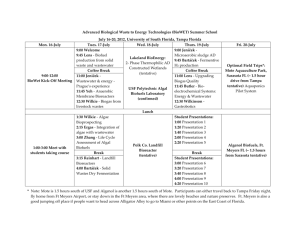

Anaerobic Wastewater Treatment: Tech & Innovations

advertisement