Fly Ash Hybrid Binders: Chemical Activation & Hydration Kinetics

advertisement

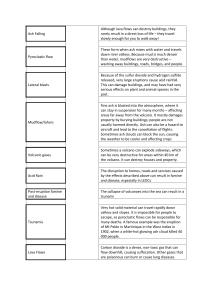

Cement and Concrete Composites 66 (2016) 10e23 Contents lists available at ScienceDirect Cement and Concrete Composites journal homepage: www.elsevier.com/locate/cemconcomp Chemical activation of hybrid binders based on siliceous fly ash and Portland cement Salaheddine Alahrache a, Frank Winnefeld a, *, Jean-Baptiste Champenois b, Frank Hesselbarth c, Barbara Lothenbach a a b c Empa, Swiss Federal Laboratories for Materials Science and Technology, Laboratory for Concrete and Construction Chemistry, Dübendorf, Switzerland Saint-Gobain Recherche, Aubervilliers, France Saint-Gobain Weber, Datteln, Germany a r t i c l e i n f o a b s t r a c t Article history: Received 5 June 2015 Received in revised form 25 September 2015 Accepted 2 November 2015 Available online 6 November 2015 The hydration of Portland cement (PC) blended with a high amount of a siliceous fly ash (70% fly ash, 30% PC) has been examined. The fly ash contributes significantly to the long-term strength development, when compared to a reference sample with quartz powder. However the long setting time and the poor early strength prevent the use of such binders. Therefore the effect of different activators (sodium carbonate, potassium sodium silicate, potassium citrate and sodium oxalate) on the setting, the hydration kinetics and the strength development of the fly ash-PC blend has been investigated. The addition of the activators increases the pH and decreases thus the calcium concentrations in the pore solution, which leads to a faster reaction of alite and thus to early setting and increased early strength. On the long term, the high alkali concentrations lower the compressive strength and lead to a (partial) destabilization of ettringite. Sodium oxalate and potassium sodium silicate accelerate both the setting of the fly ash-PC blend and increase the early compressive strength. Furthermore, they show better compressive strengths at later ages compared to the other activators. Based on these findings, they can be considered as the most suitable accelerators among the investigated activators. © 2015 Elsevier Ltd. All rights reserved. Keywords: Fly ash Chemical activation Hydration kinetics Hybrid binders Hydration degree Thermodynamic modeling 1. Introduction Coal is the biggest single source of energy for electricity production; coal-fired power plants provide over 42% of global electricity supply [1]. As a by-product large quantities of fly ash are generated. In 2004, the United States generated 70.8 million tons of coal fly ash and 60% of this ash was disposed into ground or ocean [2]. Europe produced 41 million tons of coal fly ash in 2007, and the re-utilization rate was only 47% [2]. Approximately 33% of the total fly ash is used in Europe as cement raw material, as constituent of blended cements and as mineral addition for the production of concrete [3]. The production of Portland cement consumes a lot of natural resources and energy and emits greenhouse gases, mainly CO2. In this context, using fly ash as a partial substitute for Portland cement (PC) in blended cements, dry mix mortars or concrete is a frequent solution for upcycling the fly ash and decreasing the use of * Corresponding author. E-mail address: frank.winnefeld@empa.ch (F. Winnefeld). http://dx.doi.org/10.1016/j.cemconcomp.2015.11.003 0958-9465/© 2015 Elsevier Ltd. All rights reserved. Portland cement clinker and therefore the consumption of energy and the production of CO2. However, there are limits for the use of fly ash in blended cements or concrete set by the respective standards and building codes. A possibility for the use of high quantities of fly ash in building materials is their application in alkali activated binders [4e10]. However, generally high additions of strong alkaline activators are needed in such systems. In its simplest form, the activator is a highly concentrated alkali hydroxide (up to 14 M) such as sodium hydroxide or potassium hydroxide [11e13] or alkali silicate solution [14e16]. The strongly alkaline solution promotes the reaction of fly ash and the formation of alumosilicate gels such as Na2OeAl2O3eSiO2eH2O gel (N-A-S-H) [17e19]. The high alkalinity required in this type of activation might cause health issues, especially when such binders are used in dry mix mortar formulations (e.g. tile adhesives), where the workers may get into direct contact with the highly alkaline material. A mixture of fly ash with Portland cement avoids the use of alkaline solutions. In this case, the PC hydration provides the early compressive strength and the S. Alahrache et al. / Cement and Concrete Composites 66 (2016) 10e23 Ca(OH)2 formed by the hydration of PC reacts later with the fly ash. The main hydration products of such blends are generally CeSeH, portlandite, ettringite and AFm phases [20e25]. As fly ash reacts only slowly in such systems, activation especially for blends with high fly ash contents is needed, preferably avoiding highly alkaline conditions. For fly ash blended PC, the effect of different such “mild” activators have previously been rendez-Jime nez et al. [23] found that the hydration of a ported. Ferna blend of 80 mass-% fly ash and 20 mass-% PC in the presence of 4 mass-% Na2CO3 or 4 mass-% Na2SO4 generates a mix of C-(A)-S-H and (C)eN-A-S-H gels. In addition, calcite is formed in the case of Na2CO3 and ettringite in the case of Na2SO4 activator. Na2SO4 activator accelerates also the early alite hydration. The use of other activators like CaCl2 [26,27] and alkali and alkali-earth sulfates [28,29] has been reported as well. Besides, the alkalinity of the pore solutions is increased and the initial pozzolanic reaction of the fly ash is accelerated. Recently, activators with carboxylate functions (e.g. citrates, lactates) were patented for fly ash based binders free of PC [30e33], which seem to be particularly efficient with class C fly ashes. However there is a lack of detailed studies of activators with limited alkalinity and of their efficiency in accelerating very high volume fly ash hybrid binders based on low calcium fly ash and Portland cement. In this article, a detailed study of the interaction of a siliceous fly ash-PC blend (70/30 by mass) with chemical activators (potassium sodium silicate ¼ (K,Na)2SiO3; sodium carbonate ¼ Na2CO3; sodium oxalate ¼ Na2Oxalate; potassium citrate ¼ K3Citrate) is presented. The influence of the selected activators on the hydration of a fly ash-PC blend was investigated by calorimetric, chemical shrinkage and compressive strength measurements. The chemical composition of the pore solutions was analyzed by ion chromatography at different hydration times, and the nature of the hydrate phases was examined by X-ray diffraction. The reactivity of the fly ash in a simulated PC environment (pozzolanic test using a slurry of Ca(OH)2 þ CaCO3 þ KOH according to [22]) in the presence of the different activators was studied. Thermodynamic modeling was used to calculate the reaction degree of the fly ash as derived from the pozzolanic test and the effective saturation indices of the relevant hydrate phases using the pore solution composition. A possible application of these high fly ash blended cements would be the use in dry mix mortars (e.g. tile adhesives) where a high compressive strength is not necessary. However, setting time and strength development should be rapid enough to allow an application at usual open times for a conventional (not rapidhardening) tile adhesive. 2. Materials and methods 2.1. Raw materials Portland cement (CEM I 52.5 N acc. to EN 197e1) and a siliceous fly ash (type V according to EN 197-1) were used as raw materials. Their chemical and mineralogical compositions obtained by X-ray fluorescence (XRF) and quantitative X-ray diffraction analyses (QXRD) as well as the particle characteristics of the fly ash are compiled in Table 1. As inert reference material, a quartz powder with similar particle size distribution as the fly ash was used (see Appendix). The quartz showed no significant pozzolanic reactivity at 20 C up to 91 days of hydration (see Appendix). Laboratory grade chemicals were used as activators. Their purity is as follows: (K,Na)2SiO3 (composition K2O ¼ 19.6 mass-%, Na2O ¼ 9.2 mass-%, SiO2 ¼ 59.1 mass-%, H2O ¼ 12.1 mass-%), Na2CO3 (>99.95%), Na2Oxalate (>99.5%) and K3Citrate (>99.5%). 11 Na2CO3 and Na2Oxalate were applied as fine powders (all particles < 63 mm), the K3Citrate used had a particle size mainly between 125 and 250 mm, and (K,Na)2SiO3 had a particle size distribution of 25% particles above 200 mm and 25% particles below 63 mm. The selection of the activators was based on a literature survey followed by a previous screening test regarding setting times. 2.2. Preparation of cement pastes Cement pastes containing 70 mass-% of FA and 30 mass-% of PC or 70 mass-% of quartz powder and 30 mass-% of PC were blended with a IKA Ultra-Turrax T50 mixer at 360 rpm for 30 s and then at 600 rpm for another 30 s using a water to binder ratio (w/b) of 0.40. The activators were added as dry powder to the fly ash-PC blend in the following proportions: 2 mass-% (K,Na)2SiO3, 3 mass-% Na2CO3, 8 mass-% Na2Oxalate and 3 mass-% K3Citrate referred to total binder. These amounts of activators were selected based on preliminary tests of setting time. In the case of (K,Na)2SiO3 the dosage refers to the dry matter. All experiments were carried out at 20 C. 2.3. Setting time The setting time measurements were carried out with a Vicat needle apparatus according to EN 196e3 at a relative humidity of 70%. 2.4. Conduction calorimetry The development of the hydration heat flow of the samples was investigated using a TAM Air isothermal calorimeter (TA Instruments). About 7 g of freshly mixed paste were weighed into a flask, which was then capped and placed into the calorimeter. The duration of the measurements was 7 days. The cumulative heat of hydration was determined by integration of the heat flow curve between 1 h and 7 days. 2.5. Chemical shrinkage Chemical shrinkage was measured according to Procedure A described in ASTM C 1608e07. About 5 g of freshly mixed paste were inserted in a glass vial, and de-aired and demineralized water was added. A graduated pipette with a total volume of 1.00 ml and an accuracy of 0.01 ml was inserted. Paraffin oil was added in the pipette to avoid water evaporation. The vials were immersed in a temperature-controlled water bath at 20 C. Measurements were performed by reading the watereoil interface level of the pipettes at regular intervals during 28 days on three replicate specimens. This method can be used to assess the reactivity of supplementary cementitious materials such as fly ash [22] or slag [34]. 2.6. Compressive strength Compressive strength was measured on mortars in accordance to EN 196e1 with a w/b ratio of 0.50. The filled molds were stored at 20 C and a relative humidity of >95%. The prisms were demoulded after 1 day and cured subsequently at 20 C in sealed bags. Compressive strength was tested after 1, 3, 7, 28 and 91 days. 2.7. Pozzolanic reactivity test In order to determine the reactivity of the fly ash in the presence of the activators, the consumption of portlandite due to the reaction of the fly ash (or quartz) in a simulated PC environment (i.e. a slurry of Ca(OH)2 þ CaCO3 þ KOH) was determined according to [22]. A 12 S. Alahrache et al. / Cement and Concrete Composites 66 (2016) 10e23 Table 1 Characteristics of the fly ash (FA) and the Portland cement (PC) used in this study expressed in mass percent. XRF analysis Mineralogical phase composition Average composition FA PC FA PC FA glassy phase 1 55.4 23.5 Mullite 9.5 Alite 64.6 SiO2 59.4 SiO2 Al2O3 22.2 3.9 Quartz 7.5 Belite 19.9 Al2O3 19.8 Fe2O3 8.1 1.4 Hematite 0.9 Aluminate 7.8 Fe2O3 6.8 0.02 0.01 Magnetite 1.8 Ferrite 1.6 Cr2O3 <0.1 Cr2O3 MnO 0.09 0.05 Periclase 0.6 Gypsum 0.4 MnO 0.1 TiO2 0.9 0.2 Anhydrite 0.2 Hemihydrate 0.8 TiO2 1.1 P2O5 0.7 0.2 Glassy phase 77.8 Anhydrite 2.9 P2O5 0.9 CaO 4.3 64.8 TOC 2 1.8 Calcite 1.6 CaO 5.4 MgO 1.9 0.7 Quartz 0.4 MgO 2.1 K2O 2.2 0.7 K2O 2.9 Na2O 1.1 0.04 Na2O 1.3 0.2 3.0 SO3 0.1 SO3 SrO 0.2 n.d. 3 BaO 0.2 n.d. 3 Particle characteristics of the FA 6 Density (g/cm3) d10 (µm) d50 (µm) d90 (µm) L.O.I. 4 2.3 1.5 C5 2.0 n.d. 3 2.23 2.4 21 147 1 The average composition of the fly ash glass phase was calculated by subtracting the composition of the crystalline phases from the total composition of the fly ash as determined by XRF. 2 TOC = total organic carbon, refers mainly to unburnt carbon 3 n.d. = not determined 4 L.O.I = loss on ignition 5 total carbon content determined by combustion analysis 6 The particle size distribution by laser diffraction (Malvern Mastersizer X, dispersion in isopropanol with ultrasound) is given in the Appendix. blend of 7.50 g of fly ash (or quartz as reference), 7.88 g of portlandite and 1.13 g of calcite was mixed with 20.25 g of 0.3 M KOH solution without or with activators. The samples were cast in 60 ml polyethylene flasks, sealed and stored at 20 C under agitation with a shaker until the time of testing (after 7, 28 and 91 days). The hydration of the pastes was stopped before being analyzed by solvent exchange with isopropanol and subsequent washing of the residue with diethyl ether. A short drying for 5 min at 40 C was applied to evaporate the remaining diethyl ether. The solid phase was analyzed by thermogravimetry (Mettler Toledo TGA/SDTA 851). A sample of approximately 40 mg was heated with 20 C/min from 30 C to 980 C under nitrogen atmosphere. The amount of portlandite was determined from the weight loss between 375 and 525 C using the tangential method and referred to the mass of the paste ignited at 900 C [21,22]. The decrease of portlandite content with hydration time can be used as characteristic value for the pozzolanic reaction and for the reaction degree of the fly ash. However, the partial consumption of the Ca(OH)2 by the activator (e.g. the sodium oxalate removes a part of the calcium hydroxide by the precipitation of calcium oxalate) should be taken into consideration. The reaction degree of the fly ash is calculated by thermodynamic modeling referring to the amount of the Ca(OH)2 consumed by the fly ash (see Chapter 2.10). 2.8. X-ray diffraction analyses For determining the phase compositions of the PC and the fly ash by Rietveld refinement [35e37] a Panalytical X'Pert Pro MPD diffractometer in a qe2q configuration with an incident beam monochromator and CuKa1 radiation was used. The samples were scanned for 120 min between 5 and 75 2q using the X'Celerator detector. For the quantification of the amorphous content of the fly ash, the G-factor method [38e40] was applied using CaF2 as external standard. The X-ray diffraction analyses of the hydrated pastes were carried out after a hydration time of 28 days. The hydration was stopped by solvent exchange method as described previously. A Panalytical X'Pert Pro MPD diffractometer in a qeq configuration with CoKa radiation was used. The diffractograms were recorded using the X'Celerator detector between 5 and 85 2q with a measurement time of 60 min and evaluated qualitatively. For phase identification and Rietveld refinement, X'Pert High Score Plus 3.0 software from Panalytical was used. 2.9. Pore solution analyses After 6 h, 1, 7 and 28 days of hydration, the pore solutions were extracted by the steel die method [41] using pressures up to 255 MPa. The collected solutions were filtered with nylon filters with a mesh size of 0.45 mm. The concentrations of Na, K, Ca, Al, Si and sulfate were measured by ion chromatography (Dionex DP ICS-3000). Each solution was diluted by a factor 5, 10 and/or 100 and measured in duplicate. The hydroxide concentrations of the pore solutions were determined in undiluted samples with a combined pH electrode calibrated against KOH solutions of known concentrations. 2.10. Thermodynamic modeling Thermodynamic modeling was used to study the chemical and mineralogical changes associated with the addition of the activators to the fly ash-PC blends. The calculations were performed using the Gibbs free energy minimisation software GEMS [42,43] using the Nagra/PSI Thermodynamic database [44] expanded with additional data for solids relevant for cementitious systems [45e47] and for oxalate and citrate [48e50]; a summary of the thermodynamic data used for the organics is given in Table 2. The alkali uptake by CeSeH was taken into account using a distribution ratio Rd of 0.42 ml/g [51,52] for both Na and K. The aluminum uptake in CeSeH was neglected in the calculations as it is generally low in PC dominated cements and as thermodynamic models for aluminum uptake by high Ca/Si CeSeH are not yet available for the GEMS cement database. S. Alahrache et al. / Cement and Concrete Composites 66 (2016) 10e23 13 Table 2 Summary of the thermodynamic data used for citrate and oxalate. Cit ¼ OOC-CH2-C(OH)COOeCH2eCOO, Ox ¼ OOC-COO. Species Aqueous HCit2H2Cit1H3Cit0 MgCitMgHCit0 MgH2Citþ CaCitCaHCit0 CaH2Citþ KCit2K2CitNaCit2Na2CitAlHCitþ AlCit0 AlCitOHSolids H3Cit(cr) Ca3Cit2(H2O)4(cr) Aqueous HOxH2Ox MgOx(aq) Mg(Ox)22 CaOx(aq) 2Ca(Ox)2 Solids CaOx$H2O(cr) CaOx$2H2O(cr) CaOx$3H2O(cr) Reaction Reference log KS0 HCit2 4 Cit3 þ Hþ H2Cit 4 HCit2 þ Hþ H3Cit04 H2CitMgCit 4 Mg2þ þ Cit3MgHCit0 4 Mg2þ þ HCit2MgH2Citþ 4 Mg2þ þ H2CitCaCit 4 Ca2þ þ Cit3CaHCit0 4 Ca2þ þ HCit2CaH2Citþ 4 Ca2þ þ H2CitKCit2 4 Kþ þ Cit3 K2Cit 4 2Kþ þ Cit3NaCit2 4 Naþ þ Cit3Na2Cit 4 2Naþ þ Cit3AlHCitþ 4 Al3þ þ HCit2AlCit0 4 Al3þ þ Cit3AlCitOH þ Hþ 4 AlCit0 6.36 4.78 3.13 4.81 2.60 1.31 4.80 2.92 1.53 1.03 1.39 1.00 1.81 4.70 8.00 3.40 [48] [48] [48] [48] [48] [48] [48] [48] [48] [49] [49] [49] [49] [50] [50] [50] 1.33 17.9 [48] [48] HOx 4 Ox2 þ Hþ H2Ox 4 HOx þ Hþ MgOx 4 Mg2þ þ Ox22þ Mg(Ox)2 þ 2 Ox22 4 Mg CaOx(aq) 4 Ca2þ þ Ox22Ca(Ox)2 2 4 CaOx(aq) þ Ox 4.25 1.40 3.56 5.17 3.19 0.83 [48] [48] [48] [48] [48] [48] CaOx$H2O(cr) 4 Ca2þ þ H2O(l) þ Ox2CaOx$2H2O(cr) 4 Ca2þ þ 2H2O(l) þ Ox2CaOx$3H2O(cr) 4 Ca2þ þ 3H2O(l) þ Ox2- 8.73 8.30 8.19 [48] [48] [48] H3Cit(H2O) (cr) 4 H3Cit0 þ H2O Ca3Cit2(H2O)4(cr) 4 3Ca2þ þ 4H2O þ 2Cit3- GEMS was used to calculate the activities of the aqueous species in the pore solutions using the extended DebyeeHückel equation [53]. The saturation indices (SI) of the solid phases were calculated by the equation: SI ¼ log(IAP/KS0) with IAP ¼ ion activity product calculated from the measured concentrations and KS0 ¼ solubility product of the solid. As the use of SI can be misleading when comparing phases which dissociate into a different number of ions, effective SI were calculated by dividing the SI by the number of ions participating in the reactions to form the solids, see Ref. [54] for details. A negative effective saturation index corresponds to undersaturation, a positive value corresponds to oversaturation. GEMS was also applied to calculate the hydration degree of the fly ash based on its consumption of Ca(OH)2 in the pozzolanic tests. The fraction of fly ash reacted was obtained based on the comparison of the observed consumption of portlandite with the expected consumption of portlandite per g fly ash using mass balance calculations carried out in GEMS. In the cases of Na2CO3, Na2Oxalate and K3Citrate addition the consumption of portlandite by the precipitation of the respective calcium salts is considered. Moreover, the effect of increasing amounts of the added activators on the hydrate assemblage after 28 days of the fly ash-PC blend was determined by GEMS, assuming complete hydration of the PC. For the fly ash reaction degree after 28 days a value of 7% was chosen which is in agreement to previous studies [55e57] and the results obtained in the present study for the plain PC-fly ash blend. 3. Results and discussions 3.1. Fly ash e PC blend without activator The plain fly ash-PC blend is used as a reference to understand the effect of the different activators. In addition, a quartz reference is used to study the effect of the fly ash on PC hydration. 3.1.1. Hydration kinetics The fly ash-PC blend shows an initial setting after 9 h (Table 3). This relatively late setting is in agreement with the low content of Portland cement. The calorimetric measurement shows two significant heat flow maxima during the first 30 h corresponding mainly to the PC reaction (Fig. 1a). The first peak after around 16 h is attributed to alite reaction while the second peak after around 20 h corresponds to the depletion of calcium sulfate and the renewed reaction of aluminate [58]. Some authors have reported that the fly ash increased the reactivity of PC as the higher effective water to cement ratio in the fly ash blended cement creates more space for the growth of the PC hydrates [59e61] and as the additional nucleation sites on the fly ash particles surface promote the hydration of PC [62,63]. The quartz reference shows a much faster heat development as previously shown e.g. by Deschner et al. [22], indicating that fly ash surfaces are less efficient regarding acceleration of PC hydration compared to quartz surfaces, that the presence of easily soluble solids associated with the fly ash might retard the PC reaction or that the aluminum released from the fly ash might delay alite dissolution [64]. The retarding effect of the fly ash compared to quartz is only visible during the first day of hydration. After 24 h, both mixtures show the same cumulative heat (Fig. 1b) and the Table 3 Initial and final setting time of the fly ash - PC blend (70/30 by mass) without and with activators. Activator Initial setting time (h) Final setting time (h) without activator 2 mass-% (K,Na)2SiO3 3 mass-% Na2CO3 8 mass-% Na2Oxalate 3 mass-% K3Citrate 9.0 1.5 2.5 5.3 3.3 10.0 4.5 5.3 6.0 11.3 14 S. Alahrache et al. / Cement and Concrete Composites 66 (2016) 10e23 Fig. 2. a) Chemical shrinkage of the fly ash-PC blends without and in the presence of the different activators, b) Evolution of the fly ash degree of reaction calculated by GEMS using the data from the pozzolanic test as a function of hydration reaction time in the presence of the different activators. Fig. 1. Conduction calorimetry of the fly ash-PC and of the quartz-PC blends (70/30 by mass) without and with (K,Na)2SiO3 and Na2CO3, respectively, (a) specific heat flow, (b) cumulative heat normalized to the solid content. same compressive strength (Table 3). The cumulative heat (Fig. 1b) and chemical shrinkage (Fig. 2a) of the fly ash blended PC increase with time. The early chemical shrinkage is associated to PC hydration, while the fly ash contributes rather to the late chemical shrinkage. Thus also the compressive strengths of the fly ash-PC and the quartz-PC blends are comparable during the first 7 days of curing, as mainly the PC has reacted (Table 3). The compressive strength of the quartz reference shows only a slight strength gain between 7 and 91 days and reaches a value of 13 MPa after 91 days. The compressive strength of the fly ash continues to increase with time and reaches 35 MPa after 91 days, indicating that the fly ash contributes positively to the long-term development of compressive strength. 3.1.2. Reactivity of fly ash The reactivity of the fly ash is studied in a simulated PC environment by a pozzolanic test, i.e. by measuring the portlandite consumption in samples containing Ca(OH)2 and CaCO3 in 0.3 M KOH solution to mimic the pH conditions of a Portland cement. The TGA analyses of the fly ash samples after 7, 28 and 91 days of reaction show peaks in the derivative weight loss curve indicating the presence of ettringite (the aluminate and the sulfate originate from the fly ash), hemi- and monocarbonate and portlandite at around 105 C, 125e175 C and 470 C, respectively (see Appendix); a broad peak from 50 to 400 C indicates the presence of CeSeH. The portlandite content decreases with time due to the reaction of the fly ash, while no such change is observed in the quartz sample. Fig. 2b shows the fly ash reaction degree as obtained by comparison of the observed consumption of portlandite with the expected consumption of portlandite based on mass balance calculations using GEMS. The reaction of the fly ash increases with time and reaches approximately 20% after 91 days. 3.1.3. Hydration products The hydration of the fly ash blended with PC at 20 C results in the formation of monocarbonate, hemicarbonate, ettringite and portlandite as shown by the X-ray diffraction pattern of the plain fly ash-PC paste after 28 days of curing (Fig. 3a). The TGA data confirms this finding (Fig. 3b). CeSeH cannot be detected by XRD due to its ill-crystalline/amorphous nature, but its presence can be derived from the TGA data. The observed phases are in agreement with previous observations in similar systems [23]. 3.1.4. Pore solution analyses and saturation indices The reaction of fly ash blended with Portland cement leads to the formation of a low Ca/Si CeSeH, to an increase of the silicon and to a decrease of calcium concentrations in the pore solution S. Alahrache et al. / Cement and Concrete Composites 66 (2016) 10e23 15 Fig. 3. X-ray diffraction patterns (a) and TGA thermograms (b) of the fly ash e PC blend without and in the presence of (K,Na)2SiO3 and Na2CO3, respectively, after 28 days of hydration at 20 C (A ¼ alite, B ¼ belite, C ¼ calcite, E ¼ ettringite, Hc ¼ hemicarbonate, M ¼ mullite, Mc ¼ monocarbonate, P ¼ portlandite, Q ¼ quartz). [21,22] as shown in Fig. 4 for the sample without activator. The pH values increase up to 7 days of hydration due to dissolution of alkalis from the anhydrous compounds and due to a reduction of the amount of pore solution with ongoing hydration. After 28 days the pH decreases in agreement with e.g. [22], indicating the pozzolanic reaction of the fly ash. The full data set of the measured pore solutions is given in the Appendix. The pore solutions are initially saturated with respect to CeSeH and Ca(OH)2 and oversaturated with respect to ettringite (Table 5). After 1 day, when the calcium sulfate has been consumed, the solutions are saturated with respect to ettringite and become, due to the reaction of fly ash, slowly undersaturated with respect to portlandite, which is consistent with the observed decrease of portlandite with time as found in the pozzolanic test (see Appendix). 3.1.5. Hydration mechanism of the fly ash-PC blend During the first 7 days, the hydration of PC dominates the reaction of the blend with water and is mainly responsible for setting, heat release and early compressive strength. The fly ash reacts more slowly leading to the consumption of Ca(OH)2 and the formation of additional CeSeH, ettringite and AFm phases. The reaction of the fly ash slowly but clearly increases the compressive strength at later ages. In the case of the quartz, where no (or very little) pozzolanic reaction occurs, compressive strength increases only slightly beyond 7 days as shown in Table 4. 3.2. Activation by (K,Na)2SiO3 3.2.1. Hydration kinetics Adding 2 mass-% of (K,Na)2SiO3 to the fly ash-PC blend decreases the initial setting time from 9 h to 4.5 h (Table 3). The PC hydration is accelerated; the main hydration peak in calorimetry (Fig. 1a) is shifted to earlier time compared to the sample without activator indicating a strong acceleration of the PC reaction. The peak shape is also modified significantly (no separate calcium sulfate depletion peak is visible). The cumulative heat at early age (48 h) is higher than in the case of the plain paste (Fig. 1b). The similarity between the calorimetric signals (shape and position) of the PC blended with fly ash and with quartz, respectively, shows that (K,Na)2SiO3 accelerates mainly the reaction of the PC. A similar chemical shrinkage is observed both in the absence and presence of (K,Na)2SiO3 (Fig. 2a), while the compressive strength after 1 day is enhanced in the presence of (K,Na)2SiO3 (Table 4). However, at later hydration times, the presence of 16 S. Alahrache et al. / Cement and Concrete Composites 66 (2016) 10e23 Fig. 4. Evolution of (a) Si concentration, (b) Ca concentration and (c) pH of the pore solution of the fly ash-PC blends in the presence of different activators. Accuracy is ±10% for the ion concentrations and ±0.05 for pH. Table 4 Compressive strength development of the fly ash-PC blend (70/30 by mass) without and with activators compared to the quartz reference. Activator Compressive strength (MPa) 1d quartz reference without activator 2 mass-% (K,Na)2SiO3 3 mass-% Na2CO3 8 mass-% Na2Oxalate 3 mass-% K3Citrate 3.2 3.3 4.8 3.6 4.6 0.5 3d ± ± ± ± ± ± 0.1 0.1 0.5 0.2 0.1 0.1 8.7 8.7 8.4 6.8 4.4 0.6 7d ± ± ± ± ± ± 0.3 0.3 0.1 0.2 0.2 0.1 9.9 12.7 10.0 7.4 10.3 0.8 28 d ± ± ± ± ± ± 0.4 0.3 0.4 0.4 0.1 0.1 13.1 22.0 19.0 14.8 18.0 9.3 91 d ± ± ± ± ± ± 0.2 0.4 0.6 0.1 0.3 1.8 13.4 34.5 28.0 18.9 25.0 29.1 ± ± ± ± ± ± 0.2 0.6 0.5 0.2 0.1 0.1 3.2.2. Reactivity of fly ash The pozzolanic test shows that (K,Na)2SiO3 accelerates the fly ash reaction mainly between 3 and 28 days. Both the samples with and without (K,Na)2SiO3 reach a comparable reaction degree after 91 days of approximately 20% (Fig. 2b). Thermodynamic calculations were used to clarify the effect of adding (K,Na)2SiO3 as shown in Fig. 5. They indicate that the addition of (K,Na)2SiO3 increases the total amount of CeSeH and decreases the amount of portlandite due to the reaction of portlandite with (K,Na)2SiO3 to form CeSeH in agreement with the differences observed by XRD (Fig. 3a). The calculations indicate that at higher additions of (K,Na)2SiO3 the amount of ettringite is expected to decrease due to the very high pH and higher ionic strength resulting in a decrease of the activity of water, which destabilizes the water-rich ettringite in comparison to AFm phases as e.g. shown by Albert et al. [66]. Similar to our observation, Donatello et al. [23] reported also a destabilization of ettringite upon the addition of Na2SO4. Hydrotalcite and hydrogarnet, which are predicted by the modeling without and with the addition of the activator, could not clearly be identified experimentally. 3.2.3. Hydration products The same crystalline hydration products were detected by X-ray diffraction and thermogravimetry in the fly ash blended PC with and without (K,Na)2SiO3 (Fig. 3a&b). However, the amount of portlandite is significantly lower in the sample with (K,Na)2SiO3. 3.2.4. Pore solution analyses and effective saturation indices Already after 6 h, the initial silicon concentration of 490 mM (referring to the silicon provided by (K,Na)2SiO3) is lowered to <1 mM (Fig. 4a) indicating the early formation of CeSeH. This is in agreement with the calorimetry main hydration peak that is (K,Na)2SiO3 decreases the compressive strength compared to the sample without activator (Table 4). The higher early compressive strength with (K,Na)2SiO3, is probably related to additional CeSeH formed due to the addition of silicates and the faster hydration, while the lower late strength could be related to the presence of high alkali concentrations. Sant et al. [65] observed that the addition of KOH and NaOH solutions to Portland cement pastes decreased the compressive strength and increased porosity at comparable degree of clinker reaction. S. Alahrache et al. / Cement and Concrete Composites 66 (2016) 10e23 Table 5 Calculated effective saturation indices of selected relevant hydrate phases of the studied binders. Undersaturation: <e0.5; saturation: 0.5 to 0.5; oversaturation: >0.5. Without activator €tl. Ms. Time days Portl. am. SiO2 CeS Stra Ettr. eH 0.25 0.16 6.62 0.08 0.26 0.36 0.73 1 0.04 6.30 0.02 0.32 0.01 0.07 7 0.05 6.10 0.04 0.42 0.10 0.01 28 0.31 5.03 0.04 0.08 0.16 0.15 Time days Portl. am. SiO2 CeS eH 0.25 0.13 5.36 0.05 1 0.02 6.02 0.02 7 0.04 5.99 0.01 28 0.32 4.92 0.02 Time days Portl. am. SiO2 CeS eH 0.25 0.21 4.72 0.13 1 0.33 5.32 0.14 7 0.47 4.70 0.11 28 0.39 4.35 0.05 Time days Portl. am. SiO2 CeS eH 0.25 0.60 3.57 0.07 1 0.44 4.76 0.10 7 0.55 4.35 0.09 28 0.64 3.87 0.03 Time days Portl. am. SiO2 CeS eH 0.25 0.32 5.33 0.60 1 0.09 5.69 0.23 7 0.02 5.68 0.15 28 0.11 5.55 0.29 (K,Na)2SiO3 €tl. Ms. Stra Ettr. Gypsum 0.02 1.44 1.43 1.85 Gypsum 0.34 0.13 0.59 0.11 0.46 0.06 0.39 0.42 0.41 0.12 0.04 1.53 0.27 0.27 0.22 1.80 Na2CO3 €tl. Ms. Stra Ettr. Gypsum Calcite Mc. 0.10 0.00 0.21 0.89 0.60 0.30 0.09 1.19 0.34 0.28 0.11 1.34 0.17 0.17 0.03 1.14 Na2Oxalate €tl. Ms. Stra 0.41 0.58 0.34 0.48 0.51 0.46 0.44 0.56 K3Citrate €tl. Ms. Stra Ettr. Gypsum 0.37 0.34 0.39 0.45 1.63 1.63 1.87 1.77 Ettr. Gypsum 0.59 0.12 0.55 0.14 0.54 0.09 0.01 0.11 0.30 0.45 0.59 0.73 0.00 0.13 0.16 1.43 0.24 0.08 0.07 1.74 0.21 0.00 0.06 1.46 €tl. ¼ str€ Portl. ¼ portlandite, am. SiO2 ¼ amorphous silica, Stra atlingite, Ms. ¼ monosulfate, Ettr. ¼ ettringite, Mc. ¼ monocarbonate. observed already after 6 h (Fig. 1a). The calcium ions from the alite reaction react with the silicate ions leading to CeSeH formation and a decrease of the silicon concentration in the pore solution with time. The pH is approximately 0.3 units higher (Fig. 4c) and the calcium concentration lower (Fig. 4b) than in the sample without activator. Fig. 5. Modeled hydrate phases and pH of the fly ash-PC blend after 28 days of hydration as a function of the amount of the added (K,Na)2SiO3 (the hydration degrees of PC and fly ash are considered to be 100% and 7%, respectively). The vertical dotted line indicates the studied composition. 17 The solution is saturated with respect to CeSeH and portlandite initially and becomes undersaturated with respect to portlandite with time (Table 5). The ettringite oversaturation decreases along time (Table 5). 3.2.5. Assumed mechanism of (K,Na)2SiO3 addition Less portlandite in the solid phase (Fig. 3) and lower silicon and calcium concentrations (Fig. 4a and b) in the pore solution were observed in the presence of (K,Na)2SiO3 compared to the plain system. The high pH (Fig. 4c) and the low calcium concentrations (Fig. 4b) accelerate the early alite dissolution as visible in the strong acceleration of the main peak observed by calorimetry (Fig. 1a) and the higher one day strength (Table 4). Nicoleau et al. [67] showed that alite reaction is faster in the presence of low calcium concentrations as observed here. Correspondingly, Kumar et al. [68] observed that the addition of NaOH and KOH accelerates the alite reaction as the high pH lowers the calcium concentrations. The faster reaction of alite and the formation of additional CeSeH due to the reaction of the added silica with the portlandite result in the early setting of the system (Table 3) and the relatively early high compressive strength (Table 4). The relatively lower compressive strength at later ages (Table 4) is consistent with observations in PC systems, where the addition of NaOH and KOH has decreased the compressive strength [65]. Furthermore, (K,Na)2SiO3 accelerates the fly ash reaction (Fig. 2b). 3.3. Activation by Na2CO3 3.3.1. Hydration kinetics The addition of sodium carbonate (3 mass-%) reduces the initial and final setting time of the fly ash blended PC (Table 3). The hydration of PC is accelerated; the first hydration maximum in the heat flow curve occurs after 5 h (Fig. 1a) and coincides with final setting. A second, more intense heat flow maximum can be recognized after about 14 h. The cumulative heat (Fig. 1b) and the chemical shrinkage (Fig. 2a) are increased compared to the sample without activator. The addition of Na2CO3 has little effect on the 1 day strength but decreases significantly the compressive strength at later ages (Table 4). 3.3.2. Reactivity of fly ash The reactivity of the fly ash in the PC simulated medium in the presence of Na2CO3 is similar to the samples without activator (Fig. 2b). 3.3.3. Hydration products The XRD data indicate the presence of less portlandite when Na2CO3 has been added (Fig. 3a). In addition, only low amounts of ettringite are present after 28 days, while the formation of monocarbonate is favored in the presence of the activator (Fig. 3b). In agreement with the experimental observations, thermodynamic modeling (Fig. 6) indicates that the addition of Na2CO3 results in the presence of less portlandite and a significant pH increase from 13.3 to 14 as shown in Fig. 4c (note that the calculated pH values are somewhat higher than the measured pH values as the alkali uptake model underestimates the alkali uptake by CeSeH). The modeling predicts the stabilization of monocarbonate on the expenses of ettringite due to the increase of pH and carbonate concentration, although to a somewhat lower extent than observed experimentally. The increased uptake of aluminum in CSH at high aluminum concentrations is not captured in the model. In addition, the inaccuracy of the thermodynamic data used has also to be considered as relatively small changes (±1 log unit) in the solubility products of ettringite and monocarbonate lead to the 18 S. Alahrache et al. / Cement and Concrete Composites 66 (2016) 10e23 Fig. 6. Modeled hydrate phases and pH of the fly ash-PC blend after 28 days of hydration as a function of the amount of the added Na2CO3 (the hydration degrees of PC and fly ash are considered to be 100% and 7%, respectively). The vertical dotted line indicates the studied composition. destabilization of ettringite at around 4 wt.% Na2CO3. 3.3.4. Pore solution analyses and effective saturation indices A relatively high pH is observed in the case of Na2CO3 activator (Fig. 4c), which results from the reaction (Equ. 1). Na2CO3 þ Ca(OH)2 / CaCO3 þ 2Naþ þ 2OH (1) The higher pH leads to lower calcium concentrations (z0.1 mM) than observed in the other samples (Fig. 4b) and as stated before the early alite dissolution is accelerated at low calcium concentrations as visible in the acceleration of the main calorimetry peak in Fig. 1a. The calculated effective saturation indices (Table 5) indicate that the solutions are only initially oversaturated with respect to ettringite, but become undersaturated with time, consistent with the presence of little ettringite. The destabilization of ettringite is also visible in the relatively high sulfate concentrations of z200 mM compared to <1 mM in the paste without activator (see Appendix). The solutions remain oversaturated with respect to calcite during the first week and are always undersaturated with respect to portlandite as shown in Table 5. 3.3.5. Assumed mechanism of Na2CO3 addition The early reaction of the Portland cement is somewhat accelerated due to the higher pH (Fig. 4c) and the lower calcium concentrations (Fig. 4b) resulting in an early set (Table 3). In contrast the reactivity of the fly ash is not significantly affected (Fig. 2b). The pH is increased due to the reaction of sodium carbonate with portlandite, resulting in the decrease of the amount of portlandite compared to samples without Na2CO3. The high pH values and the high carbonate concentrations in the pore solution favor the formation of monocarboaluminate instead of ettringite (Fig. 3b). The compressive strength measured after 7 days and longer (Table 4) is significantly lower than observed for the sample without activator and for the (K,Na)2SiO3 activator. Again, this is attributed to the pH as an increase of pH has been observed to decrease compressive strength in Portland cement pastes [65]. 3.4. Activation by Na2Oxalate 3.4.1. Hydration kinetics The presence of sodium oxalate accelerates the setting of the fly Fig. 7. Conduction calorimetry of the fly ash-PC and of the quartz-PC blends (70/30 by mass) without and with Na2Oxalate and K3Citrate, respectively, (a) specific heat flow, (b) cumulative heat normalized to the solid content. ash blended cement (Table 3), and the reaction of the PC in the blend is significantly accelerated as observed by calorimetry (Fig. 7a). The reaction of the PC mainly occurs already between 4 and 8 h and within shorter timespan than observed for the other activators. Again, this acceleration of the PC reaction is probably due to the relatively high pH values (Fig. 4c) and low calcium (Fig. 4b) concentrations that accelerate the PC reaction. Thus also the cumulative heat is during the first 24 h higher than for the sample without activator (Fig. 7b). After 1 day and longer, however, little difference is observed. Also the chemical shrinkage is not significantly affected by the presence of sodium oxalate (Fig. 2a), indicating a similar degree of PC and fly ash reaction as in the samples without activator. The compressive strength after one day is higher with activator than without due to the fast PC reaction (Table 4). After 7, 28 and 91 days lower compressive strength values are observed as also for Na2CO3 and (K,Na)2SiO3. The pozzolanity test indicates that sodium oxalate significantly increases the reactivity of the fly ash as shown in Fig. 2b. This acceleration could be related to the very distinct pH increase due to the high amount of sodium oxalate used and/or to a specific interaction of oxalate with the fly ash. In additional experiments, where the effect sodium oxalate on glass dissolution was studied under constant pH conditions, no signifcant influence on glass S. Alahrache et al. / Cement and Concrete Composites 66 (2016) 10e23 dissolution was observed, confirming that the observed acceleration in the presence of sodium oxalate is based on the increased pH values. Kundin et al. [69] reported the inhibition of glass dissolution at pH values < 5 for diopside glass in the presence of oxalic acid due to formation of stable calciumemagnesium oxalate complexes on the glass surface. Oelkers et al. [70] reported that there is no effect on basaltic glass dissolution rates of oxalate ion at pH between 1 and 2 or pH between 7 and 11. To our knowledge, there is no previous information about the effect of oxalate on the glass dissolution at pH around 13.5 (the pH values of the pore solution of the fly ash-PC blend in the presence of Na2Oxalate (Fig. 4c) and of the Ca(OH)2 þ CaCO3 þ KOH medium used in the pozzolanic test). 3.4.2. Hydration products Like in the case of Na2CO3, the addition of sodium oxalate results in the presence of very little portlandite after 28 days as shown in Fig. 8a&b. The formation of Ca-oxalate (CaC2O4$H2O) is observed (Equ. 2) leading to a pH increase. Na2C2O4 þ Ca(OH)2 þ H2O / CaC2O4$H2O þ 2Naþ þ 2OH 19 (2) No ettringite is observed by XRD (Fig. 8a), which is confirmed by TGA (Fig. 8b). TGA indicates that besides monocarbonate (weight loss at about 150e170 C) a second AFm phase might be present (weight loss at about 190e200 C). It can be suggested that this refers to a “hemi-oxalate” 3CaO$Al2O3$0.5Ca(OH)2$0.5CaC2O4$9H2O €llmann [71], which would fit to this TGA dehydration described by Po pattern. However it could not clearly be identified in the XRD data, as its main reflections coincide with those of monocarbonate. The absence of ettringite may again be related to the high pH (Fig. 4c) and ionic strength (see Appendix) in the pore solution and thus low activity of water leading to a destabilization of ettringite or to the high Al-uptake by CSH. The results of the thermodynamic modeling regarding the effect of sodium oxalate in Fig. 9 confirm the experimental findings. The addition of sodium oxalate lowers the amount of portlandite strongly while Ca-oxalate (CaC2O4$H2O) is formed. As there are no thermodynamic data available yet for Fig. 8. X-ray diffraction patterns (a) and TGA thermograms (b) of the fly ash e PC blend without and in the presence of Na2Oxalate and K2Citrate, respectively, after 28 days of hydration at 20 C (A ¼ alite, B ¼ belite, C ¼ CeSeH, CO ¼ calcium oxalate monohydrate, E ¼ ettringite, Hc ¼ hemicarbonate, M ¼ mullite, Mc ¼ monocarbonate, OA ¼ 3CaO$Al2O3$0.5Ca(OH)2$0.5CaC2O4$9H2O, P ¼ portlandite, Q ¼ quartz). 20 S. Alahrache et al. / Cement and Concrete Composites 66 (2016) 10e23 Fig. 9. Modeled hydrate phases and pH of the fly ash-PC blend after 28 days of hydration as a function of the amount of the added Na2Oxalate (the hydration degrees of PC and fly ash are considered to be 100% and 7%, respectively). The vertical dotted line indicates the studied composition. 3CaO$Al2O3$0.5Ca(OH)2$0.5CaC2O4$9H2O, it could not be included in the modeling. The increase of the pH and ionic strength destabilizes ettringite (although somewhat less than observed experimentally). As a relatively high amount of sodium oxalate has been added (8 mass-% corresponding to 1.64 mol/L), the increase of pH and ionic strength is more distinct than for the other additives which leads to a stronger destabilization of ettringite. 3.4.3. Pore solution analyses and effective saturation indices The silica content (Fig. 4a) and the pH (Fig. 4c) of the pore solution in the case of Na2Oxalate are particularly high due to the high quantity used, while the calcium concentration is low (Fig. 4b) due to the consumption of calcium by the precipitation of calcium oxalate. The solutions are always undersaturated with respect to portlandite (Table 5) and slightly undersaturated with respect to ettringite, consistent with the XRD and TGA results shown in Fig. 8. Note that an undersaturation with respect to a solid does not necessarily mean that none of this solid can be observed, undersaturation indicates only that a phase dissolves under these conditions, a process which can be very slow in dense cement matrices. The solutions are near saturation with respect to CeSeH, the main hydrate observed by TGA. of potassium citrate accelerates the initial setting (Table 3). Potassium citrate has been reported on the one hand to be an efficient activator for class C fly ashes [30e33]. On the other hand, however, citrate is known to retard the hydration of PC [72,73]. In fact, no PC main hydration peak could be observed by calorimetry in the presence of 3 mass-% potassium citrate within the first 7 days (Fig. 7a). The slow reactivity of the PC results also in the low chemical shrinkage observed up to 30 days (Fig. 2a) and in a very poor strength up to 28 days (Table 4). Only the sample after 91 days shows a compressive strength comparable to the other samples. Potassium citrate retards also the fly ash reaction in the PC simulated medium (Fig. 2b). While citric acid increases glass reactivity at low pH value [74], the glass dissolution rate under alkaline condition decreases in the presence of citrate [75]. Although the mechanisms responsible for the observed decrease of glass dissolution are not clear, it can be speculated that the formation of citrate complexes at the glass surface could be an explanation for the observed decrease of reaction. 3.5.2. Hydration products After 28 days, a similar amount of portlandite is observed by XRD and TGA in the presence of potassium citrate (Fig. 8) compared to the reference paste without activator. Thermodynamic modeling (Fig. 10) of the effect of potassium citrate on the hydrated fly ash-PC blend shows that adding potassium citrate is expected to lead to the formation of a small quantity of calcium citrate (Ca3(C6O7H5)2$4H2O), which could not be identified by XRD probably due to a too low content, but else does not change significantly the kind or amount of the hydration products. A slight decrease of the amount of ettringite and portlandite and an increase of the amount of AFm are calculated due to the increase in ionic strength. 3.5.3. Pore solution analyses and effective saturation indices The presence of 240 mM potassium citrate leads to relatively high alkali concentrations (see Appendix) and pH values (Fig. 4c) in the pore solution. The solutions are saturated with respect to CeSeH, portlandite and ettringite (Table 5). 3.5.4. Assumed mechanism of potassium citrate addition Potassium citrate in high concentrations retards strongly the reaction of PC (Fig. 8a) and of the fly ash (Fig. 2b) as also visible by 3.4.4. Assumed mechanism of sodium oxalate addition Sodium oxalate reacts with calcium to form calcium oxalate (Fig. 8) which lowers the amount of portlandite strongly. The reaction lowers also calcium concentrations (Fig. 4b) and increases the pH (Fig. 4c) of the pore solution which accelerates PC reaction (Fig. 7a) resulting in a fast set (Table 3) and a relatively high 1 day strength (Table 4). There is also evidence for the formation of an oxalate-containing AFm phase. After longer hydration times, a lower compressive strength compared to the reference without activator is observed, although sodium oxalate promotes the fly ash dissolution (Fig. 2b). The high pH leads to a destabilization of ettringite as also reported by [23] in the case of Na2SO4 addition. 3.5. Activation by potassium citrate 3.5.1. Hydration kinetics As observed for the other accelerators, the addition of 3 mass-% Fig. 10. Modeled hydrate phases and pH of the fly ash-PC blend after 28 days of hydration as a function of the amount of the added K3Citrate (the hydration degrees of PC and fly ash are considered to be 100% and 7%, respectively). The vertical dotted line indicates the studied composition. S. Alahrache et al. / Cement and Concrete Composites 66 (2016) 10e23 the low chemical shrinkage observed (Fig. 2a) and by the very slow development of compressive strength (Table 4). It is possible that the formation of citrate complexes at the surface of the fly ash and clinker phases could be an explanation for the observed decrease of reaction. 21 Sodium oxalate and (K,Na)2SiO3 accelerate both the setting of the fly ash-PC blend and increase the early compressive strength of the fly ash-PC blend. Furthermore, they show better compressive strengths at later ages compared to the other activators. Based on these findings, they can be considered as the most suitable activators for the fly ash-PC blend among the investigated activators. 4. Conclusion Acknowledgments The hydration of a fly ash-PC blend (70/30 by mass) without and with the addition of activators was examined. The activators (potassium sodium silicate, sodium carbonate, sodium oxalate and potassium citrate) where chosen in a way that (i) they increase pH to stimulate fly ash dissolution (ii) they e with the exception of potassium citrate - accelerate the PC reaction (setting, early compressive strength) and (iii) that highly alkaline conditions are avoided due to health issues as the binders should be suitable for dry mix mortars such as tile adhesives. In the system without activators the fly ash reacts and the reaction contributes significantly to the developement of compressive strength after 7 days and longer. The addition of the activators enhances the compressive strength at early age (i.e. sodium oxalate and (K,Na)2SiO3) but decreases strength at late age. All activators increase the pH values and decrease thus the calcium concentrations in the pore solution. Lower calcium concentrations lead to a faster reaction of alite [67,68] and thus to early setting and a high early strength. On the long term, the high alkali concentrations lower the compressive strength after 91 days and lead to a (partial) destabilization of ettringite. Thermodynamic modeling indicates that ettringite destabilization is related to the decrease of water activity due to the high ionic strength and high pH values in the pore solution due to the alkaline activators. It can be observed by XRD and TGA that the amount of ettringite after 28 days is lower with higher measured alkali and aluminum concentrations, where a higher aluminum binding by CSH is expected. The pozzolanic reaction of the fly ash (in a simulated PC medium) is not or only slightly enhanced by Na2CO3. Sodium oxalate and (K,Na)2SiO3 accelerate the fly ash reaction due to the increased pH. In additional experiments, where the effect of the different activators on glass dissolution was studied under constant pH conditions, no signifcant influence of Na2SiO3, Na2CO3 or sodium oxalate on glass dissolution was observed, confirming that the observed acceleration in the presence of sodium oxalate and (K,Na)2SiO3 is based on the increased pH. In contrast to the other activators, potassium citrate is found to hinder both the fly ash and the PC reaction. Either the potassium citrate forms complexes at the surfaces of fly ash and PC which slows down reaction strongly or alternatively it could also hinder the formation of the hydration products (e.g. AFm phases and CeSeH). The late compressive strength decreases with increasing pH values observed in the pore solution, confirming earlier observation in Portland cement pastes [65] that high pH values are negative for long-term compressive strength. However, it is unclear whether this strength decrease is related to the very fast initial reaction and thus to the formation of more dense and less well interlocked hydrate assemblage, whether the properties of CeSeH are negatively influenced or whether the (partial) destabilization of ettringite is the reason for this strength decrease at later age. Saint-Gobain Recherche is acknowledged for financial support. ^ pital, Luigi Brunetti, Boris Ingold The authors thank Emilie L’Ho (Empa) and Stephanie Dumont (Saint-Gobain Recherche, France) for their assistance in the lab, and Christian Müller (Saint-Gobain Weber AG, Switzerland) for discussions. Appendix Fig. A1. Particle size distribution of the fly ash and the quartz used in the study as determined by laser diffraction. Fig. A2. Pozzolanic test: Thermogravimetric analysis of the fly ash and the quartz after storage at 20 C for 7, 28 and 91 days in a KOH solution containing portlandite and calcite. AFm-phases include hemi- and monocarbonate. 22 S. Alahrache et al. / Cement and Concrete Composites 66 (2016) 10e23 Table A1 Pore solution composition (in mmol/l) of the fly ash - PC blend measured by IC, in the presence of the different activators and at different hydration times (0.25, 1, 7, 28 days). The concentration of carbonate, oxalate and citrate in the pore solutions was estimated based on charge balance. Ionic strength (IS) (in mmol/l) presented in the last column was calculated by GEMS. Mg, Fe and other elements with very low concentration were not determined. Sample Time/d Na K Ca SO4 Si Al Cl OH- No activator 0.25 1 7 28 31 43 62 59 59 70 100 110 29.5 5.4 1.9 0.39 27.8 0.12 0.50 0.40 0.036 0.039 0.041 0.18 0.029 0.042 0.042 0.77 4 1 0 0 47 87 133 93 time/d Na K Ca SO4 Si Al Cl OH- 0.25 1 7 28 160 160 150 120 230 190 220 210 18.6 3.06 0.87 0.22 185 79 1.8 2.4 0.096 0.061 0.096 0.59 0.019 0.028 0.080 0.35 5 4 1 1 80 163 289 189 time/d Na K Ca SO4 Si Al Cl OH- carbonate 0.25 1 7 28 1400 1100 770 740 96 71 83 93 0.51 0.18 0.15 0.24 368 179 99 194 2.71 0.59 1.22 3.75 0.66 0.10 0.55 0.73 4 5 2 2 297 342 271 278 100 150 150 10 time/d Na K Ca SO4 Si Al Cl OH- oxalate 0.25 1 7 28 2200 2700 2300 1900 49 70 120 110 0.17 0.085 0.052 0.070 401 165 179 297 65.6 5.01 19.1 35.8 0.41 0.18 1.56 0.51 4 3 2 2 400 407 575 420 300 800 500 300 time/d Na K Ca SO4 Si Al Cl OH- citrate 0.25 1 7 28 40 42 44 49 740 660 670 700 8.11 1.26 0.72 1.44 23.1 4.7 2.1 4.2 2.70 0.53 0.53 0.84 0.65 0.67 0.22 0.12 6 5 5 1 454 522 748 458 60 30 200 30 (K,Na)2SiO3 (490 mM) Na2CO3 (710 mM) Na2Oxalate (1640 mM) K3Citrate (240 mM) References [1] Report of the IEA Coal Industry Advisory Board, Power Generation from Coal Measuring and Reporting Efficiency Performance and CO2 Emissions, International Energy Agency, 2010. available at: https://www.iea.org/ciab/papers/ power_generation_from_coal.pdf. last accessed June 4 2015. [2] J.E. Oh, J. Moon, S.-G. Oh, S.M. Clark, P.J.M. Monteiro, Microstructural and compositional change of NaOH-activated high calcium fly ash by incorporating Na-aluminate and co-existence of geopolymeric gel and CeSeH(I), Cem. Concr. Res. 42 (5) (2012) 673e685. _ [3] Ş. Turhan, I.H. Arıkan, R. Küçükcezzar, Radiological consequences of the use of fly ash in construction sector and geotechnical applications, Indoor Built Environ. 20 (2) (2011) 253e258. [4] A. Palomo, M.W. Grutzeck, M.T. Blanco, Alkali-activated fly ashes: a cement for the future, Cem. Concr. Res. 29 (8) (1999) 1323e1329. nez, J.L. Provis, G.C. Lukey, A. Palomo, J.S.J. van [5] P. Duxson, A. Fern andez-Jime Deventer, Geopolymer technology: the current state of the art, J. Mater. Sci. 42 (9) (2007) 2917e2933. [6] F. Pacheco-Torgal, J. Castro-Gomes, S. Jalali, Alkali-activated binders: a review: Part 1. Historical background, terminology, reaction mechanisms and hydration products, Constr. Build. Mater. 22 (7) (2008) 1305e1314. [7] F. Pacheco-Torgal, J. Castro-Gomes, S. Jalali, Alkali-activated binders: a review. Part 2. About materials and binders manufacture, Constr. Build. Mater. 22 (7) (2008) 1315e1322. [8] M.C.G. Juenger, F. Winnefeld, J.L. Provis, J.H. Ideker, Advances in alternative cementitious binders, Cem. Concr. Res. 41 (12) (2011) 1232e1243. [9] J.E. Oh, Y. Jun, Y. Jeong, Characterization of geopolymers from compositionally and physically different class F fly ashes, Cem. Concr. Compos. 50 (1) (2014) 16e26. [10] J.L. Provis, Geopolymers and other alkali activated materials: why, how, and what? Mater. Struct. 47 (1e2) (2014) 11e25. ndez-Jime nez, A. Palomo, M. Criado, Microstructure development of [11] A. Ferna alkali-activated fly ash cement: a descriptive model, Cem. Concr. Res. 35 (6) (2005) 1204e1209. [12] D. Ravikumar, S. Peethamparan, N. Neithalath, Structure and strength of NaOH activated concretes containing fly ash or GGBFS as the sole binder, Cem. Concr. Compos. 32 (6) (2010) 399e410. [13] K. Somna, C. Jaturapitakkul, P. Kajitvichyanukul, P. Chindaprasirt, NaOHactivated ground fly ash geopolymer cured at ambient temperature, Fuel 90 (6) (2011) 2118e2124. [14] S.-S. Park, H.-Y. Kang, Characterization of fly ash-pastes synthesized at different activator conditions, Korean J. Chem. Eng. 25 (1) (2008) 78e83. [15] J. Davidovits, R. Davidovits, M. Davidovits. Geopolymeric cement based on fly ash and harmless to use. United States Patent Application Publication 2010/ IS 163 121 162 160 491 379 346 303 1306 1016 768 807 1820 1868 1717 1612 1096 825 775 862 0010139 A1, 14 Jan 2010. [16] F. Winnefeld, A. Leemann, M. Lucuk, P. Svoboda, M. Neuroth, Assessment of phase formation in alkali activated low and high calcium fly ashes in building materials, Constr. Build. Mater. 24 (6) (2010) 1086e1093. [17] M. Steveson, K. Sagoe-Crentsil, Relationships between composition, structure and strength of inorganic polymers, J. Mater. Sci. 40 (16) (2005) 4247e4259. [18] S.A. Bernal, J.L. Provis, B. Walkley, R.S. Nicolas, J.D. Gehman, D.G. Brice, et al., Gel nanostructure in alkali-activated binders based on slag and fly ash, and effects of accelerated carbonation, Cem. Concr. Res. 53 (2013) 127e144. [19] A. Palomo, P. Krivenko, I. Garcia-Lodeiro, E. Kavalerova, O. Maltseva, A. Fernandez-Jimenez, A review on alkaline activation: new analytical perspectives, Mater. Constr. 64 (315) (2014) e022, http://dx.doi.org/10.3989/ mc.2014.00314. ndez-Jime nez, G. Kovalchuk, L.M. Ordon ~ ez, M.C. Naranjo, [20] A. Palomo, A. Ferna OPC-fly ash cementitious systems: study of gel binders produced during alkaline hydration, J. Mater. Sci. 42 (2007) 2958e2966. [21] K. De Weerdt, M. Ben Haha, G. Le Saout, K.O. Kjellsen, H. Justnes, B. Lothenbach, Hydration mechanisms of ternary Portland cements containing limestone powder and fly ash, Cem. Concr. Res. 41 (3) (2011) 279e291. [22] F. Deschner, F. Winnefeld, B. Lothenbach, S. Seufert, P. Schwesig, S. Dittrich, et al., Hydration of Portland cement with high replacement by siliceous fly ash, Cem. Concr. Res. 42 (10) (2012) 1389e1400. [23] S. Donatello, A. Fern andez-Jimenez, A. Palomo, Very high volume fly ash cements. Early age hydration study using Na2SO4 as an activator, J. Am. Ceram. Soc. 96 (3) (2013) 900e906. [24] I. Garcia-Lodeiro, A. Fernandez-Jimenez, A. Palomo, Variation in hybrid cements over time. Alkaline activation of fly ash-portland cement blends, Cem. Concr. Res. 52 (2013) 112e122. [25] I. Garcia-Lodeiro, A. Fernandez-Jimenez, A. Palomo, Hydration kinetics in hybrid binders: early reaction stages, Cem. Concr. Compos. 39 (2013) 82e92. [26] C. Shi, R.L. Day, Acceleration of the reactivity of fly ash by chemical activation, Cem. Concr. Res. 25 (1) (1995) 15e21. [27] C. Shi, Early microstructure development of activated lime-fly ash pastes, Cem. Concr. Res. 26 (9) (1996) 1351e1359. [28] E. Jr. Dunstan. Fly ash-based cement. United States Patent 5,256,504, 17 Mar 1981. [29] L. Miao, Wider Application of Additions in Self-compacting Concrete, UK. University College London, London, 2009. PhD Thesis. [30] BB. Gravitt, RF. Heitzmann, JL. Sawyer. Hydraulic cement and composition employing the same. United States Patent 4,997,484, 5 March 1991. [31] JK. Hicks, RM. Scott. Rapid hardening hydraulic cement from subbituminous fly ash and products thereof. United States Patent 7,288,148 B2, 30 Oct 2007. [32] G. Schumacher, R. Patel, P. Sampson, M. Riley. High strength cement, mortar and concrete including industrial by-products. United States Patent 8,016,937 B2, Sept 13, 2011. S. Alahrache et al. / Cement and Concrete Composites 66 (2016) 10e23 [33] G. Schumacher, R. Patel. Lactate activated cement and activator compositions. United States Patent Application Publication 2011/0283921 A2, 24 Nov 2011. [34] V. Kocaba, Development and Evaluation of Methods to Follow Microstructural Development of Cementitious Systems Including Slags, PhD thesis, Ecole de rale de Lausanne EPFL, Lausanne, Switzerland, 2009. no Polytechnique Fe 4523. [35] P. Stutzman, S. Leigh, Phase analysis of hydraulic cements by X-ray powder diffraction: precision, bias, and qualification, J. ASTM Int. 4 (2007) 1e11. n-Reina, A.G. de la Torre, J.M. Porras-V [36] L. Leo asquez, M. Cruz, L.M. Ordonez, , et al., Round robin on Rietveld quantitative phase analysis of X. Alcobe Portland cements, J. Appl. Cryst. 42 (2009) 1e11. [37] G. Le Saoût, V. Kocaba, K. Scrivener, Application of the Rietveld method to the analysis of anhydrous cement, Cem. Concr. Res. 41 (2) (2011) 133e148. [38] B.H. O'Connor, M.D. Raven, Application of the Rietveld refinement procedure in assaying powdered mixtures, Powder Diffr. 3 (1) (1988) 2e6. [39] D. Jansen, F. Goetz-Neunhoeffer, C. Stabler, J. Neubauer, A remastered external standard method applied to the quantification of early OPC hydration, Cem. Concr. Res. 41 (6) (2011) 602e608. €tz-Neunhoeffer, The influence of fly ash on the [40] S. Dittrich, J. Neubauer, F. Go hydration of OPC within the first 44 h e A quantitative in situ XRD and heat flow calorimetry study, Cem. Concr. Res. 56 (2014) 129e138. [41] R.S. Barneyback Jr., S. Diamond, Expression and analysis of pore fluids from hardened cement pastes and mortars, Cem. Concr. Res. 11 (2) (1981) 279e285. [42] T. Wagner, D.A. Kulik, F.F. Hingerl, S.V. Dmytrieva, GEM-Selektor geochemical modeling package: TSolMod library and data interface for multicomponent phase models, Can. Miner. 50 (5) (2012) 1173e1195. [43] D. Kulik, T. Wagner, S. Dmytrieva, G. Kosakowski, F. Hingerl, K. Chudnenko, et al., GEM-Selektor geochemical modeling package: revised algorithm and GEMS3K numerical kernel for coupled simulation codes, Comput. Geosci. 17 (1) (2013) 1e24. [44] W. Hummel, U. Berner, E. Curti, F.J. Pearson, T. Thoenen, Nagra/PSI Chemical Thermodynamic Database 01/01, Universal Publisher/u-PUBLISH.com, Boca Raton, USA, 2002. Also published as: Nagra Technical Report NTB 02e16, Wettingen, Switzerland. €schner, F.P. Glasser, Thermodynamic [45] B. Lothenbach, T. Matschei, G. Mo modelling of the effect of temperature on the hydration and porosity of Portland cement, Cem. Concr. Res. 38 (1) (2008) 1e18. [46] B.Z. Dilnesa, B. Lothenbach, G. Renaudin, A. Wichser, D. Kulik, Synthesis and characterization of hydrogarnet Ca3(AlxFe1-x)2(SiO4)y(OH)4(3-y), Cem. Concr. Res. 59 (2014) 96e111. [47] B. Lothenbach, L. Pelletier-Chaignat, F. Winnefeld, Stability in the system CaOeAl2O3eH2O, Cem. Concr. Res. 42 (12) (2012) 1621e1634. nech, Chemical [48] W. Hummel, G. Anderegg, L. Rao, O. Tochiyama, I. Puigdome thermodynamics of compounds and complexes of U, Np, Pu, Am, Tc, Se, Ni and ne, J. Perrone Zr with selected organic ligands, in: F.J. Mompean, M. Illemasse (Eds.), Data Bank, OECD Nuclear Energy Agency, Issy-les-Moulineaux, France, 4 June 2015. Available at: https://www.oecd-nea.org/dbtdb/pubs/vol9organic-ligands.pdf. last accessed. [49] T.E. Zelenina, O.Y. Zelenin, Complexation of citric and tartaric acids with Na and K ions in aqueous solution, Russ. J. Coord. Chem. 31 (4) (2005) 235e242. [50] R.B. Martin, Citrate binding of Al3þ and Fe3þ, J. Inorg. Biochem. 28 (2e3) (1986) 181e187. [51] B. Lothenbach, F. Winnefeld, Thermodynamic modelling of the hydration of Portland cement, Cem. Concr. Res. 36 (2) (2006) 209e226. [52] S.-Y. Hong, F.P. Glasser, Alkali binding in cement pastes. Part I. The C-S-H phase, Cem. Concr. Res. 29 (12) (1999) 1893e1903. [53] H.C. Helgeson, D.H. Kirkham, Theoretical prediction of the thermodynamic behavior of aqueous electrolytes at high pressures and temperatures; II, Debye-Hückel parameters for activity coefficients and relative partial molal properties, Am. J. Sci. 274 (10) (1974) 1199e1261. [54] B. Lothenbach, Thermodynamic equilibrium calculations in cementitious systems, Mater. Struct. 43 (10) (2010) 1413e1433. 23 [55] M. Ben Haha, K. De Weerdt, B. Lothenbach, Quantification of the degree of reaction of fly ash, Cem. Concr. Res. 40 (11) (2010) 1620e1629. [56] F. Deschner, B. Münch, F. Winnefeld, B. Lothenbach, Quantification of fly ash in hydrated, blended Portland cement pastes by backscattered electron imaging, J. Microsc. 251 (2) (2013) 188e204. [57] X. Feng, E.J. Garboczi, D.P. Bentz, P.E. Stutzman, T.O. Mason, Estimation of the degree of hydration of blended cement pastes by a scanning electron microscope point-counting procedure, Cem. Concr. Res. 34 (10) (2004) 1787e1793. € tz-Neunhoeffer, B. Lothenbach, J. Neubauer, The early hydra[58] D. Jansen, F. Go tion of Ordinary Portland Cement (OPC): an approach comparing measured heat flow with calculated heat flow from QXRD, Cem. Concr. Res. 42 (1) (2012) 134e138. [59] G. Baert, S. Hoste, G. Schutter, N. Belie, Reactivity of fly ash in cement paste studied by means of thermogravimetry and isothermal calorimetry, J. Therm. Anal. Calorim. 94 (2) (2008) 485e492. [60] D.P. Bentz, Influence of water-to-cement ratio on hydration kinetics: simple models based on spatial considerations, Cem. Concr. Res. 36 (2) (2006) 238e244. [61] L. Lam, Y.L. Wong, C.S. Poon, Degree of hydration and gel/space ratio of highvolume fly ash/cement systems, Cem. Concr. Res. 30 (5) (2000) 747e756. [62] P. Chindaprasirt, C. Jaturapitakkul, T. Sinsiri, Effect of fly ash fineness on microstructure of blended cement paste, Constr. Build. Mater. 21 (7) (2007) 1534e1541. [63] V. Rahhal, R. Talero, Influence of two different fly ashes on the hydration of Portland cements, J. Therm. Anal. Calorim. 78 (1) (2004) 191e205. [64] L. Nicoleau, E. Schreiner, A. Nonat, Ion-specific effects influencing the dissolution of tricalcium silicate, Cem. Concr. Res. 5 (9) (2014) 118e138. [65] G. Sant, A. Kumar, C. Patapy, G. Le Saout, K. Scrivener, The influence of sodium and potassium hydroxide on volume changes in cementitious materials, Cem. Concr. Res. 42 (11) (2012) 1447e1455. [66] B. Albert, B. Guy, D. Damidot, Water chemical potential: a key parameter to determine the thermodynamic stability of some hydrated cement phases in concrete? Cem. Concr. Res. 36 (5) (2006) 783e790. [67] L. Nicoleau, Accelerated growth of calcium silicate hydrates: experiments and simulations, Cem. Concr. Res. 41 (12) (2011) 1339e1348. [68] A. Kumar, G. Sant, C. Patapy, C. Gianocca, K.L. Scrivener, The influence of sodium and potassium hydroxide on alite hydration: experiments and simulations, Cem. Concr. Res. 42 (11) (2012) 1513e1523. [69] J. Kundin, C.-J. Yu, R. Conradt, H. Emmerich, Simulation of adsorption processes on the glass surface in aqueous solutions containing oxalic acid, Comput. Mater. Sci. 49 (1) (2010) 88e98. [70] E.H. Oelkers, S.R. Gislason, The mechanism, rates and consequences of basaltic glass dissolution: I. An experimental study of the dissolution rates of basaltic glass as a function of aqueous Al, Si and oxalic acid concentration at 25 C and pH ¼ 3 and 11, Geochim. Cosmochim. Acta 65 (21) (2001) 3671e3681. € llmann, Mineralogisch-Kristallographische Untersuchungen an Hydra[71] H. Po tationsprodukten der Aluminatphase hydraulischer Bindemittel (Teil 1), University of Erlangen-Nürnberg, Erlangen, Germany, 1989. Habilitation Thesis. € schner, B. Lothenbach, R. Figi, R. Kretzschmar, Influence of citric acid on [72] G. Mo the hydration of Portland cement, Cem. Concr. Res. 39 (4) (2009) 275e282. [73] V.S. Ramachandran, M.S. Lowery, Conduction calorimetric investigation of the effect of retarders on the hydration of Portland cement, Thermochim. Acta 195 (0) (1992) 373e387. [74] S. Gin, N. Godon, J.P. Mestre, E.Y. Vernaz, D. Beaufort, Experimental investigation of aqueous corrosion of R7T7 nuclear glass at 90 C in the presence of organic species, Appl. Geochem. 9 (3) (1994) 255e269. [75] H. Teng, D.E. Grandstaff, Dissolution of basaltic glass: effects of pH and organic ligands, in: D.A. Knecht, M. William, W.M. Murphy (Eds.), Materials Research Society Symposium Proceedings Volume 412-1995 MRS Fall Meeting - Symposium V e Scientific Basis for Nuclear Waste Management XIX, Cambridge University Press, Cambridge, UK, 1996, pp. 249e256.