Step

00

Table of Contents

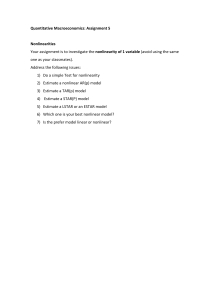

1. Introduction on Nonlinear Analysis

2. Presentation of procedure and options in Nonlinear Analysis

3. Nonlinear Geometry

4. Nonlinear material(1)-Elastoplasticity

5. Nonlinear material(2)-Hyperelasticity

6. Nonlinear Contacts

7. Conclusion and advice for a better use of Nonlinear Analysis

http://www.midasNFX.com

Nonlinear Static Analysis

1

Step

http://www.midasNFX.com

Nonlinear Static Analysis

2

Step

Introduction on Nonlinear Analysis

http://www.midasNFX.com

Nonlinear Static Analysis

3

Step

01

What is Nonlinear Analysis ?

Most of the physical phenomena are nonlinear

When nonlineary can be neglected, Analysis can be performed using linear Analysis

(more effective)

When nonlineary cannot be neglected, Nonlinear analysis should be performed

What is it???

http://www.midasNFX.com

Nonlinear Static Analysis

4

Step

02

What is Nonlinear Analysis ?

3 causes of Nonlinearity

Geometric Nonlinearity

Material Nonlinearity

When an object is subjected

When the relation between

When the contact of an

to excessive deformation or

Stress and Strain isn’t elastic,

object with another is

the load direction

Nonlinear Elasto-Plastic

changing.

ischanging

Theory has to be used.

http://www.midasNFX.com

Contact Nonlinearity

Nonlinear Static Analysis

5

Step

03

What is Nonlinear Analysis ?

What is linear Analysis?

F

K

Following Hook’s Law

Linear relation

F=Kδ

K

δ

u(=δ)

Result of linear analysis?

F

A force of 1kg create a deformation of 1mm

A force of 10kg create a deformation of 10mm

As K is always constant, F value can be obtained easily

When Stiffness is constant, Hook’s Law can be linearized.

In most structures, Constant Stiffness is taken as an assumption.

http://www.midasNFX.com

Why??

Nonlinear Static Analysis

6

Step

04

Linear Analysis VS Nonlinear Analysis

What is Nonlinear Analysis?

F

F

K3

K

K2

K=Constant

(a) Linear Analysis

K≠Constant

K1

u

(b) Nonlinear Analysis

u

When Load increases, stiffness changes.

The relation Load-displacement is a nonlinear function.

In linear Analysis, K is constant, and so displacement U can be obtained simply if Load F is known.

In other words, if the slope of the curve is known, behavior of the solid can be determined with

only one calculation. In Nonlinear Analysis, the slope of the curve is always changing, thus a

new calculation with updated slope value and several calculation steps are required.

http://www.midasNFX.com

Nonlinear Static Analysis

7

Step

05

Linear Analysis VS Nonlinear Analysis

Nonlinear Analysis Examples

http://www.midasNFX.com

Nonlinear Static Analysis

8

Step

06

Reasons to use Nonlinear Analysis

In which circumstances is nonlinear analysis required?

When more accurate data are necessary

When position where contact happens is changing

When large deformation is susceptible to happen

When stress level approaches yielding point of material

In order to determine precisely buckling load

When an unusual big displacement is observed

When hyperelastic material like rubber is used

When deformation gradually increases due to a constant load which is

applied for a long time

http://www.midasNFX.com

Nonlinear Static Analysis

9

Step

07

Numerical Analysis s Methodology of Nonlinear Analysis

Numerical Analysis Methodology of Nonlinear Analysis

Linear Analysis

F

In linear analysis, response of a structure submitted to a

Linear

load can be determined using the linear equation F=KU.

Nonlinear

Nonlinear Analysis

F=H(U) is not a linear equation, so F≠KU

In nonlinear analysis, the load can be divided in several

load steps and the equation ΔF=[Kx][ΔU] can be used

for each load step to find displacement.

u

When applying a load in nonlinear analysis, this load can de divided in

smaller load steps and then displacement can be calculated with several

iterations.

http://www.midasNFX.com

Nonlinear Static Analysis

10

Step

08

Numerical Analysis s Methodology of Nonlinear Analysis

Numerical Analysis Methodology of Nonlinear Analysis

Incremental Method

F

Newton-Raphson

F

error occurs

ΔF

ΔF

ΔF

ΔF

Improvement

ΔF

u

Error is reduced by

a supplementary

iteration at each

load step

ΔF

u

Stiffness is updated at each load step.

Stiffness is updated at each load step.

Problem: error accumulated at each load step

Error is reduced by adding an internal stiffness

will create some big error at the end of the

iteration for each load step.

analysis.

http://www.midasNFX.com

Nonlinear Static Analysis

11

Step

09

Numerical Analysis s Methodology of Nonlinear Analysis

Newton-Raphson Method

F

[KT][ΔU] = {F1} - {FIx}

iteration

In linear analysis, when F(Ext load) = F(Int load) and

F2

solution can be found (convergence) then it

verify the equation F=KU.

In nonlinear analysis, when {F1}-{FIx} is comprised

ΔF

between a certain error tolerance, solution can

F1

ΔF

FIx

be determined and load step converge.

error

error

error

There are three convergence criteria based on Load,

displacement and work.

Error is reduced progressively

F

Load

displacement

u

surface = work

u

http://www.midasNFX.com

Nonlinear Static Analysis

12

Step

10

Numerical Analysis s Methodology of Nonlinear Analysis

Convergence Criteria / Error Tolerance

F

Usually, two convergence criteria are

combined together to obtain satisfying

②Load

results.

①displacement ① displacement+③work or ② load + ③ work

(used a lot in practice)

Usually, displacement criteria is used for

systems which are not very sensible to

Surface = ③Work

F

load variation.

Use of load criteria

u

Use of displacement criteria

ΔF

In this case, tolerance criteria is converging

with ΔF, but is not regarding to Δu.

Δu

http://www.midasNFX.com

u

Nonlinear Static Analysis

13

Step

11

Numerical Analysis s Methodology of Nonlinear Analysis

Numerical Analysis Methodology of Nonlinear Analysis

Full Newton - Raphson Modified Newton - Raphson Initial Stiffness Method

F

F

F

u

u

u

Update stiffness each time

Update Stiffness at each Load step

Keep value of initial Stiffness

It takes time to calculate stiffness

Number of increments is increased

Number of increments is increased

If there is no convergence problem,

If there is no convergence problem, this

this method is faster than simple

method is faster than simple Newton-

Newton-Raphson

Raphson

In midas NFX, results can be obtained using any of these iterative methods

http://www.midasNFX.com

Nonlinear Static Analysis

14

Step

12

Numerical Analysis s Methodology of Nonlinear Analysis

What is Buckling?

All the structures have a stable equilibrium state.

When a load is applied and it create a large deformation of the structure, it is said to be in an unstable equilibrium state.

Such instability is not due to the material but to the geometrical shape of the structure.

By performing buckling analysis, it is possible to determine the buckling load (Maximum Load at which buckling will

occur) and the buckling Mode (Deformed Shape due to buckling) of the structure.

Axial Load

When a structure is submitted to an external

load, the equilibrium state external load=

Neutral equilibrium

F

state

internal load simply doesn’t apply. Structure is

said to be in a stable equilibrium state.

Buckling Load(Fcr)

Unstable

equilibrium state

u

Stable

equilibrium state

http://www.midasNFX.com

Linear Buckling Analysis vs Nonlinear buckling Analysis?

Nonlinear Static Analysis

15

Step

13

Numerical Analysis s Methodology of Nonlinear Analysis

Linear Buckling VS Nonlinear Buckling

F

Limitations of Linear Buckling Analysis

Linear Buckling

It can be dangerous if buckling load is overestimated.

Nonlinear Buckling

It cannot determine behavior after buckling

Material is supposed elastic and so nonlinear material

Real structure

behavior

u

Advantage of Nonlinear Buckling Analysis

※ In case of nonlinear buckling

F

behavior is not considered.

Possibility to calculate the real buckling load.

From this point, tangential

stiffness is either 0 or negative

-> No convergence

Nonlinear material behavior can be considered.

The use of Newton-Raphson Method to estimate structural behavior

Snap-through

after buckling is very difficult. In this case, another method has to

be used.

Arc-length, Displacement control Method

u

http://www.midasNFX.com

Nonlinear Static Analysis

16

Step

14

Numerical Analysis s Methodology of Nonlinear Analysis

Arc-length Method

F

F

ΔP

u

u

Calculation of results of a load step could be negative or null Stiffness .

Usually used when Nonlinear Buckling occurs in snap-through shape.

midas NFX provides Crisfield(CRIS), Riks(RIKS), Modified Riks(MRIKS) Methods.

http://www.midasNFX.com

Nonlinear Static Analysis

17

Step

15

Numerical Analysis s Methodology of Nonlinear Analysis

Arc-length Method

• Max No. of Increments

In function of the nonlinearity, Arc-Length Method can converge

faster than the number of increments, but it can also diverge. In order

to account for this case, sufficient number of increments has to be set.

• Load contribution scale factor

When load contribution Scale Factor is “1”, Load and displacement

are unknown. When it is equal to “0”, only displacement is unknown.

Default parameter is “0”.

http://www.midasNFX.com

Nonlinear Static Analysis

18

Step

16

Numerical Analysis s Methodology of Nonlinear Analysis

Displacement Control Method

In most of the problems, structural behavior is determined using Load control.

In case of Nonlinear Buckling, it is difficult to determine the load after buckling, so it is

better to use displacement control.

Applied Load (Buckling load) can be determined by the constraint force.

Force (Constraint)

Imposed displacement

1.2

1

0.8

0.6

0.4

0.2

0

0

Constraint

http://www.midasNFX.com

50

100

150

200

250

300

Displacement

Nonlinear Static Analysis

19

Step

http://www.midasNFX.com

Nonlinear Static Analysis

20

Step

Presentation of procedure and

options in Nonlinear Analysis

http://www.midasNFX.com

Nonlinear Static Analysis

21

Step

01

Presentation of procedure and options in Nonlinear Analysis

Analysis Procedure

Linear Analysis Procedure

Nonlinear Analysis procedure

Preparation of Geometric

Model

Preparation of Geometric

Model

Material Assignment

Material Assignment

Apply Element Properties

Apply Element Properties

Mesh Preparation

Mesh Preparation

Assignment of Boundary

Conditions

Assignment of Boundary

Conditions

Insert Loading Condition

Insert Loading Condition

Create Analysis Case and

Perform Analysis

Create Analysis Case and

Perform Analysis

Verify the Results

Verify the Results

Material Nonlinearity

Assignment

Nonlinear Contact

Assignment

Activate Geometric

Nonlinearity Option

As the process of linear and nonlinear Analysis are the same, it is a good idea to Train first by performing linear analysis

http://www.midasNFX.com

Nonlinear Static Analysis

22

Step

02

Presentation of procedure and options in Nonlinear Analysis

Analysis Option

In nonlinear analysis, different methods have to be used in order to find a different solution from linear analysis.

After creating the analysis case, diverse options can be selected.

1. Method to Create Analysis Case

2. Support Geometric Nonlinearity

3. Number of Increments, set

convergence criteria

4. Intermediate Output Request

5. Advanced Nonlinear Parameters

6. Use of Subcases

7. Use of Restart feature

http://www.midasNFX.com

Nonlinear

Analysis

Options

Nonlinear Static Analysis

23

Step

03

Presentation of procedure and options in Nonlinear Analysis

Method to Create Analysis Case

Analysis & Results >> Analysis case >> General

1

or

2

1

http://www.midasNFX.com

Nonlinear Static Analysis

24

Step

04

Presentation of procedure and options in Nonlinear Analysis

Method to Consider Geometric Nonlinearity

2

Check it to consider Geometric Nonlinearity

1

Click on Nonlinear Static (Required)

and select Subcase control button

When it is not obvious to consider large deformation, the best

way is to check it first and then evaluate the deformation results.

http://www.midasNFX.com

Nonlinear Static Analysis

25

Step

05

Presentation of procedure and options in Nonlinear Analysis

Number of Increments, Convergence

Criteria Settings

F

• Determine number of

increments (number of ΔF)

ΔF

ΔF

ΔF

Ex) For a Load of 100N divided in 20

increments, Load will be 5N for each

step.

Select a maximum of 2 convergence criteria

Usually Load + Work Convergence criteria are

used

• Usually, displacement criteria is used for systems

which are not very sensible to load variation.

•

•

With 3 Convergence Criteria, Convergence is

quite difficult to obtain.

With 1 convergence criteria, Convergence is

easy but it is difficult to obtain rational results.

http://www.midasNFX.com

u

F

Load

Disp.

Surface = Work

u

Nonlinear Static Analysis

26

Step

06

Presentation of procedure and options in Nonlinear Analysis

Intermediate Output Request

F

ΔF/2 = bisecting Increment

ΔF = Load Step

Bisecting increment: When it

cannot converge in one increment,

the increment is divided in 2 and

calculation is performed on each.

u

• Every Increment : Output of all increments results (including bisected

increments).

• Every Non-bisecting Increment : Output of all increments results except

bisected increments.

• Last Increment : Export only the result from the last increment.

• Every N Non-bisecting Increment : Export the results every N Load step.

Nonlinear analysis doesn’t provide only 1 result like linear analysis but

provide a result for every increment (even for bisected increments). In

order to set the appropriate output request , Intermediate output

request has to be chosen in the analysis control window.

http://www.midasNFX.com

Nonlinear Static Analysis

27

Step

07

Presentation of procedure and options in Nonlinear Analysis

Advance Nonlinear Parameters - 1

If you Check off “Use Default Settings”, you can set manually

the parameters for the Stiffness update scheme

Stiffness update scheme can be changed. If

you use default settings, Midas NFX will choose

automatically the method to use to update the

stiffness.

SEMI : Stiffness Update is done after 1 iteration to take account

of new load on each load increment.

ITER : Stiffness will be updated for each step.

Number of iterations before Stiffness Update = 1 : NewtonRaphson is performed.

Number of iterations before Stiffness Update = Max No. of

Iterations per Increment : Newton-Raphson is performed.

Number of iterations before Stiffness Update > Max No. of

Iterations per Increment : Stiffness is not updated

When Bisection happens, it is due to the fact that either real

Number of iteration per increment is higher than the Max No.

of Iterations per Increment or it is because solution diverges.

The default setting is "5 times".

http://www.midasNFX.com

Nonlinear Static Analysis

28

Step

08

Presentation of procedure and options in Nonlinear Analysis

Advance Nonlinear Parameters - 2

• Terminate Analysis on failed convergence

When convergence fail, analysis will be terminated. If this

option is not checked, analysis will continue even if it doesn't

converge.

• Max No. of iterations per increment

It sets the maximum number of iterations at each increment. If

it doesn’t converge after this number of increments, the load step

will be bisected and analysis will be performed again.

Ex: if 10N Load doesn’t converge, analysis will be performed again

on a 5N bisected load step.

• Max. Bisection Level

It sets the maximum number of bisection possible of 1 load step.

Ex) If the Maximum bisection level is 5, a load step of 10N can be

divided 5 times : 5N, 2.5N, 1.25N, 0.625N, 0.3125N

• Enable Line Search

If the solution of the nonlinear analysis has the particularity to

converge with some oscillations, line search method can help to

get convergence.

http://www.midasNFX.com

Nonlinear Static Analysis

29

Step

09

Presentation of procedure and options in Nonlinear Analysis

Method to use Subcases (Load Step) -1

Subcases are sets composed of Loads and boundary conditions applied to the Analysis problem.

Each Analysis Subcase results are linked with the results of the previous Subcase.

Analysis & Results >> Analysis Case >> General

Subcase Setting

• Boundary conditions, Loads and Contacts can be

[ << ] : Inactivate all the Sets

assigned to each Subcases by Drag-and-Drop.

[ >> ] : Activate all conditions for all

sets in all subcases.

Subcase Control/Subcase Output Results

have to be defined for each Subcase.

http://www.midasNFX.com

Nonlinear Static Analysis

30

Step

10

Presentation of procedure and options in Nonlinear Analysis

Method to use Subcases (Load Step) -2

F

Load2

Subcase ②

Load1

Subcase ①

Subcase ③

Time (case)

Subcase① : Load1 Applied

Subcase② : Load 2 is applied in addition to Load1

Subcase③ : All the Loads are removed

http://www.midasNFX.com

Nonlinear Static Analysis

31

Step

11

Presentation of procedure and options in Nonlinear Analysis

Method to use Subcases (Load Step) -3

Example1

1

2

Example2

1

http://www.midasNFX.com

2

Nonlinear Static Analysis

32

Step

12

Presentation of procedure and options in Nonlinear Analysis

Method to use Restart feature-1

When the solution of the nonlinear analysis is submitted to highly nonlinear environment,

convergence becomes difficult and it may happen that the analysis stop before the end.

In this case, convergence can be obtained by changing the analysis parameters (number of increments,

convergence criteria,…), but analysis has to be performed again and it can be a very time-consuming

process.

Use of restart function to begin the analysis again from the point where it stopped

http://www.midasNFX.com

Nonlinear Static Analysis

33

Step

13

Presentation of procedure and options in Nonlinear Analysis

Method to use Restart feature-2

1

2

4

5

3

6

During this 3 subcases, if analysis didn’t

converge after the 2nd subcase, analysis

4

have to be run only from the 2nd subcase.

If 3 subcases exists, 3 restart files will be

created.

http://www.midasNFX.com

Nonlinear Static Analysis

34

Step

14

Analysis method of Nonlinear Analysis Results

Equivalent Stress

Uncheck Nodal Average

to see Equivalent stress

results.

Right click

5

1

2

3

Check SOLID STRS Equivalent stress

4

When a nonlinear analysis using Material nonlinearity is performed

(Hyper elastic model), Equivalent stresses must be checked. When

material nonlinearity is not considered, von-mises stresses have to

be checked.

http://www.midasNFX.com

Nonlinear Static Analysis

35

Step

15

Analysis method of Nonlinear Analysis Results

Effective Plastic Strain

3

Right click

1

2

4

Check SOLID STRS EFFECTIVE PLASTIC

4

When equivalent stresses are superior to the yield strength

of the material, effective plastic strain are created.

http://www.midasNFX.com

Nonlinear Static Analysis

36

Step

Geometric Nonlinearity

http://www.midasNFX.com

Nonlinear Static Analysis

37

Step

01

Geometric Nonlinearity

Geometric Nonlinearity

Occurrence of large displacement/large rotation in the structure

Occurrence of large strains

Excessive deformation increases, regardless of the material properties and the stiffness

changes

Dynamic loads can be applied (direction of the load is changing in function of the

structural deformation)

M

linear

http://www.midasNFX.com

M

nonlinear

Nonlinear Static Analysis

38

Step

02

Analysis Theory of Geometric Nonlinearity

Large Displacement/ Large Rotation

When the load applied to a structure create some large deformation or rotation, the

stiffness of the Structure changes. If the elements rotate, the stiffness of the total structure

changes.

Supposing two Mesh sets submitted to different axial loads:

Horizontal stiffness

(a)

(b) horizontal and vertical stiffness

* Usually, when Geometric nonlinearity is considered, it means

that large deformation, large rotation and large strain are

present, but it is important to note that large

deformation/rotation don’t always create large strain!

Large displacement

Large rotation

ex)

Large Strain

http://www.midasNFX.com

Nonlinear Static Analysis

39

Step

03

Analysis Theory of Geometric Nonlinearity

Large Strain

When an object submitted to loads is deformed and when the surface or the area of the

elements change too much, the stiffness of the object will also change.

In the examples below, the stiffness along the axial load will progressively change:

(a)

(b)

When Material Nonlinearity is considered, usually large displacement is also

present. This is why it is better to consider the geometric linearity each time

stress-strain curve is nonlinear.

http://www.midasNFX.com

Nonlinear Static Analysis

40

Step

04

Analysis Theory of Geometric Nonlinearity

Follower force

Definition: Force which can change direction and application position according to

structural deformation.

* Why is Follower force nonlinear ?

The force direction determines structure’s deformation

Then, the structure deformation determines force direction

Thrust Force=W

(a)

http://www.midasNFX.com

(b)

Nonlinear Static Analysis

41

Step

05

Analysis Theory of Geometric Nonlinearity

Follower force

Apply follower load in midas NFX:

1

2

※ Starting node Direction of the load

kept.

3

4

http://www.midasNFX.com

Nonlinear Static Analysis

42

Step

06

Geometric Nonlinearity

Analysis method for geometric nonlinearity

When the mesh deformation is too large, some error can happen, this is why it is

better to think about the mesh size according to the deformation.

Analysis convergence is more easy for 1st order element rather than for 2nd order

element.

If the solution of the nonlinear analysis has the particularity to converge with some

oscillations, line search method can help to get convergence.

http://www.midasNFX.com

Nonlinear Static Analysis

43

Step

http://www.midasNFX.com

Nonlinear Static Analysis

44

Step

Material Nonlinearity(1)

– Elastoplasticity

http://www.midasNFX.com

Nonlinear Static Analysis

45

Step

01

Material Nonlinearity

Material Nonlinearity

In linear Analysis, Deformation of material is considered elastic

In order to consider plastic deformation of materials, Nonlinear analysis

with nonlinear material have to be used.

Types of nonlinear material models

s

s

s

sY

E

e

Elasto-plastic model

e

Hyperelastic (Nonlinear elastic) model

Creep model

time

It is important to select the right material model

http://www.midasNFX.com

Nonlinear Static Analysis

46

Step

02

Elastoplastic model

Properties of Elasto Plastic Model

σ

Uniaxial tensile test stress-strain graph

Ultima

te

stress

Yield

stress

rupture

Have to Consider the characteristics

due to cyclic loading(Stress-strain

behavior under repeated loading

alters the properties of the material)

Loading

Unloading

Elastic

Module

perfect deformati Necking

on

plasticity

hardening

http://www.midasNFX.com

ε

* If there is no cyclic loading, is it necessary

to consider the hardening model?

Nonlinear Static Analysis

47

Step

03

Elastoplastic model– Yield criterion

Yield criterion

TRESCA Model (maximum shear stress theory) Von-Mises Model (Torsional energy theory)

maximum shear stress > Simple tensile test yield

value /2

http://www.midasNFX.com

Tri-axial Stress State shape deformation energy >

deformation energy of Simple tensile test yield value

Nonlinear Static Analysis

48

Step

04

Elastoplastic model– Yield criterion

Shape deformation energy

In triaxial stress state, the cause of yielding is the torsion which causes

shape deformation, it is not the isotropic volumetric pressure.

y

y

x

z

=

y

x

z

Tri-axial stress state

Isotropic volumetric pressure

Doesn’t cause yielding

http://www.midasNFX.com

+

x

z

Shape deformation occurring due to torsion

Cause yielding

Nonlinear Static Analysis

49

Step

05

Elastoplastic model– Hardening model

Hardening model

Isotropic hardening model

Kinematic hardening model

σ

σ

sY

2sY

ε

ε

sY

Yield stress increase of the

same ration for tension and

compression

Yield stress domain is

constant

Plastic deformation moves

along with the center of yield

stress domain

http://www.midasNFX.com

Nonlinear Static Analysis

50

Step

06

Elastoplastic model– Hardening model

3D stress hardening model

Hardening model for 3D stress state stress domain is represented by a surface

Isotropic Hardening model

σ2

Kinematic Hardening model

σ2

σ1

Initial yield surface

Surface of the stress domain

increases

http://www.midasNFX.com

σ1

Initial yield surface

Center of stress domain

surface moves

(surface area is maintained)

Nonlinear Static Analysis

51

Step

07

Elastoplastic model– Hardening model

Bauschinger effect

The Bauschinger effect refers to a property of materials where the material's stress/strain characteristics ch

ange as a result of the microscopic stress distribution of the material. For example, an increase in tensile yi

eld strength occurs at the expense of compressive yield strength.

Isotropic Hardening model and Kinematic hardening model are inaccurate, so we use a

combination of the 2 models center can move and yield surface increase at the same time

σ2

σ

σ1

ε

Initial yield surface

http://www.midasNFX.com

Nonlinear Static Analysis

52

Step

08

Stress-strain curve input method

Engineering stress VS True stress

Materials stress-strain curve Obtained through tensile tests does not take into account the changes in the

area. (engineering stress- nominal strain curve)

It is better to replace the input by the true stress – true strain curve which considers the change in surface.

L0

ΔL

Undeformed

A0

L

Deformed

True stress, True Strain calculation equations:

http://www.midasNFX.com

A

* this equation is valid only for 1D problem

Nonlinear Static Analysis

53

Step

09

Stress-strain curve input method

Engineering stress VS True stress

Plastic Strain Total Strain (

e True ln(1 e eng )

Eng. Strain

(mm/mm)

Eng. Stress

(MPa)

True Strain

(mm/mm)

True Stress

(MPa)

0.00000

0.00

0.00000

0.00

0.00112

264.70

0.00112

0.00400

264.70

0.00837

Yield Stress

)

Young ' s Modulus

Plastic Strain

(mm/mm)

True Stress

(MPa)

265.00

0.00000

265.00

0.00399

265.76

0.00287

265.76

276.14

0.00834

278.45

0.00722

278.45

0.01811

332.96

0.01795

338.99

0.01683

338.99

0.03170

383.16

0.03121

395.31

0.03009

395.31

0.04574

414.51

0.04472

433.47

0.04361

433.47

0.06505

439.14

0.06302

467.71

0.06190

467.71

0.08273

451.17

0.07949

488.50

0.07837

488.50

0.10447

458.31

0.09937

506.19

0.09825

506.19

0.12521

460.50

0.11797

518.16

0.11685

518.16

s True s eng (1 e eng )

http://www.midasNFX.com

Nonlinear Static Analysis

54

Step

10

Stress-strain curve input method

Perfectly Plastic Model

Inclination of the curve in plastic range is 0.

Beginning of plastic deformation is defined by Yield Stress

σ

ε

Perfectly Plastic Model

http://www.midasNFX.com

Nonlinear Static Analysis

55

Step

11

Stress-strain curve input method

Bi-Linear Model

Inclination of the curve in plastic range is

defined by a linear curve.

Plastic Hardening Curve is defined by stressstrain plastic hardening function.

σ

ε

Bi-linear Model

http://www.midasNFX.com

Nonlinear Static Analysis

56

Step

12

Stress-strain curve input method

Stress –strain function, Plastic Hardening function

Stress-Strain function

Plastic Hardening function (Defined as the plastic

part only of the stress –strain curve)

In the first line, stress and strain are null.

In the second line, Elastic strain and yield stress

are entered.

In the third line, Plastic strain and Plastic stress

are entered

In the first line, enter 0 for the strain and yield

stress.

In the second line, enter the plastic strain and

plastic stress.

* Value of the strain should be calculated correctly

form the yield point, which is the starting point of

the curve.

http://www.midasNFX.com

Nonlinear Static Analysis

57

Step

13

Stress-strain curve input method

Multi-Linear Model

Hardening interval of the curve is composed of several segments.

Curve is defined from real test data from experiment

σ

ε

Multi-linear Model

http://www.midasNFX.com

Copy and Paste

from Excel

Nonlinear Static Analysis

58

Step

Material Nonlinearity(2) –

Hyper Elasticity

http://www.midasNFX.com

Nonlinear Static Analysis

59

Step

01

Properties of Rubber materials

Rubber Material

Incompressibility appears because of the complex link between multiple polymer chains.

Differently from metallic materials, rubber materials can be submitted to large deformation due to

nonlinear elastic forces.

Because of their elastic resilience and vibration damping properties, rubber materials are energyabsorbent, excellent dust removal, dust-proof and soundproof.

Physical

properties

of rubber

material

hyperelasticity

viscoelasticity

Strain energy function, W

Creep effect

ε

Tertiary

Creep

Primary

Creep

Steady State

Creep

time

What is viscoelasticity?

Phenomenon in which the physical

properties of the material depend on

Hysteresis effect

Vibration

damping

the time.

http://www.midasNFX.com

Nonlinear Static Analysis

60

Step

02

Hyper elastic models

What is an Hyper elastic material?

Material loaded and submitted to a deformation of 500% can recover its original shape after unloading.

As a nonlinear material, nonlinear analysis have to be used, but principle of superposition can still be

used as for linear analysis.

s

s

Elasticity

K

e

Permanent deformation

http://www.midasNFX.com

e

Nonlinear Static Analysis

61

Step

03

Hyper elastic models

What are the properties of Hyper elastic materials?

Stress can be derivated from the strain energy density function.

Stress can be assumed from integration of the strain.

Midas NFX provide Mooney-Rivlin, Polynomial, Ogden, Blatz-Ko models of the strain energy density

function W.

The best way to approximate the strain energy density function is to use stress-strain experimental

data.

s

Real Behavior

Strain energy density

function used in midas

NFX

e

http://www.midasNFX.com

Nonlinear Static Analysis

62

Step

04

Theory of hyper elastic models

Strain energy density function (W)

Polynominal

Na

Shape deformation

Volumetric change

i+j=1

Nd

i=1

, ( Aij ,Di : Material constants)

More higher-order model can better express the stress-strain experimental data but requires

more material constants

Mooney-Rivlin Model

W( J1 , J2 , J3 ) = A10(J1 – 3) + A01(J2 – 3) + D(J3 – 1)2

It is the case of Na=1 in the polynomial equation.

It is the most widely used model. (the model is rather convenient than accurate)

http://www.midasNFX.com

Nonlinear Static Analysis

63

Step

05

Theory of hyper elastic models

Strain energy (W)

Ogden Model

Na

i+j=1

μi

αi

Nd

i=1

, ( αi, μi ,Di : Material constants)

It is difficult to express clearly the behavior of the material by using energy function

expressed with principal strains (J1,J2,J3).

Material constants are not directly expressing the physical properties of the material,

whole function is expressing it.

Blatz-Ko Model

μ

2

I2

I3

For the foam materials in which incompressible nature is not strong, the material

constants are reduced to the initial shear stiffness μ only.

http://www.midasNFX.com

Nonlinear Static Analysis

64

Step

06

Theory of hyper elastic models

Strain energy density function (W)

Definitions ( J1 , J2 , J3 )

* J1 , J2 , J3 = 1,2,3 axis strain invariants

L1

λ1L1

λ2L2

L2

λ3L3

L3

Undeformed

Deformed

λ1 · λ2 · λ3 = 1 incompressible

J1 = λ12 + λ22 + λ32

J2 = λ12 · λ22 + λ22 · λ32 + λ32 · λ12

J3 = λ12 · λ22 · λ32

http://www.midasNFX.com

Nonlinear Static Analysis

65

Step

07

Hyper elastic Material Assignment

Calculation of material constants

For Hyper –elastic material, a range of test have to be performed to obtain all material

constants (for elasto-plastic materials, only uni-axial tensile test is necessary).

1. Uni-axial tensile test

2. Bi-axial tensile test

3. Simple shear test

4. Pure shear test

5. Volume change test

Eng. stress / Eng. strain measured through the following

experiment Use the least squares method to

determine the material constants.

http://www.midasNFX.com

Nonlinear Static Analysis

66

Step

08

Hyper elastic Material Assignment

Calculation of material constants

※ 시편 길이비 10:1

Uni-axial tensile test

Simple shear test

http://www.midasNFX.com

Bi-axial tensile test– can be replaced by Pure shear test– pure shear stress calculation is

simple compression experiment

achieved using tensile experiment results and

rotation at 45˚

Volume change test– 취구는 크게 만들고 재료는 작은 재료를 넣는

압축력은 강성이 크기때문에 취구의 연성이 결과에 반

Nonlinear Static Analysis

67

Step

09

Hyper elastic Material Assignment

Calculation of material constants using stress-strain data-1

④ Select the type of experiment

① Select Hyper Elastic Tab

⑥ Click Add

⑤ Enter experiment data

② Assign Model Type

⑦ enter Poisson's ratio or

volumetric deformation

experimental data

⑨ Click Add

⑧ Select Type and order of calculation

③ Click Evaluate experimental data

⑨ Click Fit to Test Data…

http://www.midasNFX.com

Nonlinear Static Analysis

68

Step

10

Hyper elastic Material Assignment

Calculation of material constants using stress-strain data-2

⑩ Click on close after verifying stability limit information of the material

http://www.midasNFX.com

Nonlinear Static Analysis

69

Step

11

Hyper elastic Material Assignment

Calculation of material constants using stress-strain data-3

shape deformation

material constants

calculated

Mooney-Rivlin Model

W = A10( J1 – 3) + A01( J2 - 3 ) + D( J3 –

1 )2

Volume change material

constant calculated

⑪ Click Save and close

⑪ Click OK

http://www.midasNFX.com

Nonlinear Static Analysis

70

Step

12

Phenomenon that cannot be expressed with Hyper elastic material

Hysteresis Effect

When a rubber material composed of complex chains of polymers is loaded and

unload some loss of energy due to friction can occur.

Rubber

molecular

structure

s

loading

Theory

unloading

Real shape

Energy loss

e

Stress softening (Mullin`s effect) : Phenomenon

which describe the stabilization of the stress-strain

curve from the initial shape to a stabilized shape

after several cyclic loading.

http://www.midasNFX.com

Nonlinear Static Analysis

71

Step

13

Phenomenon that cannot be expressed with Hyper elastic material

Precautions to take for Hyper elastic Analysis

① Local slope can have a negative value, so the low order model is more stable.

s

Low order model

After Curve fitting, if such case happen, it is

High order model

better to consider the low-order model

(If presence of a negative slope in the curve)

e

② For Elasto plastic material, Von Mises stresses are usually investigated, whereas for

Hyper elastic materials, compressive stresses only are investigated.

A10 ,A01 << D1

,

WD <<

WH

In other words, stresses which are causing shape deformation are relatively smaller than

stresses causing volume change.

③ For complex rubber hyper-elastic materials , only nonlinear elasticity is considered

( Viscosity and Hysteresis are not included)

http://www.midasNFX.com

Nonlinear Static Analysis

72

Step

Contact Nonlinearity

http://www.midasNFX.com

Nonlinear Static Analysis

73

Step

01

Contact Nonlinearity

What is the reason to use contacts?

Load application

Load influence sent and

received through the nodal

points are connected to

adjacent elements.

In other words, if the nodes are not connected together, they cannot transfer the effect

of loads.

Most of the time, real models are composed of more than 2 bodies and it is quite

difficult to connect the nodes.

http://www.midasNFX.com

How to do ?

Nonlinear Static Analysis

74

Step

02

Outline of Contact Nonlinearity

Why is contact necessary?

No contact

Penetration occurs

between the

elements

No mutual influence because the

nodes are not connected

Contact

Elements in

contact

Contact creation

http://www.midasNFX.com

Nonlinear Static Analysis

75

Step

03

Outline of Contact Nonlinearity

What makes Nonlinearity phenomenon?

100N...200N...500N

1. Contact boundary and contact stresses

cannot be guessed in advance.

Research of the contact boundary is a part of the

analysis process.

As the degree of the contact stress or the

contact area depends on the size of the load,

the stiffness value change nonlinearly.

Contact Stress

Contact

Force

2. Rapid changes occur in the contact force

Before the body touch each other contact

force is null and rapidly increases at the

moment when the contact occurs.

Penetration

http://www.midasNFX.com

Nonlinear Static Analysis

76

Step

04

Contact Nonlinearity

Classification according to the contact surface properties

Flexible-flexible contact

Body 1 and Body 2 have similar stiffness values

and can all change shape.

Body 1

Body 2

Most general condition of contact

Flexible-Rigid contact

When the stiffness of one of the body is much greater than the other, this

body can be defined as rigid.

Stiffness matrix cannot be calculated numerically.

ex) 107

107

Steel

http://www.midasNFX.com

1

1

In this situation, considering this body as

rigid can help to reach convergence.

Ex) Iron (rigid) in contact with rubber

(flexible).

Rubber

Nonlinear Static Analysis

77

Step

05

The penalty method

The penalty method

When contact happens between 2 bodies, a small penetration first occurs, then some springs are created to link nodes which

are violating contact condition and surface of contact. A load (F=KΔδ) is then applied in the opposite direction to reduce

progressively the penetration. This is the process described below:

1.

Research of nodes/segments which infringe the contact condition .

Load application

Body 1

spring

Potential contact nodes

Penetration (Δδ)

Body 2

Nodes violating contact condition

2. Input a contact force to the nodes/segments which infringe the contact condition.

Contact force (Pushing out force)

http://www.midasNFX.com

Nonlinear Static Analysis

78

Step

06

The Penalty Method

Contact Pair - Master, Slave

Contact constraints

Nodes from Slave contact are not able to penetrate Master contact surface.

Nodes from Master contact are able to penetrate Slave contact surface.

For dense mesh, there is no real difference, but for coarse mesh, a big difference

can happen in function of Master-slave choice.

Selection of principal contact face (Master) and intermediate nodes (Slave)

Rigid surface is usually set as Master surface.

Convex surface is usually set as Slave surface.

Surface mesh more densely is usually set as Slave surface.

http://www.midasNFX.com

Master

Slave

Slave

Master

Nonlinear Static Analysis

79

Step

07

Contact Force

Contact Force ?

When penetration occurs, an external pushing force is applied. This force

is called Contact Force.

The larger the penetration, the bigger is the contact force.

Contact Force (spring in compression)

FC Kn g

Penalty parameter (Kn) : Contact Stiffness

- Dependent on the stiffness of the material

- The larger is Kn, the smaller is the penetration (in order to obtain same contact force)

g<0

FC

http://www.midasNFX.com

Nonlinear Static Analysis

80

Step

08

Contact Force

Contact Stiffness Parameter

Contact stiffness is expressed as the product

of a constant and the material stiffness.

Kn SF E

SF 1.0

Elastic module of flexible body

With high contact stiffness, solution will be more accurate.

A high contact stiffness is used to limit penetration.

As we use a high contact stiffness, the model is

submitted to vibrations and it may cause a convergence

problem.

Load

Contac

t Force

< when relatively high contact stiffness is applied, it causes vibrations in the model>

http://www.midasNFX.com

Nonlinear Static Analysis

81

Step

09

Contact Force

Friction Force

Friction force

mFC

Body 1

Friction force doesn’t increase

Cause shear stress

Friction force

Kt

Relative

displacement

Stick region,

Just before slipping happens a small elastic

deformation happen. If the load is released in

this region, it will come back to the initial state.

Slip region, Kt·s doesn’t exist, only μFc is

applied

Contact force

Ff Kt s

FC

Stick (Kt: Tangent

Slip

stiffness)

In other words, the tangential stiffness determines the

status of the Stick

There is a relation with the shear strength of the material.

If Kt is high, the behavior of the contact surface is

almost rigid.

Friction

force

mFC

Kt

Relative

displacement

If Kt is small, the relative displacement depends linearly

of the friction force.

http://www.midasNFX.com

Nonlinear Static Analysis

82

Step

10

Contact Force

Horizontal Stiffness

Expressed as the product of a constant and

the material stiffness.

Kt SF E

SF 0.5

Elastic module of flexible body

http://www.midasNFX.com

Nonlinear Static Analysis

83

Step

11

Types of contact

Types of contact

Vertical

Behavior

Horizontal

Behavior

Welded Contact No separation No separation

Linear

Contact

Sliding Contact No separation Sliding occurs

Contact

Rough Contact

Separation

No Sliding

General

Contact

Separation

Sliding occurs

(Friction)

Noninear

Contact

*Linear contact can be applied in nonlinear analysis,, but

nonlinear contacts can not be used in Linear Analysis.

*If friction is used, shear stress will happen before sliding in

movement direction.

http://www.midasNFX.com

Normal Behavior

Shear Behavior

Nonlinear Static Analysis

84

Step

12

Types of contact

Types of contact

Surface – Surface Contact

User don’t need to define separately Master contact and Slave contact surfaces, because contact

occurs indifferently in the 2 directions.

It is perfect when sliding and friction in multiple directions are considered.

Surface – node Contact

In the case when contact occurs between nodes of slave contact surface and Master surface, nodes

of the slave contact surface will always penetrate the Master contact surface.

If unreasonable Slave and Master contact surface are chosen, it can results in incorrect results or in

convergence error.

In other words, Slave and Master contact surfaces have to be chosen well, with good

understanding of the penalty method defined in the previous slides.

In the penalty Method…

Master contact surface is usually chosen as the surface flat or with relatively high

stiffness, whereas, Slave contact surface is usually chosen as the surface convex or

with relatively low stiffness. Moreover, Surface meshed more densely has to be

defined as the slave surface.

http://www.midasNFX.com

Nonlinear Static Analysis

85

Step

13

Method of contact creation

Auto Contact

When contact is found within the scope of the

search, contact is automatically defined.

When search distance is set to “Auto”, search

distance is determined in function of the mesh size.

The Master contact surface and the slave contact

area are determined randomly.

ex) when search distance is set to 20mm

Contact surface is search between

meshes within 20mm of distance.

If an excessively large Searching Distance is used, meshes

which are not in contact will be included in the contact, so

an appropriate Searching Distance should be used.

http://www.midasNFX.com

Nonlinear Static Analysis

86

Step

14

Method of contact creation

Manual Contact

Master contact and Slave contact surfaces are

defined manually.

By selecting only the areas where contact is

expected to happen, duration of analysis can be

reduced.

Expected area of contact

http://www.midasNFX.com

Nonlinear Static Analysis

87

Step

15

Method of contact creation

Self Contact

When contact occur between external surface of elements of one mesh set,

self-contact is used.

Self contact is efficient when contact points are numerous and when it is

difficult to estimate the contact points.

http://www.midasNFX.com

Nonlinear Static Analysis

88

Step

16

Contact Algorithm

Contact Parameters

Contact tolerance

Constant value used for the calculation of the contact search distance.

(For welded contact and bi-linear sliding contact, contact happen when

Master and Slave contact surfaces are within defined search distance. In

case of general contact or rough contact, contact happens when Master

and Slave contact surfaces arrive within the search distance).

Master Contact Extension Ratio

Contact surface search distance is defined as the product of Master

contact surface mesh size and this value. Defaults value is 0.005 and can

be modified to increase or decrease the contact search area

Remove Initial Penetration by Adjusting Slave Nodes

At the beginning of the analysis, if the slave contact nodes are already

penetrating the master contact surface, position of the slave nodes is

changed in order to suppress automatically the penetration.

Structural Nonlinear Analysis without Geometric NonlinearityMax. Search Distance

When Geometric Nonlinearity is not considered, this option defines

the search distance from the Master contact surface to find the

slave contact surface.

•

Normal Failure force: When using breaking weld

contact, contact will be separated if the contact

force is superior to the Normal Failure Force.

•

Shear Failure Force: When using breaking weld

contact, contact will be separated if the shear

contact force is superior to the Shear Failure Force.

http://www.midasNFX.com

Nonlinear Static Analysis

89

Step

http://www.midasNFX.com

Nonlinear Static Analysis

90

Step

Conclusion and advice for a better

use of Nonlinear Analysis

http://www.midasNFX.com

Nonlinear Static Analysis

91

Step

01

Conclusion and advice for a better use of Nonlinear Analysis

Principal useful tips

① Perform Linear Analysis Case before running Nonlinear Analysis

By performing linear analysis, you can judge whether or not to perform Nonlinear Analysis (depending on the

deformation).

If stresses or displacement are too large in linear analysis, design of the product has to be reviewed.

By performing linear analysis, areas where large stresses or deformation happen can be estimated and smaller mesh

can be refined in these areas.

By performing linear analysis, areas where contacts happen can be estimated in order to create the most appropriate

and effective contact surfaces.

② Parameter settings required for Nonlinear Analysis

Load increments are one of the most important of the parameter settings. It cannot work properly for example if

the plastic state is reached since the first increment. Increment number has to be set in order to get reasonable

results (It is still possible to get difficult convergence)

Convergence criteria selection, Geometric nonlinearity option, Line search Method, Subcase activation, Contact

parameters

Use of Restart feature(Convergence-related parameters can be applied and adjusting to save a lot of time)

Understand the principle of special nonlinear analysis (geometry, contact, material)

Ex 1) Choice of hyper elastic material to estimate properties of rubber materials

Ex 2) Use of Arc-length method for nonlinear buckling analysis

http://www.midasNFX.com

Nonlinear Static Analysis

92

Step

02

Conclusion and advice for a better use of Nonlinear Analysis

Principal useful tips

③ Finite element modelling for nonlinear analysis

With appropriate modelling, analysis speed and convergence will increase substantially. Nonlinear analysis consumes a

lot of time if we compare with linear analysis and a simplification of the model is also necessary. In order to create

the best model for Nonlinear analysis, the points below have to be considered:

1)

Use symmetry condition when possible

Cannot be used for nonlinear buckling analysis or dynamic analysis

2)

Use Beam, shell, or flat idealized elements when possible

3)

Minimize the use of nonlinear material model

Use nonlinear material model only for element which are subjected to plastic deformation

4)

Create dense and smooth mesh in areas of high strain

Make even denser mesh in areas of contact

5)

Evaluate the zones where large deformation will happen and make appropriate mesh to fit deformed shape.

When possible, use rotation or extraction feature to create Hexa or Penta element meshes

Results will be much more accurate than tetrahedral elements.

Pay attention to the Mesh quality (Aspect Ratio, Skew Angle) , because it can create convergence problems in

bad mesh quality areas.

Simplify the fillets and holes which are not important for your analysis

http://www.midasNFX.com

Nonlinear Static Analysis

93