Ferrofluid Droplet Evaporation Under Magnetic Field

advertisement

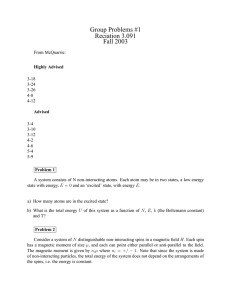

Fundamental Research 2 (2022) 222–229 Contents lists available at ScienceDirect Fundamental Research journal homepage: http://www.keaipublishing.com/en/journals/fundamental-research/ Article Evaporation and drying characteristics of the sessile ferrofluid droplet under a horizontal magnetic field Zhaonan Liu, Jiandong Zhou, Yang Li, Xin Zhuo, Xiujuan Shi, Dengwei Jing∗ State Key Laboratory of Multiphase Flow in Power Engineering and International Research Center for Renewable Energy, Xi’an Jiaotong University, Xi’an 710049, China a r t i c l e i n f o Article history: Received 23 April 2021 Received in revised form 12 July 2021 Accepted 12 August 2021 Available online 23 September 2021 Keywords: Ferrofluid Droplet Drying pattern Evaporation characteristics Magnetic field a b s t r a c t In this study, the evaporation characteristics and drying patterns of various sessile ferrofluid droplets on certain substrate under horizontal magnetic fields of controlled intensities are reported. The effects of droplet concentration and magnetic field intensity on the duration of each evaporation stage and drying patterns of droplets have been systematically investigated. It turned out that a plateau appears at the initial stage of evaporation in the absence of magnetic field and it was found that the plateau value is positively correlated with the concentration of ferrofluid droplets. Under the external magnetic field, the evaporation time of droplets decreases, the stage of contact line retreat extends, the stage of late pinning mode shortens, and the deposition area of ferrofluid droplet decreases compared to that of without magnetics field. The deposition area increases gradually and becomes more uniform with the increase of magnetic field. The decrease of friction force which is due to the decrease of the number of nanoparticles at the contact line under external magnetic field is the main reason for the observed phenomena. We found that the coffee ring and the uniform deposition inside the droplet will be destroyed when the magnetic field intensity is higher than a critical value. Our work has a significant reference value for the evaporation of sessile magnetic fluid droplets under the applied magnetic field, especially when the drying pattern needs to be precisely controlled, such as in spray or biomedicine. 1. Introduction Droplet evaporation has attracted much attention because of its wide industrial applications (e.g., drug delivery, coating technology, inkjet printing, and electronic cooling) [1–4]. The coffee ring effect can be attributed to the evaporation of nanoparticles deposited near the threephase contact line. Different particles in droplets cause different evaporation characteristics and drying patterns on various substrates, which in turn affects the formation of the coffee ring [5]. Barber et al. reported that the evaporation of sessile nanoparticle droplets on a solid substrate is crucial in cooling and two-phase heat transfer [6]. Chon et al. reported the size effect of Au, CuO, and Al2 O3 nanoparticles on droplet evaporation and drying characteristics. They found that the particle size considerably affected the drying characteristics when the heating temperature effect was negligible [3]. Focusing on the evaporation process, Crivoi and Duan experimentally investigated the evaporation-induced branching structure of water-based sessile copper nanofluid droplets [7]. Parsa et al. studied the effect of different substrate temperatures on CuO nanoparticle deposition patterns after complete evaporation [8]. Shin et al. focused on the local aggregation characteristics of Al2 O3 particles during the evaporation process on a hydrophilic glass surface and pro- ∗ posed that the local aggregation effect should be considered to predict the effective thermal conductivity and total evaporation time [9]. Among various nanoparticle-containing liquids, magnetic nanofluids are suspensions comprising nonmagnetic basic fluids and magnetic nanoparticles, which are also known as ferrofluids [5]. Ferrofluid is different from other nanofluids because its physical properties, fluid flow, particle motion, and heat transfer process can be controlled by an external magnetic field [10–13]. Without a magnetic field, nanoparticles in a ferrofluid are subject to random Brownian motion similar to nonmagnetic nanoparticles [14–16]. However, the nanoparticles will be aligned along the direction in which the external magnetic field is applied, showing a magnetic response for conciseness [17]. Owing to the aforementioned characteristic, ferrofluids have been employed in many fields, including mechanics, optics, biology, and digital electronics [17–25]. The possibility of using an external magnetic field to control droplet evaporation characteristics and drying patterns facilitate promising applications, including ferrofluid films, biosensors, and pattern corrections [26–29]. Lee et al. illustrated the change in aspect ratio and contact angle of ferrofluid droplets under a uniform external magnetic field [30]. Saroj and Panigrahi investigated the evaporation kinetics, deposition pattern, magnetic field effect, and mechanism of nailing or debonding of ferrofluid droplets on a polydimethylsiloxane (PDMS) substrate, and Corresponding author. E-mail address: dwjing@mail.xjtu.edu.cn (D. Jing). https://doi.org/10.1016/j.fmre.2021.08.016 2667-3258/© 2021 The Authors. Publishing Services by Elsevier B.V. on behalf of KeAi Communications Co. Ltd. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/) Z. Liu, J. Zhou, Y. Li et al. Fundamental Research 2 (2022) 222–229 Table 1 Physical properties of ferrofluid droplets with different nanoparticle concentrations. provided Eq. 1 [31]. The effects of magnetic field intensity, magnetic orientation on the droplet center, and duration of different evaporation modes, were also studied [32]. Lee et al. used a magnetic field to program the assembly of nonmagnetic particles in a sessile droplet to allow the preparation of complex drying patterns and functional surface coatings [33]. Guba et al. measured the contact angle of ferromagnetic fluid on different substrates under a uniform magnetic field, which decreased with the increase in magnetic field intensity and nanofluid concentration [34]. Jaiswal et al. studied the evaporation kinetics of paramagnetic suspension droplets under a magnetic field and considered that the advection of the magnetic solute is the main factor of evaporation enhancement [35]. Fattah et al. provided a scheme for printing threedimensional patterns in polymers using ferrofluid droplets [36]. Furthermore, the possibility of remote, wireless, and programmable droplets driven using a magnetic field have been investigated [37]. Thus far, only a few scholars have studied the evaporation of ferrofluids under a horizontal magnetic field. Havard et al. reported the breakup of suspended ferrofluid droplets under a horizontal magnetic field and discussed the evolution of droplet shapes [38]. Shyam et al. experimentally studied the evaporation kinetics of sessile ferrofluid droplets on a soft substrate under an alternating magnetic field and found the critical frequency for the shortest drying time [39]. Jadav et al. studied the effect of a static magnetic field on the evaporation of ferrofluid droplets on a glass substrate, indicating that the thickness of the coffee ring is related to the intensity of the vertical magnetic field [40]. Chattopadhyay et al. investigated the modulation effect of a horizontal magnetic field on the evaporation of suspended ferrofluid droplets, explaining why magnetic fields can accelerate droplet evaporation [41]. Lama et al. reported the effect of horizontal magnetic field intensity on the crack morphology and direction in the coffee ring after drying sessile ferrofluid droplets, which allowed the possibility of adjusting the crack structure [42]. Existing studies indicate the increasing attention on investigating ferrofluid droplet evaporation under a magnetic field. Nonetheless, the effects of different horizontal magnetic field intensities on the evaporation characteristics and drying patterns of ferrofluid droplets and their internal mechanism are far from being well understood. The present work reports the evaporation characteristics and drying patterns of ferrofluid droplets on a substrate and under a horizontal magnetic field. The primary purpose of this study is to understand the influence of droplet concentration and horizontal magnetic field intensity on different evaporation process modes, particularly the influence on contact line retreat and pinning. An interesting change in the drying pattern, after droplets are completely evaporated, is reported. This work has important reference value for the evaporation of droplets under an external magnetic field, particularly for applications in sprays or biomedicine. Concentration (wt%) Surface tension (mN/m) Initial contact angle (°) Viscosity (mPa•s) 0 0.01 0.05 0.10 71.99 65.44 62.96 60.26 111.07 ± 0.10 114.19 ± 0.42 111.58 ± 1.80 108.22 ± 1.58 0.98 0.97 0.97 0.98 Fig. 1. Schematic illustration of the experimental setup. factant. The zeta potential and nanoparticle diameter distribution were measured using a Zetasizer Nano-ZS90. The results showed that the zeta potential of the 0.01, 0.05, and 0.10 wt% ferrofluid droplets were 42.5, 41.6, and 40.6 mV (absolute value), respectively, indicating that the nanoparticles were well dispersed. The average diameter of the nanoparticles in the suspensions with nanoparticle concentrations of 0.01, 0.05, and 0.10 wt% were 423.4, 377.0, and 329.4 nm, respectively. This indicates that nanoparticles can be well dispersed with surfactants, although a certain degree of local aggregation and deposition occurs with time. 2.2. Surface preparation The PDMS substrate used in our experiments was prepared via a mixing method. First, a silicone elastomer (Sylgard 184) and curing agent were mixed in the ratio of 10:1. The mixture was then degassed in a vacuum chamber until the bubbles were removed from the mixture. Next, the mixture was spun on glass at 3500 rpm for 60 s. Finally, the substrate was heated at 80 °C for 12 h [39]. The physical properties of ferrofluid on a PDMS substrate with different nanoparticle concentrations were tested and are listed in Table 1. 2. Materials and methods 2.3. Experimental setup 2.1. Preparation and characterization of ferrofluids A cubic NdFeB N35 permanent magnet (50 mm × 50 mm × 3 mm) was used to apply a horizontal magnetic field at both ends of the droplets. To ensure that the magnetic field is uniform, the length of the permanent magnet is chosen such that it is much larger than the initial diameter of the droplets. The magnetic field intensity was changed by increasing the number of magnets in the range of 0–200 mT. A Gauss meter (SJ700) was used to measure the magnetic field, B, applied on the droplets. Fig. 1 shows the general arrangement of the experimental setup. Theta Lite (Biolin Scientific) and software (OneAttention) were used to measure the droplet properties. The main components of the setup are a needle, USB 3.0 digital camera, and light-emitting diode (LED)-based background lighting (Ø 20 mm). The needle has a disposable dispensing tip to precisely control droplets without the need for cleaning. The droplet was deposited onto a certain position of the PDMS substrate, which was fixed in the middle of the two magnets. For all experiments, the volume of the droplet was fixed to 5 𝜇L. Ferrofluid was prepared via a two-step method. Magnetite (Fe3 O4 ) nanoparticles with a diameter of approximately 20 nm were obtained from Aladdin (China). Sodium oleate (SO) and polyethylene glycol (PEG-4000) surfactants were used to stabilize the dispersion of nanoparticles [5]. The three nanofluid concentrations prepared were as follows: 0.01, 0.05, and 0.10 wt%. The Fe3 O4 nanoparticles were initially suspended in deionized water for 30 min. Next, the pH of the solution was adjusted to 8 by adding a small amount of NaOH and the solution was then placed in a water bath at 80 °C. The first surfactant, SO, with a surfactant-to-nanoparticle weight ratio of 5:1, was added to the suspension, followed by further stirring for 60 min. Afterward, the solution was placed in a water bath at 40 °C and the second surfactant (PEG-4000), with a surfactant-to-nanoparticle weight ratio of 5:1, was added. This was followed by stirring for another 30 min. After the aforementioned steps, a stable aqueous suspension was obtained in which the nanoparticles were coated with two layers of sur223 Z. Liu, J. Zhou, Y. Li et al. Fundamental Research 2 (2022) 222–229 Fig. 2. Schematic illustration of different evaporation stages, constant contact radius (CCR) mode, constant contact angle (CCA), mixed and late pinning modes. Fig. 3. The instantaneous images for 0.01wt%, 0.05wt% and 0.10wt% ferrofluid droplets evaporation under 0mT and 80mT magnetic fields. During the droplet placement process, a sessile drop method was adopted and a micromotion platform was used to slowly bring the suspended droplets in contact with the substrate to avoid error. The OneAttention software of the system is able to analyze droplet shape in real time and measure parameters like contact angle and contact line diameter. Because of the combined influence of measurement and image analysis errors, uncertainty exists in the measurement of the droplet diameter and contact angle. To eliminate the influence of uncertainty, the automatic drop distributor was equipped with a Theta Lite instrument to ensure that the drop volume is 5 𝜇L and the droplet diameter and contact angle are dimensionless. Moreover, each experiment was repeated three to six times to ensure repeatability. The maximum uncertainty involved in each measurement did not exceed 2%. 3. Results and discussion The evaporation of droplets on the substrate can be divided into four modes, i.e., constant contact radius (CCR), constant contact angle (CCA), mixed, and late pinning modes. Among these modes, contact line retreat stage includes CCA and mixed modes. Fig. 2 shows a schematic of the different modes of evaporation. In the CCR mode, the contact line of the droplet remains unchanged but the contact angle decreases [39]. With the spontaneous decrease in contact angle, when the depinning force is greater than the pinning barrier, the CCR mode changes to the CCA mode. In the CCA mode, the contact angle of the droplet remains unchanged but the contact line retreats [43]. Sometimes the mixed mode will be formed, and the contact angle and contact line diameter will reduce simultaneously. In the late pinning mode, nanoparticles move to the contact line, causing the formation of a coffee ring. As the first step of our study, the evaporation characteristics and drying pattern under an external magnetic field were investigated for droplets of different nanoparticle concentrations. The temperature was around 21 ± 2 °C and the relative humidity was 19 ± 2%. D is defined as the diameter of the contact line between the droplet and PDMS substrate (illustrated in Fig. 2). The evaporation process was recorded using the Theta Lite and the evaporation characteristics were analyzed based on side views of the droplet. The droplet evaporation is considered to be complete when the contact angle reduces to 0° and remains unchanged for 3 min. t0 is the time point when the droplet profile becomes stable. Particularly, the evaporation characteristics of droplets under a horizontal magnetic field have been tested, including dimensionless contact angle and contact line. In addition, the drying pattern of droplets was explored. In the following section, we will first show our results for ferrofluid droplets with different nanoparticle concentrations under a certain magnetic field (B = 80 mT, as a typical example) and, as a comparison, the counterpart cases without a magnetic field (B = 0 mT). Then, experimental results for ferrofluid droplets with a certain nanoparticle concentration and under different magnetic field intensities will be shown. Fig. 4. The initial contact angle and total evaporation time of 0.01wt%, 0.05wt% and 0.10wt% ferrofluid droplets evaporation under 0mT and 80mT magnetic fields. 3.1. Ferrofluid droplets with different nanoparticle concentrations 3.1.1. Evaporation characteristics The evaporation characteristics on the PDMS substrate for 5 𝜇L sessile ferrofluid droplets with 0.01, 0.05, and 0.10 wt% nanoparticle concentrations were initially studied. The side view of the droplets was recorded every 1 min to study the evaporation characteristics of the droplets. Fig. 3 shows a side view of the droplets with various nanoparticle concentrations without a magnetic field (0 mT) and under a horizontal magnetic field of 80 mT. The instantaneous images provide the evaporation characteristics of the ferrofluid droplets as a function of concentration and magnetic field intensity, supporting our argument that the contact angle and change in contact line are affected by the concentration and magnetic field strength. Fig. 4 shows the initial contact angle and total evaporation time for droplets with different nanoparticle concentrations both in the absence and presence of a magnetic field. The initial contact angle of the droplet decreases with the increase in the nanoparticle concentration both without an external magnetic field and with an external magnetic field of 80 mT; the difference is negligible. In particular, the total evaporation time decreased considerably for the 0.10 wt% ferrofluid droplet. Repeated experiments show that the increase in contact angle does not depend on the presence or absence of a magnetic field. Based on the side view images, the change in contact angle and contact line with time can be derived, as shown in Fig. 5. Here, we use the 224 Z. Liu, J. Zhou, Y. Li et al. Fundamental Research 2 (2022) 222–229 Table 2 Estimation of the proportion of different evaporation modes for various ferrofluid droplets under 0 and 80 mT magnetic fields. Magnetic field intensity (mT) Concentration (wt%) CCR CCA Mixed Late pinning 0 0.01 0.05 0.10 0.01 0.05 0.10 64% 45% 41% 49% 42% 30% 0% 0% 22% 0% 24% 34% 8% 13% 6% 18% 0% 12% 28% 42% 31% 33% 34% 24% 80 Fig. 5. Relations between the dimensionless contact angle (𝜽∗ ) and contact line diameter (D∗ ) for droplets of different nanoparticle concentrations with dimensionless evaporation time in the absence (B=0mT) and presence (B=80mT) of magnetic field, respectively. Fig. 6. The drying pattern of 0.01wt%, 0.05wt% and 0.10wt% ferrofluid droplets evaporation under 0mT and 80mT magnetic fields, taken at (a) 2332s, (b) 2462s, (c) 2073s, (d) 2526s, (e) 2462s and (f) 2138s after the ferrofluid droplets evaporating. dimensionless contact angle, contact line, and evaporation time of the droplet to obtain a more reasonable comparison, which are 𝜃 ∗ = 𝜃/𝜃 0 , D∗ = D/D0 , and t∗ = t/t0 , respectively, where 𝜃 0 , D0 , and t0 are the initial contact angle, contact line diameter of the droplet, and the total evaporation time of the droplet, respectively. Fig. 5a, b shows the changes in contact angle and contact line diameter of ferrofluid droplets with different nanoparticle concentrations in the absence of magnetic field with time, respectively. The nanoparticle concentration considerably affects the duration of each evaporation mode of the liquid droplet, including CCR, CCA, mixed, and late pinning modes. The changes in contact angle and contact line for the liquid droplets during evaporation in the presence of magnetic field are shown in Fig. 5c and d, respectively. The duration of each evaporation mode of the liquid droplet is closely related to the application of the magnetic field. Moreover, Fig. 5b, d shows that the dimensionless contact line diameter of the droplet (D∗ ) of the 0.10 wt% ferrofluid droplet is considerably smaller than those of the 0.01 and 0.05 wt% ferrofluid droplets whether in the absence or presence of the magnetic field. This result is different from a previous report [31], which is possibly because of the small nanoparticle concentrations selected in this study. It is worth noting that, both for the cases in the absence and presence of the magnetic fields, D∗ increases with dimensionless evaporation time (t∗ ) in the initial stage and then reaches a plateau. After reaching the plateau, D∗ begins to retreat with the CCA and mixed modes as it gradually decreases. In particular, when D∗ reaches the plateau value, the t∗ of 0.01, 0.05, and 0.10 wt% ferrofluid droplets in the absence and presence of the magnetic fields are 0.056, 0.079, and 0.094 and 0.026, 0.053, and 0.091, respectively. Similar phenomena have been observed by Shyam et al. and is called decreasing contact angle and variable radius (DCVR) mode [39]. The authors attributed the phenomena to the interplay between the forcing factors under magnetic field modulation, particularly when the applied magnetic force is greater than the combined strength of depinning and pinning forces. However, this phenomenon also appeared in our study in the absence of the magnetic field. The increase in D∗ at the initial stage in the absence of the magnetic field is clearly an interesting issue needing further investigation. The preliminary assumptions are as follows. When the droplet is placed on the substrate, several nanoparticles are deposited near the contact line and the surfactants are wrapped around the nanoparticles, which may cause higher surfactant concentration near the contact line. The droplet will further spread and wet in a short time. In fact, the plateau value of D∗ for the 0.01, 0.05, and 0.10 wt% ferrofluid droplets are 1.004, 1.014, and 1.024, respectively, in the absence of the magnetic field, as shown in Fig. 5b, and 1.003, 1.014, and 1.018, respectively, in the presence of the magnetic field, as shown in Fig. 5d. The plateau value of D∗ increases with increase in concentration, which partially supports our assumption. In summary, with the increase in nanoparticle concentration, there are more particles near the contact line and the effect of surfactants is more substantial, which likely results in the plateau value of D∗ at the initial stage of evaporation. The duration of each evaporation mode is different for droplets with different nanoparticle concentrations. Table 2 summarizes the proportion of different modes of droplets with different nanoparticle concentrations for the entire evaporation time, both in the absence and presence of a magnetic field based on Fig. 5. Taking the 0.01 wt% ferrofluid droplet without a magnetic field as an example, by estimation, the CCR mode accounts for ca. 64% of the total evaporation time. The two modes of contact line retreat, including CCA and mixed modes, account for ca. 8%, and the late pinning mode accounts for ca. 28%. As shown in Table 2, with the increase in droplet nanoparticle concentration, the proportion of the CCR mode gradually decreases and the proportion of contact line retreat (CCA and mixed modes) increases. 3.1.2. Drying pattern In this section, the droplet drying pattern characteristics with different nanoparticle concentrations in the absence and presence of magnetic fields are discussed. Fig. 6 shows the microscopic image of the dried droplet. The evaporation time of the 0.01, 0.05, and 0.10 wt% ferrofluid droplets in the absence of a magnetic field are 2332, 2462, and 2073 s, respectively. In the presence of a magnetic field, those values change to 2526, 2462, and 2138 s, respectively. A coffee ring can be observed for the 0.05 and 0.10 wt% ferrofluid droplets but is not prominent for the 0.01 wt% ferrofluid droplet. Compared with the drying pattern of 225 Z. Liu, J. Zhou, Y. Li et al. Fundamental Research 2 (2022) 222–229 Fig. 7. Gray values for droplet drying patterns along the diameter (x1 -x2 ) under (a) 0mT and (b) 80mT magnetic field, respectively. ferrofluid droplets in the absence of a magnetic field, the internal deposition pattern of the ferrofluid droplets changes in the presence of a magnetic field. The gray value indicates the density of particles deposited in a drying droplet. The brighter regime corresponds to a larger gray value, which indicates a lower particle density [32]. Accordingly, we collected gray values along the diameter (x1 − x2 ) of the drying pattern passing through the midpoint of the drying pattern along the vertical direction, as shown in Fig. 6, to obtain Fig. 7. The gray value of the drying pattern of 0.05 and 0.10 wt% ferrofluid droplets decreased sharply at the edge of the contact line and increased at the center of the droplet, as shown in Fig. 7a. This confirmed the formation of the coffee ring. The ferrofluid droplets both without and with magnetic fields show similar gray value trends with varying x value, undergoing a sharp decrease at first and then an increase. However, the amplitude and frequency of the gray value for the 0.05 wt% ferrofluid droplet under a magnetic field in Fig. 7b are considerably larger than those of the drying pattern of the 0.05 wt% ferrofluid droplet without a magnetic field (Fig. 7a). This indicates that chain-shaped precipitates could have formed in the presence of the magnetic field and partially replaced the coffee ring. The increased nanoparticle deposition for the 0.10 wt% ferrofluid droplet on the right hand side of Fig. 7b may be attributed to the “stick–slip” mode [43]. Moreover, the drying pattern of the 0.05 wt% ferrofluid droplet is symmetrical and orderly. We are thus more likely to observe the entire ferrofluid evolution under different magnetic field intensities using this nanoparticle concentration. Therefore, the 0.05 wt% ferrofluid droplet was chosen for this study under different magnetic fields in the next section. Fig. 8. Instantaneous images for 0.05wt% ferrofluid droplets evaporation under 0mT, 48mT, 80mT, 108mT and 128mT magnetic fields. 3.2. Ferrofluid droplets under different magnetic fields 3.2.1. Evaporation characteristics The evaporation characteristics of 5 𝜇L of ferrofluid sessile droplets with 0.05 wt% nanoparticle concentration on a PDMS substrate under 0, 48, 80, 108, and 128 mT magnetic fields were studied first. We recorded a side view of the droplets every 1 min. Fig. 8 shows the side view of droplets under various magnetic fields and at different t∗ . These instantaneous images provide evaporation characteristics of the droplets under different magnetic fields. Both the contact angle and contact line diameter of ferrofluid droplets are different at the same t∗ , which can be obviously related to the magnetic field strength. The initial contact angle and total evaporation time of the droplet under different magnetic fields are shown in Fig. 9. With the increase in magnetic field intensity, the initial contact angle of the droplet does not change and the total evaporation time decreases. According to the side view of the droplets in Fig. 8, the change in 𝜃 ∗ and D∗ with time for 0.05 wt% ferrofluid droplets under different magnetic fields can be obtained as shown in Fig. 10. Fig. 10a, b shows that 𝜃 ∗ and D∗ differ under different magnetic fields for the same t∗ . Clearly, the magnetic field intensity is a key parameter affecting the duration Fig. 9. Initial contact angle and total evaporation time for 0.05wt% ferrofluid droplet under different magnetic fields. of each evaporation mode of the droplets, which is listed in Table 3. Under different magnetic field intensities, D∗ increases and reaches a plateau value at the initial stage, which then changes to the droplet retreat mode. This is the same as the phenomena observed in the previous section. The t∗ under magnetic fields of 0, 48, 80, 108, and 128 mT are 0.079, 0.081, 0.079, 0.083, and 0.089, respectively, when D∗ reaches the plateau value. However, the plateau values of D∗ of droplets under these magnetic fields are 1.014, 1.013, 1.014, 1.015, and 1.009, respec226 Z. Liu, J. Zhou, Y. Li et al. Fundamental Research 2 (2022) 222–229 Table 3 Estimation of the proportion of different evaporation modes for 0.05 wt% ferrofluid droplets under different magnetic fields. Magnetic field intensity (mT) CCR CCA Mixed Late pinning 0 48 80 108 128 45% 41% 42% 39% 41% 0% 27% 24% 19% 0% 13% 5% 0% 0% 18% 42% 27% 34% 42% 41% Fig. 11. Drying patterns of 0.05wt% ferrofluid droplets under different magnetic fields taken at (a) 2462s, (b) 2397s, (c) 2462s, (d) 2332s and (e) 2202s after the ferrofluid droplets evaporation. annular sediment forms at either edge of the drying pattern, that is, this sediment was not fixed on the left or right side of the drying pattern. To analyze the particle deposition in detail and confirm the formation of chain precipitation, we measured the gray values of the drying pattern diameter (x1 − x2 ) in Fig. 11. The results are summarized in Fig. 12. In Fig. 12a, the gray values fluctuated more significantly for the drying pattern under 108 mT magnetic field than those under 0 mT magnetic field. This confirms that the deposition mode of the droplet changes after the application of a 108 mT magnetic field. The high-fluctuation frequency of the gray value of the drying pattern at 108 mT indicates that with the increase in x, the density of particle deposition repeatedly fluctuates between high and low values and chain precipitation is confirmed. When the magnetic field is 128 mT, the gray value image of the drying pattern is obviously different from those under 0 and 108 mT magnetic fields. With the increase in x, the formation of a thick coffee ring is determined by the sharp decrease in gray value. However, the high-fluctuation frequency of the gray value with further increase in x confirms the formation of chain precipitation. Tentatively, a magnetic field intensity of 128 mT appears to be a critical value. The underlying mechanism for this value deserves further in-depth investigation. Fig. 12b shows that the fluctuation range of the gray value of the drying pattern decreases gradually with the increase in magnetic field strength from 48 to 108 mT. This indicates that the deposition concentration of each chain precipitation becomes similar under the same magnetic field. That is to say, with the increase in magnetic field strength, the distribution of nanoparticles becomes uniform. Fig. 10. Values of (a) the dimensionless contact angle (𝜽∗ ) and (b) contact line diameter (D∗ ) for 0.05wt% ferrofluid droplets under different horizontal magnetic fields. tively, indicating no apparent relationship between the plateau value of D∗ and the magnetic field strength. In addition, the overall drying diameter of the droplets is the largest in the absence of a magnetic field and is the smallest when the magnetic field is 48 mT, as shown in Fig. 10b. Table 3 summarizes the proportion of different evaporation modes under different magnetic fields. With the increase in magnetic field, the proportion of CCR and mixed modes first decreases and then increases. In particular, the CCR mode decreases from ca.45% to ca.39% and then increases to ca.41%. The mixed mode decreases from ca.13% to ca.0% and then increases to ca.18%. However, the proportion of CCA and late pinning modes changed considerably after the application of external magnetic field. CCA mode increases from ca.0% to ca.27% after adding 48 mT magnetic field and then decreases to ca.0% when the magnetic field intensity was increased to a critical value (128 mT). The mode for the late pinning mode decreases from ca.42% to ca.27% after adding 48 mT magnetic field and increases to ca.41% when the magnetic field intensity was increased to 128 mT. The two modes of contact line retreat (CCA and mixed modes) accounted for ca.13%, 32%, 24%, 19%, and 18%, respectively. The overall trend also increased considerably after adding the magnetic field, and decreased to ca.18% when the magnetic field intensity was increased to 128 mT. The phenomenon is likely caused by the combined action of surface tension, frictional resistance, and magnetic force. The specific mechanism will be discussed in the next section. 3.3. Mechanism discussion Our study shows that the nanoparticle concentration and horizontal magnetic field intensity have considerable influence on the evaporation characteristics and drying pattern formation in ferrofluid droplets. The D∗ for different nanoparticle concentrations of ferrofluid droplets reaches a plateau value in the initial stage of evaporation and the plateau value is positively correlated to the ferrofluid droplet concentration. Fig. 13a is a schematic of nanoparticles coated with surfactants on the contact line. We believe that the mechanism causing the increase in the plateau value of D∗ with droplet concentration in the initial stage is that the contact angle and contact line of the ferrofluid droplets are related to the concentration of surfactants on the contact line. The surfactants near the contact line will increase with the increase in concentration of nanoparticles wrapped with surfactants. Fig. 14 shows the movement of Fe3 O4 nanoparticles with different concentrations near the contact line at 0 and 300 s after evaporation. With the evaporation of droplets, the number of nanoparticles near the contact line increases and the number of nanoparticles near the three-phase contact line of high-concentration 3.2.2. Drying pattern The following subparts of Fig. 11a-e shows the drying patterns obtained during the aforementioned times. We assumed that, around the final time, the ferrofluid droplet evaporation was complete. Compared with that without a magnetic field, nanoparticle deposition under the magnetic fields is more uniform. With increasing magnetic field, the nanoparticle distribution becomes much more uniform, as shown in Fig. 11b–d. Under a 108 mT magnetic field, the nanoparticles are almost uniformly distributed along the direction of the magnetic field, forming the chain-shaped deposition shown in Fig. 11d. It is worth noting that the coffee ring and the uniform deposition inside the droplets are destroyed when the magnetic field intensity increases to 128 mT. Half of the deposition in this case is annular and the other half is a long chain, as shown in Fig. 11e. Moreover, comparing Figs. 6f and11e, the 227 Z. Liu, J. Zhou, Y. Li et al. Fundamental Research 2 (2022) 222–229 Fig. 12. Gray values for drying patterns of 0.05wt% ferrofluid droplets along the diameter (x1 -x2 ) under different magnetic fields. Panigrahi [31]: 𝐹0 = 𝐹𝑣𝑝𝑠 + 𝐹𝑒𝑝𝑠 + 𝐹𝑔 , (1) where Fvps is the Van der Waals force, Feps is the electrostatic force, and Fg is the gravitational force. The equilibrium equation of the force is as follows: 𝐹𝑠 cos𝜃 = 𝐹𝑓 + 𝐹𝑀 . Fig. 13. Schematics of (a) nanoparticles coated by surfactant at contact line and (b) forces on nanoparticles at droplet contact line under horizontal magnetic field. (2) Eq. 2 shows that the greater the number of particles on the contact line, the larger the frictional resistance of the substrate and, correspondingly, the droplets can be more easily pinned. Similarly, the stronger the magnetic field, the greater the magnetic force on the particles, and the droplets can be more easily pinned. Under the external magnetic field, the particles tend to be arranged along the direction of the magnetic field to form a chain and single small particles will be dragged to the contact line with water. This means that when the number of particles, N, on the contact line decreases, Ff decreases and the droplet is less likely to be pinned. Therefore, the two modes of contact line retreat increase prominently and the pinning diameter decreases after adding the magnetic field. Subsequently, with the increase in the magnetic field intensity, the particles tend to migrate to the magnet and arrange themselves into chains, increasing the contact line area and inhibiting the contact line retreat. This results in the early pinning of the contact line and increase in the pinning diameter. Furthermore, early pinning increases droplet specific surface area, increasing the evaporation rate and reducing the evaporation time. 4. Conclusion This study reports the evaporation characteristics and drying patterns of ferrofluid droplets on a PDMS substrate both in the absence and presence of various magnetic field intensities. Our work investigates the effects of nanoparticle concentrations and horizontal magnetic field intensity on the evaporation process, including contact angle, contact line diameter, and drying pattern, of sessile ferrofluid droplets to have a deeper understanding of the underlying mechanism. This study complements the evaporation characteristics and drying patterns of ferrofluid droplets and demonstrates that, in practical applications, a horizontal magnetic field and magnetic nanoparticle properties can be used to precisely control the deposition pattern of droplets. The main conclusions of this study are as follows. 1. With the increase in concentration or magnetic field intensity, the evaporation time of droplets decreases. The increase in concentration causes an increase in the proportion of duration of the contact line retreat and a decrease in the droplet pinning diameter. A plateau appears at the initial stage of evaporation in the absence of a magnetic field, and the plateau value was found to be positively correlated with the nanoparticle concentration of ferrofluid droplets. Fig. 14. Fe3 O4 distribution near the three-phase contact line for droplets of various concentrations (a) 0.01wt%, (b) 0.05wt%, (c) 0.10wt% at the beginning of evaporation and (d) 0.01wt%, (e) 0.05wt%, (f) 0.10wt% after 300s of evaporation. droplets is considerably more than that of low-concentration droplets. This phenomenon supports our hypothesis. The evaporation characteristics and drying patterns of the ferrofluid droplets are closely related to the application of the magnetic field and intensity of the external magnetic field. The late pinning mode is mainly affected by the surface tension and frictional resistance of the substrate [31]. Additionally, late pinning mode is closely related to the magnetic force under a horizontal magnetic field. Fig. 13b is a schematic of the forces acting upon a particle on the contact line. In Fig. 13, FS is the surface tension, FM is the applied magnetic force, and Ff is the frictional force, which is proportional to the number of particles (N) and the sum of the forces (F0 ). F0 is given by Saroj and 228 Z. Liu, J. Zhou, Y. Li et al. Fundamental Research 2 (2022) 222–229 2. Applying an external magnetic field will change the proportion of the four evaporation modes. The proportion of the contact line retreat stage and late pinning mode also changes with magnetic field intensity. The decrease in frictional force, which is attributed to the decrease in the number of nanoparticles at the contact line under a magnetic field, is the main reason for the observed phenomena. 3. Under the magnetic field, the deposition area of a ferrofluid droplet is reduced and the particles are aligned in chains and uniformly deposited. The deposition area increases gradually with the increasing magnetic field, and the deposition becomes more uniform. 4. We found that the coffee ring and uniform deposition inside the droplet with 0.05 wt% nanoparticle concentration are destroyed when the magnetic field intensity reaches a critical value of 128 mT. The underlying mechanism for this phenomenon needs further in-depth investigation. [21] D. Ferraro, Y. Lin, B. Teste, et al., Continuous chemical operations and modifications on magnetic gamma-Fe2 O3 nanoparticles confined in nanoliter droplets for the assembly of fluorescent and magnetic SiO2 @gamma-Fe2 O3 , Chem. Commun. 51 (2015) 16904–16907. [22] Y.N. Wu, T.T. Fu, Y.G. Ma, et al., Ferrofluid droplet formation and breakup dynamics in a microfluidic flow-focusing device, Soft Matter 9 (2013) 9792–9798. [23] S. Shyam, B. Mehta, P.K. Mondal, et al., Investigation into the thermo-hydrodynamics of ferrofluid flow under the influence of constant and alternating magnetic field by InfraRed thermography, Int. J. Heat Mass Transf. 135 (2019) 1233–1247. [24] G. Katsikis, J.S. Cybulski, M. Prakash, Synchronous universal droplet logic and control, Nat. Phys. 11 (2015) 588–596. [25] Y. Zhang, N.T. Nguyen, Magnetic digital microfluidics - a review, Lab Chip 17 (2017) 994–1008. [26] M. Stromberg, K. Gunnarsson, S. Valizadeh, et al., Aging phenomena in ferrofluids suitable for magnetic biosensor applications, J. Appl. Phys. 101 (2007) 023911. [27] S. Sen, Nanoprinting with nanoparticles: concept of a novel inkjet printer with possible applications in invisible tagging of objects, J. Dispers. Sci. Technol. 25 (2004) 523–528. [28] A. Poiata, D.E. Creanga, A. Airinei, et al., Magnetite nanoparticles for biosensor model based on bacteria fluorescence, J. Eur. Opt. Soc. Rapid 4 (2009) 09024. [29] Y.P. Bao, T.L. Wen, A.C.S. Samia, et al., Magnetic nanoparticles: material engineering and emerging applications in lithography and biomedicine, J. Mater. Sci. 51 (2016) 513–553. [30] C.P. Lee, S.T. Yang, Z.H. Wei, Field dependent shape variation of magnetic fluid droplets on magnetic dots, J. Magn. Magn. Mater. 324 (2012) 4133–4135. [31] S.K. Saroj, P.K. Panigrahi, Drying pattern and evaporation dynamics of sessile ferrofluid droplet on a PDMS substrate, Colloid Surf. A 580 (2019) 123672. [32] S.K. Saroj, P.K. Panigrahi, Magnetic suppression of the coffee ring effect, J. Magn. Magn. Mater. 513 (2020) 167199. [33] J.G. Lee, V. Porter, W.A. Shelton, et al., Magnetic field-driven convection for directed surface patterning of colloids, Langmuir 34 (2018) 15416–15424. [34] S. Guba, B. Horvath, I. Szalai, Examination of contact angles of magnetic fluid droplets on different surfaces in uniform magnetic field, J. Magn. Magn. Mater. 498 (2020) 166181. [35] V. Jaiswal, R.K. Dwivedi, A.R. Harikrishnan, et al., Magnetohydrodynamics- and magnetosolutal-transport-mediated evaporation dynamics in paramagnetic pendant droplets under field stimulus, Phys. Rev. E 98 (2018) 013109. [36] A.R.A. Fattah, S. Ghosh, I.K. Puri, Printing microstructures in a polymer matrix using a ferrofluid droplet, J. Magn. Magn. Mater. 401 (2016) 1054–1059. [37] A. Ray, V.B. Varma, Z.M. Wang, et al., Magnetic droplet merging by hybrid magnetic fields, IEEE Magn. Lett. 7 (2016) 1–5. [38] N. Havard, F. Risso, P. Tordjeman, Breakup of a pendant magnetic drop, Phys. Rev. E 88 (2013) 013014. [39] S. Shyam, P.K. Mondal, B. Mehta, Field driven evaporation kinetics of a sessile ferrofluid droplet on a soft substrate, Soft Matter 16 (2020) 6619–6632. [40] M. Jadav, R.J. Patel, R.V. Mehta, Influence of magnetic field on evaporation of a ferrofluid droplet, J. Appl. Phys. 122 (2017) 145302. [41] A. Chattopadhyay, R.K. Dwivedi, A.R. Harikrishnan, et al., Ferro-advection aided evaporation kinetics of ferrofluid droplets in magnetic field ambience, Phys. Fluids 32 (2020) 082001. [42] H. Lama, R. Mondal, M.G. Basavaraj, et al., Cracks in dried deposits of hematite ellipsoids: interplay between magnetic and hydrodynamic torques, J. Colloid Interface Sci. 510 (2018) 172–180. [43] D. Orejon, K. Sefiane, M.E.R. Shanahan, Stick-slip of evaporating droplets: substrate hydrophobicity and nanoparticle concentration, Langmuir 27 (2011) 12834–12843. Declaration of Competing Interest The authors declare that they have no conflicts of interest in this work. Acknowledgments The authors gratefully acknowledge the financial support of the National Natural Science Foundation of China (Grants No. 52025061 and 51961130386) and Royal Society-Newton Advanced Fellowship (Grant No. NAF/R1/191163). This work was also supported by the China Fundamental Research Funds for the Central Universities. References [1] H.Y. Erbil, Evaporation of pure liquid sessile and spherical suspended drops: a review, Adv. Colloid Interface Sci. 170 (2012) 67–86. [2] D. Brutin, B. Sobac, B. Loquet, et al., Pattern formation in drying drops of blood, J. Fluid Mech. 667 (2011) 85–95. [3] C.H. Chon, S. Paik, J.B. Tipton, et al., Effect of nanoparticle sizes and number densities on the evaporation and dryout characteristics for strongly pinned nanofluid droplets, Langmuir 23 (2007) 2953–2960. [4] H.Y. Erbil, Control of stain geometry by drop evaporation of surfactant containing dispersions, Adv. Colloid Interface Sci. 222 (2015) 275–290. [5] J.D. Zhou, D.W. Jing, Effects of vertical magnetic field on impact dynamics of ferrofluid droplet onto a rigid substrate, Phys. Rev. Fluids 4 (2019) 083602. [6] J. Barber, D. Brutin, L. Tadrist, A review on boiling heat transfer enhancement with nanofluids, Nanoscale Res. Lett. 6 (2011) 280. [7] A. Crivoi, F. Duan, Evaporation-induced branched structures from sessile nanofluid droplets, J. Phys. Chem. C 117 (2013) 7835–7843. [8] M. Parsa, S. Harmand, K. Sefiane, et al., Effect of substrate temperature on pattern formation of nanoparticles from volatile drops, Langmuir 31 (2015) 3354–3367. [9] D.H. Shin, C.K. Choi, Y.T. Kang, et al., Local aggregation characteristics of a nanofluid droplet during evaporation, Int. J. Heat Mass Transf. 72 (2014) 336–344. [10] A. Malvandi, S.A. Moshizi, D.D. Ganji, Effect of magnetic fields on heat convection inside a concentric annulus filled with Al2 O3 -water nanofluid, Adv. Powder Technol. 25 (2014) 1817–1824. [11] H. Younes, G. Christensen, D. Li, et al., Thermal conductivity of nanofluids: review, J. Nanofluids 4 (2015) 107–132. [12] H.T. Zhu, C.Y. Zhang, S.Q. Liu, et al., Effects of nanoparticle clustering and alignment on thermal conductivities of Fe3 O4 aqueous nanofluids, Appl. Phys. Lett. 89 (2006) 023123. [13] A. Gavili, F. Zabihi, T.D. Isfahani, et al., The thermal conductivity of water base ferrofluids under magnetic field, Exp. Therm. Fluid Sci. 41 (2012) 94–98. [14] H.W. Muller, M. Liu, Structure of ferrofluid dynamics, Phys. Rev. E 64 (2001) 061405. [15] E.A. Elfimova, A.O. Ivanov, P.J. Camp, Thermodynamics of ferrofluids in applied magnetic fields, Phys. Rev. E 88 (2013) 042310. [16] M. Hernandez-Contreras, H. Ruiz-Estrada, Transport properties of ferrofluids, Phys. Rev. E 68 (2003) 031202. [17] G.Y. Huang, M.X. Li, Q.Z. Yang, et al., Magnetically actuated droplet manipulation and its potential biomedical applications, ACS Appl. Mater. Interface 9 (2017) 1155–1166. [18] S.A.A. Raza, M.I. Sajid, U. Jamshaid, et al., Ethosomes the best approach for deeper delivery of drugs through transdermal port: from preparation to biomedical applications, J Colloid Sci. Biotechol. 4 (2015) 87–98. [19] S. Chen, F. Fan, S.J. Chang, et al., Tunable optical and magneto-optical properties of ferrofluid in the terahertz regime, Opt. Express 22 (2014) 6313–6321. [20] Q.A. Pankhurst, J. Connolly, S.K. Jones, et al., Applications of magnetic nanoparticles in biomedicine, J. Phys. D Appl. Phys. 36 (2003) R167–R181. Zhaonan Liu is now studying for MA. Eng. degree in State Key Laboratory of multiphase flow in power engineering, Xi’an Jiaotong University. She finished her B.E. degree from Wuhan University of Technology in 2019. Her current research interests include interface characteristics and dynamics of nanofluids under multi-physical field coupling. Dengwei Jing is a full professor of State Key Laboratory of multiphase flow in power engineering, Xi’an Jiaotong University. He obtained his PhD degree in the same university and is now focusing on the solar energy conversion and multiphase flow. He is the winner of National Natural Science Foundation for Distinguished Young Scholars, Newton Advanced Fellowship of Royal Society, and chief scientist of China National Key R&D program. He is the editorial board member of several well-known international journals. He has published more than 130 SCI-indexed papers and 2 English books, participated in the formulation of two national standards, applied for and authorized over 20 Chinese patents. He has won the second prize of National Natural Science Award, the first prize of Shaanxi Science and Technology Award. 229