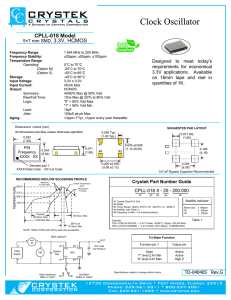

Table des matières tp cle 2 QT110(H) MC145026 1 1 Introduction 2 2 Electrical Specifications 3 3 Operating Characteristics 3.1 3.1 MC145026 3.2 3.2 MC145027 3.3 3.3 MC145028 4 4 Pin Descriptions 4.1 4.1 MC145026 Encoder 4.2 4.2 MC145027 and MC145028 Decoders 5 5 MC145027 and MC145028 Timing 6 6 Package Dimensions tx_saw_ia(1) bc-nbk 1 Pagina 1 2 10 23 23 26 30 30 31 31 31 31 32 38 40 43 44 44 Projet d’électronique Licence professionnelle CCSEE SYSTEME D’ACCES SANS CLEF BRUNO ESTIBALS FLORIAN LARRAMENDY HELENE LEYMARIE -1- « Système d’accès sans clé » VOITURE Capteur (QT110) Décodeur MC145027 DEVEROUILLE Emetteur/Récepteur Emetteur/Récepteur Encodeur MC145027 UTILISATEUR Fig. 1: Schéma synoptique de la serrure intelligente 1. Principe de fonctionnement Le système est composé de deux parties, l’une dans la voiture et l’autre sur l’utilisateur comme représentées sur la figure 1. -2- L’utilisateur s’approche de la poignée de sa voiture. Le capteur détecte la présence d’une personne et envoie une requête pour savoir si cette personne possède une « clé » qui permettrait d’ouvrir la voiture (transmission 1 : voiture/utilisateur). Une fois cette requête reçue, l’encodeur, qui se trouve sur la clé, envoie son code d’identification à la voiture (transmission 2 : utilisateur /voiture). Le message est reçu par le décodeur qui vérifie la correspondance avec sa propre identification. S’ils sont identiques alors la porte de la voiture se déverrouille. Dans ce TP ne sera réalisée que la carte voiture. La carte clé est déjà réalisée et sera distribuée en début de TP. La face avant et le schéma électrique de la carte sont donnés en annexe 0. Afin d’économiser les piles de la carte clé veuillez éteindre (OFF) l’alimentation de la carte après chaque mesure. 2. Le capteur capacitif Le QT110 est un capteur capacitif. Ce capteur permet de détecter une présence lors de son approche ou d’un « touché ». Figure 2 : principe du capteur capacitif Ce capteur permet de détecter une personne voulant ouvrir la voiture. Le principe physique repose sur la capacité que présente notre corps (de l’ordre de quelques picofarads) qui, en fermant le circuit représenté sur la figure 2, induit un courant et active la sortie du capteur à l’état bas. Pour augmenter ou diminuer la sensibilité, il existe 3 modes de sensibilité « médium, low, touché » ajustés par la capacité Cs. Il y a également 4 modes de fonctionnement (sortie à l’état haut au repos) : DC out 10 ou 60 : Après détection, ce mode met la sortie à l’état bas durant 10s ou 60s. -3- Toggle : Une détection change l’état de la sortie (Qn+1= /Qn). Pulse : Ce mode envoie une impulsion de 75 ms pour chaque détection. En vous appuyant sur le document constructeur donné en annexe1, choisissez le mode de fonctionnement le plus approprié sachant que le signal de sortie doit servir de signal de détection. C’est une impulsion à l’état bas au toucher de l’électrode. Proposer un schéma de câblage sur lequel on pourra visualiser le toucher grâce à une DEL rouge active à l’état bas. Exploitation expérimentale : Réalisez votre montage. Simulez la poignée de la porte par un grippe fil connecté à la place de l’électrode. Mesurez la distance d’approche maximale selon différentes capacités Cs (10nF < Cs < 30nF).En gardant une capacité Cs de 10nF, changez le type d’électrode. Que peut-on en déduire de la forme et des dimensions de l’électrode par rapport à la sensibilité ? Quel est l’effet de la pluie sur l’électrode? 3. L’encodeur et le décodeur Du coté de la carte clé, le code de la voiture est envoyé crypté grâce à l’encodeur. Le décodeur est alors nécessaire du côté du récepteur pour décrypter l’information. L’encodeur et le décodeur utilisés sont deux composants de chez Motorola respectivement le MC145026 et le MC145027 (documents constructeur en annexe 2). 3a) L’encodeur Le MC145026 encode deux informations successivement : - une adresse (mot binaire A de 5 bits) - des données (mot binaire D de 4 bits). Un mot est ainsi constitué de 9 bits « AD ». Chaque bit est fixé - pour le mot adresse : soit à l’état haut (dit high), soit à l’état bas (dit low) soit à l’état ouvert (dit open) - pour le mot de données soit à l’état ouvert (dit open), soit à l’état bas (dit low). Une représentation du codage de l’information est donnée sur la figure 3. Figure 3 : codage des informations sur 9 bits « AD ». (doc. Constructeur) -4- Ces informations sont séquencées par une horloge ajustable par trois composants externes RTC, CTC et RS. Elles sont envoyées en continu grâce à l’entrée TE fixée à l’état bas comme indiquée figure 3. Exploitation expérimentale Dans cette étude on n’utilise pas l’émetteur et le récepteur. Otez tous les cavaliers de la carte clé sauf le cavalier TE câblé à la masse. Visualisez à partir de la carte, le signal encodé. Modifiez les mots A et D de la carte clé et observez les modifications du signal codé. Vérifiez le codage de l’adresse et des données transmises. Mesurez la fréquence d’horloge. OFF 3b) Le décodeur Le MC145027 reçoit l’adresse et les données envoyées en série successivement. La partie correspondante à l’adresse est comparée avec sa propre adresse locale. Si les deux adresses sont identiques alors le décodeur restitue les données en parallèle. De plus, si deux mots consécutifs envoyés sont égaux, ce qui garantit une bonne réception, le décodeur valide la transmission grâce à la sortie Vt qui bascule à l’état haut. Cette sortie est utilisée pour le déverrouillage de la portière. Exploitation expérimentale Déterminez les valeurs des composants R1, C1, et R2 et C2 pour obtenir un débit à 1.71Khz égal à celui de l’encodeur. Proposez un schéma de câblage sur lequel la sortie VT du décodeur sera visualisable avec une DEL verte. Réalisez le montage. Fixez le même mot A que celui de la carte clé. Reliez à l’aide d’un fil la sortie de l’encodeur à l’entrée du décodeur. Testez votre montage. Que se passe-t-il si les adresses ne correspondent pas ou si la transmission des informations est erronée? A quoi peuvent servir les données (mot D) ? OFF 4. L’émetteur et récepteur L’émetteur et le récepteur sont deux composants qui permettent à deux systèmes distants, non reliés physiquement, de pouvoir communiquer entre eux en utilisant les ondes radios par modulation d’amplitude en tout ou rien (OOK). L’émetteur et le récepteur utilisés est un module RTL-DATA-SAW qui fonctionne à 433.92Mhz : c’est la fréquence sur laquelle l’information va être transmise. Ce module peut à la fois émettre et recevoir. C’est un transciever ou « émetteur/récepteur ». Exploitation expérimentale On teste la transmission 2 (clé/voiture). Le signal à transmettre est le code de la voiture et les données envoyés, en série, à un débit qui doit être inférieur à 3 KHz (voir documentation constructeur en annexe 3). L’émetteur /récepteur sur la carte clé est déjà précâblé. Proposez un schéma de câblage de l’émetteur/récepteur situé sur la voiture de façon à ce qu’il soit en mode récepteur (contrôle des alimentations). Faîtes valider et réalisez le montage. -5- Portée du dispositif : Dans un premier temps, on doit recevoir les données issues de l’encodeur et envoyées par la carte clé. Reliez par un cavalier la sortie de l’encodeur et l’entrée de l’émetteur. Déplacez vous dans la salle et même à l’extérieur et observez le signal reçu sur votre récepteur. Mesurez la portée maximale en mètres entre les deux cartes. La communication est –elle perturbée par votre téléphone portable en veille ou en appel ? OFF Bande passante du dispositif : Dans un deuxième temps, on envoie un signal carré à une fréquence de 500Hz à la place des données de l’encodeur. Pour cela enlevez tous les cavaliers et branchez le signal carré TTL sur l’entrée de l’émetteur. Testez la réception des données. Faites varier la fréquence de 100 Hz à 9 KHz et conclure sur l’amplitude du signal reçu et son décalage temporel. OFF 5. Réalisation finale Après avoir testé chaque bloc séparément, nous allons les assembler. Malheureusement nous ne pouvons les assembler directement entre eux. 5a) Contrôle des alimentations des « émetteur/récepteur » Une étude préalable a montré que si l’on alimente l’émetteur et le récepteur en même temps, le récepteur reçoit le signal émis par son propre émetteur. Pour éviter cela, nous devons faire un contrôle des alimentations, ce qui signifie que les deux alimentations de l’émetteur et du récepteur doivent être complémentaires. Contrôle des alimentations côté voiture L’émetteur de la voiture ne doit fonctionner que lorsqu’un toucher est détecté. Le signal transmis est une impulsion de 75ms à l’état haut. Justifiez ce dernier choix. Proposez un schéma de câblage. Après validation, réalisez le montage et testez le. Pour cela, observez les alimentations de l émetteur/récepteur côté voiture après la détection d’un touché. Puis câblez tous les cavaliers de la carte clé et observez la sortie de l’encodeur dans les mêmes conditions.. OFF Contrôle des alimentations côté clé La carte clé envoie les mots de 9 bits codés pendant 5 secondes après la détection du front montant de l’impulsion de 75 ms. Cela est réalisé grâce à un monostable qui gère le contrôle de l’alimentation du récepteur de la carte clé mais aussi du signal TE de l’encodeur. La sortie de ce monostable est à l’état bas durant 5 s. Observez sur la carte clé le signal TE et mesurez le temps à l’état bas. Conclure quant au contrôle des alimentations de l’émetteur et du récepteur de la carte clé. OFF -6- 5b) Ouverture et fermeture de la voiture La voiture doit s’ouvrir quand la carte clé correspondant à la voiture est détectée. Mettez la même adresse sur les deux cartes et testez votre montage. Observez le résultat de la sortie VT du décodeur (DEL verte) en mettant la carte à une dizaine de centimètres puis un mètre puis 3 mètres. Pourquoi la DEL verte s’allume t’-elle de moins en moins souvent quand la distance augmente ? Est-ce nécessaire ? Si vous avez le temps proposez et câblez l’affichage des données envoyées par la carte clé sur un afficheur 7 segments. Visualisation de l’ouverture et de la fermeture de la voiture: Une deuxième LED verte traduit l’ouverture de la voiture tandis qu’une LED rouge traduit sa fermeture. La voiture se verrouille à l’appui d’un bouton poussoir. Proposez un schéma de câblage et réalisez le montage. -7- Annexe 0 Schéma électrique de la carte clé -8- QProx™ ™ QT110 / QT110H CHARGE-TRANSFER TOUCH SENSOR Less expensive than many mechanical switches Projects a ‘touch button’ through any dielectric Turns small objects into intrinsic touch sensors 100% autocal for life - no adjustments required Only one external part required - a 1¢ capacitor Piezo sounder direct drive for ‘tactile’ click feedback LED drive for visual feedback 2.5 to 5V 20µ µA single supply operation Toggle mode for on/off control (strap option) 10s or 60s auto-recalibration timeout (strap option) Pulse output mode (strap option) Gain settings in 3 discrete levels Simple 2-wire operation possible HeartBeat™ health indicator on output Active Low (QT110), Active High (QT110H) versions Vdd 1 Out 2 Opt1 3 Opt2 4 QT110 ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! 8 Vss 7 Sns2 6 Sns1 5 Gain APPLICATIONS ! ! Light switches Industrial panels ! ! Appliance control Security systems ! ! Access systems Pointing devices ! ! Elevator buttons Toys & games The QT110 / QT110H charge-transfer (“QT’”) touch sensor is a self-contained digital IC capable of detecting near-proximity or touch. It will project a sense field through almost any dielectric, like glass, plastic, stone, ceramic, and most kinds of wood. It can also turn small metal-bearing objects into intrinsic sensors, making them respond to proximity or touch. This capability coupled with its ability to self calibrate continuously can lead to entirely new product concepts. It is designed specifically for human interfaces, like control panels, appliances, toys, lighting controls, or anywhere a mechanical switch or button may be found; it may also be used for some material sensing and control applications provided that the presence duration of objects does not exceed the recalibration timeout interval. The IC requires only a common inexpensive capacitor in order to function. A bare piezo beeper can be connected to create a ‘tactile’ feedback clicking sound; the beeper itself then doubles as the required external capacitor, and it can also become the sensing electrode. An LED can also be added to provide visual sensing indication. With a second inexpensive capacitor the device can operated in 2-wire mode, where both power and signal traverse the same wire pair to a host. This mode allows the sensor to be wired to a controller with only a twisted pair over a long distances. Power consumption is under 20µA in most applications, allowing operation from Lithium cells for many years. In most cases the power supply need only be minimally regulated. The IC’s RISC core employs signal processing techniques pioneered by Quantum; these are specifically designed to make the device survive real-world challenges, such as ‘stuck sensor’ conditions and signal drift. Even sensitivity is digitally determined and remains constant in the face of large variations in sample capacitor CS and electrode CX. No external switches, opamps, or other analog components aside from CS are usually required. The device includes several user-selectable built in features. One, toggle mode, permits on/off touch control, for example for light switch replacement. Another makes the sensor output a pulse instead of a DC level, which allows the device to 'talk' over the power rail, permitting a simple 2-wire interface. The Quantum-pioneered HeartBeat™ signal is also included, allowing a host controller to monitor the health of the QT110 continuously if desired. By using the charge transfer principle, the IC delivers a level of performance clearly superior to older technologies in a highly cost-effective package. TA 00C to +700C 00C to +700C -400C to +850C -400C to +850C Quantum Research Group Ltd AVAILABLE OPTIONS SOIC QT110-S QT110H-S QT110-IS QT110H-IS 8-PIN DIP QT110-D QT110H-D Copyright © 1999 Quantum Research Group Ltd R1.02/0109 1 - OVERVIEW Figure 1-1 Standard mode options The QT110 is a digital burst mode charge-transfer (QT) sensor designed specifically for touch controls; it includes all hardware and signal processing functions necessary to provide stable sensing under a wide variety of changing conditions. Only a single low cost, non-critical capacitor is required for operation. +2.5 to 5 2 Figure 1-1 shows the basic QT110 circuit using the device, with a conventional output drive and power supply connections. Figure 1-2 shows a second configuration using a common power/signal rail which can be a long twisted pair from a controller; this configuration uses the built-in pulse mode to transmit output state to the host controller (QT110 only). 3 4 OU TP UT=D C TIM EO UT= 10 S ecs TOGG LE=OF F GA IN= HIGH 1.1 BASIC OPERATION The QT110 employs short, ultra-low duty cycle bursts of charge-transfer cycles to acquire its signal. Burst mode permits power consumption in the low microamp range, dramatically reduces RF emissions, lowers susceptibility to EMI, and yet permits excellent response time. Internally the signals are digitally processed to reject impulse noise, using a 'consensus' filter which requires four consecutive confirmations of a detection before the output is activated. 2 3 O UT S NS 2 O PT 1 G A IN S E NS IN G E LE C T RO DE Cs 10 nF Cx 4 O PT 2 S NS 1 S N S1 Cs 1 0nF Cx 6 Vss 8 The internal ADC treats Cs as a floating transfer capacitor; as a direct result, the sense electrode can be connected to either SNS1 or SNS2 with no performance difference. In both cases the rule Cs >> Cx must be observed for proper operation. The polarity of the charge buildup across Cs during a burst is the same in either case. 7 5 OP T2 5 1.2 ELECTRODE DRIVE 22 µF 10V AL 1 G A IN Option pins allow the selection or alteration of several special features and sensitivity. +3V V dd OP T1 7 A simple circuit variation is to replace Cs with a bare piezo sounder (Section 2), which is merely another type of capacitor, albeit with a large thermal drift coefficient. If Cpiezo is in the proper range, no other external component is required. If Cpiezo is too small, it can simply be ‘topped up’ with an inexpensive ceramic capacitor connected in parallel with it. The QT110 drives a 4kHz signal across SNS1 and SNS2 to make the piezo (if installed) sound a short tone for 75ms immediately after detection, to act as an audible confirmation. + Tw ist e d pa ir S N S2 Cs is thus non-critical; as it drifts with temperature, the threshold algorithm compensates for the drift automatically. Figure 1-2 2-wire operation, self-powered (QT110 only) 2 . 2k Vdd OU T The IC is highly tolerant of changes in Cs since it computes the threshold level ratiometrically with respect to absolute load, and does so dynamically at all times. The QT switches and charge measurement hardware functions are all internal to the QT110 (Figure 1-3). A 14-bit single-slope switched capacitor ADC includes both the required QT charge and transfer switches in a configuration that provides direct ADC conversion. The ADC is designed to dynamically optimize the QT burst length according to the rate of charge buildup on Cs, which in turn depends on the values of Cs, Cx, and Vdd. Vdd is used as the charge reference voltage. Larger values of Cx cause the charge transferred into Cs to rise more rapidly, reducing available resolution; as a minimum resolution is required for proper operation, this can result in dramatically reduced apparent gain. Conversely, larger values of Cs reduce the rise of differential voltage across it, increasing available resolution by permitting longer QT bursts. The value of Cs can thus be increased to allow larger values of Cx to be tolerated (Figures 4-1, 4-2, 4-3 in Specifications, rear). CMOS GATE S E NS ING E LEC TRO DE 1 6 It is possible to connect separate Cx and Cx’ loads to SNS1 and SNS2 simultaneously, although the result is no different than if the loads were connected together at SNS1 (or SNS2). It is important to limit the amount of stray capacitance on both terminals, especially if the load Cx is already large, for example by minimizing trace lengths and widths so as not to exceed the Cx load specification and to allow for a larger sensing electrode size if so desired. The PCB traces, wiring, and any components associated with or in contact with SNS1 and SNS2 will become touch sensitive and should be V ss 8 -2- Figure 1-3 Internal Switching & Timing ELE C TRO DE R esult 1.3.1 ELECTRODE GEOMETRY AND SIZE Start There is no restriction on the shape of the electrode; in most cases common sense and a little experimentation can result in a good electrode design. The QT110 will operate equally well with long, thin electrodes as with round or square ones; even random shapes are acceptable. The electrode can also be a 3-dimensional surface or object. Sensitivity is related to electrode surface area, orientation with respect to the object being sensed, object composition, and the ground coupling quality of both the sensor circuit and the sensed object. If a relatively large electrode surface is desired, and if tests Figure 1-4 Mesh Electrode Geometry Single -Slo pe 14-bit Switched Cap acito r AD C 1.3 ELECTRODE DESIGN SNS2 Bu rst Controller treated with caution to limit the touch area to the desired location. Multiple touch electrodes can be used, for example to create a control button on both sides of an object, however it is impossible for the sensor to distinguish between the two touch areas. Do ne Cs Cx SNS1 C ha rg e Am p will provide ample ground coupling, since there is capacitance between the windings and/or the transformer core, and from the power wiring itself directly to 'local earth'. Even when battery powered, just the physical size of the PCB and the object into which the electronics is embedded will generally be enough to couple a few picofarads back to local earth. 1.3.3 VIRTUAL CAPACITIVE GROUNDS When detecting human contact (e.g. a fingertip), grounding of the person is never required. The human body naturally has several hundred picofarads of ‘free space’ capacitance to the local environment (Cx3 in Figure 1-5), which is more than two orders of magnitude greater than that required to create a return path to the QT110 via earth. The QT110's PCB however can be physically quite small, so there may be little ‘free space’ coupling (Cx1 in Figure 1-5) between it and the environment to complete the return path. If the QT110 circuit ground cannot be earth grounded by wire, for example via the supply connections, then a ‘virtual capacitive ground’ may be required to increase return coupling. show that the electrode has more capacitance than the QT110 can tolerate, the electrode can be made into a sparse mesh (Figure 1-4) having lower Cx than a solid plane. Sensitivity may even remain the same, as the sensor will be operating in a lower region of the gain curves. Figure 1-5 Kirchoff's Current Law 1.3.2 KIRCHOFF’S CURRENT LAW Like all capacitance sensors, the QT110 relies on Kirchoff’s Current Law (Figure 1-5) to detect the change in capacitance of the electrode. This law as applied to capacitive sensing requires that the sensor’s field current must complete a loop, returning back to its source in order for capacitance to be sensed. Although most designers relate to Kirchoff’s law with regard to hardwired circuits, it applies equally to capacitive field flows. By implication it requires that the signal ground and the target object must both be coupled together in some manner for a capacitive sensor to operate properly. Note that there is no need to provide actual hardwired ground connections; capacitive coupling to ground (Cx1) is always sufficient, even if the coupling might seem very tenuous. For example, powering the sensor via an isolated transformer -3- CX2 S e n se E le ctro de S EN SO R CX1 Su rro und in g e nv iro nm e n t C X3 millimeters of internal air gap; if the product is very thin and contact with the product's back is a concern, then some form of rear shielding may be required. Figure 1-6 Shielding Against Fringe Fields 1.3.5 SENSITIVITY Sen se w ire The QT110 can be set for one of 3 gain levels using option pin 5 (Table 1-1). If left open, the gain setting is high. The sensitivity change is made by altering the numerical threshold level required for a detection. It is also a function of other things: electrode size, shape, and orientation, the composition and aspect of the object to be sensed, the thickness and composition of any overlaying panel material, and the degree of ground coupling of both sensor and object are all influences. Sens e w ire 1.3.5.1 Increasing Sensitivity In some cases it may be desirable to increase sensitivity further, for example when using the sensor with very thick panels having a low dielectric constant. U ns hielded Electrod e S h ield ed E lec trod e A ‘virtual capacitive ground’ can be created by connecting the QT110’s own circuit ground to: (1) A nearby piece of metal or metallized housing; (2) A floating conductive ground plane; (3) A nail driven into a wall when used with small electrodes; (4) A larger electronic device (to which its output might be connected anyway). Free-floating ground planes such as metal foils should maximize exposed surface area in a flat plane if possible. A square of metal foil will have little effect if it is rolled up or crumpled into a ball. Virtual ground planes are more effective and can be made smaller if they are physically bonded to other surfaces, for example a wall or floor. 1.3.4 FIELD SHAPING The electrode can be prevented from sensing in undesired directions with the assistance of metal shielding connected to circuit ground (Figure 1-6). For example, on flat surfaces, the field can spread laterally and create a larger touch area than desired. To stop field spreading, it is only necessary to surround the touch electrode on all sides with a ring of metal connected to circuit ground; the ring can be on the same or opposite side from the electrode. The ring will kill field spreading from that point outwards. If one side of the panel to which the electrode is fixed has moving traffic near it, these objects can cause inadvertent detections. This is called ‘walk-by’ and is caused by the fact that the fields radiate from either surface of the electrode equally well. Again, shielding in the form of a metal sheet or foil connected to circuit ground will prevent walk-by; putting a small air gap between the grounded shield and the electrode will keep the value of Cx lower and is encouraged. In the case of the QT110, the sensitivity is low enough that 'walk-by' should not be a concern if the product has more than a few Sensitivity can often be increased by using a bigger electrode, reducing panel thickness, or altering panel composition. Increasing electrode size can have diminishing returns, as high values of Cx will reduce sensor gain (Figures 4-1 ~ 4-3). Also, increasing the electrode's surface area will not substantially increase touch sensitivity if its Table 1-1 Gain Setting Strap Options Gain High Medium Low Tie Pin 5 to: None Pin 6 Pin 7 diameter is already much larger in surface area than the object being detected. The panel or other intervening material can be made thinner, but again there are diminishing rewards for doing so. Panel material can also be changed to one having a higher dielectric constant, which will help propagate the field through to the front. Locally adding some conductive material to the panel (conductive materials essentially have an infinite dielectric constant) will also help dramatically; for example, adding carbon or metal fibers to a plastic panel will greatly increase frontal field strength, even if the fiber density is too low to make the plastic bulk-conductive. 1.3.5.2 Decreasing Sensitivity In some cases the QT110 may be too sensitive, even on low gain. In this case gain can be lowered further by any of a Figure 2-1 Drift Compensation S ign a l H yste resis T hr es ho ld R e fe re nce O u tpu t -4- number of strategies: making the electrode smaller, connecting a very small capacitor in series with the sense lead, or making the electrode into a sparse mesh using a high space-to-conductor ratio (Figure 1-4). A deliberately added Cx capacitor can also be used to reduce sensitivity according to the gain curves (see Section 4). Intermediate levels of gain (e.g. between 'medium' and 'low' can be obtained by a combination of jumper settings with one or more of the above strategies. 2 - QT110 SPECIFICS 2.1 SIGNAL PROCESSING The QT110 processes all signals using 16 bit math, using a number of algorithms pioneered by Quantum. The algorithms are specifically designed to provide for high 'survivability' in the face of all kinds of adverse environmental changes. sensor will compensate for the object's removal very quickly, usually in only a few seconds. 2.1.2 THRESHOLD CALCULATION Sensitivity is dependent on the threshold level as well as ADC gain; threshold in turn is based on the internal signal reference level plus a small differential value. The threshold value is established as a percentage of the absolute signal level. Thus, sensitivity remains constant even if Cs is altered dramatically, so long as electrode coupling to the user remains constant. Furthermore, as Cx and Cs drift, the threshold level is automatically recomputed in real time so that it is never in error. The QT110 employs a hysteresis dropout below the threshold level of 50% of the delta between the reference and threshold levels. 2.1.3 MAX ON-DURATION If an object or material obstructs the sense pad the signal 2.1.1 DRIFT COMPENSATION ALGORITHM Table 2-1 Output Mode Strap Options Signal drift can occur because of changes in Cx and Cs over time. It is crucial that drift be compensated for, otherwise false detections, non-detections, and sensitivity shifts will follow. Drift compensation (Figure 2-1) is performed by making the reference level track the raw signal at a slow rate, but only while there is no detection in effect. The rate of adjustment must be performed slowly, otherwise legitimate detections could be ignored. The QT110 drift compensates using a slew-rate limited change to the reference level; the threshold and hysteresis values are slaved to this reference. Once an object is sensed, the drift compensation mechanism ceases since the signal is legitimately high, and therefore should not cause the reference level to change. The QT110's drift compensation is 'asymmetric': the reference level drift-compensates in one direction faster than it does in the other. Specifically, it compensates faster for decreasing signals than for increasing signals. Increasing signals should not be compensated for quickly, since an approaching finger could be compensated for partially or entirely before even touching the sense pad. However, an obstruction over the sense pad, for which the sensor has already made full allowance for, could suddenly be removed leaving the sensor with an artificially elevated reference level and thus become insensitive to touch. In this latter case, the Figure 2-2 Powering From a CMOS Port Pin P O RT X .m 0.01µF C MO S m icro controller V dd P O RT X .n O UT Q T11 0 V ss Tie Pin 3 to: Tie Pin 4 to: Max OnDuration DC Out Vdd Vdd 10s DC Out Vdd Gnd 60s Toggle Gnd Gnd 10s Pulse Gnd Vdd 10s may rise enough to create a detection, preventing further operation. To prevent this, the sensor includes a timer which monitors detections. If a detection exceeds the timer setting, the timer causes the sensor to perform a full recalibration. This is known as the Max On-Duration feature. After the Max On-Duration interval, the sensor will once again function normally, even if partially or fully obstructed, to the best of its ability given electrode conditions. There are two timeout durations available via strap option: 10 and 60 seconds. 2.1.4 DETECTION INTEGRATOR It is desirable to suppress detections generated by electrical noise or from quick brushes with an object. To accomplish this, the QT110 incorporates a detect integration counter that increments with each detection until a limit is reached, after which the output is activated. If no detection is sensed prior to the final count, the counter is reset immediately to zero. In the QT110, the required count is 4. The Detection Integrator can also be viewed as a 'consensus' filter, that requires four detections in four successive bursts to create an output. As the basic burst spacing is 75ms, if this spacing was maintained throughout all 4 counts the sensor would react very slowly. In the QT110, after an initial detection is sensed, the remaining three bursts are spaced about 18ms apart, so that the slowest reaction time possible is 75+18+18+18 or 129ms and the fastest possible is 54ms, depending on where in the initial burst interval the contact first occurred. The response time will thus average 92ms. -5- 2.1.5 FORCED SENSOR RECALIBRATION The QT110 has no recalibration pin; a forced recalibration is accomplished only when the device is powered up. However, supply drain is so low it is a simple matter to treat the entire IC as a controllable load; simply driving the QT110's Vdd pin directly from another logic gate or a microprocessor port (Figure 2-2) will serve as both power and 'forced recal'. The source resistance of most CMOS gates and microprocessors is low enough to provide direct power without any problems. Note that most 8051-based micros have only a weak pullup drive capability and will require true CMOS buffering. Any 74HC or 74AC series gate can directly power the QT110, as can most other microprocessors. Option strap configurations are read by the QT110 only on powerup. Configurations can only be changed by powering the QT110 down and back up again; again, a microcontroller can directly alter most of the configurations and cycle power to put them in effect. 2.2 OUTPUT FEATURES The QT110 / QT110H are designed for maximum flexibility and can accommodate most popular sensing requirements. These are selectable using strap options on pins OPT1 and OPT2. All options are shown in Table 2-1. 2.2.1 DC MODE OUTPUT The output of the device can respond in a DC mode, where the output is active-low (QT110) or active-high (QT110H) upon detection. The output will remain active for the duration of the detection, or until the Max On-Duration expires, whichever occurs first. If the latter occurs first, the sensor performs a full recalibration and the output becomes inactive until the next detection. In this mode, two Max On-Duration timeouts are available: 10 and 60 seconds. 2.2.2 TOGGLE MODE OUTPUT This makes the sensor respond in an on/off mode like a flip flop. It is most useful for controlling power loads, for example in kitchen appliances, power tools, light switches, etc. Max On-Duration in Toggle mode is fixed at 10 seconds. When a timeout occurs, the sensor recalibrates but leaves the output state unchanged. 2.2.3 PULSE MODE OUTPUT This generates a pulse of 75ms duration (QT110 negative-going; QT110H - positive-going) with every new detection. It is most useful for 2-wire operation, but can also be used when bussing together several devices onto a common output line with the help of steering diodes or logic gates, in order to control a common load from several places. Max On-Duration is fixed at 10 seconds if in Pulse output mode. 2.2.4 HEARTBEAT™ OUTPUT The output has a full-time HeartBeat™ ‘health’ indicator superimposed on it. This operates by taking 'Out' into a 3-state mode for 350µs once before every QT burst. This output state can be used to determine that the sensor is operating properly, or, it can be ignored using one of several simple methods. QT110: The HeartBeat indicator can be sampled by using a pulldown resistor on Out, and feeding the resulting negative-going pulse into a counter, flip flop, one-shot, or other circuit. Since Out is normally high, a pulldown resistor will create negative HeartBeat pulses (Figure 2-3) when the sensor is not detecting an object; when detecting an object, the output will remain active for the duration of the detection, and no HeartBeat pulse will be evident. QT110H: Same as QT110 but inverted logic (use a pull-down resistor instead of a pull-up etc.) If the sensor is wired to a microprocessor as shown in Figure 2-4, the microprocessor can reconfigure the load resistor to either ground or Vcc depending on the output state of the device, so that the pulses are evident in either state. Electromechanical devices will usually ignore this short pulse. The pulse also has too low a duty cycle to visibly activate LED’s. It can be filtered completely if desired, by adding an RC timeconstant to filter the output, or if interfacing directly and only to a high-impedance CMOS input, by doing nothing or at most adding a small non-critical capacitor from Out to ground (Figure 2-5). Figure 2-3 Figure 2-4 Getting HB pulses with a pull-down resistor (QT110 shown; use pull-up resistor with QT110H) +2 .5 to 5 H eartBeat™ P ulses Using a micro to obtain HB pulses in either output state (QT110 or QT110H) 1 2 V dd O UT S NS 2 O PT 1 GAIN O PT 2 S NS 1 2 P O RT _M .x 7 OUT SN S 2 O PT1 G A IN O PT2 SN S 1 7 Ro Ro 3 4 5 3 M icro pro ce sso r 6 P O RT _M .y V ss 8 -6- 4 5 6 in Vdd, as happens when loads are switched on. This can induce detection ‘cycling’, whereby an object is detected, the load is turned on, the supply sags, the detection is no longer sensed, the load is turned off, the supply rises and the object is reacquired, ad infinitum. To prevent this occurrence, the output should only be lightly loaded if the device is operated from an unregulated supply, e.g. batteries. Detection ‘stiction’, the opposite effect, can occur if a load is shed when Out is active. Figure 2-5 Eliminating HB Pulses G ATE OR MIC RO INPU T O UT SN S 2 O PT1 GA IN O PT2 SN S 1 7 Co 100p F 3 4 5 QT110: The output of the QT110 can directly drive a resistively limited LED. The LED should be connected with its cathode to the output and its anode towards Vcc, so that it lights when the sensor is active-low. If desired the LED can be connected from Out to ground, and driven on when the sensor is inactive, but only with less drive current (1mA). 6 2.2.5 PIEZO ACOUSTIC DRIVE A piezo drive signal is generated for use with a bare piezo sounder immediately after a detection is made; the tone lasts for a nominal 75ms to create a reassuring ‘tactile feedback’ sound. The sensor will drive most common bare piezo ‘beepers’ directly using an H-bridge drive configuration for the highest possible sound level at all supply voltages; H-bridge drive effectively doubles the supply voltage across the piezo. The piezo is connected across pins SNS1 and SNS2. This drive operates at a nominal 4kHz frequency, a common resonance point for enclosed piezo sounders. Other frequencies can be obtained upon special request. QT110H: This part is active-high, so it works in reverse to that described above. 3 - CIRCUIT GUIDELINES Figure 2-6 Damping Piezo Clicks with Rx + 2.5 to 5 If desired a bare piezo sounder can be directly adhered to the rear of a control panel, provided that an acoustically resonant cavity is also incorporated to give the desired sound level. 2 3 Since piezo sounders are merely high-K ceramic capacitors, the sounder will double as the Cs capacitor, and the piezo's metal disc will act as the sensing electrode. Piezo transducer capacitances typically range from 6nF to 30nF (0.006µF to 0.03µF) in value; at the lower end of this range an additional capacitor should be added to bring the total Cs across SNS1 and SNS2 to at least 10nF, or more if Cx is large. The burst acquisition process induces a small but audible voltage step across the piezo resonator, which occurs when SNS1 and SNS2 rapidly discharge residual voltage stored on the resonator. The resulting slight clicking sound can be used to provide an audible confirmation of functionality if desired, or, it can be suppressed by placing a non-critical 1M to 2M ohm bleed resistor in parallel with the resonator. The resistor acts to slowly discharge the resonator, preempting the occurrence of the harmonic-rich step (Figure 2-6). With the resistor in place, an almost inaudible clicking sound may still be heard, which is caused by the small charge buildup across the piezo device during each burst. 2.2.6 OUTPUT DRIVE The QT110’s `output is active low (QT110) or active high (QT110H) and can source 1mA or sink 5mA of non-inductive current. If an inductive load is used, such as a small relay, the load should be diode clamped to prevent damage. Care should be taken when the IC and the load are both powered from the same supply, and the supply is minimally regulated. The device derives its internal references from the power supply, and sensitivity shifts can occur with changes S ENSING E LEC TRO DE 1 4 V dd OU T S N S1 OP T1 G A IN OP T2 S N S2 7 5 Pie zo Sounde r 10-30 nF 2 C MO S Rx Cx 6 V ss 8 3.1 SAMPLE CAPACITOR Charge sampler Cs can be virtually any plastic film or high-K ceramic capacitor. Since the acceptable Cs range is anywhere from 10nF to 30nF, the tolerance of Cs can be the lowest grade obtainable so long as its value is guaranteed to remain in the acceptable range under expected temperature conditions. Only if very fast, radical temperature swings are expected will a higher quality capacitor be required, for example polycarbonate, PPS film, or NPO/C0G ceramic. 3.2 PIEZO SOUNDER The use of a piezo sounder in place of Cs is described in the previous section. Piezo sounders have very high, uncharacterized thermal coefficients and should not be used if fast temperature swings are anticipated. 3.3 OPTION STRAPPING The option pins Opt1 and Opt2 should never be left floating. If they are floated, the device will draw excess power and the options will not be properly read on powerup. Intentionally, -7- there are no pullup resistors on these lines, since pullup resistors add to power drain if tied low. Figure 2-7 ESD Protection +2.5 to 5 The Gain input is designed to be floated for sensing one of the three gain settings. It should never be connected to a pullup resistor or tied to anything other than Sns1 or Sns2. Table 2-1 shows the configurations available. option strap + 2 OU T Vdd D1 SNS2 7 R e3 S ENSIN G ELEC TR O DE R e1 3 3.4 POWER SUPPLY, PCB LAYOUT The power supply can range from 2.5 to 5.0 volts. At 3 volts current drain averages less than 20µA in most cases, but can be higher if Cs is large. Interestingly, large Cx values will actually decrease power drain. Operation can be from batteries, but be cautious about loads causing supply droop (see Output Drive, previous section). 10µF R e2 1 4 C1 O PT1 G AIN O PT2 SNS1 D2 5 Cs 6 Vss 8 As battery voltage sags with use or fluctuates slowly with temperature, the IC will track and compensate for these changes automatically with only minor changes in sensitivity. If the power supply is shared with another electronic system, care should be taken to assure that the supply is free of digital spikes, sags, and surges which can adversely affect the device. The IC will track slow changes in Vdd, but it can be affected by rapid voltage steps. if desired, the supply can be regulated using a conventional low current regulator, for example CMOS regulators that have nanoamp quiescent currents. Care should be taken that the regulator does not have a minimum load specification, which almost certainly will be violated by the QT110's low current requirement. Since the IC operates in a burst mode, almost all the power is consumed during the course of each burst. During the time between bursts the sensor is quiescent. For proper operation a 100nF (0.1uF) ceramic bypass capacitor should be used between Vdd and Vss; the bypass cap should be placed very close to the device’s power pins. 3.4.1 MEASURING SUPPLY CURRENT Measuring average power consumption is a fairly difficult task, due to the burst nature of the device’s operation. Even a good quality RMS DMM will have difficulty tracking the relatively slow burst rate. The simplest method for measuring average current is to replace the power supply with a large value low-leakage electrolytic capacitor, for example 2,700µF. 'Soak' the capacitor by connecting it to a bench supply at the desired operating voltage for 24 hours to form the electrolyte and reduce leakage to a minimum. Connect the capacitor to the circuit at T=0, making sure there will be no detections during the measurement interval; at T=30 seconds measure the capacitor's voltage with a DMM. Repeat the test without a load to measure the capacitor's internal leakage, and subtract the internal leakage result from the voltage droop measured during the QT110 load test. Be sure the DMM is connected only at the end of each test, to prevent the DMM's impedance from contributing to the capacitor's discharge. Supply drain can be calculated from the adjusted voltage droop using the basic charge equation: i= ✁VC t where C is the large supply cap value, t is the elapsed measurement time in seconds, and ∆V is the adjusted voltage droop on C. 3.4.2 ESD PROTECTION In cases where the electrode is placed behind a dielectric panel, the IC will be protected from direct static discharge. However, even with a panel, transients can still flow into the electrode via induction, or in extreme cases, via dielectric breakdown. Porous materials may allow a spark to tunnel right through the material; partially conducting materials like 'pink poly' will conduct the ESD right to the electrode. Testing is required to reveal any problems. The device does have diode protection on its terminals which can absorb and protect the device from most induced discharges, up to 20mA; the usefulness of the internal clamping will depending on the dielectric properties, panel thickness, and rise time of the ESD transients. ESD dissipation can be aided further with an added diode protection network as shown in Figure 2-7, in extreme cases. Because the charge and transfer times of the QT110 are relatively long, the circuit can tolerate very large values of Re, more than 100k ohms in most cases where electrode Cx is small. The added diodes shown (1N4150, BAV99 or equivalent low-C diodes) will shunt the ESD transients away from the part, and Re1 will current limit the rest into the QT110's own internal clamp diodes. C1 should be around 10µF if it is to absorb positive transients from a human body model standpoint without rising in value by more than 1 volt. If desired C1 can be replaced with an appropriate zener diode. Directly placing semiconductor transient protection devices or MOV's on the sense lead is not advised; these devices have extremely large amounts of parasitic C which will swamp the capacitance of the electrode. Re1 should be as large as possible given the load value of Cx and the diode capacitances of D1 and D2. Re1 should be low enough to permit at least 6 timeconstants of RC to occur during the charge and transfer phases. -8- Re2 functions to isolate the transient from the Vdd pin; values of around 1K ohms are reasonable. As with all ESD protection networks, it is crucial that the transients be led away from the circuit. PCB ground layout is crucial; the ground connections to D1, D2, and C1 should all go back to the power supply ground or preferably, if available, a chassis ground connected to earth. The currents should not be allowed to traverse the area directly under the IC. If the device is connected to an external circuit via a cable or long twisted pair, it is possible for ground-bounce to cause damage to the Out pin; even though the transients are led away from the IC itself, the connected signal or power ground line will act as an inductor, causing a high differential voltage to build up on the Out wire with respect to ground. If this is a possibility, the Out pin should have a resistance Re3 in series with it to limit current; this resistor should be as large as can be tolerated by the load. -9- 4.1 ABSOLUTE MAXIMUM SPECIFICATIONS Operating temp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . as designated by suffix Storage temp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -55OC to +125OC VDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.5 to +6.5V Max continuous pin current, any control or drive pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±20mA Short circuit duration to ground, any pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . infinite Short circuit duration to VDD, any pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . infinite Voltage forced onto any pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.6V to (Vdd + 0.6) Volts 4.2 RECOMMENDED OPERATING CONDITIONS VDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +2.5 to 5.5V Supply ripple+noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20mV p-p max Load capacitance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 to 20pF Cs value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10nF to 30nF 4.3 AC SPECIFICATIONS Parameter Vdd = 3.0, Ta = recommended operating range Description Min Typ Max Units TRC Recalibration time 550 ms TPC Charge duration 2 µs TPT Transfer duration 2 µs TBS Burst spacing interval TBL Burst length TR Response time 75 0.5 Notes ms 7 ms 129 ms FP Piezo drive frequency 4 kHz TP Piezo drive duration 75 ms TPO Pulse output width on Out 75 ms THB Heartbeat pulse width 300 µs 4.4 SIGNAL PROCESSING Description Min Typ Max Units Notes Threshold differential, high gain 3.1 % Note 1 Threshold differential, medium gain 4.7 % Note 1 Threshold differential, low gain 6.25 % Note 1 50 % Note 2 Hysteresis 4 samples Positive drift compensation rate Consensus filter length 750 ms/level Negative drift compensation rate 75 ms/level Post-detection recalibration timer duration 10 Note 1: Of absolute full scale signal Note 2: Of signal threshold Note 3: Strap option. - 10 - 60 secs Note 3 4.5 DC SPECIFICATIONS Vdd = 3.0V, Cs = 10nF, Cx = 5pF, TA = recommended range, unless otherwise noted Parameter VDD IDD Description Min Supply voltage Typ 2.45 Supply current VDDS Supply turn-on slope VIL Low input logic level VHL High input logic level VOL Low output voltage VOH High output voltage IIL Input leakage current CX Load capacitance range IX Min shunt resistance AR Acquisition resolution S[1] Sensitivity - high gain S[2] Sensitivity - medium gain Max Units 5.25 V 20 µA 100 V/s 0.8 2.2 0.6 Vdd-0.7 0 OPT1, OPT2 V OPT1, OPT2 V OUT, 4mA sink V OUT, 1mA source µA 30 pF ✡ 14 Required for proper startup V ±1 500K S[3] Sensitivity - low gain Preliminary Data: All specifications subject to change. Notes OPT1, OPT2 Resistance from SNS1 to SNS2 bits 1 pF Refer to Figures 4-1 through 4-3 1.5 pF Refer to Figures 4-1 through 4-3 3 pF Refer to Figures 4-1 through 4-3 Figure 4-1 High Gain Sensitivity and Range @ Vdd = 3V Figure 4-2 Medium Gain Sensitivity and Range @ Vdd = 3V 3.0 4.0 Sensitivity, p F Cx=30pF Sensitivity, p F Cx=30pF 2.5 25pF 2.0 20pF 1.5 10pF 5pF 1.0 0pF 10 20 20pF 2.0 10pF 5pF 0pF 1.0 Valid operating range 0.5 25pF 3.0 Valid operating range 30 10 20 C s, nF 30 C s, nF Figure 4-3 Low Gain Sensitivity and Range @ Vdd = 3V Figure 4-4 Supply Current vs. Voltage; Cx = 10pF 180 160 8.0 Current (microamps) Sen sitivity, pF Cx=30pF 25pF 6.0 20pF 4.0 2.0 10pF 5pF 0pF 140 120 100 Cs = 100nF 80 47nF 60 22nF 40 10nF 20 Valid operating range 0 10 20 3 30 3.5 4 Vss, Volts Cs, nF - 11 - 4.5 5 Package type: 8pin Dual-In-Line SYMBOL a A M m Q P L L1 F R r S S1 Aa x Y Min Millimeters Max 6.096 7.62 9.017 7.62 0.889 0.254 0.355 1.397 2.489 3.048 0.381 3.048 7.62 8.128 0.203 7.112 8.255 10.922 7.62 0.559 1.651 2.591 3.81 3.556 4.064 7.062 9.906 0.381 Notes Typical BSC Typical BSC Min Inches Max 0.24 0.3 0.355 0.3 0.035 0.01 0.014 0.055 0.098 0.12 0.015 0.12 0.3 0.32 0.008 0.28 0.325 0.43 0.3 0.022 0.065 0.102 0.15 0.14 0.16 0.3 0.39 0.015 Notes Typical BSC Typical BSC Package type: 8pin SOIC SYMBOL Min Millimeters Max M W Aa H h D L E e ß Ø 4.800 5.816 3.81 1.371 0.101 1.27 0.355 0.508 0.19 0.381 0º 4.979 6.198 3.988 1.728 0.762 1.27 0.483 1.016 0.249 0.762 8º Notes Min Inches Max BSC 0.189 0.229 0.15 0.054 0.004 0.050 0.014 0.02 0.007 0.229 0º 0.196 0.244 0.157 0.068 0.01 0.05 0.019 0.04 0.01 0.03 8º - 12 - Notes BSC 5 - ORDERING INFORMATION PART TEMP RANGE PACKAGE MARKING QT110-D QT110-S QT110-IS QT110H-D QT110H-S QT110H-IS 0 - 70C 0 - 70C -40 - 85C 0 - 70C 0 - 70C -40 - 85C PDIP SOIC-8 SOIC-8 PDIP SOIC-8 SOIC-8 QT1 + 10 QT1 QT1 + I QT1 +10H QT1 + A QT1 + AI Quantum Research Group Ltd ©1999 QRG Ltd. Patented and patents pending 651 Holiday Drive Bldg. 5 / 300 Pittsburgh, PA 15220 USA Tel: 412-391-7367 Fax: 412-291-1015 admin@qprox.com http://www.qprox.com In the United Kingdom Enterprise House, Southampton, Hants SO14 3XB Tel: +44 (0)23 8045 3934 Fax: +44 (0)23 8045 3939 Notice: This device expressly not for use in any medical or human safety related application without the express written consent of an officer of the company. Freescale Semiconductor Technical Data MC145026/D Rev. 4, 1/2005 MC145026, MC145027 MC145028 16 16 MC145026, MC145027, MC145028 1 1 P Suffix Plastic DIP Case 648 Encoder and Decoder Pairs CMOS D Suffix SOG Package Case751B 16 1 DW Suffix SOG Package Case 751G 1 Introduction Ordering Information These devices are designed to be used as encoder/decoder pairs in remote control applications. The MC145026 encodes nine lines of information and serially sends this information upon receipt of a transmit enable (TE) signal. The nine lines may be encoded with trinary data (low, high, or open) or binary data (low or high). The words are transmitted twice per encoding sequence to increase security. The MC145027 decoder receives the serial stream and interprets five of the trinary digits as an address code. Thus, 243 addresses are possible. If binary data is used at the encoder, 32 addresses are possible. The remaining serial information is interpreted as four bits of binary data. The valid transmission (VT) output goes high on the MC145027 when two conditions are met. First, two addresses must be consecutively received (in one encoding sequence) which both match the local address. Second, the 4 bits of data must match the last valid data received. The active VT indicates that the information at the Data output pins has been updated. Device Package MC145026P Plastic DIP MC145026D SOG Package MC145027P Plastic DIP MC145027DW SOG Package MC145028P Plastic DIP MC145028DW SOG Package Contents 1 2 3 4 5 6 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Electrical Specifications . . . . . . . . . . . . . . . . 4 Operating Characteristics . . . . . . . . . . . . . . . 8 Pin Descriptions . . . . . . . . . . . . . . . . . . . . . . . 9 MC145027 and MC145028 Timing . . . . . . . . 16 Package Dimensions . . . . . . . . . . . . . . . . . . 18 Freescale reserves the right to change the detail specifications as may be required to permit improvements in the design of its products. © Freescale Semiconductor, Inc., 2005. All rights reserved. Introduction The MC145028 decoder treats all nine trinary digits as an address which allows 19,683 codes. If binary data is encoded, 512 codes are possible. The VT output goes high on the MC145028 when two addresses are consecutively received (in one encoding sequence) which both match the local address. • Operating Temperature Range: - 40 to + 85°C • Very-Low Standby Current for the Encoder: 300 nA Maximum @ 25°C • Interfaces with RF, Ultrasonic, or Infrared Modulators and Demodulators • RC Oscillator, No Crystal Required • High External Component Tolerance; Can Use ± 5% Components • Internal Power-On Reset Forces All Decoder Outputs Low • Operating Voltage Range: MC145026 = 2.5 to 18 V MC145027, MC145028 = 4.5 to 18 V MC145026 ENCODER A1 MC145027 DECODERS VDD A1 MC145028 DECODERS VDD A1 VDD A6 A2 Dout A2 D6 A2 A3 TE A3 D7 A3 A7 A4 RTC A4 D8 A4 A8 A5 CTC A5 D9 A5 A9 VT R2/C2 A6/D6 RS R1 VT R1 A7/D7 A9/D9 C1 R2/C2 C1 VSS A8/D8 VSS Din VSS Din Figure 1. Pin Assignments MC145026, MC145027, MC145028 Technical Data, Rev. 4 2 Freescale Semiconductor Introduction RS 11 TE RTC 12 CTC 13 3-PIN OSCILLATOR AND ENABLE 14 DATA SELECT AND BUFFER ÷4 DIVIDER 15 DOUT RING COUNTER AND 1-OF-9 DECODER 9 8 7 6 5 4 3 2 1 1 A1 2 A2 3 A3 4 A4 5 A5 TRINARY DETECTOR 6 A6/D6 7 A7/D7 VDD = PIN 16 VSS = PIN 8 9 A8/D8 10 A9/D9 Figure 2. MC145026 Encoder Block Diagram CONTROL LOGIC SEQUENCER CIRCUIT 5 A1 A2 A3 A4 A5 4 3 2 15 14 LATCH 4-BIT SHIFT REGISTER 11 13 12 VT D6 D7 D8 D9 1 1 2 DATA EXTRACTOR 3 9 Din 4 5 C1 7 6 10 R1 C2 VDD = PIN 16 VSS = PIN 8 R2 Figure 3. MC145027 Decoder Block Diagram MC145026, MC145027, MC145028 Technical Data, Rev. 4 Freescale Semiconductor 3 Electrical Specifications 11 CONTROL LOGIC VT SEQUENCER CIRCUIT 9 A1 A2 A3 A4 A5 A6 A7 A8 A9 8 7 6 5 4 3 2 1 1 9-BIT SHIFT REGISTER 2 3 4 5 9 DATA EXTRACTOR 15 C1 14 7 R1 6 10 13 C2 Din VDD = PIN 16 VSS = PIN 8 R2 12 Figure 4. MC145028 Decoder Block Diagram 2 Electrical Specifications Table 1. Maximum Ratings* (Voltages Referenced to VSS) Ratings Symbol Value Unit DC Supply Voltage VDD - 0.5 to + 18 V DC Input Voltage Vin - 0.5 to VDD + 0.5 V DC Output Voltage Vout - 0.5 to VDD + 0.5 V DC Input Current, per Pin Iin ± 10 mA DC Output Current, per Pin Iout ± 10 mA Power Dissipation, per Package PD 500 mW Storage Temperature Tstg - 65 to + 150 °C TL 260 °C Lead Temperature, 1 mm from Case for 10 Seconds * Maximum Ratings are those values beyond which damage to the device may occur. Functional operation should be restricted to the limits in the Electrical Characteristics tables or Pin Descriptions section. This device contains protection circuitry to guard against damage due to high static voltages or electric fields. However, precautions must be taken to avoid applications of any voltage higher than maximum rated voltages to this high-impedance circuit. For proper operation, Vin and Vout should be constrained to the range VSS ≤ (Vin or Vout) ≤ VDD. MC145026, MC145027, MC145028 Technical Data, Rev. 4 4 Freescale Semiconductor Electrical Specifications Table 2. Electrical Characteristics - MC1450261, MC145027, and MC145028 (Voltage Referenced to VSS) Guaranteed Limit Symbol - 40°C 25°C 85°C Unit Min Max Min Max Min Max VOL Low-Level Output Voltage (Vin = VDD or 0) 5.0 10 15 - 0.05 0.05 0.05 - 0.05 0.05 0.05 - 0.05 0.05 0.05 V VOH High-Level Output Voltage (Vin = 0 or VDD) 5.0 10 15 4.95 9.95 14.95 - 4.95 9.95 14.95 - 4.95 9.95 14.95 - V VIL Low-Level Input Voltage (Vout = 4.5 or 0.5 V) (Vout = 9.0 or 1.0 V) (Vout = 13.5 or 1.5 V) 5.0 10 15 - 1.5 3.0 4.0 - 1.5 3.0 4.0 - 1.5 3.0 4.0 (Vout = 0.5 or 4.5 V) (Vout = 1.0 or 9.0 V) (Vout = 1.5 or 13.5 V) 5.0 10 15 3.5 7.0 11 - 3.5 7.0 11 - 3.5 7.0 11 - (Vout = 2.5 V) (Vout = 4.6 V) (Vout = 9.5 V) (Vout = 13.5 V) 5.0 5.0 10 15 - 2.5 - 0.52 - 1.3 - 3.6 - - 2.1 - 0.44 - 1.1 - 3.0 - - 1.7 - 0.36 - 0.9 - 2.4 - (Vout = 0.4 V) (Vout = 0.5 V) (Vout = 1.5 V) 5.0 10 15 0.52 1.3 3.6 - 0.44 1.1 3.0 - 0.36 0.9 2.4 - VIH IOH IOL 1 VDD V Characteristic V High-Level Input Voltage V High-Level Output Current mA Low-Level Output Current mA Iin Input Current - TE (MC145026, Pull-Up Device) 5.0 10 15 - - 3.0 16 35 11 60 120 - - µA Iin Input Current RS (MC145026), Din (MC145027, MC145028) 15 - ± 0.3 - ± 0.3 - ± 1.0 µA Iin Input Current A1 - A5, A6/D6 - A9/D9 (MC145026), A1 - A5 (MC145027), A1 - A9 (MC145028) 5.0 10 15 - - - ± 110 ± 500 ± 1000 - - - - - - 7.5 - - pF µA Cin Input Capacitance (Vin = 0) IDD Quiescent Current - MC145026 5.0 10 15 - - - 0.1 0.2 0.3 - - µA IDD Quiescent Current - MC145027, MC145028 5.0 10 15 - - - 50 100 150 - - µA Also see next Electrical Characteristics table for 2.5 V specifications. MC145026, MC145027, MC145028 Technical Data, Rev. 4 Freescale Semiconductor 5 Electrical Specifications Table 2. Electrical Characteristics - MC1450261, MC145027, and MC145028 (continued) (Voltage Referenced to VSS) Guaranteed Limit Symbol 1 VDD V Characteristic - 40°C 25°C 85°C Unit Min Max Min Max Min Max Idd Dynamic Supply Current - MC145026 (fc = 20 kHz) 5.0 10 15 - - - 200 400 600 - - µA Idd Dynamic Supply Current - MC145027, MC145028 (fc = 20 kHz) 5.0 10 15 - - - 400 800 1200 - - µA Also see next Electrical Characteristics table for 2.5 V specifications. Table 3. Electrical Characteristics - MC145026 (Voltage Referenced to VSS) Guaranteed Limit Symbol VDD V Characteristic - 40°C 25°C 85°C Unit Min Max Min Max Min Max VOL Low-Level Output Voltage (Vin = 0 V or VDD) 2.5 - 0.05 - 0.05 - 0.05 V VOH High-Level Output Voltage (Vin = 0 V or VDD) 2.5 2.45 - 2.45 - 2.45 - V VIL Low-Level Input Voltage (Vout = 0.5 V or 2.0 V) 2.5 - 0.3 - 0.3 - 0.3 V VIH High-Level Input Voltage (Vout = 0.5 V or 2.0 V) 2.5 2.2 - 2.2 - 2.2 - V IOH High-Level Output Current (Vout = 1.25 V) 2.5 0.28 - 0.25 - 0.2 - mA IOL Low-Level Output Current (Vout = 0.4 V) 2.5 0.22 - 0.2 - 0.16 - mA Iin Input Current (TE - Pull-Up Device) 2.5 - - 0.09 1.8 - - µA Iin Input Current (A1-A5, A6/D6-A9/D9) 2.5 - - - ± 25 - - µA IDD Quiescent Current 2.5 - - - 0.05 - - µA Idd Dynamic Supply Current (fc = 20 kHz) 2.5 - - - 40 - - µA MC145026, MC145027, MC145028 Technical Data, Rev. 4 6 Freescale Semiconductor Electrical Specifications Table 4. Switching Characteristics - MC1450261, MC145027, and MC145028 (CL = 50 pF, TA = 25°C) Symbol tTLH, tTHL 1 Characteristic Output Transition Time Figure No. Guaranteed Limit VDD Unit Min Max 5, 9 5.0 10 15 - 200 100 80 ns tr Din Rise Time - Decoders 6 5.0 10 15 - 15 15 15 µs tf Din Fall Time - Decoders 6 5.0 10 15 - 15 5.0 4.0 µs fosc Encoder Clock Frequency 7 5.0 10 15 0.001 0.001 0.001 2.0 5.0 10 MHz f Decoder Frequency - Referenced to Encoder Clock 13 5.0 10 15 1.0 1.0 1.0 240 410 450 kHz tw TE Pulse Width - Encoders 8 5.0 10 15 65 30 20 - ns Also see next Electrical Characteristics table for 2.5 V specifications. Table 5. Switching Characteristics - MC145026 (CL = 50 pF, TA = 25°C) tTLH, tTHL fosc tw Guaranteed Limit Figure No. VDD 5, 9 Encoder Clock Frequency TE Pulse Width Symbol Characteristic Output Transition Time Unit Min Max 2.5 - 450 ns 7 2.5 1.0 250 kHz 8 2.5 1.5 - µs MC145026, MC145027, MC145028 Technical Data, Rev. 4 Freescale Semiconductor 7 Operating Characteristics tf ANY OUTPUT 90% 10% Din tTLH VDD 90% tTHL Figure 5. Output Transition Time 10% VSS Figure 6. Din Rise and Fall Time t/fOSC RTC tf VDD TE 50% VSS 50% tW Figure 8. TE Pulse Width Figure 7. Encoder Clock Frequency TEST POINT OUTPUT DEVICE UNDER TEST CL* * Includes all probe and fixture capacitance. Figure 9. Test Circuit 3 3.1 Operating Characteristics MC145026 The encoder serially transmits trinary data as defined by the state of the A1 - A5 and A6/D6 - A9/D9 input pins. These pins may be in either of three states (low, high, or open) allowing 19,683 possible codes. The transmit sequence is initiated by a low level on the TE input pin. Upon power-up, the MC145026 can continuously transmit as long as TE remains low (also, the device can transmit two-word sequences by pulsing TE low). However, no MC145026 application should be designed to rely upon the first data word transmitted immediately after power-up because this word may be invalid. Between the two data words, no signal is sent for three data periods (see Figure 11). Each transmitted trinary digit is encoded into pulses (see Figure 12). A logic 0 (low) is encoded as two consecutive short pulses, a logic 1 (high) as two consecutive long pulses, and an open (high impedance) as a long pulse followed by a short pulse. The input state is determined by using a weak “output” device to try to force each input high then low. If only a high state results from the two tests, the input is assumed to be hardwired to VDD. If only a low state is obtained, the input is assumed to be hardwired to VSS. If both a high and a low can be forced at an input, an open is assumed and is encoded as such. The “high” and MC145026, MC145027, MC145028 Technical Data, Rev. 4 8 Freescale Semiconductor Pin Descriptions “low” levels are 70% and 30% of the supply voltage as shown in the Electrical Characteristics table. The weak “output” device sinks/sources up to 110 µA at a 5 V supply level, 500 µA at 10 V, and 1 mA at 15 V. The TE input has an internal pull-up device so that a simple switch may be used to force the input low. While TE is high, the encoder is completely disabled, the oscillator is inhibited, and the current drain is reduced to quiescent current. When TE is brought low, the oscillator is started and the transmit sequence begins. The inputs are then sequentially selected, and determinations are made as to the input logic states. This information is serially transmitted via the Dout pin. 3.2 MC145027 This decoder receives the serial data from the encoder and outputs the data, if it is valid. The transmitted data, consisting of two identical words, is examined bit by bit during reception. The first five trinary digits are assumed to be the address. If the received address matches the local address, the next four (data) bits are internally stored, but are not transferred to the output data latch. As the second encoded word is received, the address must again match. If a match occurs, the new data bits are checked against the previously stored data bits. If the two nibbles of data (four bits each) match, the data is transferred to the output data latch by VT and remains until new data replaces it. At the same time, the VT output pin is brought high and remains high until an error is received or until no input signal is received for four data periods (see Figure 11). Although the address information may be encoded in trinary, the data information must be either a 1 or 0. A trinary (open) data line is decoded as a logic 1. 3.3 MC145028 This decoder operates in the same manner as the MC145027 except that nine address lines are used and no data output is available. The VT output is used to indicate that a valid address has been received. For transmission security, two identical transmitted words must be consecutively received before a VT output signal is issued. The MC145028 allows 19,683 addresses when trinary levels are used. 512 addresses are possible when binary levels are used. 4 4.1 Pin Descriptions MC145026 Encoder A1 - A5, A6/D6 - A9/D9 Address, Address/Data Inputs (Pins 1 - 7, 9, and 10) These address/data inputs are encoded and the data is sent serially from the encoder via the Dout pin. RS, CTC, RTC (Pins 11, 12, and 13) These pins are part of the oscillator section of the encoder (see Figure 10). MC145026, MC145027, MC145028 Technical Data, Rev. 4 Freescale Semiconductor 9 Pin Descriptions If an external signal source is used instead of the internal oscillator, it should be connected to the RS input and the RTC and CTC pins should be left open. TE Transmit Enable (Pin 14) This active-low transmit enable input initiates transmission when forced low. An internal pull-up device keeps this input normally high. The pull-up current is specified in the Electrical Characteristics table. Dout Data Out (Pin 15) This is the output of the encoder that serially presents the encoded data word. VSS Negative Power Supply (Pin 8) The most-negative supply potential. This pin is usually ground. VDD Positive Power Supply (Pin 16) The most-positive power supply pin. 4.2 MC145027 and MC145028 Decoders A1 - A5, A1 - A9 Address Inputs (Pins 1 - 5) - MC145027, Address Inputs (Pins 1 - 5, 15, 14, 13, 12) - MC145028 These are the local address inputs. The states of these pins must match the appropriate encoder inputs for the VT pin to go high. The local address may be encoded with trinary or binary data. D6 - D9 Data Outputs (Pins 15, 14, 13, 12) - MC145027 Only These outputs present the binary information that is on encoder inputs A6/D6 through A9/D9. Only binary data is acknowledged; a trinary open at the MC145026 encoder is decoded as a high level (logic 1). Din Data In (Pin 9) This pin is the serial data input to the decoder. The input voltage must be at CMOS logic levels. The signal source driving this pin must be dc coupled. MC145026, MC145027, MC145028 Technical Data, Rev. 4 10 Freescale Semiconductor Pin Descriptions R1, C1 Resistor 1, Capacitor 1 (Pins 6, 7) As shown in Figure 3 and Figure 4, these pins accept a resistor and capacitor that are used to determine whether a narrow pulse or wide pulse has been received. The time constant R1 × C1 should be set to 1.72 encoder clock periods: R1 C1 = 3.95 RTC CTC R2/C2 Resistor 2/Capacitor 2 (Pin 10) As shown in Figure 3 and Figure 4, this pin accepts a resistor and capacitor that are used to detect both the end of a received word and the end of a transmission. The time constant R2 x C2 should be 33.5 encoder clock periods (four data periods per Figure 12): R2 C2 = 77 RTC CTC. This time constant is used to determine whether the Din pin has remained low for four data periods (end of transmission). A separate on-chip comparator looks at the voltage-equivalent two data periods (0.4 R2 C2) to detect the dead time between received words within a transmission. VT Valid Transmission Output (Pin 11) This valid transmission output goes high after the second word of an encoding sequence when the following conditions are satisfied: 1. the received addresses of both words match the local decoder address, and 2. the received data bits of both words match. VT remains high until either a mismatch is received or no input signal is received for four data periods. VSS Negative Power Supply (Pin 8) The most-negative supply potential. This pin is usually ground. VDD Positive Power Supply (Pin 16) The most-positive power supply pin. MC145026, MC145027, MC145028 Technical Data, Rev. 4 Freescale Semiconductor 11 Pin Descriptions RS CTC RTC 11 12 13 INTERNAL ENABLE This oscillator operates at a frequency determined by the external RC network; i.e., f≈ 1 2.3 RTC CTC′ (Hz) The value for RS should be chosen to be ≥ 2 times RTC. This range ensures that current through RS is insignificant compared to current through RTC. The upper limit for RS must ensure that RS x 5 pF (input capacitance) is small compared to RTC x CTC. for 1 kHz ≤ f ≤ 400 kHz where: CTC′ = CTC + Clayout + 12 pF RS ≈ 2 RTC RS ≥ 20 k RTC ≥ 10 k 400 pF < CTC < 15 µF For frequencies outside the indicated range, the formula is less accurate. The minimum recommended oscillation frequency of this circuit is 1 kHz. Susceptibility to externally induced noise signals may occur for frequencies below 1 kHz and/or when resistors utilized are greater than 1 MΩ. Figure 10. Encoder Oscillator Information ENCODER PWmin 2 WORD TRANSMISSION TE 1ST DIGIT 9TH DIGIT 1ST DIGIT 184 182 180 178 122 120 118 116 114 90 88 86 84 82 80 30 28 26 24 22 20 18 16 6 4 2 ENCODER OSCILLATOR (PIN 12) CONTINUOUS TRANSMISSION 9TH DIGIT Dout (PIN 15) HIGH LOW OPEN 1ST WORD 2ND WORD ENCODING SEQUENCE DECODER 1.1 (R2C2) VT (PIN 11) DATA OUTPUTS Figure 11. Timing Diagram MC145026, MC145027, MC145028 Technical Data, Rev. 4 12 Freescale Semiconductor Pin Descriptions ENCODER OSCILLATOR (PIN 12) ENCODED “ONE” Dout (PIN 15) ENCODED “ZERO” ENCODED “OPEN” DATA PERIOD Figure 12. Encoder Data Waveforms fmax (kHZ) (REF. TO ENCODER CLOCK) 500 400 VDD = 15 V VDD = 10 V 300 200 VDD = 5 V 100 10 20 30 40 50 Clayout (pF) ON PINS 1 - 5 (MC145027); PINS 1 - 5 AND 12 - 15 (MC145028) Figure 13. fmax vs Clayout - Decoders Only MC145026, MC145027, MC145028 Technical Data, Rev. 4 Freescale Semiconductor 13 Pin Descriptions NO HAS THE TRANSMISSION BEGUN? YES DOES THE 5-BIT ADDRESS MATCH THE ADDRESS PINS? NO DISABLE VT ON THE 1ST ADDRESS MISMATCH NO DISABLE VT ON THE 1ST DATA MISMATCH YES STORE THE 4-BIT DATA DOES THIS DATA MATCH THE PREVIOUSLY STORED DATA? YES IS THIS AT LEAST THE 2ND CONSECUTIVE MATCH SINCE VT DISABLE? NO YES LATCH DATA ONTO OUTPUT PINS AND ACTIVATE VT HAVE 4-BIT TIMES PASSED? YES DISABLE VT NO NO HAS A NEW TRANSMISSION BEGUN? YES Figure 14. MC145027 Flowchart MC145026, MC145027, MC145028 Technical Data, Rev. 4 14 Freescale Semiconductor Pin Descriptions NO HAS THE TRANSMISSION BEGUN? YES DOES THE ADDRESS MATCH THE ADDRESS PINS? NO DISABLE VT ON THE 1ST ADDRESS MISMATCH AND IGNORE THE REST OF THIS WORD YES IS THIS AT LEAST THE 2ND CONSECUTIVE MATCH SINCE VT DISABLE? NO YES ACTIVATE VT HAVE 4-BIT TIMES PASSED? YES DISABLE VT NO NO HAS A NEW TRANSMISSION BEGUN? YES Figure 15. MC145028 Flowchart MC145026, MC145027, MC145028 Technical Data, Rev. 4 Freescale Semiconductor 15 MC145027 and MC145028 Timing 5 MC145027 and MC145028 Timing To verify the MC145027 or MC145028 timing, check the waveforms on C1 (Pin 7) and R2/C2 (Pin 10) as compared to the incoming data waveform on Din (Pin 9). The R-C decay seen on C1 discharges down to 1/3 VDD before being reset to VDD. This point of reset (labelled “DOS” in Figure 16) is the point in time where the decision is made whether the data seen on Din is a 1 or 0. DOS should not be too close to the Din data edges or intermittent operation may occur. The other timing to be checked on the MC145027 and MC145028 is on R2/C2 (see Figure 17). The R-C decay is continually reset to VDD as data is being transmitted. Only between words and after the end-of-transmission (EOT) does R2/C2 decay significantly from VDD. R2/C2 can be used to identify the internal end-of-word (EOW) timing edge which is generated when R2/C2 decays to 2/3 VDD. The internal EOT timing edge occurs when R2/C2 decays to 1/3 VDD. When the waveform is being observed, the R-C decay should go down between the 2/3 and 1/3 VDD levels, but not too close to either level before data transmission on Din resumes. Verification of the timing described above should ensure a good match between the MC145026 transmitter and the MC145027 and MC145028 receivers. VDD Din 0V VDD C1 2/3 1/3 0V DOS DOS Figure 16. R-C Decay on Pin 7 (C1) EOW VDD R2/C2 2/3 1/3 0V EOT Figure 17. R-C Decay on Pin 10 (R2/C2) MC145026, MC145027, MC145028 Technical Data, Rev. 4 16 Freescale Semiconductor MC145027 and MC145028 Timing VDD VDD TE VDD VDD 0.1 µF A1 5 TRINARY ADDRESSES 14 A2 1 2 3 4 5 6 7 9 10 A3 A4 A5 D6 D7 4-BIT BINARY DATA D8 Din 2.3 RTCCTC′ R1C1 = 3.95 RTCCTC R2C2 = 77 RTCCTC 9 6 R1 MC145026 13 7 RTC C1 CTC 12 10 11 RS 8 R2 CTC′ = CTC + Clayout + 12 pF 100 pF ≤ CTC ≤ 15 µF RTC ≥ 10 kΩ; RS ≈ 2 RTC R1 ≥ 10 kΩ C1 ≥ 400 pF R2 ≥ 100 kΩ C2 ≥ 700 pF 1 A1 16 16 15 Dout D9 fosc = 0.1 µF 1 2 3 4 5 MC145027 15 14 13 12 11 C2 A2 A3 A4 5 TRINARY ADDRESSES A5 D6 D7 D8 D9 VT 8 REPEAT OF ABOVE REPEAT OF ABOVE Example R/C Values (All Resistors and Capacitors are ± 5%) (CTC′ = CTC + 20 pF) fosc (kHz) RTC 362 181 88.7 42.6 21.5 8.53 1.71 10 k 10 k 10 k 10 k 10 k 10 k 50 k CTC′ 120 pF 240 pF 490 pF 1020 pF 2020 pF 5100 pF 5100 pF RS R1 C1 R2 C2 20 k 20 k 20 k 20 k 20 k 20 k 100 k 10 k 10 k 10 k 10 k 10 k 10 k 50 k 470 pF 910 pF 2000 pF 3900 pF 8200 pF 0.02 µF 0.02 µF 100 k 100 k 100 k 100 k 100 k 200 k 200 k 910 pF 1800 pF 3900 pF 7500 pF 0.015 µF 0.02 µF 0.1 µF Figure 18. Typical Application MC145026, MC145027, MC145028 Technical Data, Rev. 4 Freescale Semiconductor 17 Package Dimensions 6 Package Dimensions NOTES: 1. DIMENSIONING AND TOLERANCING PER ANSI Y14.5M, 1982. 2. CONTROLLING DIMENSION: INCH. 3. DIMENSION L TO CENTER OF LEADS WHEN FORMED PARALLEL. 4. DIMENSION B DOES NOT INCLUDE MOLD FLASH. 5. ROUNDED CORNERS OPTIONAL. -A16 9 1 8 B F C DIM A B C D F G H J K L M S L S -T- SEATING PLANE K H G D M J 16 PL 0.25 (0.010) M T A M INCHES MILLIMETERS MIN MAX MIN MAX 0.740 0.770 18.80 19.55 0.250 0.270 6.35 6.85 0.145 0.175 3.69 4.44 0.015 0.021 0.39 0.53 0.040 0.70 1.02 1.77 0.100 BSC 2.54 BSC 0.050 BSC 1.27 BSC 0.008 0.015 0.21 0.38 0.110 0.130 2.80 3.30 0.295 0.305 7.50 7.74 0˚ 10˚ 0˚ 10˚ 0.020 0.040 0.51 1.01 Figure 19. Outline Dimensions for P SUFFIX PLASTIC DIP (DUAL IN-LINE PACKAGE) (Case Outline 648-08, Issue R) 0.25 8X PIN'S NUMBER M B A 6.2 5.8 1 1.75 1.35 0.25 0.10 16X 16 0.49 0.35 0.25 T A B 14X PIN 1 INDEX 1.27 4 A 8 10.0 9.8 A 9 T 4.0 3.8 SEATING PLANE 16X B 0.1 T 5 0.50 0.25 6 M X45˚ 0.25 0.19 1.25 0.40 SECTION A-A NOTES: 1. DIMENSIONS ARE IN MILLIMETERS. 2. DIMENSIONING AND TOLERANCING PER ASME Y14.5M, 1994. 3. DATUMS A AND B TO BE DETERMINED AT THE PLANE WHERE THE BOTTOM OF THE LEADS EXIT THE PLASTIC BODY. 4. THIS DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSION OR GATE BURRS. MOLD FLASH, PROTRUSION OR GATE BURRS SHALL NOT EXCEED 0.15mm PER SIDE. THIS DIMENSION IS DETERMINED AT THE PLANE WHERE THE BOTTOM OF THE LEADS EXIT THE PLASTIC BODY. 5. THIS DIMENSION DOES NOT INCLUDE INTER-LEAD FLASH OR PROTRUSIONS. INTER-LEAD FLASH AND PROTRUSIONS SHALL NOT EXCEED 0.25mm PER SIDE. THIS DIMENSION IS DETERMINED AT THE PLANE WHERE THE BOTTOM OF THE LEADS EXIT THE PLASTIC BODY. 6. THIS DIMENSION DOES NOT INCLUDE DAMBAR PROTRUSION. ALLOWABLE DAMBAR PROTRUSION SHALL NOT CAUSE THE LEAD WIDTH TO EXCEED 0.62mm. 7˚ 0˚ Figure 20. Outline Dimensions for D SUFFIX SOG (SMALL OUTLINE GULL-WING) PACKAGE (Case Outline 751B-05, Issue K) MC145026, MC145027, MC145028 Technical Data, Rev. 4 18 Freescale Semiconductor Package Dimensions 0.25 8X PIN'S NUMBER M B A 10.55 10.05 2.65 2.35 0.25 0.10 16X 16 1 0.49 0.35 0.25 6 M T A B PIN 1 INDEX 14X 10.45 4 10.15 A A 8 1.27 9 7.6 7.4 T B SEATING PLANE 16X 0.1 T 5 0.75 0.25 X45˚ 0.32 0.23 1.0 0.4 SECTION A-A NOTES: 1. DIMENSIONS ARE IN MILLIMETERS. 2. DIMENSIONING AND TOLERANCING PER ASME Y14.5M, 1994. 3. DATUMS A AND B TO BE DETERMINED AT THE PLANE WHERE THE BOTTOM OF THE LEADS EXIT THE PLASTIC BODY. 4. THIS DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSION OR GATE BURRS. MOLD FLASH, PROTRUSION OR GATE BURRS SHALL NOT EXCEED 0.15mm PER SIDE. THIS DIMENSION IS DETERMINED AT THE PLANE WHERE THE BOTTOM OF THE LEADS EXIT THE PLASTIC BODY. 5. THIS DIMENSION DOES NOT INCLUDE INTER-LEAD FLASH OR PROTRUSIONS. INTER-LEAD FLASH AND PROTRUSIONS SHALL NOT EXCEED 0.25mm PER SIDE. THIS DIMENSION IS DETERMINED AT THE PLANE WHERE THE BOTTOM OF THE LEADS EXIT THE PLASTIC BODY. 6. THIS DIMENSION DOES NOT INCLUDE DAMBAR PROTRUSION. ALLOWABLE DAMBAR PROTRUSION SHALL NOT CAUSE THE LEAD WIDTH TO EXCEED 0.62mm. 7˚ 0˚ Figure 21. Outline Dimensions for DW SUFFIX SOG (SMALL OUTLINE GULL-WING) PACKAGE (Case Outline 751G-04, Issue D) MC145026, MC145027, MC145028 Technical Data, Rev. 4 Freescale Semiconductor 19 How to Reach Us: Home Page: www.freescale.com E-mail: support@freescale.com USA/Europe or Locations Not Listed: Freescale Semiconductor Technical Information Center, CH370 1300 N. Alma School Road Chandler, Arizona 85224 +1-800-521-6274 or +1-480-768-2130 support@freescale.com Europe, Middle East, and Africa: Freescale Halbleiter Deutschland GmbH Technical Information Center Schatzbogen 7 81829 Muenchen, Germany +44 1296 380 456 (English) +46 8 52200080 (English) +49 89 92103 559 (German) +33 1 69 35 48 48 (French) support@freescale.com Japan: Freescale Semiconductor Japan Ltd. Headquarters ARCO Tower 15F 1-8-1, Shimo-Meguro, Meguro-ku, Tokyo 153-0064 Japan 0120 191014 or +81 3 5437 9125 support.japan@freescale.com Asia/Pacific: Freescale Semiconductor Hong Kong Ltd. Technical Information Center 2 Dai King Street Tai Po Industrial Estate Tai Po, N.T., Hong Kong +800 2666 8080 support.asia@freescale.com For Literature Requests Only: Freescale Semiconductor Literature Distribution Center P.O. Box 5405 Denver, Colorado 80217 1-800-441-2447 or 303-675-2140 Fax: 303-675-2150 LDCForFreescaleSemiconductor@hibbertgroup.com MC145026/D Rev. 4 1/2005 Information in this document is provided solely to enable system and software implementers to use Freescale Semiconductor products. There are no express or implied copyright licenses granted hereunder to design or fabricate any integrated circuits or integrated circuits based on the information in this document. Freescale Semiconductor reserves the right to make changes without further notice to any products herein. Freescale Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does Freescale Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation consequential or incidental damages. “Typical” parameters that may be provided in Freescale Semiconductor data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals”, must be validated for each customer application by customer’s technical experts. Freescale Semiconductor does not convey any license under its patent rights nor the rights of others. Freescale Semiconductor products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications intended to support or sustain life, or for any other application in which the failure of the Freescale Semiconductor product could create a situation where personal injury or death may occur. Should Buyer purchase or use Freescale Semiconductor products for any such unintended or unauthorized application, Buyer shall indemnify and hold Freescale Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that Freescale Semiconductor was negligent regarding the design or manufacture of the part. Freescale™ and the Freescale logo are trademarks of Freescale Semiconductor, Inc. All other product or service names are the property of their respective owners. © Freescale Semiconductor, Inc. 2005. All rights reserved. SAW RF Transmitter Module with INTEGRATED ANTENNA TX-SAW I.A. +V (15) SAW OSCILLATOR In Mod. (2) [650200274] MATCHING NETWORK In Mod. (3) 1) Ground 2) Input Mod. Vc>8V 3) Input Mod. Vc<8V 4) Ground 7) Ground 10) Ground 13) Ground 15) +V (4V to 12V) Information subject to change without notice Pin-out @5 1 V mW Mechanical Dimensions Descrizione SAW transmitter module with integrated antenna ideal for applications when you need to modulate ON-OFF a RF carrier with digital signals. High reliability and low spurious RF emision are the main characteristics. EN 300 220 homologable (@5V). Modulo trasmettitore SAW con antenna interna per applicazioni con modulazione ON-OFF di una portante RF con dati digitali. Alta efficienza e bassa emissione di spurie sono elementi primari del modello. Omologabile EN 300 220 (@5V). 3.8 41.5 Component Side 1 2 3 4 7 10 13 CHARACTERISTICS FC PERP ES FM LI TOP Supply Voltage • Alimentazione Supply Current • Corrente assorbita Carrier frequency • Frequenza portante RF Output power (E.R.P.) • Potenza di uscita RF (E.R.P.) RF spurious emission • Emissioni RF spurie Square wave modulation • Frequenza di modulazione Input logic level • Livello logico d’ingresso Operating temperature range • Temperatura di lavoro 15 7 0.5 0.25 2.54 Technical Specification VS IS 16.3 Description Ta = 25 °C MIN TYP 5 6 433.92 0 -40 VS -1 -20 MAX +3 4 VS +80 UNIT Vdc mA MHz dBm dB KHz V °C Products not suggested for new projects or to be used in special applications. Prodotto non consigliato per nuovi progetti o destinato ad applicazioni speciali. Technical Mail : Lab-el@aurel.it AUREL S.p.A. • Via Foro dei Tigli, 4 • I 47015 Modigliana (FC) Italy • Phone : +39-0546941124 • Fax : +39-0546941660 • http://www.aurel.it • E-mail: aurel@aurel.it WIRELESS 434 Mhz Standard (OOK) Receiver +V (1,15) Antenna (3) Data Out (14) AM DET. RF AMP BC-NBK +V (1,15) LF AMP COMP T.P.(13) 3 mA max 1) +V 2) Ground 3) Antenna 7) Ground 11) Ground 13) Test Point 14) Data Output 15) +V Information subject to change without notice Pin-out 5V Description Descrizione High-miniaturization SIL thick-film hybrid circuit. Low cost, low antenna radiation and high insensitivity to power switching noises. In compliance with European Normative. Ricevitore economico su allumina ad elevata miniaturizzazione. Basso assorbimento, bassa radiazione in antenna ed alta immunità ai disturbi di alimentazione. In accordo con le Normative Europee. Mechanical Dimensions 5.5 38.1 1 2 3 7 11 13.7 Component Side 13 14 15 7 0.5 Technical Specification VS IS FW SI BW SO SL HO LO TON TOP 0.25 2.54 Ta = 25 °C CHARACTERISTICS MIN TYP MAX UNIT Supply Voltage • Alimentazione Supply Current • Corrente Assorbita Reception frequency • Frequenza di ricezione RF sensitivity • Sensibilità RF - 3dB RF Bandwidth • Banda passante RF a - 3dB Square wave output • Onda quadra in uscita Spectrum emitted level • Radiazione in antenna Output high voltage• Livello alto d’uscita Output low voltage• Livello basso d’uscita Switch-on time• Tempo di accensione Operating temperature range • Temperatura di lavoro 4.5 5 5.5 3 Vdc mA MHz dBm MHz KHz dBm V V s °C 433.92 -97 ±1.2 -65 2 -60 VS - 0.4 -20 GND + 0.4 2 +80 Product Code: 650200208 AUREL S.p.A. • Via Foro dei Tigli, 4 • I 47015 Modigliana (FC) Italy • Phone : +39-0546.941124 • Fax : +39-0546.941660 www.aurelwireless.com This information may be subject to revision without notice. AUREL makes no warranty and assumes no liability in connection with any use of this information. Variazioni senza preavviso delle presenti informazioni non implicano responsabilità da parte AUREL. L'acquirente assume ogni responsabilità derivante dall'uso del prodotto. WIRELESS