Electromagnetic Properties of γ Fe2O3/Ba4Co2Fe36O60 Composites

advertisement

Solid State Sciences 113 (2021) 106553

Contents lists available at ScienceDirect

Solid State Sciences

journal homepage: http://www.elsevier.com/locate/ssscie

Electromagnetic and radar absorbing properties of γ Fe2O3/

Ba4Co2Fe36O60-epoxy polymeric composites for stealth applications

Vivek Pratap a, *, Amit K. Soni b, Himangshu B. Baskey b, S.M. Abbas b, A.M. Siddiqui a,

N. Eswara Prasad b

a

b

Department of Physics, Jamia Millia Islamia, New Delhi, 110025, India

Defence Materials and Stores Research and Development Establishment, Kanpur, 208013, India

A R T I C L E I N F O

A B S T R A C T

Keywords:

Strategic materials

Barium hexaferrite

Gamma iron oxide

Magnetic properties

Electromagnetic properties

Reflection loss

Microwave absorbers

Various constituent ratios with 50:30, 40:40 and 30:50 wt % of U-type barium hexaferrite (Ba4Co2Fe36O60) and

Gamma iron oxide (γ Fe2O3) have been used to designing the radar absorbing composites within epoxy resin

system. In the current work, studies are done on electromagnetic and absorbing properties of γ Fe2O3 powder

dispersed Ba4Co2Fe36O60-epoxy composites. X-Ray Diffraction (XRD), Field Emission Scanning Electron Micro­

scope (FESEM) and Vibrating Sample Magnetometer (VSM) tools have been used for structural, surface

morphology and magnetic properties respectively of the synthesized powder and fabricated composites. The

electromagnetic properties (ε′ , ε", μ’ & μ") of fabricated composites were retrieved from measured reflection (S11

& S22) and transmission (S12 & S21) parameters in 2–18 GHz frequency range. Experimental finding show that the

fabricated composite having 50 wt % of γ Fe2O3 of designed Ba4Co2Fe36O60/γ Fe2O3-epoxy composites possesses

maximum absorption of 98.8% (RLmin of − 19.89 dB) at 13.2 GHz for sample thickness of 3.2 mm. The fabricated

microwave absorbers confirm the effective absorption performance which has potential for strategic applications

and stealth technology.

1. Introduction

Electromagnetic spectrums having a part of frequency range between

0.3 GHz and 300 GHz known microwaves are important for smooth

functioning electronic devices and system, and also for design and

development of microwave absorbers in this frequency region. Due to

the tremendous advancement in wireless communication, electronics

and aviation sectors, microwave absorbers are working in various sys­

tems and subsystems level under different frequencies region. Conse­

quently, electromagnetic compatibility is a major issue as the radio

frequency (RF) radiation causes concern for human health. In order to

mitigate such issues, it is of paramount importance for the synthesis of

microwave/radar absorbing filler materials which can be used for

electromagnetic interference/shielding applications. On the other hand

for military applications, microwave/radar absorbing materials can be

used in various forms such as paints and composites for reducing the

radar cross section (RCS) of various strategic targets such as aircrafts,

missiles etc [1,2]. From the past decades, microwave/radar absorbing

materials (MAMs/RAMs) have been designed and intensively explored

to remove such problems with scientific interest [3,4]. Single domain

iron oxide nanoparticles with super paramagnetic behavior; maghemite

(γ Fe2O3) is individually most demanding materials among the oxides

and are used in various applications such as; magnetic tape, recording

chip, motors, transformer cores, refrigerators and medical applications

[5,6]. While, U-type barium hexaferrite (Ba4Co2Fe36O60; BaU) have

been extensively used as radar/EM wave absorbers. Due to wide range of

application of these magnetic materials, scientific community has been

working tremendously in the field of microwave absorbing coatings and

composites. It has been observed from literature findings that particle

size and morphology of synthesized filler particulates influence the EM

properties to a large extent [7–9]. The particle size and structural

properties of synthesized materials can be controlled significantly by

optimizing various parameters of solid state synthesis technique as a

result, which ultimately helps in improving the overall microwave

absorber performances of synthesized composites [10]. Literature

studies also reveals that ferrites serve as more potential electromagnetic

* Corresponding author.

E-mail addresses: vivek.can.pratap@gmail.com (V. Pratap), amitsoni.kgp@gmail.com (A.K. Soni), himanshudmsrde@gmail.com (H.B. Baskey), abbas93@

rediffmail.com (S.M. Abbas), amsiddiqui@jmi.ac.in (A.M. Siddiqui), neswarap@rediffmail.com (N.E. Prasad).

https://doi.org/10.1016/j.solidstatesciences.2021.106553

Received 9 November 2020; Received in revised form 22 January 2021; Accepted 24 January 2021

Available online 30 January 2021

1293-2558/© 2021 Elsevier Masson SAS. All rights reserved.

V. Pratap et al.

Solid State Sciences 113 (2021) 106553

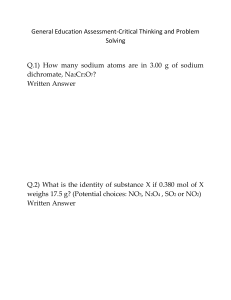

Fig. 1. XRD patterns (a) for U type BHF powder sintered at 1300 ◦ C temperature for 4 h, (b) for γ Fe2O3 powder and (c) for various wt. % ratios of Ba4Co2Fe36O60 & γ

Fe2O3 within epoxy matrix.

interference (EMI) shielding/radar absorbing materials than their

dielectric counterparts. Ferrite based absorbers consist various losses

such as; magnetic loss factor by natural, exchange resonance and

dielectric loss factor from interfacial polarization and relaxation results

it can be suitably used for scientific and industrial applications [11–13].

In this proposed scientific work, BaU and γ Fe2O3 have been used as

potential filler materials for microwave absorber, further in order to

improve its EM properties, a solid state reaction technique is employed

for synthesis of barium hexagonal U-type ferrite (Ba2Co2Fe36O60).

Further various microwave absorber composites have been fabricated

using synthesized U type ferrite along with maghemite powder in resin

system. Magnetic absorbing materials and fabricated composites have

also been characterized for structural, surface and magnetic properties

using X-Ray Diffraction (XRD), Scanning Electron Microscope (SEM),

and Vibrating Sample Magnetometer (VSM) respectively. Further under

this frame work of current research, EM properties such as complex

permittivity and complex permeability have also been retrieved in the

frequency range of 2–18 GHz using measured reflection and trans­

mission coefficients of test specimen. Moreover, studies on the micro­

wave absorption performance of various fabricated composites have

been caused entire the frequency region of 2–18 GHz.

Sigma Aldrich, USA consisting of analytical grade were used for syn­

thesis of U type hexagonal ferrite material. All starting materials have

been weighted in stoichiometric proportion for the synthesis of U-type

hexaferrite. The other prominent filler material Gamma iron oxide; γ

Fe2O3 nano particles purchased from M/s Alfa Aesar, USA along with

epoxy resin; (trade name: Araldite® LY 5052 and Aradur® HY 5052)

was purchased from M/s Huntsman Ltd., USA, used to design the

absorbing composites.

2.2. Synthesis of Ba4Co2Fe36O60 powder

U-type barium hexaferrite (Ba4Co2Fe36O60) powder was synthesized

using solid state reaction route having high purity starting materials;

BaCO3, Co3O4, Fe2O3 as previously described. Starting materials were

used as received and further mixture was prepared in stoichiometric

proportion of Ba4Co2Fe36O60 in acetone medium using ball milling for

18 h. Further wet mixture was dried and further sintered at 1300 ◦ C in

air medium using high temperature box furnace. Finally, synthesized

powder were sieved using a standard mesh in order to achieve particle

size having dimension in range lesser than 40 μm.

2.3. Fabrication of Ba4Co2Fe36O60/γ Fe2O3 -epoxy composite

2. Experimental details

A series of microwave absorbing composites was fabricated using

wet mixing technique having various compositions of 50:30, 40:40 and

30:50 wt % (Ba4Co2Fe36O60: γ Fe2O3) in Ba4Co2Fe36O60/γ Fe2O3-epoxy

composites. The thermosetting resin system were used to fabricate the

2.1. Materials

The starting materials such as BaCO3, Co3O4 and Fe2O3 from M/s

2

V. Pratap et al.

Solid State Sciences 113 (2021) 106553

Fig. 2. Scanned micrographs of (a) synthesized Ba4Co2Fe36O60 powder sintered at 1300 ◦ C temperature for 4 h (b) γ Fe2O3 powder, (c–e) morphological images of

various wt. % ratio (50:30, 40:40 and 30:50 wt %) of Ba4Co2Fe36O60 and γ Fe2O3 within epoxy matrix.

polymeric composites based on two pack of Araldite® LY 5052 and

Aradur® 5052 purchased from Huntsman Ltd., USA. The wet mixture

with proportionate ratios of filler materials and resin system was

embedded in desired toroidal shaped steel mould for preparation of

samples having inner and outer diameter of 3.0 mm and 7.0 mm

respectively. Subsequently, the loaded mould was kept in hot press at

60 ◦ C temperature under pressure of 10 MPa (MPa) for 2 h for finished

test specimens [14].

dispersive spectrometer (EDS) detector was employed to analyze the

chemical composition and crystallographic nature of sample with the

elemental attachment available together with scanning electron micro­

scope. Magnetic properties of synthesized powder and prepared com­

posite specimens were characterized using Vibrating sample

magnetometer (VSM, MicroSense, LLC technologies) at room tempera­

ture under an applied magnetic field ranging from − 18 to +18 kilo

Oersted (kOe). Further, the electromagnetic properties in terms of

complex permittivity (εr) and complex permeability (μr) for designed

composites were computed from measured scattering (reflection and

transmission) parameters using Agilent vector network analyzer (VNA)

employing a co-axial transmission line technique for the frequency

range of 2–18 GHz.

2.4. Characterization and measurement of properties

The synthesized BaU (Ba4Co2Fe36O60) powder was characterized

using X-ray diffractometer (XRD, PANalytical make, Xpert-Pro model) in

the diffraction angle (2θ) ranging from 20◦ to 60◦ with scanning rate of

0.0167◦ /s. Field emission scanning electron microscope (FE-SEM, FEI

make, Quanta 200 model) was used to examine the grain size and

morphology of synthesized powder and prepared composites. Energy

3

V. Pratap et al.

Solid State Sciences 113 (2021) 106553

Fig. 3. Corresponding EDS analysis of (a) synthesized Ba4Co2Fe36O60 powder sintered at 1300 ◦ C temperature for 4 h (b) γ Fe2O3 powder, (c–e) various wt. % ratio

(50:30, 40:40 and 30:50 wt %) of Ba4Co2Fe36O60 and γ Fe2O3 within epoxy matrix.

3. Results and discussion

of magnetic filler (50:30, 40:40 & 30:50 wt % of Ba4Co2Fe36O60 and γ

Fe2O3) in Ba4Co2Fe36O60/γ Fe2O3-epoxy composites as shown in Fig. 1

(c).

3.1. Phase confirmation and crystal structure

The structural characteristics of synthesized Ba4Co2Fe36O60, γ Fe2O3

powder and prepared composites were identified using XRD pattern and

shown in Fig. 1(a–c). It can be observed from the corresponding figure

that the synthesized powder gives evidence for U-type hexagonal phase

formation with space group of ‘R3m’. As per the literature from previous

findings, no other phase was identified and all diffraction peaks

consistently reveal the hexagonal structure.

The PANalytical’s X’pert-Pro scanning tool has been used to identify

the peaks under the angle 2θ in degree in the region from 20◦ to 60◦ .

Further, XRD peaks were indexed and the lattice parameters (a & c) were

obtained through formula (1) as given below;

) ( 2)

(

1 4 h2 + hk + k2

l

=

+ 2

(1)

d2 3

a2

c

3.2. Surface morphology

The size and morphology of synthesized Ba4Co2Fe36O60 and γ Fe2O3

powder were characterized by field emission electron microscope

(FESEM) in Fig. 2 (a & b) while, the surface and fractured morphology of

lower to higher dispersion of γ Fe2O3 filler in Ba4Co2Fe36O60/γ Fe2O3epoxy composites shown in Fig. 2(c–e). These images depicts that there

is uniform dispersion between fillers and epoxy matrix. The optimum

value of Ba4Co2Fe36O60 particles size is less than 50 μm and grain size

varies from 100 nm to 120 μm. The micrographs show that the absorbing

filler materials have hexagonal platelet like morphology which is most

suitable for radar absorbing purpose. Based on these initial findings, the

proposed composites can be suitably used for the designing of electro­

magnetic interference shielding materials and radar absorbers [16–20].

According to EDS analysis of Fig. 3(a–e), the percentage of the

chemical elements was closer to the estimated theoretical stoichiometry

in U-type barium hexaferrites and gamma iron oxide also for the

designed composites. For a comparison, in a recent study of filler ma­

terials and its composites studied through EDS detector, which unable to

identified other elements. The characteristics EDS spectra of filler ma­

terials and its composites are shown in Fig. 3(a and b) and Fig. 3(c–e)

respectively. Consequently, observed elemental composition ratio of

metallic ions are consisting expected stoichiometry is well maintained

Using the above formula (1), calculated values of lattice parameter

are: a = 5.86 Å and c = 113.7 Å; these values are shown in the same

range as previous reported in literatures for the U-type barium hex­

aferrite powder [15].

Although γ Fe2O3 powder shows cubic structure with almost equal

lattice constant (0.834 nm) as shown in Fig. 1(b), which are due to the

ordered occupancy of octahedral sites by Fe+3. The estimated cuboids

shape enhances the shape anisotropy which results in the increased

magnetic loss. Its XRD patterns are reproducible with the various ratios

4

V. Pratap et al.

Solid State Sciences 113 (2021) 106553

Fig. 3. (continued).

during synthesis process of material and designing composites.

its composites have shown a narrow hysteresis loop. Definite combina­

tion of saturation magnetization (Ms) and low coercivity (Hc) are suit­

able for high frequency in gigahertz applications. It is observed that the

saturation magnetization (Ms) value was increased from 49.32 to 55.49

emu/g of increasing the γ Fe2O3 contents in Ba4Co2Fe36O60/γ Fe2O3epoxy composites. The low coercivity of ≤153 Oe and low squareness

ratio (Mr/Ms) ratio of ≤0.051, categorize the prepared Ba4Co2Fe36O60/γ

Fe2O3-epoxy composites as soft ferrites based absorber. It can be noted

that the densification of magnetic powders results in grain growth which

evolves the multi domain particle regime. These multi domain natures of

3.3. Study of magnetic properties

The magnetic properties of both, magnetic fillers and fabricated

composites have been measured using vibrating sample magnetometer

(VSM) under the applied magnetic field from − 18 kOe to +18 kOe. The γ

Fe2O3 powder and its composites were characterized for its histogram

and properties at room temperature as shown in Fig. 4 with values

tabulated in Table 1. Synthesized Ba4Co2Fe36O60, γ Fe2O3 powder and

5

­

V. Pratap et al.

Solid State Sciences 113 (2021) 106553

optimized level for prepared series of Ba4Co2Fe36O60/γ Fe2O3-epoxy

composites. Here, we have been found a hysteresis loop and an

arrangement of saturation magnetization with low coercive values

suitable for gigahertz frequency applications.

4. Electromagnetic parameters and absorption phenomena

Electromagnetic (EM) properties of prepared composites are gener­

ally characterized in terms of is functional parameters such as complex

permittivity (ε′ -jε") and complex permeability (μ’-jμ"). These parameters

can be tuned for desired microwave absorption when the incident EM

wave interacts with the surface of absorbing materials. Absorbers are

capable to absorb the incident radar/EM energy significantly and

convert this energy into other forms (heat), which thermal imagers are

unable to detect. When an incident EM wave fall on the absorber’s

surface; attenuation, reflection and transmission of EM waves are three

major phenomena take place, as shown in Fig. 5. The complex permit­

tivity (ε′ -jε") and complex permeability (μ’-jμ") parameters of composite

specimen have been computed from the measured scattering parameters

using Agilent VNA E8364B in the 2–18 GHz frequency range. The real

parts of complex permittivity and complex permeability (ε′ and μ’)

represents the storage of electric and magnetic energy respectively.

Whereas, the imaginary parts of complex permittivity and imaginary

parts of complex permeability (ε" and μ") are responsible for the lossy

manners corresponding to dielectric and magnetic energy respectively.

Fig. 4. Magnetic hysteresis loop of (a) γ Fe2O3 as maghemite powder, (b) 30 wt

% and (c) 50 wt % dispersion of γ Fe2O3 in Ba4Co2Fe36O60/γ Fe2O3

-epoxy composites.

Table 1

Magnetic properties of synthesized U-type hexaferrite [14], γ Fe2O3 powder and

prepared composites for lower (30 wt %) and higher (50 wt %) dispersion of γ

Fe2O3 in Ba4Co2Fe36O60/γ-Fe2O3-epoxy composites.

System

Magnetization;

Ms (emu/g)

Coercivity;

Hc (Oe)

Remanence;

Mr (emu/g)

Squareness

ratio; Mr/Ms

Ba4Co2Fe36O60

powder

γ Fe2O3 powder

50:30 wt % of

ferrite and γ

Fe2O3 in

composite

30:50 wt % of

ferrite and γ

Fe2O3 in

composite

55.81

107.31

2.17

0.038 [15]

74.70

49.32

243.09

96.34

4.09

1.591

0.054

0.032

55.49

153.84

2.872

0.051

4.1. Complex permittivity

Fig. 6(a, b and c) shows the real and imaginary values of permittivity

for fabricated Ba4Co2Fe36O60/γ Fe2O3 epoxy composites with respect to

the variation in filler content. It can be observed that the values of real

permittivity increases as the filler content of γ Fe2O3 in the composites

has been increased from 30 wt % to 50 wt % with constant wt. % of

epoxy matrix. It is obvious from the corresponding figure that all the

composites show almost constant values of real permittivity through the

whole frequency region for particular filler content. The increase of real

permittivity with the high loading of γ Fe2O3 can be interpreted by the

hopping mechanism which is established for electric polarization and

dielectric loss, increases with maximum wt. % of filler materials. The

maximum value achieved of real permittivity (ε′ ) achieved 4.23 for

higher dispersion (30:50 ratio of U-ferrite and γ Fe2O3) of γ Fe2O3 in

prepared Ba4Co2Fe36O60/γ Fe2O3-epoxy composites. The imaginary part

of complex permittivity or dielectric loss factors (ε′′ ) is also constant

throughout the 2–18 GHz frequency region for an individual loading.

The increase of dielectric constant at lower frequencies is remarkable.

Such types of frequency dependent dielectric constants have improved

loss mechanism of electrical energy inside the Ba4Co2Fe36O60/γ Fe2O3epoxy composites. This is because γ Fe2O3 nano-particle having the

greater surface to volume ratio than Ba4Co2Fe36O60 particles and sub­

sequently, high dielectric permittivity. These phenomena could be

attributed to the inhomogeneity of used magnetic absorbing (micro and

nano) materials. In case of Ba4Co2Fe36O60/γ Fe2O3-polymer composites,

the contribution to real permittivity (ε′ ) and imaginary permittivity (ε′′ )

rise to heterogeneity due to interfacial polarization and interfacial

relaxation as the electric charge particles are separated by insulating

matrix grains which enhanced heterogeneity. The resonance peak at 6.2

GHz frequency is preliminary attributed to the dipole-dipole interaction

as well as interfacial polarization by adding the γ Fe2O3 content [14,21,

22]. The dielectric constant and relaxation parameters of filler disper­

sion are changed with the gradual transformation between Ba4Co2

Fe36O60 and γ Fe2O3. However, as γ Fe2O3 increases in Ba4Co2Fe36O60/γ

Fe2O3-epoxy composites from 30 wt % to 50 wt %, high and smooth

complex permittivity curves {Fig. 6(a, b and c)} are obtained and no

further peak is observed above 13.2 GHz frequency.

Fig. 5. Schematic diagram of designed toroidal shape composites for absorp­

tion mechanism.

the magnetic fillers are responsible for a lowered coercivity value of

fabricated Ba4Co2Fe36O60/γ Fe2O3-epoxy composites.

It can be observed that, increasing the γ Fe2O3 content depicts the

increased values of saturation magnetization (Ms) and coercivity (Hc) at

6

V. Pratap et al.

Solid State Sciences 113 (2021) 106553

Fig. 6. Frequency response of the complex permittivity for different loading; (a) 30 wt %, (b) 40 wt % and (c) 50 wt % of γ Fe2O3 in Ba4Co2Fe36O60/γ Fe2O3epoxy composites.

4.2. Complex permeability

frequencies. It is to be noted, that the electromagnetic properties of the

fabricated composites depends upon the fillers contents of hexagonal

ferrite obeying with the ferromagnetic materials which creates vacuum

phenomena such as eddy current effect, natural and exchange resonance

rather than magnetic permeability and space charge polarization [19,

23].

Fig. 7(a, b and c) represents the frequency versus complex perme­

ability (μ’- jμ") characteristics of fabricated Ba4Co2Fe36O60/γ Fe2O3

composites in the frequency range of 2–18 GHz. The aim of incorpo­

rating Ba4Co2Fe36O60/γ Fe2O3 into the epoxy matrix is to increases real

permeability value above the unity and to increase the magnetic loss in

the working frequency region. It can be observed from Fig. 7(a) that real

permeability for 30 wt % of γ Fe2O3 loaded composite decreases sharply

from 2 to 6.4 GHz, further remains at constant value in the frequency

range of 6.4–18 GHz. The highest value of real part of complex perme­

ability is observed in the range of 1.73–0.72, whereas its imaginary part

varies in the range of 0.72–0.24 across the entire 2–18 GHz frequency.

Fig. 7(b) shows that for the real permeability for 40 wt % of γ Fe2O3

loaded composite is in the range of 1.63–0.82, whereas its imaginary

part is in the range of 0.71–0.09. High (50 wt %) filler concentration of γ

Fe2O3 in designed composite as depicted in Fig. 7(c), the real part of

permeability increased substantially in the range of 2.06–0.85 between

the frequency ranges from 2 to 5.02 GHz, whereas magnetic loss factor

(μ") is in the range of 1.5–0.085 in the whole frequency range of 2–18

GHz. The dispersion of γ Fe2O3 nano-particles minimize the eddy current

of designed composites due to small size than skin depth, which in turns

is optimize the electromagnetic parameters. The optimized complex

permeability is present in Ba4Co2Fe36O60/γ Fe2O3-epoxy polymeric

composites; which gives rise to the circumferential demagnetizing field

as a result, diminishes the real permeability (μ′ ) at resonance

4.3. Loss tangent

Fig. 8(a and b) shows the nonlinear deviation of the dielectric

tangent loss (tanδe = ε"/ε′ ) and magnetic tangent loss (tanδμ = μ"/μ’)

with frequency. In Fig. 8(a), at starting frequency of 2.0 GHz, the nu­

merical value of dielectric tangent loss (0.023) remains almost same up

to 9.8 GHz for all wt. % of γ Fe2O3 dispersion in Ba4Co2Fe36O60/γ Fe2O3

polymer composite. However, this value is obtained greater than 0.03

for 30, 40 and 50 wt % loaded in Ba4Co2Fe36O60/γ Fe2O3-epoxy com­

posites. Maximum value of tanδe achieved was 0.34 for 50 wt %

dispersed γ Fe2O3 in Ba4Co2Fe36O60/γ Fe2O3-epoxy composites at the

corresponding frequency of 10.2–11.9 GHz. In Fig. 8(b), at starting

frequency of 2–8 GHz, the numerical value of magnetic tangent loss

increases to 1.2 for 50 wt % dispersed γ Fe2O3 in Ba4Co2Fe36O60/γ

Fe2O3-epoxy composites. Further the value of magnetic tangent loss

(tanδμ) was found to be decreasing sharply for all prepared composites

in the frequency range of 8.0–18 GHz. It can be observed from the

corresponding figure that highest value of tanδμ; 1.2 for 50 wt % was

greater than 0.68 & 5.6 for 30 wt % & 40 wt % loaded γ Fe2O3 in

7

V. Pratap et al.

Solid State Sciences 113 (2021) 106553

Fig. 7. Frequency response of the complex permeability for different loading; (a) 30 wt %, (b) 40 wt % and (c) 50 wt % of γ Fe2O3 in Ba4Co2Fe36O60/γ Fe2O3epoxy composites.

Fig. 8. Frequency response of dielectric loss tangent (a) and magnetic loss tangent (b) of Ba4Co2Fe36O60/γ Fe2O3-epoxy composites.

Ba4Co2Fe36O60/γ Fe2O3-epoxy composites. The prepared composites are

the heterogeneous combination of conducting/magnetic particles in the

insulated epoxy grains. Further the complex permittivity and complex

permeability are mainly attributed to the amount of dielectric polari­

zation and magnetic polarization for the prepared composites. The well

dispersion of hexaferrite (Ba4Co2Fe36O60) and maghemite (γ Fe2O3) in

epoxy matrix induces the mobility of charge carriers and spin of elec­

trons that produce polarization and magnetization respectively. As a

result of this, the governing polarization and magnetization with the loss

mechanism comprise the association of relaxation and resonance

8

V. Pratap et al.

Solid State Sciences 113 (2021) 106553

layer absorber by using the following equation (2) proposed by Naito

and Suetake [24]:

[

]

z− 1

(2)

RL(dB) = − 20log 10

z+1

The ratio of material’s impedance (Zin) to impedance of free space

(Zo) is accepted as normalized impedance (Z) calculated through

following equation (3).

√̅̅̅̅̅̅̅̅̅̅̅

{

( )̅

}√̅̅̅̅̅̅̅̅̅̅̅̅

zin

μr

− j2πf .d

where, z = =

tanh

(3)

(μr εr )

c

zo

εr

In the above expression RL is the reflection loss represented in

√̅̅̅̅̅̅̅

decibel (dB), j is an imaginary unit for the value of − 1, μr and εr are the

complex permeability and complex permittivity respectively, f is the

frequency of the incident EM wave, c is speed of light in free space and

d being thickness of the composite specimens.

Fig. 9(a, b and c) shows the calculated reflection loss for fabricated

Ba4Co2Fe36O60/γ Fe2O3-epoxy composites as a function of thickness in

the frequency range of 2–18 GHz. These results are analyzed by metal

backing model as proposed by Naito and Suetake. RL has been calcu­

lated for various thicknesses (2.6, 2.9 and 3.2 mm) of fabricated com­

posites through a MATLAB codes. Consequently, dip of RL gets shifted

towards the lower frequency region by increasing the absorbers thick­

ness from 2.6 to 3.2 mm. The impedance matching condition can be

justified to the microwave absorption mechanism. RL performance for

30 wt % of γ Fe2O3 in Ba4Co2Fe36O60/γ Fe2O3-epoxy composite shows

that the minimum RL (Maximum Absorption) of − 8.86 dB, − 10.36 dB

and − 11.86 dB have been observed corresponding to matching fre­

quency of 6.48 GHz, 5.84 GHz and 4.88 GHz respectively. Fig. 9 (b)

depict RL performance for 40 wt % of γ Fe2O3 in Ba4Co2Fe36O60/γ

Fe2O3-epoxy composite at 4.7 GHz has been observed from the corre­

sponding graphs that the minimum reflection minima of − 10.02 dB,

− 13.82 dB and − 14.8 dB have been observed corresponding to match­

ing frequency of 13.3 GHz, 13.0 GHz and 12.3 GHz respectively. It can

be also observed from the corresponding graphs that the 10 dB ab­

sorption bandwidth (11.7–13.3 GHz) has improved substantially by

adding equal wt. % of γ Fe2O3 and Ba4Co2Fe36O60 in Ba4Co2Fe36O60/γ

Fe2O3-epoxy composites. Similarly Fig. 9 (c) shows the variation of RL

performance for 50 wt % of γ Fe2O3 in Ba4Co2Fe36O60/γ Fe2O3-epoxy

composite, it can be analyzed from corresponding figure that the mini­

mum reflection loss of − 13.89 dB, − 15.39 dB and − 19.89 dB have been

observed corresponding matching thickness 14.5 mm, 13.8 mm and

13.2 mm respectively. The optimum performance in RLmin as compared

to maximum bandwidth 4.8 GHz (RL ≤ − 10 dB) was observed for the

absorber having composite thickness of 3.2 mm (RLmin ≤ − 19.89 dB

implies 98.9% absorption). Consequently, Ba4Co2Fe36O60/γ Fe2O3

loaded absorbers with maximum (50 wt % of γ Fe2O3) content can be

used as effective microwave absorbers for the X-band and Ku-band fre­

quency region.

Fig. 9. (a, b and c) calculated reflection loss of different percentage loading; (a)

30 wt %, (b) 40 wt % and (c) 50 wt % of γ Fe2O3 in Ba4Co2Fe36O60/γ Fe2O3epoxy composites.

5. Conclusions

In summary, U-type barium hexaferrite (Ba4Co2Fe36O60) powder was

synthesized based on solid state reaction route, the polycrystalline phase

of synthesized powder was validated using XRD technique. The surface

morphology and elemental composition of used absorbing powder and

composites were scanned together with the elemental attachment

available with the FESEM. Further, radar absorbers were fabricated

through wet mixing method based on various wt. % of magnetic filler

contents. The magnetic properties were also studied for the composites

with increasing wt. % of γ Fe2O3 in Ba4Co2Fe36O60/γ Fe2O3-epoxy

composites. The intrinsic electromagnetic parameters of prepared

polymeric composites were significantly improved with increasing the

wt. % of γ Fe2O3. It is found that the matching frequency of prepared

absorbing sample shifted towards the lower frequency band with

phenomena which are subsequently responsible for increasing the

dielectric tangent loss and magnetic tangent loss governing the ab­

sorption phenomena.

4.4. Reflection loss

The microwave absorption which is quantified in terms of reflection

loss (RL) can be estimated from measured value of complex permittivity

and complex permeability of fabricated Ba4Co2Fe36O60/γ Fe2O3-epoxy

composites using metal backed coaxial line measurement technique

using the transmission line approach. It can be measured as the single

9

V. Pratap et al.

Solid State Sciences 113 (2021) 106553

increasing the thickness of absorbers. The minimum RL was observed as

− 19.89 dB for designed absorber having the thickness of 3.2 mm (RLmin

≤ − 19.89 dB implies 98.8% absorption) corresponding its matching

frequency 13.2 GHz. The optimized absorber with highest loading in wt.

% of γ Fe2O3 nano powder in designed composites seems strong candi­

date as radar absorber and in high frequency devices for stealth

applications.

[7] R.S. Meena, S. Bhattacharya, R. Chatterjee, Complex permittivity, permeability and

microwave absorbing studies of (Co2− xMnx) U-type hexaferrite for X-band (8.212.4 GHz) frequencies, Mater. Sci. Eng. B 171 (2010) 133–138.

[8] D. Lisjak, V.B. Bregar, M. Drofenik, The influence of microstructure on the

microwave absorption of Co–U hexaferrites, J. Magn. Magn Mater. 310 (2007)

2558–2560.

[9] S.M. Abbas, A.K. Dixit, R. Chatterjee, T.C. Goel, Complex permittivity, complex

permeability and microwave absorption properties of ferrite-polymer composites,

J. Magn. Magn Mater. 309 (2007) 20–24.

[10] C.R.K. Mohan, P.K. Bajpai, Effect of sintering optimization on the electrical

properties of bulk BaxSr1-xTiO3 ceramics, Physica B 403 (2008) 2173–2188.

[11] H. Bayrakdar, Electromagnetic propagation and absorbing property of ferrite

polymer nanocomposite structure, Prog. Electromag. Res. Mat. 25 (2012) 269–281.

[12] K. Singh, A. Ohlan, P. Saini, S.K. Dhawan, Poly (3,4-ethylenedioythiophene) γ

Fe2O3 polymer composite-super paramagnetic behavior and variable range

hooping 1D conduction mechanism-synthesis, Poly, Adv. Tech. 19 (2008)

229–236.

[13] R.S. Meena, S. Bhattacharya, R. Chatterjee, Development of “tuned microwave

absorbers” using U-type hexaferrite, Mater. Des. 31 (2010) 3220–3226.

[14] V. Pratap, A.K. Soni, A.M. Siddiqui, S.M. Abbas, R. Katiyar, N.E. Prasad, Dielectric

and radar absorbing properties of exfoliated graphite dispersed epoxy composites,

J. Electron. Mater. 49 (2020) 3972–3981.

[15] V. Pratap, A.K. Soni, S. Dayal, S.M. Abbas, A.M. Siddiqui, N.E. Prasad,

Electromagnetic and absorption properties of U-type barium hexaferrite epoxy

composites, J. Magn. Magn Mater. 465 (2018) 540–545.

[16] S.R. Shannigrahi, W.Q. Au, V. Suresh Kumar, L. Liu, Z.H. Yang, C. Cheng, C.K.

I. Tan, R.V. Ramanujan, Synthesis and electromagnetic properties of U-type

hexaferrites Ba4B2Fe36O60 (B: Co, Ni, Cu), J. Magn. Magn Mater. 325 (2013)

63–68.

[17] R. Dosoudil, M. Usakova, J. Franek, J. Slama, V. Olah, RF electromagnetic wave

absorbing properties of ferrite polymer composite materials, J. Magn. Magn Mater.

304 (2006) e755–e757.

[18] P. Singh, V.K. Babbar, A. Razdan, R.K. Puri, T.C. Goel, Complex permittivity,

permeability, and X-band microwave absorption of CaCoTi ferrite composites,

J. Appl. Phys. 87 (2000) 4362–4366.

[19] S.M. Abbas, A.K. Dixit, R. Chatterjee, T.C. Goel, Complex permittivity, complex

permeability and microwave absorption properties of ferrite-polymer composites,

J. Magn. Magn Mater. 309 (2007) 20–24.

[20] S.M. Abbas, R. Chatterjee, A.K. Dixit, A.V.R. Kumar, T.C. Goel, Electromagnetic

and microwave absorption properties of (Co2+-Si4+) substituted barium

hexaferrites and its polymer composite, J. Appl. Phys. 101 (2007), 074105.

[21] V. Pratap, A.K. Soni, S.M. Abbas, A.M. Siddiqui, N.E. Prasad, J. Alloys Compd.

(2021), https://doi.org/10.1016/j.jallcom.2020.158280.

[22] J. Yacubowicz, M. Narkis, Dielectric properties of medium thermal blackpolyethylene systems, Polym. Eng. Sci. 28 (1988) 1581–1585.

[23] S.S. Kim, S.T. Kim, Y.C. Yoon, K.S. Lee, Magnetic, dielectric, and microwave

absorbing properties of iron particles dispersed in rubber matrix in gigahertz

frequencies, J. Appl. Phys. 97 (2005) 10F905 1–3.

[24] Y. Naito, K. Suetake, Application of ferrite to electromagnetic wave absorber and

its characteristics, IEEE Trans. Microw. Theor. Tech. 19 (1971) 65–72.

Credit author’s contribution statement

Vivek Pratap: Conceptualization, Design of study, Analytic and

interpretation of data, Writing review and editing investigation, Writing

– original draft preparation. Amit K. Soni: Validation, Investigation,

Formal analysis. Himangshu B. Baskey: Validation, Formal analysis. S.

M. Abbas: Methodology, Formal analysis, Supervision. A. M. Siddiqui:

Formal analysis, Supervision. N. Eswara Prasad: Resources, Formal

analysis.

Declaration of competing interest

The authors declare that they have no known competing financial

interests or personal relationships that could have appeared to influence

the work reported in this paper.

References

[1] S.E.M. Ghahfarokhi, M. Ahmadi, I. Kazeminezhad, Fabrication of the

SrFe11MnO19/CoFe1.9Bi0.1O4 ferrite nanocomposites and investigation the

properties of its microwave absorption in X-band, Phys. B Condens. Matter 594

(2020) 412290.

[2] R. Jaiswal, K. Agarwal, V. Pratap, A. Soni, S. Kumar, K. Mukhopadhyay, N.

E. Prasad, Microwave-assisted preparation of magnetic ternary core-shell nanofiller

(CoFe2O4/rGO/SiO2) and their epoxy nanocomposite for microwave absorption

properties, Mater. Sci. Eng. B 262 (2020) 114711.

[3] F.M. Idris, M.H. Hashim, Z. Abbas, I. Ismail, R. Nazlan, I.R. Ibrahim, Recent

developments of smart electromagnetic absorbers based polymer-composites at

gigahertz frequencies, J. Magn. Magn Mater. 405 (2016) 197–208.

[4] P.J. Liu, Z.J. Yao, V.M.H. Ng, J.T. Zhou, Z.H. Yang, L.B. Kong, Enhanced

microwave absorption properties of double layer absorbers based on spherical NiO

and Co0.2Ni0.4Zn0.4Fe2O4 ferrite composites, Acta Metall. Sin. 31 (2018) 171–179.

[5] H.E. Horng, C.Y. Hong, S.Y. Yang, H.C. Yang, Novel properties and applications in

magnetic fluids, J. Phys. Chem. Solid. 62 (2001) 1749–1764.

[6] D.M. Pozar, Microwave Engineering, John Wiley & Sons, New York, 2004.

10