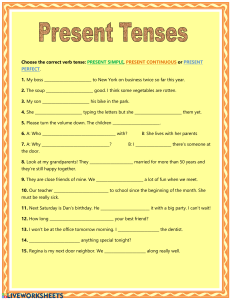

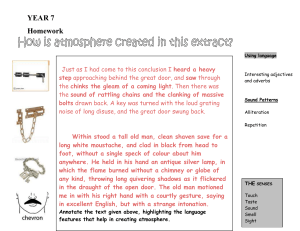

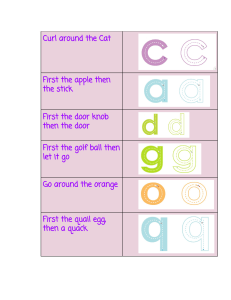

1 2 Contents 1. Introduction ......................................................................................................................................................... 4 2. Case 1: Door and Wall Connection on 3/F, Main Library ....................................................................... 5 2.1. 2.1.1. Design requirement ......................................................................................................................... 6 2.1.2. Material and design......................................................................................................................... 6 2.1.3. Present conditions and performance ........................................................................................... 6 2.1.4. Construction method ...................................................................................................................... 7 2.2. Design requirement ......................................................................................................................... 7 2.2.2. Material and design......................................................................................................................... 7 2.2.3. Pivot connection .............................................................................................................................. 8 2.2.4. Present conditions and performance ........................................................................................... 9 2.2.5. Construction method ...................................................................................................................... 9 Connection between the door and the wall ....................................................................................... 10 Case 2: Door and Wall Connection on LG/F, Centennial Campus ...................................................... 11 3.1. Wall in Case 2 ......................................................................................................................................... 11 3.1.1. Design requirements ..................................................................................................................... 11 3.1.2. Material and design....................................................................................................................... 11 3.1.3. Present conditions and performance ......................................................................................... 11 3.1.4. Construction method .................................................................................................................... 12 3.2. Door in Case 2......................................................................................................................................... 12 3.2.1. Design requirements ..................................................................................................................... 12 3.2.2. Material and design....................................................................................................................... 13 3.2.3. Present conditions and performance ......................................................................................... 14 3.2.4. Construction method .................................................................................................................... 15 3.3. 4. Door in Case 1........................................................................................................................................... 7 2.2.1. 2.3. 3. Wall in Case 1 ........................................................................................................................................... 6 Hinges and connection between the door and the wall .................................................................. 15 Comparison between the two cases ............................................................................................................. 17 References .................................................................................................................................................................. 18 3 1. Introduction Doors and walls are ubiquitous building elements yet their design and construction vary based on their design requirements, as determined by their respective locations and expected functional performance. This technical report analyses the design requirements, material and design, present conditions and performance, as well as the construction and connection methods for two sets of door-wall connection in the University of Hong Kong. They are: Case 1: Door and Wall Connection on 3/F, Main Library for a discussion room Case 2: Door and Wall Connection on LG/F, Centennial Campus of a fire exit, respectively. Figure 1.0.1 Overview of the cases covered in this report. 4 2. Case 1: Door and Wall Connection on 3/F, Main Library In Case 1, a door for Discussion Room 16, which is connected to a partition wall on the third floor of the Main Library, will be analysed. Both the door and wall are non-load bearing and thus belong to secondary structures. The elevation of the door and wall is shown in Figure 2.0.2. Figure 2.0.1 Photo of the library door and partition wall in Case 1. Figure 2.0.2 Elevation of the door and wall in Case 1. 5 2.1. Wall in Case 1 This wall is located on the 3/F of the Main Library and separates Discussion Room 16 from library corridor. It is a narrow partition wall since there is a large glass panel to its right (viewed from inside the Discussion Room). It measures 2720 mm in height and 202 mm in width, with a thickness of 54 mm. 2.1.1. Design requirement The wall is an internal partition located in a library. Therefore, it needs to meet the following requirements: 2.1.2. Structural safety: the wall has to be structurally sound and withstand certain external impact forces Sound insulation: to prevent noise from the discussion room from disturbing other library visitors outside the room Fire resistance: the library has a high occupancy, and the wall should be able to protect room occupiers from a fire for a certain amount of time Service accommodation: the wall should provide space to accommodate electric wires for the lock pad Material and design In line with common practice, partition walls are usually built on anodized aluminium frames (Everett and King, 1975). Two layers of gypsum board panels is likely to be used for the infill panels, with layers of acoustic foam sandwiched in between. The assumption that acoustic foam is used is based on the observation from the other door jamb that there are greyish foam materials sticking out of the cladding. The wall is then cladded with an aluminium cladding that is further covered by a green adhesive for decorative purposes. Meanwhile, the lowest 100 mm of the wall is covered by a layer of stainless-steel skirting to increase the strength of the lowest portion of the wall as it is susceptible to external impact, e.g., during cleaning. 2.1.3. Figure 2.1.2.1 Grey foamy material found on another door jamb might indicate the insulating material used for the wall. Present conditions and performance The wall seems to be built with two gypsum board cladded by an aluminium frame. The condition of the wall is well kept as there are not any major scratches, cracks, though the green adhesive finishes for the cladding has peeled off. There are multiple advantages of using gypsum boards like sound dampening, fire resistance, aesthetics, and lower thermal conductivity. The sound dampening effect is a necessary performance required in a library so that other people do not get disturbed by other people discussing about their work. This wall is a good sound insulator as not much noise was heard from the rooms nearby. 6 2.1.4. Construction method A frame and panel system is adopted for the construction of this partition wall. Aluminium alloy tracks are screwed into the floor and ceiling respectively and vertical metal studs are screwed into such tracks to form the frame system. Then, prefabricated gypsum boards are cut to the correct dimensions and mounted to one face of the metal frame using bugle head screws (Nuts and Bolts DIY, 2013). Next, a layer of insulation material is applied on the interior side of the gypsum board and finally covered by another slab of gypsum board. Aluminium cladding is then screwed into the drywall as the finishing material. Figure 2.1.4.1 A steel frame similar to this one is used to construct the wall (ArchDaily, 2018). 2.2. Door in Case 1 This door closes the opening of the entrance to the Discussion Room. It measures 2170 mm in length and 780 mm in width. The door leaf has a thickness of 50 mm. 2.2.1. Design requirement The door is an internal door situated in a library with frequent use by students. Therefore, it needs to meet the following requirements: 2.2.2. Structural safety: the door has to be strong and sturdy to withstand heavy use Sound insulation: to prevent noise from the discussion room from disturbing other library visitors outside the room Ease of operation: users of different heights and strengths should be able to open and close the door easily Exclusion: the door can be locked to prohibit entry for unregistered students and opened to allow entry if necessary Balance between privacy and transparency: The door should allow easy monitoring of activities occurring inside the discussion room while maintaining a certain level of privacy for the occupiers Material and design The type of the door is a medium stile door with stainless steel rails and stiles, and the infill material is assumed to be toughened glass. Stainless steel is assumed to be the material of the rails and stiles since the door is heavy. A durable material is needed to be used to withstand heavy use from library visitors. A long handle, installed on the right (viewed from inside the Discussion Room) opposite the hinge of the door, is also made of stainless steel. It has a smooth surface that prevents dirt from accumulating even when many people touch the handle, which helps maintain a shiny appearance for the ironmongery. 7 The metal rails and stiles enclosing the glass panel are necessary since glass is fragile, particularly around the edges. The stronger stainless-steel rails and stiles protect the door from breaking, while the bottom rail also acts as a kicking board for the door to protect it from any external impact made to the lower portion of the door. Clear glass is used as the infill panel of the medium stile door. 12 mm toughened plate glass is often used for glass doors (Everett and King, 1975) for safety purposes. This also ensures maximum lightning in the discussion room and allows the activities inside the room to be easily monitored to prevent misuse. However, this leads to compromised performance in terms of privacy for room users. Meanwhile, the door frame is covered by aluminium cladding. A finishing layer of pale green adhesive is further applied on the cladding. Aluminium is assumed to be used for the cladding since a duller sound is made upon impact. The finishing is presumed to be adhesive coating since there are signs of peeling that leaves behind a sticky layer on the door jamb. 2.2.3. Pivot connection A pivot hinge with a floor spring is used to join the door with the door frame (and the floor). Upon inspection, a side jamb is also seen which is mostly covered by the cladding. The pin plate carrying the pivot pin is screwed into the head of frame. Together with the base pivot on the floor spring, they allow the door to rotate about a vertical axis (the spindle). An exploded drawing shows the pivot connection in Figure 2.2.3.1. For the design of the pivot hinge, bearings are installed to prevent the knuckles from rubbing against each other when the door is used (Tobias, 2015). This reduces frictional wear and allows the hinge to be used for a longer time. Figure 2.2.3.1 Exploded diagram showing the components of pivot hinges and floor spring with reference to Everett and King (1975). 8 2.2.4. Present conditions and performance Structural safety The door is reasonably well-kept. There are some water stains on the door with minor black scratch marks on the rails and stiles. Other than that, the door remains in good condition and is structurally sound. Ease of operation Upon pushing, the door is relatively heavy and requires certain force to operate. However, the long handle installed caters for the needs of people with different heights. Exclusion: Locking and opening The door is locked by an electromagnetic lock system, limiting access to the room to those who have made a booking. The mechanism is installed above the top right corner of the door. Users can let unregistered visitors into the room by pressing the ‘Door Release’ button which unlocks the door temporarily for six seconds. Contrary to other pivot doors, this door is single-acting and can only open outwards since the lock stops it from swinging out of the discussion room. Sound insulation The door provides good sound insulation performance. This is important as it prevents disturbance to other library visitors outside the room due to the noise generated in the discussion room. Good sound insulation is achieved by the dense glass and tough door that resists vibration. The clearance between the door leaf and the jamb is also narrow. 2.2.5. Construction method The built-in method is the most likely construction method adopted, as shown by most online research materials. This is because it is more convenient to join the door frame with the wall before erecting the drywall panels so there will be no obstruction by the drywall. A more detailed explanation and drawings showing the connection are given in Section 2.3. According to the instructions from Dormakaba (n.d.), the manufacturer of the pivot door system, the pin plate is bolted into the head of frame first. The retractable pin is lowered such that the spindle on the floor plate to be installed can align with it vertically. The floor plate, which holds the spindle and floor spring, is screwed onto the floor slab. The pivot pin at the top is retracted to make way for the door. Afterwards, the door is mounted with its retractable pin rotated into the receiver at the top of the door leaf (Tobias, 2015). At last, the head jamb is cladded to cover up the metal structures. Figure 2.2.5.1 Components of the pivot hinge and floor spring manufactured by Dormakaba (n.d.). 9 2.3. Connection between the door and the wall The connection between the door frame and the wall frame exists mostly at the strike jambs. For the steel frame of the wall to be securely connected to the door frame, anchors are installed along the door jamb. The anchors have a lip that provides a surface for screws to drill through it and connect it with the wall frame, which are commonly used for steel stud partitions (Beacon Commercial Door and Lock, n.d.). Although examples on the Internet use a different type of door hinge, most of them show that at least three anchors are needed to secure the door frame with the steel studs in the wall. As the built-in method is adopted for the construction of the door, this means the drywall panels have not been inserted yet. A gap has to be reserved when the door frame and the wall studs are connected such that the gypsum boards can be partly inserted snugly inside the hollow door frame (See Figure 2.3.1). A plan and section detailing the connection is shown below: Figure 2.3.1 Section A-A of the wall-door connection. Figure 2.3.2 Plan B-B of the wall-door connection. 10 3. Case 2: Door and Wall Connection on LG/F, Centennial Campus The location of the pair of doors and walls is LG/F in Centennial Campus near the entrance of the Grand Hall. The fire exit door leads to a hallway with high pedestrian traffic, an emergency staircase, and a cargo elevator. Figure 3.0.1 Fire rated door and wall in Case 2. 3.1. Wall in Case 2 3.1.1. Design requirements For a brick wall located at a fire exit, it has the following design requirements: 3.1.2. Fire resistance: The wall is required to be fire-resistant and strong enough to bear high heat and impacts to protect the emergency staircase and the elevator lobby Functional features: A fire alarm call point has to be installed on the wall Durability: Wall skirting tiles are installed to protect the wall from damages Material and design The brick wall is 200 mm thick. After reviewing the structural building plans of the building, it is concluded that the wall is not a reinforced concrete wall but a brick wall. Since knocking the wall does not make any hollow sound, we assume it is built with solid bricks. As a part of an elevator lobby and an emergency staircase, the bricks have to be durable and fire-resistant enough to bear high temperatures. Since concrete bricks can withstand higher tensile stress, as opposed to red bricks that are brittle and could break under high temperatures, it is assumed that the wall is made of concrete bricks that are 200 mm thick. Impact and scratch resistant wall skirting tiles made of ceramic that are 150 mm in height are installed on the bottom of the wall to protect the wall from damages and dirt. 3.1.3. Present conditions and performance The wall is maintained by Estate Office. A crack in the plaster is visible but otherwise there are no significant defects. 11 Figure 3.1.3.1 A minor crack is seen in the plaster located at the top central part of the wall. The sharpness of the above photo has been increased to better show the crack. Functional features Since the wall is not made of reinforced concrete, a fire alarm system can be easily installed within the wall to the nearest initiating system device in the building through wires to comply with fire safety regulations. 3.1.4. Construction method It is assumed that the wall is made of concrete bricks, which were used to partition the elevator lobby and the emergency staircase. First, string lines are set up to make sure bricks laid later on can be accurately lined up. Lean mortars are then applied to the ground along the lines. The concrete bricks are then laid and bonded together. Next, the heights of the bricks are aligned using lines secured on anchor pins across the two ends of the wall that are level. After the construction of the wall, mortar joints are applied to completely seal off any air gaps between the brick courses (Wallender, 2022). To ensure that the wall is even before the paint can be applied, plaster is applied to the uneven concrete wall. Lean mortar was used to plaster the concrete surface to ensure a flat surface can be created before the painting of the wall. The skirting tiles are then installed to the bottom of the walls with lean mortar by using plastic shims to position and align them with uniform gaps. After removing excess mortar from the gaps, they will then be left to cure. 3.2. Door in Case 2 3.2.1. Design requirements As a fire rated self-closing door leading to a cargo elevator and a main hallway, the door is required to meet the fire code’s safety requirements and be able to withstand wear and tear. Fire resistance: the door has to be strong enough and fire resistant enough to withstand impacts and high heat. Insulation: the bottom gap of the fire door should not exceed 10 mm to protect the tenants in the room from smoke and heat in case of a fire. Ease of operation: the door should be split into two leaves if the aperture of the door is too large to improve ease of access. Transparency: viewing panels should be installed on both of the leaves to allow users to assess the safety on the other side of the door in case of a fire. 12 3.2.2. Material and design In accordance with fire safety regulations, the frame is made with fire-rated material soaked and processed solid hardwood with a wood veneer finish . The door is made of fire-rated hardwood timber, gypsum fireboards, rock wool, and fire-rated veneers (Buildings Department, 2022). The hinges, pull handle, and push plates are made of stainless steel. The viewing panels are made of tempered glass. A plan showing the door only is shown in Figure 3.2.2.1. Figure 3.2.2.1 Plan showing the materials of the doors. According to fire safety regulations, building floors with maximum occupancies above 30 are required to be equipped with fire rated doors that are 850 mm or wider. In this case, width of the aperture is 1540 mm, which complies with the code’s requirement (Buildings Department, 2022). Additionally, all fire rated doors are required to be at least 2000 mm tall, and no leaf in a double door should be over 600 mm wide. In this case, the height of the aperture of the pair of doors is 2100 mm, and the width of the smaller leaf is 595 mm, due to natural wear and tear, which meets the code’s width requirement (Buildings Department, 2022). The fire-rated doors are asymmetrical. The difference in widths is to allow users to open the doors easier as it would not be as user friendly to open a leaf that is a part of an evenly spaced double door in the 2100 mm wide entry way. As the door leads to a cargo elevator, the wider leaf together with the smaller leaf can be opened together for cargo transits in and out of the elevator for ease of access. The viewing panels of fire rated door are a pair of 10 mm fire-rated, impact safety rated glass. Each of the fire rated door has a viewing panel measuring 135 mm wide and 515 mm in length for users to view the other side of the panels. Both doors have push plates below the viewing panels to protect the doors from impacts. One pull handle is installed on each leaf of the double door. 13 Figure 3.2.2.2 Viewing panels of the door Figure 3.2.2.3 Exploded diagram showing the components of the door. 3.2.3. Present conditions and performance The door is maintained by registered Fire Services contractors on behalf of the HKU Safety Office and Estate Office. The door’s wood veneers have visible scratches and wear, and the push plates of the door have been scratched. The door is an inward opening door that opens towards to the emergency staircase. Note that the pair of doors are not connected to the fire alarm system since it is a part of a main entryway to the building. A door closer is attached to the top of the door which enables the door to self-close, as seen in Figure 3.2.3.1. Figure 3.2.3.1 Door closer of the door. Fire resistance The door has good fire resistance performance. From the building plans acquired, the door is labelled F1 which refers to a 1-hour Fire Resistance Period. This means it can withstand the action of fire for one hour. Processed hardwood is dense and can provide some fire-resistant properties. Also, an intumescent strip on the door frame and a layer of fire-retardant coating on the wood veneer finishes are applied to increase the door’s fire resistance according to the Fire Safety Ordinance (Cap.572) (Buildings Department, 2015). Figure 3.2.3.2 Building plans showing the fire rating of the door. 14 3.2.4. Construction method The door is constructed by fixed-in method. The wooden frame of the door is secured into the concrete brick wall. The wooden frame is then positioned using wooden shims to ensure the frame is level with the structural aperture. A level is used to make sure the frame is level with the aperture (JBKind Doors, 2022). As a fire rated door, the gaps must be filled with fire resistant insulation. The best insulation option is rock wool, which can withstand high heat (Buildings Department, 2022). After filling the gaps with rock wool, the hinges are installed, and the fixing lugs are fixed onto the wall with long screws to secure the frame onto the shear wall. To cover up the gaps between the frame and the wall, fire rated timber covers are installed on top of the gaps and secured onto the frame using nails. Finally, the door close position is adjusted by adjusting the heights and positions of the hinges to make sure the double doors close flush. 3.3. Hinges and connection between the door and the wall Each of the doors is connected to the frame with four stainless steel butt hinges and a door closer. The bottom three hinges are evenly spaced, while the top two hinges has a shorter separation distance as the upper part of the doors experience higher bending moment. The bottom of the door is equipped with a floor hinge as well. The frame is screwed into the wall using screws and fixing lugs (Tobias, 2015). Between the jamb and the shear walls, there is insulating rock wool that fills the gap to prolong the fire-resistant time of the door and to enhance the insulation property of the door. The gap is covered with fire-rated timber covers around the edge of the structural aperture. Details of the door-wall connection are shown in Figures 3.3.2 to 3.3.4: Figure 3.3.2 Elevation of the connection between the doors and wall. 15 Figure 3.3.1 Stainless steel hinge of the door Figure 3.3.3 Plan showing the connection between the doors and the wall. Figure 3.3.4 Section C-C showing the connection (fixing lug) between the doors and the wall. 16 4. Comparison between the two cases The features of the two cases of wall-door connections will be compared in a table below: Table 4.0.1 Comparison between Case 1 and Case 2 Case 1 (Main Library) Type of structure Type of door Hinge of door Materials Dimensions Fire resistance Sound insulation Opening, closing, and locking Present external conditions Construction method of door Connection method Case 2 (Centennial Campus) Non-load bearing superstructure Single acting, single leaf Single acting, double asymmetrical leaf Pivot hinge with floor spring with connections at Three butt hinges on each side of the door leaf top and bottom of door leaf Steel studs with infill gypsum boards for wall Plastered concrete bricks for wall to form sufficient thickness Aluminium cladding with green adhesive finishes Hardwood door with gypsum fireboard for extra fire protection Steel and glass door The doors and walls are both thinner as the The doors and walls are much thicker to partitions are not loadbearing structures, and provide fire resistance capabilities they do not need to withstand great loads in a The rebate of the door frame catches the door library leaf to ensure no gap is left between the top of There is an around 10 mm clearance in all four the door and the head of frame sides of the door since fire resistance is less important than the door-wall connection in Case 2 Fire resistance is also important but less so Rated for 1-hour fire resistance compared to Case 2 Thickness ensures good fire resistance Gypsum board used for partition serves good fire Intumescent strip installed resistance purposes Relatively good sound insulation due to thick Good sound insulation is a by-product of the and dense glass and steel used for door thick wall and door Acoustic foam inserted between drywall absorbs noise Sound insulation is an important design requirement for a library door No door closer but a floor spring is present to Two door closers to close the door close the door automatically automatically and produce a damping effect to prevent slamming of door Locking system in place to prevent entry by unregistered individuals No locking system since it is used for escape purposes Lock system not securely attached to the wall Some peeling of the adhesive finishes of the wall Slight wear on door finish Slight rust observed on the door frame A minor crack in the plaster finish is visible Built-in method since it is only possible for the Fixed-in method door frame to be connected to the metal studs before erection of drywall panels Metal stud anchors join the door frame to the Fixing lugs are used because a thick brick studs of the wall since it is a part of a frame-andwall holds the door; the wall has enough panel partition system thickness and strength for fixing lugs to be inserted To conclude, two sets of wall-door connections have been examined in this report. Both of them belong to non-load bearing structures but various differences exist in terms of their materials, functions, soundproofing and fireproofing performance, connection method, etc. This reflects changing designs of the same type of building elements based on their different requirements and functions. 17 References ArchDaily. (2018). Steel Frame and Timber Frame: The Benefits of Dry Construction Systems. https://www.archdaily.com/890732/steel-frame-and-wood-frame-the-benefits-of-dryconstruction-systems Beacon Commercial Door and Lock. (n.d.). 5 Types of Hollow Metal Frame Anchors. Retrieved November 17, 2022, from https://www.beaconcdl.com/5-types-of-hollow-metal-frameanchors/ Buildings Department. (2015, October). Code of Practice for Fire Safety in Buildings, 2011. Retrieved from Buildings Department: https://www.bd.gov.hk/doc/tc/resources/codes-andreferences/code-and-design-manuals/fs2011/fs2011_full.pdf Buildings Department. (2022, Novemeber 16). Examples of Basic and Essential Improvement Works. Retrieved from Buildings Department: https://www.bd.gov.hk/en/safety-inspection/firesafety/index_fsi_improvement.html Dormakaba. (n.d.). DORMA LM Series. Retrieved November 22, 2022, from https://www.dormakaba.com/us-en/solutions/products/door-hardware/door-closers/lm-series292450 Everett, A., & King, H. (1975). Components and finishes. B. T. Batsford Limited. JBKind Doors. (2022, June). How to Fit Internal Fire Doors. Retrieved from JBKind Doors Info Centre: https://www.jbkind.com/info-centre/how-to-door-guides/how-to-fit-internal-firedoors Nuts and Bolts DIY. (2013). How to Install Metal Stud Framing / Drywall. Retrieved on November 13, 2022, from https://www.youtube.com/watch?v=amK2edm20ss& Tobias, S. (2015). Illustrated Guide to Door Hardware: Design, Specification, Selection : Design, Specification, Selection. John Wiley & Sons, Incorporated. Wallender, L. (2022, November 17). How to Build a Cinder Block Wall. Retrieved from The Spruce: https://www.thespruce.com/how-to-build-a-cinder-block-wall-844825 Division of Work Section Section 1: Introduction Section 2: Case 1 Section 3: Case 2 Section 4: Comparison between the two cases Student responsible Chan Ho Hin Chan Ho Hin & Sarvagya Daga Yuen Chi Hang Matthew & Chung Siu Hoi Yuen Chi Hang Matthew & Chan Ho Hin 18