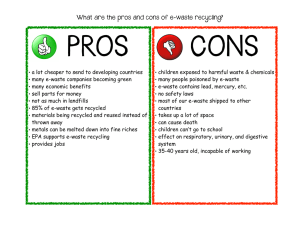

An Analysis of the Supply Chain of E-waste Management in India using the Analytical Hierarchy Process Rahul Baidyaa, Biswajit Debnathb, Sadhan Kumar Ghosha1 a Department of mechanical engineering, Jadavpur University, 188, Raja S.C. Mallick Road, Kolkata - 700032 b Department of Chemical Engineering, Jadavpur University, 188, Raja S.C. Mallick Road, Kolkata - 700032 Abstract: The main purpose of the research is to improve the sustainability of the supply chain of the e-waste management in India considering the supply chain frame work of the e-waste processing plant. Specifically this paper addresses the following three questions- What are the issues in the supply chain considering the environmental criteria, legislative criteria and other stakeholder’s requirements? What is the area needed to be improved considering the WEEE (Waste Electrical and Electronics Equipments) generator’s requirement? Which supply chain characteristics of a WEEE plant are needed to be strengthened? The study was mainly carried out based on a few case studies. Firstly a questionnaire was prepared based on the primary research with which a survey was carried out. Secondly, the answers obtained from the field study were used to analyze using the analytical hierarchy process (AHP), and thirdly, the drawbacks were interpreted from the results, finally, using the results a sustainable supply chain framework is proposed. Though there are quite a good number of researches in the field of sustainable supply chain, scanty work is available considering the requirements of the many stake holders. A very few study is available on the supply chain of the e-waste management for India. This research will be helpful for researchers and the stakeholders of e-waste. Keywords: WEEE, supply chain, AHP, Sustainibility, e-waste management. 1. Introduction Waste Electronic and Electrical Equipments (WEEE) in general termed as ‘E-waste’ is piling up all over the world. Rapid growth with rapid product obsolescence via short innovation cycles is turning e-waste as the fastest growing waste stream. India produces nearly 1.3 million tons of WEEE every year. Mumbai (96,000 tons/ year) tops the list in generating WEEE followed by Delhi-NCR (55,000 tons/ year) and Bangalore (52,000 tons/ year). Chennai, Kolkata, Ahmadabad, Hyderabad and Pune find a place in the ladder, at 47,000, 35,000, 26,000, 25,000 and 19,000 tons per year respectively. Less than 2 per cent of India's total electronic waste (ewaste) gets recycled due to absence of proper infrastructure, legislation and framework [1]. The number of telephone subscribers in India increased from 922.04 million at the end of January, 2014 to 931.95 million at the end of February, 2014, thereby showing a monthly growth of 1.08% [2]. Organization of Economic Cooperation and Development (OECD) defines, any equipment that uses electric power supply as their driving force that has reached its end of life, will fall into the category of WEEE [3, 4]. Basel Action Network [5] and Greenpeace International [6] switched the red alert about the informal processing of e-waste in different parts of Asia and Africa. Well, it is high time to re-evaluate the solutions to the e-waste problem. WEEE or e-waste, e.g., computer, TV, mobiles phones, washing machines, refrigerators and other industrial equipment contain several types of toxic materials, like Lead (Pb), Cadmium (Cd), Chromium (Cr), Mercury (Hg), Polybrominated diphenyl ethers etc which pose danger for environment and human health. It also contain a lot of precious noble metals such as Gold (Au), Silver (Ag), Copper (Cu) etc [7, 8, 9, 10]. In informal sector of WEEE reuse and recycling, toxic emission, disposal of untreated sludge and effluent due to acid cleaning and treatment etc. are very important environmental issues always in the headlines. Effective and efficient e-waste management is a difficult task that requires both environmental and economical issues to be addressed effectively. A robust supply chain is an absolute necessity for collection and segregation of e-waste. Effective and appropriate technology is required for dismantling, shredding, processing/ treatment/ recycling and disposal of e-waste that prevents hazardous materials to infiltrate into the environmental elements. *Corresponding author. Tel.: +91 9830044464. E-mail address: sadhankghosh9@gmail.com View publication stats