Steel Construction Manual: A Beginner's Guide

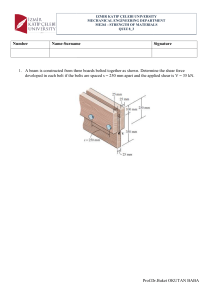

advertisement