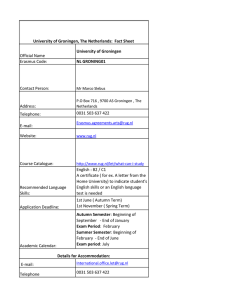

Beer Game Report Date: 27/10/2022 Atakan Yazganarikan IEM3 S5136989 1 Contents Brief Introduction........................................................................................................... 3 Round Analysis .............................................................................................................. 3 Round 1. No communication ..................................................................................... 3 Round 2. Communication .......................................................................................... 5 Round 3. Focused Communication ............................................................................ 6 Conclusion and Discussion ............................................................................................ 8 2 Brief Introduction Beer Game Report covers the three different rounds of the game and investigates how the level of cooperation effects the efficiency of the supply chain. The goal of the game is to fulfil customer demand while minimizing costs. The chain consists of 5 stages: Groningen Supermarket, Groningen Warehouse, Wholesaler, Distributor and the Manufacturer. Each stage has inventory cost per product of 0.5€ and backorder cost of 1.0€. The game’s time period is in weeks and the supply lead time is constant to 3 weeks. Each rounds of the game have a different strategy consisting of, no communication, communication and focused communication. Round Analysis Round 1. No communication First round of the game explores how absence of communication affects the supply chain. In this round communication between stages were blocked and the only information provided for each stage was the demand from the following stage. Table 1 Stage 1. and corresponding Performance Indicators Table Performance Maximum Largest order Largest Service Total Indicator Customer placed by a order to Level Cost (€) (highest vs. Demand stage (Units) Lowest (%) (Units) Stage 1 9 Ratio (%) 260 3 70 10,524 Cost ratio Number of back lowest stage) orders (%) (weeks) 19 23 The first weeks of the round every stage had low to no demand. This was due to Groningen supermarket using its stock inventory to fulfil orders without placing any orders themselves until needed. This strategy was shortly lived and resulted in a high demand crisis. Demand for each stage went from 0-4 to 20 and above. Each stage panic ordered more than required amount of units since the initial customer demand is unknown for stages other than Groningen Supermarket. This resulted in high level of backorders (24 weeks) and in the process 3 each stage tried to reduce their own cost without considering the other stages. This was due to the fact that there was a lack of information regarding the cost of other stages, thus the stages did not know the cost effect of the orders they place in other stages. In the end, no communication resulted in the bullwhip effect as seen in figure.1. The chain ended up with a poor service level of 70% and a total cost of 10,524€. Demand Per Week of the Stages Figure 1 Beer Game Round 1 Results, Demand of each stage by week. Stages: Groningen. Supermarket, Groningen. Warehouse, Wholesaler, Distributor and Manufacturer Demand thought the stages until the last had an exponential increase with the maximum customer order being 9 units in Groningen Supermarket and the maximum order within the stages being 260 units by the manufacturer, having a ratio of 3%. The effect can also be observed from the average standard deviation of demand and supply. Customer orders deviated by 1.8 units thought the round the supply chain deviated by 34.1 unites. The significant cost ratio of 19% between stages Groningen Supermarket and Manufacturer is the result from the bullwhip effect. In conclusion, lack of cooperation has resulted in the bullwhip effect which resulted in a high number of backorders (23) and a low service level while having a high cost. 4 Round 2. Communication Second round of the game communication was allowed. Each stage shared all information and coordinated to reduce overall costs. Table 2 Stage’s 1 and 2 with their corresponding Performance Indicators Performance Maximum Largest order Largest Service Total Indicator Customer placed by a order to Level Cost (€) (highest vs. Demand stage (Units) Lowest (%) (Units) Ratio (%) Cost ratio Number of back lowest stage) orders (%) (weeks) Stage 1 9 260 3 70 10,524 19 23 Stage 2 9 12 75 100 737 80 0 Communication allowed each stage to place orders depending on the following stages demand and observe the supply chain as a whole rather than only focusing on local profits. Information sharing abled the overall chain to have a plan and adjust to demand uncertainty better, thus allowing the chain to have a 100% service level and 0 backorders. In the end, cooperation allowed stages to better determine their orders which decreased the bullwhip effect significantly and had a significant decrease in total supply chain costs of 737€. Demand, Backorder and Order Per Week of the Stages Figure 2 Beer Game Round 2 Results, Demand, Backorder and Order of each stage by week. Stages: Groningen. Supermarket, Groningen. Warehouse, Wholesaler, Distributor and Manufacturer 5 Stability between order and demand thought the entire chain can be seen in figure.2. The difference between the maximum customer order demand and largest order placed is only 3 and has a ratio of 75%, indicating that there has been less unnecessarily placed orders thus less bullwhip effect. The decrease in bullwhip effect had a positive impact on decreasing the cost and having less cost difference between stages. Highest cost was by the manufacturer (163€) and the lowest was by the Groningen Supermarket (131€) which give a ratio of 80%. In conclusion, cooperation and communication has allowed the supply chain to maximize service level and have no backorders while lowering the costs down to 737€. Round 3. Focused Communication Communication has drastically increased the performance of the chain. However, too much information and a cluster of it can make the chain more complicated than it need to be. To test this Round 3 was conducted only using the customer demand and every stage would place orders based on customer demand. Table 3. Stage’s 1, 2 and 3 with their corresponding Performance Indicators Performance Maximum Largest order Largest Service Total Indicator Customer placed by a order to Level Cost (€) (highest vs. Demand stage (Units) Lowest (%) (Units) Ratio (%) Cost ratio Number of back lowest stage) orders (%) (weeks) Stage 1 9 260 3 70.0 10,524 19 23 Stage 2 9 12 75 100 737 80 0 Stage 3 9 10 90 95.4 470 69 17 6 Demand, Backorder, Order, Cost and Stock Per Week of the Stages Figure 3 Beer Game Round 3 Results, Demand, Backorder, Order, Cost and Stock of each stage by week. Stages: Groningen. Supermarket, Groningen. Warehouse, Wholesaler, Distributor and Manufacturer In a perfect scenario ordering exactly the amount of demand should be the ideal option given that the customer demand will be met by the supply while having no backorders. However, there will always be demand uncertainty and delay due to order lead time. In this case ordering only according to customer demand resulted in the slight decrease in service levels by 3.6% and resulted in 17 backorders. The effect on service level was relatively lower than Round 2 but in return Round 3 had the lowest costs of 470€ out of all rounds. The reason why service level was not effected in a large extent was because each stage had initial inventory. Initial inventory was used when the orders of the new demand had not arrived due to the lead time of 3 weeks which allowed the chain to tackle sudden changes in demand. What allowed Stage 3 to have the lowest cost was the elimination of bullwhip effect. Every stage had the same amount of orders and there weren’t any unnecessary large orders. Limiting the communication to only share important information, such as in this case only demand of customers allowed the stages to view the supply chain process in a much simpler manner compared to Stage 2 while lowering the costs. 7 Conclusion and Discussion The Beer Game has shown the importance of cooperation within a supply chain to reduce bullwhip effect and have low costs. Stage 1 has showed the drastic result of having no cooperation with its low service level and high costs. In Stage 2 cooperation was introduced and there was an information flow within the supply chain. Sharing information allowed stages within the chain to work together on minimizing costs and predict their individual demand thus place orders accordingly. Stage 2 had the best performing service level and significantly lower costs than Stage 1. Stage 3’s strategy was to focus information on critical subjects, in this case customer demand. Every stage placed their orders based on customer demand without being exposed to too much information. This allowed the chain to be more focused and efficient, almost eliminating the bullwhip effect and lowering the costs even more. Even though it had a slightly lower service level than Stage 2, this can be fixed by having slightly more initial inventory for the Groningen Supermarket. If looked at figure.3 after week 10 the stock has depleted and backorders begin to come up. Having a slightly more initial inventory for Groningen Supermarket would allow a high service level while keeping the cost low. In addition, Manufacturer can also be given more initial inventory to prevent backorders and in the end minimize the costs even more. In large companies and firm’s cooperation is key when achieving high efficiency and allowing for flexibility. Without cooperation and information flow tough the stages of the chain the entire chain is prone to flaws and it becomes harder to align goals of the chain. The absence of cooperation can lead to obstacles such as local optimization, multiple demand forecasts by each stage, rationing and shortage gaming and other behavioural obstacles. All these obstacles including more, can occur with lack of cooperation which in the end all cause the bullwhip effect, decreasing productivity and increasing overall costs of the supply chain. However, sharing every information can also be a downside. Unlike the beer game having a more complex supply chain results in many data and information at each stage. If all stages shared all the information they had it would make the chain more complex than it needs to be and would make it more difficult to sort out the information that is really required. In the end, this is why Stage 3 in the game has shown the lowest costs and focusing information sharing in a more complex supply chain would provide similar or even much better performance if only the crucial information is shared. In a managerial perspective rather than weather to cooperate or not, what is important is deciding which information is crucial to share. 8