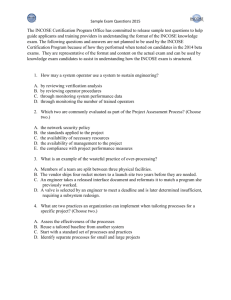

Systems Engineering Handbook: Life Cycle Processes & Activities

advertisement