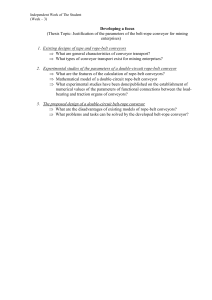

Chapter 1 1. Introduction In today's rapidly evolving industrial landscape, automation plays a pivotal role in enhancing productivity, improving efficiency, and ensuring smooth operations across various sectors. One crucial aspect of automation is the control of conveyor systems, which are extensively used for material handling in industries such as manufacturing, logistics, and assembly lines. The precise control of the direction and speed of conveyors is essential for optimizing workflow, reducing errors, and maximizing throughput. The capstone student project titled "Control of Direction and Speed of Stepper Motor-Controlled Conveyor using PLC and SCADA" aims to develop a comprehensive solution for the automation of conveyor systems. The project integrates two key technologies: Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems. PLCs are widely employed in industrial automation as versatile and robust controllers. They are designed to monitor inputs, execute logic-based decisions, and control outputs based on preprogrammed instructions. PLCs offer real-time control, reliability, and flexibility, making them ideal for managing complex processes. In the context of this project, the PLC will serve as the central control unit for the stepper motor-controlled conveyor system. Stepper motors are commonly used in automation applications due to their precise positioning and control capabilities. They provide rotational motion in discrete steps, enabling accurate movement and positioning of conveyor belts. By integrating a stepper motor with the conveyor system, the project aims to achieve precise control over the direction and speed of the conveyor. Furthermore, the project incorporates SCADA systems to enable monitoring, data acquisition, and visualization of the conveyor system's performance. SCADA systems consist of software applications that collect real-time data from various devices and present it in a user-friendly graphical interface. With the help of SCADA, operators can monitor the conveyor's operational parameters, track production metrics, and respond to any anomalies promptly. The successful implementation of the "Control of Direction and Speed of Stepper MotorControlled Conveyor using PLC and SCADA" project will result in an efficient and intelligent automation solution. It will provide industries with the ability to precisely control the direction and speed of conveyor belts, optimizing material flow, reducing errors, and enhancing productivity. Moreover, the integration of PLCs and SCADA systems will enable real-time monitoring and datadriven decision-making, empowering operators to manage the conveyor system effectively. Throughout this capstone project, the student team will explore various aspects, including hardware integration, programming, system design, and human-machine interface development. They will aim to deliver a functional prototype that showcases the potential of this automation solution and its applicability in industrial settings. By undertaking this project, the students will gain hands-on experience in automation technologies, develop their programming and control skills, and contribute to the advancement of industrial automation practices. Their efforts will not only benefit their academic growth but also offer practical solutions that can be implemented in real-world scenarios. In conclusion, the "Control of Direction and Speed of Stepper Motor-Controlled Conveyor using PLC and SCADA" capstone project embodies the integration of PLCs, stepper motors, and SCADA systems to create an intelligent and efficient conveyor automation solution. This project represents a valuable opportunity for the students to apply their knowledge, acquire new skills, and contribute to the field of industrial automation. 1.2 The project scope can be defined as follows: The scope of the capstone student project "Control of Direction and Speed of Stepper MotorControlled Conveyor using PLC and SCADA" encompasses the development and implementation of an automation solution for controlling the direction and speed of a conveyor system. The project aims to achieve the following key objectives: 1. Hardware Integration: The project will involve integrating a stepper motor with a conveyor system to enable precise control over the direction and speed of the conveyor belt. The students will explore the mechanical aspects of integrating the motor with the existing conveyor setup, ensuring compatibility and optimal performance. 2. Programmable Logic Controller (PLC) Programming: The students will develop the necessary PLC program to interface with the stepper motor and control its movement. The PLC will receive input signals from sensors or operator commands and generate output signals to regulate the motor's operation. The programming will encompass logic-based decision-making, motor control, and coordination with the conveyor system. 3. SCADA System Development: The project will include the design and implementation of a Supervisory Control and Data Acquisition (SCADA) system. The SCADA system will provide a user-friendly interface for monitoring and controlling the conveyor system. It will acquire real-time data from various sensors and present it in graphical form, enabling operators to visualize the conveyor's status, parameters, and performance metrics. 4. Human-Machine Interface (HMI) Design: The students will develop an intuitive HMI for the SCADA system, ensuring ease of use and efficient interaction between operators and the conveyor control system. The HMI will enable operators to monitor the conveyor's operation, adjust its speed and direction, and respond to any alarms or system events. 5. Testing and Validation: The project will involve rigorous testing of the implemented automation solution to ensure its reliability, accuracy, and responsiveness. The students will conduct tests to verify the motor's control over the conveyor's direction and speed, evaluate the HMI's usability, and validate the overall system's performance against defined specifications. 6. Documentation and Presentation: Throughout the project, the students will maintain comprehensive documentation, including design specifications, hardware and software configurations, and programming details. They will also create a final project report and deliver a presentation summarizing their work, methodology, findings, and recommendations. It is important to note that the project scope may be subject to limitations and constraints such as time, budget, and available resources. The students will need to manage these factors effectively to ensure successful completion of the project within the defined scope. By accomplishing the objectives outlined within the project scope, the students will gain valuable hands-on experience in automation technologies, PLC programming, SCADA system development, and human-machine interface design. They will also contribute to the advancement of conveyor control systems, providing a practical solution that can be applied in industrial settings to enhance productivity, efficiency, and operational control.