ARH Requirements: Equipment Inspection Specification

advertisement

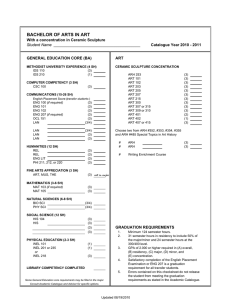

ARH REQUIREMENTS TABLE OF CONTENTS 1.0 GENERAL 2.0 TYPE OF EQUIPMENT SUBJECT TO ARH CONTROL 3.0 PRELIMINARY DOSSIER 4.0 INSPECTION BY ARH 4.1 Pressure Devices 4.2 Storage Tanks 4.3 Valves 4.4 Pressure Safety Valves 4.5 Electrical Equipment & Material 4.6 Material & Security Systems 4.7 Overhead Cranes 5.0 INSPECTION NOTIFICATION 6.0 FINAL DOSSIER 7.0 DOCUMENT DISTRIBUTION 7.1 Quantities & Format 7.2 Format 7.3 Front Cover & Spine 8.0 DETAILED REQUIREMENTS & CRITERIA 8.1 Pressure Devices 8.1.1 Gas Pressure Devices 8.2 Pumps, Turbines & Compressors 8.2.1 8.2.2. 8.2.3. 8.2.4 Pumps Turbines Compressors8 Appurtenances 8.3 Motors, Engines 8.3.1 8.3.2 8.3.3 Motors Engines Appurtenances 8.4 Mechanical Handling 8.4.1 8.4.2 Appurtenances Passenger Lifts / Man-riding Hoists 8.5 Electrical 8.6 Instruments 8.6.1 8.6.2 8.6.3 Pressure Safety Valves & Control Valves Measuring Instruments General Instruments 8.7 Piping 8.7.1 8.7.2 8.7.3 Valves Pipe & Pipe Fittings Piping Specialties 8.8 Loss Prevention, Safety 8.8.1 8.8.2 Fire Fighting Fire & Gas Detection 8.9 Sewage Networks 8.10 Hazardous Operations 13 9.0 PIPELINES ASSOCIATED WITH HYDROCARBONS PRODUCTION 9.1 General File 9.2 9.3 9.4 9.5 9.6 Technological Drawings & Schedules Equipment & Materials Submitted to Control Piping Installation Testing & Control Security Systems 9.6.1 9.6.2 9.6.3 9.6.4 9.6.5 9.6.6 Emergency Shutdown System Flare Network Fire, Heat, Smoke & Gas Detection Fire Fighting Systems Grounding Network Lighting Protection System 10.0 TECHNICAL FILE 11.0 ATTACHMENTS 1.0 GENERAL The following outlines requirements of this specification apply to the equipment, devices and material that are subject ARH (Algerian Inspection Agency). These requirements do not have any effect on the inspections required by BUYER and any waiver by ARH is not to be construed as a waiver of any other requirements for inspection by BUYER or any other obligation of the SUPPLIER noted elsewhere in this contract. SUPPLIER and SUPPLIER’s sub-suppliers will be subject to inspection of all materials and equipment being manufactured or supplied. The SUPPLIER shall pass on the requirements of these ARH inspections to all of the SUPPLIER’s contracts (purchase orders) to its subsuppliers. These inspections are in addition to any other inspection or testing requirements noted elsewhere. The SUPPLIER will undertake to facilitate all inspections made by ARH, Client personnel, or other third parties related to ARH or Owner, under authority of ARH, on the premises. The SUPPLIER further undertakes to facilitate ARH’s attendance at all inspection or acceptance tests planned or required by contract to be conducted by the SUPPLIER. 2.0 TYPE OF EQUIPMENT SUBJECT TO ARH CONTROL A. Pressure Retaining Equipment B. Compressors C. Storage Tanks D. Valves E. Pressure Safety Valves F. Electrical Equipment & Material G. Material & Security Systems H. Overhead Cranes For detailed requirements/criteria, refer to section 8.0 of this specification. A preliminary and a final dossier are required for all the equipment and material falling within ARH’s scope. No preliminary and final dossier is required for the Bulk Materials and Safety Systems. However, the SUPPLIER/MANUFACTURER shall submit a technical file to the Buyer describing the Materials and Safety Systems as described in paragraphs 8.8 and 9.6. The contents of this technical file are detailed in Section 10 of this specification. All documents must be provided in French in quantities as shown in paragraph 7.1 (Final Dossier). 3.0 PRELIMINARY DOSSIER At least six (6) weeks prior to the beginning of manufacturing in the plant, the SUPPLIER shall send to the BUYER, a Preliminary Dossier, one original and one copy in English and one original and three copies in French, to include the following documents: Section 1 A letter of request for approval of the Preliminary Dossier (Attachment A) Section 2 Certification of the manufacturer’s signature* (Attachment B) Section 3 Certificate of Compliance and Internal and External Visit *(Attachment C) Section 4 Certificate that the equipment conforms to the use in country of origin* (Attachment H) Section 5 Description of equipment (Attachment D) Section 6 Design calculations Section 7 Drawing Section 8 Welding procedures specification (WPS) Section 9 Quality inspection and test plan NOTES: 1. (*)The official seal from the closest Algerian Consulate will be required for those documents marked with an asterisk. 2. The dossier can be forwarded without the official Algerian consulate stamping for item 2, 3 and 4 in cases where these documents would require a lot of time and cause a delay in the transmission of the preliminary dossiers to the ARH. The stamped documents can be transmitted to BUYER at a later date upon obtaining the Algerian stamping and / or included in the final dossiers. 3. A series of identical equipment shall be grouped in one (1) single preliminary dossier; however, this file must indicate the item number from the complete list. A final dossier must be provided for each item. 4. For equipment description (Section 5) for reactors, columns, heat exchangers, air coolers exchangers, compressors, separators, filters, pressure vessels and tanks, the ARH model (attachment D) shall be used. For equipment description for other pressure devices (valves, pressure safety valves), electrical equipment and material and for the overhead cranes, the ARH model (attachment D) shall be modified with regard to the specifics of each kind of apparatus. 5. The calculations (Section 6), concerning the pressure devices required in the preliminary dossier shall detail principally of the thickness of the parts under pressure (Shells, heads, nozzles) and Opening reinforcements. 6. The welding procedure specification (WPS) is required only for Pressure devices, Tanks and Valves. With this Preliminary Dossier, the SUPPLIER shall provide the BUYER a tentative production schedule that can be used for planning the inspection visits. The SUPPLIER will then provide a schedule update on a monthly basis until manufacturing begins. Thereafter, the SUPPLIER shall provide a weekly schedule update. SUPPLIER may not begin manufacturing before obtaining ARH’s approval through the BUYER. The SUPPLIER shall send the dossiers and documents to the BUYER who will forward them to ARH. These documents shall not be transmitted directly by the SUPPLIER to ARH. 4.0 INSPECTION BY ARH The SUPPLIER and SUPPLIER’s sub-suppliers shall permit ARH, the BUYER, CLIENT, or representatives of each, free and open access to the SUPPLIER’s and SUPPLIER’s subSUPPLIER’s shops, whether or not they are accompanied by a representative of the SUPPLIER or SUPPLIER’s sub-supplier’s. The SUPPLIER and SUPPLIER’s subSUPPLIER’s shall provide all documents necessary for checking the equipment offered for inspection or test. The test will be conducted in the presence of ARH unless ARH waives its right through the BUYER to be present. This waiver does not release SUPPLIER of any contractual responsibilities or to other testing requirements noted elsewhere in the contract (purchase order) nor is it a waiver of testing required by the BUYER. The ARH inspections may include spare parts and auxiliary equipment. The ARH inspections will include as a minimum the following: 4.1 Pressure Devices (Gas pressure & steam pressure devices) Verification for compliance to drawings and specified requirements. • Visual appearance. • Spot control for radiographic films. • Hydrostatic test. These inspections will be performed in the fabrication shop. The Pressure Devices are detailed in section 8.1 of this specification. 4.2 4.3 4.4 4.5 Storage Tanks • Visual inspection of tanks. • Spot control for radiographic films. • Hydrostatic and vacuum test. Valves • Visual appearance. • Spot control for radiographic films. • Hydrostatic test of the body and the seat. • Leak test. Pressure Safety Valves • Visual appearance. • Functional test. • Leak test. Electrical Equipment & Material • Verification for compliance to drawing and specified requirements. • Visual inspection. • Routine electrical test. • Functional test. These inspections will be performed in the shop. 4.6 Material & Security Systems • Verification for compliance to drawing and specified requirements. • Visual inspection. • Functional test. These inspections will be performed in the job site. 4.7 Overhead Cranes • Verification for compliance to drawing and specified requirements. • Visual appearance. • Static and dynamic tests. • Functional test. These inspections will be performed in the job site. 5.0 INSPECTION NOTIFICATION The SUPPLIER shall advise BUYER in writing at least six (6) weeks prior to the planned date for testing. (SUPPLIER should use a format similar to that shown in Attachment E “Request for ARH Inspector”). At least 28 days prior to the testing date(s), the SUPPLIER shall provide in writing a fax confirmation of the scheduled date to the BUYER. Prior to the scheduled date, ARH will confirm to the BUYER, whether or not ARH plans to attend the inspection and test. BUYER will in turn notify the SUPPLIER concerning ARH’s attendance. The announced or unannounced absence from the scheduled inspections by the representatives of ARH shall be considered by ARH as a surrendering of ARH’s right to inspect that portion only of the equipment test under consideration. However, said surrender shall not release the SUPPLIER from any of its contractual obligations. 6.0 FINAL DOSSIER The SUPPLIER shall prepare the Final Dossier and forward one original and one copy in English and, and one original and four (4) copies in French of the Dossier to the BUYER within one month after final inspection, and / or shipment. This Final Dossier will include the following documents numbered from Sections 10 to 21: Section 10 The letter of approval for the Preliminary Dossier issued by ARH. Section 11 The letter or fax issued by the Supplier or Sub-Supplier requesting the presence of the ARH inspector for the plant tests and inspections. (Attachment E). Section 12 Written ARH response confirming the presence of its representative or its delegate. Section 13 Welding Procedure Qualification Record (PQR). Section 14 Welder qualifications. Section 15 Certificates of the materials (MTR) that have been used for the preparation of the parts and pieces of the device (physical-chemical properties), and the electrodes. Section 16 Destructive and non-destructive tests reports. Section 17 Heat treatment diagrams, if required. Section 18 Certificates of Inspections (Attachment F). Section 19 Testing conditions / Procedure. Section 20 Test certificate (Attachment G). Section 21 Photo of the identification plate after stamping (for Pressure devices). 7.0 DOCUMENT DISTRIBUTION 7.1 Quantities & Format Documents identified for submittal to the Algerian Authorities shall be submitted to BUYER / CONTRACTOR in the following quantities and format: 7.2 Preliminary Dossier Final Dossier For ARH 1 original French & 1 copy French 1 original French & 1 copy French For Client 1 copy French 1 copy French For EPC 1 copy French Contractor 2 copy French Total Required 1 orig. French & 4 copies French 1 orig. French/ 3 copies French Format The preliminary dossiers, final dossiers and safety dossiers shall be in binders, 8 1/2x11, preferably 3 ring view binders. Provide a general Table of Contents. If more than one (1) volume, each volume shall have a Table of Content. These dossiers shall have section dividers and numbered accordingly. Each section shall have a title page. 7.3 Front Cover & Spine The front cover and spine shall contain information as shown in the attached sample page at the back of this specification. 8.0 DETAILED REQUIREMENTS & CRITERIA If a device or material is within the ARH scope, members of ARH will conduct inspection. There will normally be a requirement for a preliminary dossier, containing design premises etc. for devices that come within the scope, to be presented for review and approval by ARH before manufacture starts. The contents of the preliminary dossier are detailed in Section 3 of this specification. 8.1 Pressure Devices The following items are considered as pressure devices: Furnaces, reactors, columns, heat exchangers, air coolers, separators, filters and pressure vessels, bottles of CO2, N2 fire extinguisher, compressors, piping, water boiler, steam generator, steam receiver. The inclusion of Pressure devices within the scope of ARH is defined below: 8.1.1 Gas Pressure Devices 8.1.1.1 Furnaces, Reactors, Columns, Heat Exchangers, Air Coolers, Separators, Filters & Pressure Vessels The inclusion of Gas Pressure vessels within the scope of the ARH is defined by a Characteristic Number, which is a function of pressure and volume, conditioned by the fluid handled and the design temperature involved. ARH is involved where the Characteristic Number derived from the design pressure (expressed in barg) multiplied by the entrained volume (expressed in liters) exceeds the values stated below for the specified process and utility fluids at given temperatures. Pressure vessels that are not steam or hot water vessels, and that have not been excluded from the ARH scope above, come within their scope if the following conditions are simultaneously met: 8.1.1.2 • The design pressure exceeds 4 barg. • The characteristic number; i.e., the product of the design pressure expressed in barg, multiplied by the capacity expressed in liters; exceeds the number 80. • The maximum operating temperature exceeds the saturation temperature at operating pressure of the liquid handled (this condition is used only for the liquid) Steam Pressure Devices (water boilers, steam generators, steam receivers) A. Water Boilers Water boilers are generally exempt from the ARH scope if the operating temperature does not, and cannot, exceed 110ºC. B. Steam Generators Steam generators with a capacity that does not exceed 25 liters or generators fitted with physical device(s) that prevent the pressure from exceeding 0.5 barg are generally exempt from the ARH scope. Steam generators that are not exempt are categorized as Steam Receivers – see Section C) below. C. Steam Receivers Vessels that receive steam or water at an operating temperature that exceeds 110ºC are within the scope of ARH. Steam receivers are exempt from the ARH scope if the capacity is not greater than 100 liters. Steam receivers that receive vapor or gas – other than inert gas – together with the steam at a design pressure exceeding 4 barg shall be governed by the conditions for pressure devices as in section 8.1.1.1 above. There are no specific requirements for pressure devices containing water provided that the operating temperature remains below 110ºC. 8.1.1.3 Storage Tanks The hydrocarbon and hazardous product storage tanks are within the scope of ARH. The water storage tanks are not subject to ARH inspection. A. Stationary Roof Tanks Tank strength and tightness tests (hydrostatic, under and over pressure tests B. Floating Roof Tanks Hydrostatic Test Before performing the above tests Engineer and Client’s inspectors shall undertake the following: • Internal inspection of tanks. • Verification of tank bottom tightness (suction cup test, etc.) • Tightness test on reinforcement rings. • Verification of tank and components vertically, horizontally and geometric shape. • Radiographic inspection of welds. • Setting of safety valves. • Reports on these tests and inspections signed by Engineer and Client shall be made available to ARH representative. These latter may participate in any aforesaid tests and inspections that they deem appropriate after prior informing of the Owner. Tanks operating at atmospheric pressure, with direct access to the atmosphere, are generally excluded from the scope of ARH. VENDOR / SUBCONTRACTOR is required to notify and obtain the advice of the PURCHASER for any tank designed to contain hazardous liquids which could, under maximum overfill conditions, be subject to a hydrostatic pressure such that the stress in any member is equal to , or exceeds, five eighths (5/8) of the elastic limit of the material being used. 8.1.1.4 Appurtenances VENDOR / SUBCONTRACTOR is reminded that instruments and interconnecting pipework may be subject to ARH scrutiny. Refer to Section 8.6 and 8.7. 8.2 Pumps, Turbines & Compressors Compressors, turbines and pumps may be subject to ARH scrutiny. If an item comes within the scope, members of ARH will conduct the scrutiny. For items within the ARH scope there will normally be a requirement for a preliminary dossier, containing design premises etc., to be presented for appraisal by the ARH before manufacture starts. The contents of the preliminary dossier are detailed in Section 3.0 of this specification and summarized on the Supplier Data Requirements List (SDRL), in the Purchase Order or Subcontract. The inclusion of Compressors, turbines and pumps within the scope of ARH is defined by a Characteristic Number that is a function of pressure and flow rate, conditioned by the pressure and fluid handled. ARH is involved where the Characteristic Number derived from the maximum delivery pressure (expressed in barg), multiplied by the maximum design flow rate under delivery conditions (expressed in cubic meters per minute) exceed the values stated below. 8.2.1 Pumps Pumps are generally excluded from the ARH scope but VENDOR / SUBVENDOR shall notify and obtain advice from PURCHASER for any pump which has a fabricated casing or body, or where the following two conditions are simultaneously met for the fluids specified: • Non hazardous liquids 1. Delivery pressure exceeds 10 barg. 2. Characteristic Number exceeds the value 50. • Hazardous liquids (Explosive, flammable, toxic or corrosive). 1. Delivery pressure exceeds 4 barg. 2. Characteristic Number exceeds the value 20. 8.2.2. Turbines ARH shall attend the hydrostatic testing of turbines within their scope. 8.2.3. Compressors Compressors of gases or vapors other than steam are within the ARH inspection scheme if the following two conditions are simultaneously met for the fluids specified: • Non hazardous liquids 3. Delivery pressure exceeds 10 barg. 4. Characteristic Number exceeds the value 50. • Hazardous liquids (Explosive, flammable, toxic or corrosive). 3. Delivery pressure exceeds 4 barg. 4. Characteristic Number exceeds the value 20. ARH shall attend hydrostatic testing of casing or body. 8.2.4 Appurtenances VENDOR / SUBCONTRACTOR is reminded that electrical ancillaries, instruments, filters, and interconnecting pipework may be subject to ARH scrutiny. Refer to Sections 8.5, 8.6 and 8.7. 8.3 Motors, Engines Low voltage utility Motor and Engine drivers are not normally subject to ARH scrutiny; high voltage and fire or emergency service Motors and Engines may come under their scrutiny. If an item comes within the scope there will normally be a requirement for a preliminary dossier as detailed in section 3.0 of this specification. 8.3.1 Motors Motors are subject to ARH scrutiny if: • The maximum voltage rating is equal to or exceeds 5.5 kV. • The motor drives fire pumps or other essential or emergency services. ARH shall attend final acceptance tests of motors within their scope. 8.3.2 Engines Engines are not normally subject to ARH scrutiny unless they drive, either directly or indirectly, fire pumps or other essential or emergency service. In these cases preliminary and final dossiers shall be prepared. 8.3.3 Appurtenances VENDOR / SUBCONTRACTOR is reminded that electrical ancillaries, instruments, fuel / oil filters, pneumatic and hydraulic accumulators, and interconnecting pipework may be subject to ARH scrutiny. Refer to Sections 8.1, 8.5, 8.6 and 8.7. 8.4 Mechanical Handling Mechanical handling equipment may be subject to ARH scrutiny. If an item comes within the scope, members of ARH will conduct the scrutiny. For items within the scope there will normally be a requirements for a preliminary dossier, containing design premises etc, to be presented for appraisal by the ARH before manufacture starts. The contents of the preliminary dossier are detailed in Section 3.0 of this specification. Its designed safe working load defines the inclusion of a mechanical handling device within the scope of ARH. ARH are involved where the designed safe working load equals, or exceeds, 5 metric tons. ARH shall attend load testing of mechanical handling equipment within their scope. 8.4.1 Appurtenances VENDOR / SUBCONTRACTOR is reminded that electric ancillaries, instruments, may be subject to ARH scrutiny. Refer to Sections 8.5, 8.6 and 8.7. 8.4.2 Passenger Lifts / Man-riding Hoists The Executive Decrees 90-245 and 90-246 are silent regarding passenger lifts and manriding hoists. VENDOR / SUBCONTRACTOR is therefore instructed to notify and seek the advice of PURCHASER for any item of mechanical handling equipment that is designed, or may be converted for the carriage or support of personnel. 8.5 Electrical Electrical equipment may be subject to ARH scrutiny. If an item comes within the scope, members of ARH will conduct the scrutiny. For items within the scope there will normally be a requirement for a preliminary dossier, containing design premises etc., to be presented for appraisal by the ARH before manufacture starts. The contents of the preliminary dossier are detailed in Section 3.0 of this specification. The following electrical equipment and material are within the ARH scope if the maximum voltage rating is equal to or exceeds 5.5 kV. • Transformers • Switchgears • Generators • Motors • Cables The inclusion of electrical equipment and material within the scope of ARH is defined by the maximum design voltage ARH are involved where an item is designed to receive, or may be subjected to, a voltage equal to, or in excess of 5.5 kV. VENDOR / SUBCONTRACTOR is advised that ARH retains an interest in emergency power supplies and other safety related aspects such as earthing arrangements, lighting protection, interlocks etc. Details of emergency switchboards and safety related aspects may be required. VENDOR / SUBCONTRACTOR is reminded that all electrical equipment and materials shall be selected and / or designed such that they are suitable for the purpose for which they are intended to be put to use. They shall be suitable for use in the area specified and defined by the Hazardous Area drawings, and as stated in the Purchase Order or Subcontract and its attachments. Suitable internationally recognized Hazardous Area Certification shall be submitted for all explosion proof electrical items intended to be located in hazardous areas. ARH shall attend final acceptance tests of electrical appliance within their scope to confirm compliance with IEEE, IEC and NEMA regulations. 8.6 Instruments With the exception of Pressure Safety valves, instruments and instrument material are not normally subject to ARH scrutiny. If an item comes within the scope for reasons of safety, members of ARH will conduct inspections. A second Algerian Authority ONML (National Office of Legal Measurement), will be concerned only with measuring components or systems. 8.6.1 Pressure Safety Valves & Control Valves Pressure Safety Valves are within the scope of ARH. These valves need to be checked for opening and closing pressures and tightness. Their primary concerns will be the disposition of PSV’s within a system, the witnessing of off-line tests and correct installation. Design appraisal and witnessing of tests of individual PSV’s in works will, if at all, be limited to large, novel or particularly critical applications. VENDOR / SUBCONTRACTOR shall notify PURCHASER of any non-standard items and obtain advice. The valve body shall be classified by the criteria shown for piping materials, Section 8.7.1 below. Control valves that will contain potential hazardous gasses or liquids under pressure may also be within the scope of ARH, in which case the above requirements for design appraisal and testing shall apply. ARH shall attend hydrostatic testing of Pressure Safety Valves and Control Valves within their scope. 8.6.2 Measuring Instruments Instruments concerned with measurement of physical properties of a product are subject to approval, calibration and certification by ONML. A preliminary dossier, generally in accordance with Section 3.0 of this specification, shall be prepared for each type of instrument. 8.6.3 General Instruments VENDOR / SUBCONTRACTOR is reminded that all instruments and instrument material shall be selected and / or designed such that they are suitable for the purpose for which they are intended to be put to use. Instruments with an electrical content that could therefore be spark or heat generating shall be suitable for use in the area specified and defined by the Hazardous Area drawings, and as stated in the Purchase Order or Subcontract and its attachments. Suitable internationally recognized Hazardous Area Certification shall be submitted for all explosion proof electrical instruments intended to be located in hazardous areas. 8.7 Piping Piping material may be subject to ARH scrutiny. If an item comes within the scope, members of ARH will conduct the scrutiny. For items within the scope there will normally be a requirement for a preliminary dossier, containing design premises etc., to be presented for appraisal by ARH before manufacture starts. The contents of the preliminary dossier are detailed in Section 3.0 of this specification. A Characteristic Number that is a function of pressure and diameter, conditioned by the fluid carried defines the inclusion of Pipes and PipeFittings within the scope of ARH. ARH is involved where the Characteristic Number derived from the maximum working pressure (expressed in barg), multiplied by the internal diameter (expressed in millimeters) exceeds the values stated below. Process Piping The piping for plant is subject to ARH inspection if the following four (4) conditions are simultaneously met: A. The design pressure exceeds 10 barg. B. The internal diameter exceeds 80 mm. C. The Characteristic Number, i.e., the product of the design pressure expressed barg, multiplied by the internal diameter expressed in mm, exceeds the number 1500. D. The vapor pressure at the maximum operating temperature exceeds 1 barg (this condition is used only for the liquid.) Piping for Pipeline All the piping for pipeline is within the ARH scope. 8.7.1 Valves Valves are considered by ARH as pressure retaining items. Valves made in accordance with internationally recognized Codes and Standards will be included in the ARH scope if the internal volume, calculated flange face to flange face, exceeds 100 liters or if the design pressure exceeds 16 barg. For non-standard valves, the criteria laid down for Pressure Valves in Section 8.1. ARH shall attend hydrostatic testing of valves within its scope 8.7.2 Pipe & Pipe Fittings Pipe and pipefittings for use in services other than steam and water where the working pressure exceeds 1 barg are within the ARH inspection scope if the following three (3) conditions are simultaneously met: • Non-hazardous gases and liquids other than steam or water. 1. Inside Diameter > 80mm 2. Design Pressure > 10 barg 3. Characteristic Number > 1500 • Explosion, flammable, corrosive or toxic gases or liquids. 1. Inside Diameter > 80mm 2. Design Pressure > 4 barg 3. Characteristic Number > 1000 • Steam and Super-heated water pipes may not be excluded from the ARH scope by reason of pressure or diameter. Steam and super-heated water pipes are considered as a system. The provision of Executive Decree Number 90-246 apply to steam pipes and systems. • Cold water pipes are not within the ARH inspection scope. ARH shall attend hydrostatic testing of piping systems within their scope. 8.7.3 Piping Specialties Piping specialties are considered by ARH as pressure retaining items. The criteria laid down for pressure vessels in Section 8.1 of this specification apply. 8.8 Loss Prevention, Safety Loss prevention systems and equipment are normally subject to ARH scrutiny. If an item comes within the scope, members of ARH will conduct the scrutiny. For items within the scope there will normally be a requirement for a preliminary dossier, containing design premises etc., to be presented for appraisal by the ARH before manufacture starts. The contents of the preliminary dossier are detailed in Section 3.0. 8.8.1 Fire Fighting Fire fighting systems are within the scope of ARH. ARH will appraise firewater distribution, drawings, firewater demand calculations, the positions of hydrants, monitors, hose-reels etc. Foam, powder and inert gas systems will similarly be examined. Fire extinguishers and other mobile or portable fire fighting devices shall also be examined for suitability of design and construction as well as their disposition on site. ARH shall attend hydrostatic testing and functional testing for all fire fighting equipment. Pressure retaining items shall be considered as pressure vessels as defined in Section 8.1 of this Specification. VENDOR / SUBCONTRACTOR shall notify and obtain the advice of PURCHASER regarding the inclusion of any pressure retaining item within the ARH scope. Bottles of CO2, N2 Bottles of CO2, N2 are within the ARH scope if the following two conditions are simultaneously met : A. Design pressure greater than 4 barg. B. The product of the design pressure expressed in barg, multiplied by the capacity expressed in liters; exceeds the number 10. Fire Extinguisher The fire extinguisher is within the ARH scope if the following three (3) conditions are simultaneously met: A. Design pressure greater than 4 barg. B. The capacity exceeds 5 liters. C. The product of the design pressure expressed in barg, multiplied by the capacity expressed in liters; exceeds the number 80. 8.8.2 Fire & Gas Detection Detection systems – gas, flame, smoke and heat detectors and alarms – shall be subject to ARH approval. Location drawings and details of each detector type deployed shall be submitted. The fire and gas system – logic, panels and data transmission – shall be subject to ARH review. ARH shall attend functional tests of Fire and Gas Detection systems. 8.9 Sewage Networks Sewage Networks shall be within ARH scope. The following shall be subject to control by ARH: 8.10 • General map of sewage networks. • Construction of sight-hold. • Hydraulic guard against flames spread. • Calculation of sewage network flow rates. • Material used. Hazardous Operations Hazardous Operations shall be permitted by ARH only after their acceptance of procedures submitted for review. The procedures for hazardous operations shall detail all perceived hazards and the methods proposed to eliminate them. Reference shall be made to internationally accepted codes, practices and regulations. Existing work practices shall be taken into account and referenced within the procedures. When required by ARH, PURCHASER and / or VENDOR / SUBCONTRACTOR shall demonstrate the application of the procedures under simulated conditions before approval is given. 9.0 PIPELINES ASSOCIATED WITH HYDROCARBONS PRODUCTION The following pipelines are considered as associated with hydrocarbons production: 1. Flowline pipelines that connect either the wellhead to the center for hydrocarbon gas processing or separation and processing centers to the re-injection facilities, or either the separation centers to the flowline main centers (C.P.C.). 2. Service pipelines that connect the re-injection facilities to injection wellhead. 3. Sewers that connect either the processing centers to the main pipelines, or either flowline main centers to main pipelines, either processing or separation centers located in an exploration license area to a re-injection center onto another exploration license area. In order to allow the central administration services to do a regulatory technical control during the installation of the pipelines for the transport of hydrocarbon liquid, under pressure liquefied and gaseous, Enterprises and Firms are required to transmit to ARH the following documents before start-up of work: 9.1 General File • Description of work. • Clauses and general conditions record book. 9.2 9.3 • Piping layout defining distances between underground and aerial work. • Layout profile. • Drawings and schedules for the execution of piping crossing with different communication lines and various work. Technological Drawings & Schedules • Input and output terminals. • Pumping and compression stations. • Cutting, purging and sectionalization stations. • Connection points. Equipment & Materials Submitted to Control • Piping and equipment specifications. • Preliminary and final dossiers for pressure equipment. • Accessories and valves specifications. • Piping, equipment, accessories and valves control statement. • Electrical equipment. For gas pressure, steam and electrical equipment, refer to Section 8 of this Specification. 9.4 9.5 Piping Installation • Welding procedures. • Coating and trenching procedures. • Description of cathodic protection system. Testing & Control • Equipment calibration procedures. • Hydrostatic tests procedures. • Gas Pipeline drying procedures. Before the control and testing operations of a section or a specific area, documents and the following information must be presented to ARH inspector or his delegate: 9.6 • Welding record. • Radiographic films. • Any non-destructive testing control certificate (ultra-sound, magnetic etc.). • Isometric plans. • Welding control. • Coating and trenching. Security Systems A Safety File dossier shall be submitted by the CONTRACTOR prior to Pre-Commissioning. As the files of the security systems must be approved by ARH, the SUPPLIER or SubSUPPLIER shall transmit to the BUYER a Technical File for the following systems. 9.6.1 Emergency Shutdown System 9.6.2 Flare Network 9.6.3 Fire, Heat, Smoke & Gas Detection 9.6.4 Fire Fighting Systems (Network of firewater, CO2 extinction system, and chemical extinction system …) 9.6.5 Grounding Network 9.6.6 Lighting Protection System 10.0 TECHNICAL FILE To facilitate approval, the SUPPLIER shall prepare a Technical File containing the documents listed below as appropriate, and send them to the BUYER. All documents must be provided in French and in English. Section A A letter of request for approval of the Technical File Dossier (Attachments A). Section B Registration of manufacturer’s authorized signatories at the Algerian Consulate (Attachment B). Section C Certificate of compliance for Internal and External Visit form *(Attachment C). Section D Description of equipment (Attachment D). Section E The letter or fax requesting the presence of the ARH inspector for the regulatory test and inspections in the plant (Attachment E). Section F Inspection certificate (Attachment F). Section G Test certificate (Attachment G). Section H Certificate of Conformity (Attachment H). The front cover for Technical File dossiers shall be modified to say Technical File (See sample Dossier Cover page). The Technical Files and documents shall be sent to The BUYER within 30 days after shipment, which will then forward it to ARH. 11.0 ATTACHMENTS To facilitate approval, the SUPPLIER shall prepare the attached documents listed below as appropriate, and send them to the PURCHASER. All documents must be provided in French and English. 1. A letter of request for approval of the Preliminary Dossier (Attachments A and A1). 2. Registration of manufacturers authorized signatories at the Algerian Consulate (Attachment B). 3. Certificate of compliance for Internal and External Visit form (Attachment C). 4. Description of equipment (Attachment D). 5. The letter or fax requesting the presence of the ARH inspector for the regulatory test and inspections in the plant. (Attachment E). 6. Inspection certificate (Attachment F). 7. Test certificate (Attachment G). 8. Certificate of Conformity (Attachment H). SUPPLIER’S LETTERHEAD Date MINISTERE DE L”ENERGIE ET DES MINES A Monsieur Le Directeur de l’Agence de Régulation des Hydrocarbures Alger, ALGERIE Subject: Request for Approval of the Preliminary Dossier Dear Sir, We hereby submit for your approval the preliminary dossier for _______________________________ Item No _____________ (Name of Equipment and Tag Number), for the “Compression/reinjection unit located at HASSI Messaoud . Please review this file and advise if you require any further information or clarifications. Your prompt reply would be greatly appreciated. Sincerely, Name: Title: Signature: ATTACHMENT A LETTRE AVEC ENTETE DU FABRICANT XXX , le MINISTERE DE L’ENERGIE ET DES MINES A Monsieur Le Directeur de l’Agence de Régulation des Hydrocarbures Alger, ALGERIE OBJET: Approbation du Dossier d’Etude Préliminaire Monsieur, J’ai l’honneur de vous soumettre pour approbation le dossier d’étude préliminaire ci-joint relatif à l’équipement __________________________ Item No______________ qui entre dans le cadre du projet “ Compression/reinjection - à HASSI Messaoud . Dans cette attente, je vous prie d’agréer, Monsieur, l’assurance de ma considération distinguée. Nom: __________________________ Titre: __________________________ Signature: ______________________ ANNEXE A MANUFACTURER’S SIGNATURES CERTIFICATION (for submittal of the Dossiers to ARH) MANUFACTURER: Name: Title (Company Officer): Signature and Stamp: LOCAL CHAMBER OF COMMERCE: Name: Title: Signature: By this document, we certify that the following signatures: Name: Title: Signature: Name: Title: Signature: Name: Title: Signature: Are signatures of those authorized to sign for: Manufacturer: STAMP OF ALGERIAN CONSULATE Date: Name and Signature: ATTACHMENT B CERTIFICATION DES SIGNATURES DU FABRICANT ( A SOUMETTRE A L’ARH - MINISTERE DE L’ENERGIE ) FABRICANT: NOM: TITRE: SIGNATURE: CHAMBRE DE COMMERCE LOCALE: NOM: Cachet et Signature : Nous certifions par la présente que les signatures ci-dessus de: NOM :_____________________ TITRE: _________________ SIGNATURE_________________ NOM _____________________ TITRE: _________________ SIGNATURE_________________ NOM :_____________________ TITRE: _________________ SIGNATURE_________________ Sont celles des signataires mandatés de: NOM DU FABRICANT: VISA DU CONSULAT ALGERIEN: DATE: SIGNATURE: ANNEXE B CERTIFICATE OF COMPLIANCE FOR INTERNAL & EXTERNAL VISIT I, the undersigned, Name Exact Title: Company: Certify that equipment Item No___________ (Tag Number) for the “Compression/reinjection unit located at HASSI Messaoud . “ will be designed and manufactured in accordance with technical documents which were submitted to ARH - Ministry of Energy for approval and all applicable Algerian regulations. Before this equipment is presented to the ARH Inspector, it will be inspected by our authorized representative. The inspection will ensure the equipment conforms with our design drawings and specifications (wall thickness, metal characteristics, fabrication, etc.). Furthermore, I certify no equipment will be presented for ARH inspection until it has passed our inspection. At:___________________ ; Date: ___________________ ; Signature: ___________________ STAMP OF ALGERIAN CONSULATE Name: Title: Signature: Date: ATTACHMENT C CERTIFICAT DE CONFORMITE ET DE VISITE INTERIEURES ET EXTERIEURES Je soussigné, Nom _______________________________ Prénom _____________________________________ Directeur Général de la Société (adresse exacte):____________________________________________________________________ certifie que l’équipement suivante ___________ (Item ou numéro de repère) destinée au Projet “ Compression/reinjection - unit à HASSI Messaoud . , sera conçue et fabriquée conformément aux documents soumis pour approbation à l’ARH - Ministère de l’Energie et répond en tous points aux règlements applicables en ALGERIE. Cet équipement sera, avant de le présenter à l’épreuve règlementaire à l’ARH , visitée par un technicien désigné par mes soins intérieurement et extérieurement. La vérification portera sur la conformité de la pièce d’équipement avec son plan de construction, l’exactitude des renseignements figurant sur l’état descriptif notamment en ce qui concerne les épaisseurs des tôles, les caractéristiques du métal et les modes d’assemblage. Je certifie par ailleurs que toutes pièces d’équipement présentant un vice quelconque de construction ne sera pas présentée … l’épreuve. A __________________________________________ le ___________________________ Visa du Consulat Algérien: Date: Signature: ANNEXE C Project : Compression/reinjection - unit à HASSI Messaoud . Client : SONATRACH- Location : HASSI- MESSAOUD DESCRIPTION OF EQUIPMENT Purchase Order No Item or Tag No Manufacturers No Department Manufacturer’s Name Address Manufacturing Year Drawing No Manufacturing Code : : : : : : : : : TECHNICAL CHARACTERISTIC - Type (Vessel, Boiler, Heat exchanger, Furnace…) Equipment Name General Form Fluid handled Maximum Operating Pressure Design Pressure Design Temperature Operating Temperature Test Pressure Type of Materials Thickness Tensile Point Allowable stress Coefficient of weld joint Radiography Heat Treatment Corrosion Allowance Non-Destructive Tests Volume ATTACHMENT D : : : : : : : : : : : : : : : : : : : Job No. : Compression/reinjection - unit à HASSI Messaoud . Client : SONATRACH- Lieu : HASSI-MESSAOUD ETAT DESCRIPTIF Ordre d’achat No No Item (repère) No Fabrication Service Nom et adresse fabricant Année de construction Plans No Code de construction : : : : : : : : CARACTERISTIQUES TECHNIQUES Type (récipient, chaudière, échanger, four, etc.) Dénomination de l’appareil Forme générale Fluide véhicule Pression maxi de service Température de calcul Température de service Pression d’essai Matériaux utilisés Epaisseur Charge limite de rupture Contrainte admissible Coefficient de joint Radiographie Traitement thermique Surépaisseur de corrosion Essais non destructifs Volume intérieur ANNEXE D : : : : : : : : : : : : : : : : : : From : To: MINISTERE DE L’ENERGIE Monsieur le Directeur Agence de Régulation des Hydrocarbures. VIA: ……………. Copy: Our References: Fax No. Subject: ________________ _on REQUEST FOR ARH INSPECTOR We request the presence of ARH Inspector for test at the plant listed below. DESIGNATION Item No. Equipment Manufacturer Facility ATTACHMENT E Test Date Facility Address FAX DE DEMANDE DE PRESENCE D’INSPECTEUR ARH Expéditeur: Destinataire: Ministère de l’Energie Monsieur le Directeur Agence de Régulation des Hydrocarbures Alger Copie: ________________________ N/Références: FAX No _____________ du ______________ Objet : CONTROLES REGLEMENTAIRES EN USINE Nous avons l’honneur de vous demander de designer un inspecteur de votre structure pour assister aux tests des équipements en Usine repris dans le programme ci dessous: DESIGNATION Item No. Equipement Fabrication ANNEXE E Date Essais Lieu INSPECTION CERTIFICATE Equipment: Description: Item No.: Service: Manufacturer Address: I hereby certify that the equipment mentioned above was inspected in accordance with specifed requirements and was found in conformance. Drawing No: Manufacturer: Name : Title : Date: Signature: ARH Inspector : Name : Date: Signature: ATTACHMENT F CERTIFICAT D’INSPECTION Equipement: Désignation: No d’item: Service: Fabricant: (adresse exacte) _ _ Je certifie par la présente que l’équipement sus-mentionné a été soumis à une inspection interne et externe et qu’il s’est avéré conforme aux : Plans No Fabricant Nom - Signature Date Inspecteur ARH Nom et Signature Date ANNEXE F TEST CERTIFICATE I hereby certify that: Equipment Description: Item No: Service: satisfactorily passed the hydraulic pressure test at : Effective bar: Duration Test: Manufacturer: Name : Title : Date: Signature: ARH Inspector : Name : Date: Signature: ATTACHMENT G CERTIFICAT D’ESSAI Je certifie par la présente que: (Désignation équipement) (No d’item) (Service) a été mis à l’épreuve d’une manière satisfaisante sous une pression hydraulique de : _______________________________ (bar effectif) _______________________________ (durée) Fabricant Name_____________________ Titre Date Signature Visiteur délégué DDP Name Date Signature ANNEXE G CERTIFICATE OF CONFORMITY I, the undersigned, Name: Exact Title: Company: certify that equipment _____________(Tag Number) for the “COMPRESSION/REINJECTION UNIT ” is manufactured conforms for use in the country of origin :___________________________________ At: ______________________.; Date: _____________________.; Signature:___________________ Stamp of Algerian Consulate Name: Title: Signature: Date: ATTACHMENT H CERTIFICAT D’ORIGINE Je, soussigné, Nom: Titre: Fabricant: certifie que la pièce d’équipement _____________ (Tag No) destinée pour le projet “ COMPRESSION/REINJECTION “ est de construction conforme pour une utilisation dans le pays d’origine : _______________________ A: ______________________.; Date: _____________________.; Signature:___________________ Visa du Consulat Algérien Nom: Titre: Signature: Date: ANNEXE H DIRECTION DE L’AGENCE DE REGULATION DES HYDROCARBURES MINISTERE DE L’ENERGIE ET MINES REALISATION DES INSTALLATIONS DE COMPRESSION/REINJECTION A HASSI MESSAOUD -ZCINA CONTRACT SONATRACH / DESIGNATION DE L’EQUIPEMENT: NO(S). ETIQUETTE: Dossier D’Etude Preliminaire Vol de DIRECTION DE L’AGENCE DE REGULATION DES HYDROCARBURES MINISTERE DE L’ENERGIE ET MINES REALISATION DES INSTALLATIONS DE COMPRESSION/REINJECTION A HASSI MESSAOUD -ZCINA CONTRACT SONATRACH / DESIGNATION DE L’EQUIPEMENT: NO(S). ETIQUETTE: Vol de Vol Dossier Final de