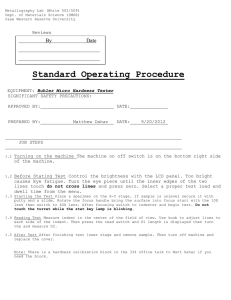

Hardness & Elastic Modulus Measurement by Instrumented Indentation

advertisement