EPE 2009, Barcelona

Keynote Speech

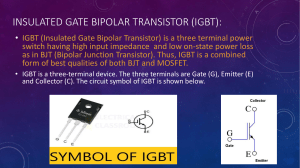

Advanced IGBT technologies for HF operation

Gourab Majumdar

Mitsubishi Electric Corporation

Contents:

1) Power module evolution and application

2) Resonant power conversion of IGBT modules

3) Future trends of Power Module technologies

M-090630-01

1

Power module applications

M-090630-01

2

Evolution

Evolution of

of Power

Power Module

Module

Simplifying User’s

assembly work

Discrete Power

Maximizing

IGBT’s inherent ability

Improving system’s

performance

IGBT Module

Drive supply and

system level functions

(micro-computer)

Power Chips

(IGBT, Diode)

IPM

Integrated

Drive/Protection

Functions

(HVIC, ASIC)

Integrated power circuit

with appropriate isolation

M-090630-01

Integrated self intelligence

(driving, protection and

diagnostic)

Integrated

system-like

solution

Integrated system level

intelligence (protection,

control and status/data

communication )

3

Application

Application of

of Power

Power Devices

Devices

Heavy PE Systems

Traction PE

Output Capacity of PE System (VA)

100M

New Energy

Renewable Energy

10M

Power Transmission

Industrial Equipment

Power Supplies

Medical Equipment

Si

GTO

GCT

1M

Large Drive

Traction

IPM

IGBT Module

10OK

Automotive

Inverter

HF Power Supply

Thyristor

10K

Bipolar

Transistor

Module

1K

PE in Automotive

Discrete

IGBT

Consumer

Electronics

Power Supply

Communication

100

MOSFET

Triac

10

10

100

1K

10K

10OK

Operation Frequency (Hz)

M-090630-01

1M

4

Power device performance improvement

For hard-switched inverter applications

‘80

‘85

High hfe

Bipolar Tr

‘90

1st Gen

’95

3rd Gen

2nd Gen

‘00

4th Gen

Power losses

Operational

power loss in

inverter circuit

Transistor

turn-off loss

‘05

‘08

5th Gen

6th Gen

Drastic reduction

100% of power losses

Transistor

on-state loss

Transistor

turn-on loss

1st Gen.

Bipolar

M-090630-01

3rd Gen.

Planar IGBT

5th Gen.

6th Gen.

Trench IGBT、CSTBTTM

5

Resonant power conversion application

of High Frequency IGBT Modules

M-090630-01

6

Basic resonant application

(1) Circuit topology: Current resonant inverter

AC/DC

Converter

Full Bridge

Inverter

Primary Secondary

Load

Load

C

L

Rectification

M-090630-01

7

Power Conversion for Welding

Basic circuit topology

P side

N side

Current pulse train through IGBT

M-090630-01

8

Power conversion for Medical equipment

(Application : High Voltage source for X-ray, CT etc.)

Current waveforms

Basic circuit topology

+

P side IGBT

N side IGBT

P side IGBT

-

+

-

N side IGBT

・ Current resonant circuit

・ Output power is controlled by changing switching

sequence of each IGBT

M-090630-01

9

Basic resonant application

(2) Operation modes and power loss factors

Welding

Welding

Current

Current

resonant

resonant

inverter

inverter

Mode

ModeAA

gate

P side

N side

>>Without

Collector P side

Withoutturn-on

turn-onloss

loss

>>With

current N side

Withturn-off

turn-offloss

loss

>>Without

WithoutFWD

FWDrecovery

recoveryloss

loss

Medical

Medical

Mode

Mode BB

>>With

Withturn-on

turn-onloss

loss

>>Without

Withoutturn-off

turn-offloss

loss

>>With

WithFwd

Fwdrecovery

recoveryloss

loss

M-090630-01

gate

P side

N side

Collector P side

current N side

10

Basic resonant application

(3) Closer look at IGBT/FWD waveforms

FWD IGBT

IGBT

FWD

FWD

FWD

recovery

IGBT turn-off

Current (i)

Current (i)

Voltage (v)

Voltage (v)

(a)

(c)

i x v (IGBT)

IGBT

(e)

(a)

i x v (IGBT)

(b)

i x v (FWD)

i x v (FWD)

Operation Mode A

Welding

Welding

(b)

Operation Mode B

(d)

Medical

Medical

Power loss components:

M-090630-01

(a) IGBT on-state loss (b) FWD on-state loss (c) IGBT turn-off loss

(d) FWD reverse recovery loss (e) IGBT forward recovery loss

11

Basic resonant application

(3) IGBT/FWD waveforms and loss factors (Mode A)

IGBT switching waveforms related to power dissipation

M-090630-01

12

Basic resonant application

(3) IGBT/FWD waveforms and loss factors (Mode B)

GATE (P-side)

GATE (N-side)

IGBT turn-on

Vce (P-side IGBT)

DIODE recovery

Ic (P-side IGBT)

P1

P2

P3

P4

P1: IGBT forward recovery loss

P2: IGBT on-state loss

P3: FWD on-state loss

Power dissipation

= P1+P2+P3+P4

P4: FWD reverse recovery loss

M-090630-01

13

Basic resonant application

(4) Distribution of different device operating losses

(c) IGBT turn-off loss

(b) FWD steady-state loss

(a) IGBT steady-state loss

Operating

power loss

発生損失

Operating

power

loss

発生損

失

(typical @ 50kHz switching)

(e) Etfr: IGBT forward recovery loss

(e) Err: FWD forward

recovery loss

(b) FWD steady-state loss

(a) IGBT steady-state loss

Mode A Operation

Mode B Operation

Welding

Welding

Medical

Medical

M-090630-01

14

Basic resonant application

(4) Higher frequency trend

# Free Resonance

# Mode B

# Mode A

・IGBT turn-OFF

Low Freq.

(20~40kHz)

・IGBT turn-ON

・Recovery

Diode recovery

only

High Freq.

(40~80kHz)

M-090630-01

*Welding Appl. A

Added

Transistor

recovery

*Med. Appl. A

*Med. Appl. B

*Med. Appl. C

15

Basic resonant application

(5) Recovery losses of IGBT & FWD

Recovery losses (@resonance) = Edrr + Etfr

FWD Reverse Recovery (Edrr)

Typical case waveforms

IGBT Forward

Recovery (25uC)

FWD Reverse

Recovery (17uC)

6mJ

@hard switching

13mJ

IGBT Forward Recovery (Etfr)

Etfr

7mJ

Edrr

3us

3us

dvdt

@dvdt delay circuit

@1200V/150A IGBT operating at 150A/125degC

M-090630-01

16

State-of-the-art

High frequency IGBT Module series

5th Gen power chip

technology

(CSTBT/FWD)

Internal design of an

NFM series package

Low package inductance

High frequency IGBTs of NFM series using 5th Gen CSTBT technology

are optimized to provide the highest level of performance in current

resonant HF applications using 10-60kHz operating frequency.

M-090630-01

17

Frequency characteristics of state-of-the-art

IGBT modules

Total power loss based comparison (IGBT+DIODE)

1200V/150A Duals

Mode A

Welding

Welding

1000

Mode B

Switching cycle

Medical

Medical

TTL(A)

1000

100

TTL(B)

NFH

NFM

Comp A

NF

Power Loss [W]

NFH

NFM

Comp A

NF

Power Loss [W]

Switching cycle

100

1

10

frequency [kHz]

NF

M-090630-01

NFM

100

NFH

1

10

frequency [kHz]

NF

NFM

In the 10 to 60kHz range NFM series using 5th Gen CSTBT/FWD

technology exhibit the lowest power loss performance

18

100

Future Trends of

Power Module Technologies

M-090630-01

19

IGBT

IGBT FOM

FOM Improvement

Improvement

FOM ratio [referenced to 1st gen.]

14

1200V IGBT

CSTBT structure

Thin wafer process

12

4th gen.

10

6th gen.

5th gen.

(with RTC)

Trench structure

8

6

4

Figure Of Merit (FOM) = Jc / {v

{vce(sat)

ce(sat) × eoff}

Fine pattern

process

2

0

1985

3rd gen.

2nd gen.

1st gen.

1990

1995

where,

Jc = device’s rated current density. [A/㎝2 ]

vce(sat) = saturation voltage drop at rated current

density conduction with Tj at 400K. [V]

eoff = turn-off switching energy per pulse of

operation at rated current density and

Tj at 400K. [mj/pulse/A]

2000

2005

2010

Year

M-090630-01

20

Advancement

Advancement of

of CSTBT

CSTBT device

device structure

structure

1200V design

5th Gen CSTBTTM

5th Gen CSTBTTM (Ⅱ)

6th Gen CSTBTTM

Emitter electrode

N emitter

High Tj capability

P base

Dummy trench

Trench gate

N+ carrier storing layer

p層

nE層

CS層

Poly-Si

N- drift layer

N+ buffer layer

P+ thin collector

Thickness = 170 um

First CSTBTTM concept

M-090630-01

n-層

Thickness = 130 um

Optimized

vertical thickness

ゲート

Narrower cell pitch for

higher cell density

Retro-graded doping for

optimizing CS layer

21

th

Characteristics

of

6

Characteristics of 6th Gen

Gen IGBT

IGBT chip

chip

VCE(sat) vs. Eoff Trade-off Improvement

25

( 150A/1200V)

Mitsubishi

6th Gen

Eoff [mJ/pulse]

20

5th Gen

15

10

0.35V

5

Tj = 125˚C

IC = 150A

0

1.0

1.5

2.0

2.5

3.0

VCE(sat) [V]

M-090630-01

22

th

Characteristics

of

6

Characteristics of 6th Gen

Gen FW

FW Diode

Diode Chip

Chip

VF vs. Qrr Trade-off Improvement

5th Gen

6th Gen

Anode

45

P+ anode layer

N- drift layer

40

Qrr [μC/pulse]

35

≒120um

≒ 250um

30

N+ cathode

layer

25

Thin LPT structure

5th Gen

20

Cathode

6th

15

Gen

10

Trade-off improvement by employing thin- LPT

vertical profile concept

5

0

1

1.2

1.4

1.6

1.8

2

2.2

2.4

2.6

2.8

3

VF [V]

M-090630-01

23

66thth Gen

Gen IGBT

IGBT Module

Module series

series using

using new

new chip

chip technologies

technologies

1.20

FOM of IGBT (1200V)

better 1.40

FOM of FWD (1200V)

1.33

1.31

30% up

1.00

1.00

0.80

5th

6th

generation generation

FOM = JC(sat) / (vCE(sat) x eOFF)

The relative FOM

[to conventional diode]

The relative FOM

[to 5th generation IGBT]

better 1.40

1.20

30% up

1.00

1.00

0.80

conventinal

diode

new diode

FOM = JF(sat) / (vF x erec)

Evolvement of advanced IGBT Modules

5th Gen NFA series Æ 6th Gen

5th Gen Nx series Æ 6th Gen

Superior performance

(New Gen chip technology)

☆ Lower loss, higher operational Tj

☆ Lower EMII

MPD Series Æ New MPDs

M-090630-01

☆ Retaining packaging compatibility

☆ Line up extended higher current range

by structural advancement

24

Evolvement

Evolvement of

of Power

Power Module

Module Technologies

Technologies

Power chip technologies

Æ5th Gen IGBT/FWD Æ6th Gen IGBT/FWD ÆNext Gen Devices

600~6500V

600~6500V

Improving FOM/ Higher Tj/ Improving ruggedness

Integrating peripheral functions

Advancement of HVIC and LV-ASIC

Refining process (0.8um Æ 0.5um Æ 0.2 um), use of SOI technology

Integrating memory function (ROM, Flash)

New trimming/sensing technologies Æ Higher functionality

Smarter, robust and standardize housings

Advancing transfer-molded and case-type packaging

solutions for higher power density and higher reliability

Solder-less terminal Better thermal conductivity

Higher integration level

Higher operating temperature

Newer bonding technologies

M-090630-01

25

Thank you for your kind attention !

M-090630-01

26