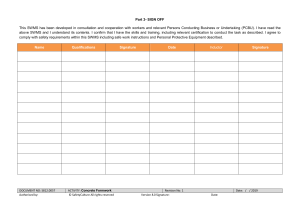

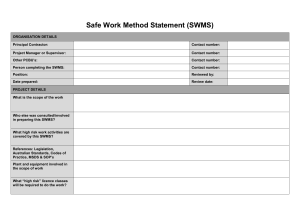

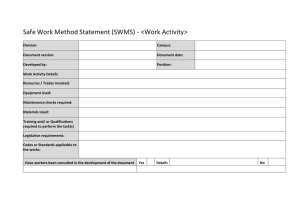

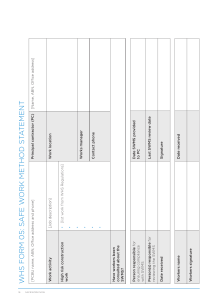

ACTIVITY: THERMOPLASTIC EXTRUSION, PROFILE AND AUDIO TACTILE SAFE WORK METHOD STATEMENT (SWMS) Company Name: Supalux Linemarking Pty Ltd Supalux Linemarking Pty Ltd Contact Names: John Mould (Project Manager) Adrian Grey (Project Coordinator) Address: 9 – 11 Tipping Rd, Kewdale, Western Australia 55 Assembly Drive, Dandenong South, Victoria Contact Details: 0407 023 178 0437 250 907 PROJECT DETAILS Project: All Supalux Thermoplastic Projects Job Address: Job Description/Activity: Maintenance and new Thermoplastic Extrusion, Profile and Audio Tactile roadmarking Relevant workers must be consulted in the development, approval and communication of this SWMS: Name: Job Title: Adrian Grey Projects Coordinator (WA) Paul Kershaw Delivery Coordinator (WA) John Mould Senior Contract Manager (VIC) Travis Bentley Project Manager (TAS) Linemarker (VIC) Jaroslav Horvath Linemarker (WA) Phil Scanlon SWMS: Approved by Safety Officer/Delegated Personnel John Mould Signature: Date: 05.12.2022 Prepared and final review by: John Mould Date SWMS Issued: 05-12-2022 Persons responsible for ensuring compliance with SWMS: Next Review Date: December 2023 Employees/Subcontractors, Linemarkers, Pilots, Surveillance Officers and Contract Managers SX SWMS Thermoplastic Extrusion Profile and Audio Tactile December 2022 - V9 Supalux Linemarking Pty Ltd December 2022 – v9 Page 1 of 12 SWMS SCOPE This SWMS covers general safety matters when carrying out roadmarking tasks, using a roadmarking machine on concrete and/or bitumen surfaces. PERSONAL PROTECTIVE EQUIPMENT REQUIRED (PPE) SELECT REQUIRED PPE ENSURE ALL PPE MEETS RELEVANT AUSTRALIAN STANDARDS. INSPECT, AND REPLACE PPE AS NEEDED. AS 1319-1994 Safety signs for the occupational environment reproduced with permission from SAI Global under licence1210-c062. Standards may be purchased at http://www.saiglobal.com Foot Protection Hearing Protection High Visibility Head Protection/ Sun Hat Eye Protection ☐ ☐ Face Protection Hand Protection Protective Clothing /Night Overalls Breathing Protection if required Sun Protection daytime ☐ Sun hat, Long pant and sleeves , SPF 30+ sunscreen, tinted safety glasses with adequate UV protection) Rings, watches and jewellery that may become entangled in machines must not be worn. Long and loose hair must be tied back. HIGH RISK CONSTRUCTION WORK DANGEROUS GOODS / HAZARDOUS CHEMICALS This work activity involves the following “High Risk Construction Work”: Thermoplastic is not classified as a Hazardous Chemical according to Safe Work Australia (SWA) and not classified as a Dangerous Good (DG) according to Australian Code for the Transport of Dangerous Goods by Road or Rail (ADG Code). however, on burning they will emit toxic fumes, including those of oxides of carbon. Based on the properties of the epoxy constituent(s), these preparations may be a skin sensitiser and an irritant. They may be irritating to eyes, mucous membrane and skin. Repeated skin contact may lead to irritation and to sensitisation. May produce an allergic reaction. Unleaded Petrol is classified as a hazardous chemical according to SWA and DG according to the ADG Code. Unleaded Petrol is classified as extremely Flammable and Harmful. Diesel is classified as a hazardous chemical according to SWA and is not DG according to the ADG Code. Diesel is classified as Harmful. • Work carried out in an area at a workplace in which there is any movement of powered mobile plant • Work carried out on, in or adjacent to a road, railway or other traffic corridor that is in use by traffic other than pedestrians Suitable Extinguishing Media: Alcohol resistant foam is the preferred fire-fighting medium but, if it is not available, normal protein foam can be used. Environmental risks may include: - Death/damage or injury to vegetation and animals - Pollution of waterways and water catchment areas - Pollution of the atmosphere by production of hazardous chemicals such as ozone chemicals. SX SWMS Thermoplastic Extrusion Profile and Audio Tactile December 2022 - V9 Supalux Linemarking Pty Ltd December 2022 – v9 Page 2 of 12 FORMAL TRAINING, LICENCES REQUIRED FOR PERSONNEL/WORKERS UNDERTAKING THIS TASK: • • • • • • • Current driver’s licence appropriate to vehicle being driven. OHS Induction White Card Traffic Control/Traffic Management First Aid Training Competent in operation of make/model of plant Emergency procedures – emergency response PPE Details of: Regulatory Permits/Licences Engineering Details/Certificates/Workcover Approvals: Traffic Management Plans SWMS Plant to be registered Plant/Tools/Equipment: (List plant and equipment to be used on the job.) • Roadmarking application equipment enclosed cabin truck, open cabin ride on plant • Pilot vehicles as required, or vehicles required to transport devices and signs • Traffic management devices/signs compliant to AS1742.3:2009 and Road Management Act (VIC) • Fire Extinguishers current and tagged • First Aid Kits • Equipment may not be limited to the above DUTIES OF PERSONNEL/ WORKERS UNDERTAKING THIS TASK: • Roadmarking operator • Traffic control • Pilot driver DETAILS OF SUPERVISORY ARRANGEMENTS FOR WORKERS UNDERTAKING THIS TASK: • • • • • Suitably qualified supervisors for job Direct on-site supervision Audits Spot Checks, etc. Reporting systems Relevant Legislation, Codes of Practice: Note: Refer only To the Legislation references applicable to your State of operation for this SWMS. • • • • Commonwealth, NSW, QLD, ACT o Work Health and Safety Act 2011 o Work Health and Safety Regulations 2011 Northern Territory o Work Health and Safety (National Uniform Legislation) Act 2011 o Work Health and Safety (National Uniform Legislation) Regulations SA, Tasmania o Work Health and Safety Act 2012 o Work Health and Safety Regulations 2012 Codes of Practice: Safe Work Australia: o First Aid in the Workplace o Managing the Risk of Falls at Workplaces o Managing the Risk of Plant in the Workplace o Managing Noise and Preventing Hearing Loss in the Workplace o How to Manage Work Health and Safety Risks o Hazardous Manual Tasks o Managing Risks of Hazardous Chemicals o WHS Consultation, Cooperation and Coordination • • • o MRWA Traffic Management for Works on Roads o Worksite Safety – Traffic Managent – Victoria o Traffic Control for works on Roads – Tasmanian Guide o SA Standards – for Workzone Traffic Management Victoria o Road Management Act 2004 o Occupational Health and Safety Act 2004 o Occupational Health and Safety Regulations 2017 o Codes of Practice and Compliance Codes Western Australia o Work Health and Safety Act 2020 Australian Standards: o o AS1742.3 2019 - Manual of Unifor Traffic Control Devices o AS 1940 Storage and Handling of Flammable and Combustible Liquids o AS/NZS 2906 Fuel Containers - Portable - Plastic and Metal o AGTTM – Guide to Temporary Traffic Management Set REFERENCE DOCUMENTS Safety Data Sheets Borum Operating Manual - (Ride On) Supalux Linemarking Pty Ltd Safety and Environmental Management Plans SX SWMS Thermoplastic Extrusion Profile and Audio Tactile December 2022 - V9 Supalux Linemarking Pty Ltd December 2022 – v9 Page 3 of 12 RISK ASSESSMENT MATRIX HB 436:2004 Risk Management Guidelines Tables 6.3 – 6.8 reproduced with permission from SAI Global under licence 1210-c062. Standards may be purchased at http://www.saiglobal.com References: Safe Work Australia (2011) - Code of Practice: How to Manage Work Health and Safety Risks, AS/NZS 31000 -2009 Risk Management Principles and Guidelines. Step 2: Determine Consequence What will be the expected effect? Level of Effect: Example of each level: Step 1: Determine Likelihood What is the possibility that the effect will occur? Criteria Description 5. Almost certain Expected in most circumstances. Effect is a common result. i. Catastrophic Multiple Permanent Total Disability injuries; multiple deaths. 4. Likely Will probably occur in most circumstances. Effect is known to have occurred at this site or it has happened. ii. Major Hospital admittance; extensive injuries; lost time injury > 7 days; Permanent Total Disability injury; death. 3. Possible Might occur at some time. Effect could occur at the site or I’ve heard of it happening. iii. Moderate Medical treatment; serious injuries, temporary partial disability; lost time injury < 7 days. 2. Unlikely Could occur at some time. Effect is not likely to occur at the site or I have not heard of it happening. iv. Minor First Aid treatment only; no lost time injury. May occur only in exceptional circumstances. Effect is practically impossible. v. Insignificant/Acceptable No effect – or so minor that effect is acceptable. 1. Rare Step 3 Determine the risk score Likelihood Consequence Step 4 Record risk score on worksheet (Note – Risk scores have no absolute value and should only be used for comparison and to engender discussion.) Insignificant Minor Moderate Major Catastrophic 5. Almost certain 3 High 3 High 4 Acute 4 Acute 4 Acute 4. Likely 2 Moderate 3 High 3 High 4 Acute 4 Acute A: Acute DO NOT PROCCED. Requires immediate attention. Introduce further high-level controls to lower the risk level. Reassess before proceeding. 3. Possible 1 Low 2 Moderate 3 High 4 Acute 4 Acute H: High Review before commencing work. Introduce new controls and/or maintain high level controls to lower the risk level. Monitor frequently to ensure control measures are working. 2. Unlikely 1 Low 1 Low 2 Moderate 3 High 4 Acute M: Moderate Maintain control measures. Proceed with work. Monitor and review regularly, and if any equipment/people/materials/work processes or procedures change. 1. Rare 1 Low 1 Low 2 Moderate 3 High 3 High L: Low Record and monitor. Proceed with work. Review regularly, and if any equipment/people/materials/work processes or procedures change. ELIMINATION - Risk will be eliminated where possible Score SUBSTITUTION ISOLATION ENGINEERING - Where risk remains, one/combination of controls will be used SX SWMS Thermoplastic Extrusion Profile and Audio Tactile December 2022 - V9 Supalux Linemarking Pty Ltd December 2022 – v9 Action ADMINISTRATIVE - Where risk remains, administrative controls will be used. PERSONAL PROTECTIVE EQUIPMENT (PPE) - Where risk still remains, it will be reduced as far as reasonably practicable with use of PPE. Page 4 of 12 Job Step Break the job/activity into key steps 1. Preparation 1.1 Pre-Start Check Daily Plant Safety Checklist 1.2 Loading vehicles for task Initial Identified Hazards 1. Personal Injury due to faulty machine/vehicle 2. Personal Impact/crushing from vehicle/forklift Risk Level A=Acute H=High M=Moderate L=Low (H) (H) Control Measures in order of preference, can hazards be 1. 2. 3. 4. 5. 3. Lifting/Bending/Manual Handling (M) 4. Unsafe Load (M) • 5. Fall/Slip at depot or truck (M) 6. Climbing onto back of trucks (Prevention of Falls) 7. Egressing (getting down) from back of truck (M) (M) Crushing hazard from loading glass beads incorrectly (M) Eliminated Substituted for a safer alternative Controlled by physical barriers, guards or mechanical aids Controlled by training and work procedures Controlled using PPE Ensure pre flight checklist is performed. Maintain maintenance logbooks/records. Check gas hoses/connections for any signs of damage. If unsure check connections with soapy water for leaks. Only licensed operators to use forklift. Pedestrians to keep to designated walk ways when forklift is in operation. All vehicle/plants are fitted with rotating lights, reversing beeper alarms. All staff to wear safety vests. Use hydraulic tail ramp, trolleys and/or forklift where possible. All employees are to use correct manual handling lifting techniques. Team lifting techniques are to be executed as often as possible. Drivers to check load, straps, tie downs etc. prior to starting to drive. Loose and excess material on depot floor/truck is to be swept and collected immediately. All plant, equipment and materials have allocated storage areas that are to be maintained and kept clear. Use provided access points and maintain 3 points of contact. Use provided egress locations and maintain 3 point contact. Residual Risk Level A=Acute H=High M=Moderate L=Low (L) (L) (L) All Workers/Crew Leader (L) (L) (L) (L) DO NOT JUMP DOWN FROM BACK OF TRUCK. When adding glass beads to the tank, whether initially in the day or during refill, ensure beads are released from the base of the bag by undoing the draw string and controlling the flow. Never cut the bag. SX SWMS Thermoplastic Extrusion Profile and Audio Tactile December 2022 - V9 Supalux Linemarking Pty Ltd December 2022 – v9 Responsibility for Control Measures (L) All workers Page 5 of 12 Job Step Break the job/activity into key steps 2. Work Site Establishment 2.1 Complete daily site prestart meeting Initial Identified Hazards 1. Injury to personnel or others, damage to vehicle, plant or equipment Risk Level A=Acute H=High M=Moderate L=Low (H) Control Measures in order of preference, can hazards be 1. 2. 3. 4. 5. 2.2 Implement Traffic control if applicable. 2.3 Unload vehicle and set up job 2. Lifting/Bending (M) 3 .Injury to worker/public through incorrect. positionning of vehicles 4. Excessive speed of vehicle entering worksite. 5. Road formation will affect establishment of TMP i.e. narrow, high embankment will prevent vehicle passing to LHS of linemarking vehicles. 6.Incorrect use of directional or communication equipment. (H) Eliminated Substituted for a safer alternative Controlled by physical barriers, guards or mechanical aids Controlled by training and work procedures Controlled using PPE Set up site in accordance with correct Traffic Management Plan. Support vehicles are to shadow staff for protection against traffic when setting up of site. Ensure gap between worker and support vehicle is in accordance with Traffic Management Plans. Utilise mirrors and spotter (if required) All vehicle/plant are fitted with rotating lights, reversing beeper alarms. Employees hold current Traffic Control and/or Traffic Management qualifications. PPE is to be worn by all staff, always when on a worksite (High Vis safety vests and reflective overalls are provided) Use hydraulic tail ramp, trolleys and/or forklift where possible. All employees are to use correct manual handling lifting techniques. Team lifting techniques are to be executed as often as possible. Ensure crew members have completed Traffic Control Course. Ensure crew members are adequately trained in the arrow boards and UHF radios. Drivers must adhere to speed limits. Position and set-up of all mobile vehicles to be checked by crew leader prior to entering trafficked lanes. Truck Mounted Attenuator to be positioned in rear pilot position as close to linemarking vehicle as terrain and sight distances permit. When traffic density or composition (i.e. very high number of extra-large heavy vehicles) creates a high-risk situation; then work can be suspended until traffic conditions ease or alternate TMP is SX SWMS Thermoplastic Extrusion Profile and Audio Tactile December 2022 - V9 Supalux Linemarking Pty Ltd December 2022 – v9 Residual Risk Level A=Acute H=High M=Moderate L=Low Responsibility for Control Measures (L) All Workers/Crew Leader/Look out Persons (L) (M) All Workers/Crew Leader/Look out Persons Page 6 of 12 Initial Job Step Identified Hazards Break the job/activity into key steps 6. 7. 8. Crush injury when deploying attenuator. Rear Pilot vehicle (Shadow vehicle) distance to Linemarking vehicle too short thereby not providing sufficient protection to the Linemarking vehicle. Rear Pilot vehicle (Shadow vehicle) distance to Linemarking vehicle too long thereby not providing adequate protection to the work vehicle and/or tester Risk Level A=Acute H=High M=Moderate L=Low Control Measures in order of preference, can hazards be 1. 2. 3. 4. 5. Eliminated Substituted for a safer alternative Controlled by physical barriers, guards or mechanical aids Controlled by training and work procedures Controlled using PPE established or obtained. Workers on foot when taking retroreflectivity and completing other Linemarking activities are to ensure the conditions of Table 4.1 AGTTM Part 4 are able to be applied If the sight distances in Table 4.2 AGTTM Part 4 can not be achieved a suitably qualified lookout person must be implemented sure 10 metre clearance of other vehicles and workers Explain this aspect using the TMP. Bad weather (rain, fog) lowers visibility – increase separation distance Sun glare – work with sun at back if possible Oversize vehicles – allow more space to be able to move to the side of the road when paint drying allows Road conditions – poor quality road - increase separation distance to allow controlled speed reduction of all vehicles Use spotters, when necessary, e.g. when testing Main consistent radio communication – use SLK readings and references e.g. signs to inform crew of location Crew leader to monitor and adjust vehicle positions as required (as per TMP) The rear Pilot vehicle shall hold at a position of good sight distance until the work vehicle has progressed to a point where the tail vehicle can move through the section with restricted sight to a point where good sight distance is regained.as per TGS 1-6 TMP 9461 Explain this aspect using the TMP. Always ensure protection of the Linemarking vehicle Heavy traffic conditions - - decrease separation distance Ensure clear communication is always maintained with Linemarker SX SWMS Thermoplastic Extrusion Profile and Audio Tactile December 2022 - V9 Supalux Linemarking Pty Ltd December 2022 – v9 Residual Risk Level A=Acute H=High M=Moderate L=Low Responsibility for Control Measures Page 7 of 12 Job Step Break the job/activity into key steps Initial Identified Hazards Risk Level A=Acute H=High M=Moderate L=Low Control Measures in order of preference, can hazards be 1. 2. 3. 4. 5. 3. Thermoplastic/ Audio Tactile Application 1. Injury to personnel or others, damage to vehicle, plant or equipment (H) 3.1 Spotting /measure out (when required) 3.2 Clean work area 3.3 Prepare material in thermoplastic pre-heater kettles (H) . 3.4 Fill applicator roadmarking machine with thermoplastic 3.5 Apply thermoplastic lines to road 2. Repetitive strain/bending and muscle soreness 3. Material spills (M) (H) 4. Material burns (H) Eliminated Substituted for a safer alternative Controlled by physical barriers, guards or mechanical aids Controlled by training and work procedures Controlled using PPE Maintain enough distance to ensure passing vehicles cannot significantly increase speed directly between Linemarking vehicle and TMA vehicle Maintain only enough distance to ensure passing vehicles does not cross the new work. Support vehicles are to shadow staff for protection against traffic when setting up of site. Ensure gap between worker and support vehicle is in accordance with Traffic Management Plans. Utilise mirrors and forward vision to observe traffic before getting out of the vehicle. When out of the vehicle, to take a measurement, Workers on foot when taking retroreflectivity and completing other Linemarking activities are to ensure the conditions of Table 4.1 AGTTM Part 4 are able to be applied If the sight distances in Table 4.2 AGTTM Part 4 can not be achieved a suitably qualified lookout person must be implemented (if client has specified) All vehicle/plant are fitted with rotating lights, reversing beeper alarms. Employees hold current Traffic Control and/or Traffic Management qualifications. Ensure you are trained and authorised to used pre-hetaer kettles. PPE must be worn by all staff, always when on a worksite Face Shield, Heat Resistant Gloves, Full sleeved shirt and safety shoes as a minimum Employees are to take short frequent breaks when spotting Vehicles carry spill kits and employees are trained to contain the spill as soon as possible in as efficient a manner as possible. SDS are available to the crew through crew resources on sitedocs PPE, gloves, safety glasses, long sleeves, long pants SX SWMS Thermoplastic Extrusion Profile and Audio Tactile December 2022 - V9 Supalux Linemarking Pty Ltd December 2022 – v9 Residual Risk Level A=Acute H=High M=Moderate L=Low Responsibility for Control Measures (L) (L) All Workers/Crew Leader (L) (L) (L) Page 8 of 12 Job Step Break the job/activity into key steps Initial Identified Hazards Risk Level A=Acute H=High M=Moderate L=Low Control Measures in order of preference, can hazards be 1. 2. 3. 4. 5. 5. Fire/explosion (H) 4. Close Down Work Site 4.1 Turn off burner 4.2 Load vehicle 4.3 Site cleanup, ensure site is safe to leave 4.4 Remove traffic control 1. Muscle Injury (M) 2. Injury to personnel or others, damage to vehicle, plant, equipment (H) Eliminated Substituted for a safer alternative Controlled by physical barriers, guards or mechanical aids Controlled by training and work procedures Controlled using PPE are to be worn when preparing/using hot material. A face shield should be used when filling/refilling the thermoplastic kettle or roadmarking applicator. Ensure inspection of gas hoses/connections are completed at pre-start to prevent fire/explosion. Ensure LPG bottles have been tested within last 10 years. Ensure the area is clear of any flammable goods. Employees are trained in lighting of the burner. Firefighting equipment is available on all vehicles. All staff are trained in using a fire extinguisher. A List of all emergency services/contact numbers are in all vehicles Use hydraulic tail ramp. All employees are to use correct manual handling lifting techniques. Team lifting techniques are to be executed as often as possible when loading heavy materials. Pack up site in accordance with correct Traffic Management Plan. Support vehicles are to shadow staff for protection against traffic when packing up of site. Ensure gap between worker and support vehicle in accordance with Traffic Management Plan. Utilise mirrors and spotter. All vehicle/plants are fitted with rotating lights, reversing beeper alarms. Employees hold current Traffic Control and/or Traffic Management qualifications. PPE is to be worn by all staff, always when on a work site (High Vis safety vests and reflective overalls are provided). Residual Risk Level A=Acute H=High M=Moderate L=Low Responsibility for Control Measures (L) (L) (L) All Workers/Crew Leader Complete Traffic Management Daily Diary, recording periodic inspections of Traffic Control devices and any incidents or near misses that may have occurred throughout SX SWMS Thermoplastic Extrusion Profile and Audio Tactile December 2022 - V9 Supalux Linemarking Pty Ltd December 2022 – v9 Page 9 of 12 Job Step Break the job/activity into key steps 5. Depot Unloading 5.1 Vehicle to be left secure and clean 5.2 Ensure all paperwork is completed Initial Identified Hazards 1. Lifting/bending/manual handling Risk Level A=Acute H=High M=Moderate L=Low (M) Control Measures in order of preference, can hazards be 1. 2. 3. 4. 5. Eliminated Substituted for a safer alternative Controlled by physical barriers, guards or mechanical aids Controlled by training and work procedures Controlled using PPE Use hydraulic tail ramp. All employees are to use correct manual handling lifting techniques. Team lifting techniques are to be executed as often as possible when loading heavy materials. Loose and excess material on depot floor/truck is to be swept and collected immediately. All plant, equipment and materials have allocated storage areas that are to be maintained and kept clear, 2. Falls/slips at depot (M) the work day. SX SWMS Thermoplastic Extrusion Profile and Audio Tactile December 2022 - V9 Supalux Linemarking Pty Ltd December 2022 – v9 Residual Risk Level A=Acute H=High M=Moderate L=Low (L) Responsibility for Control Measures All Workers/Crew Leader (L) Page 10 of 12 EMERGENCY PROCEDURES / EMERGENCY RESPONSE Emergency Response: Call 000 immediately then administer first aid to injured person following SDS's for hazardous chemicals (if applicable). Develop and implement an emergency response plan for the site. Include: Assembly points Communication Consultation methods Responsible persons Emergency contacts - names and phone numbers - First aid equipment Fire Extinguishers – accessible and serviced Develop site-specific SWMS Ensure all workers on-site are trained and familiar with emergency and evacuation procedures. REVIEW To ensure controls are implemented and monitored effectively: • Toolbox /pre-start meetings will be undertaken • Relevant persons will be consulted on hazards and contents of SWMS, work plans and other applicable information • Control measures will be monitored throughout works: o Spot checks o Consultation o Scheduled audits • Corrective actions will be recorded and rectified in a timely manner SWMS will be reviewed and updated accordingly (in consultation with relevant persons) Ensure all controls are reviewed as per the following: • If controls fail to reduce risk adequately • When changes to the workplace or work activity occur that create new / different risks where controls may no longer be effective • New hazards identified • After an incident involving work activities relevant to this SWMS • During consultation with relevant persons indicate review is needed • A Health and Safety Representative (HSR) requests a review in line with the requirements of the legislation. SHOULD ANY INCIDENT OCCUR OUT ON A JOB SITE YOU MUST FILL IN THE APPROPRIATE FORM AND SUBMIT TO YOUR SUPERVISOR ASAP. ADMINISTRATION WILL DOCUMENT DETAILS IN THE INCIDENT REGISTER. SX SWMS Thermoplastic Extrusion Profile and Audio Tactile December 2022 - V9 Supalux Linemarking Pty Ltd December 2022 – v9 Page 11 of 12 This SWMS has been developed in consultation and cooperation with workers and relevant Persons Conducting Business or Undertaking (PCBU). I have read the above SWMS and I understand its contents. I confirm that I have the skills and training, including relevant certification to conduct the task as described. I agree to comply with safety requirements within this SWMS including safe work instructions and Personal Protective Equipment described. Name SX SWMS Thermoplastic Extrusion Profile and Audio Tactile December 2022 - V9 Supalux Linemarking Pty Ltd December 2022 – v9 Signature Date Page 12 of 12