Two-Dimensional Bin Packing Problem: Algorithms & Applications

advertisement

Two-dimensional

bin packing

problem

By Jorge Isaac Merla Hernandez,

1985189

Bin packing

In the 2BP we are given a set of n rectangular

items j∈J={1,…,n}, each having width wj and

height hj, and an unlimited number of finite

identical rectangular bins, having width W and

height H. The problem is to allocate, without

overlapping, all the items to the minimum

number of bins, with their edges parallel

to those of the bins. It is assumed that the

items have fixed orientation, i.e., they cannot

be rotated.

Strip packing

In the two-dimensional strip packing problem, we are

given a strip of a finite width W but infinite height, and a

set of rectangular items each of width at most W. The

objective is to pack all the items into the strip to

minimize the height used. The items may neither overlap

nor be rotated. We describe here a list of efficient (offline) packing algorithms. A common approach is leveloriented, the items are packed from left to right, in rows

forming levels.

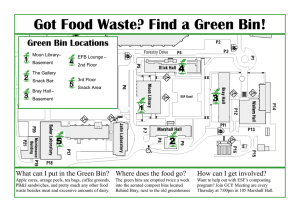

Problem 2BP has many industrial applications,

especially in cutting (wood and glass industries)

and packing (transportation and warehousing).

Certain applications may require additional

constraints...

Algorithm types for the 2BP

Off-line algorithms, for

which it is assumed that

the algorithm has full

knowledge of the whole

input

On-line algorithms,

which pack each item as

soon as it is encountered,

without knowledge of the

next items

Off-line algorithm types

Most of the them from the literature are of greedy type, and can be

classified in two families:

One-phase algorithms directly

pack the items into the finite

bins.

Two-phase algorithms start

by packing the items into a

single strip, i.e., a bin having

width W and infinite height.

In the second phase, the strip

solution is used to construct a

packing into finite bins.

In addition, most of the approaches are level

algorithms, i.e., the bin/strip packing is

obtained by placing the items, from left to

right, in rows forming levels.

The first level is the bottom of the bin/strip,

and subsequent levels are produced by the

horizontal line coinciding with the top of the

tallest item packed on the level below.

Algorithms

(examples)

First-Fit

Decreasing Height

(FFDH) algorithm

FFDH packs the next item R (in non-increasing

height) on the first level where R fits. If no level

can accommodate R, a new level is created.

Finite First-Fit

(FFF)

The current item is packed on the lowest

level of the first bin where it fits; if no level

can accommodate it, a new level is created

either in the first suitable bin, or by

initializing a new bin (if no bin has enough

vertical space available).

Finite Next-Fit (FNF)

FNF directly packs the items into finite bins in the same way as HNF.

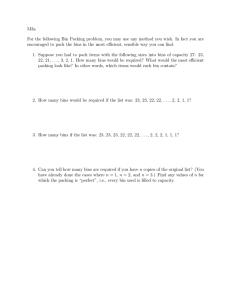

Problem examples

An easy example of a 2-dimensional bin packing

problem could involve packing rectangular

objects into rectangular bins. Let's say you have

two bins with dimensions 10x10 each, and three

rectangular objects with dimensions:

Object A: 4x5

Object B: 3x7

Object C: 6x3

The goal is to find the best way to pack these

objects into the bins while minimizing wasted

space.

In cutting, for

example

References

https://www.csc.liv.ac.uk/~epa/survey.pdf

https://www.sciencedirect.com/science/article/pii/S0166218X0100347X#BIB23

Galambos, G., Woeginger, G.J. On-line bin packing — A restricted survey. ZOR Methods and Models of Operations Research 42, 25–45 (1995).

https://doi.org/10.1007/BF01415672