Chapter 1 Quality Control in the Modern Business

Environment

1.1 The Meaning of Quality and Quality

Improvement

" SpeciÞcations

◦For manufactured product, the speciÞcations

are designed measurements for quality

characteristics of components and

subassemblies that make up he product, as well

as the designed value for quality characteristics

in Þnal products

◦Lower speciÞcation limit (LSL): smallest

allowable value for a quality characteristic

◦Upper speciÞcation limit (USL): largest allowable

value for a quality characteristic

◦Target/ nominal value: a value of a measurement

that corresponds to the desired value for that

quality characteristic

" Defective or nonconforming product/ defect or

nonconformity

◦Nonconforming products are those that fail to

meet one or more of their speciÞcations

◦A speciÞc type of failure is called a

nonconformity

◦A nonconforming product is considered

defective if it has one or more defects

◦Defects are nonconformities that are serious

enough to signiÞcantly aûect the safe or

eûective use of products

1.1.1 Eight Dimensions of Quality

◦Performance (Will the product do the intended

job?)

◦Reliability (How often does the product fail?)

◦Durability (How long does the product last?)

◦Serviceability (How easy is it to repair the

product?)

◦Aesthetics (What does the product look like?)

◦Features (What does the product look like?)

◦Perceived Quality (What does the product look

like?)

◦Conformance in Standards (What does the

product look like?)

" DeÞnition of Quality

◦Traditional deÞnition: Þtness for use

# Two general aspects:

" Quality of design: variations in grades

or levels of quality are intentional

" Quality of conformance: how well

product conforms to speciÞcations

required by the design

◦Modern deÞnition: Quality is inversely proportional

1.3 Statistical Methods for Quality Control and

to variability in the important characteristics of a

Improvement

product (implies: ³variability, ±quality)

" Fig1.1 warranty costs

quality; Fig1.2

distribution

variability

" Japanese-produced transmissions having much

lower costs (Japan: higher quality)

" US: ~75% width of speciÞcations; Japan: ~25%

width of speciÞcations (Japan: lower variability)

" Japan: Less variability in the important

characteristics

lower costs (better quality)

" US: higher variability, lower cost (lower quality)

³variability, ³costs (±quality)

" (Modern) deÞnition of quality improvement: reduction

of variability in processes and products

◦Equivalent deÞnition: elimination of waste

1.1.2 Quality Engineering Terminology

" Quality characteristics: parameters

" Critical-to-quality (CTQ) characteristics:

◦Physical: length, weight, voltage, viscosity

◦Sensory: taste, appearance, color

◦Time orientation: reliability, durability,

serviceability

" Variability Ð statistical terms: classify data on quality

characteristics as either attributes or variable data

◦Variable data: continuous measurements (ex.

Length, voltage, or viscosity)

◦Attribute data: discrete data (often taking form of

counts)

" Fig 1.3: a process as a system with a set of inputs and

an output

" In a manufacturing process, controllable input factors

x1, x2, É, xp are process variables such as

temperature, pressures, and feed rates; the input

factors z1, z2, É, zq are uncontrollable (or diûcult to

control inputs such as environmental factors or

properties of raw materials provided by an external

supplier

" The production process transforms the input raw

materials, component parts, and subassemblies into a

Þnished product that has several quality

characteristics

" The output variable y is quality characteristic Ð that is,

a measure of process and product quality

" Statistical and engineering technology useful in quality

improvement. SpeciÞcally three major areas:

◦Statistical process control

◦Design of experiments

◦Acceptance sampling

" Statistical process control (SPC):

◦Control chart: one of the primary techniques of

SPC

◦Useful in monitoring processes, reducing

variability through elimination of assignable

◦Plots averages of measurements of a quality

characteristic in sample taken from process vs.

time (or sample number)

# Upper control limit (UCL)

# Center line (CL)

# Lower control limit (LCL)

◦Center line: represents where this process

characteristic should fall if there are no unusual

sources of variability present

" Designed experiment:

◦Extremely helpful in discovering the key variables

inßuencing the quality characteristics of interest

in the process

◦An approach to systematically varying the

controllable input factors in the process and

determining the eûect these factors have on the

output product parameters

◦Invaluable in reducing the variability in the quality

characteristics and in determining the levels of

the controllable variables that optimize process

performance

◦Factorial design: One major type of designed

experiment

# factors are varied together in such a way

that all possible combinations of factor

levels are tested

◦Fig 1.5a: two factors, each two levels, low and

high four possible test combinations

◦Fig 1.5b: three factors, each two levels, low

and high

eight possible test combinations

# Eg. d measure x1 from low to high

increase average level of process

output/ shift oû target (T); e when x2

and x3 high levels process variability

seem to be substantially reduced

" Acceptance Sampling

◦DeÞnition: inspection and classiÞcation of a

sample of units selected at random from a

larger batch or lot and the ultimate decision

about disposition of the lot, usually occurs at

two points: incoming raw materials or

components, or Þnal production

◦Closely connected with inspection and testing

of product

◦One of the earliest aspects of quality control

◦Outgoing inspection & incoming inspection

◦Fig 1.6a: outgoing inspection

# Inspection operation is performed

immediately following production, before the

product is shipped to the customer

◦Fig 1.6b: incoming inspection

# A situation in which lots of batches of

products are sampled as they are received

from the supplier

◦Fig 1.6c: disposition of lots

# Sampled lots may either be accepted or

rejected

# If accepted: ship to customers

# If rejected:

" scrapped/recycled

" rework

" replaced with good units rectifying

inspection

1.4 Management Aspects of Quality Improvement

" Six sigma: eûective quality management system

" Logic of six sigma (textbook page 28-32)

" Main idea: reduce variability (Ã: standard deviation) in

critical-to-quality (CTQ) variables to level at which

failure or defects are extremely unlikely

" Recall: CTQ variables for a product are parameters/

elements that jointly describe what users/consumers

think of as quality

◦Smallest/largest value for CTQ variables: lower/

upper speciÞcation limits (LSL/USL)

" Formal description: reduce à so that LSL/USL are at

least 6Ã from the mean

◦Fig 1.12a: shows a normal probability distribution as

a model for a quality characteristic with speciÞcation

limits at three standard deviation (Ã) on either side of

mean.

◦The probability of producing a product within these

speciÞcations is 0.9973, 2700 parts per million

(ppm) defective

# Òthree sigma quality performanceÓ

If a product consists of 100 independent

components, then the probability that any

speciÞc unit of product is non-defective is

(0.9973)^100 = 0.7631

# 23.7% products defective Ð not acceptable

" The Motorola Six Sigma concept is

to reduce the variability in the

process so that the speciÞcation

limits are at least six standard

deviations from the mean.

◦The probability of producing a

component within L/USL is

0.999999998 Ð one

component

◦Probability that any speciÞc

unit of product is nondefective

is (0.999999998)^100 or 0.2

ppm (100 independent

components in a product)

◦The process mean was still

subject to disturbances that

could cause it to shift by as

much as 1.5 standard

deviations oû target

◦Under this scenario, a Six

Sigma process would produce

about 3.4 ppm defective

" Why ÒQuality ImprovementÓ is important: A simple

example

" A visit of a fast-food restaurant: Hamburger (bun,

meat, special sauce, cheese, pickle, onion, lettuce,

and tomato), fries, and a soft drink

# This product has ten components

◦Is 99% good quality satisfactory?

◦If we assume that all ten components are

independent, the probability of a good meal is:

P{Single meal good} = (0.99)^10 = 0.9044

◦Suppose family of 4, once a month:

# P{All meals good} = (0.9044)^4 = 0.6690

# P{All visits during the year good} =

(0.6690)^12 = 0.0080

# Unacceptable!

◦What if 99.9% good quality? Is it satisfactory?

# P{Single meal good} = (0.999)^10 = 0.9900

# P{All meals good} = (0.9900)^4 = 0.9607

# P{All visits during the year good} =

(0.9607)^12 = 0.6186

Chapter 2 The DMAIC Process

2.1 Overview of DMAIC

" DMAIC is a structured problem-solving procedure

widely used in quality and process improvement.

◦Consisting of the following steps:

# DeÞne

# Measure

# Analyze

# Improve

# Control

◦It is usually associated with six sigma, but I can

be used with any business or process

improvement eûort

" Tollgates:

◦Tollgates between each of major steps

◦Project is reviewed to ensure that this is on

track, evaluate whether team can successfully

complete project on schedule

◦Tollgates also present an opportunity to

provide guidance regarding the use of speciÞc

technical tools and other information about the

problem

◦Tollgates are critical to the overall problemsolving process; It is important that these

reviews be conducted very soon after the team

completes each step.

" Projects:

◦Essential part of DMAIC (quality and process

improvement)

◦Breakthrough opportunity

◦Financial systems integration

◦Value opportunity of a project must be very

clear

◦Project selection

# Completed within a reasonable time

frame

# Real impact on key business metrics

# Understand interrelationships and

develop appropriate performance

measures

" What should be considered when evaluating

proposed project?

◦Suppose a company is operating at the 4Ã

level (6210 ppm defective, assuming the 1.5Ã

shift in the mean that is customary with Six

Sigma applications)

◦Objective: achieve the 6Ã performance level

(3.4 ppm)

◦Suppose that the criterion is a 25% annual

improvement in quality level.

◦Then to reach the Six Sigma performance

level, it will take x years, where x is the

solution to this: 3.4=6210(1-0.25)^x x is

about 26 years

# Not going to work!

◦Annual improvement

# 50%

x=11 years

# 75%

x=5 years

2.2 The DeÞne Step

2.3 The Measure Step

" Objective:

" Purpose: evaluate and determine present process state

◦identify project opportunity

(evaluate and understand the current state of process)

◦verify or validate it represents legitimate

◦Identify key process input variables (KPIV) and

◦must be important to customers (voice of the

key process output variables (KPOV)

customer) and important to the business

◦Data: from historical records; from sampling; from

" project charter: a short document; a description of

observational studies

project and it scope & others

◦Histograms, box plots, scatter diagrams, stem◦a description of the project and its scope, the start

leaf diagrams

and the anticipated completion dates, an initial

◦In transaction and service business, measurement

description of both primary and secondary metrics

system

that will be used to measure success and how

# the capability of the measurement system

those metrics align with business unit and

should be evaluated. (capacity/uniformity

corporate goals, the potential beneÞts to the

±, ó)

customer, the potential Þnancial beneÞts to the

" The Measure Tollgate

organization, milestones that should be

◦Comprehensive process ßow chart or value

accomplished during the project, the team

stream map

members and their roles, and any additional

◦KPIVs and KPOVs

resources that are likely to be needed to complete

◦Measurement system capability documented

the project.

◦Assumption noted

◦Respond to requests

2.4 The Analyze Step

" Graphic aids:

◦process map and ßow charts

◦value stream maps

◦SIPOC diagram (a high level map of process)

# Suppliers

# Input

# Process

# Output

# Customer

" The DeÞne Tollgate

◦Symptoms (focus) not on possible

causes or solutions

◦Stakeholders

◦Value opportunity

◦Scope neither too small nor too large

◦SIPOC diagram

◦Obvious barriers or obstacles

◦Action plan

" Purpose: use data from the Measure step to determine

Òcause-and-eûectÓ relationships in the process

" Sources of variability:

◦Common cause: embedded in system or process

itself

◦Assignable cause: arise from an external source

" Tools:

◦control charts

# separate common cause variability from

assignable cause variability

◦hypothesis testing and conÞdence intervals

# hypothesis testing: determine if diûerent

conditions of operations process statistically

signiÞcantly diûerent results

# CIs: provide information about the accuracy

with which parameters of interest have been

estimated

◦regression models

# allows models relating outcome (eûect)

variables of interest to independent input

(cause) variables to be built

" The Analyze Tollgate

◦Opportunity targeted in the Improve step

◦Data and analysis

◦Other opportunities

◦Track

2.5 The Improve Step

" Tools:

◦Process redesign to improve work ßow and to

reduce bottlenecks

◦Mistake-prooÞng

◦Statistical tools: particularly designed

experiments are probably most important

statistical tools in the Improve step

# Physical process or a computer model of

process

" Pilot test: a form of conformation experiment

◦Evaluates and documents solution and conÞrms

solution attains the project goals

◦Iterative activity

" The Improve tollgate

◦How problem solution was obtained

◦Alternative solutions

◦Pilot test

◦Plans to implement pilot test results

◦Any risks of implementing solution

2.6 The Control Step

" Objectives:

◦Complete all remaining work on project

◦Provide the process owner with a process control

plan

" The process owner should be provided with before and

after data on key process metrics, operations and

training documents, and updated current process

maps.

" The process control plan should be a system for

monitoring the solution that has been implemented,

including methods and metrics for periodic auditing.

" Control charts are an important statistical tool used in

the Control step of DMAIC; many process control plans

involve control charts on critical process metrics.

◦Control charts: an important statistical tool in

control step

" Transition plan: new process weight include a validation

step (The transition plan for the process owner should

include a validation check several months after project

completion.)

" The Control tollgate

◦Data (before and after) available

◦Process control plan & control charts

◦Documentation

◦Summary of lessons

◦Opportunities not pursued in project

◦Opportunities use results of project in other parts

of business

Chapter 3 Modeling Process Quality

3.1 Describing Variation

" Stem-and-Leaf Plot

◦Data: x1, x2, É, xn; each number xi consist of at

least two digits, divide x1 into two parts

# A stem: one or more leading digits

# A leaf: two remaining digits

◦For example, data from 10 to 100, number 76

divide value 76 into stem 7 and leaf 6

◦Percentiles of data:

# the 100 kth percentile is a value such that

at least 100 k% of the data values are at or

below this value and at least 100 (1 2 k)%

of the data values are at or above this

value

# The Þftieth percentile of the data distribution is

called the sample median x-bar

" First, sort the observations in ascending

order (or rank the data from smallest

observation to largest observation).

" Then the median will be the observation in

rank position [(n 2 1)/2 + 1] on this list. If n is

even, the median is the average of the (n/2)st

and (n/2 + 1)st ranked observations.

◦Eg. n =11 x6; n=40 average of x20

and x21

# The tenth percentile is the observation with rank

(0.1)(40) + 0.5 = 4.5 (halfway between the fourth

and Þfth observations)

# The Þrst quartile is the observation with rank (0.25)

(40) + 0.5 = 10.5 (halfway between the tenth and

eleventh observation)

# the third quartile is the observation with rank (0.75)

(40) + 0.5 = 30.5 (halfway between the thirtieth and

thirty-Þrst observation)

# the interquartile range: IQR = Q3 2 Q1

" occasionally used as a measure of variability

Procedure:

" plot of data in time order

" take time order of observations into account

" important factors to variability in quality improvement

" plot data value versus time

" time is an important source of variability in this process

" processing cycle time for Þrst 20 claims is substantially

longer than processing cycle time for second 20 claims

" Histogram

◦A more compact summary of data

◦To construct a histogram for continuous data:

# Divide range of data into intervals called bins

# Sort data into bins, count number of obs. in

each bin

# Use horizontal axis to represent

measurement scale vertical scale to

represent counts or frequency or relative

frequencies (frequencies in each bin divided

by total number of observations (n)

◦Example 3.2 Metal Thickness in silicon wafers

◦Gives a visual impression of shape of the

distribution of measurement and inherent

variability in data

◦Shows reasonably symmetric or bell-shaped

distribution of metal thickness data

◦Histogram relatively sensitive to choice of number

and width of bin for small data sets

◦Histogram suited for larger data sets, 75 to 100 or

more observations

◦Box plot Ð hole diameter distribution is not exactly

symmetric Ð left/right boxes around median not same

" Comparative box plots Ð useful in graphical

comparisons among data sets

◦Too much variability at plant2

◦Plant 2 and 3 need to raise their quality index

performance

◦Height of each bin represents number of

observations less than or equal to upper limits of

bin

# Eg. about 75 of 100 wafer less than 460 Å

◦To construct a histogram for discrete or count

data (sample space is countable)

# Determine frequency (r relative frequency)

" Probability distributions

for each value of x, each x value

◦Sample: a collection of measurements selected

corresponds a bin

from some larger score or population

# Plot frequency (or relative frequency) on

# Eg. analyze sample layer thickness data

vertical scale and values of x on horizontal

◦

Probability

distribution: mathematical model

scale

relates value of variable with probability of

◦Example 3.3: defects in automobile hoods

occurrence of that value in the population

# Eg. layer thickness Ð a random variable

# Probability of occurrence of any value of

layer thickness in population

" DeÞnition

◦Continuous distributions

# When the variable being measured is

" Numerical summary of data

expressed on a continuous scale, its

probability distribution is called a

continuous distribution.

# The probability distribution of metal layer

thickness is continuous

◦Discrete distributions

# When the parameter being measured can

only take on certain values, such as the

integers 0, 1, 2, . . . , the probability

distribution is called a discrete distribution.

# For example, the distribution of the number

of nonconformities or defects in printed

circuit boards would be a discrete

distribution.

" Box plot

◦A graphic display; important features of the

data, such as location or central tendency,

spread or variability, departure from symmetry,

and identiÞcation of observations that lie

unusually far from the bulk of the data (these

observations are often called ÒoutliersÓ).

◦Display three quartiles, minimum and maximum

of data on a rectangular box

" Probability mass function (discrete variable)

" Scatter, spread, or variability in a distribution

◦Variance

" Probability density function (continuous variable)

◦standard deviation à Рsquare root of variance

# a measure of spread or scatter in

population express in original data

" Expected value/ mean ¿ of a probability distribution is

a measure of central tendency in the distribution, or

its location

Chapter 4 Inferences About Process Quality

4.1 Statistics and Sampling Distributions

" Statistical inference: draw conclusions about

populations (or process) based on sample data from

that system

" Random sample: a sample selected so that

observations are independent Ð same probability of

selection

" Statistics: any function of observations in sample

◦Eg: sample mean, sample variance, sample

standard deviation

" Sampling distributions

◦Statistic Ð a random variable; probability

distribution

◦Sampling distribution Ð probability distribution of

a statistics

◦Question: let x1, x2, É, xn be a random sample

size n from a distribution (population) with mean ¿

and variance Ã^2. What is the mean (expected

value) and variance of sample mean x-bar?

" Three important and useful sampling distributions

based on normal distribution

◦Chi-square distribution

If x1, x2, É, xn are normally and independently distributed

random variable with mean 0 and variance 1, then random

variable

is distributed as chi-square with n degrees of freedom

◦t distribution

if x is standard normal random variable and if y is a chisquare random variable with k degrees of freedom, and if

x and y are independent, then random variable:

is distributed as t with k d.f.

◦F distribution

if w and y are two independent chi-square random

variable with u and v degrees of freedom, then

is distributed as F with u: numerator df and v:

denominator df

4.2 Point Estimation of Process Parameters

4.3.1 Inference on mean of a population, variance known

" Distributions described by their parameters

" Parameters unknown, must be estimated

" Estimator: deÞne an estimator of an unknown

parameter as statistic that corresponds to parameter

" Point estimator: a statistic that produce a single

numerical value as ÒestimateÓ of parameter

" Example: consider random variable x~N(¿,Ã^2)

mean and variance both known

" If a random sample of n observations, then sample

mean x-bar and sample variance S^2 are point

estimators of population mean ¿ and population

variance

◦Suppose random variable x inside diameter

n=20 bearings. Sample mean x-bar = 1.495;

sample variance S^2 = 0.001

4.3 Statistical Inference for a single sample

" Three components of statistical inference

◦Point estimation

◦Hypothesis testing

# Null hypothesis vs.. alternative hypothesis

# Statistical hypothesis: a statement about

values of parameter of a probability

distribution

# Two-sided alternative hypothesis vs. onesided alternative hypothesis

◦ConÞdence intervals

# Refers to the probability that a population

parameter will fall between pair of values

around mean

# Measure two degree of uncertainty in a

sampling method

# Constructed by conÞdence levels of 95%

or 99%

" To test a hypothesis

◦Take a random sample from population

◦Compute an appropriate test statistic

◦Either reject or fail to reject the null hypothesis

◦Òcritical regionÓ or Òrejection regionÓ: set of

values of test statistic leading to rejection of H0

" Two kinds of error when testing hypothesis

◦Type I error: if null hypothesis is rejected when it

is true

◦Type II error: if null hypothesis is not rejected

when it is false

◦Power of a statistical test

" In quality control work:

◦³: producerÕs risk (probability that a good lot will

be rejected)

◦´: consumerÕs risk (probability of accepting a lot

of poor quality)

" ConÞdence interval

◦An interval estimate of a parameter is interval

between two statistics that include true value of

parameter with some probability

◦For example, construct an interval estimator of

mean ¿, must Þnd two statistics L and u such that

P{L <= ¿ <= U} = 1-³

◦Interval L <= ¿ <= U is called 100(1-³)%

conÞdence interval for unknown mean ¿

◦L and U Ð lower and upper conÞdence limits

◦1-³: conÞdence coeûcient

" Interpretation of CI:

◦If a large number of such intervals are

constructed, each resulting from a random

sample, then (1-³)% of these intervals will

contain true value of ¿

◦One-sided lower 100(1-³)% conÞdence bound

on ¿

L <= ¿

# L: lower conÞdence bound so that P{L<=¿}

=1-³

◦One-sided upper 100(1-³)% conÞdence bound

on ¿

¿ <= U

# U: upper conÞdence bound so that

P{¿<=U}=1-³

" Normal distribution, compute p value

" ConÞdence interval on mean with variance known

◦Consider random variable x, with unknown

mean ¿ and known variance. Suppose a

random sample of n observations x1, x2, É ,xn.

◦Then the 100(1-³)% two-sided CI on ¿ is:

4.3.3 Inference on Mean of a Normal Distribution,

Variance Unknown

" Hypothesis testing: x normal random variable with

unknown mean and unknown variance

4.3.2 The Use of P-Values for Hypothesis Testing

" P-value is the probability that test statistic will take

on a value that is at least as extreme as observed

value of statistic when null hypothesis is true

◦The p-value is smallest level of signiÞcance that

would lead to rejection of null hypothesis

" ConÞdence interval on mean of a normal distribution

with variance unknown

4.4 Statistical Inference for Two Samples

4.4.1 Inference on diûerence in mean, variance known

4.3.5 Inference on a Population Proportion

" Hypothesis testing: suppose test proportion p of a

population equals to a standard value,

Ònormal approximation to binomialÓ

" Suppose a random sample of n observations from

population

◦X items in sample Ð class associated with p

4.4.4 Inference on two proportions

4.4.2 Inference on diûerence in means of two normal

distribution, variance unknown

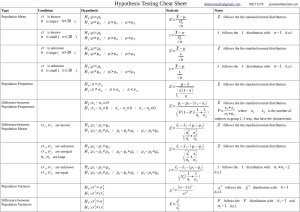

Review STAT 513 Midterm Spring 2022

Zhongyuan Chen

[Detailed instruction will be uploaded on Brightspace before the exam.]

Please do not distribute this exam.

This exam has the format: calculations (most) and short answer questions

(minor).

There are 100 points on this exam. Please show your work on each problem

on this exam, in which case liberal partial credit will be awarded.

This exam is open book and open notes.

Exam open window: March 29 (Tuesday) 9:00 a.m. EST - March 30

(Wednesday), 2022 8:59 a.m EST

Please print the exam (If you do not have a printer available, you can please

use your own paper to work the exam. Please organize your work in numerical

order.), work on the papers, scan your materials (a single PDF file, better to

use a scanner or application program, such as CamScanner, on a smart phone

or ipad), and upload it on Brightspace.

Exam time limit: 120 min

Please bring a calculator.

Chapter1: Quality improvement in the modern business environment

¯ Definitions of quality (modern definition) and quality improvement

¯ Terminology: quality characteristics, critical-to-quality (CTQ)

characteristics, specifications (lower specification limit, upper specification

limit, target or nominal values), defective or nonconforming product,

defect or nonconformity

¯ Statistical methods: statistical process control (SPC), designed

experiments, acceptance sampling.

¯ Six sigma: calculation (example: hw2.12)

1

Chapter2: The DMAIC process

¯ DMAIC: define, measure, analyze, improve, and control

¯ Tollgates

Chapter3: Modeling process quality

¯ Describing variation: histogram, boxplot, numerical summary of data

(sample mean, sample variance, sample standard deviation), probability

distribution (discrete variable: probability mass function; continuous

variable: probability density function), mathematics definition of mean

and variance.

¯ Discrete distribution: hypergeometric distribution, binomial distribution

(bernoulli trials), poisson distribution, negative binomial

distribution,geometric distribution (calculation: example: hw3.29)

¯ Continuous distribution: normal distribution (central limit theorem),

lognormal distribution, exponential distribution, gamma distribution,

weibull distribution (calculation: example: Example3.8)

Chapter4: Inference about process quality

¯ Statistics and sampling distributions: statistical inference, random sample,

statistic, sampling distribution (sampling from a normal distribution),

three important sampling distribution (chi-square distribution, t

distribution, F distribution)

¯ Point estimation of process parameter: point estimator (properties),

estimate.

2

¯ Statistical inference for a single sample: hypothesis testing, confidence

intervals.

Hypothesis testing: null hypothesis (H0), alternative hypothesis (H1),

standard procedure--- random sample---compute test statistic--- compare

with critical value--- either reject null or fail to reject null hypothesis.

Two kinds of errors:

\alpha = P(type I error)=P(reject H0 | H0 is true)

\beta = P( typeII error)=P(fail to reject H0 | H0 is false)

Power = 1 - \beta = P(reject H0 | H0 is false)

Inference on the mean of a population (variance known (z test statistic:

population variance), variance unknown (t test statistic: use sample variance

to estimate)): hypothesis testing, confidence interval

Inference on a population proportion: hypothesis testing, confidence

interval

Calculation example: Example4.3; Example4.4

(Note: population variance sigma square unknown, use sample variance

as estimate for calculation, use t test statistic)

¯ Statistical inference for two samples: hypothesis testing, confidence

intervals.

Inference on the difference in means (variance known, variance unknown

(equal/unequal variance)): hypothesis testing, confidence interval.

Inference on the difference in two proportions: hypothesis testing,

confidence interval

Calculation example: Example4.8

(Note: population variance sigma square known, use z test statistic)

3