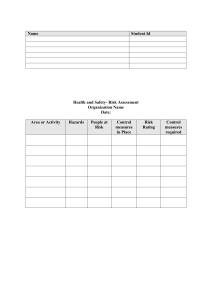

Day 3 Class 1 SY 2019-2020 Day 3 Class 1 Section 3.1.0 – Struck-by hazards Section 3.1.1 – Falling Objects Always wear an approved hard hat at all times Use tool lanyards when working at height. When working near machinery and equipment such as cranes, NEVER stand beneath or work in the fall zone When performing overhead work Use protective measures such as toe boards, debris nets, catch platforms, or canopies Do not stack materials higher than 4:1 height-to-base ratio. Section 3.1.2 – Flying Objects • Use eye and face protection. • Ensure that protective guards are in place and in good condition. • Make sure you are trained in the proper operation of pneumatic and powderactuated tools. • Use shielding to block flying debris. Section 3.1.3 – Vehicle Hazards • Stay alert at all times. • Maintain eye contact with vehicle or equipment operators. • Never get into the blind spots of equipment operators. • Keep off of mobile equipment unless authorized. • Wear reflective or high-visibility vests or other suitable garments. • Never stand between pieces of equipment unless they are secured. Section 3.2.0 – Caught-in and caught-between hazards Four (4) Causes Caught-in and caught-between hazards: 1. Trench collapse 2. Excavation collapse 3. Rotating equipment 4. Unguarded parts Section 3.2.1 – Trenches and excavation To be safe, treat soil as if it Type C soil, a competent person must inspect excavations daily and decide whether cave-ins or failures of protective systems could occur,benching system cannot be used Type C soil. WARNING! Just 2 to 3 feet (0.6 to 1 m) of soil can put enough pressure on your lungs to prevent you from breathing. Each year in the US, more than 100 people are killed and many more are seriously injured in cave-in incidents. The chances of a trapped worker being killed can be as high as 50%. Section 3.2.2 – Guards These tools and machines must have guards: Grinding tools Rolling machines Shearing tools Tools or machines with pin points Presses Tools or machines with sharp Punches Cutting tools edges CARE OF TOOL AND MACHINE GUARDS • Do not remove a guard from a tool or machine except for cleaning purposes, changing a blade, or performing other service. • Make sure the machine is turned off and tagged out during servicing. • When cleaning or maintenance is finished, replace the guard immediately. • Do not use any material to wedge a guard open. • Only use attachments that are specifically designed for that tool or machine. Section 3.2.3 – Crushing Hazards Any type of moving heavy equipment can trap and crush a worker in the wrong place. Name: ___________________________________ Date: ____________ Mark:______ Quiz No. _____ Caught-in and Caught-between Hazards A. List down the 4 causes of caught-in and caught-between hazards. 1. _______________________________ 3. _______________________________ 2. _______________________________ 4. _______________________________ B. List down the 4 names of soils you will see in your work. 1. _______________________________ 3. _______________________________ 2. _______________________________ 4. _______________________________ 5. In section 3.2.1, who will inspect the excavations daily? _____________________________________________ C. Write down three (3) tolls that need a machine guard. 1._________________________ 2._____________________3. ____________________ D. Write down one (1) rule in the caring of tool and guard. __________________________________________________________________________ __________________________________________________________________________ E. YES or NO? ___________You will replace the guard 2 hours after maintenance.