Paper Recycling Machine Design: Reducing Waste in Education

advertisement

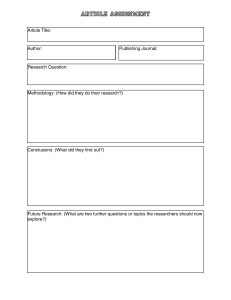

Chapter I Introduction Waste management and the enormous amount of materials without proper disposal became a common problem in every country. One good example of this is the excessive use of papers in teaching institutions like schools and colleges. Most of the used papers go to waste and become useless because they are just usually burnt and thrown away. To maximize its usage, proper recycling can be a good way to utilize it fully. Mainly, the concept of this project is to help in the reduction of paper wastage in the educational institutions and recycle them through the use of a paper recycling machine. Papers are usually made of materials obtained mainly from plants and trees which are renewable resources but the time span for its growth takes a while. A tree takes at least 10-20 years to fully grow depending on its kind, take for example; a 45ft tree can produce around 10,000 sheets of paper. About 14% of deforestation is done to supply our needs in paper. Imagine the number of trees that are taken down just to create this certain amount of paper. If used paper is not recycled properly, the possibility of more trees being cut down for paper could grow rapidly. Deforestation in the Philippines causes flood, landslides and global warming. Forest Management Bureau of the Department of Environment and Natural Resources said, that the country loses about 47,000 hectares of forest cover every year, but in 2010, the percentage of forest cover went down by 4.6 percent with an estimated of 6.8 million hectares from the 7.2 million in 2003, thus, recycling paper will help in dropping the rate of deforestation percentage 1 in the country. It also minimizes the possibility of a natural disaster to happen. In Metro Manila, approximately 720 tons per day are recycled or composted out of 6700 tons of wastes generated per day. Paper is essential to us, but the amount of waste paper produced in the Philippines is about 1 million ton every year. The production of paper is decreasing due to deforestation and other environmental issues. Another is waste management; we can reduce the waste and create new products such as recycled paper. Recycling paper may contribute to lessen methane and carbon dioxide in the atmosphere. When paper disintegrates anaerobically in landfills, it may produce methane. Many models of paper recycling machines have different kinds of mechanisms and technicalities. Recycling of waste paper is beneficial not only from an economic point of view but also for the protection of the environment. Background of the study Paper is a thin sheet of material made from wood pulp or other fibrous substances that can be used for writing, drawing, printing, or wrapping. The mass production of paper resulted to the development of writing as a means of passing down information through ages. Scarcity of raw material is a serious issue in the paper production sector. The principal raw element, wood, is quite valuable. The industry’s concern for the environment resulted in concentrating their efforts to reduce wastage of raw material. Waste paper as a raw material are shredded used papers from which the fibers come from. These fibers are then used in the recycling process to create pulp. Papers are commonly made from the woods of trees. Pulp, which is the main ingredient in the paper-making process, can be yielded by separating cellulose from the trees through 2 chemical or mechanical process. The amount of paper waste produced in the Philippines keeps on increasing in the succeeding years. Large amounts of papers are used every day. Most of them are treated as useless and they are thrown away after use, which sometimes causes environmental pollution. Hence, making a recycling machine will reduce the paper waste in the coming year and also help to lessen deforestation. Conceptual Framework Figure 1. Conceptual Framework of the Study INPUT Garnered data regarding the paper wastage in the CEAMechanical Engineering department. PROCESS Creating a design of paper recycling machine. Designing machine with the use of computer software. OUTPUT Feasible design of a paper recycling machine that can be used as a layout in producing actual machine. Note: This figure shows the conceptual framework of the study wherein the input is the data of paper wastage in the mechanical engineering department of Don Honorio Ventura State 3 University. Computer software was used in creating and designing of the machine. The researcher’s objective is to obtain and design a viable machine for the production of recycling machine. Statement of the Problem Dumping paper has a lot of various effects. In the Philippines, it was projected to surpass 2 million tons of paper consumption at the current consumption level. This is about 19 kilograms of paper waste per person in the Philippines. By recycling used paper, the negative effects of used paper in the environment will definitely be reduced. Specifically, this study aims to provide solutions to the problems with paper wastage and its effects as stated below: 1) The environmental effects of excessive usage of paper that resulted to a lot of natural phenomena. 2) The need to recycle used papers and to reduce the amount of wastage. 3) As for affordability, the challenge of designing a machine that is less in cost without putting aside its capability. 4 Objectives of the Study General Objective The study aims to produce a feasible design of a paper recycling machine that is intended to achieve specific objectives. Specific Objectives The specific objectives are as follows: 1) To achieve a design that is not complex to operate and at low cost. 2) To propose a viable design that can be used as a basis for fabrication. 3) To be of help in the reduction of paper wastage in the mechanical engineering department. Significance of the Study The generalization of this study would be a great contribution to the environmental health, and the vital results of this research could be highly significant and beneficial especially to the following: a. Students. In this study, the students will benefit because the paper they already used can be utilized again after the recycling process. b. School Employees. The findings of this study will reduce the cost of money they spend on paper items. c. Future Researchers. This study may serve as a guide and reference for their research project. 5 d. Environment Institutions. The outcome of this study will definitely be helpful for the environment because it reduces greenhouse gas emission and using recycled paper conserves natural energy. e. Entrepreneurs. It will benefit those entrepreneurs who are launching business that employs paper products and has a limited budget. Hypothesis The study will be able to develop a machine design from a manual sketch and convert it to a digital design. The proposed machine design will be beneficial to the Mechanical Engineering department in minimizing paper waste in the vicinity as well as reducing paperrelated concerns in the environment. Scope and Delimitation In general, the focus of this study is to design a paper recycling machine that will help in reducing the paper waste in Don Honorio Ventura State University. Recycling is the act of gathering and processing items that would otherwise be discarded as waste and transforming them into new goods. The community and the environment may both benefit from recycling. The proposed paper recycling machine is designed solely for the possible production of recycled paper. Most of the paper recycling designs and prototypes uses heating elements for drying while this paper proposes the usage of natural heat from the sun also known as sun drying. This method is suggested by the researchers for cost cutting since the design is intended for the usage of an educational institution. Therefore, the produced paper needs to be dried manually. 6 Since this paper is only a proposed design for fabrication, the flaw and properties associated with the output which is the recycled paper is not related with the study. Definitions of terms Cellulose – an insoluble substance which is the main constituent of plant cell walls and of vegetable fibers such as cotton. It is a polyacrylamide consisting of chains of glucose monomers. Deforestation – Deforestation is the purposeful clearing of forested land. Fibrous – consisting of or characterized by fibers. Methane – a colorless, odorless flammable gas which is the main constituent of natural gas. It is the simplest member of the alkane series of hydrocarbons. Paper Wastage – paper discarded as used, superfluous, or not fit for use. Pulp – obtained by chemically or mechanically separating cellulose from the trees Renewable Resources – A renewable resource, also known as a flow resource, is a natural resource which will replenish to replace the portion depleted by usage and consumption, either through natural reproduction or other recurring processes in a finite amount of time in a human time scale. Scarcity – the state of being scarce or in short supply; shortage. Utilize – make practical and effective use of. 7 Chapter II Review of Related Studies Conceptual Literature Teaching institutions usually produce large quantities of waste paper. Recycling the waste paper is possible and it will be an effective way to reduce paper wastage. This act can help in the protection of the environment and also with the cost saving of the institution. Creating and designing a paper recycling unit that can be used in schools and colleges can ensure a low cost production of paper products. (Pillai, A., et al. 2020) Paper recycling is a good alternative to make good use of cast-off paper. The quality and quantity of used paper may vary when we are taking the output into consideration. Recycled paper is described as a paper that is partially or entirely made up of recycled fibers. Some products that use recycled fiber as raw material are tissue, newspaper, and paperboard. Paper waste is deposited in a pulper, a large tank that agitates with huge amount of water to release the paper fibers from the paper web and breaks it down to slurry. Pulping is the process of treating wood or other plants to obtain the primary raw material used in the production of paper. According to Princeton University, the process aims to remove as much lignin (an organic compound that binds the cells, fibers, and vessels that make up wood) as possible without reducing fiber strength, thus releasing the fibers( Mombeyarara P., et al. 2017). The fabricated machine has six components consisted of disc refiner, hydro pulper, head box, conveyor, driers and the rollers. The disc refiner has a three main parts, a hopper for 8 charging the pulp slurry, a screw type conveyor that move the slurry to the treating element blade. The hydro pulper is an open cylindrical tank that has rotating blade to stir the slurry and separate the fibers. The head box is used to ensure that the flow of the slurry is at constant velocity. The conveyor has three purposes, to assist the sheet through the process, for effective water removal, and a texture cushion for passing moist sheet without crushing or significant marking. The drier consist of two hollow cylinder designed in a form of roller, it dries up and compresses the paper at the same time. From the result of an experimental analysis, the fabricated machine can produce 7.6 kg of paper from a 10 kg of used paper. (Olutoye, M. 2005) There are steps of how to recycle used paper like; waste paper collection: this is to collect the used paper, classification of paper: there are various types of paper so we need to classify the paper based on their appearance or texture, shredding and pulping: after sorting, we need to shred the paper to turn it into small bits to make a new one. And after it is shredded, water is added along with other chemicals to breakdown and to smoothen the paper, deinking and straining of paper: deinking is one of the most important procedures of making paper again. While doing the pulping of the paper other chemicals are added to create new paper because deinking removes the ink from the used paper and it will create new recycled paper. Straining is to remove the excess water and chemicals from the paper that is being recycled. Lastly is paper making: the drained pulp of paper is entering a machine to produce new one. (Bhuvenawary et al. 2020) Another similar study was conducted in an international journal Scientific & Engineering Research; the methodology and design unit is discussed. The paper showed the process of 9 recycling paper into new one. First the waste paper undergo to pulping, a process where waste paper is mixed with water, binder, deinking and whitening agent. The pulper agitates the mixture to separate the fiber from each other and create a thin solution of paper pulp. After the paper pulp was formed it will flow down through a valve on the felt conveyor to form its shape. The conveyor moves through a set of rollers to press the pulp and remove excess water. The last step is drying, after the formation of the sheet the conveyor moves to heated roller and blower, where it evaporates the water and dries the sheet. (Edlabadkar,A., et al. 2021) Research Literature Paper production was not originally meant for widespread use, but it evolved into a process that produces billions of tons of paper and also uses a lot of wood which leads us to another global issue: deforestation. Wood is one of the most essential raw materials, with numerous applications in various sectors. (Hagiopol C., Johnston J., 2011) It is worth noting that due to the amount of non-recyclable or non-collectable paper such as cigarette paper, wallpaper, tissue paper, and archive papers, the recycling potential is substantially lower than the amount of paper consumed. According to several studies, these paper grades account for 15–20 percent of overall paper usage (Ervasti, I., et al., 2016). Many recent studies have focused on the problem of paper consumption. A study at the University of Porto, Portugal aims to assess the paper consumption at six higher education schools. An environmental assessment concentrating on paper consumption used to photocopy and print in six higher education schools in Porto is part of this project. There are three main 10 institutions selected from the University of Porto, i.e., the Faculty of Sports (FADEUP), the Faculty of Engineering (FEUP), and the Faculty of Humanities (FLUP). Throughout the literature, from 2008 to 2009, data was gathered and evaluated from all of the institutes indicated above. An indicator representing the annual number of paper sheets utilized per person was determined for each institution. The data covers the number of students, teachers, and personnel at the institution, as well as the number of paper sheets used in photocopiers and printing equipment. For two years, the findings enable conclusions to be drawn correlated to the changes in consumption and for each institution. In the year 2008-2009, the Faculty of Engineering (FEUP) has a population ranging from 7022 students. The study stated that the beginning of the academic year (September) and the beginning of the assessment periods have been reported to have higher consumption than all other months (January to June). However, the total paper consumption increased in 2009 for the analyzed institutions that were further observed, the FEUP spiked its rating by 19% in that said year. Through correlation, the Faculty of Engineering (FEUP) is the largest consumer of paper sheets. In 2008, 5.5 million paper sheets were consumed, while in 2009, the consumption doubled to 7 million sheets. (Campos et al. 2011) According to a foreign study, there is around 35 percent of tress that are being cut down to produce paper. Trees are renewable resources but regardless, a huge number of trees are still at stake just to make sheets of paper. And it can greatly affect our environment. To prevent the excessive cutting down of trees, recycling the used papers can be an alternative. (Bhuvanewary, et al, 2020). 11 Designing and producing a recycling machine within an institution that produces huge number of paper wastage comes handy in cost saving. The amount of work to transport collated papers continuously may result in lack of storage place, capital loss and usually requires human work. A paper recycling machine can be of good use in a teaching institution as a replacement for human effort in transporting and processing the used papers. Proposing a machine design that can process papers for recycling is highly suggested to reduce cost and lessen the manual work. (Premkumar, et al, 2020). Relevance to the Present Study As one of the developing countries, proper waste management became one of the major problems in the Philippines these past decades. There are certain actions made by government to address the problems related to waste management and it involves proper implementation of laws, campaigns that promotes awareness with proper management of wastages and recycling. (Atienza, V. 2011.) According to the written Philippine constitution Republic Act No. 9003 also known as Ecological Solid Waste Management Act of 2000 an act providing for an ecological solid waste management program, creating the necessary institutional mechanisms and incentives, declaring certain acts prohibited and providing penalties, appropriating funds therefore, and for other purposes. 12 REPUBLIC ACT NO. 9003 SECTION 1. Short Title. — This Act shall be known as the ―Ecological Solid Waste Management Act of 2000.‖ (d) Ensure the proper segregation, collection, transport, storage, treatment and disposal of solid waste through the formulation and adoption of the best environmental practice in ecological waste management excluding incineration; (j) Strengthen the integration of ecological solid waste management and resource conservation and recovery topics into the academic curricula of formal and non-formal education in order to promote environmental awareness and action among the citizenry. (l) Ecological solid waste management shall refer to the systematic administration of activities which provide for segregation at source, segregated transportation, storage, transfer, processing, treatment, and disposal of solid waste and all other waste management activities which do not harm the environment. One of the essential building blocks of our society is also known as paper, but today as we rely on our technology such as phones, laptops, and tablets we start to take for granted the contribution of paper in our society. Paper is a common material that we use in our everyday life; most of the products in our house are made up from paper such as books, newspaper, furniture, containers, etc. Paper industry here in the Philippines comprises 39 local recycling mills, 6 abaca pulp mills and 1 integrated paper mill located in Surigao which has the resources required to transform a pulp into a paper. The supply of continuous waste papers is the main reason that recycling paper mills still operate on a day-to-day basis. Local mills provide a high quality of paper for a reasonable price as they also serve the needs of allied and related industries. The 13 demand in paper is in line with the growing school populations, and economic growth. Based on the reports, the annual capital consumption of paper here in the Philippines is 13 kg as compared to the world's average of 43 kg. According to Republic Act 9003 - Ecological Solid Waste Management Act, local governments are required to:(1) establish city level solid waste management boards,(2) develop and implement 10-year solid waste management plans; and (3) serve as members on the Metro Manila Board. Recyclable materials such as paper, plastic, glass, metals, and some biodegradable materials are mainly from the households, and other establishments. Most households in the Philippines do not segregate the waste materials in classification; this is one of the main reasons why few waste papers are being recovered. Lower class household are not aware of the benefit of the recycling paper. Most of them dispose their waste paper along with other solid materials. In addition to that business establishments also do not practice the proper waste management. The long-standing societal problems of our country Philippines, has been tackled by many over the years. Upon scrutinizing the issue of pollution, hence the waste paper floats. In totality of Municipal solid waste, a whopping nineteen percent (19%) is from paper. And paper being the second leading contributor of solid waste next to kitchen waste. This is after the fact that Philippine paper industry stays as the larger net importer of waste paper products as its number one raw material. Then the great question is why does not the local pulp and paper industry obtain all of its raw materials from local sources? Unfortunately, present paper recycling activities and infrastructure experiences low production of pulp as needed by local pulp and paper industry. Providing the requirements for the paper production has been the dilemma for the local pulp and paper industry (Parayno, Busmente, 2004). 14 Chapter III Methodology Project Research Design The researchers used a descriptive and experimental research design to tackle the research problems. A descriptive research design is purely used on a theoretical basis in which the researchers will gather, analyze and present the data in an understandable manner. Experimental research design was utilized by the researchers to follow a scientific research design; this involves an attempt to prove a credible design by scientific means. In this study, the methods were utilized to design a realistic machine that may be able to help with one of the most recurring global issues; paper waste. Figure 2. Field of Study © www.googlemaps.com 15 This was accomplished by compiling data such as the ingredients needed to make a paper, the design of the other author/s, and the amount of paper waste generated by the mechanical engineering students from Don Honorio Ventura State University's College of Engineering and Architecture department. There is also a variable that is manipulated in the study which is the paper-water mixture to obtain actual scientific data. Project Development The gathered data guides the researchers to extensively design a machine for the future research. The design will be proposed to the mechanical engineering department, thus in the future, the design will contribute to the paper waste management of the area. Furthermore, the researchers also aim to aid the long standing problem about the greenhouse gas emission due to improper burning of paper waste. In this study, making recycled paper with the design conserves natural energy that does not harm or pollute the environment. The design criteria will be evaluated to see if it is capable of performing its role, as well as being cost-effective and simple to use. The researchers will be conducting consultations among school professors, School Engineers and the Mechanical Engineering Department of Don Honorio Ventura state University. With the success of this project, the researchers would also gain the interest of other institutes and even entrepreneurs who own businesses that consumes large amount of paper products. 16 Figure 2-1 Field of Study The researchers will base on the current and past status of studies online. After the consultation about the design, the researchers will fix and analyze on how to improve the project that will be based on the given statements by the experts. The researcher will also assess the design to see if it meets the criteria so that it can be developed further. Operation Procedure This part of the paper discusses the projected procedure of the machine. After going through the design process, the researchers provided the function of each component in the machine. The operation procedure stated below is the expected manner on how the machine will work if prototyped. The raw material collected will be shredded then soak in water before putting it in the tank. 17 The paper-water mixture will then be added in the cylindrical tank with a blade to mince the paper with water until the mixture reached the expected consistency. Once the process is done from the tank, the mixed materials will pass into the valve that is manually unfastened by the operator to regulate and flow the mixture in the conveyor belt. The conveyor belt will lead the mixed materials to move into a rolling pin to press the paper and remove most of its water content. The design has a pathway for the excess water from the mixture. The pressed materials then will go through the process of sun drying. The process of producing the desired output is approximately 30 minutes from putting the paper-water mixture in the tank to sun drying process. Since the mincing of paper-water mixture will take 5 minutes, the remaining time will be based on how the operator will use it in production process. Based on the researchers experiment, the sun drying process will consume 510 minutes. 18 Instrument and Technique Used The instrument used to gather the needed data for the research was based on the researcher's discoveries, gathered data, previous studies, applicable thesis, related literature, and experimentations. In the construction of the technique used, good data collection will assist the result to gain greater product. The tool used for making recycled paper was made by the researchers and based on a usual recycling paper machine. Observing existing professional recordings provided some perspectives on the topic or research. In that case, the collected data and knowledge are combined to create the study. The research instrument consists of planning and analyzing to obtain an understanding of how to recycle paper and building a machine, which reflects on the preference of designing the machine. Additionally, the instrument was confirmed by an adviser before it was laid on to the study. The researchers conducted a simple density experiment in order to yield data in the density of the paper-water mixture. The researchers weighted 2 liters or 0.002 m 3 amount of the mixture for the researchers to be able to compute for the density and the maximum capacity of the tank in kilograms as shown below: 19 Figure 3. Density of the Paper-Water Mixture Density of mixed materials ρ= Where, m = mass of mixture v = volume of mixture ρ= ρ = 1050 Therefore: ρ= 1050 kg/m3 = m = 135.765 kg 20 Modelling and Working Drawings After conceptualizing, the researchers proceeded in the development of the design. For better visualization of the output, the design software Sketchup and AutoCAD was used. The researchers provided a rendered design to ideate how the machine will look like if prototyped. Figure 4-1 Paper Recycling Machine TITLE: SCALE: 1/12 in DWG NO: PAPER RECYCLING MACHINE DWG-1 SHEET NO: SUB TITLE: ASSEMBLY DESIGN 1 21 Figure 4-2 Paper Recycling Machine Dimensions TITLE: SCALE: DWG NO: MACHINE DIMENSIONS 1/12 in SUB TITLE: CONCEPTUAL DRAWING DWG - 2 SHEET NO: 2 22 Figure 4-3 Right, Left and Top View (Assembly Design) RIGHT SIDE VIEW LEFT SIDE VIEW TOP VIEW TITLE: SCALE: DWG NO: RIGHT, LEFT AND TOP VIEW 1/12 in DWG - 3 SHEET NO: SUB TITLE: ASSEMBLY DESIGN 2 23 Figure 4-4 Front and Back View (Conceptual Drawing) FRONT VIEW BACK VIEW TITLE: SCALE: DWG NO: FRONT AND BACK VIEW 1/12 in SUB TITLE: DWG - 4 SHEET NO: CONCEPTUAL DRAWING 3 24 Figure 4-5 Front and Back View (Assembly Design) FRONT VIEW BACK VIEW SCALE: DWG NO: TITLE: FRONT AND BACK VIEW 1/12 in SUB TITLE: DWG - 5 SHEET NO: ASSEMBLY DESIGN 3 25 Figure 4-6 Tank, Shaft and Conveyor CONVEYOR TANK SHAFT AND THE BLADE DWG NO: TITLE: SCALE: TANK, SHAFT AND CONVEYOR 1/12 in DWG - 6 SHEET NO: SUB TITLE: ASSEMBLY DESIGN 4 26 Figure 4-7 Cross Section of the Tank SCALE: DWG NO: TITLE: 1/12 in CROSS SECTION OF THE TANK DWG - 6 SHEET NO: SUB TITLE: ASSEMBLY DESIGN 5 27 Material Selection After designing and rendering the machine, the researchers proceeded in the process of selecting materials that will be compatible in the output design. The material selections were based on the specifications of each component. The properties of stainless steel are suitable for the design since it is resistant in corrosion which is crucial because of the presence of water in the process of mixing the paper-water mixture. The selections were also based on the accessibility and availability of the material in a local setup. The costs of the materials projected to be used were also taken into consideration to lessen the expenses since the design was intended for practical use. Frame Support Structure It is composed of frames or structure to form a weight supporting system without the use of other load bearing material such as fabrics and other pliable material. Projected Material to be Use 6061 Aluminum Alloy Alloys like; 6061 Aluminum Alloy is a combination of pure metal with two or more other metallic components to form a hybrid substance. The new alloy combines the qualities of each element to create a stronger, more durable, and more flexible metal that is ideal for a certain use. The new alloy is distinct, and its constituent parts cannot be separated physically. Aluminum, when alloyed with other metals, becomes nearly as strong as steel. Advantages: Offers excellent corrosion resistance and weld-ability 28 Can withstand an ultimate tensile strength of at least 290 MPa and yield strength of at least 241 MPa. 6061 Aluminum Alloy is easier to work than other alloys and stays corrosion resistant even when the surface is abraded Is suitable for medium to high strength requirements Has good toughness, making it one of the most adaptive heat-treated alloys available Table 1-1 Specification of Frame Support Structure Material 6061 General Purpose Aluminum Shape Square tube Grade Rating 6061 Thickness 4 mm Price PHP 1439.004 Table 2-1 Specification for the Project (Frame Support Structure) Material 6061 Aluminum Alloy Shape Square tube Grade Rating 6061 Thickness 3 mm Alternating Current Motor (AC Motor) AC motors are the common type of motor, like the majority of practical motors used in everyday industrial applications (as well as hobbyist projects, domestic goods, and a variety of 29 other professional equipment and consumer products); provide a relatively efficient method of producing mechanical energy from a simple electrical input signal. One of the most used motor is the universal motor. This motor is used in agitator with an output of 745 watts and a 1440 rpm is the projected specification of the motor. This specification was also used in the study of Design of Waste Paper Recycling Machine (Aparebo E.M., 2016). Advantages Has simple design that results in extreme reliability and low maintenance operation. Generates less noise and vibration High durability and long lifespan Can distribute and maintain even amount of power throughout the operation Table 1-2 Specification of the Alternating Current Motor Rated Voltage 220 V Speed 1440 rpm Output Power 745 watts Body Material Sheet Body Price PHP 3560.00 30 Table 2-2 Specification for the Project (Motor of the Conveyor Belt) Rated Voltage 220 V Speed 30 rpm Output Power 28 Watts Price PHP 1079.00 The alternating current motor used in the design for the conveyor belt has a reduction gearbox to control the output in the speed of the motor. Projected Material to be Use for the Tank, Chain & Sprocket Drive, Driveshaft and Pitched-Blade Stainless Steel 304 Stainless steel 304 is typically used because it is cheaper and mildly corrosive proficiency to the environment and chemicals. It is composed of 18-20% of chromium, 8 to 11% nickel, and 2% manganese. This grade is commonly used because it has sufficient ability to prevent corrosion in every aspect. Furthermore, it is more inexpensive than using other grades. Possessing a great austenitic metallurgical structure gives this grade versatility and is well-suited for establishing a wide variety of products. The pitched blade consist of two blades will be enough to mince the paper-water mixture since the paper was first soaked in the water before putting in the tank. Since the pitched blade will be fabricated through stainless steel 304, this material has good toughness and also suitable for high strength requirements. Hence, the two 45 degree pitched blade will able to mince the paper-water mixture. 31 Advantages: Has superior corrosive resistance than other treated steel, can withstand almost any corrosive environment such as underwater, acidic, alkali and/or etc. Has good oxidation resistance in temperature 870 0C in occasional use and temperature 925 0C in continuous use. Has little to no magnetism, can be slightly magnetic due to operation in low temperature. Cost effective. Single-walled Stainless Steel Tank Tanks are used by industrial manufacturers for handling and preserving chemicals and gases that requires strong resistance from chemical degradation. Tanks with stainless steel specifications are highly customizable, and various types and features can be integrated to administer the desired application. Table 1-3 Specification of the Single Walled Tank Thickness 1.5mm Dimensions 1219mm x 2438.4mm Material Stainless Steel Tank Usage/Application Industrial Steel Grade Stainless Steel 304 Tank type Single- Walled tank Price PHP 6994.00 per sheet 32 Chain and Sprocket Drive Despite being a hundreds of years it is still one of the most typical drive systems usually used for a bicycle and motorcycles. This is used for power transmission in which the roller chain interconnects with two or more toothed wheel or sprocket. Table 1-4 Specification of the Chain Drive Material 18-8 Stainless Steel Type Roller Chain Pitch 3.7465-76.20 mm Roller Diameter 2.285-47.63 mm Inner Width of Inner Link 1.83-47.63 mm Price PHP 242.18 Table 1-5 Specification of the Sprocket Drive Material Stainless Steel 304 Number of Teeth 10-20 Diameter 34-64 mm Pitch 9.525 mm Teeth Width 5 mm Price PHP 864.00- PHP 1433.00 33 Table 2-3 Specification for the Project (Chain Drive) Material 18-8 Stainless Steel / Stainless Steel 304 Type Roller Chain Pitch 9.525 mm Roller Diameter 5.08 mm Inner Width of Inner Link 4.78 mm Table 2-4 Specification for the Project (Sprocket Drive) Material Stainless Steel 304 Diameter 60 mm and 120 mm Pitch 9.525 mm Teeth Width 4.78 mm Driveshaft The driveshaft is used to transfer torque between components that cannot be directly linked due to distance or the need for relative motion. 34 Specification Available on the Market: Table 1-6 Specification of the Driveshaft Material Stainless Steel 304 Diameter 25mm Length 1000mm Price PHP 1518.02 Table 2-5 Specification for the Project (Driveshaft) Diameter 25mm Length 732mm Pitched-Blade It was created by angling the blades to promote axial flow rather than radial flow that improve the efficiency of mixing. The impeller axial to radial flow ratio can be modified for the individual process depending on the angle of the blade pitch. When increased power and turbulence are required, such as powder inclusion, heat transmission, and quick mixing, the 45 degree pitched-blade is most commonly and efficiently used in blending and dispersion operations. 35 Table 1-7 Specification of the Pitched-Blade Material Stainless Steel 304 Thickness 5mm Width 200mm Length 220mm Price PHP 2,199.00 Table 2-6 Specification for the Project (Pitched-Blade) Material Stainless Steel 304 Thickness 5mm Width 40mm Length 177mm Pitched Blade Angle 450 No. of Blade 2 Conveyor Belt The function of a conveyor belt is to carry the finished raw materials quickly from point A to point B. The conveyor belt will be used to transport the mixed materials then pass through for cutting process that will be manually done by the operator. Projected Material to be Use Nonstick Polytetrafluoroethylene (PTFE) Teflon Coated Fiberglass Seamless Fusing Belt. Polytetrafluoroethylene Coated conveyor belt prevents products getting stuck. If products 36 do not get stuck on the conveyor belt, they can be transported evenly and swiftly from point A to Point B, which enhances the production process. Advantages: Super smooth, non-stick Non porous surface for durability High abrasion resistant Extremely flexible and resistant to cracking Oil & Grease Resistant Available up to 1500 mm wide to suit all applications Nonstick Polytetrafluoroethylene Teflon Coated Fiberglass Seamless Fusing Belt is available worldwide and for customization. Table 1-8 Specification of the Conveyor Belt Thickness 0.18mm-0.40mm Material Polytetrafluoroethylene /Teflon Usage/Application Industrial Width 20mm-1500mm Length Customized Price PHP 524.00 per square meter 37 Table 2-7 Specification for the Project (Conveyor) Length 3657.6mm Width 406.4 mm Material PTFE/Teflon Thickness 0.30mm Rolling Pin This part used to shape and flatten the mixture that is travelling through the conveyor belt before entering the press section or the rolling pin. It helps the mixture to flatten and minimize the thickness before the sun drying process, this press section also used to reduce water content from the mixture after compressing it. Projected Material to be Use: Roller coated with Teflon is commonly used in paper industry. Using Polytetrafluoroethylene roller helps to lessen the problems that are present in paper making industries specially in the sticking issues in pressing of the paper mixture. Advantages: Non-stick, low friction Non wetting Outstanding corrosion protection Resistance to weathering High thermal stability and flame resistance Wide range of service temperature 38 Table 1-9 Specification of the Rolling Pin Diameter 10 mm Id - 50 mm Od Length 127 mm - 635 mm Roller Material Polytetrafluoroethylene / Teflon Shaft Material Stainless Steel Usage/Application Industrial Price PHP 302.58 Table 2-8 Specification for the Project (Rolling Pin) Diameter 50 mm Length 355 mm Roller Material Polytetrafluoroethylene / Teflon Shaft Material Stainless Steel 39 Table 3 Material Costing Material Unit Unit Price No. of Pieces Total Square Tube kg/m ₱244.48 - ₱4,485.95 AC motor (Tank) pc ₱ 3,560 1 ₱3,560 AC Motor ( conveyor) pc ₱1,079 1 ₱1,079 Stainless Sheet pc ₱ 6,994 1 ₱ 6,994 Chain Drive set pc ₱ 242.18 1 ₱ 242.18 Sprocket Drive pc ₱ 1,433 1 ₱ 1,433 Driveshaft pc ₱ 1,518.02 1 ₱ 1,518.02 Pitch Blade pc ₱ 2,199.00 1 ₱2,199 Conveyor Belt sqm ₱ 524 1.64 ₱ 860.36 Rolling Pin pc ₱ 302.58 1 ₱ 302.58 Total Cost ₱22,664.09 40 Table 4 Fabrication Cost Manpower Position Rate per No. of Days Total Cost Day 1 Welder ₱550.00 5 ₱2,750.00 1 Assistant Welder ₱ 450.00 5 ₱2,250.00 1 Electrician ₱550.00 1 ₱550 ₱ 5,550.00 Total Cost Table 5 Total Cost in Fabricating the Machine Total Cost of Materials ₱22,664.09 Fabrication Cost ₱ 5,550.00 Total Cost ₱28,214.09 41 Chapter IV Results and Discussion This chapter discusses the analysis and the purpose of the study: Designing and Modification of Paper Recycling Machine, to help the readers in interpreting the findings and comprehending the consequences of the research results. This covers the distinct materials and procedures that incorporate the design as well as the technical description of the project. This chapter also contains the computations needed to complete the research. Finally, a discussion for average paper consumed by the mechanical engineering students per month will also revealed in this chapter. Project Technical Description To further understand the components of the paper recycling machine, a technical description was made by the researchers. The presumed process of the machine starts with the mixing of the paper-water mixture in the tank. The premixed mixture goes to a cylindrical tank that is made with a sheet of stainless steel 304 for greater resistance in corrosion. A pitched stainless steel blades, which is powered by an alternating current motor, is placed inside the tank along with the shaft. The motors use 220 volts alternating current as source of power. Motors are manually controlled by on/off switch into the source, since each motor has a built in terminal box to protect the motor and avoid short circuit the researchers didn't add any peripherals to cut cost. A flared stainless steel nozzle is attached in the tank together with ball valve. The design also includes a Teflon Coated Fiberglass Seamless Fusing Belt which is advantageous in aspects of non-stick qualities. The clearance between the conveyor belt and rolling pin is 0.2 mm. 42 For the rollers, it is made of stainless steel covered with Teflon to prevent the mixture from sticking. The frame in the design will be providing support on the said design. As for the drying process for the paper-water mixture, the researchers will use sun drying method. Computations Figure 5 Tank For the Volume of the Tank Vc = ℼr2h r = radius of the tank = 228.6 mm h= height of the tank = 762 mm Vc= volume of the cylinder 43 Solution: Substituting the given value in the formula; Formula of Cylindrical Tank, V=ℼr2h Vc= ℼ (228.6 mm)2 (762 mm) Vc= 125099996.1 mm3 Vc= 0.1251 m3 Once the Vc is solved, Solve for Vb using the formula of hemisphere bowl; For the Volume of Hemisphere bowl. Vb = (3r2 + h2) Where: h = height of the hemisphere bowl, 50.8 mm r = radius of the tank, 228.6 mm Vb = volume of the hemisphere bowl Solution: Vb = [3(228.6mm)2 + (50.8 mm) 2 ] Vb = 4238641.843 mm3 Vb = 0.0042 m3 After the Vc and Vb is already solved, Compute for Volume Total by adding V c and Vb; Vc + Vb = Vt 44 Vt = 0.1251 m3 + 0.0042 m3 Vt = 0.1293 m3 The valve was designed to be placed as close as possible to the tank, therefore the volume of the tube that was in between the tank and the valve was neglected. Density of mixed materials ρ= Where: m = mass of mixture v = volume of mixture, 0.1293 m3 ρ = density of the mixture ρ= ρ = 1050 ρ= 45 1050 kg/m3 = m = 135.765 kg Force stress acting at the cylinder tank Sg = Where: Sg = specific gravity ρm = density of mixture ρW = density of water Sg = Sg = 1.05 Once the Sg is given, Solve for Weight of Mixture by using: Weight of Mixture formula Wm = Sg x Yw x Vt Yw = specific weight of H2O, 9.81 Vt = volume total of tank, 0.1293 m3 Wm = (1.05) (9.81 KN/m3) (0.1293 m3) Wm = 1.3393 KN Wm = 1331.9 N 46 After getting the value of Weight of mixtures; Solution for Stress: S S= Where: A = area S = stress of the cylindrical wall r = radius, 0.2286 m Wm = weight of the mixture, 1331.9 N S= S = 8112.7724 Pa S = 8.1128 KPa Maximum pressure of tank Ss304 = Where: T = thickness of cylindrical wall, 1.5 mm d = diameter of the tank, 457.2 mm Ss304 = 505 MPa = maximum pressure of Ss304 P= P= P = 3.3136MPa 47 Torque or moment of force Figure 6 Shaft P = 2ℼTf Where: P = power T = torque F = frequency of rotations Motor Specs: Rpm = 1440 P = 1 Hp / 745.7 W T= T= 48 T = 4.945 N-m Torsion Stress of solid shaft Ss = Where: Ss = torsion stress D = diameter of the shaft, 25 mm T = torque, 4.945 N-m Ss = Ss = 1611819 Pa Ss = 1611.819 KPa Angular Velocity and Rolling Pin Speed Figure 7 Conveyor 49 Formula for rpm: Nm= 1000 Where: Nm = motor rotation speed (r/min) V = linear speed / velocity (m/min) Dr = driven roller diameter (mm) D1 = first pulley / motor pulley D2 = second pulley (mm) Given: For Linear Velocity = 9 m/min Dr = 60 mm D1 = 120 mm D2 = 60 mm Nm= * Nm= 23.8732 rpm Computation of Angular Velocity given the 23.8732 rpm: w = (rpm/s) (rad/rev) Where: w = Angular Velocity Rpm = 23.8732 Rad/rev = 2ℼ w = (23. 8732 rpm / 60 s) (2ℼ / rev) w = 2.4999 rad/s 50 Since the rolling pin is connected to the motor through drive chain. The rolling pin has the same speed with conveyor belt: Average paper waste of M.E students The researchers used the data from the study made by the government of the Philippines where the paper consumption of Filipino people is 19 kg per person annually, in order to obtain the average paper waste of Mechanical Engineering Students at College of Engineering and Architecture of the Don Honorio Ventura State University. * = 1.5833 kg/months Total Population: 1165 persons 1.5833 kg/months * 1165 persons = 1844.5445 kg/month is the average paper waste of Mechanical Engineering Students. 51 Project Development Figure 8 Gantt Chart This figure shows the start and end dates of each project tasks. Also, it helps the researchers in scheduling, managing and monitoring specific tasks of the project. Every task were scheduled to be done within the specific date 52 Results and Discussion This chapter presents the results of the study conducted from experimenting and gathering data. This also presents the discussion concluded from the analysis and demonstrates the result in design of paper recycling machine for Mechanical Engineering Students of the College of Engineering And Architecture Department at Don Honorio Ventura State University. Since the study focuses on the purpose of the design, the researchers conducted a simple density experiment that was done by weighing the paper-water mixture in order to solve the density and determine the maximum mass of the cylinder tank. This experiment will also yield the maximum amount of the paper-water mixture that can fill the tank. As the data provided by educational institution, Don Honorio Ventura State University, the last year’s population of the Mechanical Engineering Department were 1165 registered students. Also, based on the article made by the national government, the average paper consumption of the Filipino people is 19 kilograms per person. With these data the researchers were able to determine the average paper consumption by the Mechanical Engineering Students, which is 1844.5445 kg per month. In terms of designing the paper recycling machine, one of the purposes of it is to reduce the excessive usage of papers within the vicinity in the College of Engineering and Architecture at Don Honorio Ventura State University specially for mechanical engineering students. The effectiveness of the design will be shown after fabricating its actual prototype. 53 Chapter V Summary of Findings, Conclusions and Recommendations This chapter contains the summary, conclusions, and recommendations which the researchers attained after a careful analysis and interpretation of the data presented in Chapter 4. These data were achieved by conducting research and computation to find out what is appropriate for the study. And also, recommendations that were based on the findings are presented for future researchers to improve the design. Summary of Findings The researchers devised a design for a paper recycling machine. The design is integrated into the most effective ways that the operator may use in a very convenient and productive operation. This study will help prevent the excessive piling up of paper for Mechanical Engineering Department at College of Engineering and Architecture of Don Honorio Ventura State University. The researchers conducted and solved for necessary computations for the design of paper recycling machine. These computations were conducted by the researchers to attain the capabilities of the study. The researchers also provided a design with good capability to present a feasible design that can be used as a foundation for fabrication. The design will help to reduce the negative effect of paper-waste on the environment and also in the Department. 54 In the design of the machine, stainless steel 304 is suggested to be use in the tank fabrication because of its non-corrosive component, durability, and its affordability, these are mainly used in large industries. For the conveyor belt, the researchers propose a Teflon-coated conveyor belt, due to its proficiency; the paper-water mixture will not easily stick. In the blade part, a pitched blade design is used because it is better for mixing the paper-water mixture. Moreover, an alternating current motor is utilized for its favorable torque required to power the entire machine. The machine design will assure the minimizing of the use of raw materials in producing paper in the industry. Furthermore, this will decrease the inflation of pollution rating issues related to paper waste. Lastly, if this machine design is fabricated, it is expected to be placed inside the university premises. Conclusions In summary, the researchers will reveal the findings of the study. The conclusions represent the results on the problems in the research paper. This paper aims to provide solutions to the problems with paper wastage and its effects as stated below: 1) The environmental effects of excessive usage of paper that resulted with a lot of natural phenomena. 2) The need to recycle used papers and to reduce the amount of wastage. 3) As for affordability, the challenge of designing a machine that is less in cost without putting aside its capability. 55 The findings revealed that the researchers successfully designed a paper recycling machine that can be used to recycle paper waste. The researchers used AUTOCAD 360 and SketchUp in designing the machine for better understanding of the final output. The final design will be in a three-dimension model that focuses on the four isometric viewpoints of the designed machine. For the generalization of material selection, the researchers mainly suggest the use of Stainless Steel 304 metal in fabricating the design. Recycling used paper will reduce the percentage of paper waste and excessive consumption of raw material. The researchers discovered that designing this paper recycling machine will be a decent way to reduce the use of resources in producing papers, the materials selected by the researchers are manageable to obtain, and the production of recycled papers will only need water and used papers for the mixture. The paper waste will come from the students of Mechanical Engineering Department. The researchers chose this department to help them recycle their used papers and also to help them minimize the paper waste of the department. This study revealed that designing the paper recycling machine is 100% eco-friendly. Sun-drying method is utilized as a drying process of the pressed paper-water mixture. The design will help the environment and also offer an extensive knowledge to the future researchers and readers on how important paper recycling machine is. This study may help the other researchers to provide a functional prototype focusing on paper recycling machines. 56 Recommendations The design of the Paper Recycling Machine that utilizes the use of a conveyor belt was thoroughly research about. Regardless of how the study went, there are still improvements that can be done with the design before it can be prototyped and be produced commercially. Improvements, suggestions and alternatives were listed below to help future researchers that produce the design. On the account of the limitations of the present researchers, here are the recommendations for the future researchers to improve the design: 1) The design can be improved by adding a cutter at the end of the conveyor belt to cut the product to the desired size of the recycled paper. 2) Adding a built in heater to lessen the moisture content of the mixture to the recommended moisture content for the mixture. 3) The cost effectiveness of this study can be improved by actually producing the design and test out various materials other than the suggested materials by the researchers. 4) The design can be enhanced by adding energy saving properties to it like: a. Utilizing an inverter to let a battery power the alternating current motor or by switching to a battery power direct current motor connected to an alternator to save consumption of energy. An Alternator can be utilized the same way as a car does, it can be used to produce electricity from the mechanical energy produced by the motor. b. Utilizing a solar panel to lessen the energy consumption of the design. Solar energy is a free energy that the sun provides; this solar energy can be converted to electrical energy that can help the system run continuously with less energy 57 consumption. Solar panels are also cost effective because they are easy to maintain. 5) The design can be better by modifying the dimensions of the design to make it compact and consume less space for a recycling machine. 6) To further improve this study, the researchers recommends a thorough research on the paper-water mixture’s properties, as listed below: a. Paper-Water Mixture’s density b. Recommended moisture content after the mixture passed through the heater (if added in the future studies) c. Moisture content of the prepared mixture d. Preparation procedure for the mixture 58