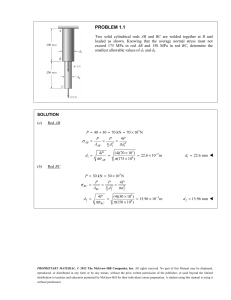

ME-549 ASSIGNMENT-1 PART-1 Name Devanshi Sawhney Entry Number 2021MEB1281 Course Name Additive Manufacturing Course Instructor Dr. Prabir Sarkar 1. INTRODUCTION The purpose of this report is to outline the steps involved in the manufacturing of a connecting rod, a critical component used in internal combustion engines. The connecting rod transfers motion from the piston to the crankshaft and plays a crucial role in the engine's operation. This report focuses on the subtractive manufacturing processes used to create the connecting rod. 2. COMPONENT DESIGN The connecting rod was designed with intricate geometry, including a rod body, cap, piston and crankshaft attachments, and threaded holes for fasteners. A drawing is attached below: 3. PROCESS OVERVIEW The manufacturing of the connecting rod involves several subtractive manufacturing processes to achieve the desired geometry, mechanical properties, and surface finish. The key processes used are as follows: 3.1 Pattern Making A pattern is created to replicate the shape of the connecting rod. This pattern serves as the basis for creating the mold for the casting process. 3.2 Casting The pattern is used to create a mold, into which molten metal is poured to form the connecting rod. Casting allows for the initial shape to be formed. 3.3 Thread Cutting Thread cutting is performed on the connecting rod to create precise threads for attachment points. Threading is essential for secure fastening of the connecting rod within the engine assembly. 3.4 Cutting Force calculation in Turning Cutting force calculations are performed during turning operations to ensure the machining process does not exceed the machine tool's capacity. 3.5. Tool Making Specialized cutting tools are manufactured to facilitate various machining operations, including turning and milling, during the subtractive manufacturing process. 3.6 Heat Treatment The connecting rod undergoes heat treatment, including quenching and tempering, to achieve the desired mechanical properties of strength and durability. 3.7 Metallography Metallographic analysis is conducted to examine the microstructure of the connecting rod material post heat treatment. This ensures that the desired material properties are achieved. 3.8 Non-destructive testing Nondestructive testing methods, such as ultrasonic testing and dye penetrant testing, are employed to detect any potential defects or flaws within the connecting rod. 3.9 Welding Welding is used for assembly if the connecting rod comprises multiple pieces, such as a forged cap attached to the main body. 4. CONCLUSION In conclusion, the manufacturing of a connecting rod involves a comprehensive sequence of subtractive manufacturing processes. These processes, including pattern making, casting, machining, heat treatment, and quality control techniques, collectively ensure the creation of a reliable and high-quality connecting rod for use in internal combustion engines.