See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/270427286

Penetration of dynamically installed anchors in clay

Article in Géotechnique · September 2013

DOI: 10.1680/geot.11.P.137

CITATIONS

READS

97

1,230

4 authors, including:

Conleth O'Loughlin

Christophe Gaudin

University of Western Australia

University of Western Australia

150 PUBLICATIONS 2,344 CITATIONS

182 PUBLICATIONS 4,162 CITATIONS

SEE PROFILE

Mark Randolph

University of Western Australia

396 PUBLICATIONS 18,211 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Pullout capacity of anchors View project

Instrumented Free Fall Sphere View project

All content following this page was uploaded by Conleth O'Loughlin on 19 April 2016.

The user has requested enhancement of the downloaded file.

SEE PROFILE

O’Loughlin, C. D. et al. (2013). Géotechnique 63, No. 11, 909–919 [http://dx.doi.org/10.1680/geot.11.P.137]

Penetration of dynamically installed anchors in clay

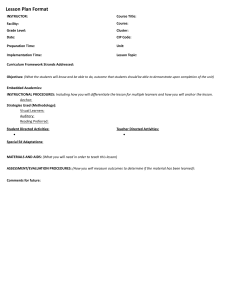

C . D. O ’ L O U G H L I N , M . D. R I C H A R D S O N † , M . F. R A N D O L P H a n d C . G AU D I N This paper utilises centrifuge data to explore the penetration response of dynamically installed anchors

in normally consolidated clay. The data indicate that for anchors with no flukes, expected anchor tip

embedment depths are two to three times the anchor length for impact velocities approaching 30 m/s,

with a strong dependence on the net density of the anchor and smaller dependence on the impact

velocity. Total energy, defined as the sum of the kinetic energy of the anchor at the mudline and the

potential energy released as it penetrates the seabed, is shown to be a useful quantity for comparing

the embedment depth of anchors with markedly different geometries and mass, impacting the soil at

different velocities. The centrifuge data were used to calibrate an analytical embedment model, based

on strain-rate-dependent shearing resistance and fluid mechanics drag resistance. The merit of the

anchor embedment model has been demonstrated by predicting the final embedment depths for a

series of offshore field trials to within 4% of the measurements.

KEYWORDS: anchors; centrifuge modelling; offshore engineering

INTRODUCTION

Dynamically installed anchors (see Fig. 1) are rocket or

torpedo shaped, with one such variant having a diameter of

1.2 m, a height of 13 m and a dry mass of 80 t (Lieng et al.,

2010). Smaller-diameter (0.76–1.07 m) anchors, 12–15 m

long and with a dry mass of between 24 and 98 t have been

used offshore Brazil (Medeiros, 2002; Brandão et al., 2006).

After release from a designated height above the seabed, the

anchor gains velocity as it falls freely through the water

column before impacting on and embedding within the

sediments. As anchor capacity is determined by the shear

strength of the soil in the vicinity of the embedded anchor,

confidence in the geotechnical performance of dynamically

installed anchors is dictated to a large degree by the success

of predicting the anchor embedment depth after free fall and

the strength recovery after installation (the latter aspect

having been investigated by Richardson et al., 2009). A key

aspect of predicting the anchor embedment depth is quantifying the penetration resistance over the high range of

penetration velocities and hence strain rates. Failure to

account for enhancement of penetration resistance due to the

high strain rates associated with dynamic installation has

been shown to give prediction errors of the order of 40%

(O’Loughlin et al., 2004).

The shear strength of clays is well known to be a function

of strain rate (Casagrande & Wilson, 1951; Graham et al.,

1983). Sheahan et al. (1996) reported shear strength increases of up to 11.5% per log cycle increase in shear strain

rate for normally consolidated Boston blue clay samples

undergoing triaxial compression. Chung et al. (2006) showed

that field T-bar penetration resistance increases by ,20%

per log cycle increase in penetration velocity for lightly

overconsolidated Burswood clay. This represents good agreement with work reported by Lehane et al. (2009) that

demonstrated a 14% and 18% increase in ball and T-bar

penetrometer resistance per log cycle increase in penetration

velocity in normally consolidated and overconsolidated kaolin clay. However, these and similar studies are generally

limited to strain-rate variations that span only two to three

orders of magnitude, compared with approximately seven

orders of magnitude in the case of dynamically installed

anchors.

This paper re-examines previously published centrifuge

data to explore the penetration behaviour of dynamically

installed anchors in normally consolidated clay. This behaviour is reflected in a simple embedment model that scales

the undrained shear strength according to logarithmic and

power functions, allowing for quantification of the strain-rate

behaviour for the more extreme dynamic anchor problem.

CENTRIFUGE TEST DATABASE

The centrifuge database compiled for this paper encompasses various series of centrifuge tests performed at 200g,

as reported in Richardson et al. (2006, 2009), Richardson

(2008) and O’Loughlin et al. (2004, 2009). It comprises 155

dynamic anchor installations in normally consolidated kaolin

clay exhibiting a prototype shear strength gradient in the

range k ¼ 1.0–1.3 kPa/m between samples. The anchor models, which varied in aspect ratio (length/diameter, L/d ), mass

m, fluke arrangement and tip geometry, were dropped

through an installation guide from (model) heights of up to

300 mm above the sample surface, resulting in anchor

impact velocities (i.e. anchor velocities at the mudline, vi )

of up to 30 m/s. Details of the 25 model anchors are

summarised in Table 1 and are shown in Fig. 2.

Anchor impact velocity, mass and embedment depth

Typically, the impact velocities achieved in the centrifuge

tests ranged from ,10 to ,30 m/s, which compares well

with field experience: vi ¼ 10–22 m/s (Medeiros, 2001),

vi ¼ 24.5–27.0 m/s (Lieng et al., 2010) and vi ¼ 16–27 m/s

(Brandão et al., 2006). The dependence of final tip embedment, ze , on mass and impact velocity is summarised in Fig.

3(a) for an anchor aspect ratio L/d ¼ 12.5. The centrifuge

data for anchor A1 exhibit a degree of scatter that reflects

slight variation in undrained shear strength both between

samples and over the course of testing in any one sample.

Over the range of measured impact velocities, anchor A1

Manuscript received 11 November 2011; revised manuscript accepted

31 October 2012. Published online ahead of print 23 April 2013.

Discussion on this paper closes on 1 February 2014, for further details

see p. ii.

Centre for Offshore Foundation Systems, The University of Western

Australia, Crawley, Australia.

† Advanced Geomechanics, Nedlands, Australia.

909

O’LOUGHLIN, RICHARDSON, RANDOLPH AND GAUDIN

910

(a)

(b)

(c)

Fig. 1. Dynamically installed anchors: (a) torpedo anchor (after Araujo et al., 2004); (b) OMNI-Max anchor (after Shelton, 2007);

(c) deep penetrating anchor (Deep Sea Anchors, www.deepseaanchors.com/News.html)

Table 1. Model anchors

Anchor ref.

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

A22

A23

A24

A25

Flukes

Tipy

Padeyey

Length,

L: mm

Diameter,

d: mm

Tip length,

Ltip : mm

L/d

Material{

Effective anchor

density: kg/m3

Mass, m: g

0

0

0

0

4

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

E

E

E

E

E

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

F

F

F

F

F

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

75.0

75.0

75.0

75.0

75.0

6.0

9.0

12.0

18.0

24.0

36.0

24.0

36.0

36.0

48.0

60.0

72.0

72.0

84.0

9.0

18.0

27.0

27.0

12.0

24.0

6.0

6.0

6.0

6.0

6.0

6.0

6.0

6.0

6.0

6.0

6.0

6.0

6.0

6.0

6.0

6.0

6.0

6.0

6.0

9.0

9.0

9.0

9.0

12.0

12.0

11.4

11.4

11.4

11.4

11.4

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

4.5

4.5

4.5

4.5

6.0

6.0

12.5

12.5

12.5

12.5

12.5

1.0

1.5

2.0

3.0

4.0

6.0

4.0

6.0

6.0

8.0

10.0

12.0

12.0

14.0

1.0

2.0

3.0

3.0

1.0

2.0

B

B/A

B/A

A

B/A

B

B

B

B

B

B

A

A

A

A

A

A

A

A

B

B

B

A

B

B

7661–7929

4088

3062

2690

3902

8135

8892

7250

6742

7508

7708

2283

2434

1945

2499

2531

2526

2395

2597

7938

7451

7447

1998

8002

7967

14.3–14.8

8.2

6.2

5.4

9.6

0.9

1.8

2.0

3.0

4.7

7.4

1.4

2.3

1.9

3.2

4.2

5.0

4.7

6.0

3.0

7.1

11.4

3.0

7.2

18.0

Fluke length, L ¼ 37 mm; fluke width, w ¼ 9 mm; fluke thickness, t ¼ 0.4 mm.

f

f

f

y

E, ellipsoidal; F, flat; H, hemispherical (Lpad ¼ Ltip ).

{

B, brass; A, aluminium.

PENETRATION OF DYNAMICALLY INSTALLED ANCHORS IN CLAY

911

wf

tf

Lf

Lpad

L

L

L

Ltip

d

Ltip

Ltip

d

d

(a)

(b)

(c)

Fig. 2. 1:200 reduced scale anchors: (a) four-fluke, ellipsoidal-tip anchor (L/d

(c) zero-fluke, hemispherical-tip anchor (L/d 1–14)

50

5

10

Impact velocity, vi: m/s

15

20

25

30

35

A1: 0 flukes, m ⫽ 14·3–14·8 g

A2: 0 flukes, m ⫽ 8·2 g

A3: 0 flukes, m ⫽ 6·2 g

A4: 0 flukes, m ⫽ 5·4 g

A5: 4 flukes, m ⫽ 9·6 g

100

150

0

0

5

Impact velocity, vi: m/s

10

15

20

12.5);

25

20

Final tip embedment, ze: mm

Final tip embedment, ze: mm

0

0

12.5); (b) zero-fluke, ellipsoidal-tip anchor (L/d

40

60

80

100

200

120

140

250

A6: m ⫽ 0·9 g, L/d ⫽ 1·0

A8: m ⫽ 2·1 g, L/d ⫽ 2·0

A10: m ⫽ 4·7 g, L/d ⫽ 4·0

(a)

(b)

Fig. 3. Anchor embedment depth dependence on impact velocity and mass for: (a) L/d

(m ¼ 14.3–14.8 g, i.e. average equivalent prototype mass ¼

115 t, L/d ¼ 12.5) achieves final tip embedments of 150–

220 mm, which corresponds to 2.1–2.9 times the anchor

length. This is in good agreement with reported field experience of 1.9–2.4 times the anchor length for a 79 t anchor

A7: m ⫽ 1·8 g, L/d ⫽ 1·5

A9: m ⫽ 3·1 g, L/d ⫽ 3·0

A11: m ⫽ 7·4 g, L/d ⫽ 6·0

12.5; (b) L/d

1–6

with L/d ¼ 10.8 and four wide flukes (Lieng et al., 2010),

2.1 times the anchor length for a 98 t anchor with L/d ¼

15.9 and four narrow flukes (Brandão et al., 2006), and 2.4

times the anchor length for a 40 t anchor with L/d ¼ 15.7

and no flukes (Medeiros, 2001).

O’LOUGHLIN, RICHARDSON, RANDOLPH AND GAUDIN

Frictional resistance

Richardson (2008) conducted several dynamic installation

tests in which the 5–10 mm layer of surface water (to ensure

sample saturation) was temporarily removed. Over the same

range of measured impact velocities, tip embedment depths

for those tests were on average 20% lower than for those in

which the surface water was present. While it is acknowledged that water will indeed be present during offshore

installations, these results suggest that water may be entrained in a boundary layer along the anchor wall during

installation. This would reduce the effective normal stress at

the anchor/soil interface, resulting in a reduction in the

friction on the anchor shaft, which would promote embedment. Tika & Hutchinson (1999) have also commented on

the reduction in strength observed in high-rate ring-shear

tests during which water was permitted to penetrate the

shear zone. Richardson et al. (2009) showed that highvelocity embedment reduced the short-term capacity of the

anchor, compared with that for low-velocity embedment

(anchor released at the soil surface). Since the short-term

capacity is dominated by the effective stress level prior to

dissipation of the excess pore water pressures generated in

the boundary layer, this also suggests significant water

entrainment during dynamic embedment.

The question as to whether the soil separation occurs

along the anchor shaft is considered in Fig. 4 by examining

data for anchors with the same diameter and mass but

different lengths. If soil separation was to occur, then short

and long anchors should reach the same final embedment

depth, as the bearing resistance would be equivalent, and

soil separation would provide no frictional resistance. However, the data in Fig. 4 show that longer anchors embed less

than shorter anchors, which is consistent with higher frictional resistance afforded by greater available wall soil/

anchor surface area. Soil separation does not appear to occur

to any significant degree for the range of velocities considered here (, 20 m/s), which is consistent with observations

by Murff & Coyle (1973), who noted that soil separation

occurred only above a critical velocity of 28 m/s.

Total energy

Figures 3(a) and 3(b) illustrate the difficulty in comparing

embedment trends between anchors of different geometries

and mass. The comparison can be simplified somewhat by

considering the sum of the kinetic and potential energy

Impact velocity, vi: m/s

0

0

5

10

15

20

25

A20: m ⫽ 3·0 g, L/d ⫽ 1

A23: m ⫽ 3·0 g, L/d ⫽ 3

A10: m ⫽ 4·7 g, L/d ⫽ 4

A18: m ⫽ 4·7 g, L/d ⫽ 12

20

Final tip embedment, ze: mm

Interestingly, the tests with zero impact velocity (anchor

tip positioned at the clay surface prior to release) also

achieve relatively high tip embedment depths, which suggests a strong dependence on anchor mass. This is supported

by the lower mass anchor data in Fig. 3(a) (anchors A2 to

A4), which clearly show an increase in tip embedment with

increasing mass. Also shown in Fig. 3(a) are the limited data

available for anchor A5 with L/d ¼ 12.5 and four flukes (see

Table 1 for fluke dimensions). Interestingly, anchor A4

(m ¼ 5.4 g, no flukes) and anchor A5 (m ¼ 9.6 g, four

flukes) show similar penetration trends, despite the difference in anchor mass. The increase in mass in anchor A5,

which would promote penetration, is offset by the increased

wall surface area and associated increase in frictional resistance, which resists penetration.

The effects of mass and aspect ratio are examined in Fig.

3(b), which plots drum centrifuge data for L/d in the range

1–6. The data clearly show an increase in tip embedment

with an increase in L/d, but this is due to increasing mass.

As will be shown later, anchors of a given mass and diameter

show decreasing tip embedment with increasing L/d.

40

60

80

100

120

140

Fig. 4. Anchor embedment depth dependence on aspect ratio

(relative to final embedment depth) of the anchor as it

impacts on the soil. This is demonstrated in Fig. 5, where

tip embedment for the entire centrifuge database is plotted

as a function of the total energy of the anchor, defined as

Etotal ¼ 12mv2i þ m9gze

(1)

where m9 is the effective mass of the anchor (submerged

in soil), and g is the Earth’s gravitational acceleration ¼

9.81 m/s2 : A unique relationship now exists for a given

anchor diameter, with larger diameters giving lower embedment. These data are re-plotted in non-dimensional form

(removing the influence of diameter and soil strength gradient) in Fig. 6, together with available field data for dynamically installed anchors. The effective anchor diameter, deff ,

accounts for the additional projected area from the anchor

flukes. The centrifuge and field data in Fig. 6 now form a

relatively tight band, particularly considering the assumptions

employed regarding shear strength gradients and anchor

geometries for the field data. A conservative fit to the data

may be expressed as

Total energy, Etotal: J

0

0

1

2

3

4

5

6

7

8

9

10

11

12

25

Final tip embedment, ze: mm

912

50

75

100

125

150

175

200

225

L/d ⫽ 12·5, d ⫽ 6·0 mm, m ⫽ 5·4–14·8 g, ellipsoidal tip, 0 flukes

L/d ⫽ 12·5, deff ⫽ 7·4 mm, m ⫽ 9·6 g, ellipsoidal tip, 4 flukes

L/d ⫽ 1–14, d ⫽ 6·0 mm, m ⫽ 0·9–7·4 g, hemispherical tip, 0 flukes

L/d ⫽ 1–3, d ⫽ 9·0 mm, m ⫽ 3·0–11·4 g, hemispherical tip, 0 flukes

L/d ⫽ 1–2, d ⫽ 12·0 mm, m ⫽ 7·2–18·0 g, hemispherical tip, 0 flukes

Fig. 5. Anchor embedment depth dependence on total energy at

mudline

PENETRATION OF DYNAMICALLY INSTALLED ANCHORS IN CLAY

913

Etotal/kd4eff

0

0

5

10

15

20

25

30

35

40 ⫻103

5

Soil buoyancy

(Fb)

10

ze /deff

15

ze

20

deff

æ E total

艐ç

ç kd 4

è eff

Fluke reverse end

bearing (Fbear)

1/3

ö

÷

÷

ø

25

Fluke friction

(Ffrict)

30

35

Fluke end

bearing (Fbear)

40

Centrifuge tests (equivalent prototype scale):

m ⫽ 43·2–118·4 t, deff ⫽ 1·20 m, ellipsoidal tip, 0 flukes

Shaft friction

(Ffrict)

m ⫽ 76·8 t, deff ⫽ 1·47 m, ellipsoidal tip, 4 flukes

m ⫽ 7·2–59·2 t, deff ⫽ 1·20 m, hemispherical tip, 0 flukes

m ⫽ 24·0–91·2 t, deff ⫽ 1·80 m, hemispherical tip, 0 flukes

Submerged weight

(Ws)

m ⫽ 57·6–144·0 t, deff ⫽ 2·40 m, hemispherical tip, 0 flukes

Field tests:

m ⫽ 79 t, deff ⫽ 1·37 m (Lieng et al., 2010)

Inertial drag

(Fd)

m ⫽ 74 t, deff ⫽ 1·17 m (Brandão et al., 2006)

m ⫽ 98 t, deff ⫽ 1·17 m (Brandão et al., 2006)

Tip end bearing

(Fbear)

m ⫽ 39 t, deff ⫽ 1·56 m (Zimmerman et al., 2009)

Fig. 6. Comparison of centrifuge and field embedment data

ze

d eff

Etotal

kd 4eff

Fig. 7. Forces acting on a dynamically installed anchor during

installation

!1=3

(2)

This relationship harmonises a very large dataset that encompasses a wide range of anchor masses, geometries and

impact velocities.

ANCHOR EMBEDMENT MODEL

As anchor capacity is determined by the local shear

strength of the soil, the prediction of anchor capacity is

dictated to a large degree by the success of predicting the

final anchor embedment depth after free fall. The embedment of projectiles penetrating the seabed after free fall in

water may be quantified by considering Newton’s second law

of motion, and the forces acting on the projectile during

penetration. Several studies (e.g. True, 1976; Levacher,

1985; Beard, 1981; Aubeny & Shi, 2006; Audibert et al.,

2006) have adopted such an approach, with variations on the

inclusion and formulation of the various forces acting on the

projectile during penetration. A similar approach is adopted

here with the forces acting on the anchor during penetration

shown by Fig. 7, leading to a governing equation of

m

d2 z

¼ W s F b Rf ðF frict þ F bear Þ F d

dt2

(3)

where m is the anchor mass, z is depth, t is time, Ws is the

submerged anchor weight (in water), Fb is the buoyant

weight of the displaced soil, Rf is a shear strain rate function, Ffrict is frictional resistance, Fbear is bearing resistance,

and Fd is inertial drag resistance. Frictional and bearing

resistances are expressed as

F frict ¼ Æsu A

(4a)

F bear ¼ N c su A

(4b)

where Æ is a friction ratio (of limiting shear stress to

undrained shear strength), Nc is the bearing capacity factor

for the anchor tip or fluke, and su is the undrained shear

strength averaged over the contact area, A. The inclusion of a

fluid mechanics drag term, Fd , in equation (3) is warranted in

view of the very soft viscous clay that is often encountered at

the surface of the seabed. Inertial drag is formulated as

F d ¼ 12C d rs Ap v2

(5)

where Cd is the drag coefficient, rs is the density of soil, Ap

is the projected anchor area, and v is the current anchor

velocity.

The frictional resistance term (equation (4a)) comprises

friction on the shaft and the flukes, whereas the bearing

resistance term (equation (4b)) comprises bearing on the

base of the anchor shaft and flukes. Reverse end bearing at

the upper end of the anchor shaft (padeye) and flukes would

also be included when the cavity created by the passage of

the advancing anchor does not remain open. It is assumed

here that full closure will occur behind the anchor flukes,

owing to their relatively low thickness and apparent planestrain conditions, whereas hole closure will occur only

behind anchor shafts with L/d < 2 (assumed limit for a flowround probe). Aubeny & Shi (2006) also assumed that a

cylindrical void forms in the wake of dynamically installed

impact penetrometers (L/d ¼ 4.25); this assumption is supported by evidence from radiographs of centrifuge clay

samples (Poorooshasb & James, 1989) showing open pathways in the wake of dynamically installed cylindrical projectiles (despite closed entrance craters).

In reality it is likely that hole closure occurs eventually,

but not within the 10–15 ms taken for dynamic penetration

in the centrifuge. In view of this assumption, the soil buoyancy term (Fb ) is calculated as the displaced volume of soil

multiplied by the effective unit weight of soil (6.4 kN/m3 ),

where the displaced volume is limited to the volume of the

anchor for L/d < 2, and the combined volume of the flukes

914

O’LOUGHLIN, RICHARDSON, RANDOLPH AND GAUDIN

and a cylindrical shaft from the anchor tip to the soil surface

for L/d . 2.

Effect of strain rate on undrained shear strength

The dependence of shear strength on shear strain rate is

generally formulated using either semi-logarithmic or power

functions (e.g. Biscontin & Pestana, 2001), and has been

accounted for in equation (2) by scaling the bearing and

frictional resistances by a rate function Rf , expressed as

ª_

ª_

or Rf ¼

(6)

Rf ¼ 1 þ º log

ª_ ref

ª_ ref

where º and are strain-rate parameters in the respective

formulations, ª_ is the strain rate, and ª_ ref is the reference

strain rate associated with the reference value of undrained

shear strength. Experimental evidence shows that the strainrate dependence of soil strength tends to increase with

increasing strain rate (Lunne & Andersen, 2007). Therefore

caution is needed in using the above expressions (particularly the semi-logarithmic function) to adjust shear strength

over several orders of magnitude difference in strain rate.

Ideally, the reference shear strength should be obtained at a

reference strain rate, ª_ ref , that is relatively close (within two

or three orders of magnitude) to that relevant for the

application.

In the centrifuge tests considered here, the shear strength

was measured using a 5 mm diameter T-bar penetrating at

1 mm/s (i.e. 0.2 diameters per second) in conjunction with

the theoretical T-bar factor of 10.5 (Randolph & Houlsby,

1984). The T-bar factor is, in principle, correlated against

low-strain-rate tests, where the effects of the high strain rates

that occur during a penetrometer test are partly compensated

for by loss of strength of the soil due to cumulative strains

(Einav & Randolph, 2005; Zhou & Randolph, 2009).

During anchor penetration, the shear strain rate will vary

through the soil body, but it is reasonable to assume that at

any given location the operational strain rate may be

approximated by the normalised velocity, v/d. As discussed

in the following section, base (static) values of friction and

end-bearing parameters were back-analysed with reference to

static penetration tests of the anchor, which were conducted

at a penetration velocity of v ¼ 1 mm/s (so v/d ¼ 0.17 s1 ).

This normalised velocity may therefore be used as a reference value for assessing the shear strength for high penetration rates. Essentially, equation (6) may be replaced by

"

#

"

#

v=d

v=d

(7)

or Rf ¼

Rf ¼ 1 þ º log

ðv=d Þref

ðv=d Þref

where (v/d )ref ¼ 0.17 s1 :

Calibration

Equation (3) requires an assessment of the shear resistance terms Æ and Nc , in addition to selection of an appropriate drag coefficient. The adhesion factor, Æ, during

installation may be conveniently estimated as the inverse of

the soil sensitivity (Andersen et al., 2005). For kaolin clay

with a sensitivity St ¼ 2.5 (Watson et al., 2000) this would

give Æ ¼ 0.4, consistent with back-figured Æ values from

suction caisson installations in kaolin (e.g. Gaudin et al.,

2006; Chen & Randolph, 2007).

O’Loughlin et al. (2009) measured the penetration resistance at the top of an ellipsoidal-tipped anchor with no

flukes and L/d ¼ 12.5 during penetration at 1 mm/s, and

showed that analysis of the measured resistance using

Æ ¼ 0.4 yielded Nc ¼ 12. For consistency, Nc ¼ 12 is adopted

here for both the ellipsoidal- and hemispherical-tipped anchors. However, as the ellipsoidal tip is almost four times

the length of the hemispherical tip, the area over which

bearing resistance acts is limited to the projected area at a

tip length ¼ d/2 (i.e. the actual tip length of the hemispherical tip). The bearing capacity at the base and upper end of

the anchor flukes has been modelled as a deeply embedded

strip footing using Nc ¼ 7.5 (Skempton, 1951).

Adopted Cd values are in line with computational fluid

dynamics results reported by Øye (2000) and Richardson

(2008): Cd ¼ 0.63 for the ellipsoidal-tipped, four-fluke anchor A5; Cd ¼ 0.24 for the ellipsoidal-tipped, flukeless

anchors A1 to A4; and for hemispherical-tipped anchors A6

to A25, Cd ¼ 0.35 for L/d ¼ 1 (i.e. a sphere) reducing to

Cd ¼ 0.23 for L/d > 4.

The motion of the anchor and hence the magnitude of the

penetration resistant forces may be estimated from a finite

difference approximation of equation (3). The contributions

of these anchor resistance forces are plotted in Fig. 8 for

anchors A6, A10 and A17 (i.e. hemispherical-tipped anchors

with no flukes and L/d ¼ 1, 4 and 12; Figs 8(a) to 8(c)

respectively), and also for anchor A5, an ellipsoidal-tipped

anchor with four flukes and L/d ¼ 12.5 (Fig. 8(d)). To

facilitate comparison, the anchor impact velocity, undrained

shear strength gradient, strain rate parameter and anchor

density were kept constant for each simulation: vi ¼ 20 m/s,

k ¼ 1.0 kPa/m, ¼ 0.06 (power law) and anchor density ¼

7850 kg/m3 (such that the model anchor mass is 0.89 g,

4.88 g, 15.54 g and 19.25 g for anchors A6, A10, A17 and

A5 respectively). The comparison of the resistant forces for

each anchor in Fig. 8 leads to the following comments.

(a) Inertial drag is seen to be the dominant resistance over

shallow penetrations, as the velocity of the anchor is high,

and the resistance from the shear strength of the soil is

low. The relative contribution of inertial drag resistance

decreases as the anchor length and hence frictional

resistance increases: for example, inertial drag is

dominant over the initial 38% embedment for anchor

A6 (L/d ¼ 1), reducing to 14% for anchor A10 (L/d ¼ 4)

and 8% for anchor A17 (L/d ¼ 12).

(b) Despite the very low projected tip area compared with

wall area, end-bearing resistance contributes significantly

to the total resistance, even for high L/d ratios. For

hemispherical-tipped anchors with no flukes, end-bearing

resistance exceeds frictional resistance up to L/d ¼ 10,

despite the wall area being 36 times the projected tip

area. For anchor A5, with relatively large flukes,

frictional resistance exceeds bearing resistance once the

full width of the fluke is embedded, and by a factor of up

to 3.5 thereafter; this is due to the significantly greater

wall area afforded by the flukes, and also the reduced

bearing area assumed for the ellipsoidal tip.

(c) Strain-rate effects are seen to increase the frictional and

bearing resistance significantly; for the cases considered

here the increase is approximately twofold

(e.g.

:

Rf ¼ [(v=d)=(v=d)ref ] ¼ [(20=0:006)=0:17]0 06 ¼ 1:81)

over the bulk of the embedment.

(d ) Soil buoyancy increases with depth where no hole closure

is assumed (L/d . 2), and in all cases is approximately

half the strain-rate-enhanced bearing resistance. Where

hole closure is assumed (L/d , 2), soil buoyancy increases until the anchor fully penetrates the soil, and then

remains constant with depth. A number of analyses were

conducted in which hole closure was assumed (for all L/d

ratios) and reverse end bearing at the anchor padeye was

modelled for L/d . 2. The results indicate that the

reduction in soil buoyancy due to hole closure is

overcompensated (by between 13% and 23% of the total

PENETRATION OF DYNAMICALLY INSTALLED ANCHORS IN CLAY

0

0

Penetration resistance: N

2

3

4

1

5

6

0

0

2

4

915

Penetration resistance: N

6

8

10

12

14

16

Fd

Tip embedment: mm

Fd

20

A1: L/d ⫽ 1

Tip embedment: mm

10

20

30

Rf · Fbear

Fb

40

Fbear

50

0

5

10

30

35

40

0

Ffrict

Fb

Rf · Ffrict

Fbear

Rf · Fbear

(b)

0

10

20

Penetration resistance: N

30

40

50

60

70

80

Fd

Tip embedment: mm

Tip embedment: mm

100

50

A17: L/d ⫽ 12

100

150

Fd

Fb Fbear

Rf · Fbear

Rf · Ff rict

Ffrict

A5: L/d ⫽ 12·5

100

150

Fb

200

250

300

80

140

(a)

Penetration resistance: N

15

20

25

50

200

60

120

60

0

A10: L/d ⫽ 4

40

Rf · Fbear

Ffrict

250

(c)

resistance for all L/d . 2) by the introduction of reverse

end-bearing resistance at the anchor padeye. However,

this increase is not only a function of the anchor

geometry, but also varies with impact velocity and the

effective unit weight of the soil.

Rf · Ffrict

(d)

Fig. 8. Penetration resistance profiles for various anchor geometries: (a) A1, L/d

(four-fluke anchor)

1; (b) A10, L/d

4; (c) A17, L/d

12; (d) A5, L/d

12.5

Velocity: m/s

0

0

5

10

15

20

25

30

50

Anchor embedment: mm

Figure 9 compares velocity profiles of the anchor during

embedment in soil for anchors A1 and A4 with anchor drop

heights in the range 0–200 mm. The instrumentation used to

measure anchor impact velocity also gives an indication of

the anchor velocity profile over the first anchor length of

penetration (shown by the symbols in Fig. 9). Strain-rate

dependence has been quantified by back-calculating º and (for the logarithmic and power laws respectively) so that the

theoretical embedment depth matches the measured embedment depth for each test. The resulting theoretical velocity

profiles are compared with the measured profiles in Fig. 9,

where the agreement between measured and calculated velocity is reasonable, particularly for the tests with non-zero

impact velocity.

The theoretical velocity profiles in Fig. 9 can be considered representative of either the logarithmic or power rate

law, as there are no observable differences in the calculated

velocity profiles using either rate function. Both the calculated and measured profiles show the anchor velocity to

increase during shallow embedment. This observation is

most prominent for the test with zero impact velocity, where

the theoretical velocity increases from 0 m/s at the clay

surface to a maximum velocity of ,6.5 m/s at ,0.5 anchor

lengths. The net increase in velocity during shallow penetration is also seen to reduce (for a given anchor) as the impact

Fbear

100

β ⫽ 0·129

λ ⫽ 0·569

β ⫽ 0·110

λ ⫽ 0·421

β ⫽ 0·112

λ ⫽ 0·443

β ⫽ 0·136

λ ⫽ 0·648

150

200

β ⫽ 0·134

λ ⫽ 0·634

β ⫽ 0·131

λ ⫽ 0·601

250

Predicted, equation (3)

A4: m ⫽ 5·4 g, 0 mm drop height (drum)

A4: m ⫽ 5·4 g, 50 mm drop height (drum)

A4: m ⫽ 5·4 g, 200 mm drop height (drum)

A1: m ⫽ 14·8 g, 100 mm drop height (drum)

A1: m ⫽ 14·3 g, 150 mm drop height (drum)

A1: m ⫽ 14·3 g, 200 mm drop height (drum)

Fig. 9. Predicted and measured anchor velocity profiles

velocity increases. This is to be expected, as the closer the

impact velocities approach the anchor’s terminal velocity, the

less acceleration will occur within the soil. As soil strength

increases with depth, at some depth the inertial drag and

O’LOUGHLIN, RICHARDSON, RANDOLPH AND GAUDIN

916

shear resistance outweigh the submerged weight of the

anchor, and the anchor decelerates. The depth at which the

anchor begins to decelerate reduces with increasing impact

velocity, reflecting the increase in inertial drag and shear

resistance with velocity (or strain rate).

Figure 9 also shows that the strain-rate parameters increase with increasing impact velocity. This is made clearer

by Fig. 10, which plots back-figured º and as functions of

vav /deff (where vav is the average anchor velocity during

penetration). Back-figured values corresponding to tests on

anchors with an effective anchor density less than

,2000 kg/m3 (see Table 1) are not included in Fig. 10, as

back-analysis for these cases yielded much lower strain-rate

parameters (º , 0.2 and , 0.06). Although the reason for

this is not yet understood, equation (3) evidently overestimates the penetration resistance for near-buoyant objects

dynamically penetrating soil. Fig. 10 shows that the ranges

of º and are typically 0.2–1.0 and 0.06–0.17 respectively

as vav /d increases from 500 to 4250 s1 (vi ¼ 0 to ,30 m/s).

Values of º ¼ 0.2–1.0 imply 20–100% increase in soil

strength, and hence in penetration resistance per log cycle of

penetration velocity or strain rate. The lower bound of this

range is compatible with previous studies: for example,

º 0.2 determined from field and centrifuge T-bar tests in

Burswood clay (Chung et al., 2006), º ¼ 0.2 and 0.15 respectively for T-bar and ball field tests in Bothkennar clay

(Boylan et al., 2007), and º 0.15 inferred from mobilised

shear strength data for three piles in soft clay (Oslo, Gothenburg and Mexico City; Bjerrum, 1973). The lower bound

¼ 0.06 is in agreement with ¼ 0.06 determined from

ball centrifuge tests in kaolin clay (Lehane et al., 2009),

whereas the entire range is similar to the ¼ 0.05–0.1 range

reported by Biscontin & Pestana (2001) and Peuchen &

Mayne (2007) for shear vane tests in various clays.

The observed variation of º and suggests that, over

several orders of magnitude increase in strain rate, shear

strength increases more rapidly than can be fitted using

either the logarithmic or power law. Similar observations

have been made by Biscontin & Pestana (2001), Peuchen &

Mayne (2007) and Lunne & Andersen (2007).

An important point is that the strain rates (proportional to

v/d ) in the centrifuge tests are on average 200 times equivalent strain rates in the field, as the absolute velocities are

comparable, but the anchor diameter is scaled by 1:200. As

shown by Fig. 10, values of vav /deff in the centrifuge tests

are in the range 500–4250 s1 , compared with vav /

deff 20 s1 for a typical dynamically installed anchor in

the field (vav ¼ 20 m/s, deff ¼ 1 m). Hence appropriate

strain-rate parameters for use in the field are likely to fall at

the lower extreme of the range quoted above, and would

therefore be similar to parameters deduced from variablerate penetrometer tests. These have tended to give º values

in the range 0.15–0.2 (Low et al., 2008), or values of

0.06–0.08 (Lehane et al., 2009).

Application to full-scale tests

Evaluation of a deep ocean nuclear waste disposal option

in the 1980s included a number of field trials in which

various projectiles were dynamically embedded in the seabed

in a manner similar to that for dynamically installed anchors. The most successful and well-documented trials took

place in the Atlantic Ocean at Great Meteor East, which is

an area at the western extremity of the Madeira Abyssal

Plain (about 800 km west of the Canary Islands), in water

depths of approximately 5000 m (Freeman & Burdett, 1986).

An extensive geotechnical database has been established for

Great Meteor East (e.g. Freeman & Burdett, 1986; Freeman &

Schüttenhelm, 1990; Baudet & Ho, 2004; Brandes, 2011).

These data indicate that the seabed sediments consist of thick

turbidite layers of up to 5 m, alternating with thin (,10 cm)

layers of pelagic sediments. The sediments are very soft, with

natural moisture contents generally in excess of the liquid

limit, and unit weights typically about 14 kN/m3 : Undrained

0·20

0·15

β 0·10

0·05

0

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

3000

3500

4000

4500

5000

vav /deff: s⫺1

1·20

1·00

0·80

λ 0·60

0·40

0·20

0

0

500

1000

1500

2000

2500

vav /deff: s⫺1

Anchors A1–A4, L/d ⫽ 12·5, m ⫽ 5·4–14·8 g, 0 flukes

Anchors A5, L/d ⫽ 12·5, m ⫽ 9·6 g, 4 flukes

Anchors A6–A25, L/d ⫽ 1–14, m ⫽ 0·9–18·04 g, 0 flukes

Fig. 10. Back-analysed strain-rate parameters

PENETRATION OF DYNAMICALLY INSTALLED ANCHORS IN CLAY

shear strength determinations have been made using a combination of miniature shear vane and triaxial tests on gravity

cores up to 35 m in length. Freeman & Schüttenhelm (1990)

suggest that the triaxial shear strength data are best approximated by su ¼ 1.3 + 1.48z kPa over the available sampling

depth of 33 m. Freeman & Burdett (1986) suggest that the

most reliable undrained shear strength ratio su = v9 ¼ 0:375,

corresponding to an su gradient k ¼ 1.5 kPa/m. This is in

reasonable agreement with su = v9 0:31 and k ¼ 1.35 kPa/m

reported by Brandes (2011) over the upper 15 m. In view of

these studies, the undrained shear strength profile for the field

predictions has been approximated by su ¼ 1.5z kPa.

Trials referred to as the ‘Tyro 86 experiments’ (Freeman

et al., 1988), focused on a hollow steel projectile with length

3.56 m, diameter 0.356 m (i.e. L/d ¼ 10) and dry mass in

the range 1755–3210 kg. Velocity profiles during seabed

embedment are shown for the successful tests in Fig. 11, in

addition to corresponding predicted profiles obtained using

equation (3). Despite the high terminal velocities in the field

trials (up to 70 m/s) and the relatively low projectile diameter, v/d does not exceed 200 s1 , and therefore a typical

lower bound ¼ 0.07 has been adopted for the predictions

(average of ¼ 0.06–0.08 from variable-rate penetrometer

tests; Lehane et al., 2009). The field predictions make the

same assumptions as for the centrifuge tests, assuming no

hole closure behind the advancing penetrometer, adopting

Nc ¼ 12 (where the tip bearing area is limited to the

projected area at a tip length ¼ d/2) and Cd ¼ 0.24. Given

that the deposits are described as being of medium to high

sensitivity (Baudet & Ho, 2004), Æ was taken as 0.2,

consistent with St ¼ 5 for a medium-sensitivity deep-water

sediment (assuming Æ ¼ 1/St ).

The predictions in Fig. 11 are seen to be in good

agreement with the measured profiles, with final embedment depths that are consistently within 4% of the measurements. This is particularly encouraging, as measured

shear strength deviates from su ¼ 1.5z kPa between 15 and

30 m (Brandes, 2011), and the available shear strength data

extend only to 35 m. The most significant deviations from

the measured embedment are for tests 8605 and 8610.

However, the predictions are in excellent agreement with

the measured profile over the initial 45 m of embedment, at

which point the predicted and measured velocities deviate.

This suggests that at these test locations the strength of the

soil below 45 m is greater than the assumed shear strength

profile.

CONCLUSIONS

This paper considers published centrifuge data to explore

the penetration response of dynamically installed anchors in

normally consolidated kaolin clay. The main findings are

summarised as follows.

(a) Anchor embedment depths are in good agreement with

published field data, and are a function of the (effective)

mass, impact velocity, geometry and fluke arrangement of

the anchor. Anchor tip embedment increases with

increasing impact velocity and anchor mass, and anchors

of a given mass and diameter show decreasing embedment with increasing length. Total energy has been shown

to be a useful approach for comparing anchors with

markedly different geometries and mass, impacting the

soil at different impact velocities. The approach produces

a unique relationship between normalised total energy

and embedment depth ratio.

(b) The question of whether soil separation occurs during

dynamic penetration was examined by comparing the

embedment response of anchors with the same mass and

diameter but with different L/d ratios. The embedment of

the short (low L/d ) anchors was consistently higher than

that of the long (high L/d ) anchors, which suggests that

Velocity: m/s

0

0

10

20

30

40

50

Velocity: m/s

60

70

80

0

10

10

20

30

40

50

60

No. 8613

m ⫽ 1755 kg

No. 8601

m ⫽ 1870 kg

20

30

No. 8606

m ⫽ 2345 kg

40

No. 8608

m ⫽ 2330 kg

50

0

10

Embedment: m

Embedment: m

20

917

No. 8605

m ⫽ 3165 kg

30

40

No. 8604

m ⫽ 2300 kg

No. 8603

m ⫽ 2345 kg

50

No. 8610

m ⫽ 3130 kg

60

60

70

No. 8612

m ⫽ 3145 kg

70

Measured

Predicted

Fig. 11. Predicted and measured velocity profiles: free-fall penetrometer tests at Great Meteor East

70

80

O’LOUGHLIN, RICHARDSON, RANDOLPH AND GAUDIN

918

soil separation does not appear to occur (over the full

length of the anchor) for impact velocities lower than

20 m/s. However, there are also indications that water

entrainment plays a role in increasing the penetration,

reducing the effective contact stress along the anchor/soil

interface.

(c) The centrifuge data have been used to calibrate an anchor

embedment model based on strain-rate-dependent shearing resistance and fluid mechanics drag resistance.

Although the inclusion of drag resistance is seen to be

important for short anchors (low L/d ) and over shallow

penetrations, as L/d increases the contribution of drag

resistance becomes small relative to the dominating effect

of strain-rate-enhanced shear resistance, which was

modelled using both logarithmic and power functions.

The back-figured strain rate parameters º (logarithmic

function) and (power function) are seen to increase with

increasing impact velocity, and are in the ranges 0.2–1.0

and 0.06–0.17 respectively as the impact velocity

increases from 0 to ,30 m/s. The lower bounds of both

strain-rate parameters are consistent with results from

variable-rate penetration tests (e.g. Low et al., 2008;

Lehane et al., 2009). These lower-bound values are

considered more appropriate for field conditions, as the

strain rates in the centrifuge tests are on average 200

times equivalent strain rates in the field, since the

absolute velocities are comparable but the anchor

diameter is scaled by 1:200.

(d ) The anchor embedment model produced velocity profile

predictions that agree well with corresponding velocity

profiles from a series of full-scale free-fall penetrometer

tests, with predicted final embedment depths that are

within 4% of the measurements.

ACKNOWLEDGEMENTS

The work described in this paper was supported by the

Australian Research Council Linkage programme and Woodside Energy Limited. It forms part of the activities of the

Centre for Offshore Foundation Systems (COFS), currently

supported as a node of the Australian Research Council

Centre of Excellence for Geotechnical Science and Engineering, and by The Lloyd’s Register Educational Trust.

NOTATION

A

Ap

Cd

d

deff

Etotal

Fb

Fbear

Fd

Ffrict

g

k

L

Lpad

Ltip

m

m9

Nc

Rf

St

su

t

tf

v

vav

contact area

projected area

drag coefficient

diameter

effective diameter

total energy

buoyant weight of displaced soil

end-bearing resistance

inertial drag resistance

frictional resistance

Earth’s gravitational acceleration

undrained shear strength gradient with depth

length

length of anchor padeye

length of anchor tip

mass

effective mass submerged in soil

bearing capacity factor

shear strain rate function

sensitivity of soil

undrained shear strength

time

fluke thickness

velocity

average velocity during penetration

vi

Ws

wf

z

ze

Æ

ª_

ª_ ref

º

rs

v9

impact velocity

submerged weight

fluke width

depth

final tip embedment

adhesion factor

strain-rate parameter (power law)

strain rate

reference strain rate

strain-rate parameter (logarithmic law)

density of soil

vertical effective stress

REFERENCES

Andersen, K. H., Murff, J. D., Randolph, M. F., Cluckey, E. C.,

Erbrich, C. T., Jostad, H. P., Hansen, B., Aubeny, C., Sharma, P.

& Supachawarote, C. (2005). Suction anchors for deepwater

applications. Proc. Int. Symp. Frontiers in Offshore Geotechnics,

ISFOG05, Perth, 3–30.

Araujo, J. B., Machado, R. D. & Medeiros, C. J. (2004). High

holding power torpedo pile – results from the first long term

application. Proc. Int. Conf. Offshore Mech. Arctic Engng,

Vancouver, paper OMAE2004-51201.

Aubeny, C. P. & Shi, H. (2006). Interpretation of impact penetration

measurements in soft clays. J. Geotech. Geoenv. Engng ASCE

132, No. 6, 770–777.

Audibert, J. M. E., Movant, M. N., Won, J-Y. & Gilbert, R. B.

(2006). Torpedo piles: laboratory and field research. Proc. 16th

Int. Polar Offshore and Polar Engng Conf., San Francisco, CA,

462–468.

Baudet, B. A. & Ho, E. W. L. (2004). On the behaviour of deepocean sediments. Géotechnique 54, No. 9, 571–580, http://

dx.doi.org/10.1680/geot.2004.54.9.571.

Beard, R. M. (1981). A penetrometer for deep ocean seafloor

exploration. Proc. IEEE Oceans ’81, Boston, MA 13, 668–673.

Biscontin, G. & Pestana, J. M. (2001). Influence of peripheral

velocity on vane shear strength of an artificial clay. Geotech.

Test. J. ASTM 24, No. 4, 423–429.

Bjerrum, L. (1973). Problems of soil mechanics and construction

on soft clays: state-of-the-art report. Proc. 8th Int. Conf. Soil

Mech. Found. Engng, Moscow 3, 109–159.

Boylan, N., Long, M., Ward, D., Barwise, A. & Georgious, B.

(2007). Full-flow penetrometer testing in Bothkennar clay. Proc.

6th Int. Offshore Site Investigation and Geotechnics Conf.,

London, 177–186.

Brandão, F. E. N., Henriques, C. C. D., Araújo, J. B., Ferreira, O.

C. G. & Amaral, C. D. S. (2006). Albacora Leste field development: FPSO P-50 mooring system concept and installation.

Proc. Offshore Technol. Conf., Houston, TX, paper OTC 18243.

Brandes, H. G. (2011). Geotechnical characteristics of deep-sea

sediments from the North Atlantic and North Pacific oceans.

Ocean Engng 38, No. 7, 835–848.

Casagrande, A. & Wilson, S. D. (1951). Effect of rate of loading

on the strength of clays and shales at constant water content.

Géotechnique 2, No. 3, 251–263, http://dx.doi.org/10.1680/

geot.1951.2.3.251.

Chen, W. & Randolph, M. F. (2007). External radial stress changes

and axial capacity for suction caissons in soft clay. Géotechnique 57, No. 6, 499–511, http://dx.doi.org/10.1680/geot.2007.

57.6.499.

Chung, S. F., Randolph, M. F. & Schneider, J. A. (2006). Effect of

penetration rate on penetrometer resistance in clay. J. Geotech.

Geoenviron. Engng ASCE 132, No. 9, 1188–1196.

Einav, I. & Randolph, M. F. (2005). Combining upper bound and

strain path methods for evaluating penetration resistance. Int. J.

Numer. Methods Engng 63, No. 14, 1991–2016.

Freeman, T. J. & Burdett, J. R. F. (1986). Deep ocean model

penetrator experiments, Final report to Commission of European

Communities, Report No. EUR 10502. Luxembourg: Commission of the European Communities, Directorate-General Telecommunications, Information Industries and Innovation.

Freeman, T. J. & Schüttenhelm, R. T. E. (1990). A geotechnical

investigation of a deep ocean site. In Geotechnical engineering

of ocean waste disposal (eds K. R. Demars and R. C. Chaney),

PENETRATION OF DYNAMICALLY INSTALLED ANCHORS IN CLAY

ASTM Special Technical Publication 1087, pp. 255–275. West

Conshohocken, PA, USA: ASTM International.

Freeman, T. J., Murray, C. N. & Schuttenhelm, R. T. E. (1988). The

Tyro 86 penetrator experiments at Great Meteor East. Proc.

Oceanology ’88, Brighton 16, 217–226.

Gaudin, C., O’Loughlin, C. D., Randolph, M. F. & Lowmass, A.

(2006). Influence of the installation process on the performance

of suction embedded plate anchors. Géotechnique 56, No. 6,

381–391, http://dx.doi.org/10.1680/geot.2006.56.6.381.

Graham, J., Crooks, J. H. A. & Bell, A. L. (1983). Time effects on

the stress–strain behaviour of natural soft clays. Géotechnique

33, No. 3, 327–340, http://dx.doi.org/10.1680/geot.1983.33.

3.327.

Lehane, B. M., O’Loughlin, C. D., Gaudin, C. & Randolph, M. F.

(2009). Rate effects on penetrometer resistance in kaolin. Géotechnique 59, No. 1, 41–52, http://dx.doi.org/10.1680/geot.

2007.00072.

Levacher, D. (1985). Pénétromètre à chute libre: impact et pénétration dans des argiles reconstituées. Can. Geotech. J. 22, No. 1,

129–135.

Lieng, J. T., Tjelta, T. I. & Skaugset, K. (2010). Installation of two

prototype deep penetrating anchors at the Gjøa Field in the

North Sea. Proc. Offshore Technol. Conf., Houston, TX, paper

OTC 20758.

Low, H. E., Randolph, M. F., DeJong, J. T. & Yafrate, N. J. (2008).

Variable rate full-flow penetration tests in intact and remoulded

soil. Proc. 3rd Int. Conf. on Site Characterization, Taipei,

1087–1092.

Lunne, T. & Andersen, K. H. (2007). Soft clay shear strength

parameters for deepwater geotechnical design. Proc. 6th Int.

Offshore Site Investigation and Geotechnics Conf., London,

151–176.

Medeiros, C. J. (2001). Torpedo anchor for deep water. Proceedings

of the deepwater offshore technology conference, Rio de Janeiro.

Medeiros, C. J. (2002). Low cost anchor system for flexible risers

in deep waters. Proc. Offshore Technol. Conf., Houston, TX,

paper OTC 14151.

Murff, J. D. & Coyle, H. M. (1973). Low velocity penetration of kaolin

clay. J. Soil Mech. Found. Div. ASCE 99, No. SM5, 375–389.

O’Loughlin, C. D., Randolph, M. F. & Richardson, M. D. (2004).

Experimental and theoretical studies of deep penetrating

anchors. Proc. Offshore Technol. Conf., Houston, TX, paper

OTC 16841.

O’Loughlin, C. D., Randolph, M. F. & Richardson, M. D. (2009).

Centrifuge tests on dynamically installed anchors. Proc. 28th

Int. Conf. on Ocean, Offshore and Arctic Engng, Honolulu,

paper OMAE2009-80238.

Øye, I. (2000). Simulation of trajectories for a deep penetrating

View publication stats

919

anchor, Report No. 250:2000. Trondheim, Norway: CFD

Norway.

Peuchen, J. & Mayne, P. (2007). Rate effects in vane shear testing.

Proc. Int. Offshore Site Investigation and Geotechnics Conf.,

London, 187–194.

Poorooshasb, F. & James, R. G. (1989). Centrifuge modelling of

heat-generating waste disposal. Can. Geotech. J. 26, No. 4,

640–652.

Randolph, M. F. & Houlsby, G. T. (1984). The limiting pressure on

a circular pile loaded laterally in cohesive soil. Géotechnique

34, No. 4, 613–623, http://dx.doi.org/10.1680/geot.1984.34.

4.613.

Richardson, M. D. (2008). Dynamically installed anchors for floating offshore structures. PhD thesis, The University of Western

Australia, Crawley, Australia.

Richardson, M., O’Loughlin, C. D. & Randolph, M. F. (2006).

Drum centrifuge modelling of dynamically penetrating anchors.

Proc. 6th Int. Conf. on Physical Modelling in Geotechnics,

Hong Kong 1, 673–678.

Richardson, M. D., O’Loughlin, C. D., Randolph, M. F. & Gaudin,

C. (2009). Setup following installation of dynamic anchors in

normally consolidated clay. J. Geotech. Geoenviron. Engng

ASCE 135, No. 4, 487–496.

Sheahan, T. C., Ladd, C. C. & Germaine, J. T. (1996). Ratedependent undrained shear behavior of saturated clay. J. Geotech. Geoenviron. Engng ASCE 122, No. 2, 99–108.

Shelton, J. T. (2007). OMNI-Max anchor development and technology. Proc. Oceans 2007, Vancouver.

Skempton, A. W. (1951). The bearing capacity of clays. Proceedings of the building research congress, London, Vol. 1, pp.

180–189.

Tika, Th. E. & Hutchinson, J. N. (1999). Ring shear tests on soil

from the Vaiont landslide slip surface. Géotechnique 49, No. 1,

59–74, http://dx.doi.org/10.1680/geot.1999.49.1.59.

True, D. G. (1976). Undrained vertical penetration into ocean

bottom soils. PhD thesis, University of California, Berkeley, CA,

USA.

Watson, P. G., Suemasa, N. & Randolph, M. F. (2000). Evaluating

undrained shear strength using the vane shear apparatus. Proc.

10th Int. Offshore and Polar Engng Conf., Seattle, WA 2, 485–

493.

Zhou, H. & Randolph, M. F. (2009). Resistance of full-flow

penetrometers in rate-dependent and strain-softening clay. Géotechnique 59, No. 2, 79–86, http://dx.doi.org/10.1680/

geot.2007.00164.

Zimmerman, E. H., Smith, M. W. & Shelton, J. T. (2009). Efficient

gravity installed anchor for deepwater mooring. Proc. Offshore

Technol. Conf., Houston, TX, paper OTC 20117.