900

A. Contin et al.: Frequency-response Analysis of Power Transformers by Means of Fuzzy Tools

Frequency-response Analysis of Power Transformers

by Means of Fuzzy Tools

Alfredo Contin, Germano Rabach

DEEI University of Trieste

Via A.Valerio, 10

34127 Trieste, Italy

Johnny Borghetto, Michele De Nigris

R.S.E. spa

Via Rubattino, 54

20134 Milano, Italy

Renzo Passaglia and Giuseppe Rizzi

Consultants R.S.E. spa

Via Rubattino, 54

20134 Milano, Italy

ABSTRACT

A novel Fuzzy algorithm for the automatic analysis of frequency response of power

transformers is described in this paper. It relies on the values of two parameters able to

quantify the difference between the present and a reference frequency response, over

three frequency ranges. These ranges are associated with different defect types, i.e.,

short circuits between turns, radial and axial displacements. Training examples

obtained mainly from experimental results have been used to select the different

ranges. Fuzzy-Logic has been adopted to reflect the uncertainty in the analysis of the

differences between the two curves in the defect-identification results. Practical

applications are also discussed to show the efficiency of the proposed diagnostic

method.

Index Terms — Power transformers, insulation, frequency response, faults

prediction, diagnostics.

1 INTRODUCTION

TRANSFORMERS are essential elements of power

delivery and their failure can cause serious problems in

electric utility operations. Among the causes of transformer

failure, those related directly or indirectly to the deformation

of windings due to bad assembly or after transportation or an

accident, are outstanding. Therefore, the development of

diagnostic methods for the identification of winding

deformations is of practical value to avoid unexpected

accidents. Short-circuit inductance measurement is widely

used to test the transformer conditions and threshold levels

have been established for pass/not pass criteria, depending

from the transformer typology [13]. Even if widely used, this

diagnostic technique does not provide details about the

potential defect typology. The Sweep Frequency Response

Manuscript received on 29 October 2010, in final form 10 February 2011.

Analysis (SFRA) gained popularity for its ability to point out

geometrical deformations, winding displacements and internal

short-circuits between turns by means of the interpretation of

the modifications in frequency-response characteristics [1, 2].

Diagnostics based on SFRA method is thus carried out

comparing the present frequency response with a reference

one that reflects the good conditions of the transformer.

Relating the curve comparison with potential internal defects

requires skilled operators and a wide specific experience [3,

4]. This fact promotes investigations having the purpose of

finding methods and algorithms that allow the automatic

interpretation of SFRA results.

The purpose of the paper is to discuss a Fuzzy-Logic

Algorithm (FLA) for the automatic analysis of frequencyresponse measurements of power transformers. It is based on

the evaluation of the curve obtained subtracting the present

and the reference frequency-response (comparison curve) over

three different frequency ranges, each one associated with a

1070-9878/11/$25.00 © 2011 IEEE

IEEE Transactions on Dielectrics and Electrical Insulation

Vol. 18, No. 3; June 2011

particular defect type, i.e., short circuit between turns, radial

and axial displacements. These frequency ranges have been

selected considering mainly SFRA experimental results

performed on transformers whose conditions were wellknown. FLA has been adopted to take into account the

uncertainty in the identification of the different defects in

these three frequency ranges (partially overlapped). Using this

approach, the different defect types are identified by means of

“defuzzyfication”, into different predicates. Each predicate is

associated to a specific defect with a membership function that

indicates the confidence degree of the output. Examples of

FLA outputs relevant to SFRA measurements carried out on

site on real transformers, are also discussed to show its

effectiveness.

2 BASICS OF SFRA

Important mechanical stresses are due to electro-dynamic

forces linked to short circuits currents. The axial forces

compress the windings while the radial ones act to buckle the

inner and open the outer windings [5]. The mechanical

stresses can affect the tightness of the connections in the

windings. Axial and radial deformations are the premises to a

mechanical and/or electrical collapse of the transformer

windings, thus representing an important indicator of an

incipient fault. Short-circuit currents can generate breakdowns

of the insulation between turns due to overheating of weak

points and can modify the residual magnetization (the latter

being a harmless effect) [1-4].

The measurement of the short-circuit inductance, widely

adopted in industry for checking the presence of such

internal defects, is effective but not sensitive enough to

distinguish among the different defect types [13]. The SFRA

method was developed to cope with this lack of sensitivity.

SFRA is based on the assumption that any mechanical

deformation as well as changes in the number of turns and

residual magnetization, modify the inductive/capacitive

couplings within the transformer. In particular, radial and

axial deformations affect the coil-to-ground and coil-to-coil

capacitances, respectively, while short circuits between turns

and variations of the residual magnetization modify the self

and mutual inductance of the windings. Some electric

models, based on equivalent ladder network circuits have

been proposed to simulate the effects of the winding

displacements, [6]. The connections of the transformer

windings in a two-port configuration allow a description of

the machine based on a transfer function whose features are

related to its zeros and poles values (the latter showing the

resonant peaks). Any winding deformation can be described

in terms of pole displacements (modification of the transferfunction resonant peaks) which correspond to a modification

of the response curve. SFRA diagnostic methods try to infer

the specific causes of modification of the response-curve

since internal short-circuits affect mainly the low-frequency

winding impedance (poles in the low-frequency range),

while radial and axial displacements modify mainly the

phase-to-ground and coil-to-coil capacitance (variations in

pole position in the middle and high frequency ranges

respectively) [6].

901

3 EXPERIMENTAL SETUP

SFRA method requires connecting the windings of the

transformer as a two-port configuration. A sinusoidal sweepfrequency generator supplies the input port while the response

of the transformer is recorded at the output terminals

connected to a suitable impedance (R=50 :) [1-3]. The

experimental transfer-function is obtained in terms of

amplitude ratio and phase delay between the output, Vout(f),

and input, Vin(f), signals [4]. The use of a sinusoidal signal is

preferred to the impulse wave-shape since the applied sweep

maintains the same voltage level for each selected frequency.

This allows obtaining a more accurate and reproducible results

both in low- and high-frequency range [12, 14]. The

frequency span adopted here, ranges from 10 Hz to 5 MHz

and the signal amplitude is constantly set at 10 Vp-p. SFRA

was carried out mainly on high power and high voltage (up to

400 kV) three-phase transformers (auto, two- and threewinding transformers, transformers with three and five limbs).

Different test setup configurations can be considered

depending on the connection of the winding terminals (star or

delta connections) and the availability of the neutral terminal.

If all the terminals are available, the different windings can be

tested one by one (end-to-end). SFRA can be applied to

evaluate the same winding before and after a potentially

damaging event such as an external short circuit or, in the

absence of reference measurements, to compare the response

of the different windings within the same transformer or with

the response of transformer of the same type and ratings [4].

When the windings are star-connected, each winding can be

tested leaving floating the other terminals of the star, or

alternatively, connecting them to ground. In the latter case,

residual magnetization is minimized. If the transformer is

delta-connected, the frequency-response of a given winding is

influenced by the other two that are connected in parallel.

Two configurations can be considered for the winding

opposite to the tested one: i.e. winding open and floating and

winding short-circuited. These test conditions allow the

selective evaluation of the presence of defects. In fact, in the

conditions in which the opposite winding is open and floating,

the effect of the mutual coupling between the two windings

can be seen in addition to the effect of the magnetic circuit. In

the other test configuration (short-circuited winding) the

effects of the mutual coupling and the magnetic circuit are

masked and the effect of the single winding is evidenced.

It is to be underlined that special precaution shall be adopted

with concern to the screening of measuring cables to avoid

interferences and noise in the frequency range above 500 kHz.

If the back-ground noise is minimized, the same testing

accuracy can be obtained in the laboratory and in the field [3].

It can be concluded that SFRA can offer reliable results

whenever the reference and the present curves are recorded in

the same setup conditions (i.e., the tap position, terminals

grounded, shorted or floating).

All the experimental test results, collected in a homogeneous

database, have been used to develop the proposed algorithm

for the evaluation of the comparison curve [12]. The measured

and the reference curves are reported in a Bode plot and

902

A. Contin et al.: Frequency-response Analysis of Power Transformers by Means of Fuzzy Tools

mutually compared to point out any significant differences.

Let us consider Vin(jZ) and Vout(jZ) the input and the output

signals, respectively. The transfer function H(jZ) is expressed

by:

H ( jZ )

Vout ( jZ )

Vin ( jZ )

(1)

The Bode diagrams are plotted considering both the

magnitude and phase as follows:

Adb ( Z )

20 log 10 H ( jZ )

AT ( Z ) tan 1 ( H ( jZ ))

(2)

Let Ar(f) and Ae(f) be the magnitude diagrams of Equation

(2) relevant to the reference and present conditions of the

investigated transformer, respectively. The comparison curve,

ǻ(f), is defined as:

'( f )

Ae ( f ) Ar ( f )

(3)

Both the Bode diagrams as well as the comparison curve are

reported in the same plot to facilitate the comparison. Changes

in the resonant peaks due to mechanical displacements or

short circuits between turns, reflected on the ǻ(f) plot, have

been analyzed deeply to extract diagnostic information.

4 FAULT CLASSIFICATION

A set of about 250 SFRA test results, obtained mainly from

tests carried out on transformers whose conditions are known,

have been studied to extract diagnostic information and

classify them into good or faulty categories.

4.1 GOOD CONDITIONS

The perfect overlapping of the present and reference SFRA

curves produce a null function of the comparison curve

(equation (3)) thus indicating the perfect invariance of the

winding conditions. Deviations between the two frequency

responses can be found during on-site SFRA measurements on

transformers in good conditions. In fact, an increase of

residual magnetization can be found after an external short

circuit as well as differences in SFRA curves due to different

magnetization can arise when internal and external windings

of the same machines are compared. Even if the instrument is

equipped with shielded connections, external high frequency

noise can affect the measurements and the comparison curve

can be distorted in the high frequency region.

The analysis of a large set of SFRA measurements

performed on transformers in good conditions was used to

evaluate the acceptable level of noise and the curve

modifications due to the residual magnetization, below 10

kHz.

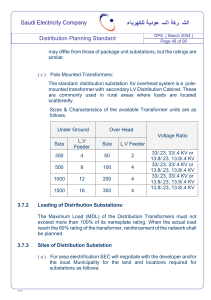

Results of SFRA measurements carried out on a three phase

transformer rated 58 MVA, 15/230 kV, delta/star connected,

are explicative in this respect. Since no reference data existed

for this specific machine, diagnostic tests were carried out

comparing the SFRA curves of the different windings. Tests

were carried out connecting the instrument to two terminals

and leaving all the others floating. Test results obtained

connecting the instrument to two low-voltage terminals are

reported in Figure 1 as an example. Similar results were

obtained using other test setup configurations. An accurate

inspection carried out after SFRA measurements confirmed

that the transformer was in good condition. The differences

were linked to the different magnetization level (below 10

kHz), while probable noise and small geometric differences

affected the curves above 100 kHz. SFRA carried out on a

large number of power transformers in good condition

allowed to establish specific threshold levels to be applied to

the comparison curve to discriminate between the “good” and

“faulty” conditions.

4.2 FAULT CONDITIONS: SINGLE DEFECTS

A wide set of transformers that showed modifications in

SFRA curves, has been analyzed deeply with the purpose to

relate these changes to their specific causes.

According to the results reported in the literature, it was

found that the short circuits between turns change the

equivalent number of turns of the winding and, as a

consequence, the total inductance. Moreover, the higher

currents associated with the short circuit between turn(s)

modify also the magnetization and structural deformations in

the magnetic circuit can produce variation in the

magnetization reluctance values. Since these defects are

linked with the magnetization field, SFRA curve

modifications can be evidenced in the low-frequency range

(below 10 kHz). An example of the effects due to a short

circuit between turns is shown in Figure 2. SFRA carried out

on a three-phase autotransformer rated 250 MVA, 400/35 kV,

before and after a short circuit test, is reported in Figure 2A

while the picture of the fault is shown in Figure 2B. As can be

seen, SFRA curves differ mainly below 10 kHz. The response

to higher frequencies is not substantially affected, thus

excluding geometrical deformations of the windings. In fact,

the short circuit occurred between the connection cables.

Analyzing the data-base, similar deviations were found in the

same range of frequencies, due to short circuits between turns

without significant geometric deformations.

Radial deformations modify mainly the phase-to-phase

and phase-to-ground capacitance distributed along the

whole windings. The resonant peaks linked with these

deformations affect mainly the medium-frequency

response. Radial deformations can be localized in a

restricted section of turns/coils or distributed along several

coils. These deformations can be pronounced or negligible.

These characteristics can be evidenced by the modification

of the resonant peaks in the medium-frequency range:

marked the former, spread the latter. Slight differences in

the resonant peak positions are often accepted as being

linked with the winding setting process. Analyzing

transformers having only radial deformations, it was found

that SFRA changes its shape in the frequency range of

about 5 – 500 kHz.

Weaknesses in upper/lower coil pressure plates and in

spacing blocks, can produce axial movements of the windings.

This can cause changes in the high frequency response (above

IEEE Transactions on Dielectrics and Electrical Insulation

Vol. 18, No. 3; June 2011

Figure 1. Comparison of SFRA measurements carried out on two phases of

LV windings delta connected while the HV terminals are open and floating.

903

A

B

A

Figure 3. Comparison of SFRA measurements carried out on a phase of a

transformer rated (60 MVA, 400 kV) before and after a breakdown event, (A),

and picture of the fault, (B).

frequency modifications as well as medium or high frequency

(or both) SFRA curve coexist.

B

Figure 2. Comparison of SFRA measurements carried out on a single phase

of a transformer before and after a breakdown event, (A), and picture of the

fault between the connecting cables (B).

400 kHz) often leading to the creation of new resonant

frequencies.

4.3 FAULT CONDITIONS: MULTIPLE DEFECTS

Faults can often produce complex deformations such that

shown in Figure 3. In this example, a single phase transformer

with two secondary windings positioned on separated

columns, was subjected to short circuit. SFRA was carried out

before and after the short circuit to check the possible effects.

The two curves differ in the range of 20 kHz – 5 MHz (Figure

3A). The machine was successively inspected and an

important deformation was found on the low-voltage winding

(see Figure 3B) due to the breaking of the axial support on the

top-end of the coil which generated also a radial deformation.

It can happen to find both axial and radial deformations

associated to short-circuited turns or coils. In this case, low-

4.4 DISCUSSION

The experimental data gathered showed that the different

defect types can be classified into three different ranges:

4.4.1 FREQUENCY RANGE BELOW 10 KHZ

Phenomena linked with the transformer magnetic core and

circuits, in particular short circuits between turns, are

evidenced in this range of frequencies. The residual

magnetization which can slightly modify SFRA curves must

be taken into consideration in the same range of frequencies

but this is a harmless phenomenon;

4.4.2 FREQUENCY RANGE BETWEEN 5 KHZ AND

500 KHZ

In this range phenomena linked with radial relative

geometrical movements between windings, are evidenced;

4.4.3 FREQUENCY RANGE ABOVE > 400 KHZ

Axial deformations of each single winding are evidenced

in this range of frequencies.

As can be seen, the frequency intervals are partially

overlapped. This implies a potential ambiguous identification

when modifications of SFRA curves fall in these overlapped

ranges. The transition from good to faulty conditions is not

necessarily abrupt but progressive degradation processes can

be evidenced resulting “negligible” in the first instance,

“potentially damaged” in a second instance and “certainly

damaged” as the final condition. Any diagnostic algorithm

904

A. Contin et al.: Frequency-response Analysis of Power Transformers by Means of Fuzzy Tools

must interpret correctly the indicators by adopting suitable

criteria to distinguish between the three different conditions. It

is to be noticed that the criteria at the base of operative

decisions (run, refurbish, replace) are closely linked to the risk

evaluation policy of the user.

Since modifications in the SFRA can also be linked with

harmless causes, i.e. residual magnetization and noise in low

and medium/high frequency, respectively, three different

tolerance belts (expressed in dB) are associated to the

different frequency ranges: the tolerance is larger in lowfrequency to take into account the residual magnetization,

thinner in medium and intermediate in high frequency ranges.

5 THE “FUZZY” ALGORITHM

Fuzzy Logic (FL) is adopted here to organize information

in a context characterized by a level of uncertainty. Initially,

the lack of information linked with the limited number of

cases is normally coped with relying on experts. About ten

clear examples for each defect typology have been selected to

build up the “knowledge-base” of FLA, that is, the ranges of

the parameter values and the rules adopted to discriminate

between the different good and fault conditions. As the

knowledge evolves, FLA can be updated including the new

information. The FLA has the purpose to automatically

identify different defect types, such as short circuited turns as

well as radial and axial displacements, giving rise to

parameters able to characterize the comparison curve.

5.1 PARAMETER SELETION

Among the different parameters proposed in the literature,

only those able to consider simultaneously both

pronounced/slight and concentrated/distributed deformations

have been considered [7]. Attention was given to the

evaluation of the comparison curve defined by equation (3). In

particular, the mean:

m

¦

N

i

'( f i )

1

N

N

Ae ( f i ) Ar ( f i )

i 1

N

¦

(4)

and the standard deviation:

V

2

1

N

¦

N

i 1

'( f i ) m

is given in an interval of {0 – 1} by using the oblique sides of

the trapezium with the limit that the sum of the different

memberships be always 1. An example of “fuzzyfication” of a

generic parameter P is reported in Figure 4. A given value P*

is associated to the attribute “Low” with a membership PL and

to “Medium” with membership PM (PL+PM=1). The choice of

the values that establish the membership limits are derived

from the heuristic analysis of the parameter/defect relationship

obtained during the analysis of the experimental results (see

section 4). In particular, the frequency range has been

partitioned according to section 4.4, while m and V2 have been

partitioned differently over the three frequency ranges

according to the experience of RSE, taking also into account

the influence of the background noise. The selected limits can

be updated easily when new information is obtained after new

data-set acquisitions.

A tri-dimensional input space is thus constituted by the

connection of the three “fuzzified” parameters. By using these

attributes, the input space is partitioned in sub-spaces each one

associated to the vector whose components are the linguistic

attributes of the input parameters and the relevant membership

values.

The output linguistic predicates (i.e., Good Conditions (G),

Slight (S) and Pronounced (P) displacement) are connected

with the input space by means of appropriate rules based on

IF..THEN..ELSE conditions. The association between

input/output predicates and the limits for the linguistic

attributes is performed on the base of the training test results

and reflects the experience of RSE.

Figure 4. Example of “Fuzzy-Set” selection of a generic parameter P:

w (L), Medium (M) and High (H).

2

(5)

have been considered to evaluate the comparison curve over

the three different frequency ranges of section 4.4. In

particular, m takes into account the amplitude dispersion and

V the frequency shift due to resonant peak displacements.

5.2 FUZZIFICATION AND DEFUZZIFICATION

Each of the three parameters f, m and V2 was “fuzzyfied”,

i.e. partitioned in three ranges, according to FL theory and

past experiences [8-11]. Three linguistic attributes (i.e., Low,

Medium and High) have been associated to each partition by

means of a characteristic function (membership function, P)

here composed of a sequence of trapezium shapes. When two

attributes range in overlapped intervals, a partial membership

The most common Fuzzy-Logic procedure that associates

logical AND to the minimum membership value while logical

OR to the maximum one, has been adopted here to provide

membership profiles to the output linguistic predicates, [9]. In

this way, the uncertainty of the result is taken into account

assigning membership values <1 (and >0) to more than one

predicate with the constraint 6P=1. In general, a P-value close

to 1 gives an indication that the output predicate has a high

confidence degree to be true. Lower P-values are related to

ambiguous situations since different outputs are activated.

Through this approach the user decision is strongly

facilitated since, if P=1, the identification is accurate while

P<1 indicates that different options should be taken into

account. As an example, if m is “Low” with membership 0.2

and “Medium” with membership 0.8 while f and V2 are “Low”

IEEE Transactions on Dielectrics and Electrical Insulation

Vol. 18, No. 3; June 2011

with membership 1, the output of FLA will be “Residual

Magnetization”: “Slight” with membership 0.8”. This result

indicates that the reference and investigated-transformer

SFRA differ because of a harmless phenomenon and the

transformer can be considered in good conditions.

6 APPLICATIONS OF THE FUZZY TOOL

FLA has been first tested by using the training examples and

validated later by processing SFRA curves recorded on field.

6.1 THE UNCERTAINTY MANAGEMENT

Among these results, specific examples are discussed here

to point out the advantages of using FLA when applied to

analyze practical cases where the curves are of difficult

reading even for a skilled operator.

The effectiveness of the FLA is evident considering SFRA

such those obtained testing a transformer rated 250 MVA,

400/135 kV. The present results, recorded after an external

short circuit event, are compared with the frequency response

of earlier tests considered as a reference. The instrument was

connected between the HV terminals and the neutral point,

leaving floating the LV terminals. The test result related to the

W-phase is plotted in Figure 5. As can be seen, it is quite

difficult to formulate any conclusion looking only at the

differences between the two curves. The comparison curve

shows slight variations over the three different frequency

ranges. The FLA output, reported in Table 1, helps

considerably in the interpretation of this test result. Neither

short circuit nor residual magnetization were found (Table 1:

Good Conditions with P=1 for both cases). Changes in the

position of the resonant peaks around 5 kHz and over 400 kHz

determine an almost negligible modification in the medium

(Table 1: slight radial displacement P=0.1) and more evident

curve modification in the high frequency range (Table 1:

pronounced axial displacement, P=0.8). The value of P=0.8

offers an idea of uncertainty in the FLA results.

This means that the axial deformation is not granted but it is

realistic to suppose that some mechanical support has been

loosened. A variation of 1.9% in the short-circuit inductance

nameplate value supported the decision to leave the machine

in service (the prescriptions of [13] and the uncertainty related

the real and the nameplate value of the reactance are also

taken into consideration). As can be seen by comparing the

information provided by the two methods, FLA shown more

detailed information. It must be pointed out once again that

the P values depend both on the training examples and on the

operator experience in SFRA analysis. Other experts can

calibrate FLA in a different way reflecting their experience.

Similar test results, but different conclusions, can be drawn

looking at SFRA carried out on the low-voltage windings of a

transformer rated 200 MVA, 400/15 kV before and after a

short circuit event. The same setup of the former example has

been used in the test. The most significant SFRA is plotted in

Figure 6 while the output of the algorithm is reported in Table

2. Changes in a resonant peak appear at 100 kHz: this may be

905

linked to a slight displacement of few turns. The FLA output

indicates a “slight” and “pronounced” radial displacement

with P=0.8 and P=0.2 respectively. Even if some changes in

the transformer geometry has been detected, RSE experts

suggest to leave the transformer in service since P=0.8 is

associated to slight deformation. The residual magnetization

appears to be negligible.

6.2 A CASE STUDY

The FLA results can considerably help also to decide upon

the measurement procedure, as shown in the next example. A

three-phase step-up transformer rated 150 MVA and 400/20

kV was artificially subjected to an internal short circuit on

phase W, HV side. SFRA was carried out adopting the phaseto-phase connection since the HV windings were connected in

star configuration and the neutral was not available. UW, UV

and VW phases were compared to each other because no

previous reference curves were available. Tests were carried

out leaving the low-voltage terminals open and floating. The

result of the comparison of the connections (UV in good

conditions and UW containing the faulted phase, W) is

reported in Figure 7. The large discrepancy between the two

frequency responses is evident in the low-frequency range

(below 5 kHz), thus indicating an internal short circuit. The

same output as of Table 3 also indicate a pronounced axial

displacement with P=0.3. Since the P value indicates an

uncertain condition, SFRA was repeated in the same setup

conditions but shorting out the LV windings.

In this way, the influence of the magnetic core (residual

magnetization and consequently the visibility of the internal

short-circuit) is removed. Hence, the frequency response in

the low-frequency range was almost deleted as can be seen in

Figure 8 where the SFRA test results with shorted LV

terminals, are reported.

In fact, when the windings opposite to the tested one are shortcircuited, the inductive coupling is very much affected and the

sensitivity at low frequencies lowers significantly. Moreover,

being the short-circuit reactance much smaller than the no-load

reactance, the signal attenuation in the low-frequency range is

much smaller. The FLA output, reported in Table 4 and related to

the data reported in Figure 8, shows a reduction of the warning

level (Slight axial displacements with P=0.95 instead of

Pronounced with P=0.3). In this way, the assumption that the

machine is in good conditions becomes stronger.

6.3 SFRA TESTS ON SISTER UNITS

It often happens that the reference curves or the phase-tophase connections are not available, as in the case of the

single-phase HV transformers discussed here. Thus, the

comparison of the frequency response of sister units

(transformers having the same design) is the only possible

option to predict the transformer conditions. However,

experience has shown that sister units may show little

variations that must be taken into account. The comparison

with a sister unit has several benefits in that reference results

may be determined for a number of transformers at one time.

906

A. Contin et al.: Frequency-response Analysis of Power Transformers by Means of Fuzzy Tools

Figure 5. Comparison of SFRA measurements carried out on a single

phase of a transformer rated 400/135 kV, before and after an external short

circuit.

Table 1. Final test results of SFRA measurements of Figure 5.

Type of Fault

Axial Displ.

Radial Displ.

Short Turns

Residual Magn.

Good Cond.

0

0.9

1

1

Slight

0.2

0.1

0

0

Pronounced

0.8

0

0

0

Figure 7. Comparison of SFRA measurements carried out on a step-up

transformer rated 150 MVA, 400/20 kV, after an internal short circuit, using a

phase-to-phase configuration (UV vs. UW connections). The LV terminals are

open and floating.

Table 3. Final test results of SFRA measurements of Figure 7.

Type of Fault

Axial Displ.

Radial Displ.

Short Turns

Residual Magn.

Good Cond.

0

1

0

1

Slight

0.7

0

0

0

Pronounced

0.3

0

1

0

good conditions by the experts of RSE. It must be pointed out

that, in few cases, the FLA applied to transformers having

nominally the same design but some differences in their

construction can give false indications. Consequently, caution

is suggested when FLA is applied to analyze SFRA carried

out on sister units.

Figure 6. Comparison of SFRA measurements carried out on a single

phase of a transformer rated 400/15 kV, before and after an external short

circuit.

Table 2. Final test results of SFRA measurements of Figure 6.

Type of Fault

Good Cond.

Slight

Pronounced

Axial Displ.

1

0

0

Radial Displ.

Short Turns

Residual Magn.

0

1

0

0.8

0

0.77

0.2

0

0.23

Three single-phase transformers rated 100 MVA, 135/18 kV

were compared to a spare unit, never used before, and therefore

considered in good conditions. The FLA outputs related to

SFRA carried out on the three machines are reported in Table 5

while the SFRA curves related to the test carried out comparing

the machine connected to the S phase and the spare unit, are

plotted in Figure 9. As can be seen, different residual

magnetization affect the FLA output in all the measurements.

Even if these machines show successive serial numbers, the

frequency response is characterized by several resonance-peak

shifts. The FLA has been designed to take into account also

these differences and the FLA output assigning a very low P

value to R- and T-Ref. (see Table 5) while a higher value was

assigned to S-Ref.: the three machines were considered in

6.4 COMPARISON BETWEEN SFRA AND SHORTCIRCUIT INDUCTANCE TEST RESULTS

A comparison between short-circuit inductance and SFRAFLA test results appears interesting to better understand the

differences in terms of diagnostic information provided by the

two methods. The short-circuit inductance variations relevant

the two transformers of Figure 2 (section 4.2) and Figure 3

(section 4.3) were found 3.4% and 6%, respectively. Both

these values indicate fault conditions but FLA test results

address to specific defect typologies named “short circuit” the

former and “axial” and “radial” displacement, the latter, thus

facilitating the user decision.

A three-phase transformer rated 200 MVA, 400/20 kV was

subjected to short circuit withstand tests and SFRA method

was used in addition to the short-circuit inductance

measurement to assess the condition of the windings after the

tests. An anomalous behavior was notified comparing SFRA

measurements obtained adopting the phase-to-phase

connection (the HV windings are star connected and the

neutral is not available). In the absence of previous reference

curves, SFRA curves of the different connections were

compared to each other. Tests were carried out leaving the LV

terminals floating. A variation of 2.7% in the short-circuit

inductance measurement suggested to open the machine and a

fault, whose picture in reported in Figure 11, was found on

phase U. FLA was verified by using this information and the

results are reported in Table 6. As can be seen, a pronounced

radial displacement is indicated with a P=0.8 while the axial

IEEE Transactions on Dielectrics and Electrical Insulation

Vol. 18, No. 3; June 2011

Figure 8. Comparison of SFRA measurements carried on a step-up

transformer rated 150 MVA, 400/20 kV, after an internal short circuit, using a

phase-to-phase configuration (UV vs. UW connections). The LV terminals are

short circuited.

907

Figure 10. Comparison of SFRA measurements carried out on a three-phase

transformer rated 200 MVA, 400/20 kV, using a phase-to-phase configuration

(UV vs. UW connections). The LV terminals are open and floating.

Table 6. Final test results of FRA measurements of Figure 7.

Table 4. Final test results of FRA measurements of Figure 8.

Type of Fault

Type of Fault

Axial Displ.

Radial Displ.

Short Turns

Residual Magn.

Good Cond.

0.05

1

1

1

Slight

0.95

0

0

0

Pronounced

0

0

0

0

Axial Displ.

Radial Displ.

Short Turns

Residual Magn.

Good Cond.

0

0

1

0

Slight

Pronounced

1

0.2

0

1

0

0.8

0

0

Figure 11. The picture of the fault of the transformer of Figure 10.

Figure 9. Comparison of SFRA measurements carried out on two singlephase sister transformers rated 100 MVA, 135/18 kV.

Table 5. Comparison of FLA outputs relevant to three single-phase sister

transformers. Output S-Ref. is relevant to SFRA measurements of Figure 9.

S-Ref.

Type of Fault

Axial Displ.

Radial Displ.

Short Turns

Residual Magn.

Good Cond.

1

0.1

1

0

Slight

0

0.9

0

0

Pronounced

0

0

0

1

R-Ref.

Type of Fault

Axial Displ.

Radial Displ.

Short Turns

Residual Magn.

Good Cond.

0.7

1

1

0

Slight

0.3

0

0

0

Pronounced

0

0

0

1

T-Ref.

Type of Fault

Axial Displ.

Radial Displ.

Short Turns

Residual Magn.

Good Cond.

0.7

1

1

0

Slight

0.3

0

0

0

Pronounced

0

0

0

1

displacement is considered “slight”. The residual

magnetization is negligible.

SFRA test can be conveniently adopted for the quality check

of new transformers, just installed. This is the case of the

transformer rated 150 MVA, 400/15 kV. SFRA tests were

carried out comparing phase-to-phase. An anomalous

behavior was found on the phase V (HV side). SFRA test

results obtained comparing U and V phases are reported in

Figure 12.

A variation of 3% in the short-circuit inductance relevant to

phase V, compared with the other phases, motivated to open

the machine and an axial deformation was found on the phase.

FLA results clearly indicated a pronounced axial displacement

as reported in Table 7 where the FLA results are summarized.

7 CONCLUSION

The experience acquired through the extended application

of SFRA both in laboratory and in the field with different

types of defects, has allowed to establish general rules for the

interpretation of SFRA. A Fuzzy-Logic Algorithm for the

automatic analysis of the frequency response in presence of

uncertain conditions has been developed. The uncertainty is

908

A. Contin et al.: Frequency-response Analysis of Power Transformers by Means of Fuzzy Tools

[3]

[4]

[5]

[6]

[7]

[8]

Figure 12. Comparison of SFRA measurements carried out on a three-phase

transformer rated 200 MVA, 400/20 kV, using a single-phase configuration

(U vs. V connections). The LV terminals are open and floating.

Table 7. Final test results of SFRA measurements of Figure 12.

Type of Fault

Axial Displ.

Radial Displ.

Short Turns

Residual Magn.

Good Cond.

0

0

1

0.8

Slight

0

0.7

0

0.2

Pronounced

1

0.3

0

0

[9]

[10]

[11]

[12]

[13]

[14]

M. DeNigris, R. Passaglia, R.Berti, L.Bergonzi and R.Maggi, "Application of

Modern Techniques for the Condition Assessment of Power Transformers”,

CIGRE, Paris, France, paper A2-207, 2004.

S. A. Ryder, “Diagnosing Transformer Faults Using Frequency Response

Analysis”, IEEE Electr. Insul. Mag., Vol. 19, No.2, pp. 16-22, 2003.

S. V. Kulkarni and S.A. Khaparde, Transformer Engineering, Design and

Practice, Marcel Dekker Inc., New York 2004.

J L.Satish and S.K.Sahoo, "An Effort to Understand What Factors Affect the

Transfer Function of a Two-Winding Transformer", IEEE Trans. Power

Delivery, Vol. 20, pp. 1430-1440, 2005.

W. Kim, B.K. Park, S.C. Jeong, S.W. Kim and P.G. Park, "Fault Diagnosis of a

Power Transformer Using an Improved Frequency-Response Analysis", IEEE

Trans. Power Delivery, Vol. 20, pp. 169-178, 2005.

J. M. Mendel, “Fuzzy Logic Systems for Engineering: A Tutorial”, Proc. IEEE,

Vol. 83, pp. 345-377, 1995.

F. Russo, “Fuzzy Model Fundamentals”, in Wiley Encyclopedia of Electrical

and Electronics Engineering, Vol.8, pp. 158-166, J. Wiley & Sons, New York,

USA, 1999.

M. M. A. Salama and R. Bartnikas, “Fuzzy logic applied to PD pattern

classification”, IEEE Trans. Dielectr. Electr. Insul., Vol. 7, pp. 118 – 123, 2000.

N. C. Sahoo, M. M. A. Salama and R. Bartnikas, “Trends in partial discharge

pattern classification: a survey”, IEEE Trans. on Dielectrics and Electrical

Insulation, Vol. 12, pp. 248 – 268, 2005.

CIGRE Working Group A2.26, “Mechanical-Condition Assessment of

Transformer Windings Using Frequency Response Analysis (FRA)”, CIGRE

Brochure N.342, 2008.

IEC Std., Power Transformers, Part 5: Ability to Withstand Short Circuits, IEC

Standard 60076-5, p.37, Third Edition 2006.

IEC Std., Power Transformers, Part 18: Measurement of Frequency Response,

Draft of IEC Standard 60076-18, First Edition 2009.

Alfredo Contin (M’1987) was born in Udine on 30

January 1955. He is currently an Associate Professor at

the Department of Electric, Electronic and Computer

Science of the University of Trieste (Italy) and he teaches

the courses of Fundamentals and Design of Electric

Machines. His field of interest is characterization, aging

and diagnostics of insulation materials and systems by

means of partial discharges.

Figure 13. The picture of the fault of the transformer of Figure 12.

taken into account by using appropriate membership functions

thus giving the users flexible tools to support the evaluation of

the transformer conditions. The validation tests show that the

algorithm is capable to distinguish between good condition and

different types and levels of winding faults. Moreover, the

algorithm seems to be independent from the connection type

adopted to test the transformers and appears less sensitive to the

background noise or small differences. The use of SFRA with

the proposed algorithm constitutes an important step forward to

the setting up of reliable diagnostics of power transformers.

ACKNOWLEDGMENT

The Ministry of Economic Development with the research

Found for the Italian Electrical System under the contract

agreement established with the Ministry Decree of 23 March

2006, is gratefully acknowledged.

REFERENCES

[1]

[2]

K. G. Nilanga B. Abeywickrama, Y.V. Serdyuk and S. Gubanski,

"Exploring Possibilities for Characterization of Power Transformer

Insulation by Frequency Response Analysis", IEEE Trans. Power

Delivery, Vol. 21, pp. 1375-1382, 2006.

M.Wang, A.J. Vandermaar and K.D. Srivastava, “Transformer Winding

Movement Monitoring in Service – Key Factors Affecting FRA

Measurements”, IEEE Electr. Insul. Mag., Vol. 20, No. 5, pp. 5-12, 2004.

Germano Rabach was born in Pirano on 5 May 1942.

He is currently Full Professor at the Department of

Electric, Electronic and Computer Science of the

University of Trieste (Italy). He teaches the courses of

Materials and Electrical Technologies. His field of

interest is characterization, aging and diagnostics of

insulation materials and diagnostics of electrical systems.

Johnny Borghetto was born in Vigevano (PV) on 10

July 1974. He is graduated in Electrical Engineering at

the University of Pavia (Italy) and he is currently

employed in ERSE, where he deals with diagnostics of

electrical components. His research interests include

partial discharge studies on generators, rotating machines

and power transformers in labs and on plants.

Michel de Nigris – (M’90, SM’94) was born in Brussels

(Belgium) in 1959, received the doctoral degree in

electrical engineering from the University of Genoa ,

Italy in 1983. From 1984 to 2005 he worked with CESI

where he has covered several roles of increasing

responsibility before being appointed as Head of the

Laboratory Division. Since 2006 he works in ERSE

(formerly CESI RICERCA) where he is Director of the

T&D Department.

His fields of interest are surge arresters (he is chairman of IEC TC 37), HV

components (he is the Italian representative in Study Committee A3 of

CIGRE): he heads a group of specialists dealing with research projects on the

lifecycle management of electrical components

IEEE Transactions on Dielectrics and Electrical Insulation

Vol. 18, No. 3; June 2011

Renzo Passaglia was born in Piacenza, Italy, in 1948. He

graduated in electrical engineering at the Milan

Polytechnic (Italy). He joined ENEL, Electrical Research

Center, in 1981 where he was mainly engaged in the field

on electrical components, with special reference to power

transformers and electrical rotating machinery. He joined

CESI in January 2000 “Tests and Components”

Business Unit and from 2006 to 2009 he worked in ERSE (formerly CESI

RICERCA) where his main fields of expertise were monitoring and

diagnostics of electrical components. He retired in 2010 and he is presently a

consultant.

909

Giuseppe Rizzi (M’90-SM’95) was born in Milano (MI)

on 1949. He received the doctoral degree in physics from

the University of Milano, Italy in 1974. From 1969 to

2005 he worked with CESI where he has covered several

roles of increasing responsibility. From 2006 to 2009 he

worked in ERSE (formerly CESI RICERCA) where he

was responsible for Asset Management in T&D

Department. He retired in 2010 and he is presently a

consultant. His fields of interest are HV measurements,

diagnostic of HV and MV components (member of

CIGRE WGD1.33)