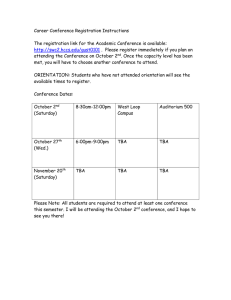

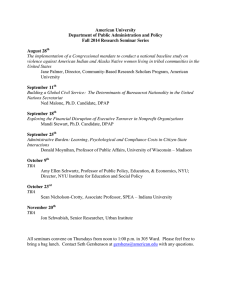

第26巻 259 第5号(1977) 総 説 The 2-Thiobarbituric Acid Reaction, An Objective Measure of the Oxidative Deterioration Occurring in Fats and Oils Russell O. Department Sinnhuber of Food Science (Corvallis, and Technology, Oregon 1 Introduction More than 30 years ago Kohn and Liver sedges' noted that aerobic oxidation of brain tissue produced a compound that when heated in an acid solution with 2-thiobarbituric acid (TBA) gave a brilliant red color with an absorption maximum at 532 nm. They postulated that the TBA reactive material was a carbonyl compound since the reaction was blocked by semicarbazine or phenylhydrazine. Bernheim et al.2' isolated an impure red TBA pigment and suggested that the reaction com pound was a 3-carbon moiety containing one oxygen atom. Wilbur et al" proposed that TBA reaction could be used as an estimation of the oxidative products of unsaturated fatty acids. Patton and Kurtz4', interested in the oxidized flavor of milk fat, tested a number of comV pounds and based on spectral measurements suggested that malonaldehyde was the come pound responsible for the red TBA color test and the material was present in rancid milk fat. Patton et al.5' reported that the TBA reaction material was of low molecular weight, water soluble, Kries test positive and that malonaldehyde could be the compound. Many years earlier, Dox and Plaisance6' a'' demonstrated that furfural and aromatic aldehydes would react with TBA to yield highly colored derivatives. Jennings et al.$' examined the TBA color reaction with milk fat and the similar color reported by Shepherd" Technical Experiment Corvallis, Paper No. 44$5 Station, Oregon Oregon 97331. Oregon State Agricultural University, and T. C. Yu Oregon State University 97331, U.S.A) and by Kohn1" for the reaction of TBA with sulfadiazine. They concluded that although both colors gave the same spectral characc teristics in the visible range that was not proof that the compound were identical with malonaldehyde. In a very significant experiment, Patton and Kurtzt s' found that freshly prepared a or /1unsaturated aldehydes did not give the TBA test but when autoxidized or heated with Cu2+a red color developed. They postulated that a low molecular weight com pound, possibly malonaldehyde, was respon= sible for the typical TBA reaction. At that time, malonaldehyde was not available as a pure compound because of its extreme instability but l , l ,3, 3-tetraethoxypropane (TEP), used as intermediate for organic syn= thesis, was obtainable. TEP hydrolyzes under mild acid conditions to yield malonaldehyde and ethyl alcohol. Sinnhuber and Yu'" used this compound as a source of malonaldehyde and as a standard for the quantitative determination of malonaldehyde in autoxidized fishery products using TBA as the reagent. TBA Pigment The TBA test has undergone a number of modifications and refinements since it was conceived by Kahn and Liversedge" but it consists basically of treating a lipid containing material or fraction derived therefrom with an acid solution of 2-thiobarbituric acid and heating the mixture to develop the red chro= mogen. The intensity of the color at 532'535 nm is a measure of the malonaldehyde content which reflects the degree of lipid 2 260 油 autoxidation which has occurred. In our laboratory when 1,1,3,3-tetraethoxypropane became available we were able to prepare the red pigment in quantity and compare its che= mical and physical properties with pigments obtained from rancid or autoxidized salmon oil and from sulfadiazine, Sinnhuber et al.111 In that report, the three red pigments were found to give the identical absorption spectra shown in Fig.-1. The main absorption a formula of C11HsN404S2 as shown Table-1 Elemental formula The absorption TBA salmon pigment spectra isolated of the from crystal= rancid oil.") mum is at 532^-535 nm with slight secondary maxima at 245 nm and 305 nm. The E;,,, of purified and vacuum dried pigments gave an average value of 4780. Employing the molecular extinction coefficient reported by Sinnhuber and Yu12> of 1.56X10' and the E,~L the molecular weight of the pigment may be estimated. The calculated value of 327 agrees quite closely with the molecular weight of a compound with two molecules of TBA and one of malonaldehyde. Further confirmation of the molecular composition of the pigment was obtained by using various combining ratios since the pigment is highly insoluble and the yield is quantitative. Various molecular ratios of TEP to TBA were used and we found that whenever that ratios exceeded 1 : 2 the yield approached 100°%, leading to the conclusion that the pigment was a condensation of one molecule of malonaldehyde with two molecules of 2-thiobarbituric acid. Elemental chemical composition of the pigments prepared from rancid salmon oil, malonaldehyde (TEP) and sulfadiazine were all similar and comparable to the theoretical assuming a molecular weight of 324.35 and 2 in Table-L . analysis of TBA pigments°. maxi= Sinnhuber 1Assuming line 学. Schmidt1" in a series of experiments, employing somewhat different conditions, confirmed the studies of Sinnhuber et al.") and the for= mula of the red TBA pigment. 'From Fig.-1 化 et al .13) a molecular weight of 324 .35 and of C11H3N404S,. Paper chromatography of the red TBA pigment, isolated from rancid salmon oil, sulfadiazine, malonaldehyde (TEP), frozen tuna and herring meal gave identical RF values using a solvent system of phenol-iso= propyl alcohol-formic acid-water (80 : 10 : 10 100 vol/vol). Fig.-2 shows a photomicrograph of the TB A reaction product derived from rancid salmon oil. The crystals are fine purple-black needles which gave no definite melting point up to 300°C. The pigment is only very slightly soluble in water, but is readily soluble in dilute alkaline solutions or pyridine. Alkaline solutions of the pigment show a bathochromic shift to a longer wave length, 541-547 nm with a decrease in intensity of spectral absorbance. The TBA pigment is readily absorbed on Fig.-2 TBA-malonaldehvde pigment, prepared from autoxidized (280 x )13) crystals salmon oil, 第26巻 261 第5号(1977) TB:1 Malonaldehvde Fig.-3 TB.\ Formation of TBA pigment pigment13~ cellulose powder or filter paper pulp from mild acid solution and may be eluted by weak alkali, phenol or pyridine solutions. In Fig.-3, the reaction of TBA with malonal dehyde and the formation of the TBA pigment is shown. It is of interest that crystals of the TBA pigment prepared in 1957 and stored since that time were recently subjected to mass spectrometry, nuclear magnetic resonance and infrared spectrometry in our laboratory15' and the results obtained confirm the proposed formula. Formation of malonaldehyde in autoxidized lipids malonaldehyde, in the free state, does not appear to be present in large amounts in autoxidized lipids but seems to exist in a weakly bound state which is released when the system is heated with mild acid. Sinnhuber et al.13' reported that less than 2° of the total malonaldehyde measured in a highly oxidized sample of salmon oil was in the free form. Kenaston et al.16' observed that when linole nate, linoleate and oleate were oxidized to the same peroxide level that linolenate produced 60'.- 100 times the TBA chromogens as lino leate and no color was found with oleate. Fig.-4 Relationship between and malonaldehyde during the oxidation tetraene, acid pentaene methyl esters. peroxide Autoxidation of linoleate and forma tion of two a /3 peroxide radicalsl7~. Dahle et al.''' at the Hormel Institute proposed a mechanism for the formation of malon aldehyde in autoxidizing lipids based upon the well-accepted autoxidation theory of Farmer and Sutton18'. Employing careful measurement of oxygen uptake of purified fatty acid esters combined with the determination of diene conjugation, TBA assay and peroxide value, they found that linoleate gave no TBA color at the early stages of oxidation. They reported TBA gave a linear color response when reacted with mildly oxidized triene, tetraene, pentaene and hexaene fatty acid esters. Fig.-4 depicts the relationship between peroxide values and malonaldehyde concentration during oxidation of the various classes of polyunsaturated fatty acid esters. From these data they reasoned that two isomeric peroxide radicals were possible from autoxidized linoleate as shown in Fig.-5 and linolenate will yield four as depicted in Fig.-6. Similarly arachidonate would give value concentrations of diene, triene, and hexaene Fig.-5 fatty Fig.-6 Autoxidation of linolenate and formav tion of two a /3 peroxide and two ,3 y peroxide radicals''. 3 ?62 油 six, pentaenoate eight and hexaenoate ten different peroxide radicals. As Dahle et al.'" significantly points out, two of the four peroxide radicals "possess unsaturation % y with respect to the peroxide function. Such a configuration is significantly absent in the isomeric radicals of linoleate." They propose that the /3 y unsaturated peroxide radical undergoes cyclization to form a 5-membered ring peroxide which under the acidic conditions of the TBA test decomposes to form malonalz dehyde as shown in the equation in Fig.-7 which in turn reacts with TBA to form the red chromogen. It should be reemphasized that this particular 5-membered ring peroxide can occur only during the oxidation of methylc ene interrupted polyunsaturated systems with three or more double bonds. As will be shown in a succeeding section, this makes the TBA test particularly well suited for the estimation of oxidative rancidity of fishery products and fats and oils which contain these highly un saturated lipids. 化 学 autoxidizing lipids found that further oxidation of 2-nonenal derived from the oxidation of methyl linoleate would give small amounts of the malonaldehyde-TBA pigment. They postulated the formation of hydroperoxides from 2-nonenal, is : three isomeric one of which Oxidative degradation of this compound would yield heptanal and malonaldehyde, the latter which was found after reaction with TBA. These studies emphasize that while the TBA test measures malonaldehyde in autoxidizing lipid systems, it is important to recognize that it is especially well-suited for the detection of oxidative rancidity in lipids which are poly unsaturated and contain three or more double bonds. Those fats or lipids which contain little or none of the more polyunsaturated fatty acids, such as corn or cottonseed, do not give a strong TBA reaction in the early stages of oxidative rancidity. The reaction that does occur is partially due to the secondary oxidation of the primary carbonyl compounds. TBA Test for Oxidative Rancidity Fig.-7 Decomposition cyclic peroxide autoxidation the conditions form of the five-membered formed during the of the linolenate of the TBA under test to malonaldehyde'" In an apparent contradiction of the preceding paragraph was the observation by Biggs and Bryant1" that in highly oxidizing systems, even oleate and linoleate gave a positive TBA color, Tarladgis and Watts', Haase and Dunkley2". Patton and Kurtz'", Patton et al."' and Tauf el and Zimmermann"' reported that oxidized 2-alkenals and 2,4-alkadienals react with TBA to form the red pigment. Lillard and Day'" in a study of autoxidative degradation of the secondary products of 4 The TBA test as devised by Kohn and Liversedge" as an indication of oxidative reactions in tissues was slightly modified by Patton and Kurtz" and used to detect milk fat oxidation. They concluded that the TBA test was more sensitive than the peroxide value or Kries test for measuring oxidative deterioc ration in milk fat and suggested this test could be applied to a wide variety of fats and fatcontaining foods. As a direct result of their suggestion, the TBA test was soon adopted by food scientists as a measure of storage stability and the quality of foods and fats. A partial list of the application of the TBA to foods follows: Dairy Products: Patton & Kurtz" Dunkley & Jennings'" Biggs & Bryant1" Sidwell et al.'" King'" 第26巻 第5号(1977) Cereal & Baked Products: Caldwell & Grogg2" Meat: Turner et al.2" Younathan & Watts3" Tarladgis et al.31) Smith et al.32' Zlpser & Watts33),34) Yu & Sinnhuber3" Keskinel et al.36) Witte et al.37) Yamauchi3" Wilson et al.3" Fish & Marine Products: Schwartz & Watts4" Yu & Sinnhuber4" Sinnhuber & Yu1" Palmateer et al.4" Andersson & Danielson43) Yu & Sinnhuber3" MacLean & Castell44) Castell et al.4" Castell & Spears46) Greig47' Botta et al.4" Fruit-Orange Juice Essence : Braddock & Petrus4" Poultry & Egg Products: Privett et al.5" Kwon & Norgaard5" Wilson et al.3" Wang et al.52' Fats & Oils : Sidwell et al.53) Kenaston et al.1" Schmidt54) Tarladgis et al.31) Jacobson et al.55) Pohle et al.56) Brownely & Lachman57' Pokorny et al.5" Yu & Sinnhuber5" Marcuse6" Asakawa et al.61) Feedstuffs: Budde & Wornick6" Yu & Sinnhuber35) Nut Meats: Holland63) The TBA test for oxidative rancidity in lipid or fat containing food or tissue has been adapted by various experimenters to the particular material under examination. In its simplest form 100-500 mg of material is 263 heated with the acid TBA reagent for 20-30 min and the intensity of the red color deter mined in a spectrophotometer at 535 nm. If the solution is not clear because of an oil emulsion that may be present, a few ml of chloroform will generally clear the colored solution for spectral examination. A reagent blank should be run simultaneously. This procedure has the advantage over the peroxide or similar tests for oxidative rancidity in that it may be conducted on the intact sample and does not require fat extraction. The method currently used in our laboratory is as follows : A. Intact sample procedure Reagents and Equipment TBA Solution : 1 g of TBA is dissolved in 75 ml of 0.1 N NaOH and diluted to 100 ml with distilled water. Trichloroacetic Acid-HC1 Reagent: 50 ml TCA solution (25%) and 30 ml HCl (0.6 N) are mixed with 420 ml of distilled water. Antioxidant Solution: 0.3 g butylated hyv droxyanisole (BHA) is dissolved in 5.4 g propylene glycol, and 0.3 g butylated hydroxy toluene (BHT) is dissolved in 4.0 g of warm Tween 20. The two solutions are mixed. This antioxidant preparation is water miscible. Test tube, screw cap with Teflon liner, 20 mm O.D., 150 mm length Pan for boiling water Test tube basket-4 3/4 X 4 x 51 J4" Sample size : Oil and fish meal samples : 100200 mg Fresh or frozen samples (homogenized) : 200-400 mg Procedure : A proper quantity of sample is introduced into a tared test-tube and accurate ly weighed. Three drops of antioxidant solution (exact weight is not necessary) and 3 ml of TBA solution are added to the tube. In case of homogenized fresh sample, the contents in the tube are mixed (Vortex Mixer) to disperse the sample. 17 ml of trichloroacetic acid-HC1 reagent is then added. The tube is flushed with N2 and then the screw cap is tightly closed. Another tube containing the same quantity of reagents, but without the sample is used as a blank. The tubes are placed in a test tube basket and heated in a boiling water bath for 30 min. The tubes are cooled to room temc ro 264 油 perature in tap water, and about 15 ml of the color solution is transferred into a 50 ml conical centrifuge tube. Approximately 5 ml of chloroform is added and the contents mixed for a few seconds with a Vortex mixer. The tubes are centrifuged for 10 min at 3,000 rpm. A part of the aqueous clear color solution is transferred into a 1 cm cuvet for absorbency measurement at 532 nm. The absorbence of a 1 g sample (in 100 ml reagent) multiplied by the factor 46 is the TBA number, or the milligram of malonaldehyde per 1,000 g of sample, Sinnhuber et al.12'. 4ccac sionally instead of the usual bright pink chromogen a yellow color is encountered due to interfering substances. These will be discussed in a later section. B. Distillation procedure A distillation method described by Tarladgis et al.31' has been used in place of the direct procedure, previously described, usually for meat samples or those which are highly colored or which contain considerable carbohydrate material. The procedure consists of heating a blended slurry of meat and water in a Kjel= dahl flask with mild acid and distilling over a measured volume containing most of the liberated malonaldehyde. The TBA test is then conducted on an aliquot of the distillate. The advantage of this procedure is the larger sample size and less interfering colors are encountered. The main disadvantage is that the distillation is an emperical procedure requiring the collec= Lion of a specified volume of distillate. Since the distillation is not complete, a correction factor is derived, based on blank determinac tions and distillation of a malonaldehyde standard (TEP). Approximately 70°'s of the added malonaldehyde is recovered. Bryant1" Interfering Pigments in TBA-Malonaldehyde Reaction Fig.-8 With certain foods and tissues, instead of the typical pink color, an orange or yellow color results with a secondary absorption peak about 450'-460 nm. If the color is of sufficient intensity, it may overlap the TBA-malonal dehyde absorption causing an erronously high value. The compounds responsible include carbohydrates, Wilbur et al.3' ; Biggs and 6 ; formic acid, Schmidt'" 化 学 ; furfural compounds, Keeney and Bassette6" ; glyoxal, Smith et at.'"; glycolic aldehyde, glyceric aldehyde and dihydroxy acetone, Landucci et al.6" ; epihydrin aldehyde and glyceralzdehyde, Patton'" Caldwell and Grogg23', in a study of rancidity of cereal and baked products, removed the yellow interfering color by selective absorption on a cellulose column. An acid distillation technique was employed by Sidwell et al.5" and Tarladgis et al."' to separate malonalde hyde from other interfering food materials. Yu and Sinnhuber36' developed a chromatoc graphic procedure for separating and purifying the pink and interfering pigments. Using this method, a correction factor may be derived for the particular product tested which obviates the need for the separation procedure in success sive determinations. This procedure has been demonstrated to be effective in products which contain sugar or carbohydrate material such as beef liver, oysters, and dehydrated ham and other food products, e.g., frozen tuna pie, dog food, dry fish food. Fig.-8 depicts the absorption spectra of the 450 and 532 pigments in dehydrated ham and the separation that can be achieved. Absorption spectra ants in dehydrated of the ham. TBA react A purified malonaldehyde pigment (o) was obtained by chromatographic separation of the interfering yellow pigment (0) from the original orange-red solution (0)35 Asakawa et al."' outlined a procedure using sodium sulfite with the TBA reagent when the 450 nm pigments are present. This modi fication appears promising in eliminating 第26巻 2651 第5号(1977) interfering pigments without affecting the malonaldehyde determination. Tarladgis et al.67' questioned the validity of the TBA test when conducted on the intact sample stating that TUBAundergoes a number of side reactions when heated with acid to produce interfering pigments which give erv roneous TBA values. Yu and Sinnhuber66' in a series of experiments refuted the work of Tarladgis et al.67'. They found that if the reagents were pure and free from contaminat ing substances, no decomposition of TBA occurred to produce interfering colors even when TBA was heated with acids, oxidizing agents or hydroperoxides. In conclusion Yu and Sinnhuber6" contend that the only com= pound responsible for the red chromogen with an absorption maximum at 532'.'535 nm is a condensation product of malonaldehyde with TBA. Ho and Brown69' demonstrated that impure solvents such as petroleum ester, acetic acid, diethyl ether and residual distillate fractions of ethanol and methanol often contain TBA reacting substances which can be removed by purification. They suggested refluxing the solvents with TBA which effectively trapped the TBA reacting material, thus rendering the distillate from such systems free of the chro= mogen. In a recent study Marcuse and Johansson7o~ examined the TBA reaction in oxidized lipids systems and with various aldehydes and im plied that the conditions for TBA test are not clearly defined and proof was lacking that red pigment with an absorption at 530 nm was due to malonaldehyde. Patton71' responded with evidence from a number of experimenters which prove that the red pigment at 532 is indeed the reaction product of malonaldehyde and TBA. Patton further stated that the TBA test has proven to be a highly sensitive and useful method of monitoring lipid oxidation in many systems. He added, however, that the test results require careful interpretation and should be compared with organoleptic findings and comparisons with other chemical tests. Relationship of TBA Value to Peroxide Number of fats and oils comparing the TBA and per oxide determinations by Sidwell et aL5° showed that higher TBA values were obtained for soybean oil than for cottonseed oil at com parable peroxide values. A partial explanation for this difference may be found in the experi ments of Kenaston et al.'° when they demon= strated that oxidizing methyl linolenate gave higher TBA and peroxide values than linoleate and no TBA values were found in oxidizing oleate. Dahle et al.17' in a series of experiments reported a linear relationship between TBAA value and peroxide value for the polyun saturated fatty acids. However, pure diene, linoleate, even when oxidized to a peroxide value of 2,000 failed to give a TBA reaction. A linear relationship between peroxide value and malonaldehyde content was also found (see Fig.-9) during the autoxidation of men Fig.-9 Relationship during oil59a. the of POV autoxidation to MA values of menhaden haden oil by Yu and Sinnhuber59'. Prior to using the TBA procedure as a measure of oxidative rancidity in fats or foodstuffs, it is important that the fatty acid composition of these products be known. Oxidative rancidity in lipids containing little or no fatty acids of the linolenate or higher unsaturation would not be expected to show significant TBA values even though these lipids gave a high peroxide value. The slight TBA color which occurs in systems containing only oleate or linoleate can be explained as the further autoxidation of a, /t unsaturated aldehydes, initially formed from the decomposition of hydroperoxides, Pattonn and Kurtz4', Patton et al.2°, Lillard and Day.24;, Early studies of the oxidative degradation τ 油 266 Relationship of the TBA Value to Oxidized Flavor in Food Systems While the peroxide value has been well correlated with the oxidation of fats and oils and the accompanying off-odors and flavors, there are many difficulties associated when the peroxide test is applied to food systems which are low in fat content. Extraction of unstable hydroperoxide, without decomposition, in suf ficient quantity for determination presents many problems. The suggestion by Wilbur et aL3' that the TBA test could be used as an estimation of oxidative products of unsaturat ed fatty acids soon received the attention of scientists who were searching for an additional method for measuring lipid oxidation in foods, particularly if it could be related to the develc opment of oxidized or rancid flavors. Dunkley' 2', Dunkley and Jennings25', Patton and Kurtz4' found a good correlation between TBA values and oxidized flavor in milk. Biggs and Bryant19' applied the TBA test to butter, -cheese and whole milk powder and reported that the test is capable of detecting several degrees of oxidation below the level of organo leptic sensitivity. Sidwell et a1.26'improved the TBA procedure for dried milk products by distillation and stated that their results corn related well with sensory evaluations. Turner et al.2" applied the TBA test to frozen pork and found it to be a more reliable index of age and quality than other chemical tests for fat rancidity. They reported a significant positive correlation between TBA results and taste test acceptability scores for wieners and pork patties. From these reports it is evident that the TBA procedure has been widely accepted as a sensitive method for the measurement of malonaldehyde in foods and the results can be correlated with the development of off-odors and flavors. It should be recognized that the fatty acid composition of the food to be ex amined is an important factor in the applica= tion of the TBA test. S 学 mogen with an absorption maximum at 532 nm is a rapid, highly sensitive and reliable procedure for the measurement of oxidative rancidity in foods and lipids and especially if these systems contain fatty acids of greater unsaturation than linoleate. Correlation with taste panels is exceptionally good in these systems. The possibility of application directly to the material to be tested without lipid extraction is a decided advantage over other chemical tests. Procedures have been devised to overcome the effects of interfering sub= stances which are sometimes encountered. Acknowledgements The authors wish to thank Dr. Noboru Matsuo of Seikei University, and the Japan Oil Chemists' Society for their generous support and sponsors ship of this review. (Received March 8, 1977) References 1) 2) H. I. Kohn 3) and col. and Exp. F. Bernheim, Wilber, K. 4) 5) 6) Patton 34, 669 S. Patton, J. Am. A. W. A. 8) 9) R. H. 11) 12) G. 14) and 2164 Kohn, 59, 21 (1945). S. Patton 38, 901 Schmidt, 881 (1959b). E. B. P. Kurtz, 391 (1951). Plaisance, J. Am. Plaisance, J. Am. Chem. W. Res., L. 20, Dunkley, 13 Anal. Chem., Proc. Soc. G. and W. H. G. (1955). 20,1150 Exp. (1948). Biol. Med., Kurtz, J. Dairy Sci., and T. C. Yu, Food Tech., and T. C. Yu, Food Res., (1958). Fette, Seifen, Pawlowski, and Soc., 32, K. F. 33 Anstrichm., Personal Kenaston, ghi, K. G. W. 28, (1916a). P. Sinnhuber H. L. G. and 626 C. Sci., (1955). 23, N. Dairy (1916b). Sinnhuber 16) W. (1958). R. O. Arch. G. 2156 Shepherd, 15) 17) and Food 9 M. (1949). J. and Soc., Jennings, R. O. 305 Kurtz, Keeney 38, Dox 38, G. K. (1948). and O. 24, W. Chem. Dox I. 12, 13) M. Oil Reiber, 10) 257 (1951). W. W. and 174, Bernheim, G. Pharma•¬ (1944). Bernheim, F. Soc., Soc., 292 Biochem., and J. 82, Chem. Arch. S. Liversedge, M. Biol. M. Wilber, Chem. 7) M. T herap., J. Shapiro, Conclusion The TBA reaction between malonaldehyde and 2-thiobarbituric acid to yield a red chron 化 M. Bernheim, 61, communication. Wilbur, J. A. Am. OttolenOil Chem. (1955). Dahle, Biochein. E. G. Hill, and and Biophys., R. T. Holman, 98, 253 第26巻 第5号(1977) (1962) 18) E. H. Farmer and D. A. Sutton. J. Chem. Soc., 1943, 119. 19) D. A. Biggs and L. K. Bryant, Can. J. Tech., 31, 138 (1953). 20) B. G. Tarladgis and B. M. Watts, J. Am. Oil Chem. Soc., 37, 403 (1960). 21) G. Haase and M. L. Dunkley, J. Lipid Res., 10, 555 (1969). 22) S. Patton, I. J. Barnes, and L. E. Evans, J. Am. Oil Chem. Soc., 36, 280 (1959). 23) H. C. K. Taufel and R. Zimmermann, Fette, Seifen, Anstrichm., 63, 226 (1961). 24) D. A. Lillard and E. A. Day, J. Am. Oil Chem. Soc., 41, 549 (1964). 25) W. L. Dunkley and W. G. Jennings, J. Dairy Sci., 34, 1064 (1951). 26) C. G. Sidwell, H. Salwin, and J. H. Mitchell, Jr., J. Am. Oil. Chem. Soc., 32, 13 (1955). 27) R. L. King, J. Dairy Sci., 65, 1165 (1962). 28) E. F. Caldwell and B. Grogg, Food Tech., 9, 185 (1955). 29) E. W. Turner, W. D. Paynter, E. J. Montie, M. W. Bessert, G. M. Struck, and F. C. Olson, Food Tech., 8, 326 (1954). 30) M. T. Younathan and B. M, Watts, Food Res., 25, 538 (1960). 31) B. G. Tarladgis, B. M. Watts, M. T. Younathan, and L. Dugan, Jr., J. Am. Oil Chem. Soc., 37, 44 (1960). 32) N. L. Smith, I. J. Tinsley, and E. C. Bubl , Food Tech., 14, 317 (1960) 33) M. W. Zipser and B. M. Watts, Food Tech., 15, 445 (1961). 34) M. W. Zipser and B. M. Watts, Food Tech., 16, 102 (1962). 35) T. C. Yu and R. O. Sinnhuber, Food Tech., 16, 115 (1962). 36) A. Keskinel, J. C. Ayres, and H. E. Snyder, Food Tech., 18, 101 (1964). 37) V. C. Witte, G. F. Krause, and M. E. Bailey, J. Food Sci., 35, 582 (1970). 38) K. Yamauchi, Bull. Fac. Agric., 19, 137 (1972). 39) B. R. Wilson, A. M. Pearson, and F. B. Shorland, J. Agr. Food Chem., 24, 7 (1976). 40) M. G. Schwartz and B. M. Watts , Food Res., 22, 76 (1957). 41) T. C. Yu and R. O. Sinnhuber , Food Tech., 11, 104 (1957). 42) R. E. Palmateer, T. C. Yu and R . O. Sinnhuber, Food Tech., 14, 528 (1960). 43) K. Andersson and C. E. Danielson, Food Tech., 15, 55 (1961). 44) J. MacLean and C. H. Castell, J. Fish. Res. Bd. Can., 21, 1345 (1964). 45) C. H. Castell, B. A. Moore, P. M. Jangaard, 26? and W. E. Neal, J. Fish. Res. Bd. Can., 23, 1385 (1966). 46) C. H. Castell and D. M. Spears , J. Fish. Res. Bd. Can., 25, 639 (1968). 47) R. A. Greig, Fish. Ind. Res., 4, 23 (1968). 48) J. K. Botta, J. F. Richards, and N. Tomlinson, J. Fish. Res. Bd. Can., 30, 63 (1973). 49) R. J. Braddock and D. K. Petrus, J. Food Sci., 36, 1095 (1971). 50) O. S. Privett, O. Romanus, and L. Kline, Food Tech., 18, 239 (1964). 51) T. W. Kwon and M. J. Norgaard, J. Food Sci., 31, 223 (1966). 52) P. L. Wang, E. J. Day, and T. C. Chen, J. Food Sci., 41, 453 (1976). 53) C. G. Sidwell, H. Salwin, M. Benca, and J. H. Mitchell, Jr., J. Am. Oil Chem. Soc., 31, 603 (1954). 54) H. Schmidt, Fette, Seifen, Anstrichm., 61, 127 (1959a). 55) G. A. Jacobson, J. A. Kirkpatrick, and H. E. Goff, Jr., J. Am. Oil Chem. Soc., 41, 124 (1964). 56) W. D. Pohle, R. L. Gregory, and B. V. Giessen, J. Am. Oil Chem. Soc., 41, 649 (1964). 57) C. A. Brownley and L. Lachman, J. Pharm. Sci., 54, 1480 (1965). 58) J. Pokorny, H. Zwain, and G. Janicek, Fette, Seifen, Anstrichm., 67, 477 (1965). 59) T. C. Yu and R. O. Sinnhuber, J. Am. Oil Chem. Soc., 44, 256 (1967). 60) R. Marcuse, Fette, Seifen, Anstrichm., 72, 635 (1970). 61) T. Asakawa, Y. Nomura, and S. Matsushita, Yuhagahu, 24, 481 (1975). 65) E. F. Budde and R. C. Wornick, Am. Assoc. of Cereal Chem., 1962, 7. 63) D. C. Holland, J. AOAC, 54, 1024 (1971). 64) M. Keeney and R. Bassette, J. Dairy Sci., 62, 945 (1959). 65) J. M. Landucci, J. Pouradier, and M. Durante, Bull. Soc. Chim. France, 22 , 857 (1955). 66) S. Patton, Food Res., 25, 554 (1960). 67) B. G. Tarladgis, A. M. Pearson, and L. R. Dugan, Jr., J. Am. Oil Chem. Soc., 39, 34 (1962). 68) T. C. Yu and R. O. Sinnhuber, J. Am. Oil Chem. Soc., 41, 540 (1964). 69) S. Y. Ho and W. D. Brown, J. Food Sci., 31, 386 (1966). 70) R. Marcuse and L. Johansson, J. Am. Oil Chem. Soc., 50, 387 (1973). 71) S. Patton, J. Am. Oil Chem. Soc., 51 , 114 (1974). 72) W.L. Dunkley, Food Tech., 5, 342 (1951). 9