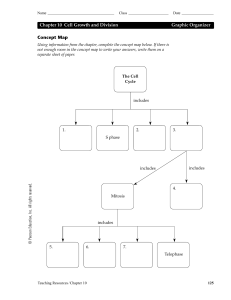

10 Job Design and Work Measurement PowerPoint presentation to accompany Heizer and Render Operations Management, 10e, Global Edition Principles of Operations Management, 8e, Global Edition PowerPoint slides by Jeff Heyl © 2011 Pearson Education 10 - 1 Rusty Wallace’s NASCAR Racing Team NASCAR racing became very popular in the 1990s with huge sponsorship and prize money High performance pit crews are a key element of a successful race team Pit crew members can earn $100,000 per year – for changing tires! © 2011 Pearson Education 10 - 2 Rusty Wallace’s NASCAR Racing Team Each position has very specific work standards Pit crews are highly organized and go though rigorous physical training Pit stops are videotaped to look for improvements © 2011 Pearson Education 10 - 3 Rusty Wallace’s NASCAR Racing Team © 2011 Pearson Education 10 - 4 Human Resource Strategy The objective of a human resource strategy is to manage labor and design jobs so people are effectively and efficiently utilized © 2011 Pearson Education 10 - 5 Human Resource Strategy 1. People should be effectively utilized within the constraints of other operations management decisions 2. People should have a reasonable quality of work life in an atmosphere of mutual commitment and trust © 2011 Pearson Education 10 - 6 Constraints on Human Resource Strategy Product strategy • Skills needed • Talents needed • Materials used • Safety Schedules • Time of day • Time of year (seasonal) • Stability of schedules Process strategy • Technology • Machinery and equipment used • Safety When HUMAN RESOURCE STRATEGY Individual differences Who • Strength and fatigue • Information processing and response Location strategy • Climate • Temperature • Noise • Light • Air quality © 2011 Pearson Education Layout strategy • Fixed position • Process • Assembly line • Work cell • Product Figure 10.1 10 - 7 Labor Planning Employment Stability Policies 1. Follow demand exactly Matches direct labor costs to production Incurs costs in hiring and termination, unemployment insurance, and premium wages Labor is treated as a variable cost © 2011 Pearson Education 10 - 8 Labor Planning Employment Stability Policies 2. Hold employment constant Maintains trained workforce Minimizes hiring, termination, and unemployment costs Employees may be underutilized during slack periods Labor is treated as a fixed cost © 2011 Pearson Education 10 - 9 Work Schedules Standard work schedule Five eight-hour days Flex-time Allows employees, within limits, to determine their own schedules Flexible work week Fewer but longer days Part-time Fewer, possibly irregular, hours © 2011 Pearson Education 10 - 10 Job Classification and Work Rules Specify who can do what Specify when they can do it Specify under what conditions they can do it Often result of union contracts Restricts flexibility in assignments and consequently efficiency of production © 2011 Pearson Education 10 - 11 Job Design Specifying the tasks that constitute a job for an individual or a group 1. Job specialization 2. Job expansion 3. Psychological components 4. Self-directed teams 5. Motivation and incentive systems © 2011 Pearson Education 10 - 12 Labor Specialization The division of labor into unique tasks First suggested by Adam Smith in 1776 1. Development of dexterity 2. Less loss of time 3. Development of specialized tools Later Charles Babbage (1832) added another consideration 1. Wages exactly fit the required skill required © 2011 Pearson Education 10 - 13 Job Expansion Adding more variety to jobs Intended to reduce boredom associated with labor specialization Job enlargement Job rotation Job enrichment Employee empowerment © 2011 Pearson Education 10 - 14 Job Enlargement Enriched job Planning (Participate in a crossfunction quality improvement team) Enlarged job Task #3 (Lock printed circuit board into fixture for next operation) Present job (Manually insert and solder six resistors) Task #2 (Adhere labels to printed circuit board) Control (Test circuits after assembly) Figure 10.2 © 2011 Pearson Education 10 - 15 Psychological Components of Job Design Human resource strategy requires consideration of the psychological components of job design © 2011 Pearson Education 10 - 16 Hawthorne Studies They studied light levels, but discovered productivity improvement was independent from lighting levels Introduced psychology into the workplace The workplace social system and distinct roles played by individuals may be more important than physical factors Individual differences may be dominant in job expectation and contribution © 2011 Pearson Education 10 - 17 Core Job Characteristics Jobs should include the following characteristics 1. Skill variety 2. Job identity 3. Job significance 4. Autonomy 5. Feedback © 2011 Pearson Education 10 - 18 Job Design Continuum Self-directed teams Self-direction Empowerment Enrichment Enlargement Specialization Job expansion Figure 10.3 © 2011 Pearson Education 10 - 19 Self-Directed Teams Group of empowered individuals working together to reach a common goal May be organized for long-term or short-term objectives Effective because Provide employee empowerment Ensure core job characteristics Meet individual psychological needs © 2011 Pearson Education 10 - 20 Self-Directed Teams To maximize effectiveness, managers should Ensure those who have legitimate contributions are on the team Provide management support Ensure the necessary training Endorse clear objectives and goals Financial and non-financial rewards Supervisors must release control © 2011 Pearson Education 10 - 21 Benefits of Teams and Expanded Job Designs Improved quality of work life Improved job satisfaction Increased motivation Allows employees to accept more responsibility Improved productivity and quality Reduced turnover and absenteeism © 2011 Pearson Education 10 - 22 Limitations of Job Expansion 1. Higher capital cost 2. Individuals may prefer simple jobs 3. Higher wages rates for greater skills 4. Smaller labor pool 5. Higher training costs © 2011 Pearson Education 10 - 23 Limitations of Job Expansion 1. Higher capital cost 2. Individuals may prefer simple jobs 3. Higher wages rates for greater skills 4. Smaller labor pool 5. Higher training costs © 2011 Pearson Education 10 - 24 Motivation and Incentive Systems Bonuses - cash or stock options Profit-sharing - profits for distribution to employees Gain sharing - rewards for improvements Incentive plans - typically based on production rates Knowledge-based systems - reward for knowledge or skills © 2011 Pearson Education 10 - 25 Ergonomics and the Work Environment Ergonomics is the study of the interface between man and machine Often called human factors Operator input to machines © 2011 Pearson Education 10 - 26 Ergonomics and Work Methods Feedback to operators The work environment Illumination Noise Temperature Humidity © 2011 Pearson Education 10 - 27 Recommended Levels of Illumination Figure 10.4A © 2011 Pearson Education 10 - 28 Levels of Illumination Task Condition Type of Task or Area Illumination Level Type of Illumination Small detail, extreme accuracy Sewing, inspecting dark materials 100 Overhead ceiling lights and desk lamp Normal detail, prolonged periods Reading, parts assembly, general office work 20-50 Overhead ceiling lights Good contrast, fairly large objects Recreational facilities 5-10 Overhead ceiling lights Large objects Restaurants, stairways, warehouses 2-5 Overhead ceiling lights © 2011 Pearson Education 10 - 29 Decibel Levels Table 10.4B © 2011 Pearson Education 10 - 30 Methods Analysis Focuses on how task is performed Used to analyze 1. Movement of individuals or material Flow diagrams and process charts 2. Activities of human and machine and crew activity Activity charts 3. Body movement Operations charts © 2011 Pearson Education 10 - 31 Flow Diagram Welding From press mach. Storage bins Mach. 3 Mach. 4 Paint shop Machine 1 Mach. 2 Figure 10.5 (a) © 2011 Pearson Education 10 - 32 Flow Diagram Machine 4 Welding Machine 3 Paint shop Machine 2 Machine 1 From press mach. Storage bins Figure 10.5 (b) © 2011 Pearson Education 10 - 33 Process Chart Figure 10.5 (c) © 2011 Pearson Education 10 - 34 Activity Chart Figure 10.6 © 2011 Pearson Education 10 - 35 Operation Chart Figure 10.7 © 2011 Pearson Education 10 - 36 The Visual Workplace Use low-cost visual devices to share information quickly and accurately Displays and graphs replace printouts and paperwork Able to provide timely information in a dynamic environment System should focus on improvement © 2011 Pearson Education 10 - 37 The Visual Workplace Visual signals can take many forms and serve many functions Present the big picture Performance Housekeeping © 2011 Pearson Education 10 - 38 The Visual Workplace Visual utensil holder encourages housekeeping © 2011 Pearson Education A “3-minute service” clock reminds employees of the goal Figure 10.8 10 - 39 The Visual Workplace Visual signals at the machine notify support personnel Visual kanbans reduce inventory and foster JIT Reorder point Line/machine stoppage Parts/ maintenance needed All systems go Part A Part B Part C Andon © 2011 Pearson Education Figure 10.8 10 - 40 The Visual Workplace Quantities in bins indicate ongoing daily requirements and clipboards provide information on schedule changes © 2011 Pearson Education Process specifications and operating procedures are posted in each work area Figure 10.8 10 - 41 Labor Standards Effective manpower planning is dependent on a knowledge of the labor required Labor standards are the amount of time required to perform a job or part of a job Accurate labor standards help determine labor requirements, costs, and fair work © 2011 Pearson Education 10 - 42 Labor Standards Started early in the 20th century Important to both manufacturing and service organizations Necessary for determining staffing requirements Important to labor incentive systems © 2011 Pearson Education 10 - 43 Meaningful Standards Help Determine 1. Labor content of items produced 2. Staffing needs 3. Cost and time estimates 4. Crew size and work balance 5. Expected production 6. Basis of wage incentive plans 7. Efficiency of employees © 2011 Pearson Education 10 - 44 Labor Standards May be set in four ways: 1. Historical experience 2. Time studies 3. Predetermined time standards 4. Work sampling © 2011 Pearson Education 10 - 45 Historical Experience How the task was performed last time Easy and inexpensive Data available from production records or time cards Data is not objective and may be inaccurate Not recommended © 2011 Pearson Education 10 - 46 Importance of Work Measurement Manpower planning Production planning and scheduling Estimating production costs Basis for incentives Training of employees © 2011 Pearson Education 10 - 47 Methods in Measuring Work Standard Historical experience Predetermined time and motion studies Work sampling Time study Observed time Basic (normal) time Standard time © 2011 Pearson Education 10 - 48 Work Measurement Analysis Work Sampling Method Time Study Method © 2011 Pearson Education 10 - 49 Allowances Giving employee breaktime (extra time) to attend personal needs. Types of allowances Relaxation allowance Contingency allowance Process allowance Policy Allowance © 2011 Pearson Education 10 - 50 (1) Work Sampling Estimates percent of time a worker spends on various tasks Requires random observations to record worker activity Determines how employees allocate their time Can be used to set staffing levels, reassign duties, estimate costs, and set delay allowances © 2011 Pearson Education 10 - 51 Work Sampling 1. Take a preliminary sample to obtain estimates of parameter values 2. Compute the sample size required 3. Prepare a schedule for random observations at appropriate times 4. Observe and record worker activities 5. Determine how workers spend their time © 2011 Pearson Education 10 - 52 Work Sampling Determining the sample size z2 p(1 - p) n= h2 where © 2011 Pearson Education n = required sample size z = standard normal deviate for desired confidence level p = estimated value of sample proportion h = acceptable error level in percent 10 - 53 Work Sampling Example Wants employees idle 25% of the time Sample should be accurate within 3% Wants to have 95.45% confidence in the results z2 p(1 - p) n= h2 where n z p h = = = = required sample size 2 for a 95.45% confidence level estimate of idle proportion = 25% = .25 acceptable error of 3% = .03 (2)2 (.25)(.75) n= = 833 observations (.03)2 © 2011 Pearson Education 10 - 54 Example 1 An operation manager for an automobile manufacturing company wants to determine the percentage of time that his workers are working and idle. The manager estimates that the employees are idle 20% of the time. How many observations are needed if the manager wants to have 95.45% confidence in the results and an error level within 4% © 2011 Pearson Education 10 - 55 Work Sampling Time Studies Salespeople Telephone sales 12% Telephone within firm 13% Sales in Travel person 20% 20% Paperwork 17% Lunch and personal 10% Meetings and other 8% Figure 10.10 © 2011 Pearson Education 10 - 56 Work Sampling Time Studies Startup/exercise 3% Assembly-Line Employees Breaks and lunch 10% Dead time between tasks 13% Productive work 67% Unscheduled tasks and downtime 4% Cleanup 3% Figure 10.10 © 2011 Pearson Education 10 - 57 Work Sampling Advantages of work sampling Less expensive than time study Observers need little training Studies can be delayed or interrupted with little impact on results Worker has little chance to affect results Less intrusive © 2011 Pearson Education 10 - 58 Work Sampling Disadvantages of work sampling Does not divide work elements as completely as time study Can yield biased results if observer does not follow random pattern Less accurate, especially when job element times are short © 2011 Pearson Education 10 - 59 (2) Time Studies Involves timing a sample of a worker’s performance and using it to set a standard Requires trained and experienced observers Cannot be set before the work is performed © 2011 Pearson Education 10 - 60 Time Studies © 2011 Pearson Education 10 - 61 Time Studies 1. Define the task to be studied 2. Divide the task into precise elements 3. Decide how many times to measure the task 4. Time and record element times and rating of performance © 2011 Pearson Education 10 - 62 Time Studies 5. Compute average observed time Average observed time = Sum of the times recorded to perform each element Number of observations 6. Determine performance rating and normal time Normal time = © 2011 Pearson Education Average observed time Performance x rating factor 10 - 63 © 2011 Pearson Education 10 - 64 Time Studies 7. Add the normal times for each element to develop the total normal time for the task 8. Compute the standard time Total normal time Standard time = 1 - Allowance factor © 2011 Pearson Education 10 - 65 Allowances Giving employee breaktime (extra time) to attend personal needs. Types of allowances Relaxation allowance Contingency allowance Process allowance Policy Allowance © 2011 Pearson Education 10 - 66 © 2011 Pearson Education 10 - 67 Exercise 1.1 The following data represents the time study observations for the process of producing furniture Job Element Observation Times (minutes) Performance Rating (%) 1 2 3 4 5 A 36 39 37 39 38 120 B 12 10 36 15 13 110 C 3 3 5 5 4 90 D 15 18 16 17 36 85 It is the practice of this company to allow workers a 30-minute coffee break and 18 minutes of personal time per day. (Assuming an 8-hour and 5 days work week) a) Compute the allowance factor b) Calculate the normal time for the process c) Calculate the standard time to complete one unit of the product d) Compute the daily output per worker e) How many workers are needed to produce 600 units per week? © 2011 Pearson Education 10 - 68 Exercise 1.2 The following data represents the time study observations for the metal working process Job Element Observation Times (minutes) Performance Rating (%) 1 2 3 4 5 A 45 53 47 51 49 120 B 23 20 46 24 21 110 C 8 8 10 10 9 90 In this company, it is a common practice to allow workers a 15-minute coffee break and 30 minutes of personal time per day. (In addition, it is estimated that there should be an extra allowance of 27 minutes per day). The working time is from 9.00 am to 5.00 pm. a) Compute the allowance factor b) Calculate the normal time for the process c) Calculate the standard time to complete one unit of the product d) Compute the daily output per worker e) How many workers are needed to produce 500 units per week? (Assuming a 5-day workweek). © 2011 Pearson Education 10 - 69 Time Study Example 1 Average observed time = 4.0 minutes Worker rating = 85% Allowance factor = 13% Normal time = (Average observed time) x (Rating factor) = (4.0)(.85) = 3.4 minutes 3.4 Normal time 3.4 Standard time = = = 1 - .13 1 - Allowance factor .87 = 3.9 minutes (masa yg diambil u sempurnak © 2011 Pearson Education 10 - 70 © 2011 Pearson Education 10 - 71 Time Study Example 2 Allowance factor = 15% Cycle Observed (in minutes) Job Element 1 2 (A) Compose and type letter 8 10 (B) Type envelope address 2 (C) Stuff, stamp, seal, and sort envelopes 2 3 Performance Rating 4 5 9 21* 11 120% 3 2 1 3 105% 1 5* 2 1 110% 1. Delete unusual or nonrecurring observations (marked with *) 2. Compute average times for each element Average time for A = (8 + 10 + 9 + 11)/4 = 9.5 minutes Average time for B = (2 + 3 + 2 + 1 + 3)/5 = 2.2 minutes Average time for C = (2 + 1 + 2 + 1)/4 = 1.5 minutes © 2011 Pearson Education 10 - 72 Time Study Example 2 3. Compute the normal time for each element Normal time = (Average observed time) x (Rating) Normal time for A = (9.5)(1.2) = 11.4 minutes Normal time for B = (2.2)(1.05) = 2.31 minutes Normal time for C = (1.5)(1.10) = 1.65 minutes 4. Add the normal times to find the total normal time Total normal time = 11.40 + 2.31 + 1.65 = 15.36 minutes © 2011 Pearson Education 10 - 73 Time Study Example 2 5. Compute the standard time for the job Total normal time Standard time = 1 - Allowance factor 15.36 = = 18.07 minutes 1 - .15 © 2011 Pearson Education 10 - 74 Determine Sample Size 1. How accurate we want to be 2. The desired level of confidence 3. How much variation exists within the job elements © 2011 Pearson Education 10 - 75 Determine Sample Size zs Required sample size = n = hx where 2 h = accuracy level (acceptable error) desired in percent of the job element expressed as a decimal z = number of standard deviations required for the desired level of confidence s = standard deviation of the initial sample x = mean of the initial sample n = required sample size © 2011 Pearson Education 10 - 76 Determine Sample Size zs Common z Values Required sample size = n = hx where 2 Desired z Value Confidence (standard deviation required for h =(%) accuracy level (acceptable error) desired level of confidence) desired in percent of the job element 1.65 expressed as a decimal =95.0 number of standard1.96 deviations required 95.45 for the desired level2.00 of confidence 2.58 =99.0 standard deviation of the initial sample 99.73 3.00 = mean of the initial sample Table 10.2 = required sample size 90.0 z s x n © 2011 Pearson Education 10 - 77 Time Study Example 3 Desired accuracy with 5% Confidence level = 95% Sample standard deviation = 1.0 Sample mean = 3.00 h = .05 x = 3.00 s = 1.0 z = 1.96 (from Table S10.1 or Appendix I) zs n= hx 2 1.96 x 1.0 n= .05 x 3 © 2011 Pearson Education 2 = 170.74 ≈ 171 10 - 78 Time Study Example 3 When the standard deviation s is not provided, it must be computed s= © 2011 Pearson Education ∑(xi - x)2 n-1 = ∑(Each sample observation - x)2 Number in sample - 1 10 - 79 © 2011 Pearson Education 10 - 80 © 2011 Pearson Education 10 - 81 Ethics and the Work Environment Fairness, equity, and ethics are important constraints of job design Important issues may relate to equal opportunity, equal pay for equal work, and safe working conditions Helpful to work with government agencies, trade unions, insurers, and employees © 2011 Pearson Education 10 - 82