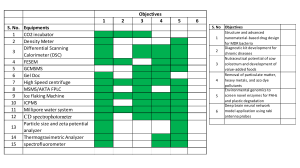

Prepared By SSGCL SCHEDULE - 3 GAS MEASUREMENT AND RECORDING The procedure for the measurement, testing and recording of KPD Gas, as referred in ArticleIX of this Agreement, shall be based on the principles defined in this Schedule-3 and shall be not more extensive or more onerous for the Sellers than: (a) The provisions, operation and maintenance of duty and standby meter runs to determine volume flow rate; (b) The equipment of each meter run with a square edged orifice plate and multi range transmitters to give adequate turn down. (c) The correction of volume flow rate for flowing pressure and temperature; (d) The continual online measurement of specific gravity and heating value of Gas; (e) The continual calculation of the volume and energy contents of the Gas using an electronic flow computer which will record volume flow rate, flowing pressure and temperature, specific gravity and heating value and will integrate corrected volume and energy content; and (f) In addition to the measurement of energy, the measurement, calculation and recording of the specification properties of Gas at the Delivery Point (or such other point as mutually agreed by the Seller and Buyer) shall be as follows: i. Hydrocarbon (calculated from C1 to C5, C6 and higher Hydrocarbon shall be lumped together as C6+), CO2, and N2 contents in the Gas shall be measured through on-line gas chromatograph and average values for the Day calculated from the measured figures shall be recorded. The frequency of the measurement should not be more than 5 minutes basis. ii. The hydrocarbon dew point of the Gas at the range of pressure (the phase envelope) shall be calculated online from the measured gas composition for the Day and average value for the day shall be calculated from measured figures and recorded. iii. Water content in the Gas shall be measured on-line and the average values for the Day shall be calculated from the measured figures and recorded. iv. H2S shall be measured once a Month, and in the event the measured results are close to the allowable limit as given in Schedule-2, then online H2S analyzer shall be installed by the Seller within a reasonable period. v. O2 contents in the Gas shall be measured through third party/ reputed lab on monthly bases. vi. H2S analyzer, moisture analyzer, hydrocarbon dew point apparatus and gas chromatograph should be capable of auto-calibration at least once daily, or as agreed between the Buyer and Seller, considering performance and capabilities of corresponding analyzer In addition the following operating principles for measurement and recording shall apply: 1. The Measurement and Recording Equipment shall be used for all measurements and recording of Gas delivered at the Delivery Point. 2. All Gas volumes delivered at the Delivery Point shall be reckoned at the base conditions (to be taken as 60 degree Fahrenheit and 14.73 psi, in accordance with ISO 5024 for Petroleum Industries) 3. All volumetric Gas measurements shall be determined by: a. Orifice metering in accordance with the recommendations of AGA No.3, 2000 edition (latest edition)with super compressibility factor in accordance with the recommendations of AGA No.8 (latest edition ), as the same may be amended or superseded from time to time, employing all other relevant corrections stipulated in AGA No.3 and gas measuring equipment shall conform to standards contained therein or; For that Purpose:a. The average absolute atmospheric pressure during each month of the deliveries shall be deemed to be 14.70 psi absolute. b. At Delivery Point, the volume of gas delivered shall be determined using a continuously integrating flow computer based upon data from orifice flow meters (multi range differential pressure transmitters, pressure transmitters, and temperature transmitters), online gas chromatograph, online H2S/ Total Sulphur analyzer (if applicable) and online moisture analyzer. c. At Delivery Point the specific gravity and the Gross Calorific Value of the Gas delivered shall be determined by an online gas chromatograph with continuous recording. Adequate back-up equipment will be provided to cover the period of gas chromatograph maintenance and /or breakdown. The back-up equipment will consist of a complete duplicate gas chromatograph installed online. The specific gravity measurement and testing shall be determined to a minimum of four decimal places. The frequency of the measurement should not be more than 5 minutes basis. d. Determination of gross calorific value for billing purpose from the measured gas composition (renormalized with H2S and moisture) shall be in accordance with GPA / ASTM standards. e. The Measurement and Recording Equipment (flow computer and gas chromatograph) at the KPD plant will preferably have the following features associated with the measurement and recording of KPD Gas; i. At least 260 alarms and events. ii. Hourly data of variables selected by the Buyer for at least thirty five (30) days. iii. Retrieval of data, alarms and events (audit trail reports). 4. The Buyer may, at its own cost, risk and expenses install downstream of the Delivery Point such ‘Check Measurement Facilities’ as it may deem necessary to verify the volume measurement of the Gas and the Gross Calorific Value of the Gas delivered to the specified facility on any Day. If the Buyer should choose to install the Check Measurement Facilities then the Buyer shall use the procedure under Article 9 (Maintenance) to notify the Seller of such work. Such Check Measurement Facilities shall not adversely affect the operation and reliability of the Seller’s Measurement and Recording Equipment or the Sellers’ Facilities. The Sellers and the Buyer shall each have the exclusive right to operate its own measurement and testing facilities but each may present itself to witness reading, calibration testing and / or instillation of the other Party’s measurement and testing facilities. The Sellers and the Buyer shall each also have the right to access at reasonable hours the other Party’s measurement facilities for inspection. 5. At least once every month, the Seller shall calibrate/ verify the accuracy of its measuring and recording equipment and the Buyer shall be invited, with seven (7) Days prior Notice to other Party, to the Delivery Point and the other applicable points of the measurement except the either Party may notify the other for a special testing to secure accuracy of any of the other’s measuring equipment whereupon the other Party shall cooperate to arrange for such a test being undertaken and the objective of the test to be achieved, provided that such special testing shall not be carried out with unreasonable frequency. 6. In the event of the Measurement and Recording Equipment installed at the delivery point being out of service or registering inaccurately, the volume and calorific value of the Gas delivered shall be estimated using the first of the following methods, whichever is feasible : a. by correcting the error if the proportion of the error is ascertainable by calibration or test, or analytical in accordance with acceptable gas industry practice; for this purpose a miss-measurement correction procedure will be mutually agreed between Seller and Buyer, or b. by estimating the volume and calorific value of Gas delivered by comparison with past deliveries during a period of similar conditions when the meter was registering accurately. c. by using the registration of Buyer Check Measurement Facilities if installed and accurately registering; or If, upon test as provided in paragraph 5 above: i. any single unit measuring equipment (other than ultrasonic flow meter, gas chromatograph, H2S/ Total sulphur analyzer, moisture analyzer and hydrocarbon dew point analyzer) is found to be inaccurate to within plus or minus zero decimal five percent (0.5%) of the measured, value then previous recording of such equipment shall be reckoned as correct for computing Gas deliveries, but the equipment shall be promptly adjusted to operate/register/record correctly; continuous operations of equipment by way of treating aforesaid allowance of plus or minus zero decimal five percent (0.5%) of true value as an all time tolerance in its acceptable accuracy shall not be permitted. ii. Any single unit measuring equipment (other than ultrasonic flow meter gas chromatograph, H2S/ Total sulphur analyzer, moisture analyzer and hydrocarbon dew point analyzer) is found to be inaccurate in excess of the plus or minus zero decimal five percent (0.5%) as aforesaid under paragraph (1) above (for ultrasonic flow meter, gas chromatograph, H2S / Total sulphur analyzer and moisture analyzer the inaccuracy tolerances are provided in paragraphs iii, iv & v below), then for the period for which such measuring equipment has been known to have been inaccurately functioning, the record/reading of such measuring equipment for the whole period shall be corrected to zero error. If, however, the period of such inaccurate functioning measuring equipment is not known or cannot be mutually agreed upon, then for the period equivalent to one half of the time elapsed since such equipment was last found to be plus or minus zero decimal five percent (0.5%) accurate the equipment’s reading/ record shall be adjusted for zero error. iii. The working of chromatograph will be verified by calibration with certified standard calibration gas (having gas composition & calorific value preferably close to KPD Gas), response factor deviation and retention time, etc. as per manufacturer’s specifications of the chromatograph and accuracy range. Maximum tolerance range of chromatograph shall not be more than plus or minus zero decimal point one percent 0.1 percent i.e. plus or minus 1 Btu / SCF per one thousand Btu / SCF(± 1 Btu / 1000 Btu). iv. The H2S analyzer, total sulphur analyzer and moisture analyzer will be calibrated/verified as per their manufacturer’s recommendations i.e. calibration/verification procedure and respective accuracy ranges specified by the manufacturers. The accuracy ranges of these analyzers, however, shall be less than the values provide below:a. Moisture analyzer; + 10% or less in case measurement range is 0-2500 ppmv. If the moisture analyzer has higher range then 0-30 ppmv then the accuracy limit shall be reduced proportionately. b. H2S/CO2/Mercaptans analyzer; +2% or less in case measurement range is 0-25 ppmv. If the H2S analyzer has higher range then 0-25 ppmv then the accuracy limit shall be reduced proportionately c. Total sulphur analyzer; same as (b). d. Hydrocarbon dew point may be measured either by installing online hydrocarbon dew point analyzer or by installing hydrocarbon dew point module in the chromatograph. If online hydrocarbon dew point analyzer is installed then its working and accuracy shall be checked according to the manufacturer recommendations. 7. The unit of volume for the purpose of measurement shall be one SCF of Gas. The unit of Gas shall be one thousand SCF expressed as ‘MCF’. The unit of energy for billing of Gas shall be MMBtu. 8. Seller shall, furnish to Buyer the following data pertaining to the Gas supplied in frequency and by mode of transmittal as indicated: a. Convey to Buyer every hour, or as may be agreed by Buyer and Seller, the following data in regard to gas delivered at the Delivery Point during the preceding hour: i. Average volumetric flow rate in MMSFD. ii. Average gauge pressure in psig iii. Average temperature in degrees F, and iv. Off-Specification gas, if any v. Average gauge pressure in psig measured immediately upstream of Sellers’ flow controller which is located immediately upstream of the Measurement Point. vi. Average differential pressure in Inches of Water Column (Inches WC). vii. Average gross calorific value in Btu per SCF. c Convey to Buyer by telephone or fax or e-mail every Day, or as may be agreed by Buyer and Seller, the following data in regard to Gas delivered at the Delivery Point during the preceding day: i) ii) iii) iv) v) vi) vii) viii) ix) x) xi) xii) xiii) xiv) xv) xvi) Total Gas deliveries in MMSCF and MMBTU. Average gas pressure in psig; Average temperature in degrees F; Average Gross Calorific Value in Btu per SCF; Average Gas Composition in mole%; Average specific gravity; Average Water Content in pounds per MMSCF; Average H2S contents, Average Hydrocarbon Dew Point in degrees F; Total Off-Specification gas delivered in MMSCF and MMBTU. Average differential pressure in inches of water column. Meter-Run Pipe ID. Meter-Run Orifice Bore. Maximum Delivery Pressure. Minimum Delivery Pressure. Wobbe Index. Any significant variation of the above data shall be communicated to Buyer as soon as possible by Seller. d) Convey by facsimile or letter Monthly, within five (5) days following the last day of the month, the following information in regard to Gas delivered during such Month at the Delivery Point:i. Daily Energy Delivered (expressed in MMBTU. ii. Daily Average volumetric flow (expressed in MMSCFD). iii. Average Gas composition in mole% iv. Average Specific Gravity. v. Average gross Calorific Value in Btu per SCF. vi. Details about Off-Specification Gas delivered, if any. vii. ACQ in MMCF viii. MDQ in MMCFD ix. Monthly Nomination in MMSCF. x. Monthly Revised Nomination in MMSCF xi. No. of days during delivery reduced xii. No. of days during Gas flowed. xiii. Take-or-Pay Quantity in MMCF. xiv.Default Gas in MMCF. xv. Default Gas Energy in MMBtu. xvi.Make-up Gas in MMCF. xvii. Balance gas delivered in MMCF 9. Seller and Buyer shall preserve for a period of at least three (3) years, all gas data record and calculations applicable for gas measurement under this Schedule. 10. The measurement record for the previous month would be available at Buyer’s office and would be available for review by Sellers for a period of 3 month after the end of billing month. 11. The Seller shall allow the Buyer for data hand-off of Flow / Pressure / Differential Pressure/ Temperature data preferably through RS-232 serial port (up to 57.6 kBaud) for onward transmission of gas data to Buyer’s Modbus SCADA network. SCHEDULE - 2 SPECIFICATIONS FOR KPD GAS 1. Gas delivered under the Agreement shall have following specifications at the Delivery Point. (a) Purity : Be commercially free from materials and dust or other solid or liquid matter, waxes, gums and gum-forming constituents which might cause interference with proper operation of the Buyer’s Facilities (b) Hydrocarbon Dew point : 1 Maximum of “thirty two” degrees Fahrenheit (32 ºF).at delivery pressure and including all pressures. (c) Water Contents : Maximum of “seven” (7) pounds per million standard cubic feet at Atmospheric Pressure and temperature of 60 °F. (d) Carbon Dioxide : Maximum of “three” mole percent (3% mole) (e) Total Sulphur : Maximum of “three decimal five” (3.5) grains of total Sulphur per 100 standard cubic feet. Maximum of “zero decimal two four” (0.24) grains per 100 standard cubic feet. (f) Hydrogen Sulphide : 1 The gas chromatograph used for measurement of Hydrocarbon Dew point shall be at least capable of measuring hydrocarbon components up to C9+. (g) Oxygen : (h) Nitrogen : (i) Gross Calorific Value GCV : (j) Wobbe Index : (k) Temperature : Maximum of “zero decimal two” mole percent (0.2% mole) of Oxygen. Maximum of “seven” mole percent (7% mole) Minimum of “nine hundred and fifty” (950) Btu per standard cubic foot. Minimum of “one thousand two hundred and twenty” (1220) Btu per SCF. Maximum of “one hundred and twenty” degrees Fahrenheit (120°F).