360

Polymers: Chemistry and Physics of Modern Materials

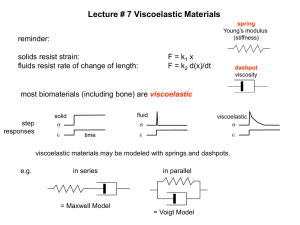

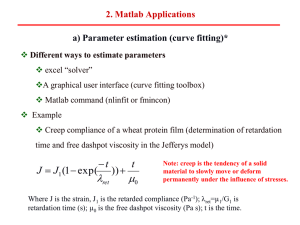

Here YR = (M/G) is known as the retardation time and is a measure of the time

delay in the strain after imposition of the stress. For high values of the viscosity, the

retardation time is long, and this represents the length of time the model takes to

attain (1 1/e) or 0.632 of the equilibrium elongation.

Such models are much too simple to describe the complex viscoelastic behavior

of a polymer, nor do they provide any real insight into the molecular mechanism of

the process, but in certain instances they can prove useful in assisting the understanding of the viscoelastic process.

13.6 LINEAR VISCOELASTIC BEHAVIOR

OF AMORPHOUS POLYMERS

A polymer can possess a wide range of material properties, and of these the hardness,

deformability, toughness, and ultimate strength are among the most signiÀcant. Certain

features such as high rigidity (modulus) and impact strength combined with low creep

characteristics are desirable in a polymer if eventually it is to be subjected to loading.

Unfortunately, these are conÁicting properties, as a polymer with a high modulus and

low creep response does not absorb energy by deforming easily and hence has poor

impact strength. This means a compromise must be sought depending on the use of

the polymer, and this requires knowledge of the mechanical response in detail.

The early work on viscoelasticity was performed on silk, rubber, and glass, and

it was concluded that these materials exhibited a delayed elasticity manifest in the

observation that the imposition of a stress resulted in an instantaneous strain, which

continued to increase more slowly with time. It is this delay between cause and

effect that is fundamental to the observed viscoelastic response, and the three major

examples of this hysteresis effect are (1) creep, where there is a delayed strain

response after the rapid application of a stress, (2) stress-relaxation (Section 13.15),

in which the material is quickly subjected to a strain and a subsequent decay of

stress is observed, and (3) dynamic response (Section 13.17) of a body to the

imposition of a steady sinusoidal stress. This produces a strain oscillating with the

same frequency as, but out of phase with, the stress. For maximum usefulness, these

measurements must be carried out over a wide range of temperature.

13.6.1 CREEP

To be of any practical use, an object made from a polymeric material must be able

to retain its shape when subjected to even small tensions or compressions over long

periods of time. This dimensional stability is an important consideration in choosing

a polymer for use in the manufacture of an item. No one wants a plastic telephone

receiver that sags after sitting in its cradle for several weeks, or a car tire that develops

a Áat spot if parked in one position for too long, or clothes made from synthetic

Àbers that become baggy and deformed after short periods of wear. Creep tests

provide a measure of this tendency to deform and are relatively easy to carry out.

Creep can be deÀned as a progressive increase in strain, observed over an

extended time period, in a polymer subjected to a constant stress. Measurements are

carried out on a sample clamped in a thermostat. A constant load is Àrmly Àxed to

Rheology and Mechanical Properties

361

one end, and the elongation is followed by measuring the relative movement of two

Àducial marks, made initially on the polymer, as a function of time. To avoid

excessive changes in the sample cross-section, elongations are limited to a few

percent and are followed over approximately three decades of time.

The initial, almost instantaneous, elongation produced by the application of the

tensile stress is inversely proportional to the rigidity or modulus of the material, i.e.,

an elastomer with a low modulus stretches considerably more than a material in the

glassy state with a high modulus. The initial deformation corresponds to portion OA

of the curve (Figure 13.13), increment a. The rapid response is followed by a region

of creep, A to B, initially fast, but eventually slowing down to a constant rate

represented by the section B to C. When the stress is removed the instantaneous

elastic response OA is completely recovered, and the curve drops from C to D, i.e.,

the distance ae = a. There follows a slower recovery in the region D to E which is

never complete, falling short of the initial state by an increment ce = c. This is a

measure of the viscous Áow experienced by the sample and is a completely nonrecoverable response. If the tensile load is enlarged, both the elongation and the

creep rate increase, so results are usually reported in terms of the creep compliance

J(t), deÀned as the ratio of the relative elongation y at time t to the stress so that

J (t ) = yE /X

(13.23)

At low loads, J(t) is independent of the load.

Stress removed

ε

C

c

B

a′

D

b

b′

A

a

E

c′

Ο

t

Stress applied

FIGURE 13.13 Schematic representation of a creep curve: a, initial elastic response; b,

region of creep; c, irrecoverable viscous Áow. This curve can be represented by the fourelement model shown in Figure 13.14.

362

Polymers: Chemistry and Physics of Modern Materials

σ

E1

E2

η2

η3

σ

(i)

(ii)

(iii)

(iv)

(v)

FIGURE 13.14 Use of mechanical models to describe the creep behavior of a polymeric

material.

This idealized picture of creep behavior in a polymer has its mechanical equivalent

constructed from the springs and dashpots described earlier. The changes a and ae

correspond to the elastic response of the polymer, and so we can begin with a Hookean

spring. The Voigt-Kelvin model is embodied in Equation 13.22, and this reproduces

the changes b and be. The Ànal changes c and ce represent viscous Áow, and can be

shown with a dashpot so that the whole model is a four-element model (Figure 13.14).

The behavior can be explained in the following series of steps. In diagram (i)

the system is at rest. The stress X is applied to spring E1 and dashpot M3; it is also

shared by E2 and M2, but in a manner that varies with time. In diagram (ii), representing zero time, the spring E1 extends by an amount X/E1(= a). This is followed

by a decreasing rate of creep with a progressively increasing amount of stress being

carried by E2 until eventually none is carried by M2, and E2 is fully extended [diagram

(iii)]. Such behavior is described by

J(t ) = (X 0 /E2 ){1 exp (t /Y R )}

(13.24)

where the retardation time YR provides a measure of the time required for E2 and M2

to reach 0.632 of their total deformation. A considerably longer time is required for

complete deformation to occur. When spring E2 is fully extended, the creep attains

a constant rate corresponding to movement in the dashpot M3. Viscous Áow continues

and the dashpot M3 is deformed until the stress is removed. At that time, E1 retracts

quickly along section ae and a period of recovery ensues (be). During this time spring

E2 forces the dashpot plunger in M2 back to its original position. As no force acts on

M3, it remains in the extended state and corresponds to the nonrecoverable viscous

Áow; region ce = Xt/M3. The system is then as shown in diagram (v). In practice, a

substance possesses a large number of retardation times, which can be expressed as

a distribution function L1(Y) where

L1 (Y) = d{J (t ) (t /M)}/d ln t.

(13.25)