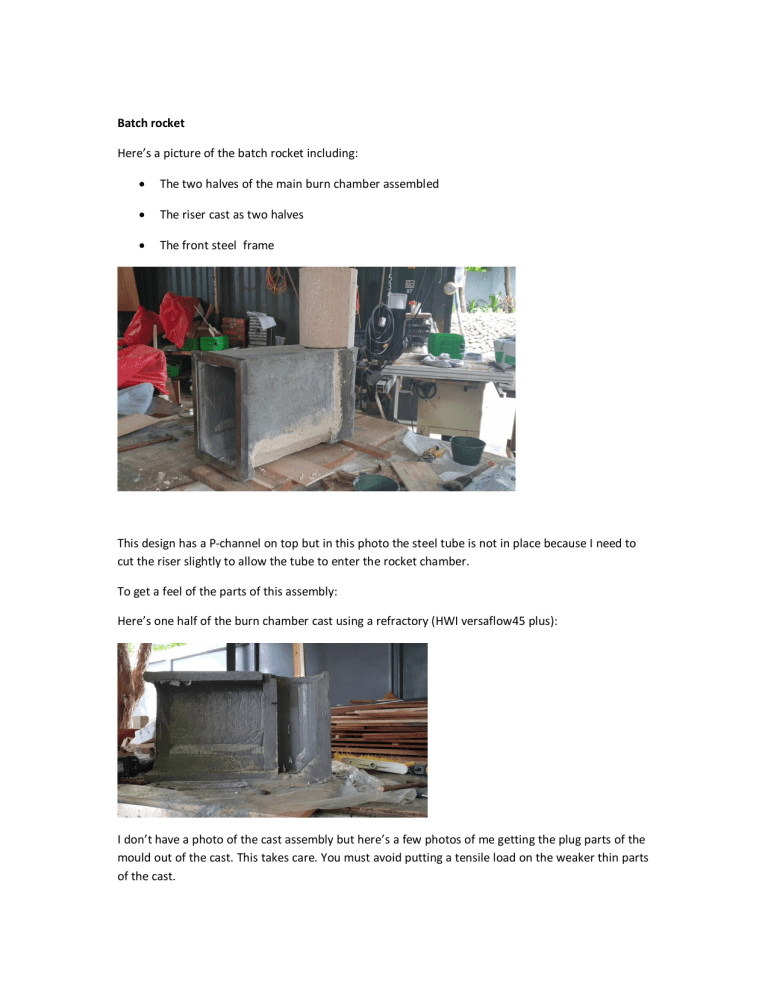

Batch rocket Here’s a picture of the batch rocket including: · The two halves of the main burn chamber assembled · The riser cast as two halves · The front steel frame This design has a P-channel on top but in this photo the steel tube is not in place because I need to cut the riser slightly to allow the tube to enter the rocket chamber. To get a feel of the parts of this assembly: Here’s one half of the burn chamber cast using a refractory (HWI versaflow45 plus): I don’t have a photo of the cast assembly but here’s a few photos of me getting the plug parts of the mould out of the cast. This takes care. You must avoid putting a tensile load on the weaker thin parts of the cast. The main burn chamber part of the mould was made from a wooden base frame with a piece of polystyrene on top, then all wrapped in plastic sheet and taped up with masking tape. Removing the polystyrene Removing the polystyrene Removing the polystyrene Removing the wooden piece that provides the hole for the gap between the main chamber and the riser. This was also wrapped in plastic and taped up. Removing the wooden piece that provides the hole for the P-channel to enter. Removing the wooden piece that becomes the riser and the collar that shapes the riser cast so that each riser piece interlocks with the piece below as stackable pieces. This half cylinder shape was made by sequentially cutting a wooden block on a table saw at gradually decreasing angles, then planing the edges to make the plug less angular.