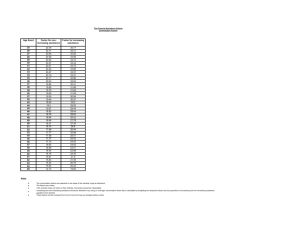

Sensorless Drive of Permanent Magnet Brushless DC Motor with 180 Degree Commutation Boyang Hu, Student Member, IEEE and Swamidoss Sathiakumar, Member, IEEE School of Electrical and Information Engineering The University of Sydney Sydney, NSW, Australia E-mail: boyang@ee.usyd.edu.au Abstract—The three-phase wye connected permanent magnet brushless dc motor is conventionally driven by 120 degree commutation. Two phases are conducting current and the other one is always floating without any torque produced in each conduction interval. Rather than the conventional 120 degree drive, all three phases of 180 degree commutation are expected to conduct current in all sectors, which results in more power delivered from inverter side to the motor side for the same power supply voltage. In this paper, a recently proposed sensorless algorithm is highlighted with well performance in low speed operation. Based on dSPACE, comparison of different dynamic conditions between 120 and 180 degree commutation is presented and analyzed comprehensively. Extensive experiment tests show excellent results on dynamic performance of 180 degree commutation, which matches the simulation results from Simulink/Matlab. 180 degree commutation is verified to work properly with the ability to deliver more power when compared with conventional 120 degree commutation. Keywords—brushless dc motor; sensorless drive; low speed;120/180 degree commutation; I. INTRODUCTION Permanent magnet brushless dc motors (BLDCM) with trapezoidal back electromotive force (EMF) are being increasingly used in last two decades. The latest advances in permanent magnet materials, solid-state devices and microelectronics have contributed to new energy efficient electric drives for BLDCM drive [1]. The Advantages of BLDC motor are with higher efficiency, higher power to weight ratio, higher torque to current ratio, faster dynamic response, less maintenance, better power factor and better output power per unit mass and volume, rather than conventional motors. Two forms of permanent magnet AC motors are commonly used in industrial drives, which are permanent magnet synchronous motor(PMSM) and brushless dc motor(BLDCM). PMSM is with sinusoidal back-EMF waveform and BLDCM is with trapezoidal waveform. Due to the absence of brushes and field windings, BLDCM has many inherent advantages, compared to PMSM, such as higher speed capability, larger application range from low speed to high speed, higher power density and so on [2]. To produce a constant electric torque, BLDCM is considered c 978-1-4244-6506-4/10/$26.00 2010 IEEE with rectangular phase current energized, which is to be in phase with back-EMF signals. It is well known that sensors have many limitations in less accessible location environment. It is necessary to eliminate the unreliable and costly position sensors by using sensorless methods. The previous sensorless methods for brushless dc motors are reviewed in the literature [3]-[8]. In summary, sensorless methods are to find the accurate rotor position information for energizing three phase windings by using algebraic manipulations, back-EMF signals, sensorless starting techniques or other novel techniques. Rotor position estimation techniques are grouped into the following four categories [2]: 1. Detection of back-EMF, which can be further categorized into the following approaches: a) Zero-crossing approach, b) Phase locked loop technique, c) Back-EMF integration approach 2. Detection of stator third harmonic voltage 3. Detection of conducting interval of free-wheeling diodes connected in anti-parallel with the solid-state switches 4. Monitoring the inductance variation of d-q axes (PMSM) Two Main drawbacks must be considered about backEMF zero-crossing approach. First of all, when motor is at standstill or very low speed operation, back-EMF is not possible to be obtained. The other disadvantage is that zerocrossing instant is with 30 degree shift from the commutation instant. Refer to Fig. 1, there is always a 30 electrical degree shift between the back-EMF zero-crossing instant and the commutation instant. In the case of dynamic performance when motor speed is variable during this offset time, position would not be accurately estimated. To solve these two problems, a novel sensorless speed and position estimation method [9] is recently proposed, which is successfully presented in theory and simulation, however, due to very limited experiment results, dynamic conditions are still not shown properly. BLDCM is conventional driven with 120-degree commutation, which is two phases “on” and the other phase floating, which is shown in Fig. 2. Due to the reason that torque production is almost directly proportional to the 106 phase current [10], the floating phase doesn’t produce any torque. As shown in Fig. 3, all the three phase are “on” in each conduction intervals of 180-degree. The 180-degree commutation can generate larger output torque than 120degree for the same given power supply, which has been investigated in [11] and [12]. In this paper, a novel 180-degree sensorless system is proposed based on the sensorless algorithm [9]. The speed and position are obtained based on the estimated back-EMF signals which are calculated by simply measuring the threephase currents and three-stator terminal voltages. The proposed 180-degree sensorless system works well in both directions. PWM mode is applied for the proposed 180degree sensorless system with satisfactory implementation results. The comparisons between the conventional 120degree and the proposed 180-degree sensorless system are fully addressed. The validity of the proposed system is verified through both simulation and implementation. II. PRINCIPLE OF OPERATION A. Switch Sequences Figure 1: Three phase back-EMF and activation phase voltage of 120degree commutation. For the conventional 120-degree sensorless commutation of BLDCM, the winding without phase current in each conduction interval can be considered as a sensor for backEFM detection. However, for the 180-degree commutation, due to all the three phases conduct current all the time in each conduction intervals without floating, there are no back-EMF available in stator terminals. The conventional back-EMF detection methods cannot be applied to 180degree commutation. The speed and position can be estimated from the estimated back-EMFs, which are calculated by simply sensing the terminal voltages and phase currents. Even though the sensorless drive with 180-degree commutation works properly in theory and simulation environment [12], experimental implementation has never been successfully addressed. Experiment verification of BLDCM sensorless drive with 180-degree commutation is of great significance. A B 1) Sensor-based Analysis As shown in Fig. 4, permanent magnet BLDCM is typically driven by six switches MOSFET inverter. T1, T3 and T5 are the high side transistors. T2, T4 and T6 are the low side transistors. Hall sensors are traditionally used for detecting the rotor position. The switching sequences are determined based on the hall sensor signals. To run the motor continuously and smoothly, next commutation switch sequence is used for the current conduction interval. Permanent magnet rotor is attracted to move to the next sector. Installation of hall sensors and motor three phases are described in Fig. 5. Based on the hall sensor signals, rotor position is simply obtained, which is shown in Fig. 6. According to the current position, the next switching sequences can be summarized into table 1. Figure 4: Three-phase six switches inverter and BLDCM C Figure 2: Conduction interval of 120-degree commutation. Figure 3: Conduction interval of 180 degree commutation. Figure 5: Hall sensor installation with three phases of U, V, W 2010 IEEE Conference on Robotics, Automation and Mechatronics 107 Equation (1) shows the mathematical model of BLDCM, where the Vabc are three-phase voltages. Rabc are the threestator resistances. I abc represent the three-phase currents. Labc are the value of the stator inductance per phase. M is mutual inductance between each two phases and Eabc represent the back-EMF in the respective three phases. Figure 6: Position of current conduction interval Sensor signals are the same for both 120 and 180 degree commutation, and the driven pattern is shown in table 1. Table 1: Switch sequences of 120 and 180 degree commutation Switch Sequences 120 degree commutation Polarities A B C 180 degree commutation Transistor “on” Polarities A B C ªVa º ª Ra «V » = « 0 « b» « «¬Vc »¼ «¬ 0 0 Rb 0 0 º ª Ia º ª La M M º ª I a º ª Ea º d« » « » 0 » « I b » + « M Lb M »» «« Ib »» + «« Eb »» (1) dt «¬ M M Lc »¼ «¬ Ic »¼ «¬ Ec »¼ Rc »¼ «¬ Ic »¼ ª « trape θ ( r) « ª Ea º « P « E » = − ψ × ω trape § θ − 2π r « ¨ r « b» 2 3 © « ¬« Ec ¼» « 4π § «trape ¨ θ r − 3 © ¬ º » » ªYa º P ·» « » ¸ » = − ψ × «Yb » 2 ¹» ¬«Yc ¼» ·» ¸» ¹¼ Intervals (degree) Transistor “on” 0 - 60 T1, T6 + 0 - T1,T4,T5 + - + 60 - 120 T3, T6 0 + - T1,T4,T6 + - - 120 - 180 T3, T2 - + 0 T1,T3,T6 + + - 180-240 T5, T2 - 0 + T2,T3,T6 - + - 240-300 T5, T4 0 - + T2,T3,T5 - + + The three-phase back-EMF signals are given in the Equation (2), where trape(θ r ) represents a piecewise linear and periodic signal with the period 2π and the magnitude 1. ψ represents the magnitude of flux linkage and ωr is rotor 300-360 T1, T4 + - 0 T2,T4,T5 - - + speed. As shown in Equation (2), the Yabc are the signals (2) with speed information. The Yabc are given by Equation (3). 2) Sensorless Algorithm Sensorless drive of 180-degree operation is simulated in [12], as well as the modeling of the BLDCM. In this section, the sensorless algorithm [9] is used. The theory of this sensorless algorithm is illustrated in Fig. 7. The main principle is to estimate the speed and position by sensing the three-phase terminal voltage and current signals to obtain the estimated back-EMF through machine equations. Yabc signals are trapezoidal waveforms with speed information. The estimated speed is the maximum value of the absolute values of Yabc signals. The position signal is obtained from the look up table of [9]. trape(θ r ) takes the extreme value of ±1 for any given value of θ r . The magnitude of rotor speed can be simply obtained by Equation (4). ªYa º ª Ea º «Y » = « E » « b» « b» «¬Yc »¼ «¬ Ec »¼ ª « trape θ ( r) « « 2π ( − P 2 )ψ = ωr «trape §¨ θ r − 3 © « « 4π § «trape ¨ θ r − 3 © ¬ ωr = max ( Ya , Yb , Yc Figure 7: Sensorless algorithm 108 ) º » » ·» ¸» ¹» ·» ¸» ¹¼ (3) (4) 3) Pulse Width Modulation (PWM) Mode Operation In order to control the speed, torque, and the power applied to the BLDCM, PWM signals are commonly used. Due to the chopping frequency is fixed, acoustic and electromagnetic noise are relatively easy to filter [10]. Hard chopping technology is to modulate both high and low side of switches at the same time. In order to minimize the chance of short circuit, soft chopping is implemented in this paper, which is only used to modulate the three switches of the high side of inverter. Theory of soft chopping technology is shown in Fig. 8. “d” is value of duty cycle from 0 to 1. 2010 IEEE Conference on Robotics, Automation and Mechatronics PWM signals are generated by comparing the duty cycle with a periodic double side triangular waveform with the magnitude from 0 to 1. The frequency of the double side triangular waveform is the PWM modulation frequency. The modulated activation phase voltage signals of both 120degree and 180-degree commutation are shown in Fig. 9. 20 15 10 5 0 -5 -10 -15 -20 0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4 0.45 0.5 Time (s) Figure 10: Phase current and terminal voltage of BLDCM 120-degree sensorless commutation Figure 8: PWM soft chopping Figure 9: Modulated phase voltage of 120 and 180 degree commutation III. SIMULATION ANALYSIS The 120 and 180 degree sensorless systems are simulated in Simulink/Matlab environment. The BLDCM parameters are shown in table 2. Simulation results of phase current, terminal voltage, estimated back-EMF, estimated speed and position of 120 and 180 degree commutation are shown respectively in this section. Figure 11: Phase current and terminal voltage of BLDCM 180-degree sensorless commutation Table 2: Table of motor parameters Motor parameters Pole pairs 1 Friction Coefficient (B) 0 Stator Resistance (R) 5.85 Ω Stator Inductance (L) 0.966 mh (ψ ) 0.115 Wb 3 gcm 2 Flux Linkage Inertia of Rotor (J) Figure 12˖Estimated back- EMF, estimated speed and estimated position signals of the proposed180-degree sensorless system. 2010 IEEE Conference on Robotics, Automation and Mechatronics 109 IV. EXPERIMENT RESULTS A. Sensorless of 120 and 180-degree commutation A 20W BLDCM with manufacturer type-number EC22200118 is used in experiment. Tests are implemented based on the dSPACE DS1104 controller board. This controller board is appropriate for motion control applications and fully programmable from Simulink/Matlab, which can efficiently generate and download the code to the dSPACE boards. Current transducer LEM HY 5-P and voltage transducer LEM LV 25-P are used to accurately sense the phase current and terminal voltage signals for sensorless algorithm. DMC550 is a digital motor controller designed for BLDCM with both sensor and sensorless based drive from Taxas Instruments. Fig.13 and Fig.14 show the implementation results of phase current and stator terminal voltage of the sensorless 120-degree commutation respectively. The phase conducts current for 120 electrical degrees and floats for the other 60 electrical degrees. The back-EMF is available when the phase is floating, which is described in Fig.14. Figure 16: Terminal voltage of 180-degree sensorless commutation. Figure 17: Estimated position of clockwise direction of 180-degree sensorless commutation. Figure 18: Estimated position of counter-clockwise direction of 180-degree sensorless commutation. Figure 13: phase current of 120-degree sensorless commutation. An incremental encoder is used to obtain the actual speed signal, which is solely used for the comparison and not for the control purposes. Fig.19 describes the actual speed of the 180-degree sensorless commutation. The estimated speed is shown in Fig20. The proposed sensorless algorithm works satisfactorily to estimate the rotor speed and energize the motor stator windings. Figure 14: Terminal voltage of 120-degree sensorless commutation. The experimental results of the proposed 180-degree phase current and stator terminal voltage are shown in Fig.15 and Fig.16. It can be seen that the phase of the sensorless 180degree commutation conducts current in each conduction intervals. The stator terminal connects to either the positive or the negative of the dc power supply, which results in no back-EMF appeared at the stator terminals. The estimated position signals of the proposed 180-degree sensorless system are satisfactorily shown in two opposite directions in Fig.17 and Fig18. Figure 19: Actual speed of 180-degree sensorless commutation. Figure 20: Estimated speed of 180-degree sensorless commutation. Figure 15: Phase current of 180-degree sensorless commutation. 110 In order to present the validity with speed, position and torque control of the proposed 180-degree sensorless system, it is necessary to demonstrate the implementation with PWM operation. Fig.21 and Fig.22 describes the phase 2010 IEEE Conference on Robotics, Automation and Mechatronics current and stator terminal voltage of the 120-degree sensorless commutation, which are for the comparison purpose. The PWM results of the phase current and stator terminal voltage are successfully shown in Fig23 and Fig.24 respectively. Figure 21: Phase current of 120-degree sensorless commutation (PWM). V. CONCLUSION In this paper, a novel 180-degree sensorless commutation system of BLDCM is proposed and verified to work properly through both the simulation and implementation. The simulation is carried out in the Simulink/Matlab and the experiments are implemented through the dSPACE DS1104 controller board. The conventional 120-degree and the proposed 180-degree sensorless commutation systems are compared with satisfactory simulation and experimental results. The proposed 180-degree sensorless commutation system is able to work successfully in both directions with accurate speed and position estimations. Finally, the proposed 180-degree sensorless commutation system is discussed to deliver more power from the inverter side to the BLDCM side for the same given power supply voltage. Since the generated torque of the BLDCM only depends on the value of the phase current, the proposed 180-degree sensorless system is able to generate more torque than the conventional 120-degree system with the same dc supply. REFERENCES Figure 22: Terminal voltage of 120-degree sensorless commutation (PWM). [1] Figure 23: Phase current of 180-degree sensorless commutation (PWM). Figure 24: Terminal voltage of 180-degree sensorless commutation (PWM). B. Discussion The validity of the proposed 180-degree sensorless commutation system shows well performance on both directions with accurate speed and position estimations. The PWM operation is also applicable for the proposed system, which provides the validity of speed control, position control and torque control. Due to the three stator resistors are allocated as one is in series with the parallel connection of the other two resistors, the overall phase to phase resistance is less than the value of 120-degree. The phase current of 180-degree is larger than that of 120-degree commutation under the same power supply voltage, which results in more power is delivered from inverter side to the motor side. Somanatham, R. Prasad, P.V.N. and Rajkumar, A.D. “Modeling and simulation of sensorless control of PMBLDC motor using zerocrossing back E.M.F. detection,” Proc, IEEE Symp. Power Electronics, Electrical Drives, Automation and Motion, May. 2006, pp984-989. [2] JawadFaiz, M.R.Azizian and M.Aboulghasemian-Azami. ”Simulation and analysis of brushless DC motor drives using hysteresis, ramp comparison and predictive current control techniques,”Science, Vol 3, Jan. 1996, pp.347-362, doi: 10.1016/0928-4869(95)00014-3. [3] J.P.Johnson, M.Ehsani, Y.Guzelqunler, “Review of Sensorless Methods for Brushless DC,” Proc, IEEE Conf. Industry Applications Conference, Oct. 1999, IEEE press, vol.1pp. 143-150. [4] T. Senjyu and K. Uezato, “Adjustable Speed Control of Brushless DC Motors without Position and Speed Sensores”, Proc, IEEE Conf. Industrial Automation and Control: Emerging Technologies, May. 1995. pp. 160-164. [5] P.W.Lee and C.Pollock, “Sensorless Commutation Techniques for Brushelss Permanent-Magnet and Reluctance Motor Drives,” IEE Colloquium on Variable Speed Drives and Motion Control 1992. [6] J. Holtz. “Speed Estimation and Sensorless Control of AC Drives”, Proc of the 19th Annual Conf. of IEEE Industrial Electronics, pp.649654, 1993. [7] K. Ohnishi, N. Matsui, and Y.Hori, “Estimation, Identification, and Sensorless Control in Motion Control System”, Proc. of IEEE, Vol 82, pp1253-1265, Aug. 1994. [8] J. Holtz, “State of the Art of Controlled AC Drive without Speed Sensor”, IEEE Proc. of Int’l Conf. on Power Electronics and Drive Systems, pp1-6,1995. [9] J. Lee, S. Sathiakumar, Y. Shrivastava, “A novel speed and position estimation of the brushless dc motor at low speed”, Proc of Conf. AUPEC 18th conference, Australia, Dec. 2008, pp1-6. [10] Texas Instruments Europe, “DSP Solution for BLDC Motors”, 2001 [11] B.Hu, S.Sathiakumar, Y. Shrivastava, “180-Degree Commutation System of Permanent Magnet Brushless DC Motor Drive Based on Speed and Current Control”, Proc of Conf. ICICTA, 2009, pp723-726. [12] B.Hu, S.Sathiakumar, Y. Shrivastava,” Sensorless Drive of Brushless DC Motor with 180-degree Commutation”,Proc of Conf. CCCM, 2009, pp579-582. 2010 IEEE Conference on Robotics, Automation and Mechatronics 111