Physics of VLSI Devices –

MVLD501L (Module 1)

Dr. Rajan Pandey

Associate Professor, SENSE

Semiconductors

Cubic Lattices

Unit cells for three types of cubic lattice structures

Nearest neighbours

6

Simple Cubic (SC)

8

Body-Centred Cubic (BCC)

12

Face-Centred Cubic (FCC)

How many atoms per unit cell in each unit cell type?

Types of Cubic Cells

𝑃𝐹 =

𝐴𝑡𝑜𝑚𝑠 𝑝𝑒𝑟 𝐶𝑒𝑙𝑙 . 4/3. 𝜋𝑟

𝐿𝑎𝑡𝑡𝑖𝑐𝑒 𝑐𝑜𝑛𝑠𝑡𝑎𝑛𝑡

Different cubic cells result from different packing of atoms

First nearest

neighbours

Cubic Lattices

Reference

atom

Nearest neighbours

8x1=8

First nearest

neighbours 6

Second nearest

neighbours

Reference

atom

Body-Centred

Cubic (BCC)

Third nearest

neighbour

Simple Cubic (SC)

Reference

atom

Face-Centred

Cubic (FCC)

First nearest neighbours

6 x 2 = 12

Face Centered Cubic (FCC)

Atomic packing pactor (APF): 0.74

Number of atoms per unit cell: 4

• The face is a square of side a and the

diagonal is 𝑎 + 𝑎 or 𝑎 2.

• The diagonal has one atom at the center of

diameter 2R, which touches two atoms

centered at the corners.

• The diagonal, going from corner to corner, is

therefore R + 2R + R.

• Thus, 4R = 𝑎 2 and a = 4R∕ 2 = 2R 2.

The FCC unit cell. The atomic radius is R and the lattice parameter is a

Types of Solids

• In the basic building blocks of todays integrated circuits, there are all kinds of

materials: metals, alloys, semiconductors, low, ultra-low, and high-k insulators.

• Also, these materials have various physical forms or states, namely crystalline,

amorphous, and polycrystalline.

• Amorphous solids lack a regular three-dimensional arrangement of atoms. They

lack long-range structural order.

• Crystalline solids have atoms/ions/molecules arranged in regular, repeating

patterns. They possess long-range periodicity.

• Polycrystals contain multiple grains of crystallites. They have short range order.

Crystalline

Polycrystalline

Amorphous Polycrystalline

Amorphous Crystalline

Silicon Crystal Structure

• Unit cell of silicon crystal is

cubic. 8 atoms in the unit

cell.

Average bond length = 2.35 Å

Conventional unit cell

Electron wavefunction in a

periodic crystal:

• Each Si atom has 4 nearest

neighbors.

• Cell volume = (5.43 Å)3

= 1.6 X 10-22 cm3

• Density of Si atoms:

= 8/1.6 X 10-22 = 5 X 1022 cm-3

Lattice parameter = 5.43 Å

2.35 Å

uk has the same periodicity

as the crystal.

k = 2π/a, a = lattice parameter

Similar to k = 2π/λ for a wave

Diamond structure:

Two interpenetrating FCC lattices 1/4, 1/4, 1/4 along the body diagonal.

FCC Face Centred Cubic Lattice (there are 14 Bravais lattices)

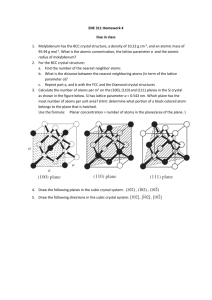

Silicon Wafers and Crystal Planes

z

z

z

(100) plane

x [100] direction

y

x

(110) plane

y

[110] direction

Si (111) plane

x

[111]

direction

(111) plane

y

Si (100)

Si (110)

• The standard notation for

crystal planes is based on the

cubic unit cell.

• Silicon wafers are usually cut

along the (100) plane with a

flat or notch to help orient the

wafer during IC fabrication.

Si (111)

• As electrons move along (100) direction, they see a

particular arrangement of Si atom.

• If they move along (110) or (111) direction, they will see a

very different arrangements of Si atoms in space.

• The electron transport in (100) or (110) or (111) orientations,

will be different from each other.

Directions in the cubic crystal system

100 [100], [010], [001], [ 1 00], [0 1 0], [00 1 ]

<100> - Cube edges

<110> - Face diagonals

<111> - Body diagonals

Properties of crystals may

be different along different

directions because atomic

periodicities are different.

Wafer Type and Orientation

Wafer flats: Indicates the

type and orientation of the

crystal.

Primary flat (P): The flat of

the longest length located in

the circumference of the

wafer. The primary flat has a

specific crystal orientation

relative to the wafer surface

(major flat).

Secondary flat (S): Indicates

the crystal orientation and

doping of the wafer.

Questions

• Why the device fabrication has to be in a certain crystallographic

orientation?

• Why some specific types of devices are fabricated in a certain

crystal orientation e.g. CMOS along <100> and <110>?

• Whereas certain other type of devices are fabricated in some

other crystal orientation e.g. BJT along <111>?

Wafer Type and Orientation

Processed wafer

with identical chips.

• The crystal is usually doped p- or n-type while grown.

• Only a thin layer of the wafer, approximately 1-μm to 15- μm deep, is used to

define the device structure (out of 600 – 800 μm).

• The remainder of the wafer acts as a mechanical support.

• Several process parameters and device characteristics are sensitive to wafer

orientation.

• These include rate of crystal growth, rate of thermal oxidation, diffusivity of

impurities, electronic band structure, electronic transport etc.

• Since the {111} planes have the smallest separation, silicon grows faster along

a <111> direction than along a <110> or <100> direction.

• Also, since {111} planes have the highest density of atoms, the dissolution of

silicon in an etching solution is slowest in the <111> direction.

• The oxidation rate of silicon is largest in the <111> direction and smallest in

the <100> direction.

• Electronic traps created at the silicon surface increase the surface charge and

alter device parameters. The density of these interface traps depends on the

crystallographic orientation.

• It is highest in <111> oriented wafers and lowest in <100> oriented wafers. This

is one reason for choosing <100> oriented wafers for MOS devices fabrication.

• The current flow is higher along <110> compared to <100>.

Questions

• Why the device fabrication has to be in a certain crystallographic orientation?

• Why some specific type of devices are fabricated in a certain crystal orientation?

• Whereas the certain other type of devices are fabricated in some other crystal

orientation?

• We have got the answers of the above questions. But we just figured out that

the density of interface traps are highest along <111> oriented wafers and

lowest along <100> oriented wafers. So then why Bipolar devices are fabricated

along <111> oriented wafers, whereas MOS devices are not?

• The answer lies in the way of functioning of these devices. Whereas MOS

devices are sensitive to the interface traps, the bipolar devices may not be.

Interplanar spacing

The interplanar spacing is given by

A more generalized form is

d

hkl

1

h2

k 2

l2

2

2

2

a

b

c

Example: The lattice constant for aluminum is 4.041 angstroms. What is d between

adjacent (220) planes, i.e. d220?

Aluminum has fcc structure, so a = b = c = 4.041 Å

d hkl

1

h2 k2

a2

1

22 22

4 . 041 2

1 . 43 angstroms

Angles between planes

The angle θ between two directions

[h1 k1 l1] and [h2 k2 l2] is given by

the relation:

As an example the angle between

(111) and (100) planes will be

°

The angle between (111) and (100) surface is 54.74 degrees.

Elemental and Compound Semiconductors

Elemental

IV Compound

III-V Compound II-VI Compound

Si

SiC

AlP

ZnS

Ge

SiGe

AlAs

GaP

ZnSe

ZnTe

GaAs

InAs

CdS

CdSe

InSb

InP

HgS

ZnO

GaN

HgSe

• Most semiconductors have diamond or zinc blende crystal structures.

• What is crystal structure? What is diamond or zinc blende crystal structure?

Effective Mass

Ex

An external force Fext applied to an

electron in a vacuum results in an

acceleration avac = Fext /me

Ex

An external force Fext applied to an

electron in a crystal results in an

acceleration acryst = Fext /me*

Electrons in solids under electric force field behave as if they have effective

mass rather than free electron mass, due to crystal potential.

Effective Mass

In an electric field, E, an electron or a hole accelerates.

∗

𝒆

Electrons,

∗

holes

Electrons and holes in solids under electric force field behave

as if they have effective mass rather than free electron mass,

due to crystal potential.

=

∗

∗

∗

Effective mass is a measure of the curvature of the band.

Larger the curvature, smaller the effective mass and vice versa.

k = 2π/a,

a = lattice parameter

Electron and hole effective masses

In semiconductors or metals

we are only concerned about

the regions very close to the

band edges for transport or

optical properties.

m*e / m0

m*h / m0

Si

Ge

GaAs

InAs

0.2

0.49

0.08

0.33

0.067

0.51

0.026

0.42

Free hole band will also be parabolic close to the

band edge but the curvature will be opposite.

The bands are parabolic in

the close vicinity of the

band edges.