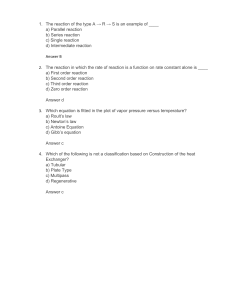

CHEE 3369 Transport Processes LP15. Heat Exchangers Department of Chemical and Biomolecular Engineering Heat Exchanger Design & Analysis Heat Exchanger Configurations Textbook reading 7th ed. Ch. 22 Sections 22.1, 2, 3, 4 2 Shell-and-tube heat exchanger Fig_22-3 Copyright © 2014 John Wiley & Sons, Inc. All rights reserved. Compact heat exchangers Fig_22-4 Copyright © 2014 John Wiley & Sons, Inc. All rights reserved. Two kinds of crossflow heat exchangers: Fluid A is unmixed. Fluid B can be mixed or unmixed Copyright © 2014 John Wiley & Sons, Inc. All rights reserved. Left: A very large shell-and-tube heat exchanger. Right: Shelland-tube heat exchanger baffles. A worker Copyright © 2014 John Wiley & Sons, Inc. All rights reserved. Double – Pipe Heat Exchanger Fig_22-1 Copyright © 2014 John Wiley & Sons, Inc. All rights reserved. Double – Pipe Heat Exchanger Fig_22-1 Copyright © 2014 John Wiley & Sons, Inc. All rights reserved. Temperature Profiles – Single Pass, Double –Pipe Heat Exchangers 9 Temperature profile in a condenser with subcooling Fig_22-6 Copyright © 2014 John Wiley & Sons, Inc. All rights reserved. Diagram of temperature vs. contact area for singlepass counterflow heat exchanger Fig_22-7 Copyright © 2014 John Wiley & Sons, Inc. All rights reserved. Heat Exchanger Design & Analysis: Single Pass Counterflow “1” Nomenclature: TH 1 T= TH 2 TH in H out , TC1 T= TC 2 TC out C in , TH2 TC2 TH1 z Thermal Energy Balances Across dA: = dQ U (TH − TC )dA “2” TC1 (1) dQ = m H c pH dTH (2) dQ = m C c pC dTC (3) “H” z dA=wdz “C” H m C m Flat plate heat exchanger 1 1 − d (TH − T= dQ From (2) and (3): C) m H c pH m C c pC 1 1 Using (1): d (TH − T= − U (TH − TC ) dA C) m H c pH m C c pC (4) 12 Heat Exchanger Design & Analysis: Single Pass Counterflow Integrating Eq. (4) assuming constant U z=L d (TH − TC ) 1 1 − U ∫ wdz ∫∆T (TH= − T m c m ) C H pH C c pC 0 z= 1 ∆T2 (5,6) ∆T2 1 1 − ln UA, = ∆T1 m H c pH m C c pC A= Lw Overall thermal energy balances: = Q m H c pH (TH 2 − T = m C c pC (TC 2 − TC1 ) H1) (7,8) 13 Using Eqs. (7) and (8) in Eq. (6): ∆T2 (TH 2 − TH 1 ) (TC 2 − TC1 ) − ln UA = = Q Q ∆T1 or = Q ∆T2 − ∆T1 ) ( = UA ln ( ∆T2 ∆T1 ) UA ( ∆T2 − ∆T1 ) Q UA ∆Tlm (9) ∆Tlm is called “logarithmic-mean temperature difference (LMTD).” Even though eq. (9) was derived for single-pass counterflow parallelplate exchangers, Eq. (9) is also applicable to single-pass tubular heat exchangers for both counterflow and parallel flow. In fact, it applies to all types of heat exchangers shown in fig. 22.5 of the textbook. 14 Heat Exchanger Design & Analysis (Cont.) Problem arises in using eq. (9) when ∆T2 ≈ ∆T1 Solution: If ∆T2 ∆T1 < 1.5 then the simple arithmetic mean is within 1% of the logarithmic mean temperature difference and = Q UA ∆TAM can be used, where 1 ∆TAM ≡ ( ∆T1 + ∆T2 ) 2 If U = a(1 + bT), it can be shown that: Q = A (U1∆T2 − U 2 ∆T1 ) U1∆T2 ln U ∆ T 2 1 15 Summary – Heat Exchanger Design & Analysis For an exchanger of any configuration with hot and cold streams and with the heat transfer coefficient and the heat capacities specified, the 8 variables are: TH in , TH out , TC in , TC out , Q , A, m H , m C , (1) or equivalently TH in , TH out , TC in , TC out , Q , A, CH , CC , (2) where CH ˆ m= CC m C cˆ pC H c pH , (3), (4) 16 Basic Heat Exchanger Equations Stream equations for any exchanger: Q= CH (TH in − TH out ) , Q = CC (TC out − TC in ) For any single pass, double-pipe heat exchanger, (counterflow or parallel flow), condenser, or evaporator: Q = UA∆Tlm = UA ∆T1 − ∆T2 ∆T − ∆T1 = UA 2 ∆T ∆T ln 1 ln 2 ∆T2 ∆T1 (5), (6) (7) For parallel flow heat exchanger ∆T= 1 (T H in − TC in ) , ∆T= 2 (T H out − TC out ) For counterflow heat exchanger ∆T= 1 (T H in − TC out ) , ∆T= 2 (T H out (7a,b) − TC in ) 17 Heat Exchanger Design & Analysis (Cont.) Structure of Simple Heat Exchangers (one pass each side) • Variables • Four end temperatures 4 • Two flow rates 2 • Area of heat exchanger 1 • Heat duty 1 Exchanger is completely described by these variables. Key to problem is determining what is given and what is unknown. • Equations • Energy balance – stream 1 • Energy balance – stream 2 • Performance equation = Q UA ( ∆T2 − ∆T1= ) ln ( ∆T2 ∆T1 ) 1 1 1 UA ∆Tlm No. degrees of freedom = No. variables – No. equations = 8 – 3 = 5 Exchanger is uniquely defined only if 5 of the variables (above) are specified. 18 Overall Heat Transfer Coefficient: Double Pipe Heat Exchanger From the lecture on conduction through multiple resistances, the total heat transfer rate between the two fluids is given by: Q= or = Q 2π L(T fi − T fo ) 1 Ro 1 1 + ln + hi Ri k p Ri ho Ro 2π Ri L(T fi − T fo ) = U i Ai ∆T 1 Ri Ro Ri + ln + h k R h R i p i o o 1 Ui ≡ 1 Ri Ro Ri + ln + h k R h R p i o o i Inside Fluid (1) Ri Ro Outside Fluid Ri = inside radius Ro = outside radius (2,3) (4) Based on the inside area of the inner tube Ai = 2π Ri L 19 Similarly, Inside Fluid Q = 2π R0 L(T fi − T fo ) = U o Ao ∆T , Outside R0 Ro Ro 1 + ln + Fluid hi Ri k p Ri ho U0 ≡ 1 Ri Ro Ri = inside radius Ro = outside radius R0 Ro Ro 1 + ln + hi Ri k p Ri ho Based on the outside area of the inner tube, A0 = 2π R0 L Ui and Uo are different from one another, but the product UA 20 is the same for the inside and outside radius. Fouling Resistance In practical applications, the performance of a heat exchanger diminishes with time because of the buildup of scale on the tube walls. The thermal resistance of the scale is given by 1 1 R = − S U f U0 where U0 is the overall heat transfer coefficient of the clean exchanger and Uf is that of the fouled exchanger. The overall coefficient can be monitored with time and the exchanger cleaned when the fouling resistance becomes sufficiently high. See Table 22.1 for fouling resistances and Table 22.2 for estimates of typical exchanger overall heat transfer coefficients. Time in service Scale Buildup 21 Design of More General Types of Heat Exchangers Use modified equation for Q: = Q UA ( F ∆Tlm ) where F is a correction factor which must be specified for each exchanger. F values for different shell-and-tube, as well as crossflow heat exchangers are given in the textbook. ∆Tlm has to be calculated on the basis of counterflow. The correction factor is represented in terms of two variables: Y and Z F = F (Y , Z ) Subscripts “t” or “s” mean “tube” or “shell” side, respectively Y≡ Tt , out − Tt , in Ts , in − Tt , in m t c p , t Ct Ts , in − Ts , out Z≡ == m s c p , s Cs Tt , out − Tt , in This approach is used to design a heat exchanger to perform a specific task of heating a stream from a known temperature to another known temperature, and cooling a different stream from a known temperature to 22 still another known temperature. Finding the correction factor F Z≡ Ts ,in − Ts ,out Tt ,out − Tt ,in TH 1 − TH 2 Tt ,out − Tt ,in TC 2 − TC1 = Y = = Ts ,in − Tt ,in TH 1 − TC1 TC 2 − TC1 23 The factor F is defined such that the LMTD should always be calculated for the equivalent counterflow heat exchanger with the same hot and cold temperatures. 24 For various types of exchangers for which correction factors are available: T ( Q = UAF H in − TC out ) − (TH out − TC in ) TH in − TC out ln TH out − TC in (8) (9) where F = F (Y , Z ) Tt ,out − Tt , in and Y ≡ , Ts , in − Tt , in Ts , in − Ts , out Ct Z ≡ = Cs Tt, out − Tt , in (10),(11) 25 Fig_22-9c Copyright © 2014 John Wiley & Sons, Inc. All rights reserved. The NTU method for heat exchanger design The LMTD design equation Q = UA∆Tlm for heat exchangers is useful, provided that the inlet and exit temperatures of both hot and cold streams are known. If only the inlet temperatures are known a trial-and-error procedure is necessary to find the exit temperatures. There is another, namely, the number of transfer units (NTU), method to find the exit temperatures without trial-and-error. However, this requires that we know (or we can determine) the heat exchanger effectiveness (ε). The effectiveness is defined as the actual heat transfer divided by the maximum possible heat transfer that would take place if infinite surface area were available for heat exchange. 27 Observe that the fluid with a smaller capacity coefficient (designated as Cmin), suffers a greater total temperature change. If Cc=Cmin (left figure), and if there is an infinite area available for energy transfer, the exit temperature of the cold fluid will equal the inlet temperature of the hot fluid. In such case, Fig_22-11 Copyright © 2014 John Wiley & Sons, Inc. All rights reserved. CH (TH in − TH out ) Cmax (TH in − TH out ) = CC (TC out − TC in ) max Cmin (TH in − TC in ) ε (12) If the hot fluid has the minimum heat capacity coefficient (right fig. of previous page) the effectiveness equation becomes: ε CC (TC out − TC in ) Cmax (TC out − TC in ) = CH (TH in − TH out ) max Cmin (TH in − TC in ) (13) Note that the above two equations have the same denominator and that the numerator is the actual heat transfer load, Q. 29 Use either eq. (12) or eq. (13) to get = Q ε Cmin (TH in − TC in ) (14) Thus, if ε and the hot and cold stream inlet temperatures are known, one can calculate the heat transfer rate. In practice, this situation arises when someone wants to use an existing heat exchanger (that was designed for a different process). The heat exchanger effectiveness ε has been calculated for a variety of heat exchanger geometries and designs and can be found in tables (see for example W. M. Kays and A. L. London, Compact Heat Exchangers 3rd edition McGraw-Hill, New York 1984) or in the form of graphs, see for example next page. 30 For example, for a single-pass counterflow heat exchanger, the effectiveness is given by (see textbook) Cmin )] Cmax C exp[− NTU (1 − min )] Cmax 1 − exp[− NTU (1 − ε= 1− Cmin Cmax UA where the number of transfer units NTU = Cmin 31 Heat exchanger effectiveness for a shell-and-tube configuration with one shell pass and two (or multiples of two) tube passes. Fig_22-12c Copyright © 2014 John Wiley & Sons, Inc. All rights reserved. Example 1 A shell-and-tube heat exchanger must be designed to heat 2.5 kg/s of water from 15 °C to 85 °C. The heating is to be accomplished by passing hot engine oil which is available at 160 °C, through the shell side of the heat exchanger. The oil is known to provide an average heat transport coefficient of h0=400 W/m2-K on the outside of the tubes. Ten tubes pass the water through the shell. Each tube is thin walled, of diameter D=25 mm and makes eight passes through the shell. If the oil leaves the exchanger at 100 °C, what is its flow rate? How long must the tubes be to accomplish the desired heating? At the average temperature of 130 °C, the oil heat capacity is 2350 J/kg-K. At the average temperature of 50 °C the properties of water are: Cp=4181 J/kg-K, µ=548 x 10-6 N-s/m2, k=0.643 W/m-K, Pr=3.56 Solution An overall energy balance on the water stream gives the heat load required of the exchanger Q mC C pC (TC out −= TC in ) 2.5 x 4181 x (85-15)=7.317 x 105 W Copyright © 2014 John Wiley & Sons, Inc. All rights reserved. Schematic for Example 1. Copyright © 2014 John Wiley & Sons, Inc. All rights reserved. This amount of heat comes by cooling of the oil. = Q mH C pH (TH in − TH out ) ⇒ 7.317 x 105 W= 5.19 kg/s. mH 2350 x (160-100) ⇒ mH = The required tube length is found using Now 1 U= 1/hi +1/h0 = Q UAF ∆Tlm Assumes no conduction resistance through the tube wall (thin wall, eq. 1 with Ri≈R0). hi is calculated using a heat transfer correlation for flow inside tubes. m1 = mC / N =2.5/10=0.25 kg/s per tube (note N=10 tubes). 4m1 4 x 0.25 = Re D = = 23, 234 ⇒ turbulent flow -6 π Dµ 3.14 x 0.025 x 548 x 10 = Use NuD = 0.023 ReD4/5 Pr 0.4 0.023 = x (23,234) 4/5 x (3.56)0.4 119 Copyright © 2014 John Wiley & Sons, Inc. All rights reserved. Finding the correction factor F Z≡ Ts ,in − Ts ,out Tt ,out − Tt ,in TH 1 − TH 2 Tt ,out − Tt ,in TC 2 − TC1 = Y = = Ts ,in − Tt ,in TH 1 − TC1 TC 2 − TC1 36 0.643 k 119 3060 W/m 2 -K = hi = NuD = 0.025 D 1 U= = 354 W/m 2 -K 1/400+1/3060 The correction factor F maybe obtained from ther fig. on slide # 16. Z TC 2 − TC1 85 − 15 TH 1 − TH 2 160 − 100 Y = = 0.48 = = 0.86= TH 1 − TC1 160 − 15 TC 2 − TC1 85 − 15 From the figure one reads F =0.87 (TH in − TC out ) − (TH out − TC in ) 75 − 85 = ΔTlm = = 80 C Now ln(75 / 85) (TH in − TC out ) ln T T − ( ) H out C in 37 The total area of the 10 pipes is A = N π DL Finally = L Q = UN π DF ∆Tlm 7.317 x 105 = 37.8 m 354 x 10 x 3.14 x 0.025 x 0.87 x 80 Observations: 1. With L/D=37.8/0.025=1516 the assumption of fully developed conditions throughout the tube is justified. 2. With 8 passes the length of the shell is approximately 37.8/8=4.7 m Assumptions made: 1. Negligible heat losses to the environment and negligible kinetic and potential energy changes. 2. Constant physical and transport properties. 3. Negligible thermal resistance of tube wall. 4. No fouling resistance. 5. Fully developed velocity and temperature profiles in the tubes. 38 Example 2 Hot exhaust gases enter a finned-tube , crossflow heat exchanger at 250 °C with a flow of 1.5 kg/s. The hot gaseous stream is used to heat pressurized water at a flow of 1 kg/s, which enters the heat exchanger at 35 °C. The gas side overall heat transfer coefficient is 100 W/m2-K and the corresponding surface area is 40 m2. What is the heat transfer load of the exchanger and what is the exit temperature of each of the two streams? Data: CpC=4197 J/kg-K, CpH=1000 J/kg-K Solution Use the NTU method since the exit temperatures are not known and you can’t calculate the LMTD. You can guess the exit temperature of one of the streams and use the LMTD method (and iterate, as necessary, i.e., trial-and-error), but the NTU approach is more convenient in this case. The heat capacity rates are: 39 = CH m= 1.5 x 1000=1500 W/K H C pH CC =mC C pC = 1.0 x 4197=4197 W/K Cmin 1500 Cmin =CH and = = 0.357 Cmax 4197 UA 100 x 40 = = = 2.67 The number of transfer units is NTU Cmin 1500 Use Fig.22.13(a) of textbook to get ε = 0.82 Then use eq. (14) to calculate the heat load 5 = Q ε Cmin (TH in − T= ) 0.82 x 1500 x (250-35)=2.65 x 10 W C in The exit temperatures are then easily calculated using 5 Q = CH (TH in − TH out ) ⇒ 2.65 x 10= 1500 (250-TH out ) ⇒ TH out= 73.3 °C = Q CC (TC out − TC in ) ⇒ 2.65 x = 105 4197 (TC out − 35) ⇒ T= 98.1 °C C out 40 Heat exchanger effectiveness for cross flow with both fluids unmixed Fig_22-13a Copyright © 2014 John Wiley & Sons, Inc. All rights reserved.