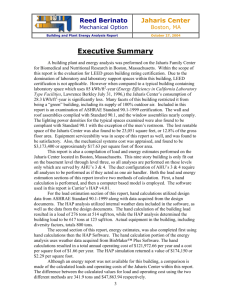

Journal of the Australian Ceramic Society (2022) 58:803–815 https://doi.org/10.1007/s41779-022-00730-5 RESEARCH Theoretical and experimental characterization of Sn‑based hydroxyapatites doped with Bi A. Aksogan Korkmaz1 · Lana Omar Ahmed2 · Rebaz Obaid Kareem3 · Hanifi Kebiroglu4 · Tankut Ates5 · Niyazi Bulut4 · Omer Kaygili4 · Burhan Ates6 Received: 6 December 2021 / Revised: 19 January 2022 / Accepted: 24 February 2022 / Published online: 17 March 2022 © The Author(s) under exclusive licence to Australian Ceramic Society 2022 Abstract This is the first report, including both theoretical and experimental results, on Bi and Sn co-doped hydroxyapatite (HAp) structures. Sn content was kept at a constant amount of 0.22 at.%, and Bi content was changed from 0 to 0.44 at.% by using the steps of 0.11at.%. Theoretical results from density functional theory (DFT) calculations revealed an increase in density from 3.154 g ­c m−3 to 3.179 g ­c m −3, as well as gradual decreases in the bandgap from 4.5993 eV to 4.4288 eV and the linear absorption coefficient. The spectroscopic data obtained from both Raman and Fourier transform infrared (FTIR) spectra confirmed the HAp structure for all the samples. The thermal behavior and morphology, as well as all X-ray diffraction (XRD) related parameters, were all considerably impacted by Bi-content. In vitro assays showed that all the samples can be accepted as the biocompatible materials. Keywords Hydroxyapatite · X-ray diffraction · Spectroscopic analysis · Bandgap Introduction Hydroxyapatite (HAp, ­C a 10(PO 4) 6(OH) 2) is a naturally occurring mineral of calcium apatite [1]. HAp has a hexagonal crystal system. When it is pure, it is in the form of white granules and can be found in colors such as colorless, gray, yellow, yellowish-green depending on the impurities it contains [2, 3]. HAp can be obtained * Tankut Ates tankut.ates@ozal.edu.tr 1 Department of Mining Technology, Malatya Turgut Özal University, Malatya, Turkey 2 Department of Physics, Faculty of Science and Health, Koya University, Koya KOY45, Kurdistan Region – F.R, Iraq 3 Physics Department, College of Science, University of Halabja, 46018 Halabja, Iraq 4 Department of Physics, Faculty of Science, Firat University, 23119 Elazig, Turkey 5 Department of Engineering Basic Sciences, Faculty of Engineering and Natural Sciences, Malatya Turgut Özal University, Battalgazi, , Malatya, Turkey 6 Department of Chemistry, Faculty of Arts & Science, Inonu University, 44280 Malatya, Turkey naturally from bones such as bovine bone, fishbone, fish shell, oyster shell, chicken eggshell, and coral [4]. HAp is widely used in biomedical applications (hard tissue repair, substitution, augmentation and as a coating for orthopedic implants) due to its chemical stability, non-toxicity, high bioactivity and biocompatibility [5–8]. It is also used as an adsorbent in engineering barriers for environmental repair. In addition, it has great potential as a biomaterial for other applications such as catalysis, chromatographic adsorption [9]. Further, it is also used as an agent in bioimaging and as hyperthermia for cancer [10]. HAp nanoparticles have attracted great interest for biomedical applications due to their favorable stoichiometry and purity. HAp nanoparticles have not only an ultrafine structure but also high surface reactivity similar to minerals found in bones. HAp nanoparticles show enhanced densification and sintering properties due to their high surface energy. Therefore, problems such as micro-cracks can be avoided [11]. Due to its high wear resistance, chemical stability, and chemical composition similar to natural bone, HAp is more advantageous than metal or polymer in bone-tissue applications [12]. However, in new bone formation, HAp has disadvantages such as low bone-binding ability and susceptibility to bacterial 13 Vol.:(0123456789) 804 Journal of the Australian Ceramic Society (2022) 58:803–815 Table 1 The moles of the as-used chemicals Sample Ca(NO3)2·4H2O (mmol) Bi(NO3)3·5H2O (mmol) SnCl4·5H2O (mmol) (NH4)2HPO4 (mmol) 0.22Sn-HAp 0.11Bi-0.22Sn-HAp 0.22Bi-0.22Sn-HAp 0.33Bi-0.22Sn-HAp 0.44Bi-0.22Sn-HAp 49.890 49.835 49.780 49.725 49.670 0.055 0.110 0.165 0.220 0.110 0.110 0.110 0.110 0.110 30.000 30.000 30.000 30.000 30.000 activity [13–16]. To improve its low bone-binding ability, its composites using some polymers (e.g., chitosan and polyetheretherketone) or special glasses have been used [17–19]. Additionally, some antimicrobial agents a b Energy gap (Eg) = 4.5993 eV 20 ­(Fe 3O4, ­Ag +, ­C u 2+, and ­Ti 4+, etc.) can be substituted in HAp to give it better antibacterial properties in comparison with its un-doped form [16]. 10 Energy (eV) Energy (eV) 10 0 0 -10 -20 Energy gap (Eg) = 4.5376 eV 20 -10 G A H K γ M L H 0 10 20 30 40 50 60 70 -20 80 G A K γ H M L 0 H c 20 d Energy gap (Eg) = 4.4946 eV 30 40 50 60 70 80 10 Energy (eV) Energy (eV) 20 Energy gap (Eg) = 4.4562 eV 20 10 0 -10 -20 10 Density of states (electrons/eV) Density of states (electrons/eV) 0 -10 G A H K γ M L H 0 10 20 30 40 50 60 70 80 -20 G A H K γ M L 0 H Density of states (electrons/eV) e 10 20 30 40 50 60 70 80 Density of states (electrons/eV) Energy gap (Eg) = 4.4288 eV 20 Energy (eV) 10 0 -10 -20 G A H K γ M L H 0 10 20 30 40 50 60 70 80 Density of states (electrons/eV) Fig. 1 The bandgap and density of states of the a) 0.22Sn-HAp, b) 0.11Bi-0.22Sn-HAp, c) 0.22Bi-0.22Sn-HAp, d) 0.33Bi-0.22Sn-HAp and e) 0.44Bi-0.22Sn-HAp structures 13 Journal of the Australian Ceramic Society (2022) 58:803–815 In biological apatites, some cations (­ Na +, ­K +, ­M g 2+, ­Z n 2+, ­S r 2+, ­F e 2+ etc.) and anions ­( F −, ­C l −, ­C O 32− etc.) can substitute at the HAp lattice. This reduces the Ca/P ratio, possibly improving solubility and affecting the crystal structure [6, 20]. Polarizability, electronegativity, valence and ionic radii are important factors in cationic substitutions. The physical and chemical properties of HAp are affected by its surface morphology, size and crystal structure [21, 22]. Even though some cationic substitutions are minimal, significant changes can be observed in the structural properties of HAp such as lattice parameters, crystal structure, morphology, and important properties such as thermal stability, magnetic and mechanical properties [1]. HAp synthesis is an alternative way to provide better control of material properties [23]. Various techniques have been used to synthesize HAp, such as sol–gel, hydrothermal, solid-state reaction, microwave irradiation, spray pyrolysis, hydrolysis, chemical precipitation, emulsion or sonochemical process [5, 21, 24]. Although there are very few studies of Bi and Sndoped hydroxyapatite in the literature, there are many studies in which different metals are doped. Bi and Sn have no known biological role and are non-toxic. Especially, Bi, which is a heavy metal, has been widely used in the most applications in the chemistry, physics and materials science due to its non-toxic nature and different chemical and physical properties in comparison with other elements [25]. Bi and its complexes have been used in the biological applications as well as Sn and its oxide form [26–30]. Ramesh et al. [31] investigated the sinterability of HAp with different amounts of ­Bi 2O3 doped (from 0.05% to 1% by wt.) and compared it with the un-doped HAp. They investigated phase stability, relative density, Vickers hardness, fracture toughness and Young’s modulus. They determined that the ­B i 2O 3 additive had a negligible effect on HAp particle morphology and crystal size. The best densification, Young's modulus, hardness and fracture toughness values were obtained in HAp doped with 0.5% by weight ­Bi2O3 when sintered at 1000ºC [31]. Moussa et al. [32] investigated the effect of 0.5% Sn and Bi addition as alloying on the microstructure and in vitro degradation behavior of as-cast Mg-4wt% Zn alloy without and with Ca-P coating. It was determined that the alloy containing Sn showed the lowest degradation rate, while the alloy containing Bi showed the highest degradation rate [32]. Ahmed et al. [33] synthesized Bi and Sr doped nano-sized hydroxyapatites by precipitation microwaveassisted method for applications, particularly in bone tissue engineering. They determined that the B ­ i3+ and S ­ r2+ dual substitutions were successfully incorporated into the HAp lattice. Bi–Sr-doped HAp has been demonstrated to 805 exhibit a high reactivity to E. coli. Radha and Sreekanth [34] used Sn as an alloying element to evaluate its effect on the mechanical and corrosion properties of Mg/HAp composites. They determined that the addition of Sn also plays an important role in increasing both the mechanical and the corrosion resistance of Mg/HAp. There are some reports on Bi- and Sn-doped HAps as mentioned above, but to the best of our knowledge, there is no study in the literature on the effects of Bi/ Sn co-dopants on the HAp structure. We present a more detailed experimental and theoretical investigation report on these samples the first time. Materials and Methods Synthesis and characterization Di-ammonium hydrogen phosphate ((NH4)2HPO4, ≥ 98.0%, Sigma-Aldrich, France), calcium nitrate tetrahydrate (Ca(NO 3) 2·4H 2O, 99%, Carlo-Erba, France), tin (IV) chloride pentahydrate (­ SnCl 4 ·5H 2 O, 98.0%, Sigma-Aldrich, France) and bismuth (III) nitrate pentahydrate (Bi(NO3)3·5H2O, ≥ 98.0%, Sigma-Aldrich, France) were used as the starting chemicals of the wet chemical synthesis of the Sn-based HAps doped with Bi at different amounts (e.g., 0, 0.11, 0.22, 0.33 and 0.44 at. %). For each sample, the appropriate amount of the as-mentioned chemicals given in Table 1 was used. 100 mL solution of Ca(NO 3 ) 2 ·4H 2 O, ­S nCl 4 ·5H 2 O and Bi(NO 3)3·5H2O was prepared in a flask and poured into a beaker. 100 mL solution of ­( NH 4) 2HPO4 was prepared in another flask, then poured drop by drop into the first solution and a milky solution was obtained. The pH value of this solution was adjusted to the value of 10 by adding an ammonia solution ­( NH4OH, Sigma-Aldrich, France), this solution was stirred at 65 ºC for 90 min, and it was put in an oven at 120 ºC for 20 h for drying. The as-dried sample was calcined in an electric furnace at 850 ºC for 120 min. X-ray diffraction (XRD) data were recorded by a Rigaku Rad B-DMAX II diffractometer (Japan) at 40 kV and 30 mA using Cu-Kα radiation having the wavelength of 0.15406 nm, scanning at 2θ = 20–60°. Fourier transform infrared (FTIR) data were collected in the wavenumber range from 400 ­c m −1 to 4000 ­c m −1 by a PerkinElmer Spectrum One spectrometer (U.S.A.) using the KBr method. To record the Raman spectra, Renishaw’s inVia confocal microscope (United Kingdom) with a 532 nm diode laser was used. A Leo Evo-40 XVP scanning electron microscope (SEM, Germany) was used to investigate the morphology. Differential thermal analysis (DTA, Japan) was performed by using a Shimadzu DTA 13 806 50 from room temperature to 1000 °C at a heating rate of 10 °C ­min −1. In vitro biocompatibility assay of Bi/Sn co‑doped HAp samples Bi/Sn co-doped HAp samples in powder form were weighed separately 0.1 g each under sterile conditions and put into sterile tubes with a volume of 2 mL. Then, 1 mL of DMEM was added on each material and was kept in the incubator for 72 h. L929 (Mouse Fibroblast) cells were grown in a flask at 37 °C in 5% C ­ O2 incubator by using high glucose DMEM medium, which is a mixture of 10% FBS and 1% Penicillin–Streptomycin. It was inoculated into each well in the 96 well plate as 10,000 L929 cells. It was expected to stick and spread in the ­CO2 incubator until the next day. After 24 h, the medium in the well plate was removed and discarded. Instead, the media kept with the material for 72 h were carefully filtered from the materials and added to the wells. Cells were incubated with material-suspended media for 24 h in the incubator. MTT dye was dissolved in PBS (pH 7.4 in phosphate buffer) to 5 mg/mL. After 24 h, the soaked medium in the well plate was withdrawn and discarded. Instead, 90 µL of DMEM and 10 µL of 5 mg/mL prepared MTT (3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide) mixture was placed in each well and incubated in a ­CO 2 incubator for 4 h. After the incubation, the medium with MTT in the well plate was taken and discarded. 100 μL of DMSO was added to each well. Well plates were read at 540 nm wavelengths immediately after loading DMSO. Results and Discussion Theoretical results Bandgap and density of states calculations Our prior research includes theoretical calculations of band structure and density of states [35]. Here in this subsection, a brief overview will be given. The formula can be used to calculate the density of states (DOS) as a function of energy ∑ ( ) DOS(E) = g E − 𝜀i (1) where g is a Gaussian with a fixed FWHM, E is the total energy, and ε i is the energy of the ­ith molecular orbital. 13 Journal of the Australian Ceramic Society (2022) 58:803–815 The interaction between atoms causes the atomic levels to break into numerous closely related levels, which is what the band structure and density of states measurements are based on. These are the molecular energy levels that have been examined in the system. The number of splitting in a solid molecule is determined by the interatomic distances between two or more atoms. When the number of nuclei in an atom grows, the number of splitting grows as well, potentially resulting in a lot more energy splitting due to overlapping spin-orbits and other factors. The band structure and density of states of the system may vary as a result of these splitting. A density functional theory (DFT) tool was used in conjunction with the CASTEP Software [36]. Figure 1a1e depicts the estimated density of state and band structure for all synthesized samples of tin (Sn)-based HAp with doped bismuth (Bi) at various atomic percentages such as 0.22Sn-HAp, 0.11Bi-0.22Sn-HAp, 0.22Bi0.22Sn-HAp, 0.33Bi-0.22Sn-HAp, 0.44Bi-0.22Sn-HAp. The band gaps in all figures were measured at an interval of (G-H). Figure 1a shows the band structure calculations and DOS results for an Sn-based HAp molecule. Tin (Sn) has the electronic configuration [Kr] ­5s24d105p2. The closed-shell atomic levels of the Krypton configuration result in highly strong bound bands of the remaining electrons of the Sn atom. The splitting of the 4d level is bigger than that of the 5 s level due to the relatively small and near constraint of the 5 s orbital. The energy bandgap of this structure was determined to be 4.5993 eV. The d orbital contribution to the bands corresponds to the region in the picture with a large density of states, which is more dominating at positive energy and even in a negative energy zone. The low contribution of s orbitals to the DOS structure can also be expected. Figure 1a-e shows the HAp molecule with Sn and Bi-doped to it. The energy gap of the molecule was reduced to 4.4288 eV from 4.5993 eV by adding atom Bi at various amounts. The electron structure of bismuth is [Xe] 4­ f145d106s26p3. Because of its higher energy, when paired with the Bismuth and other atoms in the HAp molecule, this configuration minimizes the device's energy gap. As energy levels rise, more splitting happens in general. By introducing the Bi atom into the doping HAp molecule, the result of a greater energy contribution to the energy gap can be seen very clearly in Fig. 1b-e. The energy bandgap values drop as Bi is introduced to the Sn-based HAp structure, as shown in the figures. In comparison with the studies reported in the literature, the bandgap value calculated for each element doped structure is lower than those of the reported ones for the pure HAp as 4.92, 5.05 and 5.23 eV [37, 38]. For 0.40at%Ce and 0.47at.%Ce-doped HAp structures, the bandgap values were reported as 4.6078 eV and 4.5905 eV, respectively Journal of the Australian Ceramic Society (2022) 58:803–815 Table 2 Comparison between theoretical and experimental values of the lattice parameters and unit cell volume 807 Sample Theoretical 0.22Sn-HAp 0.11Bi-0.22Sn-HAp 0.22Bi-0.22Sn-HAp 0.33Bi-0.22Sn-HAp 0.44Bi-0.22Sn-HAp Experimental a (nm) c (nm) V (nm) a (nm) c (nm) V (nm)3 0.9354 0.9348 0.9347 0.9331 0.9324 0.6797 0.6797 0.6794 0.6801 0.6803 0.5150 0.5144 0.5140 0.5128 0.5122 0.9410 0.9421 0.9358 0.9398 0.9363 0.6867 0.6876 0.6838 0.6867 0.6836 0.5266 0.5285 0.5186 0.5252 0.5190 [39, 40]. Additionally, this value was calculated as 5.1915 eV for 0.35at.%Sr-doped HAp [41]. In this work, we calculated the bandgap value for 0.22at.%Sn-doped HAp structure as 4.5993 eV. Although the amount of this dopant is lower than those of both Ce and Sr-doped ones, the bandgap value for the Sn-doped structure is lower than those structures. This result can be associated with the higher electrical conductivity of Sn (0.0917 × ­106 Ω−1 ­cm−1) in comparison with both Sr (0.0762 × ­106 Ω−1 ­cm−1) and Ce (0.0115 × ­106 Ω−1 ­cm−1) [42]. The lattice parameters and volume of the unit cell values for all the as-modeled structures were also estimated. These theoretical results are listed in Table 2 together with the experimental ones to make a better comparison among them. 3 0.33Bi-0.22Sn-HAp and 0.44Bi-0.22Sn-HAp, respectively. The densities of Sn (7.265 g ­c m −3 ) and Bi (9.78 g ­c m −3) are higher than that of Ca (1.55 g ­c m −3) [43]. Even though the amount of Sn was kept at a constant value, the addition of Bi caused an increase in the density of the HAp system. Briefly, the higher amount of Bi means the higher density. The linear absorption coefficient (LAC) as a function of photon energy for each structure is illustrated in Fig. 2. For all structures, with rising photon energy, a downward tendency persists. Additionally, the LAC value increases gradually with increasing amount of Bi. The Indexed peaks: HAp (JCPDS 09-0432) : β -TCP (JCPDS 09-0169) 0.44Bi-0.22Sn-HAp Density and linear absorption coefficient calculations 1200 0.22Sn-HAp 0.11Bi-0.22Sn-HAp 0.22Bi-0.22Sn-HAp 0.33Bi-0.22Sn-HAp 0.44Bi-0.22Sn-HAp 1000 710 800 0.33Bi-0.22Sn-HAp Intensity (a.u.) Using the as-modeled structures, both density and linear absorption (or attenuation) coefficients were computed and reported in this section. The density values were estimated as 3.154, 3.161, 3.168, 3.173, and 3.179 g ­cm−3 for 0.22Sn-HAp, 0.11Bi-0.22Sn-HAp, 0.22Bi-0.22Sn-HAp, 0.22Bi-0.22Sn-HAp 700 0.11Bi-0.22Sn-HAp 600 (211) 630 (322) (313) (213) (321) (410) (402) (004) (222) (312) (203) (302) (113) (212) (310) (210) (200) (111) 200 0.22Sn-HAp (301) 7 (202) 6 (0 2 10) 5 (002) 610 (112) (300) 620 400 (102) µ (cm-1) 690 0 5 10 15 20 25 30 Energy (keV) Fig. 2 The linear absorption coefficient dependence on the energy and composition of the as-modeled systems 20 30 40 2θ (°) 50 60 Fig. 3 XRD patterns of the Sn-based HAp samples doped with Bi at various amounts 13 808 Sample XC% DS (nm) DWH (nm) ε × ­10–4 σ (MPa) u (kJ m ­ −3) 0.22Sn-HAp 0.11Bi-0.22Sn-HAp 0.22Bi-0.22Sn-HAp 0.33Bi-0.22Sn-HAp 0.44Bi-0.22Sn-HAp 71.693 71.698 71.811 72.380 68.499 28.87 26.66 27.75 25.93 26.76 26.26 26.01 23.15 23.07 22.18 -2.085 -1.606 -8.318 -6.168 -9.509 -226.496 -317.347 126.002 -288.186 212.803 420.595 760.892 33.663 911.616 117.965 as-observed results are in very good agreement with the literature and can be evaluated that due to their weakening property for electromagnetic radiation, all of the samples are ideal candidates for radiation shielding and medical applications. [35, 41, 44]. Experimental results XRD analysis Figure 3 shows the XRD results of Sn/Bi co-doped HAp samples. For the 0.44Bi-0.22Sn-HAp, a single-phase distribution of the HAp (JCPDS pdf no: 09–0432) was observed. For the rest samples, the major phase is the HAp, and the minor phase is the beta-tricalcium phosphate (β-TCP, JCPDS pdf no: 09–0169). The amounts of the β-TCP phase were computed as 1.04%, 2.44%, 1.26%, 0.95% and 0% for 0.22Sn-HAp, 0.11Bi-0.22Sn-HAp, 0.22Bi-0.22Sn-HAp, 0.33Bi-0.22Sn-HAp and 0.44Bi0.22Sn-HAp, respectively. It was seen that the amount of the as-mentioned phase was affected significantly by Bi-content. The calculation of the lattice parameters (a and c) and unit cell volume (V) was carried out using the following Eq. (2) and Eq. (3) [45] ( ) 1 4 h2 + hk + k2 l2 = + (2) 3 d2 a2 c2 V = 0.866a2 c (3) where d corresponds to the distance between adjacent planes. Both theoretical and experimental calculation results for the parameters of a, c and V are given in Table 2. While the theoretical results imply that there is a gradual decrease in the lattice parameter of the a and unit cell volume, the experimental ones point out that there are non-gradual changes in the lattice parameters and unit cell volume. The addition of Bi to the HAp structure affects significantly all of these three parameters. Using the intensity of the pit (V112/300) between (112) and (300) reflections and the intensity (I 300 ) of (300) reflection, the crystallinity percent (XC%) value for each sample was estimated by using Eq. (4) [46]. 13 XC % = ( 1− V112∕300 I300 × 100 ) (4) The as-computed values of the crystallinity percent for all the samples are listed in Table 3. The introduction of Bi into the HAp structure causes variations in the crystallinity and the XC% values for all the samples are in the range of 68.5%-72.4%. For the estimation of the crystallite size for all the samples, the following Scherrer (D S) and WilliamsonHall (DWH) equations were used, respectively [41] 0.8 0.0100 0.0075 1.0 1.2 1.4 1.6 1.8 1.4 1.6 1.8 0.44Bi-0.22Sn-HAp 0.0050 0.0025 0.0000 0.0075 0.33Bi-0.22Sn-HAp 0.0050 0.0025 0.0000 cos Table 3 The calculation results for the parameters of the crystallinity percent, crystallite size, lattice strain, stress and anisotropic energy density Journal of the Australian Ceramic Society (2022) 58:803–815 0.0075 0.22Bi-0.22Sn-HAp 0.0050 0.0025 0.0000 0.0075 0.11Bi-0.22Sn-HAp 0.0050 0.0025 0.0000 0.0075 0.22Sn-HAp 0.0050 0.0025 0.0000 0.8 1.0 1.2 4sin Fig. 4 The βcosθ vs. 4sinθ plots of the Sn-based HAps doped with Bi Journal of the Australian Ceramic Society (2022) 58:803–815 DS = 0.9𝜆 𝛽cos𝜃 𝛽cos𝜃 = 0.9𝜆 + 4𝜀sin𝜃 DWH 809 0.9𝜆 4𝜎sin𝜃 + DWH Y (5) 𝛽cos𝜃 = (6) where σ and Y are the lattice stress and Young’s modulus, which can be calculated by using Eq. (8), respectively. where β, λ, ε and θ correspond the full width at half maximum, wavelength of the incident X-rays, lattice strain and angle of Bragg diffraction, respectively. Using Eq. (6), the value of the DWH for each sample was found from the intercept of the βcosθ vs. 4sinθ shown in Fig. 4. The ε parameter was also calculated using the slope of each plot in the same figure. As can be seen from the results given in Table 3, the crystallite size is affected by the amount of Bi. Non-gradual changes for the D S value and a gradual decrease for the DWH value were observed. All the as-estimated values of the ε are negative. This is associated with the compressive strain [47]. Using the relation of the ε = σ/Y, a new relationship can be derived as (7) [ h2 + Y= ( 7.49 × 10−12 h2 + )2 2 (h+2k) 3 (h+2k)2 3 + 10.9 × 10−12 + ( )2 ]2 al c ( )4 al c ( − 7.1 × 10−12 h2 + (h+2k)2 3 )( )2 al c (8) where the h, k and l are Miller indices. From the slope of the βcosθ vs. 4sinθ Y −1 plots illustrated in Fig. 5, the σ values of the samples were estimated. The positive and negative values are respectively due to the tensile and compressive stresses [48]. To compute the anisotropic energy density (u) value, the following expression may be used [41] 𝛽cos𝜃 = ( )1∕2 2u 0.9𝜆 + 4sin𝜃 DWH Y (9) The u values were calculated from the βcosθ vs. ­25/2sinθ Y −1/2 plot shown in Fig. 6. All the as-estimated 0.0100 0.0075 0.0100 0.44Bi-0.22Sn-HAp 0.0075 0.0050 0.0050 0.0025 0.0025 0.0000 0.0075 0.0000 0.33Bi-0.22Sn-HAp 0.0075 0.0050 0.0025 0.0000 0.22Bi-0.22Sn-HAp β cosθ β cosθ 0.0000 0.0050 0.0025 0.0075 0.0050 0.0000 0.11Bi-0.22Sn-HAp 0.0075 0.0050 0.0050 0.0025 0.0025 0.11Bi-0.22Sn-HAp 0.0000 0.0000 0.0075 0.22Bi-0.22Sn-HAp 0.0025 0.0000 0.0075 0.33Bi-0.22Sn-HAp 0.0050 0.0025 0.0075 0.44Bi-0.22Sn-HAp 0.22Sn-HAp 0.0075 0.22Sn-HAp 0.0050 0.0050 0.0025 0.0025 0.0000 4.0x10-125.0x10-126.0x10-127.0x10-128.0x10-129.0x10-121.0x10-111.1x10-11 0.0000 3.0x10-6 4sin Y Fig. 5 The βcosθ vs. 4sinθ Y with Bi −1 -1 -1 (Pa ) graphs of the Sn-based HAps doped 3.5x10-6 4.0x10-6 5/2 2 sin Y 4.5x10-6 -1/2 (Pa 5.0x10-6 5.5x10-6 -1/2 ) Fig. 6 The βcosθ vs. 2­ 5/2sinθ Y −1/2 plots of the Sn-based HAps doped with Bi 13 810 Journal of the Australian Ceramic Society (2022) 58:803–815 Fig. 7 FTIR results of the asprepared HAps 0.44Bi-0.22Sn-HAp Transmittance (a.u.) 0.33Bi-0.22Sn-HAp 3560 3570 3580 3590 0.22Bi-0.22Sn-HAp 0.11Bi-0.22Sn-HAp 0.22Sn-HAp 4000 3600 3200 2800 2400 2000 1600 1200 800 400 Wavenumber (cm -1) FTIR and Raman spectroscopy results Figure 7 shows FTIR plots of the as-produced HAp samples. The bands belonging to both phosphate and hydroxyl groups were observed. The bands at the wavenumber positions of 466 ­cm−1, 561 ­cm−1, 594 ­cm−1, 957 ­cm−1, and 1018 ­cm−1 are related to the vibration modes of the phosphate group [50–52]. The bands detected at 636 ­cm−1 and 3569 ­cm−1 are related to the vibration mode of the hydroxyl group [53, 54]. All the as-observed bands on the FTIR spectra confirm the formation of the HAp structure for each sample [55]. The intensities of the band of 3569 ­cm−1 related to the hydroxyl group for all the Bi-doped samples are lower than that of the Bi-free sample. Also, the intensity of the band centered at 1018 ­cm−1, belonging to the phosphate group, are significantly affected by Bi-content. These changes in the band intensities support the influence of the dopant(s) into the HAp structure. Figure 8 illustrates the Raman spectra of the samples recorded over the range of 200—4000 ­c m −1 . For all the samples, five intense bands at the positions of 435 ­c m −1 , 585 ­c m −1 , 962 ­c m −1 having the highest intensity, 1039 ­c m −1, and 3574 ­c m −1 were observed on the Raman spectra. The bands observed at 435 ­c m −1 , 585 ­cm−1, 962 ­cm −1 and 1039 ­c m−1 are associated with the symmetric bending (υ2), antisymmetric bending (υ4), 13 symmetric stretching (υ1) and antisymmetric stretching (υ3) modes of the phosphate group, respectively [56, 57]. The band detected at 3574 ­cm−1 is related to the stretching mode of the hydroxyl group [56]. With the adding of Bi to the HAp structure, significant changes in the intensities of the bands were detected. Especially for the intensities of the bands of 962 ­cm−1 and 3574 ­cm−1, quite obvious changes were seen. Morphological investigations SEM images and EDX results of the as-produced co-doped HAps are shown in Fig. 9. All the samples are consisted of 0.44Bi-0.22Sn-HAp Intensity (a.u.) u values given in Table 3 are higher than the value of 12 kJ ­m−3 reported for the un-doped HAp [49]. 0.33Bi-0.22Sn-HAp 0.22Bi-0.22Sn-HAp 0.11Bi-0.22Sn-HAp 0.22Sn-HAp 0 400 800 1200 1600 2000 2400 2800 Raman shift (cm -1) Fig. 8 Raman spectra of the as-synthesized HAps 3200 3600 4000 Journal of the Australian Ceramic Society (2022) 58:803–815 811 Fig. 9 SEM images and EDX analysis report for each sample 13 812 Journal of the Australian Ceramic Society (2022) 58:803–815 be caused by the deposition of this element on the HAp surface. Additionally, the Ca/P molar ratios of the samples were found to be 0.94, 0.99, 0.97, 1.05, and 0.94 for 0.22SnHAp, 0.11Bi-0.22Sn-HAp, 0.22Bi-0.22Sn-HAp, 0.33Bi0.22Sn-HAp and 0.44Bi-0.22Sn-HAp, respectively. 60 0.22Sn-HAp 0.11Bi-0.22Sn-HAp 0.22Bi-0.22Sn-HAp 0.33Bi-0.22Sn-HAp 0.44Bi-0.22Sn-HAp Heat flow (mW) 50 40 Differential thermal analysis 30 20 10 0 200 400 600 800 1000 Temperature (°C) Fig. 10 DTA thermograms of the as-prepared HAp samples stacked nanoparticles having sphere-like shapes. The EDX results support the introduction of both Sn and Bi into the HAp structure. With the addition of Bi, the as-detected Bi content increases as expected, but the introduction of Bi into the apatitic structure is limited. For this reason, it can be said that the higher amounts of the dopant of Bi may In vitro biocompatibility result of Bi/Sn co‑doped HAp samples 60 Mouse fibroblast cells (L-929) of the genus Mus musculus were used in the biocompatibility test of the formulations carried out by the indirect method. Cell viability results were given Fig. 11 and Table 4. The biocompatibility of the HAp samples co-doped with Bi and Sn is above 80%. The reduction of cell viability by more than 30% is considered as a cytotoxic effect for biomaterials according to ISO-10993–5. Therefore, we can say the all the HAp samples have acceptable biocompatibility. The image of L-929 cells exposed with samples was also given Fig. 12. These images were confirmed our cell viability result in term of cell morphology. 40 Conclusions 120 Cell Viability (%) DTA curves of the as-prepared HAp samples co-doped with Sn and Bi are illustrated in Fig. 10. For all the samples, an exothermic peak, which is due to the removal of the physically adsorbed water molecule, which is weakly bound to the sample, is observed in the temperature range of 200–350 °C [58]. These peaks are detected as 214.50 °C (weak), 284.98 °C (sharp), 214.53 °C (weak), 244.54 °C (sharp), and 227.04 °C (sharp) for 0.22Sn-HAp, 0.11Bi-0.22Sn-HAp, 0.22Bi-0.22SnHAp, 0.33Bi-0.22Sn-HAp and 0.44Bi-0.22Sn-HAp, respectively. It can be concluded that Bi content affects significantly the thermal behavior of the sample. 100 80 20 C O N 0. 11 0.2 TR O B 2 0. i-0 Sn- L 2 2 .2 H B 2 S Ap 0. i-0 n33 .2 H B 2 S Ap 0. i-0 n44 .2 H B 2 S Ap i-0 n .2 - H 2 S Ap nH A p 0 Fig. 11 Effect of the Bi/Sn co-doped HAp samples on the viability of L929 mouse fibroblast cells 13 For the first time, HAp samples doped with Bi and Sn were prepared and characterized theoretically and experimentally. Theoretically, adding Bi to a Sn-based HAp Table 4 Effect of the Sn-HAp samples on the viability of L929 mouse fibroblast cells Sample Cell Viability % CONTROL 0.22Sn-HAp 0.11Bi-0.22Sn-HAp 0.22Bi-0.22Sn-HAp 0.33Bi-0.22Sn-HAp 0.44Bi-0.22Sn-HAp 100.00 ± 6.35 89.63 ± 3.35 96.98 ± 8.58 82.32 ± 6.24 90.07 ± 8.12 97.28 ± 6.77 Journal of the Australian Ceramic Society (2022) 58:803–815 813 Fig. 12 Optical microscopic images of L-929 cells treated with the Bi/Sn co-doped HAp samples structure results in a progressive increase in density and continuous decreases in the bandgap and linear absorption coefficient. The lattice parameters were affected by the dopant of Bi. Significant variations in the crystallite size and crystallinity percent were detected. It was observed that the addition of Bi to Sn-based HAp caused the formation of the lattice strain and stress. Both Raman and FTIR spectra verified the formation of the HAp structure for each sample. Nano-sized morphology was observed for all the samples. The thermal behavior of the Sn-based HAp was affected significantly by Bi content. All the as-prepared samples in this study can be accepted as the biocompatible material and can be used in biological and medical applications. Declarations Conflicts of interest The authors declare that they have no conflict of interest. References 1. Othmani, M., Bachoua, H., Ghandour, Y., Aissa, A., Debbabi, M.: Synthesis, characterization and catalytic properties of copper-substituted hydroxyapatite nanocrystals. Mater. Res. Bull. 97, 560–566 (2018) 2. Jouda, N.S., Essa, A.F.: Preparation and study of the structural, physical and mechanical properties of hydroxyapatite nanocomposite. Mater. Today: Proc. (2021). https://d oi.o rg/ 10.1016/j.matpr.2021.04.550 13 814 3. Sharma, P., Trivedi, A., Begam, H.: Synthesis and characterization of pure and titania doped hydroxyapatite. Mater. Today: Proc. 16, 302–307 (2019) 4. Odusote, J.K., Danyuo, Y., Baruwa, A.D., Azeez, A.A.: Synthesis and characterization of hydroxyapatite from bovine bone for production of dental implants. J. Appl. Biomater. Funct. 17(2), 2280800019836829 (2019) 5. Kaygili, O., Keser, S.: Sol–gel synthesis and characterization of Sr/Mg, Mg/Zn and Sr/Zn co-doped hydroxyapatites. Mater. Lett. 141, 161–164 (2015) 6. Nouri-Felekori, M., Khakbiz, M., Nezafati, N.: Synthesis and characterization of Mg, Zn and Sr-incorporated hydroxyapatite whiskers by hydrothermal method. Mater. Lett. 243, 120–124 (2019) 7. Wang, Z., Jiang, S., Zhao, Y., Zeng, M.: Synthesis and characterization of hydroxyapatite nano-rods from oyster shell with exogenous surfactants. Mater. Sci. Eng. C. 105, 110102 (2019) 8. Stanić, V., Dimitrijević, S., Antić-Stanković, J., Mitrić, M., Jokić, B., Plećaš, I.B., Raičević, S.: Synthesis, characterization and antimicrobial activity of copper and zinc-doped hydroxyapatite nanopowders. Appl. Surf. Sci. 256(20), 6083– 6089 (2010) 9. Ashrit, S.S., Chatti, R.V., Sarkar, S.: Synthesis and characterization of hematite based calcium rich hydroxyapatite-A nano material from LD slag fines. J. Environ. Chem. Eng. 8(1), 103581 (2020) 10. Jose, S., Senthilkumar, M., Elayaraja, K., Haris, M., George, A., Raj, A.D., Sundaram, S.J., Bashir, A.K.H., Maaza, M., Kaviyarasu, K.: Preparation and characterization of Fe doped n-hydroxyapatite for biomedical application. Surf. Interfaces. 25, 101185 (2021) 11. Rajabnejadkeleshteri, A., Kamyar, A., Khakbiz, M., Basiri, H.: Synthesis and characterization of strontium fluor-hydroxyapatite nanoparticles for dental applications. Microchem. J. 153, 104485 (2020) 12. Jang, J.H., Oh, B., Lee, E.J.: Crystalline hydroxyapatite/graphene oxide complex by low-temperature sol-gel synthesis and its characterization. Ceram. Int. 47(19), 27677–27684 (2021) 13. Ofudje, E.A., Adeogun, A.I., Idowu, M.A., Kareem, S.O.: Synthesis and characterization of Zn-Doped hydroxyapatite: scaffold application, antibacterial and bioactivity studies. Heliyon. 5(5), e01716 (2019) 14. Ullah, I., Siddiqui, M.A., Kolawole, S.K., Liu, H., Zhang, J., Ren, L., Yang, K.: Synthesis, characterization and in vitro evaluation of zinc and strontium binary doped hydroxyapatite for biomedical application. Ceram. Int. 46(10), 14448–14459 (2020) 15. Singh, G., Jolly, S.S., Singh, R.P.: Cerium substituted hydroxyapatite mesoporous nanorods: synthesis and characterization for drug delivery applications. Mater. Today: Proc. 28, 1460–1466 (2020) 16. Singh, S., Singh, G., Bala, N.: Synthesis and characterization of iron oxide-hydroxyapatite-chitosan composite coating and its biological assessment for biomedical applications. Prog. Org. Coat. 150, 1060115 (2021) 17. Yoshida, A., Miyazaki, T., Ishida, E., Ashizuka, M.: Preparation of bioactive chitosan-hydroxyapatite nanocomposites for bone repair through mechanochemical reaction. Mater. Trans. 45(4), 994–998 (2004) 18. Ma, R., Li, Q., Wang, L., Zhang, X., Fang, L., Luo, Z., Xue, B., Ma, L.: Mechanical properties and in vivo study of modified-hydroxyapatite/polyetheretherketone biocomposites. Mater. Sci. Eng. C 73, 429–439 (2017) 19. So, K., Fujibayashi, S., Neo, M., Anan, Y., Ogawa, T., Kokubo, T., Nakamura, T.: Accelerated degradation and improved 13 Journal of the Australian Ceramic Society (2022) 58:803–815 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. bone-bonding ability of hydroxyapatite ceramics by the addition of glass. Biomaterials 27(27), 4738–4744 (2006) Bastan, F.E., Rehman, M.A.U., Ustel, F.: Thermo-physical insights into a series of strontium substituted hydroxyapatite. Mater. Chem. Phys. 258, 123910 (2021) Chen, J., Liu, J., Deng, H., Yao, S., Wang, Y.: Regulatory synthesis and characterization of hydroxyapatite nanocrystals by a microwave-assisted hydrothermal method. Ceram. Int. 46(2), 2185–2193 (2020) Bulina, N.V., Chaikina, M.V., Vinokurova, O.B., Prosanov, I.Y., Lyakhov, N.Z.: Low-temperature mechanochemical synthesis of zinc-Substituted hydroxyapatite. Chem. Sustain. Dev. 3, 281–286 (2019) Cor rea-Piña, B.A., Gomez-Vazquez, O.M., LondoñoRestrepo, S.M., Zubieta-Otero, L.F., Millan-Malo, B.M., Rodriguez-García, M.E.: Synthesis and characterization of nano-hydroxyapatite added with magnesium obtained by wet chemical precipitation. Prog. Nat. Sci. 31(4), 575–582 (2021) Sobczak-Kupiec, A., Pluta, K., Drabczyk, A., Włoś, M., Tyliszczak, B.: Synthesis and characterization of ceramic-polymer composites containing bioactive synthetic hydroxyapatite for biomedical applications. Ceram. Int. 44(12), 13630–13638 (2018) Kanatzidis, M., Sun, H., Dehnen, S.: Bismuth-The Magic Element. Inorg. Chem. 59(6), 3341–3343 (2020) Yang, N., Sun, H.: Biocoordination chemistry of bismuth: Recent advances. Coord. Chem. Rev. 251(17–20), 2354–2366 (2007) Prakash, M., Kavitha, H.P., Abinaya, S., Vennila, J.P., Lohita, D.: Green synthesis of bismuth based nanoparticles and its applications - A review. Sustain. Chem. Pharm. 25, 100547 (2022) Ozturk, I.I., Banti, C.N., Hadjikakou, S.K., Panagiotou, N., Tasiopoulos, A.J.: Bismuth(III) halide complexes of aromatic thiosemicarbazones: Synthesis, structural characterization and biological evaluation. Polyhedron 208, 115388 (2021) Hwa, K.Y., Santhan, A., Sharma, T.S.K.: Fabrication of Sn-doped ZnO hexagonal micro discs anchored on rGO for electrochemical detection of anti-androgen drug flutamide in water and biological samples. Microchem. J. 160B, 105689 (2021) Raj, V., Kamaraj, P., Sridharan, M.: Arockiaselvi, J: Green synthesis, characterization of yttrium oxide, stannous oxide, yttrium doped tin oxide and tin doped yttrium oxide nanoparticles and their biological activities. Mater. Today: Proceed. 36(4), 920–922 (2021) Ramesh, S., Tan, C.Y., Yeo, W.H., Tolouei, R., Amiriyan, M., Sopyan, I., Teng, W.D.: Effects of bismuth oxide on the sinterability of hydroxyapatite. Ceram. Int. 37(2), 599–606 (2011) Moussa, M.E., Mohamed, H.I., Waly, M.A., Al-Ganainy, G.S., Ahmed, A.B., Talaat, M.S.: Comparison study of Sn and Bi addition on microstructure and bio-degradation rate of as-cast Mg-4wt% Zn alloy without and with Ca-P coating. J. Alloys Compd. 792, 1239–1247 (2019) Ahmed, M.K., Mansour, S.F., Mostafa, M.S., Darwesh, R., El-Dek, S.I.: Structural, mechanical and thermal features of Bi and Sr co-substituted hydroxyapatite. J. Mater. Sci. 54(3), 1977–1991 (2019) Radha, R., Sreekanth, D.: Mechanical and corrosion behaviour of hydroxyapatite reinforced Mg-Sn alloy composite by squeeze casting for biomedical applications. J. Magnes. Alloy. 8(2), 452–460 (2020) Ibrahimzade, L., Kaygili, O., Dundar, S., Ates, T., Dorozhkin, S.V., Bulut, N., Koytepe, S., Ercan, F., Gürses, C., Hssain, Journal of the Australian Ceramic Society (2022) 58:803–815 36. 37. 38. 39. 40. 41. 42. 43. 44. 45. 46. 47. 48. 49. A.H.: Theoretical and experimental characterization of Pr/Ce co-doped hydroxyapatites. J. Mol. Struct. 1240, 130557 (2021) Clark, S.J., Segall, M.D., Pickard, C.J., Hasnip, P.J., Probert, M.J., Refson, K., Payne, M.C.: First principles methods using CASTEP. Z. Kristallogr. 220, 567–570 (2005) Bystrov, V.S., Piccirillo, C., Tobaldi, D.M., Castro, P.M.L., Coutinho, J., Kopyl, S., Pullar, R.C.: Oxygen vacancies, the optical band gap (Eg) and photocatalysis of hydroxyapatite: comparing modelling with measured data. Appl. Catal. B Environ. 196, 100–107 (2016) Slepko, A., Demkov, A.A.: First-principles study of the biomineral hydroxyapatite. Phys. Rev. B. 84(13), 134108 (2011) Kaygili, O., Vural, G., Keser, S., Yahia, I., Bulut, N., Ates, T., Koytepe, S., Temuz, M.M., Ercan, F., Ince, T.: Ce/Sm codoped hydroxyapatites: synthesis, characterization, and band structure calculation. J Aust Ceram Soc. 57, 305–317 (2021) Acar, S., Kaygili, O., Ates, T., Dorozhkin, S.V., Bulut, N., Ates, B., Koytepe, S., Ercan, F., Kebiroglu, H., Hssain, A.H.: Experimental characterization and theoretical investigation of Ce/Yb co-doped hydroxyapatites. Mater. Chem. Phys. 276, 125444 (2022) Mahmood, B.K., Kaygili, O., Bulut, N., Dorozhkin, S.V., Ates, T., Koytepe, S., Gürses, C., Ercan, F., Kebiroglu, H., Agid, R.S., İnce, T.: Effects of strontium - erbium co-doping on the structural properties of hydroxyapatite: An Experimental and theoretical study. Ceram. Int. 46(10), 16354–16363 (2020) https://www.angstromsciences.com/elements-electr ical-condu ctivity, Accessed 16 November 2021. Speight, J.G.: Lange’s Handbook of Chemistry. McGraw-Hill, New York (2005) Priyadarshini, B., Vijayalakshmi, U.: Development of cerium and silicon co-doped hydroxyapatite nanopowder and its in vitro biological studies for bone regeneration applications. Adv. Powder Technol. 29(11), 2792–2803 (2018) Cullity, B.: Elements of X-ray diffraction. Addison-Wesley Pub. Co., Inc., Boston (1978) Landi, E., Tampieri, A., Celotti, G., Sprio, S.: Densification behavior and mechanisms of synthetic hydroxyapatites. J. Eur. Ceram. Soc. 20(14–15), 2377–2387 (2000) Rabiei, M., Palevicius, A., Monshi, A., Nasiri, S., Vilkauskas, A., Janusas, G.: Comparing Methods for Calculating Nano Crystal Size of Natural Hydroxyapatite Using X-Ray Diffraction. Nanomaterials 10(9), 1627 (2020) Fluri, A., Pergolesi, D., Roddatis, V., Wokaun, A., Lippert, T.: In situ stress observation in oxide films and how tensile stress influences oxygen ion conduction. Nat Commun. 7, 10692 (2016) Venkateswarlu, K., Chandra Bose, A., Rameshbabu, N.: X-ray peak broadening studies of nanocrystalline hydroxyapatite 815 50. 51. 52. 53. 54. 55. 56. 57. 58. by Williamson-Hall analysis. Physica B Condens. Matter. 405(20), 4256–4261 (2010) Goldberg, M.A., Gafurov, M.R., Murzakhanov, F.F., Fomin, A.S., Antonova, O.S., Khairutdinova, D.R., Pyataev, A.V., Makshakova, O.N., Konovalov, A.A., Leonov, A.V., Akhmedova, S.A., Sviridova, I.K., Sergeeva, N.S., Barinov, S.M., Komlev, V.S.: Mesoporous Iron(III)-Doped Hydroxyapatite Nanopowders Obtained via Iron Oxalate. Nanomaterials 11(3), 811 (2021) Goldberg, M.A., Akopyan, A.V., Gafurov, M.R., Makshakova, O.N., Donskaya, N.O., Fomin, A.S., Polikarpova, P.P., Anisimov, A.V., Murzakhanov, F.F., Leonov, A.V., Konovalov, A.A., Kudryavtsev, E.A., Barinov, S.M., Komlev, V.S.: Iron-Doped Mesoporous Powders of Hydroxyapatite as MolybdenumImpregnated Catalysts for Deep Oxidative Desulfurization of Model Fuel: Synthesis and Experimental and Theoretical Studies. J. Phys. Chem. C. 125, 11604–11619 (2021) ­ a3+ and F Erdem, U., Turkoz, M.B.: L ­ − dual-doped multifunctional hydroxyapatite nanoparticles: Synthesis and characterization. Microsc. Res. Tech. 84(12), 3211–3220 (2021) Murzakhanov, F.F., Mamin, G.V., Goldberg, M.A., Knotko, A.V., Gafurov, M.R., Orlinskii, S.B.: EPR of RadiationInduced Nitrogen Centers in Hydroxyapatite: New Approaches to the Study of Electron-Nuclear Interactions. Russ J Coord Chem. 46, 729–737 (2020) Goldberg, M.A., Protsenko, P.V., Smirnov, V.V., Antonova, O.S., Smirnov, S.V., Konovalov, A.A., Vorckachev, K.G., Kudryavtsev, E.A., Barinov, S.M., Komlev, V.S.: The enhancement of hydroxyapatite thermal stability by Al doping. J. Mater. Res. Technol. 9(1), 76–88 (2020) Sánchez-Campos, D., Reyes Valderrama, M.I., López-Ortíz, S., Salado-Leza, D., Fernández-García, M.E., MendozaAnaya, D., Salinas-Rodríguez, E., Rodríguez-Lugo, V.: Modulated Monoclinic Hydroxyapatite: The Effect of pH in the Microwave Assisted Method. Minerals. 11(3), 314 (2021) Siniscalco, D., Dutreilh-Colas, M., Hjezi, Z., Cornette, J., El Felss, N., Champion, E., Damia, C.: Functionalization of Hydroxyapatite Ceramics: Raman Mapping Investigation of Silanization. Ceramics. 2(2), 372–384 (2019) Yilmaz, B., Evis, Z.: Raman Spectroscopy Investigation of Nano Hydroxyapatite Doped with Yttrium and Fluoride Ions. Spectrosc. Lett. 47(1), 24–29 (2014) Popa, C.L., Albu, M., Bartha, C., Costescu, A., Luculescu, C., Trusca, R., Antohe, S.: Structural Characterization and Optical Properties of Hydroxyapatite/Collagen Matrix. Rom Rep Phys. 68(3), 1149–1158 (2016) Publisher's Note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations. 13