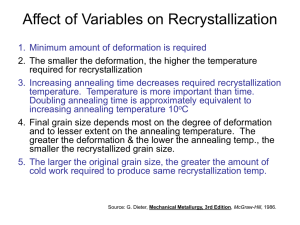

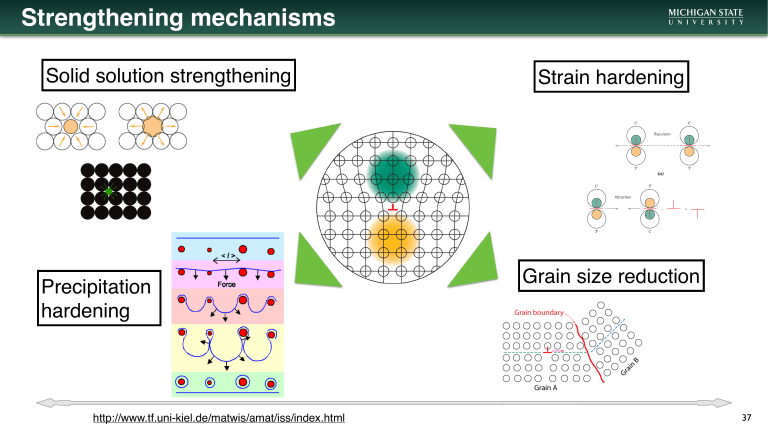

Strengthening mechanisms Solid solution strengthening Precipitation hardening http://www.tf.uni-kiel.de/matwis/amat/iss/index.html Strain hardening Grain size reduction 37 Strain Hardening • Deformation at room temperature (for most metals). • Common forming operations reduce the cross-sectional area 38 Flashback: Mechanical properties F Strength: maximum stress values Engineering tensile stress <latexit sha1_base64="Cp0Jp1c0murhyueCMmF24CgnNck=">AAACvXicZVFLbxMxEHaWR8vySuEGF4sIxKGKdhGoXBBFSAhuRSJtpXgVeb2zqRXbu/J400bWStz5H1zh7/Bv8CZ7aJqR7Pn0eb7xPPJaSXRJ8m8Q3bp95+7e/r34/oOHjx4PD56cYtVYARNRqcqe5xxBSQMTJ52C89oC17mCs3zxuXs/W4JFWZkfblVDpvncyFIK7gI1Gz5jKOea01cfKCstF/5L6z/NkpaxeDYcJeNkbXQXpD0Ykd5OZgeDX6yoRKPBOKE44jRNapd5bp0UCtqYNQg1Fws+h2mAhmvAzK+baOnLwBS0rGw4xtE1u6UolrLGXnO1EV179lyj5u7iMHhc6bzz60x42NEWSwx/dBCvZ/W53qrLo2yMdFfbpJZKgb3RgCvfZ16aunFgxKb+slHUVbQbNC2kBeHUKgAurAwjoOKChxG7sI44ZgYuRaU1N4VnS+FsO00zz8BgY6Er07Puzks/Stu23Y2fW4DFrijXvSCsL725rF1w+macvhsn39+Ojr/1i9wnz8kL8pqk5Igck6/khEyIID/Jb/KH/I0+RhCpyGxCo0GveUq2LLr8D/rf3xw=</latexit> True tensile stress F = A0 <latexit sha1_base64="3ReoSVoCvA1FBc4cJuClHrrNeHk=">AAACv3icZVFNb9QwEPUGSktaYAtHerC6AnGoVgkClQtSKyTU3orUbSuto8hxJqm1thPZztKVlQtX/ghX+Df8mzq7OXS7I9nz9DxvPB9ZLbixUfR/EDx5uvVse+d5uLv34uWr4f7rK1M1msGEVaLSNxk1ILiCieVWwE2tgcpMwHU2+9a9X89BG16pS7uoIZG0VLzgjFpPpcMDYngpaXqJ33/FpNCUue+tO015S0iYDkfROFoa3gRxD0aot4t0f/Cb5BVrJCjLBDVmGke1TRzVljMBbUgaAzVlM1rC1ENFJZjELdto8TvP5LiotD/K4iW7psjnvDa95m4levDsqDSS2tsj781CZp1fZjJHHa1NYfwfHTQPs7pMrtXlDG8Ut3frpORCgH7UgC2+JI6rurGg2Kr+ohHYVrgbNc65BmbFwgPKNPcjwOyW+hFbv5AwJAp+skpKqnJH5szqdhonjoAyjYauTEe6OyvcKG7bdjO+1ACzTVEme4FfX/x4WZvg6uM4/jyOfnwanZz3i9xBb9Eh+oBidIxO0Bm6QBPE0C/0B/1F/4LToAxUUK9Cg0GveYPWLFjcA2wt4Bw=</latexit> T F = Ai Ductility: plastic strain at fracture <latexit sha1_base64="/8D/DF0lEIbLkeKLoXKgTG50MCk=">AAACwXicZVFda9swFFW8bu2yj6br46CYhcAYXZDHyvYyKJTBCn1ooWkLkTGyfJ2KSLKR5KxB+K1v/Sd9Xf9M/83kxA9Nc0FXh3N1pKt70lJwYzF+7AQvNl6+2tx63X3z9t377d7OhwtTVJrBiBWi0FcpNSC4gpHlVsBVqYHKVMBlOj1q6pcz0IYX6tzOS4glnSiec0atp5LeHhn8PvlFck2ZE0n+VSS4dk36EmFMBkmvj4d4EeE6iFrQR22cJjudO5IVrJKgLBPUmHGESxs7qi1nAuouqQyUlE3pBMYeKirBxG7xkToceCYL80L7pWy4YFcU2YyXptXcLEVPyo5KI6m93ve7mcu02Rc3mf2G1iY3/o0Gmqe3ulSu9OUMrxS3N6uk5EKAfvYBm/+MHVdlZUGxZf95JUJbhM2ww4xrYFbMPaBMcz+CkF1TP2vrLel2iYK/rJCSqsyRGbO6HkexI6BMpaFp05Emp7nrR3Vdr5+faIDpuiiVrcDbFz03ax1cfBtGB0N89r1/eNwauYU+ok/oM4rQD3SI/qBTNEIM3aJ79A89BEcBD8pAL48GnVazi1YicP8B4AHgOw==</latexit> %EL = lf l0 l0 <latexit sha1_base64="mD4BDLvRgUdDQKEAKNWT3CCRIzY=">AAACwXicZVHPa9swFFbcdu2ybku342CYhUApXZBHx3YZNPSy3drStIXIGFl+TkUk2Uhy1iB8623/ya7bP7P/ZnLiQ9M8kN7Hp/c9vR9pKbixGP/rBFvbO8929553X+y/fPW6d/Dm2hSVZjBmhSj0bUoNCK5gbLkVcFtqoDIVcJPOzpr3mzlowwt1ZRclxJJOFc85o9ZTSe89GVyOvpFcU+ZGCf44SvK6AfVRhDEZJL0+HuKlhZsgakEftXaeHHR+kaxglQRlmaDGTCJc2thRbTkTUHdJZaCkbEanMPFQUQkmdstG6nDgmSzMC+2PsuGSXVNkc16aVnO/Ej16dlQaSe3dsfdmIdPGLzOZ44bWJjf+jwaax1ldKtfqcoZXitv7dVJyIUA/acDmX2PHVVlZUGxVf16J0BZhM+ww4xqYFQsPKNPcjyBkd9TP2vqVdLtEwU9WSElV5sicWV1PotgRUKbS0JTpSHOnuetHdV1vxk81wGxTlMpW4NcXPV3WJrj+NIw+D/HFSf/0R7vIPfQOfUCHKEJf0Cn6js7RGDH0gH6jP+hvcBbwoAz0KjTotJq3aM0C9x+7tt+8</latexit> ⇤ 100% %RA = A0 Af A0 ⇤ 100% 39 Strain Hardening • Deformation at room temperature (for most metals). • Common forming operations reduce the cross-sectional area Ao − Ad %CW = x 100 Ao 40 Grain Structure Before and After Heavy Deformation (Rolling) before rolling rolling direction https://en.wikipedia.org/wiki/Rolling_(metalworking) after rolling adapted from Fig. 7.11 Callister Textbook 41 Strain hardening — dislocation interaction • Forming processes lead to introduction of more defects undeformed: dislocation density = 103 cm-2 0%CW 25%CW Dislocations entangle with one another during cold work. Dislocation motion becomes more difficult. deformed: dislocation density = 1010 cm-2 50%CW from: Schaffer, J.P. et al: The Science and Design of Engineering Materials 2nd Ed., WCB/McGraw-Hill, 1999: ISBN: 0-256-24766-8 out of print 42 Strengthening Mechanisms and Annealing An application calls for a brass rod of 7.5 mm diameter and the following mechanical properties: minimum tensile strength = 380 MPa minimum ductility = 15 %EL The only brass material available has a diameter of 10 mm, a tensile strength of 310 MPa and a ductility of 67 %EL. How can we achieve the geometry and property requirements? Impact of cold work low carbon steel As cold work is increased • • • Adapted from Fig. 7.20, Callister & Rethwisch 8e. Yield strength (σy) increases Tensile strength (TS) increases Ductility (%EL or %RA) decreases 43 Recovery, Recrystallization and Grain Growth • Is there a way to repair the worst defects without undoing the benefits of cold work? Annealing 0%CW 25%CW heat treatment to reduce the defect concentration and regain some ductility f(T, t, %CW, material) 50%CW from: Schaffer, J.P. et al: The Science and Design of Engineering Materials 2nd Ed., WCB/McGraw-Hill, 1999: ISBN: 0-256-24766-8 out of print 44 Annealing Treatment Brass Alloy 1 hour treatment @ Tanneal Recovery Grain Growth Stages of Annealing Recrystallization Recovery, Recrystallization Adapted from Fig. 7.22, Callister & Rethwisch 8e. (Fig. 7.22 is adapted from G. Sachs and K.R. van Horn, Practical Metallurgy, Applied Metallurgy, and the Industrial Processing of Ferrous and Nonferrous Metals and Alloys, American Society for Metals, 1940, p. 139.) 45 Annealing: Recovery heat treatment at low temperatures (or short times) ➜dislocations get eliminated or rearranged into arrays that minimize energy driving force: Strain field energy around dislocations tilt boundary 46 Annealing: Recovery even if half the dislocations get annihilated there are still a lot left 47 Annealing: Recrystallization New grains are formed that: • have low dislocation densities ⬌ internal energy decrease • are small in size • consume and replace parent cold-worked grains. 0.6 mm 33% cold worked brass 0.6 mm New crystals nucleate after 3 sec. at 580°C. Adapted from Fig. 7.21(a),(b), Callister & Rethwisch 8e. (Fig. 7.21(a), (b) are courtesy of J.E. Burke, General Electric Company.) 0.6 mm 0.6 mm After 4 seconds After 8 seconds 48 Grain Growth • At high temperatures (or longer times), average grain size increases. 0.6 mm 0.6 mm driving force: reduction in grain boundary area coefficient dependent on material and T. • Empirical Relation: After 8 s, 580ºC After 15 min, 580ºC Adapted from Fig. 7.21(d),(e), Callister & Rethwisch 8e. (Fig. 7.21(d), (e) are courtesy of J.E. Burke, General Electric Company.) exponent typ. ~ 2 grain diam. n d at time t. n o − d = Kt elapsed time 49 Summary: Recrystallization Temperature º TR = recrystallization temperature 0.4 - 0.7 Tmelt [K] TR Recrystallization Temperature Temperature at which recrystallization just reaches completion in 1h º Adapted from Fig. 7.22, Callister & Rethwisch 8e. 50 Summary: Recrystallization Temperature º TR = recrystallization temperature 0.4 - 0.7 Tmelt [K] TR For a specific metal/alloy TR depends on: • %CW • purity of the metal º Adapted from Fig. 7.22, Callister & Rethwisch 8e. 50 Coldworking and Annealing Summary Cold working and annealing are utilized • to facilitate large amounts of deformation in forming processes while retaining specific mechanical properties e.g. production of thin sheets and wires • to achieve a specific microstructure e.g. large grains exhibit better electrical or magnetic properties; small grains have an increased strength 51 Deformation - microstructure relationship deformation / %CW An nea ling Tem per Grain size atu re Effect of prior deformation on annealing temperature 52 Deformation - microstructure relationship An deformation / %CW nea ling Tem per Grain size atu re Effect of prior deformation on grain size 53 Deformation - microstructure relationship An deformation / %CW nea ling Tem per Grain size atu re Effect of annealing temperature on grain size 54 Cold working vs. Hot working • Hot working deformation above TR Continuous recrystallization during the hot working process large deformations possible • Cold working deformation below TR better control of final dimensions 55 Practice Problems Chapter 7 WileyPlus: Practice Deformation Strengthening and Recrystallization Callister 10th Edition Chapter 7 7.01, 7.04, 7.11-7.13, 7.18, 7.29, 7.30 57