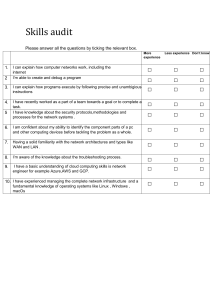

Structures Congress 2015 2735 Wind Performance and Evaluation Methods of Multi-Layered Wall Assemblies Murray J. Morrison1 and Anne D. Cope2 1 Downloaded from ascelibrary.org by New York University on 06/24/15. Copyright ASCE. For personal use only; all rights reserved. Insurance Institute for Business & Home Safety, 5335 Richburg Rd., Richburg, SC 29729. E-mail: mmorrison@ibhs.org 2 Insurance Institute for Business & Home Safety, 5335 Richburg Rd., Richburg, SC 29729. E-mail: acope@ibhs.org Abstract Wind loads on different layers of a multi-layer wall assembly were determined under realistic loading conditions in the IBHS test chamber. The current results indicated the PEF of 0.36 currently used in the ASTM D3679-13 for vinyl siding is likely too low and a more suitable PEF would be in the range of 0.4 to 0.7, with an optimal value likely between 0.55 and 0.6.. In contrast, the results from the present study on foam backed vinyl siding indicated that the PEF in ASTM D7445-09 of 0.7 are too high and may be overly conservative. The current results indicate most PEF values for foam backed vinyl fall between 0.2 and 0.55. INTRODUCTION The determination of design wind loads for multilayer walls systems is challenging since it is difficult to determining how much of the external wind load acts on each layer of the wall. Relatively large cavities that extend over large portions of the wall, such as those between typical residential sheathing and siding are a particular challenge. The pressure and pressure variation along these cavities is dependent on both the air paths and the temporal and spatial variation of the external pressures on the wall. It is extremely difficult using traditional air boxes to test siding under conditions it is likely to experience in the field due to the inherent limitations of the conventional airbox technique where a static or spatially uniform time varying pressure is applied over the entire surface of the specimen. For example Kopp and Gavanski (2011) have shown that the net load on vinyl siding is nearly zero when a uniform external pressure is applied to a wall using an airbox. That being said several standards such as ASTM D3679-13 (2013) to test vinyl siding and ASTM D7445-09 (2009) to test foam backed vinyl have been developed. The ASTM D3679-13 (2013) allows use of a pressure equalization factor (PEF) of 0.36 applied to the external design pressure on the wall to arrive at the siding design pressure, while ASTM D7445-09 (2009) allows a PEF of 0.7. In other words vinyl siding needs to only resist 36% of the external design pressure, due to the equalization of pressures across the siding. Recent results by Cope et al. (2012) at the Insurance Institute for Business & Home Safety (IBHS) have shown that the siding can experience up to 75% of the external wind load or a PEF=0.75, which is significantly larger than the PEF for vinyl siding provided in ASTM D3679-13 (2013). The current investigation expands on the previous study of Cope et al. (2012) and aims to quantify the wind loads on several different siding products. © ASCE Structures Congress 2015 Structures Congress 2015 2736 EXPERIMENTAL SETUP Downloaded from ascelibrary.org by New York University on 06/24/15. Copyright ASCE. For personal use only; all rights reserved. Test Specimen and Instrumentation In order to test different siding products a single story building was built and tested in the IBHS test chamber. The building had plan dimensions of 9.1 m (30 ft.) by 12.2 m (40 ft.), and eaves height of 2.7 m (9 ft.). The roof was a half hip, half gable roof with a roof slope of 4 on 12 and 0.3 m (1 ft.) overhangs. The four walls of the test building were divided into 8 different walls sections for siding installation and testing purposes. Each wall was divided into two sections which were isolated from each other structurally and aerodynamically by using an air seal at the dividing line. Significant effort was made during the construction of the walls to match typical wall construction as closely as possible. The walls of the test building were typical of residential construction with studs at 0.4 m (16 in.) on center and 11 mm (7/16 in.) OSB sheathing on the exterior. The OSB was then covered with standard building wrap. Insulation was installed in the stud bays and sheetrock installed on the interior of the walls (including taping and mudding) to match typical construction. A total of four different residential siding products were tested. These include vinyl, foam backed vinyl, wood and cement siding products. Each product was installed with strict adherence to the manufactures installation guidelines. Figure 1 presents a plan view of the test building outlining the location of the 8 test wall sections, details of the product installed on each wall is provided in Table 1. In order to test all 8 walls shown in Figure 1 the building was tested at 36 wind angles over a full 360° rotation at 10° increments. Pressures on the surface of the walls and between the different layers of the wall assembly were measured in a similar manner to that described in Cope et al. (2012). The pressures on each wall were measured at 12 locations on walls 2, 3, 5 and 7, and at 16 locations for walls 1, 4, 6, 8. Figure 2 shows the pressure tap locations for walls 1, 4, 6, 8. Regardless of the orientation of the wall on the building the coordinate system for each wall remains similar to that shown in Figure 2, with the origin at the bottom corner of the wall closest to the corner of the building. As outlined in Table 1 each wall used either a 2 or 3 pressure tap configuration. A two pressure tap configuration uses two independent differential pressure transducers at each tap location; the first to measure the net pressure across the siding (“siding”) and the second to measure the net pressure across the OSB sheathing (“sheathing”). A 3 pressure tap configuration adds a third differential pressure transducer to measure the external pressure on the wall (“external”) relative to the static reference pressure in the IBHS test chamber. The pressures on all walls are measured simultaneously at a rate of 100 Hz. Wind Flow details General details of the IBHS large wind tunnel can be found in Liu et al. (2011) and Morrison et al. (2012). The flow simulation used for the current experiments were designed to model an open country terrain (zo=0.01). Specific details the flow simulation in the IBHS test chamber, including turbulence and spectral characteristics can be found in Morrison et al., (2012). In order to examine the effect, if any, of scaling wind speeds, 4 different wind speeds were tested in the current study. The 3s gust wind speeds (V3s,H) at roof height used in the current study were 18.8, 22.0, 28.5 and 31.5 m/s. © ASCE Structures Congress 2015 Structures Congress 2015 2737 Downloaded from ascelibrary.org by New York University on 06/24/15. Copyright ASCE. For personal use only; all rights reserved. Datta Reductio on The currrent study presents p all pressures p ass GCp coeffi ficients that are directly com mparable to ASCE7-10 (2010). Whhen reportingg peak GCp values, as in i Figure 3, Figgure 5 and Table 2 the peeak GCp coeefficients prresented hereein are statisstical peaks. Thee time history is divided into 3 secctions, a gum mbel distribbution is theen fit to the peaak value from m each secttion using a Liebline BL LUE formullation (Lieblline, 1974). Thee median vaalue from thhis distributiion is then reported as the peak foor this time histtory. The Pressure P equualization facctor (PEF), which is thee ratio betw ween the net loadd across the siding and the t external pressure p is calculated c ussing Eq. 1. (1) It should s be noted n that when w examinning PEF as a a functionn of externnal GCp no stattistical proceedure is appllied to eitherr the externaal or Siding GCp G values. Figuree 1 Plan view of the tesst building in ncluding waall location and wind direction n nomenclaature © ASCE Structures Congress 2015 Downloaded from ascelibrary.org by New York University on 06/24/15. Copyright ASCE. For personal use only; all rights reserved. Structures Congress 2015 2738 Figure 2 Pressure Tap locations for 6.1 m (20 ft.) walls Table 1 Product and pressure tap details for walls shown in Figure 1 Wall Product 1 2 3 4 5 6 7 8 Vinyl Vinyl (Stiffened) Vinyl Cement board Cement borad Foam backed vinyl Foam backed vinyl Wood # Pressure Tap Configuration (2 or 3) 3 3 2 2 2 3 3 2 RESULTS AND DISCUSSION Effect of Wind angle on external and siding GCp Coefficients Figure 3 presents the peak minimum external GCp for each tap locations on wall 1 at all wind speeds and wind angles tested. For wall1 the highest suctions occurs at wind angles between 140° and 190°. While there is some variability between results obtained using different scaling wind speeds, this is likely natural variability in peak values from test to test. The mean external GCp coefficients shown in Figure 4 indicate good agreement with between results obtained using different scaling. Figure 5 and Figure 6 show the peak minimum and mean siding GCp coefficients respectively for all tap location on wall 1. Similar to the peak external GCp the highest pressure coefficients on the siding occur at wind angles © ASCE Structures Congress 2015 Structures Congress 2015 2739 Downloaded from ascelibrary.org by New York University on 06/24/15. Copyright ASCE. For personal use only; all rights reserved. between 140° and 190°. However, the siding coefficients also exhibit high peak values between wind angles of 40° and 100°. Interestingly, over the wind angles of 40° to 100° the mean siding GCp values shown in Figure 6 seem to separate into two groups. One group of taps over this wind angle range exhibit relatively low magnitude pressure coefficients while a second group exhibit the largest negative mean siding GCp values over all wind angles. Over the wind angles of 40° to 100° wall 1 experienced largely positive external pressures as shown in Figure 4. The positive external pressures likely have a high spatial correlation over the wall and thus likely result in a high positive pressures between the siding and the OSB sheathing. In areas where the external pressure are substantially lower i.e. near the corner of the wall, this would result in a relative high outward load on the siding. Similarly where the external pressure is high the load on the siding is relatively small. Based on the variation of external and siding GCp values presented in Figure 3 through Figure 6 wind angles ranging from 40° to 190° will be examined in detail in further analysis. Similarly, analysis on other walls will follow the same relative wind angle swath (i.e. wind angles for wall 6 would range from 220° to 10°). Figure 3 Peak external Pressures for all 16 taps on Wall 1. Black Squares V3s,H=18.8m/s., Red circles V3s,H=22.0 m/s, Green Triangles V3s,H=28.5 m/s, Blue Asterisk V3s,H =31 m/s © ASCE Structures Congress 2015 Structures Congress 2015 2740 Downloaded from ascelibrary.org by New York University on 06/24/15. Copyright ASCE. For personal use only; all rights reserved. Siding Pressure Equalization Factors Figure 7 and Figure 8 presents the PEF versus external GCp for the largest 0.7% of the entire external GCp pressure time histories for each tap over all wind angles for wall 1 and wall 6. In general, pressure taps closer to the edge of the wall, close to the corner have both the highest external pressure and PEF values, in some cases exceeding 1. The external GCp values for walls 1 and 6 are similar, however, wall 6 exhibits lower PEF values than wall 1. This finding is interesting, since ASTM D3579-13 (2013) to which vinyl siding is tested allows a PEF of 0.36, while ASTM D7445-09 (2009) to which foam backed vinyl is tested allows a PEF of only 0.7. The current results suggest that foam backed vinyl should have a lower PEF than vinyl siding and that possibly that these test standard PEF values should be switched. Figure 4 Mean external Pressures for all 16 taps on Wall 1. Black Squares V3s,H=18.8m/s., Red circles V3s,H=22.0 m/s, Green Triangles V3s,H=28.5 m/s, Blue Asterisk V3s,H=31 m/s © ASCE Structures Congress 2015 Structures Congress 2015 2741 Downloaded from ascelibrary.org by New York University on 06/24/15. Copyright ASCE. For personal use only; all rights reserved. Figure 5 Peak Pressures across vinyl siding for all 16 taps on Wall 1. Black Squares V3s,H=18.8m/s., Red circles V3s,H=22.0 m/s, Green Triangles V3s,H=28.5 m/s, Blue Asterisk V3s,H=31 m/s Figure 6 Mean Pressures across vinyl siding for all 16 taps on Wall 1. Black Squares V3s,H=18.8m/s., Red circles V3s,H=22.0 m/s, Green Triangles V3s,H=28.5 m/s, Blue Asterisk V3s,H=31 m/s The PEFs calculated in Figure 7 and Figure 8 are for single taps and are thus point measurements. To examine the spatial correlation of PEFs area average external and siding GCp time histories were computed for 24 area of different sizes and locations on wall 1 and 6. Resulting PEF time histories were then computed for each area. Table 2 shows the location and dimensions of the 24 areas following the coordinate system shown in Figure 2. Figure 9 and Figure 10 show the PEF values plotted versus corresponding external GCp values for the highest 0.7% of external GCp time history values for each Area defined in Table 2 over all wind angles for wall 1 and wall 6 respectively. The trends of the PEF values versus external GCp values for the different areas is similar to that for the individual taps. In general the PEFs decrease with increasing peak external GCp. The PEF for foam backed vinyl (wall 6) continue to be lower than for vinyl (wall 1). For wall 1 areas 1, 7 and 13 all have PEFs greater than 1. The common link between these three areas is that the tributary area for Tap 1 (see Figure 2) accounts for over 33% percent of the overall area. This represents a far greater percentage than for any other area which includes Tap 1. Figure 11 shows the PEFs for all areas for wall 1 with the exception of areas 1, 7 and 13. The PEF values correspond to the largest 10 peak external GCp coefficients for each area are shown as black circles in Figure 11. While there are some outliers the PEFs for most of the largest external GCp coefficients are between 0.4 and 0.7. However, determining a precise recommendation of an exact PEF for vinyl siding is challenging, requiring some degree of engineering judgment. Figure 12 uses the largest PEF values corresponding to a certain number of the external GCp coefficients for each area, shown in black in Figure 11, on wall 1 and ranks them © ASCE Structures Congress 2015 Structures Congress 2015 2742 Downloaded from ascelibrary.org by New York University on 06/24/15. Copyright ASCE. For personal use only; all rights reserved. from largest to smallest and presents a cumulative average of the PEFs for the sorted external GCp coefficients. For example for a horizontal axis value (referred to as n in the text) of 2, the corresponding PEFmean is the average of the PEFs from the largest two external GCp, while when n=3, the corresponding PEFmean is the average of the PEFs from the largest three external GCp. For areas with PEFmean at n=1, greater than 0.7, the PEF values reduce to less than 0.7 once n>6. For areas with PEFmean less than 0.7, the PEFmean are relatively constant over all n. Figure 13 presents PEFmean versus n for wall 6, while Figure 14 presents PEFmean versus n for wall 1 for V3s,H=28.5 m/s. Figure 13 clearly shows consistently lower PEF for foam backed vinyl than for vinyl siding. Figure 14 shows less scatter than Figure 12. Nevertheless, the range of PEF values for wall 1 seem largely independent of the wind speeds tested in the current study. Figure 7 PEF versus external GCp for all Taps on Wall 1 for V3s,H=18.8 m/s © ASCE Structures Congress 2015 Downloaded from ascelibrary.org by New York University on 06/24/15. Copyright ASCE. For personal use only; all rights reserved. Structures Congress 2015 2743 Figure 8 PEF versus external GCp for all Taps on Wall 6 for V3s,H=18.8 m/s Figure 9 PEF versus external GCp for Different Areas on Wall 1 as Defined in Table 2 for V3s,H=18.8 m/s © ASCE Structures Congress 2015 Downloaded from ascelibrary.org by New York University on 06/24/15. Copyright ASCE. For personal use only; all rights reserved. Structures Congress 2015 2744 Figure 10PEF versus external GCp for Different Areas on Wall 6 as Defined in Table 2 for V3s,H=18.8 m/s Figure 11 PEF versus external GCp for all Areas on Wall 1 as Defined in Table 2 for V3s,H=18.8 m/s. Highest 10 external GCp coefficients for each area are shown in black. © ASCE Structures Congress 2015 Downloaded from ascelibrary.org by New York University on 06/24/15. Copyright ASCE. For personal use only; all rights reserved. Structures Congress 2015 2745 Figure 12 PEFmean calculated using different number of peak external GCp coefficients for each Area on Wall 1 for V3s,H=18.8 m/s. Figure 13 PEFmean calculated using different number of peak external GCp coefficients for each Area on Wall 6 for V3s,H=18.8 m/s. © ASCE Structures Congress 2015 Downloaded from ascelibrary.org by New York University on 06/24/15. Copyright ASCE. For personal use only; all rights reserved. Structures Congress 2015 2746 Figure 14 PEFmean calculated using different number of peak external GCp coefficients for each Area on Wall 1 (for V3s,H=28.5 m/s. Comparison of loads on siding with ASTM D3679-13 Table 2 presents a design example for the 24 area averages for both Wall 1 and 6. Column 3 presents the ASCE7-10 (2010) GCp coefficients calculated for each area using Figure 30.4-1 in ASCE7-10 (2010). Column 4 shows the factored GCp value (GCpfactored) by applying a PEF of 0.36 from ASTM D3679-13 (2013). It should be noted that ASTM D3679-13 (2013) uses the maximum GCp value for walls found in Figure 30.4-1 of ASCE7-10 (2010) of -1.4 which leads to a GCPfactored of 0.5 for all areas. Columns 5 and 6 of Table 2 present the peak external GCp and peak siding GCp for wall 1, while columns 7 and 8 present the peak external GCp and peak siding GCp for wall 6. All results in columns 5-8 in Table 2 are for V3s,H=18.8 m/s. The external GCp valuesbetween Wall 1 and Wall 6 match relatively well with all values from the two walls being within 10% of each other and most values being within 5%. When compared to the ASCE7-10 (2010) the external pressure coefficients in the current study are approximately 20% lower, indicating, at least for the current study, that the ASCE7-10 (2010) peak wall coefficients are conservative. When comparing the siding GCp between the two walls, wall 1 has larger loads on the siding than wall 6. This result is consistent with the previous findings in the current study that the PEFs for foam back vinyl are lower than those for vinyl. siding GCp values that exceed the GCpfactored used in ASTM D3679-13 (2013) (i.e. -0.5) by more than 10% are highlighted in yellow in Table 2. For wall 1 siding GCp exceeds GCpfactored for approximately 40% of the areas, while the load on the siding for wall 6 never exceeds GCpfactored. Table 2 Area Average Load locations on the walls. ASCE7-10 GCp and factored GCp coefficients along with measured peak GCp coefficients (x,y,Δx,Δy,) m 1* 2 (0,0,0.61,2.4) (0.61,0,0.61,2.4) ASCE7 GCp -1.33 -1.2 GCpfactored -0.48 -0.43 external GCp (Wall 1) -1.05 -0.93 © ASCE Structures Congress 2015 siding GCp (Wall 1) -0.85 -0.55 external GCp (Wall 6) -0.94 -0.89 siding GCp (Wall 6) -0.45 -0.42 Structures Congress 2015 Downloaded from ascelibrary.org by New York University on 06/24/15. Copyright ASCE. For personal use only; all rights reserved. 3 4 5 6 7* 8 9 10 11 12 13* 14 15 16 17 18 19 20 21 22 23 24 (1.2,0,0.61,2.4) (1.8,0,0.61,2.4) (2.4,0,0.61,2.4) (3.0,0,0.61,2.4) (0,0,1.2,1.2) (0,0,1.8,1.8) (0,0,2.4,2.4) (0.61,0,1.2,1.2) (0.61,0,1.8,1.8) (0.61,0,2.4,2.4) (0,0,1.2,0.61) (0,0,1.8,0.61) (0,0,2.4,0.61) (0.61,0,1.2,0.61) (0.61,0,1.8,0.61) (0.61,0,2.4,0.61) (0.61,0,1.2,1.2) (0.61,0,1.8,1.2) (0.61,0,2.4,1.2) (0.61,0,1.2,1.8) (0.61,0,1.8,1.8) (0.61,0,2.4,1.8) 2747 -1.06 -1.06 -1.06 -1.06 -1.26 -1.1 -1.02 -1.13 -1.04 -0.98 -1.35 -1.23 -1.16 -1.2 -1.13 -1.1 -1.13 -1.07 -1.04 -1.09 -1.04 -1 -0.38 -0.38 -0.38 -0.38 -0.45 -0.4 -0.37 -0.41 -0.37 -0.35 -0.49 -0.44 -0.42 -0.43 -0.41 -0.39 -0.41 -0.39 -0.37 -0.39 -0.37 -0.36 -0.82 -0.9 -0.89 -0.68 -0.93 -0.9 -0.87 -0.88 -0.83 -0.77 -1 -0.89 -0.84 -0.94 -0.86 -0.77 -0.88 -0.82 -0.76 -0.88 -0.83 -0.76 -0.51 -0.58 -0.64 -0.42 -0.82 -0.5 -0.42 -0.61 -0.44 -0.45 -0.88 -0.65 -0.49 -0.71 -0.54 -0.44 -0.61 -0.48 -0.42 -0.54 -0.44 -0.44 -0.9 -0.89 -0.81 -0.75 -0.84 -0.85 -0.82 -0.89 -0.84 -0.76 -0.84 -0.86 -0.84 -0.91 -0.87 -0.79 -0.89 -0.85 -0.76 -0.9 -0.84 -0.76 -0.4 -0.47 -0.46 -0.33 -0.33 -0.29 -0.28 -0.45 -0.31 -0.26 -0.37 -0.37 -0.34 -0.48 -0.42 -0.32 -0.45 -0.37 -0.28 -0.38 -0.31 -0.25 *Tap 1 accounts for over 33% of the total area for these areas CONCLUSIONS The current study examined the wind loads on several common residential siding products. Loads on both vinyl and foam back vinyl are examined in the current analysis. Load reduction factors in the form of pressure equalization factors (PEF) from the external pressure are warranted for both products. However, the current results indicated the PEF of 0.36 currently used in the ASTM D3679-13 for vinyl siding is likely too low and a more suitable PEF would be in the range of 0.4 to 0.7, with an optimal value likely between 0.55 to 0.6. In contrast, the results from the present study on foam backed vinyl siding indicated that the PEF in ASTM D7445-09 (2009) of 0.7 is too high and may be overly conservative. The current results indicate most PEF values for foam backed vinyl fall between 0.2 and 0.55. The current results indicate no significant wind speeds dependence on PEF values. REFERENCES American Society of Civil Engineers (ASCE 7-10) (2010). Minimum Design Loads for Buildings and Other Structures, American Society of Civil Engineers, Reston, Virginia. ASTM D3679-13 (2013), Standard Specification for Rigid Poly (Vinyl Chloride) (PVC) Siding, ASTM International, West Conshohocken, PA. ASTM D7445-09 (2009), Standard Specification for Rigid Poly(Vinyl Chloride) (PVC) Siding with Foam Plastic Backing (Backed Vinyl Siding), ASTM International, West Conshohocken, PA. Cope, A.D., Crandell, J. H., Johnston, D., Kochkin, V, Liu, Z., Stevig, L., Reinhold, T.A. (2012). “Wind Loads On Components Of Multi-Layer Wall Systems © ASCE Structures Congress 2015 Structures Congress 2015 2748 Downloaded from ascelibrary.org by New York University on 06/24/15. Copyright ASCE. For personal use only; all rights reserved. With Air-Permeable Exterior Cladding”, Applied Technology Council, Miami, FL, USA. Kopp, G.A., Gavanski E. (2011). “Effects Of Pressure Equalization On The Performance Of Residential Wall Systems Under Extreme Wind Loads”, Journal of Structural Engineering, 138 (4), 526-538. Lieblein J. (1974). Efficient Methods of Extreme-Value Methodology. National Bureau of Standards, NBSIR 74-602. Liu, Z., Brown, T.M., Cope, A.D., Reinhold, T.A. (2011). “Simulation Wind Conditions/Events in the IBHS Research Center Full-Scale Test Facility”, 13th International Conference on Wind Engineering, Amsterdam, Netherlands. Morrison, M.J., Brown, T.M. Liu, Z., (2012). “Comparison of Field and FullScale Laboratory Peak Pressures at the IBHS Research Center”, Applied Technology Council, Miami, FL, USA, 2012. © ASCE Structures Congress 2015