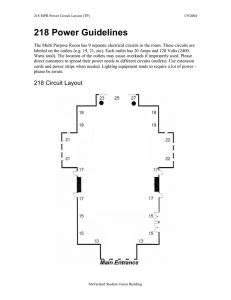

HB1 BUNAWAN LOCATION: BUNAWAN PROPER, DAVAO CITY, DAVAO DEL SUR, PHILIPPINES, 8000 Technical Specifications for MEPFS Works Prepared by: NIMBUS MANNAT EXIM, INC Yap Building, Quimpo Boulevard, Ecoland, Davao City Davao Del Sur Philippines, 8000 16 June 2023 LEO CAMADING, PME, RMP Professional Mechanical Engineer Reg. No : 0005578 PTR No. : 7933828 Date Issue : Jan.12, 2023 Issued at : Davao City TIN No : QUIRLIE Q. QUIBA, PEE Professional Electrical Engineer Reg. No : 0004159 PTR No. : 7868003 Date Issue : Jan 03,2023 Issued at : Davao City TIN No : LEO CAMADING, PME, RMP Registered Master Plumber Reg. No : PTR No. : Date Issue : Issued at : TIN No : DARWIN C. BEDANIA Professional Electronics and Communication Engineer Reg. No : 0000876 PTR No. : 7929034 Date Issue : Jan 5, 2023 Issued at : Davao City TIN No : Table of Contents: 3. Electrical Works 3.1 Power Distribution 3.2 Lighting Fixtures 3.3 Power Outlets 3.4 Data and Communication Wiring 3.5 Fire Detection and Alarm System 3.6 Security System 4. Plumbing Works 5. MVAC (Mechanical, Ventilation, and Air Conditioning) Works 5.1 Air Conditioning System 5.2 Ventilation System 6. Joinery and Millwork 7. Security and Safety 7.1 CCTV and Surveillance System 3. Electrical Works 3.1 Power Distribution General Requirements: a. The power distribution system shall comply with local electrical codes, regulations, and safety standards. b. The system design should be based on the anticipated electrical load and future expansion requirements. c. All materials and equipment used in the power distribution system shall be of high quality, durable, and approved by relevant authorities. d. The system should incorporate safety features, such as circuit breakers, ground fault circuit interrupters (GFCIs), and surge protectors. Main Electrical Panel: a. A main electrical panel shall be installed to receive power from the utility company and distribute it to various circuits within the store. b. The panel shall have an adequate number of breaker slots to accommodate the required number of circuits. c. The panel shall be clearly labeled to identify each circuit. d. Brand as per approved or approved equal. Circuit Design: a. The electrical circuits should be designed to meet the specific power requirements of Page 3 of 18 different areas within the store. b. Lighting circuits and power circuits should be separated to allow for independent control and troubleshooting. c. Circuit loads should be balanced to avoid overloading any single circuit. d. Dedicated circuits should be provided for equipment that requires high power, such as HVAC systems, refrigerators, or heavy machinery. Wiring and Conduits: a. Wiring should be installed in accordance with local electrical codes and regulations. b. Copper wiring of suitable gauge and insulation should be used for power distribution. c. Conduits should be used to protect the wiring and facilitate maintenance and future modifications. d. Conduit sizes should be selected based on the number and size of conductors passing through them. Circuit Protection: a. Circuit breakers shall be installed to provide overcurrent protection for each circuit. b. Breaker sizes should be selected based on the anticipated load of the respective circuit. Emergency Power Backup: a. If required, an emergency power backup system (e.g., generator or uninterruptible power supply) should be installed to provide power during electrical outages. b. The backup power system should be capable of supporting critical equipment, such as emergency lighting, security systems, and essential communication devices. Electrical Outlets: a. Sufficient electrical outlets should be installed throughout the store to accommodate various equipment, lighting, and customer needs. b. Outlets should be strategically placed to ensure convenient access while maintaining aesthetic considerations. c. Outlets should be grounded and of appropriate voltage and current ratings for the intended purpose. Electrical Safety Measures: a. All electrical connections should be properly insulated and enclosed in junction boxes. b. Adequate grounding should be provided to minimize the risk of electrical shocks. c. All electrical installations should be inspected and approved by a qualified electrical inspector. 3.2 Lighting Fixtures General Requirements: a. All lighting fixtures shall comply with local electrical codes, safety standards, and energy efficiency regulations. b. The lighting design should provide adequate illumination levels while considering the intended use, ambiance, and energy efficiency of the store. c. Lighting fixtures should be of high quality, durable, and suitable for the specific application and environment within the store. Page 4 of 18 Lighting Types: a. General Lighting: Provide overall illumination throughout the sales floor and other common areas. Energy Efficiency: a. LED Lighting: Specify energy-efficient LED (Light Emitting Diode) fixtures for general, accent, and task lighting. LEDs offer long lifespan, low energy consumption, and reduced maintenance costs compared to traditional lighting technologies. Lighting Placement and Distribution: a. Lighting Layout: Develop a lighting plan that ensures uniform distribution of light throughout the store, avoiding dark spots or glare. Emergency Lighting: a. Emergency Exit Lighting: Install illuminated exit signs and emergency lighting fixtures to meet safety regulations and ensure safe evacuation during power outages. b. Battery Backup: Specify lighting fixtures with built-in battery backup systems to provide illumination in case of power failure. 3.3 Power Outlets General Requirements: a. Power outlets shall comply with local electrical codes, safety standards, and regulations. b. Outlets should be durable, reliable, and suitable for the intended application and environment within the store. c. The outlet design should consider aesthetic considerations and blend well with the overall store design. Outlet Types: a. Standard Power Outlets: Install standard electrical outlets (Type A or Type B) suitable for general-purpose use, such as powering small appliances, charging devices, or operating office equipment. b. USB Outlets: Consider installing outlets with integrated USB ports to conveniently charge USB-powered devices without the need for adapters. c. Specialized Outlets: Identify any specific requirements for specialized outlets, such as highpower outlets for equipment or appliances that require higher voltage or current ratings. Outlet Placement: a. Plan the location and number of outlets based on the store layout, intended use of each area, and electrical load requirements. b. Place outlets strategically to provide convenient access for customers and staff without cluttering the walls or interfering with store fixtures and displays. c. Ensure proper spacing between outlets to accommodate various plug types and prevent Page 5 of 18 overcrowding. d. Consider placing outlets near workstations, checkout counters, seating areas, and product displays to facilitate customer and employee needs. Outlet Ratings: a. Determine the appropriate voltage and current ratings based on the electrical load requirements and specific equipment to be used. b. Consult with electrical engineers or professionals to ensure that the outlets can safely handle the expected power demands. Outlet Covers: a. Install outlet covers to protect the outlets when not in use and to prevent accidental contact with live electrical parts. Wiring and Circuitry: a. All outlets should be properly wired and connected to a dedicated circuit to prevent overloading and ensure electrical safety. b. Use appropriate gauge wiring to match the outlet's current rating and comply with electrical codes and regulations. c. Employ professional electricians to handle the installation and ensure compliance with electrical standards. ALL MATERIALS AS PER APPROVED BRAND OR EQUAL. 3.4 Data and Communication Wiring General Requirements: a. Data and communication wiring shall comply with industry standards and regulations. b. Use high-quality, certified cabling products that meet the performance requirements of the intended data and communication applications. c. The wiring design should accommodate current needs while allowing for future scalability and upgrades. Cable Types: a. Category 6 (Cat 6) or higher: Use Cat 6 or higher-grade Ethernet cables for data networking applications. Cat 6 cables offer improved bandwidth and performance compared to lower categories. Cable Layout and Installation: a. Cable Paths: Plan the cable pathways, such as conduits, cable trays, or raceways, to ensure proper cable management and prevent signal interference. b. Separation from Power Cables: Maintain separation between data and communication cables and power cables to minimize the risk of EMI and signal degradation. c. Cable Lengths: Keep cable lengths within the specified limits to maintain signal integrity and minimize data loss. d. Cable Labels: Label all cables clearly for easy identification and troubleshooting. Page 6 of 18 Use standardized labeling conventions to ensure consistency and ease of maintenance. Termination and Connectivity: a. Patch Panels: Install patch panels to terminate and organize data cables at central distribution points. Patch panels facilitate easy connection and reconfiguration of network equipment. b. Data Outlets: Install data outlets or wall plates at desired locations for network connectivity. The number and placement of outlets should be based on the specific needs and layout of the store. c. Data Jacks and Connectors: Use high-quality data jacks and connectors that match the cable category for reliable and efficient data transmission. Network Equipment: a. Racks and Cabinets: Install suitable racks or cabinets to house network equipment, such as switches, routers, and servers. Ensure proper ventilation and cable management within the racks. b. Power and Surge Protection: Provide adequate power supply and surge protection for network equipment to ensure uninterrupted operation and safeguard against power surges or electrical faults. Testing and Certification: a. Cable Testing: Perform cable testing using appropriate equipment to verify the integrity and performance of the installed data and communication wiring. Telecommunication Infrastructure: a. Voice Cabling: If required, install voice cabling using suitable cables and connectors to support telephone systems or other voice communication devices. b. Wireless Access Points: Plan and install wireless access points strategically for WiFi network coverage within the store. Coordinate with IT professionals for proper placement and configuration. Note: The data and communication wiring specifications may vary based on the specific requirements of the store, network infrastructure, and industry standards. 3.5 Fire Detection and Alarm System General Requirements: a. The fire detection and alarm system shall comply with local fire codes, regulations, and safety standards. b. The system design should consider the size, layout, and occupancy of the store, as well as the specific fire risks associated with the business. c. All components and equipment used in the system should be approved and certified by relevant authorities. Fire Detection Devices: a. Smoke Detectors: Install smoke detectors in appropriate locations throughout the store, including selling area, storage area. Alarm Notification Devices: Page 7 of 18 a. Audible Alarms: Provide audible alarm devices, such as sirens or horns, to alert occupants in case of a fire emergency. Place the devices strategically to ensure audibility throughout the store. Manual Call Points: a. Install manual call points, also known as fire alarm pull stations or break glass units, in easily accessible locations throughout the store. These allow occupants to manually initiate a fire alarm signal in case of emergency. b. Clearly label and mark the manual call points with appropriate instructions for activation. 3.6 Security System Camera Types: a. Dome Cameras: Indoor b. Bullet Cameras: Install bullet cameras for outdoor surveillance. Camera Specifications: a. Resolution: 1080p (Full HD) resolution or higher. Camera Placement: a. Identify critical areas and vulnerabilities within the store that require surveillance coverage, such as entrances, exits, cash registers, storage areas, and blind spots. b. Ensure cameras are strategically positioned to provide optimal coverage and minimize blind spots. Recording System: b. Network Video Recorder (NVR): IP-based. 30 days retention camera. Network Connectivity: a. If the CCTV system is IP-based, ensure reliable network connectivity to support video transmission and remote access. 4. Plumbing Works Water Supply System: a. Potable Water Connection: Connect the store to a reliable and approved potable water supply system. Comply with local regulations and obtain necessary permits for water connection. b. Pipe Material: Use approved materials, c. Pipe Sizing: Determine appropriate pipe sizes based on anticipated water demand and flow rates. Ensure adequate water pressure and flow for all fixtures and appliances. Fixtures and Appliances: a. Lavatory Sinks: Install sinks made of durable materials such as stainless steel or ceramic. Ensure proper sealing to prevent leaks. Page 8 of 18 b. Faucets: Choose faucets made from durable materials to withstand regular use. Drainage System: a. Drainage Piping: Use approved materials, such as PVC (polyvinyl chloride) or ABS (acrylonitrile butadiene styrene), for drainage pipes. Size the pipes adequately to accommodate anticipated wastewater flow and prevent clogs. b. Ventilation: Install ventilation pipes to allow for the proper flow of air and prevent the build-up of gases or odors in the drainage system. Place vents strategically to ensure adequate ventilation and proper functioning of traps. c. Traps: Install P-traps or S-traps at every fixture to create a water seal and prevent sewer gases from entering the store. Ensure traps are accessible for cleaning and maintenance. Backflow Prevention: a. Backflow Prevention Devices: Install backflow prevention devices, such as check valves or backflow preventers, to prevent the reverse flow of contaminated water into the potable water supply system. Follow local regulations and consult with plumbing professionals for appropriate device selection and installation. . 5. MVAC (Mechanical, Ventilation, and Air Conditioning) Works 5.1 Air Conditioning System Capacity and Cooling Load: a. Determine the cooling load requirements of the space to determine the appropriate capacity of the FCUs. Consider factors such as room size, occupancy, heatgenerating equipment, and insulation levels. b. Select FCUs with the appropriate cooling capacity to meet the cooling demands of the space effectively. Base on cooling load, 2TR 3HP FCU is enough. FCU Types: a. Wall-Mounted FCU Energy Efficiency: a. Energy Recovery: Consider incorporating energy recovery systems within the FCU system to recover and utilize waste heat or cooling energy, thereby improving overall system efficiency. 5.2 Ventilation System Ventilation Design: a. Determine the ventilation requirements based on the occupancy, activity level, and size of the space. Follow local building codes and standards for ventilation rates. Mechanical Ventilation Equipment: a. Air Handling Units (AHUs): Install AHUs to condition and distribute fresh air throughout the building. AHUs should be sized appropriately to handle the required airflow volume. b. Fans: Wall fans as per approved brand Page 9 of 18 Air Distribution: Exit Grilles: Install exit grilles or exhaust grilles. Select grilles that provide appropriate air throw, spread, and aesthetics for the space. 6. Joinery and Millwork – As per approved Architectural plans and finishes. Page 10 of 18 Page 11 of 18