well from top of the shrouding up to the bottom of sanitary seal by withdrawn selected soil or by local clay free from any substances harmful to pipes and health as per standard specification and accepted by the Engineer-in-charge. meter Tk. 31.00 27.17 Protective top cover: Supplying and fitting fixing of best quality 150 mm dia 4 mm thick MS. Pipe 1.0 m (3'-4") long one end blocked with 200 mm dia 4 mm thick M.S. plate and other end minimum 300 mm (1'-0") embedded in sanitary seal for protection of uPVC Housing Pipe as per standard specification and accepted by the Engineer-in-charge. each Tk. 4,549.00 PWD SoR 2018 for Civil Works DEEP TUBE-WELL Item No. Description of Item Unit 199 Unit Rate INSTALLATION OF 75 mm x 150 mm DIA SHROUDED PRODUCTION WELL WITH PVC PIPE 27.18 Boring: Execution of 350 mm dia boring through all sorts of strata by reverse circulation or any other approved method (Method other than reverse circulation is to be applied only for wells deeper than 152 meter). Boring for 350 mm dia vertical hole up to designed depth and collection of soil samples at every 3 meter interval or as required and at every change in soil stratum including sinking and withdrawing necessary casing pipe and all necessary arrangements complete as per specification and accepted by the Engineer-in-charge. (Measurement will be allowed from E.G.L. to bottom of the blind pipe and the rate is inclusive of the cost of extra depth or of further boring required due to caving and siltation) 27.18.1 From 0.0 m to 50 m = 50 m meter Tk. 988.00 27.18.2 From 50 m to100 m = 50 m meter Tk. 1,136.00 27.18.3 From 100 m to 152 m = 52 m meter Tk. 1,307.00 27.18.4 From 152 m to 200 m = 48 m meter Tk. 1,503.00 27.18.5 From 200 m to 250 m = 50 m meter Tk. 1,728.00 27.18.6 Beyond 250 m meter Tk. 1,987.00 27.19 Supplying the following tube well fixtures and pipes having density 1350 kg/m3, opacity 0.2% of visible light as per ISO 7686, minimum required strength 25 MPa conforming to BDS-1:2013, 4.4.1, 4.4.2 at working site as per standard practice and accepted by the Engineer-in-charge. 27.19.1 Best quality 75 mm dia uPVC cap each Tk. 145.00 27.19.2.1 75 mm dia water grade (Class C) uPVC blind pipe/sand trap of wall thickness 3.5 mm to 4.1 mm meter Tk. 313.00 27.19.2.2 75 mm dia water grade (Class D) uPVC blind pipe/sand trap of wall thickness 4.6 mm to 5.3 mm meter Tk. 403.00 27.19.2.3 75 mm dia water grade (Class E ) uPVC blind pipe/sand trap of wall thickness 5.7 mm to 6.6 mm meter Tk. 878.00 27.19.3.1 75 mm dia strainer of any slot as per design made with water grade (Class C) uPVC pipe of wall thickness 3.5 to 4.1 mm meter Tk. 359.00 27.19.3.2 75 mm dia strainer of any slot as per design made with water grade (Class D) uPVC pipe of wall thickness 4.6 mm to 5.3 mm meter Tk. 450.00 27.19.3.3 75 mm dia strainer of any slot as per design made with water grade (Class E) uPVC pipe of wall thickness 5.7 mm to 6.6 mm meter Tk. 924.00 27.19.4 Best quality 75 mm x 150 mm dia uPVC Reducer each Tk. 881.00 27.19.5.1 150 mm dia water grade (Class C) uPVC housing pipe having wall thickness 6.6 mm to 7.6 mm meter Tk. 1,138.00 PWD SoR 2018 for Civil Works DEEP TUBE-WELL 200 Item No. Description of Item Unit 27.19.5.2 150 mm dia water grade (Class D) uPVC housing pipe having wall thickness 8.8 mm to 10.2 mm meter Tk. 1,540.00 27.19.5.3 150 mm dia water grade (Class E) uPVC housing pipe having wall thickness 10.8 mm to 12.5 mm meter Tk. 1,842.00 27.19.6 Supplying of centralizer made with 12 mm dia M.S. rod of approved design meter Tk. 379.00 27.20 Complete installation of 75 mm dia uPVC tube-well fixtures such as expanded top pipes, reducer, tube-well pipes, strainer, blind pipe, pipe cap etc fitting and fixing with best quality uPVC solution, iron screws and uPVC tape and placing in position with proper size M.S. centralizer @ 3 meter c/c .in strainer portion including blind pipe etc. complete as per standard practice and accepted by the Engineer-in-charge. meter Tk. 89.00 27.21 Complete development of the well by suitable air compressor and pump of suitable capacity by alternate surging and pumping untill satisfactory yield, sand free water and the turbidity condition is reached using necessary quantity of calgon and conducting step draw down test before and after the development as per specification and accepted by the Engineer-in-charge. (Development should be started within 24 hours of completion of shrouding) 27.21.1 Wells up to 200 m depth each Tk. 31,419.00 27.21.2 Wells beyond 200 m depth each Tk. 37,702.00 27.22 Pumping test of the well by designed turbine/submersible pump with supply of testing equipments for pressure/ velocity/ discharge etc. and all materials for 72 hours including yield drawn and recovery test etc. complete as per specification and accepted by the Engineer. hour Tk. 935.00 27.23 Disinfections of the well including supply of sufficient quantity of bleaching powder (33% strength) chlorinated water having 150 ppm available free chlorine complete as per standard specification and accepted by the Engineer-in-charge. each Tk. 1,511.00 27.24 Filling of the bore-hole around the tube well from top of the shrouding up to the bottom of sanitary seal by withdrawn selected soil or local clay free from any substances harmful to pipes and health as per standard specification and accepted by the Engineer-in-charge. meter Tk. 37.00 27.25 Protective top cover: Supplying and fitting fixing best quality 200 mm dia 4 mm thick M.S. pipe 1.0 m (3'-4") long, one end blocked with 250 mm dia 4 mm thick M.S. plate and other end minimum 300 mm (1'-0) embedded in sanitary seal for protection of uPVC housing pipe as per standard specification and accepted by the Engineer-in-charge. each Tk. 6,113.00 INSTALLATION OF 100 mm x 200 mm DIA SHROUDED PRODUCTION WELL WITH PVC PIPE 27.26 Boring: Execution of 400 mm dia of boring through all sorts of strata by reverse circulation or any other approved method (Method other than reverse circulation is to be applied only for wells deeper than 152 meter) Boring for 400 mm dia vertical hole up to designed depth and collection of soil samples at every 3 meter interval or as required and at every change in soil stratum including sinking and withdrawing necessary casing pipe and all necessary arrangements complete as per specification and accepted by the Engineer-in-charge. (Measurement will be allowed from E.G.L. to bottom of the blind pipe and the rate is inclusive of the cost of extra depth or of further boring required due to caving and siltation) Unit Rate PWD SoR 2018 for Civil Works DEEP TUBE-WELL Item No. Description of Item Unit 201 Unit Rate 27.26.1 From 0.0 m to 50 m = 50 m meter Tk. 1,031.00 27.26.2 From 50 m to 100 m = 50 m meter Tk. 1,186.00 27.26.3 From 100 m to 152 m = 52 m meter Tk. 1,364.00 27.26.4 From 152 m to 200 m = 48 m meter Tk. 1,569.00 27.26.5 From 200 m to 250 m = 50 m meter Tk. 1,804.00 27.26.6 Beyond 250 m meter Tk. 2,074.00 27.27 Supplying the following tube well fixtures and pipes having density 1350 kg/m3, opacity 0.2% of visible light as per ISO 7686, minimum required strength 25 MPa conforming to BDS-1:2013, 4.4.1, 4.4.2 at working site as per standard practice and accepted by the Engineer-in-charge. 27.27.1 Best quality 100 mm dia uPVC cap each Tk. 226.00 27.27.2.1 100 mm dia water grade (Class C) uPVC blind pipe/ sand trap having wall thickness 4.5mm to 5.2mm meter Tk. 498.00 27.27.2.2 100 mm dia water grade (Class D) uPVC blind pipe/ sand trap having wall thickness 6.0 mm to 6.9 mm meter Tk. 649.00 27.27.2.3 100 mm dia water grade (Class E) uPVC blind pipe/ sand trap having wall thickness 7.3 mm to 8.4 mm meter Tk. 811.00 27.27.3.1 100 mm dia strainer of any slot as per design made with water grade(Class C) uPVC pipe having wall thickness 4.5 mm to 5.2 mm meter Tk. 544.00 27.27.3.2 100 mm dia strainer of any slot as per design made with water grade(Class D) uPVC pipe having wall thickness 6.0 mm to 6.9 mm meter Tk. 695.00 27.27.3.1 100 mm dia strainer of any slot as per design made with water grade(Class E) uPVC pipe having wall thickness 7.3 mm to 8.4 mm meter Tk. 857.00 27.27.4 Best quality 100 mm x 200 mm dia uPVC reducer each Tk. 980.00 27.27.5.1 200 mm dia water grade (Class C) uPVC housing pipe having wall thickness 7.8 mm to 9.0 mm meter Tk. 1,138.00 27.27.5.2 200 mm dia water grade (Class D) uPVC housing pipe having wall thickness 10.3 mm to 11.9 mm meter Tk. 1,540.00 27.27.5.3 200 mm dia water grade (Class E) uPVC hjousing pipe having wall thickness 12.6 mm to 14.8 mm meter Tk. 1,842.00 27.27.6 Supplying centralizer made with 12 mm dia M.S. rod of approved design each Tk. 379.00 27.28 Complete installation of 100 mm dia uPVC tube-well fixtures such as expanded top pipes,. reducer, tube-well pipes, strainer, blind pipe, pipe cap etc. fitting and fixing with best quality PVC solution, iron screws and uPVC tape and placing in position with proper size M.S. centralizer @ 3 meter c/c. in strainer portion including blind pipe etc. complete as per standard practice and accepted by the Engineer-in-charge. meter Tk. 103.00 PWD SoR 2018 for Civil Works DEEP TUBE-WELL Item No. Description of Item 202 Unit Unit Rate 27.29 Complete development of the tube-well by air compressor and pump of suitable capacity by alternate surging and pumping until satisfactory yield of sand free water and the turbidity condition is reached using necessary quantity of calgon and conducting step draw down test before and after the development as per specification and accepted by the Engineer-in-charge. (Development should be started within 24 hours of completion of shrouding) 27.29.1 Wells up to 200 m depth each Tk. 38,560.00 27.29.2 Wells beyond 200 m depth each Tk. 46,272.00 27.30 Pumping test of the well by designed turbine/submersible pump with supply of testing equipments for pressure/ velocity/ discharge etc. and all materials for 72 hours including yield drawn and recovery test etc. complete as per specification and accepted by the Engineer-in-charge. hour Tk. 984.00 27.31 Disinfections of the well including supply of sufficient quantity of bleaching powder (33% strength) chlorinated water having 150 ppm available free chlorine etc. complete as per standard specification and accepted by the Engineer-in-charge. each Tk. 1,777.00 27.32 Filling of the borehole around the tube-well from top of the shrouding up to the bottom of sanitary seal by withdrawn selected soil or local clay free from any substances harmful to pipes and health as per standard specification and accepted by the Engineer-in-charge. meter Tk. 42.00 27.33 Protective top cover: Supplying and fitting fixing best quality 250 mm dia 4 mm thick M.S. pipe, 1.0 m (3'-4") long one, end blocked with 300 mm dia 4 mm thick M.S. plate and other end minimum 300 (1'-0") embedded in sanitary seal for protection of uPVC Housing pipe as per standard specification and accepted by the Engineer-in-charge. each Tk. 9,356.00 INSTALLATION OF 150 mm x 200 mm & 150 mm x 250 mm DIA SHROUDED PRODUCTION WELL WITH uPVC PIPE 27.34 Boring: Execution of 600 mm dia boring through all sorts of strata by reverse circulation or any other approved method (Method other than reverse circulation is to be applied only for wells deeper than 152 meter). Boring for 600 mm dia vertical hole up to designed depth and collection of soil samples at every 3 meter interval or as required and at every change in soil stratum including sinking and withdrawing necessary casing pipe and all necessary arrangements complete as per specification and accepted by the Engineer-in-charge. (Measurement will be allowed from E.G.L. to bottom of the blind pipe and the rate is inclusive of the cost of extra depth or of further boring required due to caving and siltation) 27.34.1 From 0.0 m to 50 m = 50 m meter Tk. 1,279.00 27.34.2 From 50 m to 100 m = 50 m meter Tk. 1,470.00 27.34.3 From 100 m to 152 m = 52 m meter Tk. 1,691.00 27.34.4 From 152 m to 200 m = 48 m meter Tk. 1,945.00 27.34.5 From 200 m to 250 m = 50 m meter Tk. 2,236.00 27.34.6 Beyond 250 m meter Tk. 2,572.00 PWD SoR 2018 for Civil Works DEEP TUBE-WELL Item No. Description of Item Unit 203 Unit Rate 27.35 Supplying the following tube well fixtures and pipes having density 1350 kg/m3, opacity 0.2% of visible light as per ISO 7686, minimum required strength 25 MPa conforming to BDS-1:2013, 4.4.1, 4.4.2 at working site as per standard practice and accepted by the Engineer-in-charge. 27.35.1 Best quality 150 mm dia uPVC cap for blind pipe/ sand trap. each Tk. 537.00 27.35.2.1 150 mm dia water grade (Class C) uPVC blind pipe/ sand trap having wall thickness 6.6 mm to 7.6 mm meter Tk. 1,138.00 27.35.2.2 150 mm dia water grade (Class D) uPVC blind pipe/ sand trap having wall thickness 8.8 mm to 10.2 mm meter Tk. 1,339.00 27.35.2.3 150 mm dia water grade (Class E) uPVC blind pipe/ sand trap having wall thickness 10.8 mm to 12.5 mm meter Tk. 1,842.00 27.35.3.1 150 mm dia strainer of any slot as per design made with water grade (Class C) uPVC pipe of wall thickness 6.6 to 7.6 mm meter Tk. 1,196.00 27.35.3.2 150 mm dia strainer of any slot as per design made with water grade (Class D) uPVC pipe of wall thickness 8.8 to 10.2 mm meter Tk. 1,397.00 27.35.3.3 150 mm dia strainer of any slot as per design made with water grade (Class E) uPVC pipe of wall thickness 10.8 to 12.5 mm meter Tk. 1,900.00 27.35.4.1 Best quality 150 mm x 200 mm dia uPVC Reducer each Tk. 1,246.00 27.35.4.2 Best quality 150 mm x 250 mm dia uPVC Reducer each Tk. 1,488.00 27.35.5.1 200 mm dia water grade (Class C) uPVC housing pipe of wall thickness 7.8 mm to 9.0 mm meter Tk. 1,721.00 27.35.5.2 200 mm dia water grade (Class D) uPVC housing pipe of wall thickness 10.3 mm to 11.9 mm meter Tk. 2,295.00 27.35.5.3 200 mm dia water grade (Class E) uPVC housing pipe of wall thickness12.6 mm to 14.8 mm meter Tk. 2,687.00 27.35.5.4 250 mm dia water grade (Class C) uPVC housing pipe of wall thickness 9.7 mm to 11.2 mm meter Tk. 2,687.00 27.35.5.5 250 mm dia water grade (Class D) uPVC housing pipe of wall thickness 12.8 mm to 14.8 mm meter Tk. 3,753.00 27.35.5.6 250 mm dia water grade (Class E) uPVC housing pipe of wall thickness 15.7 mm to 18.1 mm meter Tk. 4,458.00 27.35.6 Supplying of centralizer made with 12 mm dia M.S. rod of approved design meter Tk. 379.00 27.36 Complete installation of 150 mm dia uPVC tube-well fixtures such as expanded top pipes, reducer, tube-well pipes, strainer, blind pipe, pipe cap etc. fitting and fixing with best quality uPVC solution, iron screws and uPVC tape and placing in position with proper size M.S. centralizer @ 3 meter c/c in strainer portion including blind pipe etc. complete as per standard practice and accepted by the Engineer-in-charge. meter Tk. 106.00 PWD SoR 2018 for Civil Works DEEP TUBE-WELL Item No. Description of Item 204 Unit Unit Rate 27.37 Complete development of the tube well by suitable air compressor and pump of suitable capacity by alternate surging and pumping until satisfactory yield, sand free water and the turbidity condition is reached using necessary quantity of calgon and conducting step draw down test before and after the development as per specification and accepted by the Engineer-in-charge. (Development should be started within 24 hours of completion of shrouding) 27.37.1 Wells up to 200 m depth each Tk. 46,104.00 27.37.2 Wells beyond 200 m depth each Tk. 52,252.00 27.38 Pumping test of the well by designed turbine/submersible pump with supply of testing equipments for pressure/ velocity/ discharge etc. and all materials for 72 hours including yield drawn and recovery test etc. complete as per specification and accepted by the Engineer-in-charge. hour Tk. 1,120.00 27.39 Disinfections of the well including supply of sufficient quantity of bleaching powder (33% strength) chlorinated water having 150 ppm available free chlorine etc. complete as per standard specification and accepted by the Engineer-in-charge. each Tk. 2,133.00 27.40 Filling of the borehole around the tube well from top of the shrouding up to the bottom of sanitary seal by withdrawn selected soil or local clay as free from any substances harmful to pipes and health per standard specification and accepted by the Engineer-in-charge. meter Tk. 57.00 27.41 Protective top cover: Supplying fitting and fixing of best quality 250 mm dia 4 mm thick M.S. pipe 1.0 m (3'-4") long one end blocked with 300 dia 4 mm thick M.S. plate and other end minimum 300 (1'-0") embedded in sanitary seal for protection of uPVC Housing pipe as per standard specification and accepted by the Engineer-in-charge. each Tk. 9,261.00 INSTALLATION OF 150 mm x 300 mm DIA SHROUDED PRODUCTION WELL WITH G.I. PIPE 27.42 Boring: Execution of 600 mm dia boring through all sorts of strata by reverse circulation or any other approved method (Method other than reverse circulation is to be applied only for wells deeper than 152 meter) for boring 600 mm dia vertical hole up to designed depth and collection of soil samples at every 3 meter interval and at every change of formation including sinking and withdrawing necessary casing pipe and all necessary arrangements complete as per specification and accepted by the Engineer-in-charge. (Measurement will be allowed from G.L. to bottom of the blind pipe and the rate is inclusive of the cost of extra depth of boring required for caving and siltation) 27.42.1 From 0.0 m to 50 m = 50 m meter Tk. 1,279.00 27.42.2 From 50 m to 100 m = 50 m meter Tk. 1,470.00 27.42.3 From 100 m to 152 m = 52 m meter Tk. 1,691.00 27.42.4 From 152 m to 200 m = 48 m meter Tk. 1,945.00 27.42.5 From 200 m to 250 m = 50 m meter Tk. 2,236.00 27.42.6 Beyond 250 m meter Tk. 2,572.00 PWD SoR 2018 for Civil Works DEEP TUBE-WELL Item No. Description of Item Unit 205 Unit Rate 27.43 Supplying the following tube well fixtures and pipes conforming to standard BS-1387 & BDS-1031, having chemical composition (in%) carbon 0.17-0.25, manganese 0.95-1.20, sulphur 0.060 max, phosphorous 0.060 max, tensile properties: miminum yield strength 188 MPa, minimum tensile strength 313 MPa and marking for a) manufacturer b) material c) wall thickness d) nominal outside dia e) intended use etc. on the body of the pipe at working site as per standard practice and accepted by the Engineer-in-charge. 27.43.1 150 mm dia M.S. cap 6 mm thick for blind pipe/sand trap each Tk. 1,362.00 27.43.2 150 mm dia G.I. Pipe having wall thickness 5.4 mm, weight 21.2 kg/m can withstand 50 kg/ cm2 hydraulic pressure for blind pipe/sand trap meter Tk. 3,509.00 27.43.3 150 mm dia strainer of slot opening as per design including tagging 4 Nos. 12 mm dia M.S. rod continuously. 27.43.3.1 Stainless steel strainer of continuous slot having weight 28.84 kg per meter. meter Tk. 16,003.00 27.43.3.2 2.50 mm thick stainless steel Bridge type strainer. meter Tk. 11,836.00 27.43.4 150 mm x 300 mm dia M.S. reducer of minimum thickness of 6 mm. each Tk. 2,850.00 27.43.5 300 mm dia 6 mm minimum thick M.S. housing pipe (Welded) meter Tk. 6,772.00 27.43.6 300 mm dia 6 mm minimum thick M.S. housing pipe (Seamless) meter Tk. 9,249.00 27.43.7 Centralizer made with 12 mm dia M.S. rod of approved design. each Tk. 379.00 27.43.8 350 mm dia M.S. cap having 6 mm thick for housing pipe covering. each Tk. 2,275.00 27.44 Complete installation of 150 mm dia deep tube-well fixtures such as expanded top pipes, reducer, tube-well pipes, strainer, blind pipe, pipe cap etc. fitting and fixing socket, welding and additional welding with fibre and placing in position with proper size M.S. centralizer @ 3 meter c/c in strainer portion including. blind pipe etc. complete as per standard practice and accepted by the Engineer-in-charge. meter Tk. 461.00 27.45 Complete development of the tube well by suitable air compressor and pump of suitable capacity by alternate surging and pumping until satisfactory yield, sand free water and the turbidity condition is reached using necessary quantity of calgon and conducting step draw down test before and after the development as per specification and accepted by the Engineer-in-charge. (Development should be started within 24 hours of completion of shrouding) 27.45.1 Wells up to 200 m depth each Tk. 46,104.00 27.45.2 Wells beyond 200 m depth each Tk. 52,252.00 27.46 Pumping test of the well by designed turbine/submersible pump with supply of testing equipments for pressure/ velocity/ discharge etc. and all materials for 72 hours including yield drawn and recovery test etc. complete as per specification and accepted by the Engineer-in-charge. hour Tk. 1,153.00 27.47 Disinfections of the well including supply of sufficient quantity of bleaching powder (33% strength) chlorinated water having 150 ppm available free chlorine etc. complete as per standard specification and accepted by the Engineer-in-charge. each Tk. 2,177.00 PWD SoR 2018 for Civil Works DEEP TUBE-WELL Item No. 27.48 206 Description of Item Unit Unit Rate Filling of the borehole around the tube well from top of the shrouding up to the bottom of sanitary seal by withdrawn selected soil or local clay free from any substances harmful to pipes and health as per standard specification and accepted by the Engineer-in-charge. meter Tk. 57.00 INSTALLATION OF 200 mm x 400 mm DIA SHROUDED PRODUCTION WELL WITH G.I. PIPE 27.49 Boring: Execution of 800 mm dia boring through all sorts of strata by reverse circulation or any other approved method (Method other than reverse circulation is to be applied only for wells deeper than 152 meter). For boring 800 mm dia vertical hole up to designed depth and collection of soil samples at every 3 meter interval and at every change of formation including sinking and withdrawing necessary casing pipe and all necessary arrangements complete as per specification and accepted by the Engineer-in-charge. (Measurement will be allowed form G.L. to bottom of the blind pipe and the rate is required for caving and siltation) 27.49.1 From 0.0 m to 50 m = 50 m meter Tk. 1,518.00 27.49.2 From 50 m to 100 m = 50 m meter Tk. 1,745.00 27.49.3 From 100 m to 152 m = 52 m meter Tk. 2,007.00 27.49.4 From 152 m to 200 m = 48 m meter Tk. 2,308.00 27.49.5 From 200 m to 250 m = 50 m meter Tk. 2,655.00 27.49.6 Beyond 250 m meter Tk. 3,053.00 27.50 Supplying the following tube-well fixtures and pipes conforming to standard BS-1387 & BDS-1031, having chemical composition (in%) carbon 0.17-0.25, manganese 0.95-1.20, sulphur 0.060 max, phosphorous 0.060 max, tensile properties: miminum yield strength 188 MPa, minimum tensile strength 313 MPa and marking for a) manufacturer b) material c) wall thickness d) nominal outside dia e) intended use etc. on the body of the pipe at working site as per standard practice and accepted by the Engineer-in-charge. 27.50.1 200 mm dia M.S. cap 6mm thick for blind pipe/ sand strap each Tk. 1,747.00 27.50.2 200 mm dia 6 mm thick tube well pipe and blank G.I. pipe of wt. 33.45 kg per meter can withstand minimum 700 psi hydraulic pressure. meter Tk. 7,505.00 27.50.3 200 mm dia strainer of slot opening as per design including tagging 4 nos 12 mm dia M.S. rod continuously. meter 27.50.3.1 200 mm dia stainless steel strainer of continuous slot having 38.36 kg per meter. meter Tk. 18,719.00 27.50.3.2 200 mm dia 2.5 mm thick stainless steel bridge type strainer meter Tk. 12,529.00 27.50.4 200 mm x 400 mm dia 6 mm thick M.S. reducer. each Tk. 27.50.5 400 mm dia 6 mm thick M.S. housing pipe (Welded) meter Tk. 10,536.00 27.50.6 400 mm dia 6 mm thick M.S. housing pipe (Seamless) meter Tk. 12,871.00 27.50.7 Centralizer made with 12 mm dia M.S. rod of approved design each Tk. 379.00 2,932.00 PWD SoR 2018 for Civil Works DEEP TUBE-WELL Item No. Description of Item Unit 207 Unit Rate 27.50.8 450 mm dia M.S. cap of 6 mm thick for housing pipe covering. each Tk. 490.00 27.51 Complete installation of 200 mm dia deep tube well fixtures such as expanded top pipes, reducer, and tube well pipes, strainer, blind pipe. pipe cap etc. Fitting and fixing socket, welding and additional welding with fibre and placing in position with proper size M.S. centralizer @ 3 meter c/c in strainer position including blind pipe etc. complete as per standard practice and accepted by the Engineer-in-charge. meter Tk. 503.00 27.52 Complete development of the tube well by suitable air compressor and pump of suitable capacity by alternate surging and pumping until satisfactory yield, sand free water and the turbidity condition is reached using necessary quantity of calgon and conducting step draw down test before and after the development as per specification and accepted by the Engineer-in-charge. (Development should be started within 24 hours of completion of shrouding). 27.52.1 Wells up to 200 m depth each Tk. 42,896.00 27.52.2 Wells beyond 200 m depth each Tk. 47,943.00 27.53 Pumping test of the well by designed turbine/submersible pump with supply of testing equipments for pressure/ velocity/ discharge etc. and all materials for 72 hours including yield drawn and recovery test etc. complete as per specification and accepted by the Engineer-in-charge. hour Tk. 1,198.00 27.54 Disinfections of the well including supply of sufficient quantity of bleaching powder (33% strength) chlorinated water having 150 ppm available free chlorine complete as per standard specification and accepted by the Engineer-in-charge. each Tk. 2,488.00 27.55 Filling of the borehole around the tube well from top of the shrouding up to the bottom of sanitary seal by withdrawn selected soil or local clay free from any substances harmful to pipes and health as per standard specification and accepted by the Engineer-in-charge. meter Tk. 57.00 INSTALLATION OF 50 mm x 150 mm DIA SHROUDED PRODUCTION WELL WITH G.I. PIPE 27.56 Boring: Execution of 325 mm dia boring through all sorts of strata by reverse circulation or any other approved method (Method other than reverse circulation is to be applied only for wells deeper than 152 meter) for boring 325 mm dia vertical hole up to designed depth and collection of soil samples at every 3 meter interval and at every change of formation including sinking and withdrawing necessary casing pipe and all necessary arrangements complete as per specification and accepted by the Engineer-in-charge. (Measurement will be allowed from G.L. to bottom of the blind pipe and the rate is inclusive of the cost of extra depth of boring required for caving and siltation) 27.56.1 From 0.0 m to 50 m = 50 m meter Tk. 939.00 27.56.2 From 50 m to 100 m = 50 m meter Tk. 1,080.00 27.56.3 From 100 m to 152 m = 52 m meter Tk. 1,242.00 27.56.4 From 152 m to 200 m = 48 m meter Tk. 1,428.00 27.56.5 From 200 m to 250 m = 50 m meter Tk. 1,642.00 27.56.6 Beyond 250 m meter Tk. 1,889.00 PWD SoR 2018 for Civil Works DEEP TUBE-WELL Item No. Description of Item Unit 208 Unit Rate 27.57 Supplying the following tube-well fixtures and pipes conforming to standard BS-1387 & BDS-1031, having chemical composition (in%) carbon 0.17-0.25, manganese 0.95-1.20, sulphur 0.060 max, phosphorous 0.060 max, tensile properties: miminum yield strength 188 MPa, minimum tensile strength 313 MPa and marking for a) manufacturer b) material c) wall thickness d) nominal outside dia e) intended use etc. on the body of the pipe at working site as per standard practice and accepted by the Engineer-in-charge. 27.57.1 150 mm dia 6mm thick M.S. cap for blind pipe/ sand trap. each Tk. 1,362.00 27.57.2 50 mm dia 4.85 mm thick tube well pipe and blank G.I. pipe meter Tk. 592.00 27.57.3 50 mm dia strainer of slot opening as per design including tagging 4 nos 12 mm dia M.S. rod continuously. 27.57.3.1 50 mm dia stainless steel strainer of continuous slot having 28.84 kg per meter. meter Tk. 6,283.00 27.57.3.2 50 mm dia 2.5 mm thick stainless steel bridge type strainer meter Tk. 6,283.00 27.57.4 50 mm x 150 mm dia 6 mm thick M.S. reducer. each Tk. 1,099.00 27.57.5 150 mm dia 6 mm thick M.S. housing pipe (Welded). meter Tk. 5,023.00 27.57.6 150 mm dia 6 mm thick M.S. housing pipe (Seamless). meter Tk. 4,419.00 27.57.7 Centralizer made with 12 mm dia M.S. rod of approved design. each Tk. 379.00 27.57.8 150 mm dia M.S. cap of 6 mm thick for housing pipe covering. each Tk. 1,795.00 27.58 Complete installation of 50 mm dia deep tube-well fixtures such as expanded top pipes, reducer, tube-well pipes, strainer, blind pipe, pipe cap etc. fitting and fixing socket, welding and additional welding with fibre and placing in position with proper size M.S. centralizer @ 3 meter c/c in strainer portion including. blind pipe etc. complete as per standard practice and accepted by the Engineer-in-charge meter Tk. 461.00 27.59 Compete development of the tube well by suitable air compressor and pump of suitable capacity by alternate surging and pumping until satisfactory yield, sand free water and the turbidity condition is reached using necessary quantity of calgon and conducting step draw down test before and after the development as per specification and accepted by the Engineer-in-charge (Development should be started within 24 hours of completion of shrouding) 27.59.1 Wells up to 200 m depth each Tk. 23,272.00 27.59.2 Wells beyond 200 m depth each Tk. 26,375.00 27.60 Pumping test of the well by designed turbine/submersible pump with supply of testing equipments for pressure/ velocity/ discharge etc. and all materials for 72 hours including yield drawn and recovery test etc. complete as per specification and accepted by the Engineer-in-charge. hour Tk. 962.00 27.61 Disinfections of the well including supply of sufficient quantity of bleaching powder (33% strength) chlorinated water having 150 ppm available free chlorine etc. complete as per standard specification and accepted by the Engineer-in-charge. each Tk. 1,244.00 PWD SoR 2018 for Civil Works DEEP TUBE-WELL Item No. 27.62 209 Description of Item Unit Unit Rate Filling of the borehole around the tube well from top of the shrouding up to the bottom of sanitary seal by withdrawn selected soil or local clay free from any substances harmful to pipes and health as per standard specification and accepted by the Engineer-in-charge. meter Tk. 33.00 INSTALLATION OF 75 mm x 150 mm DIA SHROUDED PRODUCTION WELL WITH G.I. PIPE 27.63 Boring: Execution of 350 mm dia boring through all sorts of strata by reverse circulation or any other approved method (Method other than reverse circulation is to be applied only for wells deeper than 152 meter) for boring 350 mm dia vertical hole up to designed depth and collection of soil samples at every 3 meter interval and at every change of formation including sinking and withdrawing necessary casing pipe and all necessary arrangements complete as per specification and accepted by the Engineer-in-charge. (Measurement will be allowed from G.L. to bottom of the blind pipe and the rate is inclusive of the cost of extra depth of boring required for caving and siltation) 27.63.1 From 0.0 m to 50 m = 50 m meter Tk. 988.00 27.63.2 From 50 m to 100 m = 50 m meter Tk. 1,136.00 27.63.3 From 100 m to 152 m = 52 m meter Tk. 1,307.00 27.63.4 From 152 m to 200 m = 48 m meter Tk. 1,503.00 27.63.5 From 200 m to 250 m = 50 m meter Tk. 1,728.00 27.63.6 Beyond 250 m meter Tk. 1,987.00 27.64 Supplying the following tube-well fixtures and pipes conforming to standard BS-1387 & BDS-1031, having chemical composition (in%) carbon 0.17-0.25, manganese 0.95-1.20, sulphur 0.060 max, phosphorous 0.060 max, tensile properties: miminum yield strength 188 MPa, minimum tensile strength 313 MPa and marking for a) manufacturer b) material c) wall thickness d) nominal outside dia e) intended use etc. on the body of the pipe at working site as per standard practice and accepted by the Engineer-in-charge. 27.64.1 150 mm dia 6mm thick M.S. cap for blind pipe/ sand trap. each Tk. 1,357.00 27.64.2 75 mm dia 4.85 mm thick tube well pipe and blank G.I. pipe meter Tk. 883.00 27.64.3 75 mm dia strainer of slot opening as per design including tagging 4 Nos. 12 mm dia M.S. rod continuously. 27.64.3.1 75 mm dia stainless steel strainer of continuous slot having 28.84 kg per meter. meter Tk. 8,411.00 27.64.3.2 75 mm dia 2.5 mm thick stainless steel bridge type strainer meter Tk. 8,411.00 27.64.4 75 mm x 150 mm dia 6 mm thick M.S. reducer. meter Tk. 1,099.00 27.64.5 150 mm dia 6 mm thick M.S. housing pipe (Welded) meter Tk. 5,023.00 27.64.6 150 mm dia 6 mm thick M.S. housing pipe (Seamless) meter Tk. 4,419.00 27.64.7 Centralizer made with 12 mm dia M.S. rod of approved design each Tk. 379.00 PWD SoR 2018 for Civil Works DEEP TUBE-WELL Item No. Description of Item Unit 210 Unit Rate 27.64.8 150 mm dia M.S. cap of 6 mm thick for housing pipe covering. meter Tk. 1,795.00 27.65 Complete installation of 75 mm dia deep tube-well fixtures such as expanded top pipes, reducer, tube-well pipes, strainer, blind pipe, pipe cap etc. fitting and fixing socket, welding and additional welding with fibre and placing in position with proper size M.S. centralizer @ 3 meter c/c in strainer portion including blind pipe etc. complete as per standard practice and accepted by the Engineer-in-charge. meter Tk. 447.00 27.66 Complete development of the tube well by suitable air compressor and pump of suitable capacity by alternate surging and pumping until satisfactory yield, sand free water and the turbidity condition is reached using necessary quantity of calgon and conducting step draw down test before and after the development as per specification and accepted by the Engineer-in-charge (Development should be started within 24 hours of completion of shrouding). 27.66.1 Wells up to 200 m depth each Tk. 31,419.00 27.66.2 Wells beyond 200 m depth each Tk. 35,608.00 27.67 Pumping test of the well by designed turbine/submersible pump with supply of testing equipments for pressure/ velocity/ discharge etc. and all materials for 72 hours including yield drawn and recovery test etc. complete as per specification and accepted by the Engineer-in-charge. hour Tk. 1,041.00 27.68 Disinfections of the well including supply of sufficient quantity of bleaching powder (33% strength) chlorinated water having 150 ppm available free chlorine etc. complete as per standard specification and accepted by the Engineer-in-charge. each Tk. 1,511.00 27.69 Filling of the borehole around the tube well from top of the shrouding up to the bottom of sanitary seal by withdrawn selected soil or local clay free from any substances harmful to pipes and health as per standard specification and accepted by the Engineer-in-charge. meter Tk. 38.00 INSTALLATION OF 100 mm x 200 mm DIA SHROUDED PRODUCTION WELL WITH G.I. PIPE 27.70 Boring: Execution of 400 mm dia boring through all sorts of strata by reverse circulation or any other approved method (Method other than reverse circulation is to be applied only for wells deeper than 152 meter) for boring 400 mm dia vertical hole up to designed depth and collection of soil samples at every 3 meter interval and at every change of formation including sinking and withdrawing necessary casing pipe and all necessary arrangements complete as per specification and accepted by the Engineer-in-charge. (Measurement will be allowed from G.L. to bottom of the blind pipe and the rate is inclusive of the cost of extra depth of boring required for caving and siltation) 27.70.1 From 0.0 m to 50 m = 50 m meter Tk. 1,031.00 27.70.2 From 50 m to 100 m = 50 m meter Tk. 1,186.00 27.70.3 From 100 m to 152 m = 52 m meter Tk. 1,364.00 27.70.4 From 152 m to 200 m = 48 m meter Tk. 1,569.00 27.70.5 From 200 m to 250 m = 50 m meter Tk. 1,804.00 27.70.6 Beyond 250 m meter Tk. 2,074.00 PWD SoR 2018 for Civil Works DEEP TUBE-WELL Item No. Description of Item Unit 211 Unit Rate 27.71 Supplying the following tube-well fixtures and pipes conforming to standard BS-1387 & BDS-1031, having chemical composition (in%) carbon 0.17-0.25, manganese 0.95-1.20, sulphur 0.060 max, phosphorous 0.060 max, tensile properties: miminum yield strength 188 MPa, minimum tensile strength 313 MPa and marking for a) manufacturer b) material c) wall thickness d) nominal outside dia e) intended use etc. on the body of the pipe at working site as per standard practice and accepted by the Engineer-in-charge. 27.71.1 Supplying 150 mm dia 6mm thick M.S. cap for blind pipe/ sand trap. each Tk. 1,362.00 27.71.2 Supplying 100 mm dia 6 mm thick tube well pipe and blank G.I. pipe meter Tk. 1,325.00 27.71.3 100 mm dia strainer of slot opening as per design including tagging 4 Nos. 12 mm dia M.S. rod continuously. 27.71.3.1 Supplying 100 mm dia stainless steel strainer of continuous slot having 28.84 kg per meter. meter Tk. 7,256.00 27.71.3.2 Supplying 100 mm dia 2.5 mm thick stainless steel bridge type strainer meter Tk. 7,256.00 27.71.4 Supplying 100 mm x 200 mm dia 6 mm thick M.S. reducer. each Tk. 1,362.00 27.71.5 Supplying 200 mm dia 6 mm thick M.S. housing pipe (Welded) meter Tk. 4,184.00 27.71.6 Supplying 200 mm dia 6 mm thick M.S. housing pipe (Seamless) meter Tk. 4,585.00 27.71.7 Supplying centralizer made with 12 mm dia M.S. rod of approved design each Tk. 227.00 27.71.8 Supplying 200 mm dia M.S. cap of 6 mm thick for housing pipe covering. each Tk. 2,320.00 27.72 Complete installation of 100 mm dia deep tube-well fixtures such as expanded top pipes, reducer, and tube-well pipes, strainer, blind pipe, pipe cap etc. fitting and fixing socket, welding and additional welding with fibre and placing in position with proper size M.S. centralizer @ 3 meter c/c in strainer portion including blind pipe etc. complete as per standard practice and accepted by the Engineer-in-charge meter Tk. 503.00 27.73 Complete development of the tube well by suitable air compressor and pump of suitable capacity by alternate surging and pumping until satisfactory yield, sand free water and the turbidity condition is reached using necessary quantity of calgon and conducting step draw down test before and after the development as per specification and accepted by the Engineer-in-charge (Development should be started within 24 hours of completion of shrouding) 27.73.1 Wells up to 200 m depth each Tk. 38,560.00 27.73.2 Wells beyond 200 m depth each Tk. 43,701.00 27.74 Pumping test of the well by designed turbine/submersible pump with supply of testing equipments for pressure/ velocity/ discharge etc. and all materials for 72 hours including yield drawn and recovery test etc. complete as per specification and accepted by the Engineer-in-charge hour Tk. 1,086.00 27.75 Disinfections of the well including supply of sufficient quantity of bleaching powder (33% strength) chlorinated water having 150 ppm available free chlorine etc. complete as per standard specification and accepted by the Engineer-in-charge each Tk. 1,777.00 PWD SoR 2018 for Civil Works DEEP TUBE-WELL Item No. 27.76 212 Description of Item Unit Unit Rate Filling of the borehole around the tube well from top of the shrouding up to the bottom of sanitary seal by withdrawn selected soil or local clay free from any substances harmful to pipes and health as per standard specification and accepted by the Engineer-in-charge meter Tk. 43.00 INSTALLATION OF 40 MM DIA uPVC HAND TUBE WEL 27.77 Supplying and sinking of 40 mm dia water grade uPVC tube well pipe having wall thickness 2.5 mm to 3.0 mm including trial boring and with all necessary fittings as required etc. all complete and accepted by the Engineer-in-charge. 27.77.1 40 mm dia pipe up to 60 m depth meter Tk. 182.00 27.77.2 40 mm dia pipe beyond 60 m depth meter Tk. 329.00 27.78 Supplying and sinking of 3 m long uPVC strainer with all necessary fittings as required etc. complete and accepted by the Engineer-in-charge. each Tk. 500.00 27.79 Supplying, fitting and fixing of No. 6 pump for 40 mm dia tube well with all necessary fittings including 0.61 m long 40 mm dia G.I. Pipe etc. all complete as per accepted by the Engineer-in-charge. each Tk. 3,252.00 27.80 Construction of platform of size 1.4 m x 1.0 m and outlet drain up to1 meter long, as per drawing with 75 mm thick cement concrete of f'c min 17 MPa with brick chips and cement content relates to 1:2:4, over a brick flat soling and providing 125 mm x 75mm brick band in 1:6 all around, including finished with 12 mm thick cement plaster in 1:4 followd by neat cement finishing all complete and accepted by the Engineer-in-charge. each Tk. 4,946.00 DEEP SET HAND OPERATED TUBE WELL 27.81 Supplying and sinking uPVC, tube well pipe, uPVC strainer including trial boring with all necessary fittings as required etc. all complete and accepted by the Engineer-incharge. 27.81.1 50 mm dia water grade uPVC pipe having wall thickness 2.5 mm to 3 mm meter Tk. 466.00 27.81.2 40 mm dia water grade uPVC pipe having wall thickness 2.5 mm to 3 mm meter Tk. 266.00 27.81.3 40 mm dia uPVC strainer 3.0 m long each Tk. 500.00 27.82 Supplying, fitting and fixing of deep set tube well pump (Hand set) with all necessary fittings as required such as No. 6 pump, 50 mm dia G.I. pipe 0.61 m long, 50 mm x 40 mm reducing socket, 40 mm dia pipe Nipple 1.22 m long cylinder, tie foot ball, tie plunger, 3 Nos. 10 mm dia sockets, 4 Nos. 10mm dia nuts, 5 Nos. end threaded 10 mm dia M.S. rod 3 m long, necessary quantity of solution and tape etc. complete and accepted by the Engineer-in-charge. each Tk. 6,187.00 PWD SoR 2018 for Civil Works DEEP TUBE-WELL 213 uPVC pipe selection for deep tube well depending on depth Normal size (inner dia) Class C Pipe Class D Pipe Class E Pipe mm Wall Thickness (mm) Depth of well to be continued (ft) Wall Thickness (mm) Depth of well to be continued (ft) Wall Thickness (mm) Depth of well to be continued (ft) 50 2.5 - 3.0 260‟-0” 3.1 – 3.7 600‟-0” 3.9 - 4.5 900‟-0” 75 3.5 – 4.1 200‟-0” 4.0 – 4.6 600‟-0” 5.7 – 6.6 900‟-0” 100 4.5 – 5.2 200‟-0” 6.0 – 6.9 600‟-0” 7.3 – 8.4 900‟-0” 125 5.5 – 6.4 200‟-0” 7.3 - 8.4 400‟-0” 9.0 – 10.4 800‟-0” 150 6.6 – 7.6 200‟-0” 8.8 – 10.2 400‟-0” 10.8 – 12.5 800‟-0” 200 7.8 – 9.0 200‟-0” 10.3 – 11.9 400‟-0” - - 250 9.7 -11.12 200‟-0” 12.8 – 14.8 400‟-0” - - ………………….. END OF DIVISION TWENTY SEVEN ………………….. PWD SoR 2018 for Civil Works GAS CONNECTION WORKS 214 DIVISION 28 : GAS CONNECTION WORKS Item No. Description of Item Unit Unit Rate PART-A (LOW PRESSURE LINE) 28.1 Pipe line installation: Installation of 50 psi, APl, 5L, Grade-B, ERW Natural pipe line for supplying Titas Gas including, supplying, fitting, fixing and laying different sizes M.S. pipes with necessary tape and primer including cutting trenches (450 mm x 910 mm) in all kinds of soil, cleaning, cutting, applying coal-tar, wrapping the pipes and back filling the trenches, excavating earth including leveling, dressing and removing excess earth in all respect as per specification of Titas Gas T and D Co. Ltd. and accepted by the Engineerin-charge. [Rate is excluding the cost of welding and back filling with sand at the bottom by 300 mm in thickness (compacted)] (Pipes manufactured by National Tubes Limited under Steel & Engineeing Corporation, Ministry of Industries, Government of Bangladesh shall be given priority) 28.1.1 75 mm N.D (88.90 mm O.D) M.S pipe, weight of min 8.3 kg/m, standard test pressure 176 kg/ m2, wall thickness of min 11.29 mm meter Tk. 1,768.00 28.1.2 50 mm N.D. (60.30 mm O.D) M.S pipe, weight of min 5.44 kg/m, standard test pressure 176 kg/ m2, wall thickness of min 3.91 mm meter Tk. 1,198.00 28.1.3 25 mm N.D. (33.40 mm O.D) M.S pipe weight of min 2.50 kg/m, standard test pressure 50 kg/ m2, wall thickness of min 3.38 mm meter Tk. 682.00 28.1.4 20 mm N.D. (26.70 mm O.D) M.S pipe weight of min 1.68 kg/m, standard test pressure 50 kg/ m2, wall thickness of min 2.87 mm meter Tk. 522.00 28.2 Back filling the trenches with sand (F.M 0.8) in 150 mm layer, compaction of each layer up to finished level as per standard practice and accepted by the Engineer-in-charge. cum Tk. 683.00 28.3 Providing Butt welded joints with pipes to Tees, Elbows, Saddles, end caps etc above or below ground including. cutting and V-leveling in each end of the pipe, grinding by machine etc. complete as per specification of Titas Gas T and D C Ltd. and accepted by the Engineer-in-charge. 28.3.1 75 mm N.D (88.90 mm O.D) each Tk. 192.00 28.3.2 50 mm N.D (60.30 mm O.D) each Tk. 163.00 28.3.3 25.mm N.D (33.40 mm O.D) each Tk. 128.00 28.3.4 20 mm N.D (26.70 mm O.D) each Tk. 109.00 28.4 Supplying, fitting and fixing the following materials including carriage to the work site from Titas Gas Store as per specification of Titas Gas (T and D) Co. Ltd. and accepted by the Engineer-in-charge. (Rate is excluding the cost of welding) 28.4.1 50 mm x 50 mm x 50 mm (N.D) equal tee each Tk. 303.00 28.4.2 50 mm x 50 mm x 25 mm (N.D) reducing tee each Tk. 337.00 28.4.3 25 mm x 25 mm x 25 mm (N.D) equal tee each Tk. 208.00 28.4.4 50 mm x 90º elbow each Tk. 241.00 PWD SoR 2018 for Civil Works GAS CONNECTION WORKS Item No. Description of Item Unit 215 Unit Rate 28.4.5 25 mm x 90º elbow each Tk. 88.00 28.4.6 50 mm x 25 mm 45º elbow each Tk. 116.00 28.4.7 50 mm x 25 mm reducer. each Tk. 126.00 28.4.8 20 mm plug, socket each Tk. 353.00 28.4.9 50mm X 20 mm saddle each Tk. 275.00 28.4.10 50 mm dia end cap each Tk. 103.00 28.4.11 25 mm dia end cap each Tk. 72.00 28.5 Supplying, welding, fitting and fixing of different size valve tee/ service tee to connect the pipe line with the Titas Gas Main pipe line etc. all complete in all respect as per specification of Titas Gas T and D Co. Ltd. approved and accepted by the Engineer-incharge. 28.5.1 50 mm x 50 mm Valve Tee (50 mm and above 50 mm low pressure line) each Tk. 24,007.00 28.5.2 50 mm x 25 mm Valve Tee each Tk. 3,199.00 28.5.3 25 mm x 25 mm Service Tee each Tk. 4,262.00 28.5.4 50 mm x 25 mm Service Tee each Tk. 5,787.00 28.6 Supplying, fitting and fixing in position different dia I/F (Insulated Flange) etc. all complete in all respect as per specification of Titas Gas T and D Co. Ltd. approved and accepted by the Engineer-in-charge. 50 mm N.D. (60.30 mm O.D) Insulation Flange. each Tk. 7,305.00 28.7 Construction of 1520 mm x 1520 mm x 1370 mm (depth) water-tight valve pit, enclosed by 250 mm thick brick wall in 1:6, plastered on each face in 1:4 with net cement finishing, having a 75 mm thick C.C (1:3:6) bed upon a layer of brick flat soling, over laid by 38 mm thick patent stone flooring including standard M.S. sheet valve pit cover as per drawing and specification of Titas Gas T and D Co. Ltd. etc. all complete in all respect and accepted by the Engineer-in-charge. each Tk. 74,053.00 28.8 Testing and purging the pipe lines properly as per specification of Titas Gas T and D Co. Ltd. and accepted by the Engineer. meter Tk. 28.9 Supplying, fitting and fixing of ball valve class 150 RF including supplying of 2 Nos. flange along with necessary nuts and bolts, welding the flange etc. all complete in all respect as per specification of Titas Gas T and D Co. Ltd. approved and accepted by the Engineer-in-charge. 28.9.1 50 mm ball valve class 150 RF. 2" dia each Tk. 17,234.00 28.9.2 25 mm ball valve class 150 RF.1" dia each Tk. 12,233.00 28.10 Cutting of permanent pucca (rigid/flexible) road and mending good the damages etc. all complete in all respect and accepted by the Engineer-in-charge. 28.10.1 Bituminous Road sqm Tk. 28.00 756.00 PWD SoR 2018 for Civil Works GAS CONNECTION WORKS Item No. 28.10.2 Description of Item R.C.C. Road Unit 216 Unit Rate sqm Tk. 1,131.00 Part - B (Domestic & Commercial line) 28.11 Installation of Domestic or Commercial House line for supplying Titas Gas including supplying, fitting and fixing in position different dia best quality G.I. Pipe (NT or equivalent) along with all necessary G.I. fitting and accessories, cutting trenches, walls and floors etc. and back filling the trenches, restoring walls and floors etc. all complete in all respect as per specification of Titas Gas T and D Co. Ltd. and accepted by the Engineer-in-charge. 28.11.1 20 mm N.D meter Tk. 246.00 28.11.2 12 mm N.D. meter Tk. 212.00 28.12 Supplying, fitting and fixing in position different dia one-way brass stop cock (best quality and heavy type) etc. complete in all respect as per specification of Titas Gas T and D Co. Ltd. approved and accepted by the Engineer-in-charge. meter 28.12.1 12 mm x 6 mm N.D. each Tk. 268.00 28.12.2 20 mm x 20 mm N.D. each Tk. 428.00 28.13 Testing and purging of the house line properly as per specifications Titas Gas T and D Co. Ltd. and accepted by the Engineer-in-charge. meter Tk. 20.00 ………………….. END OF DIVISION TWENTY EIGHT ………………….. PWD SoR 2018 for Civil Works TERMITE TREATMENT WORKS 217 DIVISION 29 : TERMITE TREATMENT WORKS Item No. Description of Item Unit Unit Rate 29.1 Supplying anti-termite chemicals named DURS BAN 20 EC and mixing the same with pure water in required proportion (For DURSBAN 20 EC I Ltd. in 19 liters of pure water) and spraying the emulsified mixture @ 5 liters per square meter of soil surface by chemical sprayer or by any other means to the sides and bottom of the foundation trench and over plinth filling or floor bed accepted by the Engineer-in-charge. sqm Tk. 287.00 29.2 Extra cost for supplying anti termite chemicals named DURS BAN 20 EC and mixing the same with pure water as per specification in item No. 1 and using the same emulsified water as mixing water in cement-sand mortar of brick works in foundation and up to plinth and accepted by the Engineer-in-charge. cum Tk. 2,113.00 29.3 Supplying anti-termite chemicals named DURS BAN 20 EC and mixing the same with pure water as per specification in item No. 1 and spraying the emulsified mixture with hand sprayer over both outside and inside back fill in foundation trenches @ 7.50 liters per sqm of the vertical surface area of the foundation wall accepted by the Engineer-in-charge. (The maximum depth of the back fill to be treated is 500 mm. and the measurement for depth should not be given more than 500 mm) sqm Tk. 431.00 29.4 Anti-termite treatment in existing super structures by making downwardly slanting holes at a required depth of 9" from the existing finished F.L/G.L inside and outside the building and applying the emulsion of anti termite chemicals, named DURS BAN 20 EC into the holes preparing chemical solution mixing with water at the ratio of chemical: water = 1:19 maintaining a dosage rate of 250 ml per hole including supplying all materials and repairing the holes all complete and accepted by the Engineer-in-charge. per hole Tk. 51.00 29.5 Trench treatment for protection against incoming termites to the establishment through underground by making trench around existing building /structures at a required depth of 750 mm from existing level including supplying anti-termite chemicals named DURS BAN 20 EC preparing the solution to be mixed with water in the ratio of chemical: water = 1:19, applying the solution into trench with the help of a chemical sprayer in three layers and each layer follows a 250 mm thick back-fill in trench etc all complete and accepted by the Engineer-in-charge. meter Tk. 279.00 29.6 Fumigation treatment (Pest Control) against mosquitoes, flies, bees, cockroaches, spiders, silver fishes, lizards and other common pests and insects in wooden walls, bricks walls, floors, doors and windows, furniture fanlight, carpets, records, curtains, electrical conduits etc. with the application of fumigants such as Syngeata or NEOCIDOL-60 EC or similar chemically equivalent govt. registered pest control products preparing chemical solution mixing with water in the ratio of chemical: water = 1:100, applying with the help of electrically/mechanically operated jet fogging machine, swing fog, dyna fog, pneumatic hand sprayer, knap sac hand sprayer in air-tight position, after fumigation the surface will be kept remain at air-tight condition at least for 3 (three) hours etc. complete and accepted by the Engineer-in-charge.(Volume of the room will be considered towards measurement.) cum Tk. 32.00 29.7 Anti termite treatment of all wooden doorframes, window frames, wood paneling etc. by using DURS BAN 20 EC emulsion in the ratio of 1 liter. DURS BAN 20 EC + 19 liters of Kerosene oil suitable for wood, plywood, particle board, hard board etc. on both surfaces by brush on both surfaces by brush-on-method etc. complete and accepted by the Engineer-in-charge. sqm Tk. 175.00 PWD SoR 2018 for Civil Works TERMITE TREATMENT WORKS Item No. 218 Description of Item Unit 29.8 Anti-termite treatment of electric telephone wiring system by inserting a plugging materials (cotton, foam etc.) soaked in anti-termite chemical DURS BAN 20 EC to an electric switch board point for all floors and spraying the emulsion (to be mixed at the ratio of 1 liters DURS BAN 20 EC + 19 liter of water) to the casings and grooving of electric wirings, telephone cables utility pipes etc. for all floors etc. complete and accepted by the Engineer-in-charge. per board Tk. 328.00 29.9 Destruction of termite nest around an infested building, tree stumps in lawn with the treatment of DURS BAN 20 EC by excavation of soil in affected area up to a depth of 1.5 meter, mixing the DURS BAN 20 EC solution to be mixed with water in 1:19 ratio with the soil and laying the same in same place etc. all complete as per direction including. cost of all materials and chemicals etc. complete and accepted by the Engineer-in-charge. each nest Tk. 2,043.00 ………………….. END OF DIVISION TWENTY NINE ………………… Unit Rate CONCRETE HOLLOW BLOCK, FACINGS AND PAVING STONE, NON FIRE BLOCK PWD SoR 2018 for Civil Works 219 DIVISION 30 : CONCRETE HOLLOW BLOCK, FACINGS AND PAVING STONE, NON FIRE BLOCK Item No. Description of Item Unit Unit Rate 30.1 70 mm thick partition wall excluding plaster thickness with concrete hollow block having compressive strength of 4.14~5 N/mm2, size 390 mm x 70 mm x 190 mm, in compliance with ASTM C129, fairly uniform thickness and texture and individual block shell thickness should not be less than 16 mm, water absorption not more than 7%, laying with 8-10 mm thick mortar (with admixture) of cement, lime and sand in a ratio of 1:1:6 (sand not less than 1.2 F.M), filling the interstices with mortar and making bond with connecting walls including necessary scaffolding and curing for minimun 3 (three) days on mortar joints by jute /brush in wet, followed by impervious /wet covering for another 4 (four) days etc all complete and accepted by the Engineer-in-charge. 30.1.1 Ground floor sqm Tk. 699.00 30.1.2 Add for each additional floor up to 5th floor sqm Tk. 31.00 30.1.3 Add for each additional floor for 6th floor to 9th floor sqm Tk. 42.00 30.1.4 Add for each additional floor for 10th floor and above sqm Tk. 52.00 30.2 70 mm thick partition wall excluding plaster thickness with concrete hollow block having compressive strength of 4.14~5 N/mm2, size 390 mm x 70 mm x 190 mm, in compliance with ASTM C129, thickness of individual Block shell should not be less than 16 mm, water absorption not more then 7 % lying with 8 to 10 mm thick mortar (with admixture) of cement and sand in a ratio of 1:6 (sand not less than 1.2 F.M), filling the interstices with mortar and making bond with connecting walls including necessary scaffolding and curing for minimun 3 (three) days on mortar joints by jute/brush in wet, followed by impervious/wet covering for another 4 (four) days etc all complete and accepted by the Engineer-in-charge. 30.2.1 Ground floor sqm Tk. 677.00 30.2.2 Add for each additional floor up to 5th floor sqm Tk. 31.00 30.2.3 Add for each additional floor for 6th floor to 9th floor sqm Tk. 42.00 30.2.4 Add for each additional floor for 10th floor and above sqm Tk. 52.00 30.3 90 mm thick partition wall with concrete hollow block having strength of 4.14~5 N/mm2, size 390 mm x 90 mm x 190 mm, in compliance with ASTM C129, thickness of individual block shell should not be less than 16 mm, water absorption not more then 7%, lying with specified mortar (with admixture) of cement, lime and sand in a ratio of 1:1:6 (sand not less than 1.2 F.M), filling the interstices with mortar and making bond with connecting walls including necessary scaffolding and curing for minimun 3 (three) days on mortar joints by jute /brush in wet, followed by impervious /wet covering for another 4 (four) days curing etc all complete and accepted by the Engineer-in-charge. 30.3.1 Ground floor sqm Tk. 887.00 30.3.2 Add for each additional floor up to 5th floor sqm Tk. 31.00 30.3.3 Add for each additional floor for 6th floor to 9th floor sqm Tk. 42.00 CONCRETE HOLLOW BLOCK, FACINGS AND PAVING STONE, NON FIRE BLOCK Item No. PWD SoR 2018 for Civil Works Description of Item 30.3.4 Add for each additional floor for 10th floor and above 30.4 90 mm thick partition wall with concrete hollow block having compressive strength of 4.14~5 N/mm2, size 390 mm x 90 mm x 190 mm, in compliance with ASTM C129, thickness of individual block shell should not be less than 16 mm, water absorption not more than 7%, lying with specified mortar (with admixture) of cement, and sand in a ratio of 1:6 (sand not less than 1.2 F.M), filling the interstices with mortar and making bond with connecting walls including necessary scaffolding and curing for minimun 3 (three) days on mortar joints by jute /brush in wet, followed by impervious /wet covering for another 4 (four) days curing etc. all complete and accepted by the Engineer-in-charge 30.4.1 Unit 220 Unit Rate sqm Tk. 52.00 Ground floor sqm Tk. 1,121.00 30.4.2 Add for each additional floor up to 5th floor sqm Tk. 31.00 30.4.3 Add for each additional floor for 6th floor to 9th floor sqm Tk. 42.00 30.4.4 Add for each additional floor for 10th floor and above sqm Tk. 52.00 30.5 140 mm thick non load bearing wall with concrete hollow block having compressive strength of 13~18 N/mm2, size 390 mm x 140 mm x 190 mm, in compliance with ASTM C90, thickness of individual block shell should not be less then 25 mm, water absorption not more than 7%, laying with mortar (with admixture) of cement, lime and sand in a ratio of 1:1:6 (sand not less than 1.2 F.M), filling the interstices with mortar and making bond with connecting walls including necessary scaffolding and curing for minimun 3 (three) days on mortar joints by jute /brush in wet, followed by impervious /wet covering for another 4 (four) days etc all complete and accepted by the Engineer-in-charge. 30.5.1 Ground floor sqm Tk. 1,291.00 30.5.2 Add for each additional floor up to 5th floor sqm Tk. 42.00 30.5.3 Add for each additional floor for 6th floor to 9th floor sqm Tk. 52.00 30.5.4 Add for each additional floor for 10th floor and above sqm Tk. 62.00 30.6 140 mm thick partition wall with concrete hollow block having compressive strength of 4.14~5 N/mm2, size 390 mm x 140 mm x 190 mm, in compliance with ASTM C129, thickness of individual Block shell should not be less than 16 mm, water absorption not more than 7%, laying with specified mortar (with admixture) of cement and sand in a ratio of 1:6 (sand not less than 1.2 F.M), filling the interstices with mortar and making bond with connecting walls including necessary scaffolding and curing for minimun 3 (three) days on mortar joints by jute /brush in wet, followed by impervious /wet covering for another 4 (four) days curing etc all complete and accepted by the Engineer-in-charge. 30.6.1 Ground floor sqm Tk. 1,261.00 30.6.2 Add for each additional floor up to 5th floor sqm Tk. 42.00 30.6.3 Add for each additional floor for 6th floor to 9th floor sqm Tk. 52.00 30.6.4 Add for each additional floor for 10th floor and above sqm Tk. 62.00 CONCRETE HOLLOW BLOCK, FACINGS AND PAVING STONE, NON FIRE BLOCK Item No. PWD SoR 2018 for Civil Works Description of Item Unit 221 Unit Rate 30.7 140 mm thick load bearing wall with concrete hollow block having compressive strength of 13~18 N/mm2, size 390 mm x 140 mm x 190 mm compliance with ASTM C90, thickness of individual Block shell should not be less then 25 mm, water absorption not more than 7%, laying with mortar (with admixture) of cement, lime and sand in a ratio of 1:1:6 (sand not less than 1.2 F.M), filling the interstices with mortar and making bond with connecting walls including necessary scaffolding and curing for minimun 3 (three) days on mortar joints by jute /brush in wet, followed by impervious /wet covering for another 4 (four) days etc all complete and accepted by the Engineer-in-charge. 30.7.1 Ground floor sqm Tk. 1,337.00 30.7.2 Add for each additional floor up to 5th floor sqm Tk. 42.00 30.7.3 Add for each additional floor for 6th floor to 9th floor sqm Tk. 52.00 30.7.4 Add for each additional floor for 10th floor and above sqm Tk. 62.00 30.8 140 mm thick load bearing wall with concrete hollow block having compressive strength of 13~18 N/mm2, size 390 mm x140 mm x 190 mm, in compliance with ASTM C90, thickness of individual block shell should not be less than 25 mm, water absorption not more than 7%, laying with mortar (with admixture) of cement and sand in a ratio of 1:6 (sand not less than 1.2 F.M), filling the interstices with mortar and making bond with connecting walls including necessary scaffolding and curing for minimun 3 (three) days on mortar joints by jute /brush in wet, followed by impervious /wet covering for another 4 (four) days etc all complete and accepted by the Engineer-in-charge. (Rate is excluding the cost of grouting and reinforcement) 30.8.1 Ground floor sqm Tk. 1,307.00 30.8.2 Add for each additional floor up to 5th floor sqm Tk. 42.00 30.8.3 Add for each additional floor for 6th floor to 9th floor sqm Tk. 52.00 30.8.4 Add for each additional floor for 10th floor and above sqm Tk. 62.00 30.9 190 mm thick load bearing wall with concrete hollow block having compressive strength of 4.14~5 N/mm2, size 390 mm x 190 mm x 190 mm, in compliance with ASTM C90, thickness of individual block shell should not be less than 25 mm, water absorption not more than 7%, laying with mortar (with admixture) of cement, lime and sand in a ratio of 1:1:6 (sand not less than 1.2 F.M), filling the interstices with mortar and making bond with connecting walls including necessary scaffolding and curing for minimun 3 (three) days on mortar joints by jute /brush in wet, followed by impervious /wet covering for another 4 (four) days etc all complete and accepted by the Engineer-in-charge. (Rate is excluding the cost of grouting and reinforcement) 30.9.1 Ground floor sqm Tk. 1,410.00 30.9.2 Add for each additional floor up to 5th floor sqm Tk. 52.00 30.9.3 Add for each additional floor for 6th floor to 9th floor sqm Tk. 62.00 30.9.4 Add for each additional floor for 10th floor and above sqm Tk. 73.00 CONCRETE HOLLOW BLOCK, FACINGS AND PAVING STONE, NON FIRE BLOCK Item No. PWD SoR 2018 for Civil Works Description of Item Unit 222 Unit Rate 30.10 190 mm thick load bearing wall with concrete hollow block having compressive strength of 13~18 N/mm2, size 390 mm x 190 mm x 190 mm, in compliance with ASTM C90, thickness of individual block shell should not be less than 25 mm, water absorption not more than 7%, laying with mortar (with admixture) of cement and sand in a ratio of 1:6 (sand not less than 1.2 F.M), filling the interstices with mortar and making bond with connecting walls including necessary scaffolding and curing for minimun 3 (three) days on mortar joints by jute /brush in wet, followed by impervious /wet covering for another 4 (four) days etc all complete and accepted by the Engineer-in-charge. (Rate is excluding cost of grouting and reinforcement) 30.10.1 Ground floor sqm Tk. 1,381.00 30.10.2 Add for each additional floor up to 5th floor sqm Tk. 52.00 30.10.3 Add for each additional floor for 6th floor to 9th floor sqm Tk. 62.00 30.10.4 Add for each additional floor for 10th floor and above sqm Tk. 73.00 30.11 100 mm thick partition wall with sand cement hollow block wall (SCHB) having compressive strength of 4.14~5 N/mm2, size 400 mm x 200 mm x 100 mm, in compliance with ASTM C129, thickness of individual Block shell should not be less than 20 mm, water absorption not more than 7%, lying with specified mortar (with admixture) of cement, and sand in a ratio of 1:6 (sand not less than F.M = 1.2), filling the interstices with mortar and making bond with connecting walls including necessary scaffolding and curing for minimun 14 days on mortar joints by jute /brush in wet, followed by impervious /wet covering for another 7 days including cost of water, electricity and other charges etc. in all complete accepted by the Engineer-in-charge. 30.11.1 Ground Floor sqm Tk. 736.00 30.11.2 Add for each additional floor up to 5th floor sqm Tk. 25.00 30.11.3 Add for each additional floor up to 6th floor to 9th floor sqm Tk. 37.00 30.11.4 Add for each additional floor for 10th floor and above sqm Tk. 45.00 30.12 Supplying, carrying and placing of 600 mm x 200 mm x 150 mm concrete ceiling block on properly leveled shutter accepted by the Engineer-in-charge. 30.12.1 Ground floor each Tk. 104.00 30.12.2 Add for each additional floor up to 5th floor each Tk. 4.00 30.12.3 Add for each additional floor for 6th floor to 9th floor each Tk. 5.00 30.12.4 Add for each additional floor for 10th floor and above each Tk. 6.00 30.13 Supplying, carrying and placing of 600 mm x 200 mm x 200 mm concrete ceiling block on properly leveled shutter accepted by the Engineer-in-charge. 30.13.1 Ground floor each Tk. 140.00 30.13.2 Add for each additional floor up to 5th floor each Tk. 5.00 30.13.3 Add for each additional floor for 6th floor to 9th floor each Tk. 9.00 CONCRETE HOLLOW BLOCK, FACINGS AND PAVING STONE, NON FIRE BLOCK Item No. PWD SoR 2018 for Civil Works Description of Item 30.13.4 Add for each additional floor for 10th floor and above 30.14 Minimum 10 mm thick cement plaster in cement : sand =1:5 in outer surface of external wall with specified external plaster mix applied in two coats (first coat 6/7 mm and second coat 4/3 mm), finishing the corner and edge including washing of sand, cleaning the surface, scaffolding and curing for minimun 3 (three) days on mortar joints by jute/brush in wet, followed by impervious/wet covering for another 4 (four) days etc. all complete etc. all complete and accepted by the Engineer-in-charge. (Rate is excluding the cost of grouting and reinforcement) 30.14.1 Unit 223 Unit Rate each Tk. 10.00 Ground floor sqm Tk. 246.00 30.14.2 Add for each additional floor up to 5th floor sqm Tk. 14.00 30.14.3 Add for each additional floor for 6th floor to 9th floor sqm Tk. 21.00 30.14.4 Add for each additional floor for 10th floor and above sqm Tk. 28.00 30.15.1 Supplying and placing of approx. 60 mm thick grey uni-block paving for walk way having compressive strength of 15 N/mm2 on compacted sand bed of 50 mm on stabilized soil base, and filling all interstices with sand, cleaning etc. accepted by the Engineer-incharge. sqm Tk. 1,074.00 30.15.2 Supplying and placing of approx. 60 mm thick coloured uni-block for paving walk way having compressive strength of 15 N/mm2 on compacted sand bed of 50 mm on stabilized soil base, and filling all interstices with sand, cleaning etc. accepted by the Engineer-incharge. sqm Tk. 1,276.00 30.16.1 Supplying and placing of 60 mm thick grey uni-block for paving foot-path, major walk way, car porch having compressive strength of 49 N/mm2 on compacted sand bed of 50 mm on stabilized soil base, and filling all interstices with sand, cleaning etc. accepted by the Engineer-in-charge. sqm Tk. 1,226.00 30.16.2 Supplying and placing of 60 mm thick coloured uni-block for paving foot-path, major walk way, car porch having compressive strength of 49 N/mm2 on compacted sand bed of 50 mm on stabilized soil base, and filling all interstices with sand, cleaning etc. accepted by the Engineer-in-charge. sqm Tk. 1,377.00 30.17.1 Supplying and placing of 80 mm grey uni-block for paving heavy trafic areas, roads rounds abuts, industrial yards etc having compressive strength of 49 N/mm2 on compacted sand bed of 50 mm on stabilized soil base, and filling all interstices with sand, cleaning etc. accepted by the Engineer-in-charge. sqm Tk. 1,478.00 30.17.2 Supplying and placing of 80 mm thick coloured uni-block for paving heavy trafic areas, road, industrial yard etc having compressive strength of 49 N/mm2 on compacted sand bed of 50 mm on stabilized soil base, and filling all interstices with sand, cleaning etc. accepted by the Engineer-in-charge. sqm Tk. 1,780.00 30.18.1 Supplying and placing of grey 200 mm x 100 mm x 60 mm rectangular block having compressive strength of 15 N/mm2 on 50 mm thick compacted sand bed, and filling all interstices with sand, cleaning etc. accepted by the Engineer-in-charge. sqm Tk. 1,258.00 30.18.2 Supplying and placing of coloured 200 mm x 100 mm x 60 mm rectangular block having compressive strength of 15 N/mm2 on 50 mm thick compacted sand bed, and filling all interstices with sand, cleaning etc. accepted by the Engineer-in-charge. sqm Tk. 1,443.00 CONCRETE HOLLOW BLOCK, FACINGS AND PAVING STONE, NON FIRE BLOCK Item No. PWD SoR 2018 for Civil Works Description of Item Unit 224 Unit Rate 30.19.1 Supplying and placing of grey engraved cement concrete tiles (250 mm x 250 mm in size) having minimum thickness of 24 mm over 12 mm sand cement mortar (4:1) each at a distance of 6 mm apart and filling the joints with cement sand mortar (1:4) including raking out joints and cutting the tiles to required sizes wherever necessary with high class recessed pointing, cleaning and washing of sand, curing for minimun 3 (three) days on mortar joints by jute /brush in wet, followed by impervious /wet covering for another 4 (four) days etc. all complete and accepted by the Engineer-in-charge. 30.19.1.1 Ground floor sqm Tk. 1,084.00 30.19.1.2 Add for each additional floor up to 5th floor sqm Tk. 42.00 30.19.1.3 Add for each additional floor for 6th floor to 9th floor sqm Tk. 52.00 30.19.1.4 Add for each additional floor for 10th floor and above sqm Tk. 62.00 30.19.2 Supplying and placing of coloured engraved cement concrete tiles (250 mm x 250 mm in size) having minimum thickness of 24 mm over 12 mm sand cement mortar (4:1) each at a distance of 6 mm apart and filling the joints with cement sand mortar (1:4) including raking out joints and cutting the tiles to required sizes wherever necessary with high class recessed pointing, cleaning and washing of sand, curing for min 3 (three) days on mortar joints by jute /brush in wet, followed by impervious /wet covering for another 4 (four) days etc. all complete and accepted by the Engineer-in-charge. 30.19.2.1 Ground floor sqm Tk. 1,217.00 30.19.2.2 Add for each additional floor up to 5th floor sqm Tk. 42.00 30.19.2.3 Add for each additional floor for 6th floor to 9th floor sqm Tk. 52.00 30.19.2.4 Add for each additional floor for 10th floor and above sqm Tk. 62.00 30.20.1 225 mm thick wall with 215 mm x 100 mm x 65 mm concrete solid block having minimum compressive strength of 21 N/mm2 with 6 mm thick cement sand mortar in 1:6 in superstructure including racking out the joints, filling the interstices with mortar and making bond with connecting walls including necessary scaffolding and curing for minimun 3 (three) days on mortar joint by jute/ brush in wet followed by impervious covering for another 4 (four) days etc. all complete and accepted by the Engineer-in-charge. 30.20.1.1 Ground floor sqm Tk. 2,700.00 30.20.1.2 Add for each additional floor up to 5th floor sqm Tk. 42.00 30.20.1.3 Add for each additional floor for 6th floor to 9th floor sqm Tk. 52.00 30.20.1.4 Add for each additional floor for 10th floor and above sqm Tk. 62.00 30.20.2 112 mm thick wall with 215 mm x 100 mm x 65 mm concrete solid block having minimum compressive strength of 21 N/mm2 with 6 mm thick cement sand mortar in 1:6 in superstructure including racking out the joints, filling the interstices with mortar and making bond with connecting walls including necessary scaffolding and curing for minimun 3 (three) days on mortar joint by jute/ brush in wet followed by impervious covering for another 4 (four) days etc. all complete and accepted by the Engineer-in-charge. 30.20.2.1 Ground floor sqm Tk. 1,385.00 CONCRETE HOLLOW BLOCK, FACINGS AND PAVING STONE, NON FIRE BLOCK Item No. PWD SoR 2018 for Civil Works Description of Item Unit 225 Unit Rate 30.20.2.2 Add for each additional floor up to 5th floor sqm Tk. 42.00 30.20.2.3 Add for each additional floor for 6th floor to 9th floor sqm Tk. 52.00 30.20.2.4 Add for each additional floor for 10th floor and above sqm Tk. 62.00 30.21 115 mm thick partition wall with sand-cement solid block wall (SCSB) having compressive strength of 4.0–5.0 N/mm2 and of size 250 mm x 115 mm x 115 mm, in cement sand (F.M. 1.2) mortar (1:4) and making bond with connected walls including necessary scaffolding, raking out, joints, cleaning, at least 24 hours before use and washing of sand curing at least for 7 days in all floors including cost of water, electricity and other charges etc. all complete and accepted by the Engineer-in-charge. 30.21.1 Ground floor sqm Tk. 658.00 30.21.2 Add for each additional floor up to 5th floor sqm Tk. 32.00 30.21.3 Add for each additional floor up to 6th floor to 9th floor sqm Tk. 40.00 30.21.4 Add for each additional floor for 10th floor and above sqm Tk. 50.00 30.22 115 mm thick partition wall with thermal block having compressive strength 4.0–5.0 N/mm2 and of size 300 mm x 115 mm x 115 mm, in compliance with ASTM C129 fairly uniform thickness and texture and each side of thermal block not be less than 12mm (1 part cement with 2 parts and having F.M.>2.0) thick, water absorption not more than 7%, laying with 8-10mm thick mortar of cement and sand in ratio 1:4 (sand not less than 1.2 F.M), filling the interstices with mortar and making bond with connecting walls including scaffolding and curing for minimum 3 (three) days on mortar joints by jute/brush, followed by impervious/wet covering for another 4 (four) days including cost of water, electricity and other charges all complete and accepted by the Engineer-in-charge. 30.22.1 Ground floor sqm Tk. 993.00 30.22.2 Add for each additional floor up to 5th floor sqm Tk. 18.00 30.22.3 Add for each additional floor up to 6th floor to 9th floor sqm Tk. 24.00 30.22.4 Add for each additional floor for 10th floor and above sqm Tk. 28.00 30.23 100 mm thick partition wall with compressed stabilized earth block wall (CSEB) having compressive strength of 4.14~5 N/mm2 and of size 240 mm x 115 mm x 70 mm, in cement sand (F.M. 1.2) mortar (1:4) and making bond with connected walls including necessary scaffolding, raking out, joints, cleaning, at least 24 hours before use and washing of sand curing at least for 7 days in all floors including cost of water, electricity and other charges etc. all complete and accepted by the Engineer-in-charge. 30.23.1 Ground Floor sqm Tk. 756.00 30.23.2 Add for each additional floor up to 5th floor sqm Tk. 30.00 30.23.3 Add for each additional floor up to 6th floor to 9th floor sqm Tk. 39.00 30.23.4 Add for each additional floor for 10th floor and above sqm Tk. 50.00 CONCRETE HOLLOW BLOCK, FACINGS AND PAVING STONE, NON FIRE BLOCK Item No. PWD SoR 2018 for Civil Works 226 Description of Item Unit Unit Rate 30.24 100 mm thick soil-cement stabilization bed for sub-grade preparation of ground floor etc. with minimum cement content relates to mix ratio 1:6 having minimum compressive strength of 3.0 N/mm2 and cement conforming to BDS EN-197-1-CEM-1, best quality fine sand (F.M. = 0.5), placing, compacting at least for 7 days in all floors including cost of water, electricity and other charges etc. all complete and accepted by the Engineer-incharge. sqm Tk. 444.00 30.25 One layer of sand cement solid block 250 mm x 115 mm x 70 mm Soling in floor/foundation including preparation of bed and filling the interstices with fine sand (F.M. = 0.5), leveling etc. all complete and accepted by the Engineer-in-charge. sqm Tk. 410.00 30.26.1 38 mm thick grey cladding work in facing on superstructure with 200 mm x 90 mm x 38 mm size concrete clad pested with 20 mm thick cement mortar (1:4) to be placed at 6 mm apart, filling the interstices with same mortar, raking out joints and cutting the clad to required sizes wherever necessary with high class recessed pointing, cleaning and washing of sand, necessary scaffolding, curing for minimum 3 (three) days on mortar joints by jute /brush in wet, followed by impervious /wet covering for another 4 (four) days etc. all complete and accepted by the Engineer-in-charge. 30.26.1.1 Ground floor sqm Tk. 1,474.00 30.26.1.2 Add for each additional floor up to 5th floor sqm Tk. 42.00 30.26.1.3 Add for each additional floor for 6th floor to 9th floor sqm Tk. 52.00 30.26.1.4 Add for each additional floor for 10th floor and above sqm Tk. 62.00 30.26.2 38 mm thick coloured cladding work in facing on superstructure with 200 mm x 92 mm x 38 mm size concrete clad pested with 20 mm thick cement mortar (1:4) to be placed at 6 mm apart, filling the interstices with same mortar, raking out joints and cutting the clad to required sizes wherever necessary with high class recessed pointing, cleaning and washing of sand, necessary scaffolding, curing for minimum 3 (three) days on mortar joints by jute /brush in wet, followed by impervious /wet covering for another 4 (four) days etc. all complete and accepted by the Engineer-in-charge. 30.26.2.1 Ground floor sqm Tk. 1,599.00 30.26.2.2 Add for each additional floor up to 5th floor sqm Tk. 42.00 30.26.2.3 Add for each additional floor for 6th floor to 9th floor sqm Tk. 52.00 30.26.2.4 Add for each additional floor for 10th floor and above sqm Tk. 62.00 30.26.3 50 mm thick grey cladding work in facing on superstructure with 400 mm x 100 mm x 50 mm size concrete clad pested with 20 mm thick cement mortar (1:4) to be placed at 6 mm apart, filling the interstices with same mortar, raking out joints and cutting the clad to required sizes wherever necessary with high class recessed pointing, cleaning and washing of sand, necessary scaffolding, curing for minimum 3 (three) days on mortar joints by jute /brush in wet, followed by impervious /wet covering for another 4 (four) days etc. all complete and accepted by the Engineer-in-charge. 30.26.3.1 Ground floor sqm Tk. 1,121.00 30.26.3.2 Add for each additional floor up to 5th floor sqm Tk. 42.00 30.26.3.3 Add for each additional floor for 6th floor to 9th floor sqm Tk. 52.00 CONCRETE HOLLOW BLOCK, FACINGS AND PAVING STONE, NON FIRE BLOCK Item No. PWD SoR 2018 for Civil Works Description of Item 30.26.3.4 Add for each additional floor for 10th floor and above 30.26.4 50 mm thick coloured cladding work in facing on superstructure with 400 mm x 100 mm x 50 mm size concrete clad pested with 20 mm thick cement mortar (1:4) to be placed at 6 mm apart, filling the interstices with same mortar, raking out joints and cutting the clad to required sizes wherever necessary with high class recessed pointing, cleaning and washing of sand, necessary scaffolding, curing for minimum 3 (three) days on mortar joints by jute /brush in wet, followed by impervious /wet covering for another 4 (four) days etc. all complete and accepted by the Engineer-in-charge. 30.26.4.1 Unit 227 Unit Rate sqm Tk. 62.00 Ground floor sqm Tk. 1,259.00 30.26.4.2 Add for each additional floor up to 5th floor sqm Tk. 42.00 30.26.4.3 Add for each additional addl floor for 6th floor to 9th floor sqm Tk. 52.00 30.26.4.4 Add for each additional floor for 10th floor and above sqm Tk. 62.00 30.26.5 15 mm thick grey/coloured cladding work in facing on superstructure with 420 mm x 330 mm x 15 mm size concrete clad pested with 20 mm thick cement mortar (1:4) to be placed at 6 mm apart, filling the interstices with same mortar, raking out joints and cutting the clad to required sizes wherever necessary with high class recessed pointing, cleaning and washing of sand, necessary scaffolding, curing for minimum 3 (three) days on mortar joints by jute /brush in wet, followed by impervious /wet covering for another 4 (four) days etc. all complete and accepted by the Engineer-in-charge 30.26.5.1 Ground floor sqm Tk. 805.00 30.26.5.2 Add for each additional floor up to 5th floor sqm Tk. 42.00 30.26.5.3 Add for each additional floor for 6th floor to 9th floor sqm Tk. 52.00 30.26.5.4 Add for each additional floor for 10th floor and above sqm Tk. 62.00 30.27.1 Supplying, carrying, placing, providing 418 mm x 330 mm x 17 mm size of red colour concrete roof tiles on pre-fixed and pre-fabricated truss and fixing each tile to the roof members of truss accepted by the Engineer-in-charge. sqm Tk. 206.00 30.27.2 Supplying, carrying, placing, providing 418 mm x 330 mm x 17 mm size of oriental colour concrete roof tiles on pre-fixed and pre-fabricated truss and fixing each tile to the roof members of truss accepted by the Engineer-in-charge. sqm Tk. 74.00 30.27.3 Supplying, carrying, placing, providing 418 mm x 330 mm x 17 mm size of antique red colour concrete roof tiles on pre-fixed and pre-fabricated truss and fixing each tile to the roof members of truss accepted by the Engineer-in-charge. sqm Tk. 80.00 30.27.4 Supplying, carrying, placing, providing 418 mm x 330 mm x 17 mm size of green colour concrete roof tiles on pre-fixed and pre-fabricated truss and fixing each tile to the roof members of truss accepted by the Engineer-in-charge. sqm Tk. 85.00 30.28 Supplying, carrying, placing, providing of concrete Kerb stone size 600 mm x 300 mm x 100 mm approved and accepted by the Engineer-in-charge. sqm Tk. 238.00 ………………….. END OF DIVISION THIRTY ………………….. PWD SoR 2018 for Civil Works SUB-SOIL INVESTIGATION WORKS 228 DIVISION 31 : SUB-SOIL INVESTIGATION WORKS Item No. Description of Item Unit Unit Rate 31.1 Mobilization and demobilization of boring equipment and man-power: at site (drilling rig comprising drilling pipe, drop hammer, tripod, pulley, chain, wrange, sample collection devices etc tools and plants; tripol for temporary camp, necessary work-force etc) (Once for one site) per site Tk. 11,693.00 31.2 Sub-soil investigation by 100 mm dia wash boring and / or by CPT, DCP etc. including collecting disturbed and undisturbed soil samples in numbers as required for classification of soil, conducting SPT, stratification of layers, analysing physical parameters of soils like Atterberg limits, specific gravity, gain size distribution(by wet seive, hydrometer if required) ,ground water table location, direct shear test, unconfined compression test, unit weight(dry/weight), natural moisture content ; c - ф values and other strength parameters to ascertain bearing capacity , skin friction, end bearings etc at every 1.5m interval as per respective national/international standards and entering all these data & information in necessary tables & graphs and finally furnishing them in the form of standard sub-soil investigation report duly signed by competent engineer & exploratory office. 31.2.1 Bore hole depth from 0 to 20 m per bore hole Tk. 26,528.00 31.2.2 Additional charge for bore hole depth above 20.0 m and upto 30.0 m meter Tk. 389.00 31.2.3 Additional charge for bore hole depth above 30.0 m and upto 40.0 m meter Tk. 424.00 31.2.4 Additional charge for bore hole depth above 40.0 m and upto 50.0 m meter Tk. 448.00 31.3 Sub-soil investigation by 100 mm dia wash boring and/ or by CPT, DCP etc.including collecting disturbed and undisturbed soil samples in numbers as required for classification of soil, conducting SPT, stratification of layers, and entering all these data & information in necessary tables & graphs, furnishing them in the form of standard sub-soil investigation report duly signed by competent engineer & exploratory office.(Only after written advice from concerned design division/circle) 31.3.1 Bore hole depth from 0 to 20m per bore hole Tk. 7,644.00 31.3.2 Additional charge for bore hole depth above 20.0 m and upto 30.0 m meter Tk. 216.00 31.3.3 Additional charge for bore hole depth above 30.0 m and upto 40.0 m meter Tk. 239.00 31.3.4 Additional charge for bore hole depth above 40.0 m and upto 50.0 m meter Tk. 255.00 31.4 Extra cost per bore hole, if the same is under water by more than 1.5 m in depth per bore hole Tk. 5,089.00 31.5 Carrying out different tests on soil samples in BUET laboratory collected from the sub-soil investigation site accepted by the Engineer-in-Charge. (Only after written advice from concern design division/circle) 31.5.1 Void ratio per set of test Tk. 3,600.00 PWD SoR 2018 for Civil Works SUB-SOIL INVESTIGATION WORKS Item No. Description of Item 229 Unit Unit Rate 31.5.2 Organic matter content per set of test Tk. 3,300.00 31.5.3 Permeability for cohesive soil per set of test Tk. 24,000.00 31.5.4 Permeability non-cohesive soil per set of test Tk. 9,500.00 31.5.5 Consolidation test for cohesive soil per set of test Tk. 22,000.00 31.5.6 Triaxial shear Test 31.5.6.1 Consolidated undrained triaxial test with pore pressure for cohesive and non co-hesive soil per set of test Tk. 52,000.00 31.5.6.2 Consolidated undrained triaxial test without pore pressure for cohesive soil per set of test Tk. 46,000.00 31.5.6.3 Consolidated drained triaxial test per set of test Tk. 52,000.00 31.5.6.4 Unconsolidated undrained triaxial test without pore pressure per set of test Tk. 24,000.00 31.5.7 One dimensional swelling / settlement potential of cohesive soil. per set of test Tk. 10,000.00 31.5.8 Modified proctor compaction test per set of test Tk. 1,6500.00 31.6 Conducting plate load test as per ASTM D1194 or equivalent standard providing required arrangement of three circular steel plates with minimum thickness of 25 mm and varying in diameter from 305 mm to 762 mm respectively or square steel bearing plates of equivalent area for minimum 50 tons loading capacity of hydraulic or mechanical jack assembly and applying load in 2 cycles with maintainging time interval of each loading increment of not less than 15 minutes. Continue each test until a peak load is reached or until the ratio of load increment to settlement increment reaches a minimum, steady magnitude. If sufficient load is available, continue the test until the total settlement reaches at least 10 percent of the plate diameter, unless a well defined failure load is observed and all other required materials, excavation, protection against collapse, preparation of test pit, calibration of hydrauic jacks with pressure guage (with an error not exceeding ± 2 % of the load increment used ) & dial gauges (an accuracy of at least 0.25 mm.) including plants and equipment, platform for loading & unloading, mobilization, demobilization, hire charge of load testing equipment (joist, jacks and other necessary devices), gunny bags, filling with sand & stiching gunny bags, execution of tests by engineer, data acquisition and preparation of test results in standard forms and other incidental charges as per standard practice and procedures including submission of plate load test report, furnishing all graphs and charts etc. all complete and accepted by the Engineer-in-charge. At least 03 no of tests must be conducted at one site. (Only after written advice from concern design division/circle) per test Tk. 90,592.00 PWD SoR 2018 for Civil Works SUB-SOIL INVESTIGATION WORKS Item No. 230 Description of Item Unit Unit Rate 31.6.1 Per test rate for conducting additional plate load test at the same site after first 03(Three) tests. per test Tk. 20,543.00 31.6.2 Additional charge per km (beyond 25 Km) outside Dhaka city (two ways)/any city for mobilization & demobilization per km Tk. ………………….. END OF DIVISION THIRTY ONE………………….. 192.00 PWD SoR 2018 for Civil Works REPAIR WORKS 231 DIVISION 32: REPAIR WORKS Item No. Description of items Unit Unit rate 32.1 Stripping of unserviceable plaster including racking out joints, cleaning etc. sqm Tk. 25.00 32.2.1 Picking-up of unserviceable patent stone from floor and dado etc. and removal of debris to a safe distance. sqm Tk. 39.00 32.2.2 Picking-up of unserviceable tiles including bonding mortar from floor, walls and dado etc. and removal of debris to a safe distance. sqm Tk. 51.00 32.3 Picking up of damaged/unserviceable terraced (lime concrete) floor or roof etc. and removal of debris to a safe distance. sqm Tk. 53.00 32.4 Dismantling of unserviceable/damaged terraced roof including beam, column, borga & tiles etc. and removal of debris to a safe distance. sqm Tk. 138.00 32.5.1.1 Dismantling of unserviceable/damaged brick works (with cement or lime mortar) of thickness 250 mm in foundation and superstructure and removal of debris to a safe distance. cum Tk. 434.00 32.5.1.2 Dismantling of unserviceable/damaged brick works (with cement or lime mortar) of thickness 75/125 mm in foundation and superstructure and removal of debris to a safe distance. sqm Tk. 53.00 32.5.2 Dismantling of plain concrete made of lime or cement and removal of debris to a safe distance. cum Tk. 1,325.00 32.5.3 Dismantling of brick flat soling and removal of debris to a safe distance and removal of debris to a safe distance. sqm Tk. 15.00 32.5.4 Dismantling of H.B.B. Brick soling and removal of debris to a safe distance and removal of debris to a safe distance. sqm Tk. 21.00 32.6.1.1 Dismantling of R.C.C. beam, lintel, column, drop wall, sun shade from any height and removal of debris to a safe distance. cum Tk. 3,347.00 32.6.1.2 Dismantling of R.C.C. Railing of any kind, jally brickwork, and hollow block wall from any height and removal of debris to a safe distance. sqm Tk. 183.00 32.6.2 Dismantling of R.C.C. in roof slab and removal of debris to a safe distance. cum Tk. 2,790.00 32.6.3 Recovery of reinforcing bars and metals during dismantling of RCC including cleaning, making bundle, stacking or storing as per direction of engineer in charge and removal of debris to a safe distance. quintal Tk. 442.00 32.6.4 Recovery of bricks during dismantling of brick works including cleaning, stacking or storing etc. all complete as per direction of engineer in charge and removal of debris to a safe distance. % 0 nos Tk. 1,275.00 32.6.5 Recovery of bricks during dismantling of soling including cleaning, stacking or storing all complete as per direction of engineer in charge and removal of debris to a safe distance. % 0 nos Tk. 811.00 PWD SoR 2018 for Civil Works REPAIR WORKS Item No. 232 Description of items Unit Unit rate 32.6.6 Recovery of brick bats during dismantling of soling, brick works, HBB etc. including cleaning, stacking or storing as per direction of engineer in charge and removal of debris to a safe distance. cum Tk. 213.00 32.7 Repairs to minor/fine (non-structural affecting aesthetic) cracks in brick walls, floor and roof etc. meter Tk. 34.00 32.8.1 Cutting and polishing of old mosaic on wall with pumice stone etc. sqm Tk. 87.00 32.8.2 Cutting and polishing of old mosaic on floor with pumice stone and mosaic cutting machine etc. sqm Tk. 79.00 32.8.3 Cleaning and washing the mosaic floor etc. sqm Tk. 17.00 32.8.4 Cleaning and refilling of wornout joints between glazed tiles, marble etc. in floor or walls. sqm Tk. 64.00 32.9 Repairing of terraced roof cracks by cutting in 'traphozoided' shape meter Tk. 452.00 32.10 Taking out and relaying of old brick soling including replacement of 10% brick sqm Tk. 106.00 32.11 Taking out and relaying of brick soling after redressing the surfaces sqm Tk. 68.00 32.12.1 Taking out of old brick on edge pavement and resetting (Herring bone bond) including replacement of 10% brick sqm Tk. 170.00 32.12.2 Taking out of old brick on edge pavement and restting Herring bone bond and redressing the surface sqm Tk. 96.00 32.13 Taking out of old roof tiles and ridges sqm Tk. 59.00 32.14 Supplying and fitting-fixing of wind tie with M.S. Flat bar clamp meter Tk. 459.00 32.15 Supplying and fitting-fixing of J-hook including nuts, washers each Tk. 40.00 32.16 Supplying and fitting-fixing of M.S. U-hook including nuts, washers each Tk. 60.00 32.17 Taking out of old & unserviceable wooden chowkat /door or window frame each Tk. 274.00 32.18 Taking out of old wooden chowkat/door or window frame and refitting and refixing after minor repair (excluding the cost of wood and M.S. clamp) each Tk. 857.00 32.19 Taking out and refitting of wooden shutter after easing excluding the cost of wood sqm Tk. 408.00 32.20.1 Thorough repairs to wooden door and window Pannel shutter excluding the cost of wood sqm Tk. 669.00 32.20.2 Thorough repairs to wooden door and window Batten shutter excluding the cost of wood sqm Tk. 620.00 32.20.3 Thorough repairs to wooden door and window Venetian shutter excluding the cost of wood sqm Tk. 602.00 32.20.4 Thorough repairs to wooden door and window Glazed shutter excluding the cost of glass & wood sqm Tk. 535.00 32.21.1 Renewing of 3 mm glass panes in wooden frame including supply of glass sqm Tk. 869.00 32.21.2 Renewing of 3 mm glass panes in steel frame including supply of glass sqm Tk. 989.00 PWD SoR 2018 for Civil Works REPAIR WORKS Item No. 233 Description of items Unit Unit rate 32.22 Renewing of 5 mm glass panes including supply of glass sqm Tk. 1,101.00 32.23 Cleaning and washing of glass panes including supply of necessary fresh putty, pins etc. per pane Tk. 3.00 32.24.1 Replacing / renewing of fly proof wire net (with all new materials) the excluding cost of wood sqm Tk. 659.00 32.24.2 Replacing / renewing of synthetic fly proof net (with all new materials) the excluding cost of wood sqm Tk. 713.00 32.25 Renewing of fly proof wire netting (with old and new materials) the excluding cost of wood sqm Tk. 630.00 32.26 Renewing of 12 x 12 mm mesh wire netting the excluding cost of wood sqm Tk. 540.00 32.27 Taking out of hard board ceiling, walling sqm Tk. 18.00 32.28 Renewing of hard board ceiling or walling excluding cost of wood sqm Tk. 576.00 32.29 Replacing of wooden cleat, making, finishing and fixing with chowkat by means of 40 mm hinge each Tk. 75.00 32.30 Replacing of cleat with brass hinge each Tk. 79.00 32.31 Replacing of wooden buffer block each Tk. 55.00 32.32 Replacig of wooden catcher block each Tk. 81.00 32.33.1 Replacing of 75 mm long galvanized iron catch hook each Tk. 14.00 32.33.2 Replacing of 100 mm long galvanized iron catch hook each Tk. 16.00 32.33.3 Replacing of 150 mm long galvanized iron catch hook each Tk. 19.00 32.33.4 Replacing of 200 mm long galvanized iron catch hook each Tk. 21.00 32.33.5 Replacing of 225 mm long galvanized iron catch hook each Tk. 27.00 32.34 Replacing of iron socket bolt : 50 mm dia, 100 mm long each Tk. 26.00 32.35.1 Replacing of iron socket bolt : 50 mm dia, 100 mm long (SS) each Tk. 58.00 32.35.2 Replacing of iron socket bolt : 50 mm dia, 150 mm long each Tk. 31.00 32.35.3 Replacing of iron socket bolt : 50 mm dia, 150 mm long(SS) each Tk. 84.00 32.35.4 Replacing of iron socket bolt : 50 mm dia, 200 mm long each Tk. 45.00 32.35.5 Replacing of iron socket bolt : 50 mm dia, 200 mm long(SS) each Tk. 106.00 32.36.1 Replacing of brass socket bolt: 50 mm dia, 150 mm long each Tk. 153.00 32.36.2 Replacing of brass socket bolt : 50 mm dia, 200 mm long each Tk. 192.00 32.36.3 Replacing of brass socket bolt : 50 mm dia, 250 mm long each Tk. 246.00 PWD SoR 2018 for Civil Works REPAIR WORKS Item No. Description of items Unit 234 Unit rate 32.37.1 Replacing of 75 mm long iron hinge each Tk. 46.00 32.37.2 Replacing of 100 mm long iron hinge each Tk. 78.00 32.38.1 Replacing of 75 mm long brass hinge each Tk. 153.00 32.38.2 Replacing of 100 mm long brass hinge each Tk. 204.00 32.39.1 Replacing of 50 mm dia iron ring each Tk. 29.00 32.39.2 Replacing of 75 mm dia brass ring each Tk. 60.00 32.40.1 Supplying, fitting and fixing of 25 x 25 mm expanded mesh metal net of wooden or steel frame (excluding the cost of wood or steel sections and painting) sqm Tk. 917.00 32.40.2 Supplying, fitting and fixing of 25 x 25 mm expanded mesh metal net in F.I. Bar frame ( including the cost of F.I. Bar) sqm Tk. 1,687.00 32.41.1 Renewing of white washing: 1 coat sqm Tk. 12.00 32.41.2 Renewing of white washing: 2 coats sqm Tk. 18.00 32.42.1 Renewing of colour washing with yellow ochre: 1 coat sqm Tk. 19.00 32.42.2 Renewing of colour washing with yellow ochre: 2 coats sqm Tk. 21.00 32.43.1 Renewing of Exterior standard acrylic emulsion paint of approved brand and quality sqm Tk. 132.00 32.43.2 Renewing of Exterior premium acrylic emulsion paint of approved brand and quality sqm Tk. 146.00 32.44.1 Renewing of standard synthetic enamel paint to door-windows frame and shutter:1coats sqm Tk. 96.00 32.44.2 Renewing of premium synthetic enamel paint to door-windows frame and shutter: 1coats sqm Tk. 100.00 32.45.1 Renewing of standard synthetic enamel paint to door-windows frame and shutter: 2 coat sqm Tk. 148.00 32.45.2 Renewing of premium synthetic enamel paint to door-windows frame and shutter: 2coat sqm Tk. 154.00 32.46.1 Renewing of synthetic polyvinyl distemper : 1 coats sqm Tk. 82.00 32.46.2 Renewing of synthetic polyvinyl distemper : 2 coat sqm Tk. 115.00 32.47.1 Renewing of Interior standard acrylic emulsion paint (Plastic) to walls and ceiling: 1 coat sqm Tk. 92.00 32.47.2 Renewing of Interior Premium acrylic emulsion painting (silky finish)to walls and ceiling: 1 coat sqm Tk. 108.00 32.47.3 Renewing of Interior super premium acrylic emulsion painting (odorless) to walls and ceiling: 1 coat sqm Tk. 117.00 32.48.1 Renewing of Interior standard acrylic emulsion paint (Plastic) to walls and ceiling: 2 coat sqm Tk. 130.00 32.48.2 Renewing of Interior Premium acrylic emulsion painting (silky finish)to walls and ceiling: 2 coat sqm Tk. 152.00 PWD SoR 2018 for Civil Works REPAIR WORKS Item No. 235 Description of items Unit Unit rate 32.48.3 Renewing of Interior super premium acrylic emulsion painting (odorless) to walls and ceiling 2 coat sqm Tk. 165.00 32.49 Washing of painted wall surface with suitable soap or any other detergent sqm Tk. 30.00 32.50.1 Renewing of chlorinated rubber paint: 1 coats sqm Tk. 166.00 32.50.2 Renewing of chlorinated rubber paint: 2 coat sqm Tk. 221.00 32.51.1 Renewing of french polishing: 1 coats sqm Tk. 117.00 32.51.2 Renewing of french polishing: 2 coat sqm Tk. 183.00 32.51.3 Providing of 2 coats laqure spray painting with spray machine to high decorative Teak or similar wooden furniture sqm Tk. 147.00 32.52.1 Renewing of painting with synthetic black enamel Paint to plinth and skirting :1 coats sqm Tk. 103.00 32.52.2 Renewing of painting with synthetic black enamel Paint to plinth and skirting :2 coat sqm Tk. 144.00 32.53 Renewing of painting to C.I. Roof with red corrugal paint: 2 coats sqm Tk. 142.00 32.54.1 Renewing earth oiling with solignum or equivalent materials: 1 coat sqm Tk. 80.00 32.54.2 Renewing earth oiling with solignum or equivalent materials: 2 coat sqm Tk. 119.00 32.55.1 Renewing of wood varnishing with varnish (yacht) sqm Tk. 103.00 32.55.2 Renewing of wood varnishing with varnish (egg-shell) sqm Tk. 103.00 32.55.3 Renewing of wood varnishing with varnish (matt) sqm Tk. 103.00 32.56 Scrapping of old paint from wood sqm Tk. 39.00 32.57 Scrapping of old mosses from wall and roof sqm Tk. 28.00 32.58 Renewing of painting to old 100 mm dia rain-water pipe meter Tk. 31.00 32.59 Renewing of painting to old 50mm dia G.I. Pipe: 1 coat meter Tk. 16.00 32.60 Stopping of roof leakage of C.I. sheet roof with putty sqm Tk. 26.00 32.61 Labour for taking out C.I. sheet roofing sqm Tk. 32.00 32.62 Labour for taking out and refitting of old G.I. Ridge/valley meter Tk. 128.00 32.63 Labour for C.I. Sheet roofing including supply of limpet, washer, screws, putty etc. sqm Tk. 103.00 32.64 Labour for C.I. Sheet walling including supply of limpet, washer, screws, putty etc. sqm Tk. 77.00 32.65 Labour for taking out barbed wire fencing meter Tk. 7.00 32.66 Labour charge for refitting of barbed wire fencing meter Tk. 16.00 32.67 Labour charge for tightening of old loose barbed wire fencing meter Tk. 2.00 PWD SoR 2018 for Civil Works REPAIR WORKS Item No. Description of items Unit 236 Unit rate 32.68 Renewing, supplying and fitting-fixing of 300 mm long F.I. Clamp in CC (1:2:4) each Tk. 96.00 32.69 Renewing, supplying and fitting-fixing of 150 mm long F.I. Clamp in CC (1:2:4) each Tk. 63.00 32.70 Cutting jungles and shrub including removing and cleaning the spot/site sqm Tk. 6.00 32.71 Supplying of the following items related to ARBORICULTURE work approved by the officer-in-charge 32.71.1 200 mm size earthen tub each Tk. 39.00 32.71.2 250 mm size earthen tub each Tk. 48.00 32.71.3 300 mm size earthen tub each Tk. 68.00 32.71.4 350 mm size earthen tub each Tk. 99.00 32.71.5 400 mm size earthen tub each Tk. 175.00 32.71.6 300 mm x 300 mm size earthen plate each Tk. 29.00 32.71.7 Supply of mustard oil-cake kg Tk. 48.00 32.71.8 Supply of Bone mele kg Tk. 48.00 32.71.9 Supply of steel spade each Tk. 543.00 32.71.10 Supply of Urea fertilizer kg Tk. 24.00 32.71.11 Supply of Murate of potash kg Tk. 24.00 32.71.12 Supply of T. S. P. kg Tk. 36.00 32.71.13 Supply of 5 liter capacity spray machine (plaotic) each Tk. 2,173.00 32.71.14 Supply of 450 mm size Steel funna with wooden handle each Tk. 423.00 32.71.15 Supply of 225 mm long hand hoe with wooden handle each Tk. 109.00 32.71.16 Supply of standard steel hand trolly as per direction of officer-in-charge each Tk. 7,245.00 32.71.17 Supply of China made or equivalent Hedge Scissors each Tk. 1,449.00 32.71.18 Supply of 250 mm size China made or equivalent Secature each Tk. 785.00 32.71.19 Supply of 2.5 gallon capacity 22 BWG G.I. Water cane each Tk. 423.00 32.71.20 Supply of 350 mm size G.I. bucket each Tk. 302.00 32.71.21 Supply of best quality 19 mm dia plastic hose pipe each Tk. 22.00 32.71.22 Supply of insecide perfecthion 40 EC 1 pics, 100 ml bottle each Tk. 278.00 32.71.23 Supply of Redomil gold 68WG (metalexil+mencojeb) 1 pack, 500 gm pack each Tk. 869.00 PWD SoR 2018 for Civil Works REPAIR WORKS Item No. Description of items Unit 237 Unit rate 32.71.24 Supply of Ripcord 400EC, 1 pics, 100 ml bottle each Tk. 241.00 32.71.25 Supply of Proclaim 5SG(emamectin benzoet) 1 box, (10 pack, each pack 10gm) each Tk. 724.00 32.71.26 Supply of Vertimec 018ECG (ebamectin) 1 pics, 50 ml bottle each Tk. 145.00 32.72 Painting to earthen tub: 2 coats over a prime coat 32.72.1 200mm and 250mm size tub each Tk. 16.00 32.72.2 300 mm, 350 mm and 400 mm size tub each Tk. 27.00 32.73.1 Levelling & dressing the compound or plant/flower bed as per direction of Engineer-incharge. sqm Tk. 7.00 32.73.2 Lawn grass cutting, dressing, brooming and removing debris etc. as per direction of Officer in charge sqm Tk. 15.00 32.73.3 Spading, pulverizing soil lump etc. as per direction of Officer in charge sqm Tk. 5.00 32.74.1 Labour for picking-up and cleaning damaged bituminous road surface sqm Tk. 67.00 32.74.2 Repairing the potholes of the road by picking up and removing damaged materials with stone chips cum Tk. 24,489.00 32.75 Applying necessary coat of bitumenous aluminium paint seal-coat on top surface of newly laid roofing felt sqm Tk. 32.76.1 Supplying timber (unfinished) for repairing in wood works: Garjan/Jam/local Sal cum Tk. 85,282.00 32.76.2 Supplying timber (unfinished) for repairing in wood works: Jarul cum Tk. 76,754.00 32.76.3 Supplying timber (unfinished) for repairing in wood works: Shilkorai/Chickrashi cum Tk. 106,176.00 32.76.4 Supplying timber (unfinished) for repairing in wood works: Teak Chambal cum Tk. 144,979.00 32.76.5 Supplying timber (unfinished) for repairing in wood works: Chittagong Teak cum Tk. 187,194.00 32.76.6 Supplying timber (unfinished) for repairing in wood works: Kathal cum Tk. 95,942.00 32.76.7 Supplying timber (unfinished) for repairing in wood works: Gamari cum Tk. 72,490.00 32.76.8 Supplying timber (unfinished) for repairing in wood works: Chapalish cum Tk. 101,912.00 32.76.9 Supplying timber (unfinished) for repairing in wood works: Loha/Pyiankado cum Tk. 110,867.00 32.76.10 Supplying timber (unfinished) for repairing in wood works: Burma teak cum Tk. 277,166.00 32.76.11 Supplying timber (unfinished) for repairing in wood works: Ordinary timber (Mehogoni) cum Tk. 76,754.00 32.77 Labour charge for cleaning, washing, brooming from all heights and stacking of debris at a place beyond plinth area of the the site during execution of repair works as per direction of the engineer-in-charge cum Tk. 89.00 1,256.00 PWD SoR 2018 for Civil Works REPAIR WORKS Item No. 238 Description of items Unit Unit rate 32.78 Cleaning, washing, brooming and taking away of debris from the site during and or after the completion of the repair works in all heights by truck or by any other means as per direction of the engineer-in-charge cum Tk. 716.00 32.79 Repairing of steel grill/window frame and shutter/stair railing, veranda grill, rolling shutter excluding the cost of steel materials. sqm Tk. 739.00 32.80 Supply of steel materials for repairing work: 32.80.1 40-grade deform bar kg Tk. 70.00 32.80.2 60-grade deform bar kg Tk. 73.00 32.80.3 M.S. angle, T, and Z - section, Channel etc. kg Tk. 66.00 32.80.4 M.S. plain bar, F.I. Bar kg Tk. 66.00 32.80.5 M.S. sheet, plate used in repairing work kg Tk. 73.00 32.80.6 38 mm dia G.I. pipe used in repairing work meter Tk. 586.00 32.80.7 25 mm dia G.I. pipe used in repairing work meter Tk. 297.00 32.80.8 20 mm dia G.I. pipe used in repairing work meter Tk. 277.00 32.80.9 12 mm dia G.I. pipe used in repairing work meter Tk. 206.00 32.80.10 Spring for rolling shutter used in repairing work meter Tk. 59.00 32.80.11 Spring box for rolling shutter used in repairing work each Tk. 145.00 32.81 Cleaning and mending good the damages surrounding the mouth of spout/rain water down pipe each Tk. 146.00 32.82 Cleaning rain water down pipe meter Tk. 5.00 32.83 Cleaning, renewing of drain and apron with cement concrete or cement mortar etc as per direction of Engineer-in-charge. meter Tk. 193.00 32.84.1 Reexcavation of kutcha drain of 0.30 m width and average 0.6 m deep meter Tk. 18.00 32.84.2 Reexcavation of kutcha drain of 0.61 m width and average 1.22 m deep meter Tk. 68.00 32.85 Clearing chocked up masonry surface drain meter Tk. 28.00 32.86 Clearing silt from soak well up to 1.4 m dia each Tk. 2,009.00 32.87 Clearing sludges & night soil from septic tank removing to a safe place/distance without affecting environment 32.87.1 10 usser septic tank each Tk. 1,956.00 32.87.2 20 user septic tank each Tk. 2,922.00 32.87.3 30 user septic tank each Tk. 3,405.00 PWD SoR 2018 for Civil Works REPAIR WORKS Item No. Description of items Unit 239 Unit rate 32.87.4 50 user septic tank each Tk. 5,458.00 32.87.5 100 user septic tank each Tk. 9,563.00 32.87.6 200 user septic tank each Tk. 16,808.00 32.87.7 Clearing sewege or similar hazardous substances & removing to a safe place/ distances cum Tk. 1,461.00 32.88 Clearing sludges & night soil from Inspection pit each Tk. 502.00 32.89 Clearing sludges & night soil from RCC soil pipe & sewer line meter Tk. 103.00 32.90 Supplying, fitting-fixing of 400 gallon capacity ferro-cement water tank each Tk. 8,235.00 32.91 Taking out 40 mm dia tube-well pipe and strainer up to 70 m depth meter Tk. 102.00 32.92 Labour for re-sinking 40 mm dia tube-well pipe meter Tk. 273.00 32.93 Renewing Check Valve each Tk. 881.00 32.94 Renewing of 40 mm dia best quality G.I. Socket each Tk. 223.00 32.95 Taking out broken Long Pan each Tk. 196.00 32.96 Taking out broken European type Commode each Tk. 176.00 32.97 Providing 37 mm dia and 600 mm long PVC spout each Tk. 228.00 32.98 Providing 25 mm dia and 450 mm long PVC spout each Tk. 214.00 32.99 Supplying and fitting-fixing of plastic low-down including necessary internal and external fittings each Tk. 1,541.00 32.100 Supplying and fitting fixing of syphone for plastic low-down each Tk. 674.00 32.101 250 mm and above thick brick work (1:6) in old/unserviceable septic tank cum Tk. 6,743.00 32.102 125 mm thick brick work (1:6) in old/unserviceable septic tank sqm Tk. 1,069.00 32.103 12 mm plaster (1:4) with neat cement finishing in old/dilapitated septic tank sqm Tk. 391.00 32.104 Hire charge of welding set including welder cum fabricator and helper per day Tk. 1,397.00 32.105 Hire charge of suspended scaffolding (gondula) made of rope per day Tk. 382.00 32.106 Per day rate for Aluminium fabricator (labour rate) per day Tk. 1,207.00 32.107 Supply of essential hard wares and consumables for repairing aluminium door-widow frame and shutter, partition etc. 32.107.1 Swing door clouser each Tk. 3,260.00 32.107.2 Swing door lock each Tk. 755.00 32.107.3 Swing door Mohiar meter Tk. 20.00 PWD SoR 2018 for Civil Works REPAIR WORKS Item No. Description of items Unit 240 Unit rate 32.107.4 Fixed Neoprene meter Tk. 10.00 32.107.5 Flush bolt each Tk. 386.00 32.107.6 Sliding door /window key lock each Tk. 241.00 32.107.7 Sliding door /window wheel each Tk. 85.00 32.107.8 Sliding door /window Mohiar meter Tk. 5.00 32.107.9 Sliding Neoprene meter Tk. 11.00 32.107.10 Sealant gm Tk. 4.00 32.107.11 Sliding door key lock (for window) each Tk. 97.00 32.107.12 4-bar hinge each Tk. 845.00 32.107.13 Casement handle each Tk. 314.00 32.107.14 Rivet for Aluminium work each Tk. 6.00 32.107.15 Screws for Aluminium work each Tk. 1.50 ………………….. END OF DIVISION THIRTY TWO ………………….. LABORATORY TESTS OF ENGINEERING MATERIALS Instruction to Procuring Entity: DIVISION 33 A : LABORATORY TESTS OF ENGINEERING MATERIALS Quantification guide to enter in tender documents. Every tender shall bear related items from this division. PWD SoR 2018 for Civil Works 241 a) The following table is provided as one of many quality controlling factors with the objective of estimating cost of material tests and to ensure quality leading to durable and safe structure. Sampling of construction materials and products considered to be tested shall be done under the direct control and guidance of Procuring Entity. Representative(s) of the contractor shall be liable to collect or prepare sample etc., send to the testing laboratories in an acceptable manner and collect authenticate copy / copies of test results / reports and duly submitted to the office of the Procuring Entity. Procuring Entity shall recommend the contractor to prepare bill for payment. It is to be noted that materials and products to be tested and its frequencies described here are merely as minimum and Procuring Entity may consider for more tests from Table A of this division b) Tests are to be done in the nearest laboratory as far as possible. c) Procuring Entity may include any other material or tests in their estimate with intimation to Convener, Schedule of Rates Committee, PWD. d) Laboratory testing service provider: Description of item HBRI : Housing and Building Research Institute. 120/3 Darus-Salam, Mirpur, Dhaka. Phone: +8802-9035057. BUET (BRTC) : Bangladesh University of Engineering & Technology. Dhaka-1000. (Bureau of Research, Testing & Consultation) Phone: +8802-55167228-57, Ext: 7226. KUET (CRTS) : Khulna University of Engineering & Technology. Khulna-9203. (Centre for Research Testing & Services). Phone: +88041-769468-75 RUET (DCE) : Rajshahi University of Engineering & Technology. (Department of Civil Engineering). Phone: +880721-750372. SUST (CRTC) : Shahjalal University of Science & Technology. Sylhet-3114. (Centre for Research Testing & Consultancy). Phone: +880821-713491, Ext: 269. CUET (BRTC) : Chittagong University of Engineering & Technology, Chittagong-4349. (Bureau of Research, Testing & Consultation). Phone: +880031-714948, +8801765596552. DUET (DCE) : Dhaka University of Engineering & Technology, Gazipur-1700. (Department of Civil Engineering). Phone: +88-02-9204708, +8801711661176 Item 1. 2. 3. 4. 5. 6. 7. 33.0 Conducting laboratory test of engineering materials during construction in progressive manner well fitted with physical progress of work, by the procuring entity, with all logistic support supposed to be given by the contractor; where sampling, sample sending to laboratory and collecting test results from the samples to laboratory shall be under strict control and guidance of procuring entity following the norms elucidated in respective material standards like BDS, EN, ASTM, ISO, IS etc. and paid to the contractor after complete and proper documentation on: 1) laboratory test results in original 2) evidence of receiving samples in the laboratory in correct order 3) forwarding letter of procuring entity addressed to laboratory for testing 4) evidence of receiving “forwarding letter” with recipients’ full address and contact number 5) conformation on samples tested that sent in sealed condition bearing the signature and date of procuring entity 6) ensurance documents of sealing, signing and sending the samples. LABORATORY TESTS OF ENGINEERING MATERIALS 7 days strength: 1 set of 3 samples per Building Unit. 3 Foundation 28 days strength: 1 set of 3 samples per 3000 sft or less of PLA per floor. 7 days strength: 1 set of 3 samples per Building Unit. 4 Column 7 days strength: 1 set of 3 samples per floor per Building Unit. 28 days strength: 1 set of 3 samples per 1500 sft or less of PLA per floor. 7 days strength: 1 set of 3 samples per floor per Building Unit. 5 Slab, Beam, Wall/ Brick Wall 6 Others Structural Components & Testing Frequency Compressive strength: Concrete cylinders 100 x 200 mm 28 days strength: 1 set of 3 samples per 1500 sft or less of PLA. 7 days strength: 1 set of 3 samples per Building Unit. Lab Test Items Compressive strength: Concrete cylinders 100 x 200 mm 7 days strength: 1 set of 3 samples per Building Unit. 28 days strength: 1 set of 3 samples per 1500 sft or less of PLA per floor. Item No. Compressive strength: Concrete cylinders 150x 300 mm 28 days strength: 1 set of 3 samples per 3000 sft or less of PLA per floor. In - situ Core cutting & testing without Scanning excluding field visit* - Average Compressive Strength, f'cr CONCRETE Compressive strength: Concrete cylinders 150x 300 mm 28 days strength: 1 set of 3 samples per 1500 sft or less of PLA. 1 set of 3 samples per Building Unit. 2 33.1.3 1 set of 3 samples per Building Unit. 1 33.1 33.1.1.1 33.1.1.2 33.1.2.1 33.1.2.2 33.1.1 33.1.2 Remarks 7 1. Any one of 100mm x 200mm and 150mmx300 Cylinder may be tested. 2. in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. More tests might be needed as and when deemed by the Design Office. PWD SoR 2018 for Civil Works - - - 8 HBRI 3900.00 3900.00 2200.00 2200.00 9 BUET (BRTC) - 3500.00 3500.00 2200.00 2200.00 10 KUET (CRTS) - 2800.00 2800.00 2800.00 2800.00 11 RUET (DCE) - 1800.00 1800.00 1500.00 1500.00 12 SUST (CRTC) - 3000.0 3000.0 2000.0 2000.0 13 CUET (BRTC) - 3900.00 3900.00 2200.00 2200.00 14 DUET (DCE) 242 - 6400.00 UNIT RATES PER SET OF TEST in BDT - - Once for getting approval of cement type & brand, per 5000 sft or less of PLA. Once per brand. Once for getting approval of cement type & brand, per 5000 sft or less of PLA per floor. Once per brand. - - 5250.0 - - 7500.0 - 3000.00 4000.00 9200.00 - 243 13300.00 6600.00 1800.00 2500.0 PWD SoR 2018 for Civil Works - 9900.00 2500.00 1200.00 - This test is not a general requirement, however needs to be carried out as and when deemed by the Design Office. 9900.00 4000.00 2000.00 Randomly once per 500 sft of PLA. 6000.00 4300.00 3000.00 Randomly once per 500 sft of PLA. 2500.00 3100.00 Randomly once per 500 sft of PLA. in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. - Once for getting approval of cement type & brand, per 5000 sft or less of PLA per floor. Once for getting approval of cement type & brand, per 5000 sft or less of PLA per floor. in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. Once for getting approval of cement type & brand, per 5000 sft or less of PLA per floor. Once per brand. Once for getting approval of cement type & brand, per 5000 sft or less of PLA. - LABORATORY TESTS OF ENGINEERING MATERIALS 33.1.4 In-situ Core cutting & testing with Scanning, excluding field visit* CEMENT Slump Test at field 33.2 33.1.5 33.2.1 Fineness Setting time: Initial & Final Compressive Strength (3, 7 and 28 days) 33.2.2 33.2.3 in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. Composition Analysis Soundness Once per brand. Once per brand. LABORATORY TESTS OF ENGINEERING MATERIALS 33.2.4 33.2.5 Once per brand. Once per brand. - - 244 - PWD SoR 2018 for Civil Works 7500.00 - - consult lab - Once per brand. - in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. - - - consult lab - Once per brand. REBAR 2400.00 (up to 25mm) 3500.00 (above 25mm & up to 32mm) in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. 33.3 - 2200.0 (up to 25mm) 3000.0 (above 25mm & up to 32mm) - 33.3.1 TENSILE STRENGTH TESTS: Yield Strength Ultimate strength % Elongation etc. 1800.00 (up to 25mm) 2400.00 (above 25mm & up to 32mm) 2400.00 (up to 25mm) 3500.00 (above 25mm & up to 32mm) 1 set of 3 samples. /4800 sft or less of PLA/floor, Minimum 1 set. additional set for each change in brand. 2500.00 (up to 25mm) 3700.00 (above 25mm & up to 32mm) 1 set of 3 samples /12000 sft or less of PLA/floor, Minimum 1 set. additional set for each change in brand. 1000.00 (up to 25mm) 1100.00 (above 25mm) in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. 1 set of 3 samples. /2000 sft or less of PLA. Minimum 1 set. additional set for each change in brand. - 1000.0 (up to 25mm) 1100.0 (above 25mm) 900.00 Bend 33.3.2 in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. 1000.00 (up to 25mm) 1200.00 (above 25mm) 1 set of 3 samples. /4800 sft or less of PLA/floor, Minimum 1 set. additional set for each change in brand. 1000.00 (up to 25mm) 1200.00 (above 25mm) 1 set of 3 samples /12000 sft or less of PLA/floor, Minimum 1 set. additional set for each change in brand. - 1500.00 (up to 25mm) 1650.00 (above 25mm) 1200.00 (up to 25mm) 1300.00 (above 25mm) 1 set of 3 samples /2000 sft or less of PLA. Minimum 1 set. additional set for each change in brand. 33.3.3 1400.0 (up to 25mm) 1500.0 (above 25mm) - Rebend Test in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. 1000.00 (up to 25mm) 1200.00 (above 25mm) 1 set of 3 samples. /4800 sft or less of PLA/floor, Minimum 1 set. additional set for each change in brand. 1600.00 (up to 25mm) 1800.00 (above 25mm) 1 set of 3 samples /12000 sft or less of PLA/floor, Minimum 1 set. additional set for each change in brand. 1700.00 (up to 25mm) 1900.00 (above 25mm) 1 set of 3 samples /2000 sft or less of PLA. Minimum 1 set. additional set for each change in brand. - - - LABORATORY TESTS OF ENGINEERING MATERIALS Fatigue Test Composition Analysis 33.3.4 33.3.5 Carbon Equivalent COARSE AGGREGATE 33.3.6 33.4 1 set of 3 samples /1500 sft or less of PLA. Minimum 1 set. 1 set of 3 samples /1500 sft or less of PLA. Minimum 1 set. 1 set of 3 samples /1500 sft or less of PLA. Minimum 1 set. Sieve Analysis Aggregate crushing value (ACV) Absorption and Specific Gravity Unit Weight 33.4.1 33.4.2 33.4.3 33.4.4 1 set of 3 samples /1500 sft or less of PLA. Minimum 1 set. - - - 1 set of 3 samples/2500 sft or less of PLA. Minimum 1 set. 1 set of 3 samples/2500 sft or less of PLA. Minimum 1 set. 1 set of 3 samples/2500 sft or less of PLA. Minimum 1 set. 1 set of 3 samples/2500 sft or less of PLA. Minimum 1 set. 1 set of 3 samples /3000 sft or less of PLA. Minimum 1 set. 1 set of 3 samples /3000 sft or less of PLA / Building Unit, Minimum 1 set. - - - in case of non compliance of test results etc. contractor will be liable for additional tests and costs. in case of non compliance of test results etc. contractor will be liable for additional tests and costs. Only if demanded by the design office. Only if demanded by the design office. Only if demanded by the design office. 2500.00 1500.00 2500.00 7700.00** 6800.00** 5000.00** 6800.00** 6000.00 6000.00 4000.00 6000.00 3000.00 - 2000.00 2700.00 Consult Laboratory Consult Laboratory Consult Laboratory 2500.00 - - 1500.00 4000.0 - 2500.0 3500.0 6000.00 4000.00 4000.00 3800.00 245 1 set of 3 samples /3000 sft or less of PLA. Minimum 1 set. in case of non compliance of test results etc. contractor will be liable for additional tests and costs. 3000.00 PWD SoR 2018 for Civil Works 1 set of 3 samples /3000 sft or less of PLA. Minimum 1 set. in case of non compliance of test results etc. contractor will be liable for additional tests and costs. Salt content or Sulphate content C.B.R 1 set 3 times per 3000 sft. (applicable to road work). 1 set of 3 samples /1500 sft or less of PLA. Minimum 1 set. LABORATORY TESTS OF ENGINEERING MATERIALS 33.4.5 33.4.6 LOS ANGELES ABRASION TEST FINE AGGREGATE 33.4.7 33.5 Sieve Analysis 1 set 3 times per 3000 sft. (applicable to road work). 33.5.1 1 set of 3 samples /1500 sft or less of PLA. Minimum 1 set. 1 set of 3 samples/2500 sft or less of PLA. Minimum 1 set. 2 set 3 times per 3000 sft. (applicable to road work). 1 set 3 times per 3000 sft. (applicable to road work). 1 set of 3 samples/2500 sft or less of PLA. Minimum 1 set. 30000.0 2000.00 2500.00 10000.0 1500.00 2500.0 4500.0 31000 2000.0 3800.00 7000.00 55000.00 3000.00 246 50000.00 3600.00 1500.00 PWD SoR 2018 for Civil Works 59800.00 7000.00 1500.00 3500.00 1 set 0f 3 samples /3000 sft or less of PLA. Minimum 1 set. in case of non compliance of test results etc. contractor will be liable for additional tests and costs. - 7700.00 3000.00 - 3 set 3 times per 3000 sft. (applicable to road work). in case of non compliance of test results etc. contractor will be liable for additional tests and costs. 4000.00 3800.00 3200.00 (Salt content) 1 set 3 times per 3000 sft. (applicable to road work). in case of non compliance of test results etc. contractor will be liable for additional tests and costs. 1500.00 3000.00 (Sulphate content) 1 set of 3 samples /3000 sft or less of PLA. Minimum 1 set. in case of non compliance of test results etc. contractor will be liable for additional tests and costs. Unit Weight Absorption and Specific Gravity Bulking of Sand - - Once per Building Unit Once per Building Unit 1 set of 3 samples /1500 sft or less of PLA. Minimum 1 set. 1 set 3 samples /1500 sft or less of PLA. Minimum 1 set. LABORATORY TESTS OF ENGINEERING MATERIALS 33.5.2 33.5.3 33.5.4 Mica content (Visual observation/Microsc opic) 33.5.5 33.5.6 Organic Impurities Salt content or Sulphate content 33.5.7 1 set 3 samples/2500 sft or less of PLA. Minimum 1 set. 1 set of 3 samples/2500 sft or less of PLA. Minimum 1 set. Once per floor of Building Unit. Once per floor of Building Unit. - - 1500.00 6800.00 4500.00 5000.00 6000.00 3000.00 3600.00 - 1700.00 - - - 5000.0 - 2500.0 3000.00 5500.00 4000.00 4000.00 247 1 set 3 samples /3000 sft or less of PLA. Minimum 1 set. in case of non compliance of test results etc. contractor will be liable for additional tests and costs. 2500.00 5500.00 / 15000.00 2000.0 PWD SoR 2018 for Civil Works 1 set of 3 samples /3000 sft or less of PLA. Minimum 1 set. in case of non compliance of test results etc. contractor will be liable for additional tests and costs. - 1500.00 Once per floor of Building Unit. 2000.00 - in case of non compliance of test results etc. contractor will be liable for additional tests and costs. 3500.00 7000.0 3000.00 - 3200.00 (Salt content) - 2500.0 Once per floor of Building Unit. 4000.00 1500.00 3000.00 (Sulphate content) 10000.00 / 18000.00 3000.00 in case of non compliance of test results etc. contractor will be liable for additional tests and costs. - 16600.00 / 26200.00 3500.00 - 3500.00 Only demanded by design office or, felt by PE on visit site sample /source. 2000.00 - Only demanded by design office or, felt by PE on visit site sample /source. Once when Building Unit in brick work. Once when Building Unit in brick work. Once when Building Unit in brick work. - LABORATORY TESTS OF ENGINEERING MATERIALS Clay lump and friable particles BRICKS 33.5.8 33.6 Crushing Strength Size & Shape Unit Weight Water Absorption 33.6.1 33.6.2 33.6.3 33.6.4 Once when Building Unit in brick work. - Once per floor of Building Unit. Once per floor of Building Unit. Once per floor of Building Unit. Once per floor of Building Unit. 1 set of 3 samples/2500 sft or less of PLA. Minimum 1 set. 1 set of 3 samples/2500 sft or less of PLA. Minimum 1 set. - in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. Only demanded by design office or, felt by PE on visit site sample /source. - 1500.00 2500.00 2300.00 3100.00 4300.00 2400.00 4800.00 5700.00 3000.00 4000.00 2000.00 4000.00 5700.00 2300.00 2300.00 1500.00 2700.00 2500.00 1800.00 1800.00 1500.00 - - 2500.0 3000.0 2000.0 4000.0 3000.0 3100.00 4000.00 2400.00 4800.00 5000.00 248 1 set of 3 samples/2500 sft or less of PLA. Minimum 1 set. in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. 2000.00 PWD SoR 2018 for Civil Works 1 set of 3 samples/2500 sft or less of PLA. Minimum 1 set. in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. Efflorscence LABORATORY TESTS OF ENGINEERING MATERIALS 33.6.5 HOLLOW BRICKS - - Once when Building Unit in brick work. 33.7 Absoprtion Unit Weight 33.7.1 33.7.2 Once per floor of Building Unit. - - 1 set of 3 samples/2500 sft or less of PLA. Minimum 1 set. in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. - 2500.00 4300.00 2400.00 4800.00 4000.00 2000.00 4000.00 2200.00 1500.00 3000.00 - - 2100.00 - - 3500.0 - - 4500.00 249 1 set of 3 samples/3000 sft or less of PLA. Minimum 1 set. in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. - PWD SoR 2018 for Civil Works 1 set of 3 samples/3000 sft or less of PLA. Minimum 1 set. in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. - LABORATORY TESTS OF ENGINEERING MATERIALS Compresive Strength TILES (FLOOR & WALLS) 33.7.3 33.8 - - - Size & Shape Modulus of Rupture Absorption 33.8.1 33.8.2 33.8.3 - - - - 1 set 3 samples/2000 sft or less of PLA/floor. Minimum 1 set. 1 set 3 samples/2000 sft or less of PLA/floor. Minimum 1 set. 1 set of 3 samples/2000 sft or less of PLA/floor. Minimum 1 set. 1 set of 3 samples/3000 sft or less of PLA. Minimum 1 set. in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. - - PWD SoR 2018 for Civil Works - 4000.00 3000.00 4400.00 - - 2500.0 2200.00 - 2200.00 - - - - 3100.00 2000.0 3100.00 - - - 2900.00 - 2900.00 250 Flexural - - - - LABORATORY TESTS OF ENGINEERING MATERIALS 33.8.4 Wrape PAINT 33.8.5 33.9 Resistance to heat Resistance to water 33.9.1 33.9.2 - - - - 1 set of 3 samples/2000 sft or less of PLA/floor. Minimum 1 set. 1 set of 3 samples/2000 sft or less of PLA/floor. Minimum 1 set. 1 set of 3 samples/2000 sft or less of PLA/floor. Minimum 1 set. in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. - - - 2900.00 - - Consult Laboratory. Consult Laboratory. - - - - - 3000.0 - - PWD SoR 2018 for Civil Works 1 set of 3 samples/2000 sft or less of PLA/floor. Minimum 1 set. in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. 251 Spreading capacity Washability Weight per 10 litres Member Size & Shape. 1 set of 3 samples/2000 sft or less of PLA/floor. Minimum 1 set. 1 set of 3 samples/2000 sft or less of PLA/floor. Minimum 1 set. in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. in case of brand change, non compliance of test results etc. contractor will be liable for additional tests and costs. Consult Laboratory Consult Laboratory Consult Laboratory. Consult Laboratory. Consult Laboratory. - 1 set of 3 samples/3000 sft or less of PLA/floor. Minimum 1 set. As and when required by the PE - - To be recorded by PE. - - - - - - - - - - LABORATORY TESTS OF ENGINEERING MATERIALS 33.9.3 33.9.4 33.9.5 uPVC PIPE - - - - METAL MADE GRILLS 33.10.2 1/2" - 4" 33.10 33.11 Pressure Test Tensile Strength. 33.11.1 33.10.1 33.11.1.1 - - As and when required by the PE - - PWD SoR 2018 for Civil Works - 252 Aceton Test Dimension Test - - - - - - - - - - - - LABORATORY TESTS OF ENGINEERING MATERIALS 33.11.1.2 33.11.1.3 Heat Reversion Test Impact Test 33.11.1.5 Tensile Test 33.11.1.4 33.11.1.6 Filter Test 5" - 6" 33.11.1.7 32.11.2 Pressure Test Aceton Test Dimension Test 33.11.2.1 33.11.2.2 33.11.2.3 Heat Reversion Test Impact Test 33.11.2.5 Tensile Test 33.11.2.4 33.11.2.6 - - - - - - - - - - - - - - - - - - - - - - - As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - PWD SoR 2018 for Civil Works - As and when required by the PE 253 - - - - - - - - - - - - LABORATORY TESTS OF ENGINEERING MATERIALS Filter Test 7" - 8" 33.11.2.7 33.11.3 Pressure Test Aceton Test Dimension Test 33.11.3.1 33.11.3.2 33.11.3.3 Heat Reversion Test Impact Test 33.11.3.5 Tensile Test 33.11.3.4 33.11.3.6 Filter Test 10" 33.11.3.7 33.11.4 Pressure Test Impact Test Aceton Test Dimension Test 33.11.4.1 33.11.4.2 33.11.4.3 33.11.4.4 - - - - - - - - - - - - - - - - - - - - - - - As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - PWD SoR 2018 for Civil Works - As and when required by the PE 254 33.11.4.5 Tensile Test Heat Reversion Test - - - - - - - - - - - - LABORATORY TESTS OF ENGINEERING MATERIALS 33.11.4.6 Filter Test 12" 33.11.4.7 33.11.5 Pressure Test Tensile Test Heat Reversion Test Impact Test Aceton Test Dimension Test 33.11.5.1 33.11.5.2 33.11.5.3 33.11.5.4 33.11.5.5 33.11.5.6 Filter Test 14" 33.11.5.7 33.11.6 Pressure Test Dimension Test 33.11.6.1 33.11.6.2 - - - - - - - - - - - - - - - - - - - - - - - As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - PWD SoR 2018 for Civil Works - As and when required by the PE 255 Aceton Test - - - - - - - - - - - - LABORATORY TESTS OF ENGINEERING MATERIALS 33.11.6.3 Heat Reversion Test Impact Test 33.11.6.5 Tensile Test 33.11.6.4 33.11.6.6 Filter Test 16" 33.11.6.7 33.11.7 Pressure Test Aceton Test Dimension Test 33.11.7.1 33.11.7.2 33.11.7.3 Impact Test Heat Reversion Test 33.11.7.4 33.11.7.5 Tensile Test Filter Test 33.11.7.6 33.11.7.7 - - - - - - - - - - - - - - - - - - - - - - - As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE As and when required by the PE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - PWD SoR 2018 for Civil Works - As and when required by the PE Note: Follow Division 33 B : Laboratory charge for testing of materials or consult laboratory for the rates of test items not found here. 256 2 Materials and Name of Tests 3 Sample Size BRTC, BUET 6 CRTS, KUET 7 DCE, RUET 8 CRTC, SUST 9 BRTC, CUET 10 DCE, DUET 257 HBRI 5 PWD SoR 2018 for Civil Works 4 RATE DIVISION 33 B: LABORATORY CHARGE FOR TESTING OF MATERIALS LABORATORY CHARGE FOR TESTING OF MATERIALS SL.No. 1 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 Modified Proctor or Vibrating Hammer Standard Proctor test of aggregate (MDD) Effect of organic impurities Organic Impurities Mica content (Visual observation/Microscopic) L.A. Abrasion (ASTM C535 or ASTM C131) Flakiness Index (FI) Elongation Index (EI) Coal and lignite Clay lump and friable particles CBR of base and sub-base material Bulking of Sand Angularity Number in/c sp. gr. Aggregate impact value (AIV) Aggregate crushing value (ACV) Absorption and Specific Gravity 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. - 2500.00 - - - - 2000.00 - 4000.00 3000.00 3000.00 - 2300.00 - - - - 3000.00 2500.00 Tk. 8700.00 Tk. 6800.00 Tk. 3500.00 Tk. 39500.00 Tk. 24100.00 Tk. 19200.00 Tk. 3500.00 Tk.16600/26200 Tk. Tk. 8000.00 Tk. 8700.00 Tk. - - Tk. 5700.00 Tk. 59800.00 Tk.5500/15000 Tk. 9600.00 Tk. 5700.00 Tk. 7700.00 Tk. 6800.00 Tk. 6000.00 Tk. 5000.00 Tk. 3200.00 Tk. 32000.00 Tk. 21000.00 Tk. 17200.00 Tk. 3500.00 Tk.10000/18000 Tk. 7000.00 Tk. 6000.00 Tk. 5000.00 Tk. 2400.00 Tk. 5700.00 Tk. 50000.00 Tk. 5000.00 Tk. 4500.00 Tk. 5000.00 Tk. 6000.00 Tk. 6000.00 Tk. 3300.00 Tk. 2700.00 Tk. 2000.00 Tk. 18000.00 Tk. 12000.00 Tk. 11000.00 Tk. 3000.00 Tk. 4000.00 Tk. 3600.00 Tk. 3300.00 Tk. 2500.00 Tk. 2500.00 Tk. 2500.00 Tk. 30000.00 Tk. 3600.00 Tk. 3300.00 Tk. 3000.00 Tk. 3000.00 Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. - 1500.00 1500.00 - - - 1500.00 - 2500.00 2000.00 3000.00 - - - 3000.00 2500.00 2500.00 2700.00 Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. - 3500.00 2000.00 20000.00 12000.00 10000.00 2500.00 7000.00 4500.00 4200.00 4500.00 3500.00 3000.00 31000.00 5000.00 5000.00 3000.00 4000.00 - Tk. 3800.00 Tk. 3000.00 Tk. 30000.0 Tk. 20000.0 - Tk. 3000.00 - Tk. 7000.00 Tk. 8000.00 Tk. 8000.00 - Tk. 5000.00 Tk. 55000.0 Tk. 5500.00 - Tk. 5000.00 Tk. 6000.00 Tk. 4000.00 AGGREGATES 16 Salt content or Sulphate content 1 Tk. - 17 Sieve analysis (CA) 1 10000.00 18 Sieve analysis (Ballast) - 19 RATE PWD SoR 2018 for Civil Works 258 Tk. 3800.00 Materials and Name of Tests LABORATORY CHARGE FOR TESTING OF MATERIALS SL.No. 2500.00 Tk. 3800.00 DCE, DUET Tk. - Tk. 19000.0 BRTC, CUET 1500.00 Tk. 10000.00 Tk. 21000.0 CRTC, SUST Tk. - Tk. 10000.00 Tk. 10000.0 DCE, RUET Tk. 1500.00 Tk. - Tk. 6000.00 Tk. 4000.00 CRTS, KUET Tk. 3000.00 Tk. 1800.00 Tk. - Tk. 2500.00 Tk. 4000.00 BRTC, BUET Tk. 3800.00 Tk. 3000.00 Tk. 10500.00 Tk. 2500.00 Tk. 2500.00 Tk. 6000.00 HBRI 1500.00 Tk. 3800.00 Tk. 17500.00 Tk. 12000.00 Tk. - Tk. 4000.00 Sample Size Tk. 2000.00 Tk. 19200.00 Tk. 17500.00 Tk. 4800.00 Tk. - Tk. 10 1 Tk. Tk. 19200.00 Tk. 10000.00 Tk. 2000.00 Tk. 1500.00 9 Sieve analysis (FA) 1 Tk. Tk. 11500.00 Tk. 4000.00 Tk. 1700.00 Tk. 8 20 Wash sieve analysis 1 Tk. - Tk. 5000.00 Tk. 3000.00 Tk. 3000.00 7 21 Soundness with Na2SO4 1 Tk. 1500.00 Tk. 4500.00 Tk. 4000.00 6 22 Soundness with Mg2SO4 1 Tk. 1500.00 Tk. 7700.00 5 23 Ten percent fines (10% fines) 1 Tk. 3000.00 4 24 Unit weight of aggregate (CA) 1 Tk. 3 25 Unit weight of aggregate (FA) 1 2 26 Void ratio / Porosity 1 27 30 29 28 Concrete cylinders casting & testing Concrete Spun Compressive strength: Concrete cylinders (150 x 300 mm) Compressive strength : Concrete cylinders (100 x 200 mm) 3 3 3 3 3 Tk. Tk. Tk. Tk. Tk. - 3,920.63 - - - - Tk. 11700.00 Tk. 8400.00 Tk. - Tk. 3400.00 Tk. 3900.00 Tk. 2200.00 Tk. 10000.00 Tk. 8000.00 Tk. 15000.00 Tk. 3000.00 Tk. 3500.00 Tk. 2200.00 Tk. Tk. 5000.00 Tk. 13000.00 Tk. - - Tk. 2800.00 Tk. 2800.00 Tk. Tk. Tk. Tk. Tk. Tk. Tk. - - 5000.00 - - 1800.00 1500.00 Tk. Tk. Tk. Tk. Tk. Tk. Tk. 60000.00 55000.00 - 6500.00 18000.00 - 3000.00 2000.00 - - Tk. 10000.0 Tk. 8400.00 - - Tk. 3900.00 Tk. 2200.00 CEMENT CONCRETE 31 Concrete beam in flexure Tk. Tk. 45000.00 Tk. - 32 3 Tk. 60000.00 - - Concrete slab in flexure Tk. 66000.00 Tk. Tk. 33 Tk. 30,000.00 Tk. 45000.00 - 1 Tk. 65000.00 Tk. Design of concrete mixes without admixture [up to 25 MPa] Tk. 72000.00 Tk. 45000.00 - 34 Tk. 40,000.00 Tk. 65000.00 - 1 Tk. 72000.00 Tk. Design of concrete mixes using admixture [up to 25 MPa] - - 35 Tk. Tk. 1 Tk. 45000.00 Design of concrete mixes without admixture [> 25 MPa] Tk. 75000.00 36 Tk. 80000.00 1 - Design of concrete mixes using admixture [>25 MPa] Tk. 37 Materials and Name of Tests DCE, RUET CRTC, SUST BRTC, CUET DCE, DUET 259 CRTS, KUET PWD SoR 2018 for Civil Works BRTC, BUET RATE HBRI Tk. 3400.00 Sample Size 3000.00 Tk. 4000.00 10 Tk. 3500.00 9 - Tk. 8 Tk. - 7 Tk. 2300.00 Tk. 6 Tk. 3200.00 - 5 Tk. 3400.00 Tk. 4 - Tk. 3800.00 3 Tk. Tk. 4000.00 2 LABORATORY CHARGE FOR TESTING OF MATERIALS SL.No. 1 3 - Cubes (< 200 mm) Tk. 38 3 Tk. 6800.00 Cubes (> 200 mm - 300 mm) 5500.00 39 Tk. - - - Tk. Tk. - - Tk. Tk. Tk. 6800.00 1 - - Tk. - - - Tk. - - Tk. - Tk. - Tk. 6400.00 Tk. - Tk. - 5,000.00 - Tk. - - Tk. Tk. 7100.00 Cubes (> 300 x 300 mm), for per core cutting, each 1 Tk. - Tk. Tk. - Tk. - - Tk. 9200.00 Tk. - Tk. Tk. 7500.00 Tk. 3000.00 Tk. Tk. 2,700.00 Tk. - Tk. 4400.00 Tk. 2500.00 - Tk. 6,700.00 Tk. - 5250.00 Tk. Tk. - Tk. 6,100.00 Tk. Tk. 1200.00 - Tk. - - Tk. 6600.00 Tk. 1800.00 Tk. Tk. - Tk. Tk. 9900.00 Tk. 2000.00 Tk. 1000.00 - Tk. - Tk. 9900.00 Tk. 3000.00 Tk. 2500.00 Tk. - Tk. Tk. 6,000.00 Tk. 3,100.00 Tk. 4000.00 Tk. 1800.00 Tk. Tk. 13,300.00 1 Tk. 2000.00 Tk. 4,300.00 - 10,000.00 Compressive strength, 3 & 7 days 1 Tk. 2500.00 Tk. 4000.00 Tk. Tk. - 40 a.In - situ Core cutting & testing without Scanning excluding field visit* 1 Tk. 41 b. In-situ Core cutting & testing with Scanning excluding field visit* 43 Compressive strength, 3, 7 and 28 days 1 Tk. Tk. 2900.00 Tk. 4000.00 c.In- Lab Supplied Core Testing (3 Nos) 44 Fineness 1 2000.00 Tk. 4,300.00 b. In situ Winsor Pin test ( Per spot 3-test) excluding field visit* Tk. - 13,000.00 Tk. 81,500.00 Tk. 7,300.00 Tk. 15,400.00 Tk. 60000.00 Tk. 4800.00 Tk. 14000.00** Tk. 35000.00 Tk. - Tk. 9000.00 Tk. Tk. Tk. - - - Tk. Tk. Tk. Tk. Tk. 42000.00 - 11000.00 3500.00 5000.00 Tk. 60000.0 Tk. 6000.00 Tk. 16000.0 Tk. 4000.00 CEMENT 1 Tk. - Tk. 2500.00 Bitumen content 1 Tk. 1 45 Setting time Tk. 3000.00 a. In situ Per spot Impact hammer test ( 3test) excluding field visit* 46 Normal Consistency Tk. 42 47 Density/ Sp.Gr 49 Coating and stripping test 1 Tk. 4000.00 48 50 Design of A.C. mixes (Marshall) BITUMEN 51 CRTC, SUST 9 BRTC, CUET 10 DCE, DUET 260 DCE, RUET 8 PWD SoR 2018 for Civil Works CRTS, KUET 7 RATE BRTC, BUET 6 62 61 60 59 58 57 56 55 54 53 52 Thin film oven Theoretical Max. Sp. Gr. A.C. mixes Standard penetration Spot test Specific gravity Solubility Softening point (R&B) Loss on heating Float test Flash and fire-points Ductility Distillation 1 1 1 1 1 1 1 1 1 1 1 1 1 Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. 6800.00 - - - - 3000.00 - 3000.00 3000.00 - - - - - - Tk. 9600.00 Tk. 11500.00 Tk. 12,600.00 Tk. 9,600.00 Tk. 6,400.00 Tk. 7,700.00 Tk. 5,200.00 Tk. 5,200.00 Tk. 5,200.00 Tk. 5,000.00 Tk. 5,000.00 Tk. 6,400.00 Tk. 5,200.00 Tk. 5,200.00 Tk. 5,000.00 Tk. Tk. 10000.00 Tk. 7000.00 Tk. 9000.00 Tk. 10000.00 Tk. 7500.00 Tk. 5000.00 Tk. 6000.00 Tk. 4000.00 Tk. 4000.00 Tk. 4000.00 Tk. 4200.00 Tk. 4200.00 Tk. 4000.00 Tk. 4000.00 Tk. 4000.00 Tk. 4000.00 Tk. 6000.00 Tk. 4000.00 Tk. 3800.00 Tk. 4800.00 Tk. 5000.00 Tk. 3600.00 Tk. 2300.00 Tk. 3000.00 Tk. 2000.00 Tk. 2000.00 Tk. 2000.00 Tk. 2000.00 Tk. 2000.00 Tk. 2000.00 Tk. 2000.00 Tk. 2000.00 Tk. 2000.00 Tk. 6500.00 Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. - - - - 3000.00 - - 1500.00 - 1500.00 1500.00 1500.00 1500.00 1500.00 1500.00 1500.00 - Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. - 4000.00 5500.00 6000.00 4500.00 - 3500.00 2500.00 - 2500.00 2500.00 2500.00 4000.00 2500.00 2500.00 2500.00 7500.00 Tk. 13000.0 Tk. 8000.00 Tk. 8000.00 - Tk. 7500.00 Tk. 5000.00 Tk. 6000.00 Tk. 4000.00 Tk. 4000.00 Tk. 4000.00 Tk. 4000.00 Tk. 4000.00 - Tk. 4000.00 Tk. 4000.00 Tk. 4000.00 - Materials and Name of Tests LABORATORY CHARGE FOR TESTING OF MATERIALS SL.No. HBRI 5 63 Viscosity (S.F.) 1 Tk. - Tk. 15400.00 Sample Size 4 64 Viscosity (Kinemetic) 1 Tk. - 3 65 Water content 1 Tk. 2 66 Any test on residue from loss-on-heating test 1 1 67 Any test on residue from thin film oven test - 68 - - - - Tk. Tk. Tk. 2400.00 - - 2000.00 Tk. 4800.00 Tk. Tk. Tk. 4000.00 Tk. 4000.00 - - Tk. Tk. 8200.00 Tk. Tk. - Tk. 9600.00 Tk. 10000.00 Tk. 1500.00 Tk. 5700.00 Tk. 11500.00 Tk. 2000.00 Tk. 2700.00 Tk. - Tk. 2400.00 Tk. 4000.00 1 Tk. 1500.00 Tk. 4800.00 Ash content / Inorganic matter Tk. 2500.00 69 5 Tk. In-situ Core Cutting & Test excluding Field visit* Absorption 5 70 71 Crushing strength BRICKS 72 Materials and Name of Tests LABORATORY CHARGE FOR TESTING OF MATERIALS SL.No. PWD SoR 2018 for Civil Works 261 DCE, DUET RATE BRTC, CUET Tk. 4500.00 CRTC, SUST 3500.00 Tk. 3100.00 DCE, RUET Tk. 2500.00 Tk. 4000.00 CRTS, KUET 2100.00 Tk. 3000.00 - BRTC, BUET Tk. 1800.00 Tk. 3500.00 HBRI Tk. 3000.00 Tk. 1800.00 Tk. Sample Size Tk. 4000.00 Tk. 2300.00 Tk. - 10 Tk. 4800.00 Tk. 3000.00 Tk. 2300.00 Tk. 9 Tk. 3100.00 Tk. 4000.00 Tk. 6500.00 8 2500.00 Tk. 6100.00 Tk. 5300.00 7 Tk. 2000.00 - 6 10 Tk. Tk. 5 Efflorescence 5 Tk. - 4 73 Size and shape 5 Tk. 3 74 Unit weight 5 2 75 Acid Resistance (Vitriol) 1 76 77 Compressive strength of Road Kerb Stone Compressive strength of hollow bricks, Paver, Concrete blocks etc. 3 3 Tk. Tk. - - Tk. 2400.00 Tk. 4400.00 Tk. 3600.00 Tk. 2000.00 Tk. 4000.00 Tk. 3000.00 Tk. 1500.00 Tk. 3000.00 Tk. 3000.00 Tk. Tk. Tk. - - - Tk. Tk. Tk. - - - - - - HOLLOW / SPECIAL BRICK BLOCKS 78 - - Tk. - 3 Tk. Tk. 5400.00 Absorption - 4500.00 Tk. 30000.0 79 Tk. Tk. 20000.00 Tk. 50000.0 - - Tk. - - Tk. Tk. - Tk. 25000.00 Tk. Tk. 4000.00 Tk. - Tk. Tk. Tk. 21000.00 Tk. - Tk. Tk. 5000.00 - Tk. Tk. 3700.00 Tk. 2200.00 Tk. 6100.00 Tk. 20000.00 Tk. - 3000.00 Tk. 5700.00 Tk. 4000.00 Tk. 5400.00 - Tk. Tk. 4500.00 Tk. 6600.00 Tk. 4300.00 - Tk. 33100.00 Tk. - - Tk. 5500.00 Tk. 7900.00 - Tk. - Tk. 60000.00 Tk. Tk. - Tk. 6500.00 - Tk. Tk. - - Tk. 2500.00 Tk. - Tk. 9000.00 3 1 Tk. - Tk. Tk. 3500.00 Tk. 3000.00 Tk. - Tk. Unit Weight Pressure gauge/ dial gauge 1 Tk. - Tk. 3700.00 Tk. 5000.00 Tk. 4000.00 Tk. - 80 82 Hydraulic Jack with Pressure Gauge regular 1 Tk. - Tk. 6000.00 Tk. 6000.00 Tk. 5500.00 Tk. 89 88 Proving ring (> 500 kN) 1 - 83 Hydraulic Jack with Pressure Gauge large 1 Tk. - Tk. 7000.00 Tk. 7000.00 Tk. 6500.00 3 84 Hydraulic Jack with Pressure Gauge, above 800 ton 1 Tk. - Tk. 8500.00 Tk. 12000.00 Compressive strength of hollow bricks, Paver, Concrete blocks etc. in/c unit weight 85 Deflection dial 1 Tk. - Tk. 17500.00 81 86 Proving ring (< 100 kN) 1 Tk. - Compression Testing machine excluding field visit* GAUGES (Calibration) 87 Proving ring (100 kN - 500 kN) 1 Tk. 90 Materials and Name of Tests LABORATORY CHARGE FOR TESTING OF MATERIALS SL.No. 262 DCE, DUET PWD SoR 2018 for Civil Works BRTC, CUET RATE CRTC, SUST Tk. 10000.0 DCE, RUET 9000.00 - CRTS, KUET Tk. 8000.00 - BRTC, BUET - Tk. - - HBRI Tk. - Tk. - Sample Size Tk. 9000.00 Tk. - Tk. 10 Tk. 10000.00 Tk. 6500.00 Tk. - 9 Tk. 10700.00 Tk. 9000.00 Tk. 6500.00 Tk. 8 Tk. 9700.00 - 7 Tk. - Tk. 9000.00 Tk. 6 1 Tk. Tk. 15000.00 Tk. 9000.00 5 Dynamometer 1 Tk. 15000.00 4 91 Balance up to 20 kg Tk. - 3 92 Blaine Apparatus Tk. 2 93 Vibration Machine 1 94 106 105 104 103 102 101 100 99 98 97 96 95 Re-bend test (above 25 mm) Bend test (above 25 mm) Re-bend test (up to 25 mm) Bend test (up to 25 mm) Tension (plain bar > 25 mm) Tension (deformed bar > 25 mm) Tension (plain bar up to 25 mm) Tension (deformed bar up to 25 mm) In-situ pipe testing excluding field visit* Pipes (dia above 1200 mm & up to 1524 mm) Pipes (dia above 900 & up to 1200 mm) Pipes (dia above 600 & up to 900 mm) Pipes (dia up to 600 mm) 3 3 3 3 3 3 3 3 3 1 1 1 1 1 Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. - - - - 900.00 - 900.00 - - - - - - - - - Tk. 4000.00 Tk. 4000.00 Tk. Tk. 1900.00 Tk. 1300.00 Tk. 1700.00 Tk. 1200.00 Tk. Tk. 3700.00 Tk. - Tk. 2500.00 Tk. 8700.00 Tk. 13000.00 Tk. 10200.00 Tk. 7900.00 Tk. 7200.00 Tk. 3000.00 Tk. 2500.00 Tk. 2000.00 Tk. 1800.00 Tk. 1200.00 Tk. Tk. Tk. 1000.00 - Tk. 3500.00 Tk. 1600.00 - Tk. 2400.00 Tk. 8000.00 Tk. 12000.00 Tk. 10000.00 Tk. 7500.00 Tk. 7000.00 Tk. 2,352.38 Tk. 1800.00 Tk. 2500.00 Tk. 1200.00 Tk. 1200.00 Tk. 1000.00 Tk. 1000.00 Tk. 2400.00 Tk. 2500.00 Tk. 1800.00 Tk. 1800.00 Tk. 3800.00 Tk. - Tk. 8000.00 Tk. 6000.00 Tk. 4500.00 Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. - - - - - - - - - - - - - - - - Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. 3000.00 2000.00 3500.00 1500.00 1100.00 1400.00 1000.00 - 3000.00 - 2200.00 - - - - - Tk. 3500.00 - - Tk. 1650.00 Tk. 1100.00 Tk. 1500.00 Tk. 1000.00 - - - - - RCC PIPES (Max. length of pipe is 2'- 6") 107 Shear test 3 Tk. STEEL 108 Hardness (rock-well) 3 - - Tk. 3500.00 - Tk. 2400.00 109 Impact - 110 LABORATORY CHARGE FOR TESTING OF MATERIALS 116 115 114 113 112 111 Strand H.T. Wire Weight Tension (eye-hooks, anchor bolt) Spring test Deformation measurement Stress-strain curves (modulus of elasticity) 3 3 3 3 1 1 3 3 Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. HBRI - - - - - - - 6,000.00 4 - Tk. 2900.00 Tk. 3100.00 Tk. 2200.00 Tk. Tk. 14400.00 Tk. 8000.00 Tk. Tk. 6200.00 Tk. 3300.00 Tk. 3000.00 Tk. 10000.00 5 BRTC, BUET Tk. 22500.00 Tk. Tk. 2900.00 Tk. 3100.00 Tk. 2200.00 Tk. Tk. 13000.00 Tk. 7000.00 Tk. Tk. 4000.00 Tk. 3000.00 Tk. 2500.00 Tk. 8000.00 6 - CRTS, KUET Tk. 6000.00 Tk. 16000.00 Tk. Tk. Tk. Tk. Tk. - - - Tk. 3600.00 750.00 Tk. 3000.00 Tk. 2400.00 Tk. 1800.00 Tk. 7000.00 7 - Tk. 8500.00 Tk. - DCE, RUET Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. 1600.00 6000.00 10000.00 - - - - - - 900.00 - - - 6500.00 8 - CRTC, SUST Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. 1800.00 4500.00 2000.00 6000.00 17000.00 3000.00 2000.00 2500.00 - - - 1000.00 4000.00 2500.00 - 7000.00 9 - BRTC, CUET Tk. 1500.00 Tk. 1800.00 Tk. 4600.00 Tk. 1900.00 - Tk. 20000.0 - - - - - - Tk. 7500.00 - Tk. 5000.00 Tk. 3300.00 Tk. 3300.00 Tk. 8700.00 10 DCE, DUET 263 117 Angle / Plate 5 Tk. - Tk. - Tk. 4000.00 Tk. 1500.00 Tk. 3000.00 PWD SoR 2018 for Civil Works 118 Size and shape 5 Tk. - Tk. 24000.00 Tk. Tk. 1800.00 Tk. - Tk. 3000.00 RATE 119 Absorption 5 Tk. - Tk. Tk. 2100.00 Tk. 4500.00 Tk. 1500.00 Tk. Materials and Name of Tests 120 Flexural 5 Tk. - Tk. 2300.00 Tk. 5500.00 Tk. 1500.00 Tk. 1500.00 SL.No. 121 Wrape 1 Tk. - Tk. 6600.00 Tk. 2000.00 Tk. 2000.00 Tk. Sample Size 122 CBR of soils (three points) 1 Tk. - Tk. 2200.00 Tk. 1700.00 Tk. 2500.00 3 123 Field density (8spot+2proctor+2seives/Hydrometer excluding field visit * 1 Tk. - Tk. 2000.00 Tk. 3600.00 2 124 Sp. gr. 1 Tk. - Tk. 4400.00 1 125 Hydrometer, sieve analysis & sp. gr 1 Tk. - SOIL - - - - - 126 Linear shrinkage 1 Tk. - 127 Shrinkage limit 1 1000.00 128 Liquid limit / Plastic Limit TILES 129 LABORATORY CHARGE FOR TESTING OF MATERIALS 134 133 132 131 130 Organic matter content Moisture content Void ratio (Sp. Gr. & Unit Wt.) Unit weight (wet & dry) Modified proctor Standard proctor 1 1 1 1 1 1 1 Tk. Tk. Tk. Tk. 1050.00 Tk. Tk. Tk. Tk. 4 HBRI - - - - - - - - Tk. 4800.00 Tk. 3800.00 Tk. Tk. 3300.00 Tk. Tk. 1100.00 Tk. 3600.00 Tk. 2200.00 Tk. 16500.00 Tk. 13000.00 5 - BRTC, BUET Tk. 8500.00 Tk. 20000.00 Tk. 4500.00 Tk. - Tk. 3200.00 Tk. 2200.00 Tk. 3000.00 Tk. 1000.00 Tk. 3300.00 Tk. 2000.00 Tk. 12000.00 Tk. 10000.00 6 - CRTS, KUET Tk. Tk. Tk. 3800.00 Tk. 1800.00 Tk. 1500.00 Tk. 2300.00 Tk. 3000.00 750.00 Tk. 2500.00 Tk. 1500.00 Tk. 6000.00 Tk. 5000.00 7 - Tk. 5000.00 Tk. - DCE, RUET Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. - - - - - 2000.00 - - - 800.00 2500.00 1600.00 6500.00 6500.00 8 - CRTC, SUST Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. 5500.00 28000.00 7000.00 14000.00 5500.00 12000.00 4000.00 - - 2500.00 2700.00 1000.00 3000.00 2000.00 8000.00 7000.00 9 - BRTC, CUET - - Tk. 10000.0 Tk. 6000.00 Tk. 10000.0 Tk. 8000.0 Tk. 18000.0 - Tk. 2400.00 - - Tk. 2700.00 Tk. 900.00 Tk. 3000.00 Tk. 1800.00 Tk. 12000.0 Tk. 9500.00 10 DCE, DUET 264 135 Loss on ignition 1 Tk. - Tk. 24000.00 Tk. Tk. 11000.00 Tk. - Tk. PWD SoR 2018 for Civil Works 136 Grain Size Analysis 1 Tk. - Tk. 9500.00 Tk. 18000.00 Tk. 6000.00 Tk. - RATE 137 Grain Size Analysis by wash sieving 1 Tk. - Tk. - Tk. 25000.00 Tk. - Materials and Name of Tests 138 Sand equivalent test 1 Tk. - Tk. 22000.00 Tk. - Tk. 5000.00 23000.00 SL.No. 139 Permeability (cohesive) 1 Tk. - Tk. 15500.00 Tk. - Tk. Sample Size 140 Permeability - falling head for non-cohesive sample 1 Tk. - Tk. 52000.00 Tk. - 3 141 One dimensional Consolidation (full) 1 Tk. - - Tk. - 2 142 One dimensional Consolidation (e - log p) 3 Tk. Tk. Tk. 20000.00 22000.00 1 143 Consolidated drain test (direct shear test) 3 - - Tk. - - - 144 Consolidated drained tri-axial test Tk. Tk. - 145 3 Tk. 52000.00 Tk. Consolidated quick test (direct shear test) - Tk. 20000.00 146 Tk. - 3 Tk. Consolidated un-drained tri-axial test with pore pressure Tk. 46000.00 147 - Tk. 6000.00 Tk. 3500.00 3 Tk. Consolidated un-drained tri-axial test without pore pressure 3500.00 148 Tk. - Tk. 3000.00 Tk. Tk. 8000.00 1 Tk. 9000.00 Unconfined compression test - 149 4500.00 Tk. Tk. - - Tk. Tk. 3 Tk. 4000.00 Unconsolidated quick test (direct shear test) Tk. 6000.00 150 Materials and Name of Tests LABORATORY CHARGE FOR TESTING OF MATERIALS SL.No. 265 DCE, DUET PWD SoR 2018 for Civil Works BRTC, CUET RATE CRTC, SUST - DCE, RUET - Tk. 7500.00 CRTS, KUET Tk. - - BRTC, BUET - Tk. 4000.00 - HBRI Tk. - Tk. 3000.00 - Sample Size Tk. 9000.00 Tk. - Tk. - - 10 Tk. 20000.00 Tk. 5000.00 Tk. - Tk. - - 9 Tk. 8000.00 Tk. 3500.00 Tk. - Tk. 4000.00 - 8 Tk. 24000.00 Tk. 4000.00 Tk. 2500.00 Tk. - Tk. - 7 Tk. 9000.00 Tk. 3000.00 Tk. 2500.00 Tk. - Tk. - 6 Tk. - Tk. 4800.00 Tk. 3000.00 Tk. 2500.00 Tk. - - - 5 Tk. - Tk. 3600.00 Tk. 3000.00 Tk. 3500.00 Tk. Tk. 1200.00 - 4 Tk. - Tk. 3600.00 Tk. 4000.00 Tk. 5000.00 - Tk. - - 3 3 Tk. - Tk. 3600.00 - Tk. - Tk. 1900.00 - 2 Apparent/ effective opening size (AOS/EOS) or pore size 3 Tk. - Tk. 4800.00 Tk. Tk. 3500.00 Tk. - Tk. - - 1 153 Burst test index 3 Tk. - Tk. 10500.00 Tk. 4000.00 Tk. 1000.00 Tk. - Tk. - - 3 154 Index puncture resistance or CBR puncture 3 Tk. - Tk. 4800.00 Tk. 1000.00 Tk. 3800.00 Tk. - Tk. - - Unconsolidated un-drained tri-axial test (without pore pressure) 155 Cone penetration test 3 Tk. - Tk. 1400.00 Tk. 4000.00 Tk. 1800.00 Tk. - Tk. - - 151 156 Grab tensile test 3 Tk. - Tk. 4800.00 Tk. 2000.00 Tk. 7000.00 Tk. - Tk. - 3 157 Hor. water permeability under 2 kN/m2 pressure 3 Tk. - Tk. 2300.00 Tk. 9000.00 Tk. 4500.00 Tk. - Tk. Max. and Min density of cohesion less soil 158 Seam strength 3 Tk. - Tk. 9400.00 Tk. 5000.00 Tk. 3500.00 Tk. - 152 159 Thickness 3 Tk. - Tk. 5800.00 Tk. 4000.00 Tk. 5000.00 Tk. 164 163 162 161 Water permeability by permittivity Ver. permeability under 2 kN2/m Pressure Ver. permeability under 2 kN2/m and 200 kN2/m Unit weight/mass 3 3 3 Tk. Tk. - Tk. 165 - Horizontal water permeability test. Tk. 166 3 GEOTEXTILES 160 Trapezoidal tearing strength 3 Tk. - Tk. 4800.00 Tk. 9000.00 Tk. 3500.00 - Tk. 5000.00 Tk. 5800.00 3 - Strip/wide-width tensile test (tensile elongation) Tk. 167 2 Materials and Name of Tests 3 Sample Size LABORATORY CHARGE FOR TESTING OF MATERIALS SL.No. 1 MISCELLLANEOUS RATE PWD SoR 2018 for Civil Works 2900.00 - - 266 DCE, DUET Tk. - - BRTC, CUET - Tk. 3400.00 - CRTC, SUST Tk. - Tk. 3400.00 - DCE, RUET Tk. 2500.00 Tk. - Tk. 4700.00 CRTS, KUET Tk. 3000.00 Tk. 1500.00 Tk. - Tk. BRTC, BUET Tk. 3500.00 Tk. 2000.00 Tk. 3000.00 Tk. - HBRI Tk. 2200.00 Tk. 3500.00 Tk. 3500.00 Tk. 10 Tk. - Tk. 4100.00 Tk. 3500.00 Tk. 4000.00 9 5 Tk. - Tk. 4100.00 Tk. 5000.00 8 Tension 1 Tk. - Tk. 5700.00 7 168 Hardness 5 Tk. - 6 169 Flexure 1 Tk. 5 170 Compression set 1 4 171 Compression stiffness Rubber/Plastic/PVC materials 172 180 179 178 177 176 175 174 173 Tension test of fiber glass strainer/pipes Load test on man-hole cover (>18 inch dia) Load test on man-hole cover (< 18 inch dia) Flexure test of timber Design of deep tube-well (depth above 600')inc. 11nos sand test Design of deep tube-well (depth up to 600') inc 8nos sand test Compression of timber Compression of fibre glass(one sample) Tension tests on Bolt, hooks 1 1 1 1 1 1 1 1 3 Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. - - - - - - - - - Tk. Tk. 8700.00 Tk. 7900.00 Tk. 19700.00 Tk. 40000.00 Tk. 33000.00 Tk. Tk. - - - Tk. Tk. Tk. Tk. 7900.00 7200.00 Tk. 19200.00 Tk. 4800.00 - - Tk. 8800.00 Tk. 2000.00 Tk. 3500.00 Tk. 3000.00 Tk. 5500.00 Tk. 5000.00 Tk. 5500.00 Tk. Tk. - Tk. 9000.00 Tk. 1500.00 Tk. - - Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. - - - - - - - - - Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. - 6500.00 6000.00 - - - - - - - - - Tk.19500.00 Tk. 40000.00 Tk. 33000.00 Tk. 8800.00 - - OTHERS 181 Elastomeric Bearings RATE PWD SoR 2018 for Civil Works - Tk. Tk. 9000.00 4500.00 4500.00 - - - - Materials and Name of Tests LABORATORY CHARGE FOR TESTING OF MATERIALS SL.No. Tk. - Tk. 7300.00 - 267 DCE, DUET - Tk. - Tk. 7300.00 - BRTC, CUET Tk. - Tk. - Tk. - - CRTC, SUST Tk. 8000.00 Tk. - Tk. - Tk. 3700.00 - DCE, RUET Tk. 20500.00 Tk. - Tk. - Tk. - CRTS, KUET Tk. 9400.00 - Tk. 26000.00 Tk. - Tk. - Tk. - BRTC, BUET - Tk. - Tk. 8800.00 Tk. - Tk. - 1900.00 HBRI Tk. - Tk. Tk. 5600.00 Tk. - Tk. Tk. Sample Size 3 Tk. - Tk. 8800.00 Tk. 3700.00 Tk. - - 10 Vulcanized rubber and thermoplastic elastomer in tension & elongation at break ASTM D412 1 Tk. - Tk. 8800.00 Tk. 3700.00 Tk. Tk. 9 182 Short duration compression test on plain and steel laminated elastomeric bearings for bridges, ASTM D 4014 1 Tk. - Tk. 3700.00 - Tk. 3000.00 - 8 183 Long duration compression test on plain and steel laminated elastmeric bearings for bridges, ASTM D4014 3 Tk. - Tk. - Tk. 7 184 Determination of shear modulus, ASTM D4014 4 Tk. - Tk. - 6 185 Test for compression set, ASTM D395 1 Tk. - Tk. 5 186 Determination of durometer hardness, ASTM D2240 3 Tk. Tk. 5700.00 4 187 Test for rubber durability-deterioration in an air oven, ASTM D573 1 - 3 188 Test for determining the adhesion on rigid substrates, ASTM D429 Tk. 2 189 1 1 190 Dimensional test (external and internal) giving number & thickness of steel plates, elastomer parallelism, elastomer thickness, ASTM D4014 - Tk. 8500.0 3000.00 7000.00 Tk. Tk. - - Tk. Tk. - - Tk. Tk. Tk. 5800.00 - Tk. 9600.00 Tk. - Tk. 8500.00 Tk. - 1 Tk. Ash content 1 191 WATER Water (Drink + As), Total Package Fee Drinking Water 192 - Tk. 500.00 400.00 268 Tk. 400.00 Tk. 300.00 PWD SoR 2018 for Civil Works Tk. 500.00 Tk. 800.00 LABORATORY CHARGE FOR TESTING OF MATERIALS Tk. Tk. 300.00 Tk. 600.00 RATE Materials and Name of Tests Tk. 7000.00 Tk. Tk. 800.00 Tk. 800.00 198 Iron (Fe) 1 Tk. SL.No. 300.00 Tk. Tk. 500.00 Tk. 199 Manganese (Mn) 1 Tk. 2000.00 Tk. 4,500.00 Tk. 1700.00 Tk. 1800.00 Tk. 3000.00 Tk. 3000.00 Tk. Tk. Tk. - - - - 1200.00 - 1000.00 600.00 200.00 200.00 Tk. 2000.0 400.0 Tk. 11000.0 DCE, DUET Tk. 300.00 Tk. - Tk. Tk. 1700.0 200 Nitrate-Nitrogen (NO3-N) BRTC, CUET 400.00 Tk. 300.00 Tk. - 1300.00 700.00 201 Tk. CRTC, SUST Tk. 500.00 Tk. 700.00 Tk. Tk. 1500.00 Tk. 700.00 1 Tk. DCE, RUET 400.00 Tk. 300.00 Tk. 750.00 Tk. 600.00 Tk. Alkalinity / Bicarbonate 1 2000.00 Tk. 2200.00 CRTS, KUET Tk. - Tk. 800.00 Tk. Tk. Tk. 500.00 202 Total hardness Tk. - Tk. - BRTC, BUET - Tk. 300.00 Tk. 600.00 Tk. 1200.00 Tk. 1000.00 - Tk. Tk. 1000.0 203 1 Tk. Tk. Tk. Tk. HBRI Sample Size 1000.00 Tk. 800.00 Tk. 1100.00 Tk. 1400.00 Tk. 200.00 800.00 Tk. 1000.0 Total dissolved solids (TDS) 1 Tk. Tk. 1500.00 Tk. 1000.00 10 - Tk. 600.00 Tk. 600.00 Tk. Tk. 900.00 204 Arsenic (As) - Tk. 1300.00 Tk. 1500.00 9 3 Tk. - Tk. - 1200.00 Tk. 500.00 600.00 Tk. Tk. 1700.0 205 Tk. - Tk. 1300.00 8 2 1 Tk. - Tk. Tk. 700.00 Tk. Tk. 750.00 1500.00 Tk. 1 Tk. - Tk. Tk. 400.00 Turbidity 1 Tk. - 400.00 206 Faecal Coliform (FC) 1 Tk. 7 1 Water (Drink + As + TC & FC), Total Package Fee 1 Tk. - Tk. 1700.00 Tk. 500.00 700.00 Tk. Tk. 400.00 Tk. 1300.0 207 Total coliform (TC) 1 6 193 pH/Hydrogen Ion density 1 Tk. - 700.00 Tk. Tk. - Tk. - Tk. 1300.0 208 Magnesium (Mg) Tk. 4500.00 5 194 Color (filtered) 1 Tk. - Tk. 700.00 1000.00 Tk. 1500.00 Tk. - - 209 - 4 195 Carbon dioxide (CO2) / Acidity 1 Tk. - Tk. Tk. 1000.00 Tk. 200.00 Tk. - - Tk. - 1800.00 Tk. 10000.00 196 Chlorine (Cl) 1 Tk. 2000.00 Tk. 1000.00 Tk. Tk. 1500.00 Tk. - Tk. - 1 Tk. Tk. Tk. 11000.00 197 Fluoride (Fl) 1 Tk. 3000.00 Tk. 1000.00 Tk. 1400.00 300.00 Tk. - Tk. Sodium (Na) density (SAR) 1 210 Bio-chemical Oxygen Demand (BOD)-drinking water Pollution Study 211 269 Tk. 2000.0 PWD SoR 2018 for Civil Works 600.0 LABORATORY CHARGE FOR TESTING OF MATERIALS 1800.00 Tk. 700.0 RATE Materials and Name of Tests Tk. 500.00 Tk. - 220 219 218 217 Aluminium (Al) Nitrate -Nitrogen (NO2-N) Ammonia-Nitrogen (NH3-N) Carbonate (CO3) Selenium (Se) 1 1 1 1 1 1 Tk. Tk. Tk. Tk. Tk. Tk. Tk. - - - - - - - - Tk. 8500.00 Tk. Tk. Tk. 700.00 Tk. 4000.00 Tk. 1100.00 Tk. 700.00 Tk. 1700.00 Tk. 700.00 700.00 Tk. 3300.00 Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. 800.00 8500.00 700.00 700.00 700.00 1400.00 4000.00 700.00 Tk. 1100.00 Tk. 700.00 700.00 - Tk. 4500.00 Tk. Tk. Tk. Tk. Tk. Tk. 600.00 600.00 600.00 Tk. 3800.00 Tk. 600.00 Tk. 1500.00 Tk. 600.00 Tk. 7000.00 Tk. 750.00 800.00 800.00 900.00 - Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. - 600.00 - - 600.00 6000.00 - - - 1500.00 - - - 300.00 - Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. Tk. 600.00 800.00 4300.00 600.00 800.00 7800.00 600.00 600.00 600.00 1500.00 3500.00 600.00 1000.00 1000.00 - Tk. Tk. Tk. Tk. Tk. - 700.0 700.0 Tk. 1100.0 Tk. 700.0 Tk. 1700.0 - 800.0 Tk. 8500.0 Tk. 700.0 Tk. 1200.0 - 221 Arsenic (As) 1 Tk. - 800.00 Tk. 4500.00 Tk. 750.00 - 222 Bromine content (Br) 1 Tk. - Tk. 700.00 900.00 Tk. - 223 Total Chlorine content, Cl2 1 Tk. - Tk. Tk. - 1200.00 224 Free Chlorine content, Cl2 1 Tk. - Tk. 4700.00 - Tk. SL.No. Tk. Tk. 600.00 DCE, DUET Tk. Tk. - Tk. - BRTC, CUET Tk. 1800.00 Tk. 400.00 Tk. CRTC, SUST Tk. 2300.00 600.00 Tk. - DCE, RUET Tk. 2000.00 Tk. 600.00 Tk. CRTS, KUET - - Tk. 700.00 BRTC, BUET Tk. - Tk. 600.00 Tk. HBRI Sample Size Tk. - Tk. 1000.00 10 3 Tk. Tk. - Tk. 9 2 1 Tk. Tk. - 8 1 Bio-chemical Oxygen Demand (BOD)-waste water 1 Tk. Tk. 7 212 Chemical Oxygen Demand (COD)Dichromate 1 Tk. - 6 213 Dissolved Oxygen (DO) 1 Tk. 5 214 Sulphate(SO4) 1 4 215 Color (Scanning) 225 Break-point Chlorination 1 Tk. - Tk. - Tk. 216 226 Hydrogen Sulphide (H2S) 1 Tk. - Tk. Miscellaneous Parameters 227 Iodine content (I) 1 Tk. - - 900.0 700.0 700.0 228 Mercury (Hg) 1 Tk. 700.00 229 Phosphate content (PO4) 1 - 230 Sulphite (SO3) Tk. 231 RATE PWD SoR 2018 for Civil Works 270 - Tk. Tk. 1200.00 1500.00 1000.00 - Tk. 1700.0 Tk. 1100.0 Materials and Name of Tests LABORATORY CHARGE FOR TESTING OF MATERIALS SL.No. Tk. - Tk. DCE, DUET Tk. 750.00 Tk. BRTC, CUET Tk. 750.00 Tk. 2800.0 CRTC, SUST Tk. 1400.00 Tk. Tk. - Tk. DCE, RUET Tk. 2500.00 Tk. - - Tk. - Tk. 1000.0 CRTS, KUET Tk. Tk. Tk. - Tk. 900.00 BRTC, BUET Tk. 1100.00 Tk. 1700.00 Tk. 2000.00 Tk. 250.00 Tk. Tk. 2000.0 HBRI - Tk. 3000.00 Tk. 2500.00 Tk. 750.00 900.00 - Sample Size Tk. - Tk. 500.00 Tk. Tk. 1600.00 - 10 - Tk. - Tk. 2500.00 Tk. 750.00 750.00 Tk. 2000.00 - 9 Tk. - Tk. - Tk. 2800.00 Tk. Tk. - Tk. 2000.00 8 1 Tk. - Tk. Tk. Tk. 1500.00 Tk. - Tk. 7 Silica-content (SiO2) 1 Tk. - Tk. 2800.00 Tk. 1000.00 Tk. 1500.00 Tk. - 6 232 Ba/Ca/Cr/Cu/Cd/K/Na/Ni/Pb/Zn 1 Tk. - Tk. Tk. 2000.00 - Tk. 5 233 Oil and Grease content in Water 1 Tk. - Tk. 1000.00 Tk. 1500.00 Tk. - 4 234 Oil and Grease content in Waste Water 1 Tk. - Tk. 2000.00 - Tk. 3 235 Organic Matter 1 Tk. - - Tk. - 2 236 Boron (B) 1 Tk. - Tk. - Tk. 1 237 Electrical conductivity (EC) 1 Tk. - Tk. - Tk. Tk. - 600.00 - Tk. 1000.00 Tk. 2500.00 Tk. Tk. 500.00 - Tk. 1500.00 Tk. Tk. 2700.00 Tk. Tk. 750.00 500.00 - Tk. Tk. Tk. Tk. Tk. Tk. - - - - - - - Tk. Tk. Tk. Tk. Tk. Tk. Tk. 1200.00 2800.00 2400.00 800.00 2700.00 500.00 - - - Tk. 3000.0 - - - Tk. - Tk. Tk. 2200.00 Tk. 3000.00 Tk. 2100.00 Tk. - Tk. 1000.00 Tk. 2200.00 Tk. 1100.00 500.00 1 Tk. - Tk. 3300.00 - Tk. 1200.00 - pH 1 Tk. - Tk. - 750.00 238 Total Solids (TS) 1 Tk. - Tk. 1100.00 239 (TSS) or (TSS + TDS) 1 Tk. - - 240 Pb or Cd release of Tableware 1 Tk. - 241 Extraction charge for oil 1 - 242 Extraction charge for salt 1 245 Boron (B) 1 Tk. - Tk. 600.0 243 Extraction of TCLP(Toxic Characteristic Leaching Procedure) excluding metal test 246 Electrical conductivity (EC) 1 Tk. - 600.00 244 247 Organic matter for solid, sludge 1 Tk. Environmental Quality of Soil 248 Organic matter(Wet Combustion Method) 1 600.0 249 Ammonia-Nitrogen (NH3-N) Tk. 250 RATE PWD SoR 2018 for Civil Works - Tk. Tk. 3800.00 2700.00 2600.00 - - - - Materials and Name of Tests LABORATORY CHARGE FOR TESTING OF MATERIALS SL.No. Tk. - Tk. 2200.00 - 271 DCE, DUET Tk. 1100.00 Tk. - Tk. 4300.00 BRTC, CUET Tk. 3000.00 Tk. - Tk. - CRTC, SUST Tk. 2500.00 Tk. 4000.00 Tk. - Tk. 1500.00 - DCE, RUET - Tk. 2500.00 Tk. 2000.00 Tk. - Tk. 2000.00 - CRTS, KUET Tk. - Tk. 4500.00 Tk. 4000.00 Tk. - Tk. - - BRTC, BUET Tk. - Tk. 2200.00 Tk. 2000.00 Tk. - Tk. - - HBRI - Tk. Tk. 5200.00 Tk. 1800.00 Tk. - Tk. - Sample Size Tk. - Tk. 2200.00 - Tk. 6800.00 Tk. - Tk. 10 1 Tk. - Tk. 5200.00 Tk. - Tk. 5500.00 Tk. - 9 Phosphate content (PO4) 1 Tk. - Tk. Tk. - Tk. 1800.00 Tk. 8 251 Exchangeable Sodium (Na) 1 Tk. - Tk. 2200.00 Tk. - - 7 252 Aluminium (Al) 1 Tk. - Tk. 6000.00 Tk. - Tk. 6 253 Arsenic (As) 1 Tk. - - Tk. - 5 254 Mercury (Hg) 1 Tk. - Tk. - Tk. 4 255 Sulphite (SO3) 1 Tk. - Tk. - 3 256 Ca, Cd, Cl, K, Mg, Na, Pb 1 Tk. - Tk. 2 257 Toxic Characterstics Leaching Procedure (TCLP) 1 Tk. - 1 258 TOC 1 Tk. Tk. Tk. - - - Tk. Tk. Tk. Tk. - - - - Tk. Tk. - - Tk. 7000.00 Tk. 7000.00 Tk. 6800.00 Tk. 4500.00 Tk. Tk. - - Tk. Tk. Tk. 6000.00 Tk. 6000.00 - - Tk. Tk. Tk. 6500.00 Tk. 6500.00 - - - - Tk. 6500.0 Tk. 6500.0 - 259 Other Metals 1 1 Tk. - - 260 Oil and Grease Sampling for Bacteriological Analysis excluding field visit * 1 1 Tk. - 261 262 Sampling for physical and chemical Analysis excluding field visit * Sampling 263 264 Concreting: pH, Turbidity, Total Dissolved Solids, Chloride, Alkalinity, Organic Matter, Inorganic Matter, SO4 1 Parametric Analysis of Water 265 Swimming Pool: pH, Alkalinity, Color, Turbidity, Total Suspended Solids, Chloride, TC, FC, Fe, NO3, PO4 268 267 266 1 Tanning: pH, Alkalinity, Color, Turbidity, Hardness, Fe, Mn Textile (Boiler) pH, Alkalinity, Turbidity, Hardness, Chemical Oxygen Demand (KMnO), Total Chlorine, Ca, Fe, Mn, SiO2, SO4 Textile (Only Dyeing) pH, Alkalinity, Turbidity, Hardness, Chemical Oxygen Demand (KMnO), Total Chlorine, NO3, NO2, Fe, Mn, Cu, TS. 2 Materials and Name of Tests 1 1 1 1 3 Sample Size LABORATORY CHARGE FOR TESTING OF MATERIALS 269 Cooling: pH, Hardness, Turbidity, Total Dissolved Solids, Fe, Mn, COD, (KMnO4), PO4 1 SL.No. 270 Paper and Pulp (Ground wood): pH, Alkalinity, Color, Turbidity, Hardness, Total Dissolved Solids, Fe, Mn, SiO2, CO2 RATE PWD SoR 2018 for Civil Works - - - 272 DCE, DUET Tk. - - BRTC, CUET - Tk. - - CRTC, SUST Tk. - Tk. - - DCE, RUET Tk. 6800.00 Tk. - Tk. - CRTS, KUET - Tk. 6800.00 Tk. - Tk. - BRTC, BUET Tk. - Tk. 2700.00 Tk. - - HBRI - Tk. - Tk. 4500.00 Tk. Tk. 10 Tk. - Tk. - Tk. 4800.00 - 9 - Tk. - Tk. - Tk. 8 Tk. - Tk. - Tk. Tk. 6000.00 7 Tk. - Tk. - - 6 Tk. - Tk. Tk. 5 Tk. - - 4 Tk. Tk. - Tk. 8500.0 - - - Tk. 13500.0 Tk. - - - 271 - - - 1 - - - Boiler Feed Water (including oil & grease): pH, Alkalinity, Color, P-Alkalinity, M-Alkalinity, Turbidity, Hardness, Total Dissolved Solids, Total Suspended Solids. - - - - - - 272 3 - 1 (CO, SO, NO, CH4) excluding visit visit 3 Boiler Feed Water (excluding oil & grease): pH, Alkalinity, Color, P-Alkalinity, M-Alkalinity, Turbidity, Hardness, Total Dissolved Solids, Total Suspended Solids. 273 SPM per three spot Air Pollution 274 Pile Load Test LABORATORY CHARGE FOR TESTING OF MATERIALS - - - 4 HBRI - - - - 5 BRTC, BUET - - - - Tk. 35000.00 6 CRTS, KUET - - - - - - 7 DCE, RUET - - - - - - - 8 CRTC, SUST - - - - - - - - 9 BRTC, CUET - - - - - - - - - 10 DCE, DUET 273 - - - - - - - PWD SoR 2018 for Civil Works 1 - - - - - - - RATE Soil boring + Relevent test (per bore inside Dhaka) depth up to 60'-0" 1 - - - - - - - Materials and Name of Tests 278 Soil boring + Relevent test (per bore inside Dhaka) depth up to 100'-0" 1 - - - - - - SL.No. 279 Soil boring + Relevent test (per bore outside Dhaka) depth up to 60'-0" 1 - - - - - Sample Size 280 Soil boring + Relevent test (per bore outside Dhaka) depth up to 100'-0" 1 - - - - 3 281 Site Visit inside Dhaka 1 - - - 2 282 Site Visit inside Dhaka (for concrete core cutting/scanning/load cell ) 1 - - 1 283 Field Visit within greater Dhaka 1 - Pile integrity Test up to 10 per pile excluding visit and transportation & overstay costs 1 1 Pile integrity Test 276 Per Pile integrity test beyond 10 piles Site Visit Soil Boring 277 1 284 Field visit outside grater Dhaka 1 Test supervision and Report (per pile) exluding field visit 285 Field visit remote area 275 286 uPVC Pipe 1/2" - 4" LABORATORY CHARGE FOR TESTING OF MATERIALS 297 296 295 294 293 292 291 290 289 288 Impact Test Aceton Test Dimension Test Pressure Test Filter Test Tensile Test Heat Reversion Test Impact Test Aceton Test Dimension Test Pressure Test - - - - - - - - - - - - 4 HBRI - - - - - - - - - - - - - 5 BRTC, BUET - - - - - - - - - - - - - - 6 CRTS, KUET - - - - - - - - - - - - - - - 7 DCE, RUET - - - - - - - - - - - - - - - - 8 CRTC, SUST - - - - - - - - - - - - - - - - - 9 BRTC, CUET - - - - - - - - - - - - - - - - - - 10 DCE, DUET 274 298 Heat Reversion Test - - - - - - - PWD SoR 2018 for Civil Works 299 Tensile Test - - - - - - - RATE 300 Filter Test - - - - - - - Materials and Name of Tests 301 Pressure Test - - - - - - SL.No. 302 Dimension Test - - - - - Sample Size 303 Aceton Test - - - - 3 304 Impact Test - - - 2 305 Heat Reversion Test - - 1 306 Tensile Test - 5" - 6" 307 Filter Test 7" - 8" 308 LABORATORY CHARGE FOR TESTING OF MATERIALS 311 310 309 Heat Reversion Test Impact Test Aceton Test Dimension Test Pressure Test - - - - - - 4 HBRI - - - - - - - 5 BRTC, BUET - - - - - - - - 6 CRTS, KUET - - - - - - - - - 7 DCE, RUET - - - - - - - - - - 8 CRTC, SUST - - - - - - - - - - - 9 BRTC, CUET - - - - - - - - - - - - 10 DCE, DUET 275 312 Tensile Test - - - - - - - PWD SoR 2018 for Civil Works 313 Filter Test - - - - - - - RATE 314 Pressure Test - - - - - - - Materials and Name of Tests 316 Dimension Test - - - - - - - SL.No. 317 Aceton Test - - - - - - - Sample Size 318 Impact Test - - - - - - 3 319 Heat Reversion Test - - - - - 2 320 Tensile Test - - - - - 1 321 Filter Test - - - - 10" 322 Pressure Test - - - 325 14" 12" 323 Dimension Test - - 315 324 Aceton Test Impact Test - - 326 LABORATORY CHARGE FOR TESTING OF MATERIALS BRTC, CUET 10 DCE, DUET 276 CRTC, SUST 9 PWD SoR 2018 for Civil Works DCE, RUET 8 RATE CRTS, KUET 7 - Materials and Name of Tests BRTC, BUET 6 - SL.No. HBRI 5 - Sample Size 4 - 3 - 2 - 1 - - - Heat Reversion Test - - - 327 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Pressure Test - - - - - - - 330 Dimension Test - - - - - - 331 Aceton Test - - - - Tensile Test 332 Impact Test - - - 328 333 Heat Reversion Test - - - 334 Tensile Test - Filter Test 335 Filter Test 329 16" 336 NOTE-1 (as of BUET) : a. [* Field visit fee: inside Dhaka City=Tk. 14,000; Outside Dhaka City (No overnight stay)= Tk. 24,000; Near Districts = Tk. 37,000 without overnight stay and Tk. 30,000 per day for overnight stay; Farthest Districts = Tk. 50,000 without stay and Tk. 38,000 per day for overnight stay, Remote Areas with overnight stay = Tk. 44,000 per day] [*& Transport, local hospitalities, accommodation (in case of overnight stay) etc. are to be provided by the client]. b.**Sample preparation charge Tk. 2000 per sample. c. For PIT- Test Rate per pile = Tk. 2500+* with the conditions (a) Min total fees: within Dhaka City - Tk. 75,000; Outside Dhaka City Tk. 1,15,000; Near Districts Tk. 1,50,000 and Farthest District Tk. 1,75,000 (b) Integrity Tests be done on all piles for a structure. (c) Pile load test be done on at least 1% of piles selected on the basis of integrity results. NOTE-2 : Consult laboratory for the rates of test items not found here. ANNEXURE ANNEXURE-A PWD SoR 2018 for Civil Works 277 Annexure-A NOTES ON PLINTH AREA RATES (PLAR) 1. PLAR are the rates to assess the cost of buildings when detail architectural and structural design are not available. 2. PLAR are formulated by studying huge variables, data and assumptions only provide hints on the cost of construction over a couple of years. 3. A wide range variation of actual cost from PLAR directs to study (i) architectural & structural design (ii) site condition (iii) decision built up. 4. Exclusive works related to high density of cost like glazed curtain wall, aluminium composite curtain wall/cladding are beyond the scope of PLAR. 5. PLAR never resembles an actual cost; instead it’s a probabilistic cost for fund conformity after time dependent tender and agreement procedure to run a smooth project. 6. PLAR costs for buildings are to be assessed after confirming the building category namely ‘standard’, ‘super’ and ‘special’. 7. ‘Special’ category for office buildings are to be decided by Chief Engineer, PWD and Chief Architect, Department of Architecture. 8. PLAR includes 20.745% extra cost for providing contractor's profit, overhead charge and VAT. SCOPE OF PLINTH AREA Plinth area is the area bounded by exterior perimeter of a floor or the perimeter formed by joining the lines on the outer faces of columns in the floor, including any area kept opening what so ever, except courtyard open to sky. SCOPE OF BUILDING CATEGORY The category of buildings should be understood by the terms standard, super, special on their usual meanings. But as a guide- Standard category of buildings is that, made in quality and provided with general basic facilities and finished components are mostly of local materials, bricks, sand, cement and lime based but a hygienic finish in toilets, lavatory & kitchen. PWD SoR 2018 for Civil Works ANNEXURE-A 278 s TABLE-1: PWD PLAR 2018 SUBSTRUCTURE, Foundation Up to Plinth Level Deep Foundation f'c=25MPa f'cr = 30MPa, concrete with crushed stone chips, Cement Content to Nominal Mix Ratio 1: 1.5:3 and Cement CEM - 1, 52.5N INDIVIDUAL OR COMBINED FOOTING SYSTEM MICRO PILE without with 300 mm basement infill basement floor slab Allowable Bearing capacity, qa PILE FOUNDATION*2,3,4,5,6 with 300 mm without infill basement basement floor slab MAT FOUNDATION*1 qa = 2.0 ksf qa = 2.50 ksf qa = 3.0 ksf qa=3.5 ksf qa = 4.0 ksf qa = 4.50 ksf qa = 5.0 ksf Df=1.25 m Df= 3.0 m Df=1.25 m Df=3.0m Df=3.0m per sqm 1 7890 9355 11250 13494 16283 19402 per sqm 2 7668 8724 10091 11709 13720 15970 18176 per sqm 3 7534 8345 9393 10634 12178 13904 15597 17415 19351 21398 23550 25802 per sqm 4 7446 8095 8935 9929 11165 12548 13904 15360 16911 18550 20274 22078 23959 25913 27938 per sqm 5 7385 7921 8615 9437 10459 11602 12723 13927 15208 16564 17988 19479 21034 22649 24324 26055 27841 29680 per sqm 6 7340 7794 8382 9078 9943 10911 11860 12880 13965 15113 16319 17582 18898 20266 21684 23150 24662 26220 27821 29465 per sqm 7 7306 7698 8206 8806 9553 10388 11208 12088 13024 14015 15056 16146 17282 18463 19687 20952 22258 23602 24984 26403 27859 per sqm 8 5953 7402 9257 11364 13814 16491 17714 20123 22630 25228 27913 30681 33530 36455 39454 per sqm 9 13002 14116 15608 17251 19027 20923 22930 25040 27246 29544 31929 34398 36946 39571 42271 per sqm 10 16547 17327 18166 19512 20594 22930 26387 28831 33140 36632 41530 46069 49766 53462 57925 61672 67592 71467 75342 81774 85777 90905 94959 99013 104985 109116 113937 118093 122249 126405 131354 136354 141406 146508 151661 156866 per sqm 11 20639 21420 22258 23562 24579 26766 30072 32366 36461 39738 44421 48746 52228 55710 59958 63491 69197 72857 76518 82735 86524 91437 95277 99116 104873 108790 113396 117338 121280 125222 129956 134742 139578 144466 149405 154395 per sqm 12 9009 12502 15077 17363 19451 21392 23218 24949 26602 28188 29717 31195 32628 34021 35378 36702 37997 39862 42841 45902 49044 52265 55564 58938 62385 65906 69497 73158 76888 80686 84550 88479 92472 96528 100647 104828 Storey (basement shall be counted as storey) Storey (basement shall be counted as storey) (Rate in BDT per sqm) Shallow Foundation 1 1 2 2 3 3 4 4 5 5 6 6 7 7 8 8 9 9 10 10 11 11 12 12 13 13 14 14 15 15 16 16 17 17 18 18 19 19 20 20 21 21 22 22 23 23 24 24 25 25 26 26 27 27 28 28 29 29 30 30 31 31 32 32 33 33 34 34 35 35 36 36 Notes: *1. Mat foundation leading to basement floor Tk. 800.00 per sqm to be deducted, but to add cost from basement construction system (Table-4) *2. Precast Pile of length 18m and size 350mmx350mm considered *3. For pile length of 18m to 24m, Tk.9,670 per sqm to be added, *4. For pile length of 24m to 30m, Tk.16,615 per sqm to be added, *5. For pile length of 30m to 36m, Tk.23,565 per sqm to be added, *6. For Cast-in-situ pile foundation, 20% cost to be added, *7. Add 4% for f'c=32MPa f'cr = 40MPa, with crushed stone chips, Cement Content to Nominal Mix Ratio 1: 1.25: 2.5 and Cement CEM - 1, 52.5N *8. Add 7% for f'c=40MPa f'cr = 49MPa, with crushed stone chips, Cement Content to Nominal Mix Ratio 1: 1: 2 and Cement CEM - 1, 52.5N. Df = Depth of foundation PWD SoR 2018 for Civil Works ANNEXURE-A 1 1 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 2 GF Park GF: Habitation 1st Floor 2nd Floor 3rd Floor 4th Floor 5th Floor 6th Floor 7th Floor 8th Floor 9th Floor 10th Floor 11th Floor 12th Floor 13th Floor 14th Floor 15th Floor 16th Floor 17th Floor 18th Floor 19th Floor 20th Floor 21st Floor 22nd Floor 23rd Floor 24th Floor 25th Floor 26th Floor 27th Floor 28th Floor 29th Floor 30th Floor 31st Floor 32nd Floor 33rd Floor 34th Floor 35th Floor Roof Top LC Porch 3 11077 19531 18533 18811 19093 19380 19671 19867 20064 20261 20457 4 12406 21875 20757 21069 21385 21705 22031 22251 22472 22692 22912 5 14267 25156 23871 24229 24592 24961 25336 25589 25842 26096 26349 6 11592 20438 19394 19685 19981 20280 20585 20790 20996 21202 21408 7 12982 22891 21722 22048 22378 22714 23055 23285 23516 23746 23977 8 14930 26325 24980 25355 25735 26121 26513 26778 27043 27308 27573 2619 5585 2619 5585 2619 5585 2619 5585 2619 5585 2619 5585 RCC FRAME STRUCTURE: f'c= 22 To 25 MPa (ADD 4% for 32 MPa, ADD 7% for 40 MPa Concrete) NON RESIDENTIAL: NRRCS C2 RESIDENTIAL: RRCS B2 Concrete with Stone-chips Concrete with Stone -chips Standard Super Special Standard Super Special 9 12040 21007 19934 20233 20536 20844 21157 21368 21529 21690 21850 22011 22172 22332 22493 22654 22814 22975 23135 23296 23457 23617 23778 23939 24099 24260 24421 24581 24742 24902 25063 25224 25539 25858 26182 26509 26840 2619 6144 10 13485 23527 22326 22661 23000 23345 23696 23933 24113 24292 24472 24652 24832 25012 25192 25372 25552 25732 25912 26092 26272 26451 26631 26811 26991 27171 27351 27531 27711 27891 28071 28251 28604 28961 29323 29690 30061 2619 6144 11 15508 27056 25674 26060 26451 26847 27250 27522 27729 27936 28143 28350 28557 28764 28971 29178 29385 29592 29798 30005 30212 30419 30626 30833 31040 31247 31454 31661 31867 32074 32281 32488 32894 33305 33722 34143 34570 2619 6144 12 12599 22216 21081 21397 21718 22044 22374 22598 22768 22938 23108 23278 23448 23618 23787 23957 24127 24297 24467 24637 24807 24977 25147 25316 25486 25656 25826 25996 26166 26336 26506 26676 27009 27347 27688 28034 28385 2619 6144 13 14111 24881 23611 23965 24324 24689 25059 25310 25500 25691 25881 26071 26261 26452 26642 26832 27022 27213 27403 27593 27784 27974 28164 28354 28545 28735 28925 29115 29306 29496 29686 29877 30250 30628 31011 31399 31791 2619 6144 14 16228 28614 27152 27559 27973 28392 28818 29107 29325 29544 29763 29982 30201 30419 30638 30857 31076 31295 31513 31732 31951 32170 32389 32608 32826 33045 33264 33483 33702 33920 34139 34358 34788 35222 35663 36108 36560 2619 6144 15 1 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 FLOOR RCC FRAME STRUCTURE: f'c = 19 To 21 MPa (Not suggested in Coastal Area) NON RESIDENTIAL: NRRCB A2 RESIDENTIAL: RRCB A2 (Concrete with Brick-chips) (Concrete with Brick-chips) Standard Super Special Standard Super Special Level Index FLOOR Level Index TABLE 2: PWD PLAR 2018 - SUPER STRUCTURE: rates in BDT per sqm ADD STRUCTURAL MEMBER WEIGHTAGE RATES (TABLE - 3) IN ADDITION TO THE RATES OF THIS TABLE B U I L D I N G C A T E G O R Y 16 GF Park GF: Habitation 1st Floor 2nd Floor 3rd Floor 4th Floor 5th Floor 6th Floor 7th Floor 8th Floor 9th Floor 10th Floor 11th Floor 12th Floor 13th Floor 14th Floor 15th Floor 16th Floor 17th Floor 18th Floor 19th Floor 20th Floor 21st Floor 22nd Floor 23rd Floor 24th Floor 25th Floor 26th Floor 27th Floor 28th Floor 29th Floor 30th Floor 31st Floor 32nd Floor 33rd Floor 34th Floor 35th Floor Roof Top LC Porch Notes: *1 .Cost of Retaining walls etc included in Table-4, *2. Floor height (h) is considered as 3.35 meter (11'-0"), *3. If floor height h > 3.35 meter (11'-0") and ≤ 3.66 meter (12'-0"), add 3%, *4. If floor height h > 3.66 meter (12'-0")and ≤ 4.0 meter(13'-0"), add 5%, *5 . Regular shaped building with span up to 7.5m has been considered. 279 PWD SoR 2018 for Civil Works ANNEXURE-A 280 TABLE 3 : PWD PLAR 2018 - STRUCTURAL MEMBER WEIGHTAGE : ADDITIONAL COST PER SQUARE METER in BDT Level index (Floor) 35 34 7270 7056 6842 6628 6415 6201 5987 5773 5559 5345 5132 4918 4704 4490 4276 4063 3849 3635 3421 3207 2993 2780 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 7056 6842 6628 6415 6201 5987 5773 5559 5345 5132 4918 4704 4490 4276 4063 3849 3635 3421 3207 2993 2780 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 Basement 7267 7054 GF 1st 2nd 3rd 4th 5th 6th 7th 8th 9th 10th 11th 12th 13th 14th 15th 16th 17th 18th 19th 20th 21st 22nd 23rd 24th 25th 26th 27th 28th 29th 30th 31st 32nd 33rd 34th To deduct 15% for f'c = 19-21MPa (min f'cr = 24-28 MPa) , To increase 4% for f'c = 32 MPa (min f'cr = 40 MPa) and To increase 7% for f'c = 40 MPa (min f'cr = 49 MPa) S t o r e y D e s i g n e d For 33 6840 6842 6628 6415 6201 5987 5773 5559 5345 5132 4918 4704 4490 4276 4063 3849 3635 3421 3207 2993 2780 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 32 6626 6628 6415 6201 5987 5773 5559 5345 5132 4918 4704 4490 4276 4063 3849 3635 3421 3207 2993 2780 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 31 6412 6415 6201 5987 5773 5559 5345 5132 4918 4704 4490 4276 4063 3849 3635 3421 3207 2993 2780 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 30 6198 6201 5987 5773 5559 5345 5132 4918 4704 4490 4276 4063 3849 3635 3421 3207 2993 2780 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 29 5984 5987 5773 5559 5345 5132 4918 4704 4490 4276 4063 3849 3635 3421 3207 2993 2780 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 28 5771 5773 5559 5345 5132 4918 4704 4490 4276 4063 3849 3635 3421 3207 2993 2780 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 27 5557 5559 5345 5132 4918 4704 4490 4276 4063 3849 3635 3421 3207 2993 2780 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 26 5343 5345 5132 4918 4704 4490 4276 4063 3849 3635 3421 3207 2993 2780 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 25 5129 5132 4918 4704 4490 4276 4063 3849 3635 3421 3207 2993 2780 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 24 4915 4918 4704 4490 4276 4063 3849 3635 3421 3207 2993 2780 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 23 4702 4704 4490 4276 4063 3849 3635 3421 3207 2993 2780 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 22 4488 4490 4276 4063 3849 3635 3421 3207 2993 2780 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 21 4274 4276 4063 3849 3635 3421 3207 2993 2780 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 20 4060 4063 3849 3635 3421 3207 2993 2780 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 19 3846 3849 3635 3421 3207 2993 2780 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 18 3632 3635 3421 3207 2993 2780 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 17 3419 3421 3207 2993 2780 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 16 3205 3207 2993 2780 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 15 2991 2993 2780 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 14 2777 2780 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 13 2563 2566 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 12 2350 2352 2138 1924 1711 1497 1283 1069 855 641 428 214 11 2136 2138 1924 1711 1497 1283 1069 855 641 428 214 10 1922 1924 1711 1497 1283 1069 855 641 428 214 9 1708 1711 1497 1283 1069 855 641 428 214 8 1494 1497 1283 1069 855 641 428 214 7 1280 1283 1069 855 641 428 214 6 1067 1069 855 641 428 214 5 853 855 641 428 214 4 3 639 425 641 428 428 214 214 2 211 Level index 1 (Floor) Basement Notes: 1. N no. of Basements are to be counted as storey, 2. For N no .of basements, at first the column to be selected on the basis of no. of storey, then for the 1st basement-1st value to be read, and then values from left (N-1)-th column-1st cell to be selected for N-th basement. example: For 20 storied building with 3 no. of basements, values from column-20 to be read on the basis of no. of storey, **for the 1st basement-Tk. 4060 to be taken, **for the 2nd basement-Tk. 4274 to be taken from the immediate left column, i.e. from column-21, **for the 3rd basement-Tk. 4488 to be taken from 2nd left column, i.e. from column-22 GF 1st 2nd 3rd 4th 5th 6th 7th 8th 9th 10th 11th 12th 13th 14th 15th 16th 17th 18th 19th 20th 21st 22nd 23rd 24th 25th 26th 27th 28th 29th 30th 31st 32nd 33rd 34th PWD SoR 2018 for Civil Works ANNEXURE-A 281 Table - 4 : PWD PLAR-2018: BASEMENT CONSTRUCTION*1 (Rate in BDT per sqm) Concrete, f'c = 25 MPa & min f'cr = 30 MPa, fy = 400 MPa (max. fy= 418MPa & Ratio fu to fy ≥1.25) Cement BDS EN-197 CEM-I,52.5N Elements Of Basement Construction Retaining Piles & Bracing Single basement RCC Retaining Wall Tk. per sqm of wall Tk. 6,038 Basement Floor as Parking Total Taka/sqm Rate from Structural weightage Table-3 + Two Basements Three Basements Bracing: Steel (fy=36ksi) truss system Water proofing: Wall & Foundation Bed Back Wall to Retaining Wall (125 mm b/w) Excavation, carrying & safety System management Retaining Pile Retaining Pile Retaining Pile Taka per meter of perimeter Taka per meter of perimeter Taka per meter of perimeter Taka per sqm of Basement Taka per sqm of hor/vertical surface Taka per sqm of wall Taka per m depth per sqm of Basement Taka per sqm of Basement Tk. 87,455 Tk. 217,704 Tk. 252,015 Tk. 2,320 Tk. 1,606 Tk. 1,426 Tk. 1,068 Tk. 115 Tk. 7,127 *1 PLAR (Plinth Area Rate) to be calculated as sum of the costs divided by plinth area. PWD SoR 2018 for Civil Works ANNEXURE-A ADDITIONAL COST CHART 1. Saline zone, to use concrete of min f’c = 25 MPa 1% of PLAR 2. Wind (other than coastal area) & earth-quake load resisting structure : to use concrete of min f’c = 25 MPa 2% of PLAR 3. Coastal area : affected by cyclone & water surge : to use concrete of min f’c = 25 MPa 3% of PLAR 4. Roof top RCC parapet Tk. 2,776 5. Roof-top RCC water tank in/c beams & supports etc. : Tk. 155 6. Internal Sanitary and Water Supply : Rate in BDT (i) Residential Building (ii) 7. Tk. 1,044.00 per sqm Super Tk. 1,519.60 per sqm Special Tk. 2,111.20 per sqm Standard Tk. 835.20 per sqm Super Tk. 1,215.68 per sqm Special Tk. 1,688.96 per sqm Standard Tk. 1,702.00 per sqm Super Tk. 2,017.00 per sqm Special Tk. 2,229.00 per sqm Standard Tk. 1,299.00 per sqm Super Tk. 1,570.00 per sqm Special Tk. 1,727.00 per sqm (i) Ground Floor Tk. 342.20 per sqm (ii) Other Floors Tk. 136.88 per sqm Internal Electrification : Residential Building (ii) 9. per gallon Standard Non-residential Building (i) 8. per sqm Non-residential Building Gas Connection : External Water Supply and Sanitation: (i) (ii) Underground Water Reservoir : (a) Up to 20,000 gallon Tk. 92 per gallon (b) Above 20,000 gallon Tk. 77 per gallon Distribution line, water pump, pump house, Estimate WASA / Municipal Charge as per requirement. (iii) Septic Tank, Soak well, Inspection pit. Estimate 282 PWD SoR 2018 for Civil Works ANNEXURE-A 10. External Electrification: (i) (ii) (iii) (iv) (v) (vi) (vii) (viii) (ix) (x) 11. 283 Sub-station building. Sub-station equipment/transformer. Pump & motor set including installation. H.T./ LT Line. PDB /DESA /REB charge. Standby power & source. Earthing system. Over head transmission. Underground cable laying. Compound light, wiring system & other safety systems. Estimate to be prepared on the basis of requirements. Boundary Wall: (i) Boundary wall in RCC Frame, 1.80 m in height, level difference between FGL and EGL up to 0.45m: Construction of RCC (fc'=22 MPa, minimum fcr=27 MPa in nominal mix ratio of 1:2:4 with stone chips) frame boundary wall of height 1.8m above FGL and foundation depth 1.5m from EGL, having column size 250mm X250mm @ 10'-0" c/c, 250 mm X 250 mm size grade beam at FGL, 75mm thick and 375mm width RCC coping, 125mm thick brick work with mortar (1:4) in between columns. 12mm plaster (1:6) on brick surface and 6mm plaster (1:4) on RCC and providing standard acrylic emulsion paint at exterior surface etc. (ii) (iii) Boundary wall in RCC Frame, 1.80m in height, level difference between FGL and EGL= 0.45 m to 1.50m: Construction of RCC (fc'=22MPa, minimum fcr=27 MPa in nominal mix ratio of 1:2:4 with stone chips) frame boundary wall of height 1.8m above FGL and depth of foundation 1.5m from EGL, having column size 250mmX250mm @ 10'-0" c/c, 250 mmX250 mm size grade beam at FGL and one additional grade beam on EGL, 75mm thick and 375mm width RCC coping, 125mm thick brick work with mortar (1:4) in between columns. 12mm plaster (1:6) on brick surface and 6mm plaster (1:4) on RCC and providing standard acrylic emulsion paint at exterior surface etc. Boundary wall in RCC Frame, 1.80m in height , level difference between FGL and EGL= 1.50m to 3.00m: Construction of RCC (fc'=22MPa, minimum fcr=27 MPa in nominal mix ratio of 1:2:4 with stone chips) frame boundary wall of height 1.8m above FGL and depth of foundation 1.5m from EGL, having column size 250mmx250mm @ 10'-0" c/c with 250mmx250mm RCC struts, one grade beam at ground level and 2(two) additional grade beams in between EGL and FGL, 75mm thick and 375mm width RCC coping, 125mm thick brick work with mortar (1:4) in between columns. 12mm plaster (1:6) on brick surface and 6mm plaster (1:4) on RCC and providing standard acrylic emulsion paint at exterior surface etc. Tk. 11,523/- meter Tk. 19,317/- meter Tk. 31,213/- meter PWD SoR 2018 for Civil Works ANNEXURE-A (iv) (v) (vi) (vii) Boundary wall in RCC Frame, 1.80m in height , level difference between FGL and EGL= 1.50m to 3.00m; with PILE foundation: Construction of RCC (fc'=22MPa, minimum fcr=27 MPa in nominal mix ratio of 1:2:4 with stone chips) frame boundary wall of height 1.8m above FGL and depth of foundation 1.5m from EGL, having column size 250mmx250mm @ 10'-0" c/c, one grade beam at ground level and 2(two) additional grade beams in between EGL and FGL, 75mm thick and 375mm width RCC coping, 125mm thick brick work with mortar (1:4) in between columns. 12mm plaster (1:6) on brick surface and 6mm plaster (1:4) on RCC and providing standard acrylic emulsion paint at exterior surface. 2 nos. of (250mmx250mm) 10 m long precast pile per column. Boundary wall in RCC Frame, 1.80m in height , level difference between FGL and EGL= 3.00m to 4.50m; with RCC retaining wall (without PILE): Construction of RCC(fc'=22MPa, minimum fcr=27 MPa in nominal mix ratio of 1:2:4 with stone chips) frame boundary wall of height 1.8m above FGL and depth of foundation 1.5m from EGL, Retaining wall up to FGL and column size 250mmx250mm @ 10'-0" c/c above FGL, 75mm thick and 375mm width RCC coping, 125mm thick brick work with mortar (1:4) in between columns; 12mm plaster (1:6) on brick surface, 6mm plaster (1:4) on RCC, exterior standard acrylic emulsion paint. Soil Bearing Capacity assumed=1.5 Ksf Boundary wall in RCC Frame, 1.80m in height , level difference between FGL and EGL= 3.00m to 4.50m; with RCC retaining wall (with PILE): Construction of RCC(fc'=22MPa, minimum fcr = 27 MPa in nominal mix ratio of 1:2:4 with stone chips) frame boundary wall of height 1.8m above FGL and depth of foundation 1.5m from EGL, Retaining wall up to FGL and column size 250mmx250mm @ 10'-0" c/c above FGL, 75mm thick and 375mm width RCC coping, 125mm thick brick work with mortar (1:4) in between columns; 12mm plaster (1:6) on brick surface, 6mm plaster (1:4) on RCC, exterior standard acrylic emulsion paint. Assumed 2 (two) nos of 300 mm X 300 mm size 12 m long pile @ 1.5m c/c along the length of the retaining wall. Additional cost for ornamental works at the front side of the Boundary Wall (considered only portion of work above GB) 284 Tk. 46,342/- meter Tk. 75,869/- meter Tk. 101,891/- meter Tk. 2,300/- meter PWD SoR 2018 for Civil Works ANNEXURE-A (viii) Main Gate : Manufacturing, supplying, fitting and fixing collapsible gate of any design and shape made of 25 mm x 25mm x 3 mm S.S. angle placed @ 112 mm c/c vertically and connecting the same with each other by 25 x 3 mm S.S flat bar scissors 525 mm/ 600 mm long provided in 3 rows including cutting the different S.S. members to required sizes, fabricating, welding, riveting with required size rivets, providing required size wheels, pulling handles on both sides, suitable locking arrangement, electrodes, grease and finally placing the same in position in between 2 (two) Nos. 50 mm x 50 mm x 6 mm S.S. Tee rail made by welding 2 Nos. 50 x 6 mm S.S. flat bar fitted and fixed at top and bottom with R.C.C. lintel/roof slab, floors and side wall with required Nos. 150 mm to 225 mm long 38 x 6 mm S.S. flat bar clamps one end welded with the gate member and the other end bifurcated and embedded in C.C. at the respective point including cutting holes and mending good the damages by pouring concrete (1:2:4) into the holes and finishing, both end carriage, including greasing, electrodes, curing etc. complete as per drawing and design and accepted by the Engineer in charge. 12. 285 Tk. 35,046/- meter Tk. 962.40 meter Tk. 2,427.00 meter Barbed wire fencing over boundary wall : (i) Type-1 (Y-shape) : barbed wire in fencing work @ 150 mm c/c in both horizontally and vertically Supplying, fitting and fixing 12 BWG barbed wire (2 ply, 4 points) in fencing work @ 150 mm c/c in both horizontally and vertically, supported by 38 mm x 38 mm x 6 mm M.S. Y-shape angle post (300 mm embedded in R.C.C. or in brick work with a cement concrete base of 75 mm x 75 mm x 300 mm) 600 mm vertical and 450 mm inclined @ 2.4 m c/c including straightening, binding the joints with 18 BWG wire making holes in the angle etc. in /c supplying of all necessary materials complete in all respect and accepted by the Engineer-in-charge. (Rate is excluding the cost of R.C.C. or brick work or C.C. which is to be paid as per corresponding items in the schedule) (ii) Type-2 (Spiral-type) : barbed wire of 600 mm dia in fencing work Supplying, fitting and fixing 12 BWG barbed wire fencing in a circular shape of 600 mm dia and 76 mm pitch fitted with ms rod casing (made by 8 nos. 10 mm dia plain bar in a circular pattern and placed at equal interval ), 38 x 38 x 6 mm M.S. angle post (300 mm embedded in R.C.C. or in brick work with a cement concrete base of 75 mm x 75 mm x 300 mm) and 600 mm vertical and 450 mm inclined placed @ 3000 mm c/c including straightening, binding the joints with 18 BWG wire, making holes in the angle etc. including supply of all necessary materials complete in all respect and accepted by the Engineer-in-charge. (Rate is excluding the cost of R.C.C or brick work or C.C. which is to be paid as per corresponding items in the schedule) PWD SoR 2018 for Civil Works ANNEXURE-A 13. Road Work : (i) R.C.C. Road: Construction of R.C.C. (minimum f'cr = 30 MPa, and satisfying a specified compressive strength f’c = 25 MPa at 28 days on standard cylinders, crushed stone chips as coarse aggregate, cement content related to mix ratio 1:1.5:3) road with 250mm thick guide wall of height 0.30 meter, 150 mm thick R.C.C work over one layer 1st class brick flat soling and polythene sheet including the cost of reinforcement 10 mm dia MS rod 175 mm c/c in both direction. (ii) per sqm Tk. 2,080.74 per sqm Tk.11,241.25 per sqm Tk. 2,760.00 meter Semi Permanent Structure: Plinth area rates for standard semi-permanent building with C.I sheet roofing on metal truss, supported on brick pillars & walls in 1:4 cement sand mortar having 75 mm thick D.P.C in/c earth work, back filling in foundation and plinth ≤ 1 m & 125 mm thick panel brick work in superstructure with 150 mm x 250 mm intermediate pillar at 2.4 m to 3 m C/C, doors and windows made of best local timber with standard window grills, R.C.C work (1:2:4) in lintel, patent stone flooring (1:2:4), minimum 12 mm thick cement plaster (1:4) in plinth , steps and dado, aesthetically accepted low cost false ceiling, white /color washing and necessary earth work in foundation, earth and sand filling in plinth and other petty items as required and complete to function in all respect. 15 Tk. 2,745.93 Bituminous Carpeting Road : Construction of 38 mm thick compacted bituminous carpeted road over 150 mm thick sand surface with 75 mm thick end edging, 62 mm–37 mm size brick bats khoa consolidation and compacted water bound macadam of 150 mm thickness, providing tack coat, seal coat and prime coat as per requirement. 14. 286 Drain and Apron: (i) Surface drain of 300 mm clear width and depth up to 300 mm: Constructing RCC (fc'=22MPa, minimum fcr=27MPa in nominal mix1:2:4 with stone chips) surface drain of 300 mm clear width and depth up to 300 mm with 125 mm thick check walls and 125 mm thick base over one layer of brick flat soling. The surface having minimum 12 mm thick cement sand (F.M. 1.2) plaster (1:3) and neat cement finishing with cement curing at least for 7 days including excavation in all kinds of soil, back filling with fine sand (F.M. 0.8), consolidating and dressing, cost of water, electricity, other charges etc. complete and accepted by the Engineer in charge. (Cement: CEM-II/A-M) PWD SoR 2018 for Civil Works ANNEXURE-A (ii) Surface drain of 225 mm clear width and 600 mm (av.) depth : Constructing RCC(fc'=22MPa, minimum fcr=27MPa in nominal mix1:2:4 with stone chips) surface drain of 600 mm (av.) depth and 225 mm clear width at the bottom and 525 mm at the top, having 125 mm thick check walls maintaining side slopes and 125 mm thick base over one layer of polythene on top of brick flat soling. The surface having minimum 12 mm thick cement sand (F.M. 1.2) plaster (1:3) including neat cement finishing the surfaces and back of the drain up to 150 mm below ground level with fresh cement (conforming to BDS 232) curing at least for 7 days, including excavation of all kinds of soil, back filling with fine sand (F.M. 0.8) consolidating and dressing, including cost of water, electricity, other charges etc. complete and accepted by the Engineer in charge. (Cement: CEM-II/A-M) (iii) 287 Tk. 4,881.00 meter Tk. 917.00 sqm. Apron: Providing apron with 50 mm thick cement concrete (1:2:4) with cement, coarse sand and picked jhama chips including breaking chips and one layer brick flat soling at bottom with first class or picked jhama bricks including cutting earth for preparation of bed and filling the interstices with local sand (F.M. 0.8) including finishing, dressing, curing at least for 7 days etc. all complete, including cost of water, electricity, other charges accepted by the Engineer in charge. (Cement: CEM-II/A-M) PWD SoR 2018 for Civil Works ANNEXURE-B 288 Annexure-B GUIDELINES FOR PREPARATION OF PRELIMINARY ESTIMATES TYPE OF ESTIMATES: Preliminary Estimate Detail Estimate PRELIMINARY ESTIMATE: HEAD OF ACCOUNTS Revenue Development REQUIREMENTS OF PRELIMINARY ESTIMATE 1. Request letter from requiring body. 2. Approved site plan by the Department of Architecture. 3. Approved building plan by the Department of Architecture. 4. If approved building plan is not available, in case of urgency, preliminary estimates may be prepared based on space requirements furnished by the Department of Architecture. CHECK LIST BEFORE PREPARATION OF PRELIMINARY ESTIMATE: 1. Apparent soil condition and approximate cost for sub-soil investigation. 2. Need for site improvement and approach road. 3. Source of water supply. 4. Surface water & sewerage disposal. 5. Source of power supply. 6. Source of gas supply. 7. Need for special type boundary wall or retaining wall. 8. Structure type and structural system. 9. Additional cost in foundation due to poor soil condition. 10. Special type foundation: Raft or pile. COMPONENTS OF ESTIMATE 1. Project Profile. 2. Report. 3. Abstract of Cost. 4. Estimate. 5. Site plan. 6. Building Plan. PWD SoR 2018 for Civil Works ANNEXURE-B 289 REPORT SHOULD CONTAIN THE FOLLOWING COMPONENTS: 1. Background and Objectives. 2. Description of the Project. 3. Rates of Estimate. 4. Mode of Financing. 5. Charges. COST FOR CONSTRUCTION BY DEPARTMENT AND PRIVATE OWNER: 1. Structure constructed departmentally & private owner: The cost will be reduced by 17.18% DETAIL ESTIMATE DETAIL ESTIMATE SHALL CONTAIN: 1. Report. 2. Detail Building Plan, Elevation, Section & Structural Drawings. 3. Detail measurement of each individual item along with their information in drawings, sites etc. 4. An abstract of cost. 5. Proposed works specially boundary wall, gate, road, external water supply, sewerage line shown in red. DETAILED ESTIMATES ARE PREPARED: 1. For preparation of tender documents & bill of quantity. 2. For according technical sanction. 3. To receive fund through “schedule process” from the revenue budget. 4. For administrative approval of items of works, which are not components of approved scheme. IMPORTANT POINTS TO REMEMBER: 1. Rates of items not covered by PWD’s schedule of rate shall be accompanied by analysis. 2. Site improvement by carted earth must be accompanied by contour map duly signed by appropriate authority. 3. Detail estimate of approved projects implemented through ADP must not be sent to Chief Engineer’s Office for checking and approval. Additional chief Engineer has the full power to approve it. 4. Detail estimates sent to Chief Engineer’s office require prior approval of respective S.E. and A.C.E. PWD SoR 2018 for Civil Works ANNEXURE-B SAMPLE FORMAT OF PRELIMINARY ESTIMATE 1. SOIL INVESTIGATION : TK. A 2. CONSTRUCTION OF BUILDING : TK. B A. FOUNDATION COST: from PLAR Table 1. Add cost for saline zone 2. Add cost for f'c = 32 MPa (1: 1:25: 2.5) or f'c = 40 MPa (1: 1: 2) concrete with stone chips 3. Add cost for high risk costal area 4. Add additional cost for extra depth of foundation 5. Add additional cost for basement floor (basement wall, floor and retaining piles if required) 6. Add cost for member weightage table-3 (For basement floor) 7. Add additional cost for wind and earthquake 8. Add additional cost for extra length of Pile beyond 18m B. SUPER STRUCTURE COST: from PLAR Table 1. Add cost for saline zone 2. Add cost for f'c = 32 MPa (1: 1:25: 2.5) or f'c = 40 MPa (1: 1: 2) concrete with stone chips 3. Add cost for high risk costal area 4. Add cost for member weightage table-3 (Including basement floor) 5. Add additional cost for wind and earthquake 6. Add additional cost for extra height of floor beyond 3.35m (11’-0”) 3. INTERNAL WATER SUPPLY AND SANITATION : Tk. C 4. INTERNAL ELECTRIFICATION : Tk. D 5. EXTERNAL WATER SUPPLY : Tk. E 1. Construction of underground reservoir 2. Sinking of deep tube well/arranging water from WASA, Municipality or Public Health Engineering sources 3. Laying of distribution pipe lines 4. Construction of pump house 5. Supplying and installation of pumps 6. EXTERNAL ELECTRIFICATION 1. Construction of Sub-station building 2. Supplying and installation of Sub-Station Equipment/Transformer 3. Supplying and installation of pump and motor set : Tk. F 290 PWD SoR 2018 for Civil Works ANNEXURE-B 4. HT/LT Line 5. P.D.B/DESA/R.E.B connection charges 6. Stand-by power and source 7. Earthling system 8. Overhead transmission line 9. Underground cable laying 10. Compound light 7. ELECTRO-MECHANICAL COMPONENT : TK. G 1. Lift (................Passenger ...........stop) : Nos. x Unit Cost 2. Air conditioner and exhaust fans etc: Nos. x Unit cost 8. GAS CONNECTION NETWORK AND CHARGES . : TK. H 9. CONSTRUCTION OF COMPOUND DRAIN (Cost per meter of length). : TK. I 10. CONSTRUCTION OF CULVERT/BRIDGE. : TK. J 11. CONSTRUCTION OF INTERNAL / COMPOUND / APPROACH ROAD AND PAVEMENT. : TK. K 12. CONSTRUCTION OF BOUNDARY WALL AND GATES, RETAINING WALL. : TK. L 13. DEVELOPMENT OF SITE (cost on approximate quantity in cum) . : TK.M 14. ARBORICULTURE / LANDSCAPE / PLAYGROUND. : TK. N 15. FIRE FIGHTING. : TK. O SUB TOTAL : TK. P 16. QUALITY ASSURANCE, MATERIAL SAMPLE COLLECTION & TESTING, ETC (1.00% on Tk. P) : TK. Q 17. CONTINGENCY (Probable unforeseen expenditure related to work). A. Price Contingency (maximum 8.00% on Tk. P) B. Physical Contingency (maximum 2.00% on Tk. P) : Tk. R : Tk. S SUB TOTAL 18. COST OF LAND : TK. T : TK. U GRAND TOTAL : TK. V (The Project cost stands at Tk. ‘V’ lakh) 291 PWD SoR 2018 for Civil Works ANNEXURE-B 292 WORKED OUT EXAMPLE ON PREPARATION OF PRELIMINARY ESTIMATE Building type : Residential. Building Category : Super (1800 sft/flat, 2 flats per floor). Type of structure : R. C. C. frame structure with 1: 1.5: 3 concrete (stone chips). Soil type : Bearing Capacity of Soil = 3 ksf. Foundation : Shallow foundation, 6 storeys. Plinth Area : 4003.93 sft. (371.97 sqm). Ground Floor : Parking. Site : Other than coastal area. A. FOUNDATION COST Quantity/Amount 1. Soil Investigation : L.S. or Actual cost (BH Nos. as primary, say) 2. Foundation cost : From PLAR Table - 1, (For B.C.qa=3ksf) 371.97 sqm @ Tk. 13,904.00 per sqm 3. Add extra 2% cost for wind (other than coastal area) & earthquake load: 2% on Tk. 5,171,036.64 Tk. Unit Rate (Tk.) 5 Nos. Tk. 26,675.00 /No. Total Amount (Tk.) Tk. 133,375.00 371.97 sqm Tk. 13,904.00 /sqm Tk. 5,171,036.64 5,171,036.64 2% Tk. "A" = 103,420.73 Tk. 5,407,832.37 B. SUPER STRUCTURE COST. 4. 5. 6. (i) Ground floor as Parking (from PLAR Table-2) 371.97 sqm @ Tk. 14,111.00 371.97 sqm Tk. 14,111.00 /sqm Tk. 5,248,022.01 (ii) Add extra cost for Member Weightage (M.W.) (from PLAR Table-3.) 371.97 sqm @ Tk. 1,069.00 per sqm. 371.97 sqm Tk. 1,069.00 /sqm Tk. (i) 1st floor (from PLAR Table-2.) 371.97 sqm @ Tk. 23,611.00 per sqm 371.97 sqm Tk. 23,611.00 /sqm Tk. 8,781,167.01 (ii) Add extra cost for M.W (from PLAR Table-3.) 371.97 sqm @ Tk. 855.00 per sqm 371.97 sqm Tk. /sqm Tk. (i) 2nd floor (from PLAR Table-2) 371.97 sqm @ Tk. 23,965.00 per sqm 371.97 sqm Tk. 23,965.00 /sqm Tk. 8,912,823.15 (ii) Add extra cost for M.W (from PLAR Table-3) 371.97 sqm @ Tk. 641.00 per sqm. 371.97 sqm Tk. Tk. 855.00 641.00 /sqm 397,571.79 317,983.05 238,394.31 PWD SoR 2018 for Civil Works ANNEXURE-B 7. 8. 9. 293 (i) 3rd floor (from PLAR Table-2) 371.97 sqm @ Tk. 24,324.00 per sqm 371.97 sqm Tk. 24,324.00 /sqm Tk. 9,046,338.84 (ii) Add extra cost for M.W (from PLAR Table-3) 371.97 sqm @ Tk. 428.00 per sqm. 371.97 sqm Tk. Tk. (i) 4th floor (from PLAR Table-2) 371.97 sqm @ Tk. 24,689.00 per sqm 371.97 sqm Tk. 24,689.00 /sqm Tk. 9,182,085.99 (ii) Add extra cost for M.W (from PLAR Table-3) 371.97 sqm @ Tk. 214.00 per sqm. 371.97 sqm Tk. Tk. 371.97 sqm Tk. 25,059.00 /sqm 5th floor (from PLAR Table-2) 371.97 sqm @ Tk. 25,059.00 per sqm 428.00 /sqm 214.00 /sqm "B" = 159,177.48 79,588.74 Tk. 9,319,692.69 Tk. 51,682,845.06 C. ADDITIONAL SUPPER STRUCTURE COST 10. Add extra super structure cost 2% for wind (other than coastal area) & earth quake load resisting structure.): 2% on Tk. 51,682,845.06 Tk. 51,682,845.06 11. Extra cost for Rooftop & Chillakotha (From PLAR Table-2): 371.97 sqm @ Tk. 2,619.00 per sqm 371.97 12. Extra cost for Roof top R.C. C Parapet (From Additional Cost Chart item-4): 4x19.28x1n=77.14sqm @ Tk. 2,776.00 per sqm 77.14 13. Extra cost for Roof top R.C.C water tank (From Additional Cost Chart. item-5): 2000 gal. @ Tk. 155.00 per gal 2000 sqm sqm Tk. 2% Tk. 1,033,656.90 Tk. 2,619.00 /sqm Tk. 2,776.00 gallon Tk. 155.00 "C" Tk. 974,189.43 /sqm Tk. 214,140.64 /gal 310,000.00 = Tk. Tk. 2,531,986.97 D. OTHER BUILDING COST 14. Internal Sanitary & Water Supply (From additional cost chart, item-6): Consider G.F Parking area cost 50%. 5.5x371.97 sqm @ Tk. 1519.60 per sqm 2045.84 sqm Tk. 1,519.60 /sqm Tk. 3,108,850.87 15. Internal Electrification (From additional cost chart, item7): Consider G.F Parking area cost 50%. 5.5x371.97 sqm @ Tk. 2,017.00 per sqm 2045.84 sqm Tk. 2,017.00 /sqm Tk. 4,126,449.20 16. External Water Supply. 10000 gallon Tk. Tk. (i) Construction of underground reservoir (From aditional cost chart, item-9-i-a) : 10,000 gal. @ Tk. 92.00 per gal. (ii) Sinking of Deep tube well/ Distribution line, water pump, pump house, WASA/Municipal charge as per requirement. Actual cost. 1 No. 92.00 /gal M 920,000.00 M PWD SoR 2018 for Civil Works ANNEXURE-B 17. 294 External Electrification (i) Sub-station building. (ii) Sub-station Equipment/Transformer. (iii) Pump & Motor set in/c installation (iv) H.T./L.T. Line (v) PDB/DESA/REB Charge. (vi) Standby Power & Source. (vii) Earthing System. (viii) Overhead Transmission. (ix) Underground cable laying. (x) Compound light. Wiring system & other safety system. 1 No. N N P P Electro-Mechanical Component. 18. (i) Lift. Not required (ii) Air Condition Not required 1 No. 185.99 sqm Tk. 342.20 /sqm Tk. 63,644.07 1859.85 sqm Tk. 136.88 /sqm Tk. 254,576.27 Gas Connection. 19. 20. 21. 22. (i) Ground Floor. (From Additional Cost Chart item-8-i) Consider 50% cost as parking. 0.50x371.97 sqm @ Tk. 342.20 per sqm (ii) Other floor (From Additional Cost Chart item-8-ii): 5x371.97 sqm @ Tk. 136.88 per sqm Construction of Compound drain Cost on meter basis (From Additional Cost Chart item-15i/ii/iii) Q Approach Road. As per requirement. (From Additional Cost Chart item-13-i/ii) R (i) Boundary Wall. As per requirement. (From Additional Cost Chart item-11-i/ii/iii/iv/v/vi/vii) (ii) Gate, As per requirement. (From Additional Cost Chart item-11-viii) S 23. Site improvement. T 24. Testing of materials as per requirement U 25. Arboriculture/Landscape (As per requirement): V 26. Fire Fighting (As per requirement): W Total "D" = Sub-Total "X" = sum of cost from item 14 to 26 (A+B+C+D) 27. Quality Assurance , Material Sample Collection & Testing ( 1% of X ) "Y" = 1% of "X" 28. Contingency (5% of X) or Actual need. "Z" = 5% of "X" Or Actual need Grand Total = (X+Y+Z) PWD SoR 2018 for Civil Works ANNEXURE-C Annexure-C Element FINISH SCHEDULE Name of Space Standard Super Special PARKING SPACE Paving block/ Casting(rough) Brick/Paving block/ Casting(rough/stamped) Brick/Paving block/ Casting(rough/stamped) STAIR Local best quality non-skid floor tiles. (Size: Minimum 300mmX300mm) Local/ Foreign best quality non-skid floor tiles. (Size: Minimum 600mmX300mm) Local/ Foreign best quality non-skid floor tiles/ Marble/ Granite. (Size: Minimum 600mmX300mm, For Designed floor Random size as per design) LIFT LOBBY Local best quality non-skid floor tiles. (Size: Up to 600mmX600mm) Local/ Foreign best quality non-skid floor tiles. (Size: Minimum 600mmX600mm) Local/ Foreign best quality non-skid floor tiles/ Marble/ Granite. (Size: Minimum 600mmX1200mm, For Designed floor Random size as per design) BED ROOM Local best quality non-skid floor tiles or Terrazzo (Cast in Situ/Tiles). (Size: Up to 600mmX600mm) Local/ Foreign best quality Matt/ Mirror Polished floor tiles (Size: Minimum 600mmX600mm) Local/ Foreign best quality Matt/ Mirror Polished floor tiles/ Marble/ Granite. (Size: Minimum 600mmX1200mm, For Designed floor Random size as per design) DRAWING Local best quality non-skid floor tiles or Terrazzo (Cast in Situ/Tiles). (Size: Up to 600mmX600mm) Local/ Foreign best quality Matt/ Mirror Polished floor tiles (Size: Minimum 600mmX600mm) Local/ Foreign best quality Matt/ Mirror Polished floor tiles/ Marble/ Granite. (Size: Minimum 600mmX1200mm, For Designed floor Random size as per design) DINING Local best quality non-skid floor tiles or Terrazzo (Cast in Situ/Tiles). (Size: Up to 600mmX600mm) Local/ Foreign best quality Matt/ Mirror Polished floor tiles (Size: Minimum 600mmX600mm) Local/ Foreign best quality Matt/ Mirror Polished floor tiles/ Marble/ Granite. (Size: Minimum 600mmX1200mm, For Designed floor Random size as per design) KITCHEN Local best quality non-skid floor tiles or Terrazzo (Cast in Situ/Tiles). (Size: Up to 600mmX600mm) Local/ Foreign best quality Non Skid floor tiles. Local/ Foreign best quality Non Skid floor tiles/ Marble/ Granite. (Size: Minimum 600mmX1200mm, For Designed floor Random size as per design) TOILET Local best quality non-skid floor tiles or Terrazzo (Cast in Situ/Tiles). (Size: Up to 600mmX600mm) Local/ Foreign best quality Non Skid floor tiles. Local/ Foreign best quality Non Skid floor tiles/ Marble/ Granite. (Size: Minimum 600mmX1200mm, For Designed floor Random size as per design) CORRIDOR / PASSAGE Local best quality non-skid floor tiles. (Size: Up to 600mmX600mm) Local/ Foreign best quality non-skid floor tiles. (Size: Minimum 600mmX600mm) Local/ Foreign best quality non-skid floor tiles/ Marble/ Granite. (Size: Minimum 600mmX1200mm, For Designed floor Random size as per design) Floor 295 PWD SoR 2018 for Civil Works ANNEXURE-C Element Interior Wall Name of Space Standard Super Special VERANDAH Local best quality non-skid floor tiles or Terrazzo (Cast in Situ/Tiles). (Size: Up to 600mmX600mm) Local/ Foreign best quality non-skid floor tiles. (Size: Minimum 600mmX600mm) Local/ Foreign best quality non-skid floor tiles/ Marble/ Granite. (Size: Minimum 600mmX1200mm, For Designed floor Random size as per design) PARKING SPACE Plastered and Painted with Acrylic Emulsion paint. Plastered and Painted with Acrylic/ Satin Emulsion paint. Plastered and Painted with Acrylic/ Satin/ Granulated/ Textured Emulsion paint. OR Local/ Foreign best quality Glazed/ Matt Ceramic tiles. STAIR Plastered and Painted with Acrylic Emulsion paint. Plastered and Painted with Acrylic/ Satin Emulsion paint. Plastered and Painted with Acrylic/ Satin/ Granulated/ Textured Emulsion paint. LIFT LOBBY Plastered and Painted with Acrylic Emulsion paint. Plastered and Painted with Acrylic/ Satin Emulsion paint. Plastered and Painted with Acrylic/ Satin/ Granulated/ Textured Emulsion paint. OR Local/ Foreign best quality Matt/ Glazed wall tiles/ Marble/ Granite.(Size: Random as per design) BED ROOM Plastered and Painted with Acrylic Emulsion paint. Plastered and Painted with Acrylic/ Satin Emulsion paint. Plastered and Painted with Acrylic/ Satin/ Granulated/ Textured Emulsion paint OR Wall Paper. DRAWING Plastered and Painted with Acrylic Emulsion paint. Plastered and Painted with Acrylic/ Satin Emulsion paint. Plastered and Painted with Acrylic/ Satin/ Granulated/ Textured Emulsion paint OR Wall Paper. DINING Plastered and Painted with Acrylic Emulsion paint. Plastered and Painted with Acrylic/ Satin Emulsion paint. OR Local/ Foreign best quality Glazed Ceramic tiles (Size: Minimum 600mmX300mm) Plastered and Painted with Acrylic/ Satin/ Granulated/ Textured Emulsion paint. OR Local/ Foreign best quality Matt/ Glazed wall tiles/ Marble/ Granite.(Size: Random as per design) KITCHEN Local best quality Glazed Ceramic tiles (Size: Up to 600mmX300mm) Local/ Foreign l best quality Glazed Ceramic tiles (Size: Minimum 600mmX300mm) Local/ Foreign best quality Matt/ Glazed wall tiles/ Marble/ Granite.(Size: Random as per design) TOILET Local best quality Glazed Ceramic tiles (Size: Up to 600mmX300mm) Local/ Foreign best quality Glazed Ceramic tiles (Size: Minimum 600mmX300mm) Local/ Foreign best quality Glazed Ceramic tiles (Size: Minimum 600mmX300mm) CORRIDOR / PASSAGE Plastered and Painted with Acrylic Emulsion paint. Plastered and Painted with Acrylic/ Satin Emulsion paint. Plastered and Painted with Acrylic/ Satin Emulsion paint. OR Local/ Foreign best quality wall tiles/ Marble/ Granite.(Size: Random as per design) VERANDAH Plastered and Painted with Acrylic Emulsion paint. Plastered and Painted with Acrylic/ Satin/ Matt Enamel Emulsion paint. Plastered and Painted with Acrylic/ Satin/ Matt Enamel Emulsion paint. OR Local/ Foreign best quality wall tiles/ Marble/ Granite.(Size: Random as per design) 296 PWD SoR 2018 for Civil Works ANNEXURE-C Name of Space Standard Super Special Exterior wall ALL Plastered and Painted with Standard Exterior Emulsion paint. For exposed brick or concrete facing wall painted with Water Repellent /Clear sealer/ Lacquer with pointing. Plastered and Painted with Standard/Premium Exterior Emulsion paint. For exposed brick or concrete facing wall painted with Water Repellent Clear sealer/ Lacquer with pointing. Plastered and Painted with Premium Exterior Emulsion paint. For exposed brick or concrete facing wall painted with Water Repellent Clear sealer/ Lacquer with pointing. Ceiling ALL Plastered and Painted with Acrylic Emulsion paint. Plastered and Painted with Acrylic/ Satin Emulsion paint. Plastered and Painted with Acrylic/ Satin Emulsion paint. Door frame-of Teak Chamble. Shutter- Chittagong Teak Wood Solid/ Designed door with best quality polish. Door frame-of Teak Chamble/ Chittagong Teak. Shutter- Burma Teak Wood Solid/ Designed door with best quality polish. OTHER DOOR Door frame-of Teak Chamble. Shutter- Teak Chamble Veneered Particle Flush door with best quality polish. Door frame-of Teak Chamble/ Chittagong Teak. Shutter- BurmaTeak Veneered Particle Flush door with best quality polish. Door frame-of Burma Teak/ Chittagong Teak. Shutter- Burma Teak Wood Solid/ Designed door with best quality polish. KITCHEN DOOR Door frame- of Teak Chamble. Shutter- Inside Melamine / Plastic Board Cladded, Outside Teak Chamble Veneered Particle Flush door with best quality polish and paint. Door frame- of Teak Chamble/ Chittagong Teak. Shutter- Chittagong Teak Wood Solid/ Designed (with Glass Panel) door with best quality polish. Door frame-of Burma Teak/ Chittagong Teak. Shutter- Burma Teak Wood Solid/ Designed (with Glass Panel) door with best quality polish. Door frame-of UPVC/ Teak Chamble. Shutter- UPVC / Inside Melamine or Plastic Board Cladded, Outside Teak Chamble Veneered Particle Flush door with best quality polish and paint. Door frame- of Teak Chamble/ Chittagong Teak. Shutter- Inside Melamine / Plastic Board Cladded, Outside Burma Teak Veneered Particle Flush door with best quality polish and paint. Door frame-of Burma Teak/ Chittagong Teak. Shutter- Inside Melamine / Plastic Board Cladded Burma Teak Wood Solid/ Designed door with best quality polish and paint. Door frame- of Teak Chamble/ Chittagong Teak. Shutter- Burma Teak Veneered Particle Flush door with best quality polish and paint. Door frame-of Burma Teak/ Chittagong Teak. Shutter- Burma Teak Wood Solid/ Designed door with best quality polish and paint. Element MAIN DOOR Door BATHROOM DOOR VERANDAH DOOR Door frame- of Teak Chamble. Shutter- Teak Chamble Veneered Particle Flush door with best quality polish and paint. Door frame-of Burma Teak/ Chittagong Teak. Shutter- Burma Teak Wood Solid/ Designed door with best quality polish. 297 PWD SoR 2018 for Civil Works ANNEXURE-C Element Window Name of Space Standard Super Special Grill-6 mm x 25 mm. Flat Bar or 16mm Square Bar with Enamel paint. Grill-6 mm x 25 mm. Flat Bar or 16mm Square Bar with Enamel paint. Grill-6 mm x 25 mm. Flat Bar or 16mm Square Bar with Enamel paint. Frame-100 mm Aluminium Section with Mosquito net of Silver/ Bronze Colour. Frame-100 mm Aluminium Section with Mosquito net of Silver/ Bronze Colour. Shutter-Sliding Aluminium Panel fabricated with Glass shutter. Shutter-Sliding Aluminium Panel fabricated with Glass shutter. Shutter-Sliding Aluminium Panel fabricated with Glass shutter. OR Shutter-Pivoted Aluminium Panel fabricated with Glass shutter. STAIR Metal (M.S.) Vertical and Horizontal Posts with Wooden Top Rail. Metal (M.S./S.S./Casting) Vertical and Horizontal Posts with Wooden Top Rail. Metal (M.S./S.S./Casting) Vertical and Horizontal Posts or Tempered Glass Panel with Wooden/Metal Top Rail. VERANDAH Metal (M.S.) Vertical and Horizontal Posts with Metal Top Rail. Metal (M.S./S.S./Casting) Vertical and Horizontal Posts with Metal Top Rail. Metal (M.S./S.S./Casting) Vertical and Horizontal Posts or Tempered Glass Panel with Metal Top Rail. ALL Rail Frame-100 mm Aluminium Section with Mosquito net of Silver/ Bronze Colour or Powder Coated. NOTE: 1) Generally for Residential Buildinga) Unit size 500 sft to 1250 sft shall be considered for Standard Category b) Unit size 1500 sft to 2500 sft shall be considered for Super Category c) Unit size >2500 sft shall be considered for Special Category In special cases, irrespective of unit size building category will be decided as per finish schedule. 2) For Non-Residential Building the category shall be considered as per significance of the building. 298 PWD SoR 2018 for Civil Works ANNEXURE-D Annexure-D 299 NAME OF THE MATERIAL BRAND AS USER GUIDE* (SUBJECT TO SATISFY THE STANDARD TESTS AND APPROVAL BY PWD) SL. NAME OF THE MATERIAL AND STANDARD** BRAND NAME 1.1 AKIJ 1.2 ANWAR BRAND 1.3 ANCHOR 1.4 AMAN CEM 1.5 BASHUNDHARA 1.6 CAMEL BRAND 1.7 CROWN 1.8 DESHBONDHU 1.9 DIMOND BRAND 1.10 FIVE RINGS CEMENT 1. BDS EN 197-1: CEM-I, 52.5N PORTLAND CEMENT (BDS EN 197-1:2003) MANUFACTURER Akij Cement Ltd. 27, Dilkusha C/A, Dhaka-1000. Anwar Cement Ltd. Baitul Hossain Building, 14th Floor, 27 Dilkusha Commercial Area, Dhaka-1000. Phone: 02-02-9564033;Fax:02-8837464; 02-7124264 E-mail:agi@agni.com; Web:www.anwargroup.com Olympic Cement Ltd. Green Grandeur 58/E, Kemal Ataturk Avenue (11th Floor), Banani, Dhaka-1213 Phone: 9821503, 9821504 Aman Cement Industries Ltd. 2 Ishakha Avenue,Sector#6, Uttara, Dhaka-1230; Phone:02-7911691-3;8962297; Fax:02-8920510; E-mal:info@amangroupbd.com;Web:www .amangroupbd.com. Bashundhara industrial Complex Ltd. Bashundhara Industrial Headquarters Plot no. 03, Block # G, Umme Kulsum Road Bashundhara R/A Dhaka-1229 Phone : 02-8401024-8,01730328882 Aramit Cement Ltd. 53/A Kalurghat Heavy Industrial Area, Chittagong Phone : 031-670 368 M.I Cement Factory Ltd. House # 1 & 7 Road # 95 Block # CEN(A) North Avenue, Gulshan-2, Dhaka-1212 Phone: 9852633, 9852634, 9852636 Deshbondhu Cement Mills Ltd. House No-59, Road-27, Block-K, Banani, Dhaka-1213. Phone- +880-1755552875 Dimond Cement Ltd. 220 Strand Road, Chittagong-4000 Phone: 031-611041-3 Dubai Bangladesh Cement Mills Ltd House # 06, Road # 1, Dhanmond, Dhaka-1212 Phone: 02-9663393-3 * USER'S are requested to collect respective Bangladesh Standards (BDS) from BSTI: in absence of BDS one shall collect ASTM/BS/EN/ISO/IS etc. to select tests and acceptable criteria. ** To comply mentioned standard (s) or standard (s) subsequently released from Bangladesh Standard and Testing Institute (BSTI). NB: List of the companies arranged in alphabetic sequence. PWD SoR 2018 for Civil Works ANNEXURE-D SL. NAME OF THE MATERIAL AND STANDARD** BRAND NAME 1.11 FRESH 1.12 HOLCIM 1.13 KING BRAND 1.14 LION 1.15 MEGHNACEM DELUXE 1.16 METROCEM 1.17 MIR CEMENT 1.18 NGS 1.19 PREMIER 1.20 ROYAL 1.21 SEVEN HORSE 1.22 SEVEN RING 1.23 SHAH CEMENT 1.24 TIGER BRAND 1.25 ULTRATECH CEMENT BDS EN 197-1: CEM-I, 52.5N PORTLAND CEMENT (BDS EN 197-1:2003) 300 MANUFACTURER Unique Cement Industries Limited Fresh Villa, House-15, Road-34, Guilshan-1, Dhaka-1212 Phone: 9889306, 9889490 Holcim (Bangladesh) Ltd. House No.8, Road No-14 Baridhara, Dhaka-1212 Phone: 02-988 1003, 8812485 Meghna Cement Mills Ltd. Road No-3(Umme Kulsum Road), Block-G Bashundhara R/A, Dhaka-1229. Phone: 02-9401024, 8401025-8 Confidence Cement Ltd. Ispahani Building (3rd Floor), Sk.Mujib Road, Agrabad C/A Chittagong.Phone: 7114713,711475 Unique Cement Industries Limited Meghnaghat, Sonargaon, Narayangonj. Metrocem Cement Ltd. Uenus center (level-12), 52-53 Dilkusha C/A, Dhaka-1000. Mir Cement Ltd. House # 8, Level # 3, Road # 14 Dhanmond R/A, Dhaka-1209. Phone : 8110554, 8122883, 91047215 NGS Cement Industries Ltd. Uttar Patenga, Chittagong. Premier Cement Mills Limited TK Bhaban (12th Floor), 13 Kawan Bazer, Dhaka-1215 Phone : 02-9144788, 9127610, 9129826, 9126220 Royal Cement Co. Ltd. Kabir Monil, SK Mujib Road Agrabad, Chittagong. Phone: 31-715222, 726293. Eastern Cement Industries Ltd. Walsow Tower, Level-1&2 21 &23,Kazi Nazru Islam Avenue, Dhaka.1000. Seven Circle (Bangladesh) Ltd. LANDVIEW 7th Floor, 28 Gulshan North. Gulshan-2, Dhaka-1212 Phone: 8817690-3 Shah Cement Industries Ltd. 13, Dilkusha C/A (4th Floor), Dhaka-1000 Phone : 02-9550324, 9572201-2 Madina Cement Industries Ltd. Madina Green Vila-5, Green Square Green Road, Dhaka-1205 Phone : 9663706, 9663714 Emirates Cement Bangladesh Ltd. Chandiwala Mansion, Level-4, House-32, Road11, Block-G, Banani, Dhaka-1213. Phone-+8802-9870069 PWD SoR 2018 for Civil Works ANNEXURE-D SL. NAME OF THE MATERIAL AND STANDARD** BRAND NAME 2.1 AKS 2.2 ANWAR 2.3 STEEL 2. FOR THE REINFORCEMENT OF CONCRETE Grade: 300, 400 BDS ISO 6935-2: 2006 Max fy ≈ 330 and 450 Ratio fu to fy ≥ 1.25 ASBRM 2.4 BSI 2.5 BSRM 2.6 CSRM 2.7 ELITE 2.8 GPH 2.9 HKG 2.10 HI-TECH 2.11 HRRM 2.12 KSRM 2.13 MAGNUM 2.14 METROCEM 2.15 PHP 301 MANUFACTURER Abul Khair Steel Ltd. House#75, Road# 9/A, Dhanmondi R/A,Dhaka. 031-752181-2; 714541-4, Fax:031720239,710051. www.abulkhairsteel.com Anwar Steel Ltd. Baitul Hossain Building, 14th Floor, 27 Dilkusha Commercial Area, Dhaka-1000. Phone:02-029564033;Fax:02-8837464; 02-7124264 Email:agi@agni.com; Web:www.anwargroup.com Ambient Steel (BD) Ltd. Shah Makhdum Avenue, Sector #12, House #07, Uttara, Dhaka Phone : 02-55085571, 55085572 Bandar Steel Industries Ltd. 15/5, Bijoynogor, Akram Tower2.1 (10th Floor, Room # 06), Dhaka-1000 Phone: 02-8391331, 01715345151. Bangladesh Steel Re-rolling Mills Ltd. BSRM Steels Limited Mahbub Castie (2nd $ 4th Floor) 35/A Purana Paltan Line, Dhaka-1000 Phone: 02-8311994, 9358135, 9344136 Chakda Steel and Re-rolling Mills Ltd. Rasulpur, Fatulla, Narrayangon. Elite Iron & Steel Ind. Ltd. South Avenue Tower (2nd Floor), House # 50, Road # 3.7, Gulshan Avenue Gulshan-1, Dhaka1212 Phone: 02-9857884, 9857910, 9857890 GPH Ispat ltd. Crown chamber, 325, Asadjonj, chittagong-4000. HKG Steel Mills Ltd. Mridhakandi, Newtown, Sonargoan, Narayangonj. Phone: +8801711561143 Hi-tech Steel & Re-Rolling Mills Ltd. Bulta, Rupgonj,.Narayangonj. HR Steel Re-rolling Mills Ltd. Road 13,Plot-7/9,Shampur, Kadamtoli,Dhaka. KSRM Steel Plant Ltd. Kabir Manzil SK Mujib Road Agrabad, Chittagong Phone : 880-31-711501-5, 2513791-4 Magnum Steel Industries Limited Rubayat, House-15, Road-24, Gulshan, Dahaka1212, Contact: 02-9881699;58814247; 9896740;Fax:02-9851584 E-mail:info@magnumbd.com; Web:www.magnumbd.com Metrocem Ispat Limited G-9/1 Chandra, Gazipur. PHP Ispat Limited. Bagdi, Gorashal, Plash, Norshindi. PWD SoR 2018 for Civil Works ANNEXURE-D SL. NAME OF THE MATERIAL AND STANDARD** STEEL FOR THE REINFORCEMENT OF CONCRETE Grade: 300, 400 BDS ISO 6935-2: 2006 Max fy ≈ 330 and 450 Ratio fu to fy ≥ 1.25 PAINT 3. 4. Plastic Emulsion Interior BDS 1097 (para-1):1984 Plastic Emulsion Exterior BDS 1097 (para-2):1984 Cement Paint BDS 1706:2002 Synthetic Enamel Paints BDS 1423/1993 Mild steel (MS), Galvanized (C.I) Pipes and Fittings BDS 1031:2006 BRAND NAME 2.16 RSRM 2.17 SAS 2.18 SCRM 2.19 SSRM 2.20 TIGER 3.1 AQUA PAINT 3.2 ASIAN PAINT 3.3 BERGER 3.4 ELITE PAINT 3.5 NIPPON 3.6 PAILAC 3.7 RAK 3.8 ROXY 4.1 FALCON 4.2 HATIM 302 MANUFACTURER Ratangpur Steel Re-Rolling Mills. Ltd. 99, Gulshan Avenue, Gulshan-2, Dhaka-1212 Phone: 02-9892936, 9890457, 9891415, 8812621. Shafiul Alam Steel Re-Rolling Mills Suite-A-1, House-4, Road-18 Block-A, Banani, Dhaka-1213 Phone : 02-8838012 Salam Steel Concast Re-Rolling Mills Ltd. Police Piaza Concord, Flat No # 9/H, Plot # 02, Road No # 144, Gulshan Model Town, Dhaka1212. Shahriar Steel Mills Ltd. Konapara, Jatrabari, Dhaka-1362 SS Steel Pvt. Ltd. SS Steel Building, 17/C Panthapath, Dhaka1207. Phone: +8802-9101111 Octagon Fibres & Chemicals Ltd. Elite House, 54 Motijheel C/A(2nd Floor) Dhaka-1000 Phone: 9561376, 7160132. Asian Paints (Bangladesh) Ltd. House # 428/A( 3rd & 5 th Floor) Road # 30 New DOHS, Mohakhali, Dhaka-1206 Phone : 9859329, 9893283 Berger House, House # 08, Road # 02, Section # 03 Uttara Model Town, Dhaka. Phone: 028953669 Elite Paint & Chemical In. Ltd. Syed Grand Centre, Level. 9 Plot 89, Road, 28 Sector 7 Uttara, Dhaka-1230 Phone: 8913674, 8913558. Nippon Paint (Bangladesh) Pvt .Ltd 60/E/2, Purana Paltan (Dewan Manjil), Dhaka-1000 Phone: +8802 9559889, 01730376000. Pailac Chemical Co. 3/7, Sonatangore, Hazarrbagh, Dhaka-1209 Phone: 02-966 2345, 9672303. RAK Paints (Pvt.) Ltd. RAK Tower (12th Floor), Plot # 1/A, Jasimuddin Avenue, Sector # 3, Uttara Model Town. Dhaka-1230 Phone: 8923297 Roxy Paints Limited House # 08, Road # 14 (New) Dhanmondi R/A Dhaka Phone: 9118481, 9126154. Rangpur Metal Industries Ltd. Cilipm, shahzileayer, shachagonj, Hobigonj. Hatim Industries Ltd. 188/A, Jubilee Road, Chittagong, Bangladesh. PWD SoR 2018 for Civil Works ANNEXURE-D SL. NAME OF THE MATERIAL AND STANDARD** BRAND NAME 303 MANUFACTURER Anwar Polymer Ltd. Baitul Hossain Building, 14th Floor, 27 Dilkusha commercial area, Dhaka-1000. Phone:02-029564033;Fax:02-8837464; 02-7124264 Email:agi@agni.com; Web:www.anwargroup.com Bengal Plastics Pipes Ltd. Bengal house, 75 Gulshan Avenue, Gulshan-1, Dhaka-1212. Hatim Polymer Industries Ltd. 188/A, Jubilee Road, Chittagong, Bangladesh. National Polymer Industries Ltd. 36, Lake Circus Kalabagan, Dhaka Phone: 02-811 5054-57 RFL Plastics Ltd. Bagpara, Palash, Narshindi. 5.1 ANWARS A1 5.2 BENGAL 5.3 HATIM 5.4 NPI 5.5 RFL PP-R PIPES FOR POTABLE WATER SUPPLY AND FITTINGS 6.1 HATIM Hatim Polymer Industries Ltd. 188/A, Jubilee Road, Chittagong, Bangladesh. 7.1 HDPE COIL PIPE 7.1.1 HATIM Hatim Polymer Industries Ltd. 188/A, Jubilee Road, Chittagong, Bangladesh. 7.2 HDPE PIPE & FITTINGS FOR SANITARY WORKS 7.2.1 RFL RFL Plastics Ltd. Bagpara, Palash, Narshindi. uPVC PIPES FOR POTABLE WATER SUPPLY AND FITTINGS 5. 6. BDS 1496:2006 BS 3505:1996 ISO 4422-2:1996 (E) BDS 1878:2014 BDS ISO 4422-1:2008 BDS ISO 4422-3:2007 BDS ISO 4422-4:2008 DIN 8077/8078 , DIN 16962 DIN 16963 Part 1-14 ISO 4427-2:2007 (Pipes) ISO 4427-3:2007 (Fittings) SANITARY FIXTURES 8. 9. BDS 632,635,1361: 1992, 1356:1992 1357:1992, 1507:1992, 1508:1992 1509:1992, 1593:1998 ASTM: 1245-89 (2001) WATER STORAGE TANKS (PORTABLE) 8.1 SATTAR 8.2 SARKAR 9.1 GAZI TANK 9.2 MADINA TANK 9.3 SERA 10.1 BARAKA BDS 1699:2002 10. PAVING BLOCK, UNIPAVER & KERB STONE BS 6717-1:1993 ASTM C 42 Sattar Metal Industries 27, Dilkhusha C/A (5th Floor), Suite # 602, Dhaka-1000 Phone: 02-9551147 Sarker Metal Engineering & Industries Ltd. 78/B/7/6, North Zatrabari, Dhaka. Gazi Tanks 18-20 kadamtali Road, Shampur 1/A Shampur, Dhaka-1204 Phone: 02-9551147 Madina Polymer Industries Ltd. Green Villa, 5 Green Square, Green Road, Dhaka-1205 Phone : 02-9668640 Banga Building Materials Ltd. Pran-RFL Center, 105 Middle Badda, Dhaka-1212. Phone:02-8837464;Fax:02-8837464 E-mail:rpl@prangroup.com; Web:www.rflplastics.com Baraka Engineers Ltd. House #25, Road#34, Gulshan-2, Dhaka-1212. PWD SoR 2018 for Civil Works ANNEXURE-D SL. 11. 12. NAME OF THE MATERIAL AND STANDARD** BRAND NAME 11.1 BISF 11.2 RAK 11.3 STAR 11.4 STELLA 12.1 AKIJ 12.2 ATI 12.3 CBC Tiles 12.4 DBL 12.5 FU-WANG 12.6 GREAT WALL 12.7 MIR CERAMIC 12.8 RAK SANITARY WARES BDS 1162:2012 CERAMIC TILES BDS ISO 13008:2006 304 MANUFACTURER Bangladesh Insulator & Sanitary Wares Factory Ltd. Bux Nagar, Mirpur, Dhaka-1216 Phone: 02-8012 327 RAK Ceramics (Bangladesh) Ltd. RAK Tower (7th, 8th & 9 Floor), Plot # 1/A, Jasimuddin Avenue, Sector # 3, Uttara Model Town, Dhaka-1230 Phone : 8917393, 8922285, 8912303. Star Ceramics Ltd. House#44; Road#10; Sector#11; Uttara; Dhaka1230. Phone: 88 02 8950384, 88 02 7913322; Fax: 88 02 7914830 E-mail:sales@starceramicsbd.com; Web: www. starceramicsbd.com Abul Khair Ceramic Industries Limited. Empori Financial Center; Level-13; Plot-6;Road93,North Avenue, Gulshan-2; Dhaka-1212.Phone: +88 02 88812-21,23; Fax: +88 02 88810-57,51,52:Web: www.stellasanitary.com Akij Ceramics Ltd. Mofiz Chamber, 75 Dilkusha, C/A, Dhaka-1000. Phone-+880-1755581643 ATI Ceramic Ltd. khwaja Enayetpure Tower, 17, Bir Uttam K.M. Shafiullah Road(Green Road), Dhaka-1230 Phone: 02-966 2611-4, 8628423-4 China Bangla Ceramic Industries Ltd. National Plaza (5th floor) 109, Bir Uttam. C.R Dutta Road Dhaka-1205 Phone: 8615922, 9668278-9 DBL Ceramics Ltd. Dhanua, Sreepur, Gazipur Fu-Wang Ceramic Industry Ltd. 204/B (4th Floor), Bir Uttam Mir Shawkat Road, Teigaon Gulshan Link Road, Dhaka-1208 Phone: 9883274-5, 8825573, 8823985 Great Wall Ceramic Industries Ltd. 13/1, Paribagh, Bir Uttom C.R.Dutte Road, Dhaka-1209 Phone : 966308, 9664607 Mir Ceramic Ltd. House No.13, Road No.12, Dhanmondi R/A Dhaka-1209. Phone : 8110131, 8110997, 9134572-3 RAK Ceramics (Bangladesh) Ltd. RAK Tower (7th, 8th & 9 Floor), Plot # 1/A, Jasimuddin Avenue, Sector # 3, Uttara Model Town, Dhaka-1230 Phone : 8917393, 8922285, 8912303. PWD SoR 2018 for Civil Works ANNEXURE-D SL. 13. NAME OF THE MATERIAL AND STANDARD** PARTICLE BOARD BRAND NAME 12.9 STAR 12.10 SUN POWER 12.11 X-CERAMICS 13.1 PARTEX 13.2 SUPER BOARD 14.1 ALCO 14.2 BTA(THAI ALUMINIUM) 14.3 NIKKI BDS 799:2006 BDS 1159:1986 ALUMINUM SECTIONS 14. BS EN 755-1:2008 BS EN 755-2:2008 BS EN 755-9:2008 BDS EN 2013 AAMA Standard 305 MANUFACTURER Star Ceramics Ltd. House#44; Road#10; Sector#11; Uttara; Dhaka1230. Phone:88 02 8950384, 88 02 7913322; Fax: 88 02 7914830 E-mail: sales@starceramicsbd.com; Web: www. starceramicsbd.com Sun Power Ceramics Co. Ltd. House-9, Shayesta Khan Avenue, Sector # 4, Uttara , Dhaka-1230, Phone : 88-02-58957030, 01713060791-3 X Ceramics Ltd. Building 34, Road-12, Block-K, Baridhara Diplomatic Zone Dhaka-1212 Phone : 02-9882852, 8827141, 8826853 Star Particle Board Mills Ltd. Shanta Westem Tower, Level-13, Bir Uttam Mir Shawkat Road 186, Tejgaon Industrial Area, Dhaka-1208 Phone: 02-8878800 Super Board Mills Ltd. TK Bhaban. 2nd Floor, 13 Kawran Bazar, Dhaka. Phone-+8802-9144136 Dhaka Thai Ltd. House # 4 (2nd floor), Road 14, Baridhara Dhaka Phone : 02-9882666, 8818745, Mobile:01819221163 Bangladesh Thai Aluminium BTA Tower (12-14 floor), 29 Kamal Ataturk Avenue, Road No-17, Banani C/A, Dhaka Phone: 02-9882111, 9883337 Nikki Thai Aluminium Ind. Ltd. House #7B Levle #5, Road # 13, Gulshan-1, Dhaka Phone: 02-9884125, 9863283, 9863319.