Salt & Boron Removal in Reverse Osmosis: Modeling & Optimization

advertisement

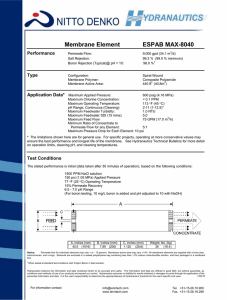

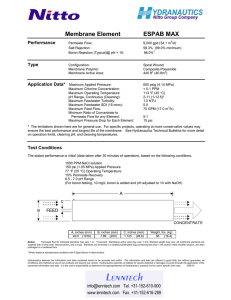

Desalination 562 (2023) 116699 Contents lists available at ScienceDirect Desalination journal homepage: www.elsevier.com/locate/desal Modeling and optimization of salt and boron removal in reverse osmosis system Ridha Ben Mansour Interdisciplinary Research Center for Renewable Energy and Power Systems, Research Institute, King Fahd University of Petroleum & Minerals, Dhahran 31261, Saudi Arabia H I G H L I G H T S • Solution-diffusion and irreversible thermodynamic models for salt and boron transport model are presented. • Salt and boron concentration polarization effect is considered. • Variation of solution properties and transport mechanisms are considered. • Solute rejection sensitivities to operating conditions of feed are discussed • Design Optimization study for low energy consumption and high solute rejection is conducted. A R T I C L E I N F O A B S T R A C T Keywords: Desalination Reverse osmosis Boron Rejection Optimization Energy consumption Seawater reverse osmosis (SWRO) is a mature technology that has significantly evolved over the past few de­ cades. However, boron removal remains a serious challenge. A new RO transport model was developed by combining the irreversible thermodynamic theory and solution-diffusion theory and considering the solute concentration polarization phenomenon. The developed RO model supplemented by the use of variable solution properties and transport parameters was validated with existing data and, it was then applied to identify the main operation parameters and assess their effect on SWRO performance, with the aim of minimizing specific energy consumption and satisfying water quality requirements. The results showed that the solution-diffusion approach, cannot capture the interaction between transported boron and water species. For high pH, applied feed pressure, and flow rate, the convective transport of boron through the seawater membrane is remarkable and its contribution to the overall boron flux can reach over 20 %. The feed operating conditions have signifi­ cantly influenced the quality of the water production and the amount of energy used. The results showed that the optimal SEC increased by approximately 40 %, and the recovery ratio decreased by 11.6 % as the feed flow rate increased from 0.002 to 0.005 m3/s. 1. Introduction The availability of portable water is one of the most severe chal­ lenges in many arid and semi-arid countries, such as those in the Gulf region. The demand for freshwater is continually increasing because of rapid population growth, prolonged droughts in many coastal areas, and the limited availability of underground water. Therefore, seawater desalination is important. Various thermal and membrane-based desa­ lination technologies have evolved to fulfill this growing demand. Traditionally, thermal technologies such as multi-effect distillation (MED) and multi-stage flash (MSF) have dominated the desalination market in Gulf Arab countries. Thermal desalination technologies, on the other hand, require too much energy because of the latent heat of vaporization. Therefore, in the mid-90s, reverse osmosis (RO) began to dominate thermal technologies as the primary desalination technology. It is because of the low specific energy consumption and the major breakthroughs in the operating efficiency of membrane-based systems [1,2]. In desalination processes, RO encounters a variety of challenges; however, fouling is the major problem when it comes to membrane applications since it affects the produced water quality, capital, main­ tenance, and operation costs [3,4]. The capital cost is affected by fouling due to the need for additional pre-treatment units, chemicals, energy, and materials to overcome membrane fouling [5]. Boron removal is an additional challenge for membranes in the reverse osmosis desalination E-mail address: ridha.benmansour@kfupm.edu.sa. https://doi.org/10.1016/j.desal.2023.116699 Received 4 January 2023; Received in revised form 24 April 2023; Accepted 13 May 2023 Available online 24 May 2023 0011-9164/© 2023 Elsevier B.V. All rights reserved. R.B. Mansour Desalination 562 (2023) 116699 Nomenclature Symbols A BR Cbb Cbm Cbp Cbbo Csb Csm Csp Cspo Db DS i Jb Js Jv ka1 kb ks l Lb Lso Ls Lvo Lv N ΔPhyd P Q RR RO S SEC SR T cross-sectional area, m2 boron rejection bulk boron concentration, kg/m3 boron concentration at wall membrane, kg/m3 boron concentration in permeate, kg/m3 total boron concentration in permeate, kg/m3 bulk salt concentration, kg/m3 salt concentration at wall membrane, kg/m3 salt concentration in permeate, kg/m3 total salt concentration in permeate, kg/m3 solute diffusion coefficient of boron, m2/s solute diffusion coefficient of NaCl, m2/s section element boron flux, kg/m2.s salt flux, kg/m2.s water flux, m3/s apparent acid dissociation constant, mol/L mass transfer coefficient of boron, m2/s mass transfer coefficient of NaCl, m2/s membrane length, m boron permeability coefficient, m/s intrinsic solute transport parameter, m/s salt permeability coefficient, m/s intrinsic solvent transport parameter, m/s.Pa Greek symbols γ0 fraction of boric acid γ1 fraction of borate ions εERD energy recovery device efficiency εp pump efficiency π osmotic pressure, kPa σb boron reflection coefficient Subscript b conv diff f s Year MAC (mg/l) 2011 2001 2011 1998 2000 2004 1984 2001 2.4 1.5 4 1 1.4 <1.5 0.5 1 Advisory and targeted values Ashkelon (Israel) Canada Dhekelia (Cyprus) Perth (Australia) State of Florida (USA) State of Minnesota State of New Hampshire (USA) State of Wisconsin (USA) Sydney (Australia) <0.4 2.4 <1 <1 0.63 0.6 0.63 0.9 <1 a boron convective diffusive feed salt weight loss [7,10]. Several countries and international groups such as the World Health Organization (WHO) and European Commission (EC) have set new drinking water standards or advisory values for MAC in drinking water and treated sewage [7,9,10]. Boron standards for drinking water in several regions are listed in Table 1. For agriculture, boron toxicity has shown a negative effect on plant and crop growth when the amount is greater than the maximum acceptable concentration (MAC) of boron. For instance, Eaton [15] found that a boron concentration of 0.5 p.p.m. was optimal for the growth of the sunflower but 1.0 p.p.m. proved definitely toxic. Nidal et al. [16] reported in their comprehensive review paper on boron removal that the maximum acceptable concentration (MAC) of boron in soil water vary from 0.3 to 0.5 mg.L− 1 for extremely sensitive plants (e. g., blackberry, lemon), 0.5 to 2 mg/l for sensitive plants (e.g., avocado, grapefruit, orange, apricot, peach, Garlic, sweet potato, mung beam, red paper) and 2–4 mg.L− 1 for tolerant plants (e.g., turnip, kentucky blue­ grass, tomato sorghum, cotton). The toxic effects of boron on plants have been reviewed [16,17]. The morpho-anatomical, physiological and biochemical effect of boron involves the impairment of root cell divi­ sion, retarded shoot and root growth, inhibition of photosynthesis, decrease in leaf chlorophyll, reduction of the cytosolic pH, etc. [17]. The MAC of boron concentration for irrigation applications recommended by the World Health Organization (WHO) is <1 mg/l [11]. Furthermore, to compensate for the deficiency of renewable water resources in many world regions, such as the Middle East and North Africa (MENA), seawater reverse osmosis is commonly used to provide clean water for human and agricultural applications. A significant portion of desali­ nated water or treated water is contaminated with high levels of boron, which can cause toxic effects on crop yield. Consequently, boron removal from desalinated water is essential for producing portable and irrigation water [8,12]. Having >90 % boron removal is often difficult with a single-pass RO membrane [18]. The most significant methods for managing boron concentration are multi-pass reverse osmosis with membrane and pH adjustment, ion exchange methods using boronselective resins (BSRs), and hybrid processes based on adsorption Table 1 Guidelines for MAC of boron in drinking water adapted from [11–14]. Regulatory values WHO Abu Dhabi Australia European Commission New Zealand Israel Saudi Arabia (SASO)a Singapore water permeability coefficient, m/s.Pa number of modules hydraulic pressure drop along a spiral wound element, Pa pressure, Pa volumetric flow rate, m3/s recovery ratio, % reverse osmosis salinity, ppm specific energy consumption, kWh/m3 salt rejection, % temperature, K Saudi Arabian Standards Organization process in order to achieve freshwater quality requirements [6]. Existing commercial RO desalination membranes have been shown to success­ fully reject most dissolved ions (>99 %). However, the surface chemistry of polyamide membranes is not effective at separating nonpolar and small-sized molecules, such as boric acid (B(OH)3 ), the primary form of boron in aquatic environments (seawater) at low pH. Boron is present in water at a relatively low concentration, typically varying between 4 and 6 mg/l [7] and reaches up to 7 mg/l in the Gulf countries [8]. Exces­ sively high boron levels are disastrous for humans, animals, and the environment [9]. Boron poisoning in humans can cause, for example, nausea, vomiting, diarrhea, dermatitis, lethargy, loss of appetite, and 2 R.B. Mansour Desalination 562 (2023) 116699 High Pressure Pump (HPP) RO module stack Product water Qp,Csp,Cbp, Tf Feed Solution Qf,Csf,Cbf, Tf Booster pump Brine discharge Qb,Csb,Cbb, Tf Energy Recovery Devise (ERD) Fig. 1. Illustration of the RO desalination system. Fig. 2. Schematic of the ith element of the RO membrane. membrane filtration [6,16,19,20]. Integrating these alternatives into many real reverse osmosis pilot plants has reduced boron content to an acceptable value. However, this integration can cause additional oper­ ational issues that may lead to an increase in product water costs [20]. It is believed that improving RO operation will be possible by using boron and fouling mitigation measures that contribute to boosting RO opera­ tion without compromising product quality, or energy consumption. The performance of RO plants is sensitive to the quality of feed water, operating conditions (i.e., permeate recovery, flux, feed tem­ perature, solute concentration polarization, and fouling), and the configuration of the RO membrane [21–24]. Various mechanisms and thermodynamic models of membrane transports and chemical equilib­ rium have been proposed to predict the RO performance and the quality of the produced water [25–28]. RO thermodynamic transport models are classified into three categories according to membrane surface structures: diffusion-based, pore-based, and irreversible thermodynamic models [18,29–31]. Among these models, the solution-diffusion model for salt transport through RO membranes is the most widely accepted for explaining and predicting the performance of RO systems [18]. In this case, the solute (salt) reflection coefficient (σs) is close to unity. Thus, the convective effect on salt is neglected and, thus the solute and solvent species diffuse independently across the membrane. Nevertheless, the convective transport of boron through the seawater membrane is remarkable, and the coupling of the mass transport of boron and water in RO process modeling should be considered; the boron reflection co­ efficient (σB) is usually lower than unity. The thermodynamic solution- diffusion model, commonly used to describe salt and boron transport, cannot accurately predict boron distribution through RO membranes [7,28]. Thus, the irreversible thermodynamic model, which considers both diffusion and convection for mass transport, can successfully simulate boron rejection under different operating conditions [28,32,33]. How­ ever, several studies have made simplified approximations of the irre­ versible thermodynamic model (i.e., a single-species approach, constant properties and transport parameters of seawater, and no concentration polarization effect) [28,32]. Using a single-species approach, the effect of pH on boron rejection was ignored. However, boron management strongly depends on pH, as reported in many experimental works [8,34,35]. Furthermore, at least two major ionic species of boron are present in seawater: boric acid and borate. Their evaluation and distri­ bution are critical for studying the kinetics of the boric acid-borate equilibrium and the borate‑carbonate system [31,36,37]. Dissolved boron can also affect the alkalinity balance, buffering, and physical properties of seawater [16]. Given that the majority of published research articles have focused on the solution-diffusion approach that assumes the solute and solvent species diffuse independently across the membrane and neglect the possible interaction between transported water, salt and boron, and the membranes [38]. However, this study aimed to develop a new RO transport model by combining the irreversible thermodynamic theory and solution-diffusion theory and taking into account the solute con­ centration polarization phenomenon. The developed RO model 3 R.B. Mansour Desalination 562 (2023) 116699 supplemented by the use of variable solution properties and transport parameters will be utilized to optimize RO process performance under a wide range of operating conditions (feed flow rate, applied pressure, temperature, pH, and seawater salinity) and configurations (different numbers of membrane elements). The validated model was then applied to identify and investigate the operation window for different con­ straints on the specific energy consumption and water product quality. Js (i) = ( ) Qs (i) = Ls Csm (i) − Csp (i) A(i) (2) where Jv (i) and Js (i) are the average permeate and salt fluxes, respec­ tively, in the ith element section. Qp(i) and Qs(i) are the volumetric flow rates of water and salt, respectively. The driving pressure (Δpm (i)– Δπm (i) ) in Eq. (1) represents the difference between the net hydraulic and osmotic pressures along the ith element of the RO membrane. 2. Mathematical modeling of RO ΔPd (i) 2 (3) 2.1. System description Δpm(i) = Pf (i) − Pp(i) − A schematic of a typical RO desalination system is shown in Fig. 1. Raw water, with a feed concentration of TDS and a feed flow rate, is pretreated by a filtration process (dual-media filter, ultrafiltration, or microfiltration) to provide suitable RO feed water quality. After pretreatment, the feed water is pressurized by a high-pressure pump to the PF and enters a reverse osmosis membrane, where over 99 % of the dissolved ions (e.g., salt, sodium, and calcium) from the raw water are rejected. Consequently, the feed water is split into two streams: one with a low solute (permeate stream) and the other with a high solute (concentrate stream). In improving the efficiency of the entire RO sys­ tem, the mechanical energy of the concentrate stream at high pressure is transferred to the feed flow through an energy recovery device (ERD). where Pf(i) and Pp (i) are the feed and permeate hydraulic pressures in the ith element section, respectively. Shock and Miquel [37] developed the following equations to calculate the pressure loss (ΔPd (i)) in a spiral wound element: ( 2) λρν ΔPd = (4) 2d λ = 6.23Re− Re = This section presents a mathematical model of the RO process based on a thermodynamic transport model for water, salt, and boron solu­ tions. This model considers the concentration polarization effects of both the salts and boron. Subsequently, the governing system of equa­ tions, composed of the mass transfer, pressure drop, and concentration polarization equations, was solved using the finite difference approach. This approach, based on the discretization of the RO membrane stack into a series of elements (i.e., modules), is used to estimate the profiles of both the state and process variables for each element (Fig. 2). Thus, the main overall performance parameters of the RO system (i.e., recovery, salt and boron removal, and energy consumption) can be adequately deduced. The developed process model for RO was formulated through the adaptation of the following assumptions: (6) Ls(i) = Lsoexp [( )] β1 (Tb (i) − 293 ) 293 (8) The salt concentration on the permeate side (Csp ) of the ith element membrane is calculated as follows: Csp(i) = - The transport parameters for dissolved components in seawater are the same as those for salt (NaCl), except for boron. The dissolved boric and borate components were considered in this study. - The solution-diffusion model applies to the transport of water and salt through a membrane. - The irreversible model is valid for boron transport, and the driving forces are pressure and concentration gradients. - The diffusion coefficient is independent of solute concentration. - The electrostatic interactions between the solute and the membrane are not considered. - The brine concentration varies linearly along the RO element. - The pressure drop on the permeate side is neglected. - The concentration polarization effect for the salt and boron systems is adequately estimated using thin film theory. Qs (i) Js (i) = Qp (i) Jp (i) (9) Based on thin film theory [41], the salt concentration at the mem­ brane wall (Csm ) is related to the bulk salt concentration (Csb ) by the following equation: ( ) Jp (i) Csm(i) = Csp(i) + (Csb(i) − Csp(i) )exp (10) ks where ks is the salt mass transfer coefficient related to the Sherwood and Schmidt numbers (Sh, Sc) by [37]: Sh = ks Ds = 0.065 Re0.875 Sc0.25 dh (11) Sc = μ ρDs (12) where dh is the hydraulic diameter of the spacer-filled flow channel for spiral wound modules as estimated using Shock and Miguel’s correlation [28]. 2.3. Water and salt transport model According to the diffusion model, the following relations define the fluxes of water and salt passage through the ith element section along the feed flow direction: Qp (i) = Lv (i)(Δpm(i)–Δπm(i) ) A(i) ρνd μ where λ and Re are the friction factor and Reynolds number, respec­ tively, calculated based on bulk seawater properties. ( ) In Eq. (2), the term Csm (i)–Csp (i) represents the difference in average salt concentrations at the ith membrane wall and permeate compartment. Lv and Ls are the water and salt permeability constants, respectively, and are calculated using Eqs. (7) and (8) [39,40]. [( ]( ) ) α1 (Tb (i) − 293 ) As Lv (i) = Lvoexp − α2 Pf (i) 1 − (7) 293 Am 2.2. Model development Jv (i) = (5) 0.3 2.4. Boron transport model (1) Based on the irreversible thermodynamic model introduced by Spiegler and Kedem [42], the boron flux is the sum of the diffusive and convective fluxes through the ith element section, which can be 4 R.B. Mansour Desalination 562 (2023) 116699 expressed as follows: Jb (i) = Lb (Cbm(i)–Cbp(i) ) + (1 − σb )Cb Jv (i) Cboric and Cborate are the concentrations of borate acid (B(OH3 )) and borate ions (B(OH)− 4 ), respectively, which can be estimated for a given pH and apparent first acid dissociation constant for boric acid (Ka1 ) which can be derived from the dissociation reaction of boron species in seawater, as defined by Eq. (22). Notably, Ka1 was assumed to be tem­ perature- and salinity-dependent and was calculated from Eq. (24) using the salt concentration at the membrane wall (Csm) [46]. (13) where Lb isthe overall boron permeability constant; σb is the overall boron reflection coefficient, which represents the boron water coupling phenomenon; and Cb is the average boron concentration of feed at the permeate side. In order to investigate the relative importance of the contribution of the mechanisms to the overall boron transfer, two flux terms, boron diffusive flux (Jb,diff ) and boron convective flux (Jb,conv ), were defined. They represent the contributions of diffuse and convective transport, respectively, in the passage of boron through the ith element section. Jb (i) = Jb,diff (i) + Jb,conv (i) Rb,diff (i) = Jb,diff Jb,diff (i) (i) + Jb,conv (i) B(OH)3 + H2 O ⇔ B(OH)− 4 + H + ka1 (i) = (14) − logK a1 (i) = BRt (i) = (19) Qf (i + 1) = Qf (i) − Qp (i) γ1 = Ka1 Cborate = + Ka1 Cboric+borate [H + ] (26) (27) Csf (i + 1) = Qf (i)Csf (i) − Qp (i)Csp (i) Qf (i + 1) (28) Cbf (i + 1) = Qf (i)Cbf (i) − Qp (i)Cbp (i) Qf (i + 1) (29) 2.5. Performance parameters for RO system Salt and boron rejection (SR and BR), water recovery ratio (Rec), and specific energy consumption (SEC) are the most important parameters characterizing the performance of an overall RO system. They are defined as follows: SR = 1 − Cspo = Cspo Csf 0 ∑n ∑n Cspi ΔQpi i=1 Cspi ΔQpi ∑n = i=1 Qpo i=1 Qpi BR = 1 − where Lboric,0 and Lborate,0 are the permeability constants of boric acid (B(OH3 )) and borate ions (B(OH)− 4 ) estimated at T0 = 298 k. a and b are experimentally estimated constants. γ0 and γ1 are the fractions of boric acid and borate ions, respectively, and calculated using the following equations [46]: Cboric [H + ] γ0 = + = [H ] + Ka1 Cboric+borate (25) Furthermore, the permeate mass balance and total solute (salt and boron) balance relationship were also used to calculate the permeate flow rate and salt and boron concentrations for the subsequent element (i + 1): whereas ω and φ are constants experimentally estimated [36]. Eq. (13) implies that boron flux through the ith element section may result from the concentration and pressure gradients defined by water flux (Eq. (1)). In contrast with the irreversible thermodynamic model, the diffusion model does not consider the convective effect on solute transport; salt flux is directly proportional to the concentration gradient (Eq. (2)). Therefore, only two transport parameters (salt permeability and mass transfer coefficients) should be experimentally estimated to predict the performance of the membrane [33,43–45] However, in an irreversible thermodynamic model, three transport parameters, namely, boron permeability (Lb), mass transfer (kb), and reflection coefficients (σb) should be simultaneously evaluated by experimental studies com­ bined with a non-linear optimization method [31,46,47]. Based on the experimental work of Hung and Kim [46], the overall permeability and reflection coefficients (Lb , σ b ) can be expressed as functions of the permeability and reflection parameters of borate ions and boric acid and temperature: σ b = γ0 .σboric,0 + γ1 .σ borate,0 Cbm (i) − Cbp (i) σb .[1 − exp( − Jv (i)(1 − σ b )/Lb ) ] = Cbm (i) [1 − σ b .exp( − Jv (i)(1 − σ b )/Lb ) ] BR(i) Cbb (i) − Cbp (i) σ b .[1 − exp( − Jv (i)(1 − σ b )/Lb ) ] ( ) = = 1 − BR(i) Cbb (i) (1 − σb ) exp Jvk(i) b (17) (18) (24) By combining Eqs. (13), (16), and (25), the observed rejection BR of the boron through the ith element section can be calculated as follows [31,42]: whereas kb is the boron mass transfer coefficient that can be expressed as follows: Lb = γ0 .Lboric,0 exp[(a(Tb − T0 ) ] + γ0 .Lborate,0 exp[(b(Tb − T0 ) ] 2291.9 + 0.01756 Tb (i) − 3.385 − 3.904 Csm 1/3 Tb (23) To solve the problem of boron transport coupled with concentration polarization in reverse osmosis membranes, Spiegler and Kedem [42] substituted the average concentration (Cb ) in Eq. (13) to obtain the following equation for true boron rejection (BRt ): (15) The fraction of diffusion flux, expressed by Eq. (15), is close to unity, and the mass transport of boron and water may be decoupled. Conse­ quently, the irreversible thermodynamic model can be simplified to a solution-diffusion model to study and simulate both salt and boron removal during the reverse osmosis desalination process. Similar to the concentration polarization of salt, Eq. (10), the con­ centration of boron at the membrane wall (Cbm ) is higher than that in the bulk solution (Cbp ) and can be derived from film theory as follows: ( ) Jp (i) Cbm(i) = Cbp(i) + (Cbb(i) − Cbp(i) )exp (16) kb kb = ω.exp[(φ(Tb − T0 ) ] [Cborate ][H + ] [Cboric ] (22) Cbpo Cbf 0 ∑n i=1 Cbpi ΔQpi Cbpo = RR = (20) Qpo Qf 0 SEC = (21) 5 Qpo ( )− 1 Pf Qf εp − Pb Qb εERD Qpo (30) (31) (32) (33) (34) (35) R.B. Mansour Desalination 562 (2023) 116699 Fig. 3. Estimation of model parameters for the following operating conditions: Tf = 15–35 ◦ C, Pf = 4000–8000 kPa, pH = 6–9,Qf = 5.4–12.6 m3/h and Csf = 35,000 ppm. Table 2 Comparison of model predictions with experimental data for a typical RO plant (Tf = 19◦ C, Csf = 42,000 ppm) [49]. Pf (kPa) 6300 6100 5800 5700 5200 Qf (m3/h) 43.5 40.7 33.8 39.5 35.9 Qp (m3/h) Permeate TDS (ppm) Experimental [49] Model Error (%) Experimental [49] Model Error (%) 12.5 11.7 9.8 10.0 7.9 13.2 12.1 10.1 10.4 8.0 5.6 3.4 3.1 4 1.3 191 210 250 215 270 208 219 258 234 289 4.1 1.9 2.4 8.8 7.1 comprises the following steps: - The input data include the feed conditions, feed channel character­ istics, and the number of elements in the RO module integrated into the model. - For each element, the membrane-specific model parameters of water, salt, and boron transport, namely, the mass transfer coefficients and permeability constants, are calculated using Eqs. (7), (8), (9), (17), and (18). - For each element, the water and salt transport and concentration polarization equations (Eqs. (1), (2), and (10)) are solved simulta­ neously to obtain the water and salt fluxes (Jv and Js), which are considered inputs for the boron transport simulation program. Sub­ sequently, Jb,diff and Jb,conv through each elemental section can be estimated (Eqs. (13)–(16)). - The key RO performance parameters for all RO membranes (e.g., water recovery, boron and salt rejection, and specific energy) are estimated from Eqs. (30)–(35). Fig. 4. Boron rejection at different pH levels, based on model predictions and experimental data [46]. 3. Model calibration and validation The model parameters, including the solvent and solute mass transfer coefficients, permeability constants, and boron reflection coefficient, were estimated experimentally [36,46] or determined using the design software FilmTec Reverse Osmosis System Analysis (ROSA 6) [48]. For large variations in operating conditions, the system equations were solved using a non-linear regression method to determine the water and salt transport parameters of the SW30HR380 wound spiral membrane [48]. As shown in Fig. 3, the predictions of the present model agree well with the ROSA design software data. Additional verification was performed using the experimental results from a typical RO plant that used the same modules. Table 2 presented the experimental data [49] and the predicted data at 19 ◦ C for the where Qpo is the total permeate volumetric flow rate. Parameters εp and εERD are the pump and ERD efficiencies, respectively. 2.6. Numerical procedure In this section, we explain how to determine the profiles of RO process variables for any seawater composition, membrane, or feed conditions. The governing Eqs. (1)–(26) are improved using the updated seawater thermophysical properties library, which comprises the effects of salinity, temperature, and pressure on the correlations of the prop­ erties [36]. These equations are non-linear, implicit, and should be solved using iterative methods. The proposed simulation procedure 6 R.B. Mansour Desalination 562 (2023) 116699 spiral wound membrane modules (FilmTec SW30HR-380) and produces ~600 m3/day of fresh water. All membrane module characteristics used in this comparison were presented in Table 5. Table 6 presented the experimental data [50] and the predicted data for the outlet pressure, permeate flow and salt concentration at two values of feed pressure and temperatures. The predictions of our model showed a good agreement with field data reported by Geraldes et al. [50]. The relative errors were found to be 3.18 %–9.81 % and 2.18 %–7.58 %, in terms of permeate water and salt concentration, respectively. Based on these calculations, the membrane parameters of SW30HR-380, Lvo and Ls0 were estimated to be 8.05 10− 12 and 12.33 10− 9 and these values with the membrane module characteristics were used in the subsequent simulation. Table 3 Membrane module characteristics and performance parameters used in actual simulation and experimental work [28]. Parameter RE4040-SR Length of the membrane, (m) Width of the membrane, (m) Feed channel height, (m) Permeate channel height, (m) Number of membrane leaves Membrane area, (m2) Salt transport parameter, (Ls)25 ◦ C, m/s, Water transport parameter, (Lv)25◦ C,800psi, m/s-Pa Reflection coefficient for H3BO3, σboric,0 Reflection coefficient for (B(OH)−4 ), σborate,0 Permeability constant for (H3BO3)25◦ C, Lboric,0 , (m/day) Permeability constant for (B(OH)−4 ) 25◦ C, Lborate,0 , (m/day) 0.88 0.8 8.10− 4 5.10− 4 5 3.52 1.58310− 5.29810− 0.975 0.998 0.0473 0.0076 8 12 4. Results and discussion 4.1. Factors involving in boron rejection permeate flow and concentration at various feed flow rates and feed pressure. An excellent agreement was observed between the model predictions and the experimental data as the maximum variations in permeate flow rate and permeate concentration were <5.6 % and 8.8 %, respectively. For boron rejection, the permeability constants and the reflection coefficients were initially predicted based on Hyung and Kim’s experi­ mental work [46] and used to validate the proposed boron model. The permeability constants at 25◦ C were Lboric,0 =0.0473 m/day and Lborate,0 =0.0076 m/day for boric acid and borate ions, respectively. Fig. 4 presents a comparison between the simulation and experimental results of the boron rejection values against the water flux values for two pH values: 6.2 and 9.5. Other operating conditions were kept constant: Tf = 25 ◦ C; feed salt concentration; Csf = 32,000 ppm; and overall re­ covery ratio, RR = 8 %. An excellent agreement was found between the model prediction and the experimental data for boron rejection because the maximum deviation was <2 %. Additionally, the performance of the presented model has been compared against experimental data reported by Mane et al. [28] for the permeate flow, salt concentration and boron rejection in a multicom­ ponent mixture at various feed flow, feed pressure and pH values and using RE40440-SR spiral wound membrane type. The operating condi­ tions were maintained constant: Tf = 25◦ C; Csf = 32,000 ppm; RR = 8 %. Other parameters related to the characteristics and performance of the RE40440-SR membrane element used in the simulation are provided in Table 3. Table 4 presented the experimental data [28] and the predicted data for the permeate flow and salt rejection. An excellent agreement was observed between the model predictions and the experimental data as the maximum errors in permeate flow rate and salt rejection were <5.4 % and 0.20 %, respectively. Furthermore, Fig. 5 showed the variation of boron rejection with applied pressure (600–800 psi) for different pH values based on model predictions and experimental data [28]. An excellent agreement was observed between the results obtained from the model predictions and the experimental data as the relative error was lower than 2.5 % for all the ranges of pHs and pressures considered. Finally, the model performance has been compared against the field data of a full-scale SWRO train of the desalination plant of Porto Santo Island (Portugal) [50]. This train comprises 12 pressure vessels with 4 Some significant results related to the boron mechanisms obtained by the application of thermodynamic approaches for salt, boron, and water transport coupled with concentration polarization are presented and discussed in this section, with an emphasis on the effects of the main variables (e.g., pH, temperature, salinity pressure, and feed flow rate) on the presence and rejection of boron by the RO membrane. The RO Fig. 5. Boron rejection at various applied pressures and pHs, based on model predictions and experimental data [28] (Tf = 25 ◦ C, Csf = 32,000 ppm, RR = 8 %). Table 5 Main parameters for SW30HR-380 membrane [22,48–50]. Membrane specific parameters Value Cross section area of RO element, A, (m) Hydraulic diameter, (m) Brine channel height of RO element, (m) Spacer thickness, (m) The brine channel length of RO element, lbr, (m) The brine channel width of RO element, wbr, (m) The overall void fraction of the brine channel The specific surface area of the spacer, α, (m− 1) constant for solvent transport, α1 constant for solvent transport, α2, (bar− 1) constant for solute transport, β1 35.3 9.35 10− 0.84 10− 7.11 10− 0.8665 1.34 0.9 11,249 8.6464 0.0149 14.648 4 3 4 Table 4 Comparison of model predictions with experimental data for RE40440-SR membrane element (Tf = 25 ◦ C, Csf = 32,000 ppm) [28]. Pf (psi) 800 750 700 650 600 Qf (m3/day) 50 44.625 41 33.75 28.25 Qp (m3/day) Salt removal (BR) Experimental [28] Model Error (%) Experimental [28] Model Error (%) 4.00 3.57 3.28 2.70 2.26 4.04 3.61 3.15 2.64 2.14 1.0 % 1.1 % 4.1 % 2.2 % 5.4 % 0.997 0.997 0.997 0.996 0.996 0.999 0.998 0.998 0.998 0.997 0.20 0.13 0.10 0.20 0.15 7 % % % % % R.B. Mansour Desalination 562 (2023) 116699 Table 6 Comparison of model predictions with experimental data for SW30HR-380 membrane (Csf = 38,000 ppm) [28]. Tf (◦ C) 19 19 19 18 Pf (Mpa) Qf (L/s) 5.90 5.90 5.90 5.71 22.5 22.9 20.2 19.5 Outlet pressure (Mpa) Qp (L/s) Permeate TDS (ppm) Experimental [50] Model Experimental [50] Model Experimental [50] Model 5.80 5.80 5.80 5.65 5.83 5.83 5.84 5.66 6.96 7.36 6.60 6.01 6.52 6.64 6.39 5.78 287 275 264 278 271 269 284 297 Fig. 6. Distribution of boric acid and borate ions in seawater by the change in pH for N = 6, Pf = 6000 kPa, Qf = 0.0025 m3/s, Csf = 35,000 ppm, Cbf = 5 ppm, and Tf = 25◦ C. Fig. 8. Variation in boron flux by the change in pH for N = 6, Pf = 6000 kPa, Qf = 0.0025 m3/s, Csf = 35,000 ppm, Cbf = 5 ppm, and Tf = 25◦ C. Fig. 9. Variation in boron concentration by the change in pH for N = 6, Pf = 6000 kPa, Qf = 0.0025 m3/s, Csf = 35,000 ppm, Cbf = 5 ppm, and Tf = 25◦ C. Fig. 7. Variation in boron permeability and reflection coefficient by the change in pH N = 6, Pf = 6000 kPa, Qf = 0.0025 m3/s, Csf = 35,000 ppm, Cbf = 5 ppm, and Tf = 25◦ C. pH, and reached a value close to unity at pH > 10 (Fig. 6). This behavior can be explained by the small size of boric acid and negatively charged borate ions, (B(OH)− 4 ). According to the reaction shown in Eq. (22), increasing the applied pH (e.g. decreasing the [H+] in the solution) leads to an enhancement of the dissociation of (B(OH)3 ), which increases the concentration of B(OH)− 4 . The electrostatic repulsive forces that are generated between the negatively charged borate ions and the nega­ tively charged membrane surface can effectively improve boron removal. Figs. 7 and 8 show that when the pH changed, the overall flux of boron (Jb ) and the permeability coefficient (Lb ) followed the same pattern. For pH ranges of 7 and 10, both parameters (Jb and Lb ) signif­ icantly decreased. For instance, Jb decreased from 3.98 × 10− 6 to 0.76 × 10− 6 kg/m2.s as pH increased from 7 to 10. On the other hand, the pH had no effect on Jb and Lb at low pH (below 7) and high pH (>10). Regarding the boron transport mechanism across the RO membrane, process model and commercial membrane specifications were estimated from [19,45–47], as listed in Table 5. 4.1.1. Effect of pH feed solution To investigate the effect of pH variation on boron removal and to assess the relative importance of the contributing mechanisms, the profiles of boron transport parameters and boron diffusive and convective fluxes are presented in Figs. 6–9. The curves are plotted at various values of pH for N = 6, Pf = 6000 kPa, Qf = 0.0025 m3/s, Csf = 35,000 ppm, Cbf = 5 ppm, and Tf = 25 ◦ C. An example of the variation in the distribution of boron species with changes in the solution feed pH is shown in Fig. 6. At low pH values, the fraction of boric acid (γ0) is high, which indicates that the dominant species in the boron system is boric acid (B(OH)3 ). At high pH, borate ions (B(OH)− 4 ) prevail. Overall boron reflection constant (σb ) ranged from 0.982 and 0.998, increased with 8 R.B. Mansour Desalination 562 (2023) 116699 Fig. 10. Distribution of boric acid in seawater against the feed temperature for N = 6, Pf = 6000 kPa, Qf = 0.0025 m3/s, ppm, Cbf = 5 ppm, Tf = 25 ◦ C and pH = 8. Fig. 12. Variation in boron flux against the feed temperature for N = 6, Pf = 6000 kPa, Qf = 0.0025 m3/s, ppm, Cbf = 5 ppm, Tf = 25 ◦ C and pH = 8. Fig. 11. Variation in boron transport parameters against feed temperature for N = 6, Pf = 6000 kPa, Qf = 0.0025 m3/s, ppm, Cbf = 5 ppm, Tf = 25 ◦ C and pH = 8. Fig. 13. Variation in boron concentration and boron rejection against feed temperature for N = 6, Pf = 6000 kPa, Qf = 0.0025 m3/s, ppm, Cbf = 5 ppm, Tf = 25 ◦ C and pH = 8. Fig. 8 shows that the values of diffusion flux (Jb,dif f ) are usually more important than those of convective flux (Jb,conv ), particularly for high pH values. Thus, the fraction of diffusive flux (Rb,diff ) represents >90 % of total boron flux for pH beyond 8.2. This trend results from the fact that boric acid dissociates readily at high pH levels (Fig. 6), which causes an increase in the reflection coefficient (σb), reducing then the convective contribution (Jb,conv ) in boron transport. This suggested that the coupling of water and boron transport might be ignored, and a diffusion-based approach could estimate the boron transport through the membrane with acceptable accuracy. Decreasing the permeability values (Lb ) with increasing pH reduces the boron flux, which involves a reduction in boron concentration on the permeate side (Fig. 9). Consequently, the boron rejection rates (BR and BRt ), estimated using Eqs. (25), (32), were improved at high pH values, confirming the strong correlation between boron rejection and the pH of the feed solution. Experimental data has consistently shown a correlation between pH and boron rejection for different reverse osmosis membranes [46,51–53]. For instance, under natural pH conditions, the BRt is 85.5 %, and it approaches unity at high values of pH beyond 10. An enhancement of boron removal from seawater can be achieved by adjusting feed solution pH. Based on boron concentration polarization (Eq. (16)), the boron permeate flux influences the boron wall concen­ tration (Cbm) and boron rejections (BR and BRt ). The maximum con­ centration polarization level occurs at low pH values, corresponding to a high permeate flux, as shown in Figs. 8 and 9. For seawater conditions and the single-stage SWRO considered in this study, the feed solution pH suggested should be higher than 8.3 to ensure the performance guideline of concentration of boron for irrigation and drinking water purpose (0.5 mg/l boron in permeate). 4.1.2. Effects of feed temperature and salinity In illustrating the effect of feed temperature and salinity on boron transport, the distribution of boric acid (B(OH)− 4 ), borate ions (B(OH)− 4 ), and boron transport parameters (Kb and Lb) have been considered for several cases with a temperature range from 10 to 50◦ C and three feed salinity values (Csf = 25,000 ppm, 35,000 ppm, and 45,000 ppm). Based on the correlation of the apparent acid dissociation constant (Ka1 ), (see Eq. (24)), an increase in feed temperature or salinity results in a decrease Ka1 , which directly enhances (B(OH)− 4 ) content in seawater. As illustrated in Fig. 10, the borate acid fraction (γ0) decreases 9 R.B. Mansour Desalination 562 (2023) 116699 by approximately 17 % as the feed temperature increases from 10 to 50 ◦ C. Theoretically, this behavior may lead to an increase in boron rejection with increasing temperature if we neglect the strong effects of other boron transport parameters (Kb and Lb ). Furthermore, there is a strong correlation between the solution temperature and boron transport parameters, according to Eqs. (17) and (18), respectively. As shown in Fig. 11, an increase in temperature leads to an exponential growth of Kb and Lb. Thus, the coefficients (Lb and kb) are respectively augmented by 13 times and five times as the tempera­ ture is increased from 10 to 50 ◦ C. The effect of boron concentration polarization is reduced as the mass transfer coefficient (kb) increases, resulting in a theoretically high boron rejection by the SWRO mem­ brane. The boron permeability coefficient increased with temperature and had a positive effect on boron transport through the RO membrane, resulting in low boron rejection. As shown in Figs. 12 and 13, the boron flux and boron concentration in the permeate significantly increase as the temperature increases, indicating that the effect of temperature on boron permeability is much stronger than the corresponding decrease in the pKa1 of boric acid and the boron concentration polarization caused by the increase in Kb. These predictions are consistent with those of experimental and analytical studies [28,46,52,53]. Regarding the effect of feed salinity on boron transport mechanisms, the variation in the inlet feed salinity slightly affects the distribution of B(OH)− 4 , B(OH)− 4 , parameters Kb and Lb, as shown in Figs. 10 and 11. Fig. 12 shows a slightly reduced boron flux as the feed salinity increases from 25,000 to 45,000 ppm. These findings can be attributed to the pressure driving force that decreased with the increased feed salinity, resulting in a decrease in water and boron fluxes and, consequently, an increase in boron concentration on the permeate side. This suggested that high boron rejection was obtained at low seawater salinity. For instance, at high seawater temperatures (50◦ C), BR decreased from 69 % to 65 % as Csf increased from 25,000 to 45,000 ppm. As shown in Fig. 13, high values of boron rejection can be achieved in the seawater reverse osmosis process at low salinity and temperatures. These findings are consistent with those of Farhat et al. [15], who observed an increase in boron rejection at low temperatures and salinity for various SWRO membranes. Regarding the boron transport contribution, Fig. 13 shows that increasing the feed temperature had a positive effect on the boron diffusive flux. For instance, the fraction of diffusive flux increases from 74 % to 97 % in the case of low salinity feed (i.e., Csf = 25,000 ppm) as temperature increases from 10 to 50◦ C. Hence, under high feed tem­ perature conditions, the thermodynamic solution-diffusion model can accurately predict boron removal through RO membranes. Nonetheless, in low temperature and low salinity cases, convective boron transport cannot be neglected because its contribution to overall boron flux is relatively high and can be >20 %. For a typical single-pass, reverse osmosis seawater desalination plant, the feed temperature should be <17.5 ◦ C, and the same operating conditions should be used to remove boron up to the target value, which is suitable for irrigation and drinking purposes. However, most of the countries that are at risk of running out of water and rely heavily on seawater desalination technologies are in dry, hot places where the average seawater temperature can be above 20 ◦ C. Fig. 14. Variation in boron flux against the feed pressure for N = 6, Csf = 35,000 ppm, Cbf = 5 ppm, Tf = 25 ◦ C, and pH = 8. Fig. 15. Variation in boron concentration and boron rejection against feed pressure for N = 6, Csf = 35,000 ppm, Cbf = 5 ppm, Tf = 25 ◦ C, and pH = 8. 4.1.3. Effects of feed pressure and flow rate In investigating the effect of applied pressure and flow rate on the boron transport process, the distribution of boric acid and borate ions, boron transport parameters and boron flux have been considered for a range of applied pressure from 4000 to 10,000 kPa and two feed flow rates (Qf = 0.002 m3/s and 0.005 m3/s). Figs. 14 and 15 depict that the feed pressure and flow rate affect boron transport. For the same flow feed rate, increasing the applied feed pressure results in an increased pressure driving force, which causes an increase in the water and boron fluxes. Similarly, increasing the feed flow rate led to an increase in the boron flux. The simulation results also showed that at high flow rates, Fig. 16. Variation in boron concentration and boron rejection for different membrane modules for Pf = 8000 kPa, Qf = 0.0025 m3/s, Csf = 35,000 ppm, Cbf = 5 ppm, Tf = 25 ◦ C, and pH = 8. 10 R.B. Mansour Desalination 562 (2023) 116699 Fig. 17. Variation in main performance parameters for different applied feed pressure and flow rate. Simulation conditions: Csf = 35,000 ppm, Cbf = 5 ppm, Tf = 25 ◦ C, and pH = 8: a) Recovery ratio, b) Salt rejection, c) Boron rejection d) Energy consumption. 11 R.B. Mansour Desalination 562 (2023) 116699 pressures (>8000 kPa), the convective boron transport cannot be neglected because the fraction of diffusive flux is lower than 80 %. This behavior is also shown in Fig. 15, in which the boron concentration on the permeate side and boron rejection are plotted for various applied pressures and feed flow rates. In the lower-pressure region, boron rejection increased mainly because of the increase in the pressure driving force. At high pressures, the boron concentration polarization layer played a vital role in reducing the boron concentration increment on the permeate side. Based on the results of these simulations, a high boron removal rate was obtained at a high feed flow rate and applied pressure. Table 7 Optimization results for imposed feed flow rate. Applied feed flow rate (m3. s− 1) 0.0020 0.0025 0.0030 0.0035 0.0040 0.0045 0.0050 Optimal feed pressure (kPa) RR (%) Average flux (L. m− 2 h− 1) SEC (kWh/ m3) SR (%) BR (%) 4600 4800 4950 5150 5300 5500 5650 35.91 35.82 34.99 34.61 33.67 33.14 32.17 12.21 15.22 17.84 20.59 22.89 25.34 27.34 2.52 2.65 2.80 2.96 3.13 3.32 3.52 99.34 99.47 99.56 99.62 99.66 99.70 99.72 84.60 86.65 87.98 89.00 89.70 90.29 90.70 4.1.4. Effect of the number of modules The effect of the number of RO modules on boron concentration and rejection is displayed in Fig. 16 for the following operating conditions: N = 8, Pf = 8000 kPa, Qf = 0.0025 m3/s, Csf = 35,000 ppm, Cbf = 5 ppm, and Tf = 25 ◦ C. Boron concentration on the permeate side increases substantially along the vessel from the first to the last module. This variation is due to the decrease in the net pressure force along the membrane, leading to an increase in the feed boron concentration and a decrease in the permeate flux, which reduces the boron rejection factors, as presented in Fig. 6. A reduction BRt from 95.57 % at the vessel inlet to 92.89 % at the outlet of the vessel is observed. The last module had the highest permeate boron concentration and lowest boron rejection factor. Despite the increase in the overall permeate flow and recovery ratio, vessels with a high number of elements (i.e., high membrane area) produced higher salt and boron rejection. 4.2. Performance analysis of the RO system The main process variables reflecting the water quality and energy consumption of the SWRO system were the total water recovery rate, specific energy consumption, and rejection ratios. Therefore, studying the influence of the operating conditions (e.g., feed flow rate, feed pressure, seawater temperature, and seawater salinity) on SWRO per­ formance to minimize the specific energy consumption and satisfy water quality standards in terms of the MAC of boron and salt for portable and irrigation water is important. Figs. 17 (a–d) depict the main performance variables for a singlestage SWRO using six membrane modules in series, operating with feed TDS of 35,000 ppm and seawater temperature Tf = 25 ◦ C, as a function of applied pressure and feed flow rate. These results indicate that the recovery rate increased as the applied pressure increased. For a feed flow rate of 0.002 m3/s, for example, the recovery ratio increased from 32 % at low pressure (40 bar) to 69 % at high pressure (100 bar). This increase is explained by the increase in the pressure driving force (i. e., increased applied pressure), which has a strong effect on salt and boron rejection, particularly in the lower-pressure region (Pfeed < 5000 kPa). The effect of solute concentration polarization in the feed brine solution was more pronounced at higher applied pressures, attenuating the effect of the pressure gradient on solute removal. Figs. 17 (b and c) showed nearly constant rejection ratios for applied pressures >6000 kPa. As shown in Figs. 17 (a and c), increasing the feed flow rate results in a low recovery ratio (RR) and increased salt and boron rejection (SR and BR) at the same applied pressure. Fig. 17 (d) shows how the specific energy consumption changes with the applied pressure under typical operating conditions aforementioned. The specific energy consumption behavior is affected by both applied pressure and feed flow rate. Increasing the applied pressure increased the pumping energy and the amount of water produced. Consequently, the specific energy consumption (SEC), corresponding to the total en­ ergy consumption per unit of water production, has an optimum value. Under the previous operating conditions, the optimum value for specific energy was 2.52 kWh/m3 at a recovery ratio of 35.9 % and a feed flow rate of 0.002 m3/s. Optimum SEC varies with the main operating vari­ ables, as shown in Fig. 17 (a) and Table 7. Table 7 presents also the Fig. 18. Variation in main performance parameters for different applied feed temperatures and salt concentration. Simulation conditions: Qf = 0.0025 m3/s, Cbf = 5 ppm, Tf = 25 ◦ C, and pH = 8: a) Recovery ratio and b) Energy consumption. the proportion of diffusive flux decreased as the feed pressure increased. As shown in Fig. 14, for a high feed flow rate (Qf = 0.005 m3/s), the fraction of diffusive flux decreases linearly in the lower-pressure region (Pf < 7000 kPa) owing to an increase in the pressure driving force. At high pressures, the decrease in the diffusive flux across the membrane was low. This trend is because of the possible accumulation of boron on the membrane, which results in an increased concentration of driving force. As the operating pressure increased, the concentration polariza­ tion layers of salt and boron gradually built up on the membrane surface, lowering the permeate water, salt, and boron fluxes. Thus, for high 12 R.B. Mansour Desalination 562 (2023) 116699 Fig. 19. Contours of specific energy and salt and boron concentration for imposed feed flow rate and pressure. Simulation conditions: Cbf = 5 ppm, Tf = 25 ◦ C, and pH = 8. a) Csf = 35,000 ppm, b) Csf = 25,000 ppm. optimal energy consumption and other important operating variables as a function of the applied feed flow rate with an interval of 0.005 m3.s− 1. The results show that optimum SEC and corresponding applied pressure increases as the feed flow rate increases. Moreover, because the recovery ratio is inversely proportional to the applied flow rate, it decreased. As the feed flow rate increased from 0.002 to 0.005 m3/s, the optimal SEC increased by approximately 39.6 %, and the recovery ratio decreased by 11.6 %. In addition, the optimum permeate water flux increased linearly with increased feed flow rate, improving from 12.21 to 27.34 L.m− 2 h− 1 for the same increment of the feed flow rate. According to Eqs. (9) and (13), the permeate salt and boron concentrations decreased as the permeate water flux increased. The increased flow rates caused the salt and boron rejections (SR and BR) to increase from 99.34 % to 99.72 % and 84.60 % to 90.70 %, respectively. These results findings confirm the relationship between salt and boron permeabilities. The boron and salt fluxes increase (mainly due to the increased salt and boron permeabil­ ities) with the recovery decreases. These findings are consistent with those of Taniguichi et al. [33], who determined a correlation between salt and boron permeabilities. As discussed in Section 4.1, high salt and boron rejection rates were achieved at low recovery ratios and high applied feed flow rates. Figs. 18 (a) and (b) show the effect of seawater temperature on the RO system recovery ratio and energy consumption for various feed salts. The mass transfer equations for salt and boron are strongly correlated with salinity and temperature, as described in the previous section. As the temperature increased, the salt and boron flow rates across the membrane increased, reducing solute rejection and negatively affecting the product water quality. For instance, at high seawater temperatures, high levels of salt and boron concentrations on the permeate side can be reached and can harm human health. On the other hand, a high seawater salinity reduces the solute rejection and recovery ratios and increases energy consumption, as shown in Fig. 18. Therefore, RO plants require a lot of energy to operate in seawater with high salinity, such as that near the Gulf countries. Figs. 19 (a) and (b), which show the contours of the specific energy consumption, salt, and boron concentrations for a given feed flow rate and pressure, can be used to determine the operating window for different constraints and optimize the RO process in terms of energy use and water quality. The simulation conditions are: Cbf = 5 ppm, Tf = 25 ◦ C, and pH = 8; a) Csf = 35,000 ppm and b) Csf = 25,000 ppm. Ac­ cording to the following performance guidelines; the specific energy and permeate boron and salinity concentrations must be <3 kWh/m3, 0.5 13 R.B. Mansour Desalination 562 (2023) 116699 mg/l, and 500 ppm, respectively, and the corresponding contour curves must be overlaid to determine the operation window satisfying the guidelines. The colored areas in Figs. 19 (a) and (b) represent the ranges of the operational conditions. For the selected combination of flow rate and pressure, the salinity concentrations were always lower than the target permeate salinity concentration at different feed salinity values. However, the high osmotic pressure caused by an increase in feed salinity had a significant impact on the boron rejection and specific energy. For instance, to satisfy the performance guidelines at Csf = 35,000 ppm, the feed flow rate and applied pressure should be lower than 0.0036 m3/s and 7470 kPa, respectively. Fig. 19 (b) shows a wide range of operating conditions for the same performance guidelines at Csf = 25,000 ppm. Acknowledgments The authors acknowledge the resources provided by the Interdisci­ plinary Research Center for Renewable Energy and Power Systems at the King Fahd University of Petroleum and Minerals through the IRC-REPS project (No. INRE2223). References [1] N. Voutchkov, Desalination Project Cost Estimating and Management, CRC Press, 2018. [2] D. Curto, V. Franzitta, A. Guercio, A review of the water desalination technologies, Appl. Sci. 11 (2021) 1–36, https://doi.org/10.3390/app11020670. [3] S. Jiang, Y. Li, B.P. Ladewig, A review of reverse osmosis membrane fouling and control strategies, Sci. Total Environ. 595 (2017) 567–583, https://doi.org/ 10.1016/j.scitotenv.2017.03.235. [4] W. Guo, H.H. Ngo, J. Li, A mini-review on membrane fouling, Bioresour. Technol. (2012), https://doi.org/10.1016/j.biortech.2012.04.089. [5] E. Alhseinat, R. Sheikholeslami, A completely theoretical approach for assessing fouling propensity along a full-scale reverse osmosis process, Desalination (2012), https://doi.org/10.1016/j.desal.2011.12.014. [6] A. Farhat, F. Ahmad, N. Hilal, H.A. Arafat, Boron removal in new generation reverse osmosis (RO) membranes using two-pass RO without pH adjustment, Desalination 310 (2013) 50–59, https://doi.org/10.1016/j.desal.2012.10.003. [7] K.L. Tu, L.D. Nghiem, A.R. Chivas, Boron removal by reverse osmosis membranes in seawater desalination applications, Sep. Purif. Technol. 75 (2010) 87–101, https://doi.org/10.1016/j.seppur.2010.07.021. [8] D. Escarabajal-Henarejos, D. Parras-Burgos, L. Ávila-Dávila, F.J. CánovasRodríguez, J.M. Molina-Martínez, Study of the influence of temperature on boron concentration estimation in desalinated seawater for agricultural irrigation, Water (Switzerland) 13 (2021) 1–10, https://doi.org/10.3390/w13030322. [9] H. Koseoglu, N. Kabay, M. Yüksel, S. Sarp, Ö. Arar, M. Kitis, Boron removal from seawater using high rejection SWRO membranes - impact of pH, feed concentration, pressure, and cross-flow velocity, Desalination 227 (2008) 253–263, https://doi.org/10.1016/j.desal.2007.06.029. [10] C.D. Hunt, C. Benjamin, Born, Encycloped, Encyclopedia of Food Sciences and Nutrition, Academic Press, 2003. [11] R.W. Herschy, Water quality for drinking: WHO guidelines, Encycl. Earth Sci. Ser. (2012) 876–883, https://doi.org/10.1007/978-1-4020-4410-6_184. [12] A. Ben-Gal, U. Shani, Yield, transpiration and growth of tomatoes under combined excess boron and salinity stress, Plant Soil 2472 (247) (2002) 211–221, https:// doi.org/10.1023/A:1021556808595. [13] Health Canada, Boron in Drinking Water Guideline Technical Document, 2020. [14] M.M. Haque, H.A. Al Attas, M.A. Hassan, Health risk assessment of trace elements in drinking water from Najran City, southwestern Saudi Arabia, Arab. J. Geosci. 9 (2016), https://doi.org/10.1007/s12517-016-2501-z. [15] S.V. Eaton, Effects of boron deficiency and excess on plants, Plant Physiol. 15 (1940) 95–107, https://doi.org/10.1104/pp.15.1.95. [16] N. Hilal, G.J. Kim, C. Somerfield, Boron removal from saline water: a comprehensive review, Desalination 273 (2011) 23–35, https://doi.org/10.1016/j. desal.2010.05.012. [17] M. Landi, T. Margaritopoulou, I.E. Papadakis, F. Araniti, Boron toxicity in higher plants: an update, Planta 250 (2019) 1011–1032, https://doi.org/10.1007/ s00425-019-03220-4. [18] K. Kezia, J. Lee, A.J. Hill, S.E. Kentish, Convective transport of boron through a brackish water reverse osmosis membrane, J. Membr. Sci. (2013), https://doi.org/ 10.1016/j.memsci.2013.05.041. [19] N. Nadav, Boron removal from seawater reverse osmosis permeate utilizing selective ion exchange resin, in: Desalination, Elsevier Science Publishers B.V., 1999, pp. 131–135, https://doi.org/10.1016/S0011-9164(99)00097-1. [20] A. Ruiz-García, F.A. León, A. Ramos-Martín, Different boron rejection behavior in two RO membranes installed in the same full-scale SWRO desalination plant, Desalination 449 (2019) 131–138, https://doi.org/10.1016/j.desal.2018.07.012. [21] A. Abbas, On the performance limitation of reverse osmosis water desalination systems, Int. J. Nucl. Desalin. 2 (2007) 205–218, https://doi.org/10.1504/ IJND.2007.013545. [22] H.J. Oh, T.M. Hwang, S. Lee, A simplified simulation model of RO systems for seawater desalination, Desalination 238 (2009) 128–139, https://doi.org/ 10.1016/j.desal.2008.01.043. [23] J. Carta, J. González, P. Cabrera, Preliminary experimental analysis of a small-scale prototype SWRO desalination plant, designed for continuous adjustment of its energy consumption to the, Appl. Energy 137 (2015) 222–239. http://www.scienc edirect.com/science/article/pii/S0306261914010502. [24] A.S.A.-A. Kwanghee Shin, Seungwon Ihm, Ridha B. Mansour, Ali A. Aithan, Amr M. Mahmoud, Jangyong You, Hwanchul Cho, Hyunsung Choi, A. Mohammed Farooque, New concept to characterize seawater quality for RO plant design and operation, Desalin. Water Treat. 109 (2018) 8–16, https://doi.org/ 10.5004/dwt.2018.22151. [25] J.S. Kim, J. Chen, H.E. Garcia, Modeling, control, and dynamic performance analysis of a reverse osmosis desalination plant integrated within hybrid energy systems, Energy 112 (2016) 52–66, https://doi.org/10.1016/j. energy.2016.05.050. 5. Conclusion A mathematical model of the RO system was developed based on two thermodynamic approaches for salt and boron transport coupled with membrane concentration polarization. The validated model was used to investigate and optimize RO process performance under a wide range of operating conditions. The main conclusions are summarized as follows: • Boron rejection is primarily controlled by diffusion transfer, and a thermodynamic diffusion-based model can be considered for large simulation conditions. Convective boron transport, however, cannot be ignored in some cases (i.e., high pH, applied feed pressure, and flow rate) because its contribution to boron flux can reach 20 %. • pH, applied feed pressure and flow, salinity and pressure had sig­ nificant effects on the quality of the water production and the amount of energy used; therefore, they should all be included. Increasing the feed salinity and flow rate significantly reduced the recovery ratio and increased salt and boron rejection. An increase in recovery ratio of approximately 20 % can be achieved by assuming that seawater salinity can be reduced by 20,000 ppm. • Boron and salt rejection increased when the applied feed pressure increased from 40 to 55 bar. At high pressure (>60 bar), the solute concentration polarization layer is important for reducing the in­ crease in solute concentration on the permeate side, which is caused by an increase in the pressure driving force. • Increasing the applied feed pressure increased the amount of pumping energy and water produced. Consequently, SEC has an optimum value that varies according to the main operating condi­ tions. This optimum value is 2.52 kWh/m3 at a recovery ratio of 35.9 % and feed flow rate of 0.002 m3/s. The optimization results showed that the optimum SEC and corresponding applied pressure increased and the recovery decreased as the feed flow rate increased. The optimal SEC increased by approximately 39.6 %, and the re­ covery ratio decreased by 11.6 % as the feed flow rate increased from 0.002 to 0.005 m3/s. CRediT authorship contribution statement Ridha Ben Mansour: Conceptualization, Methodology, Software, Visualization, Investigation, Writing – review & editing. Declaration of competing interest The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. Data availability No data was used for the research described in the article. 14 R.B. Mansour Desalination 562 (2023) 116699 [26] L. Song, C. Liu, A total salt balance model for concentration polarization in crossflow reverse osmosis channels with shear flow, J. Membr. Sci. 401–402 (2012) 313–322, https://doi.org/10.1016/j.memsci.2012.02.023. [27] M.A. Al-Obaidi, C. Kara-Zaitri, I.M. Mujtaba, Modeling of a spiral-wound reverse osmosis process and parameter estimation, Desalin. Water Treat. 69 (2017) 93–101, https://doi.org/10.5004/dwt.2017.0641. [28] P.P. Mane, P.K. Park, H. Hyung, J.C. Brown, J.H. Kim, Modeling boron rejection in pilot- and full-scale reverse osmosis desalination processes, J. Membr. Sci. 338 (2009) 119–127, https://doi.org/10.1016/j.memsci.2009.04.014. [29] H.K. Lonsdale, U. Merten, R.L. Riley, Transport properties of cellulose acetate osmotic membranes, J. Appl. Polym. Sci. 9 (1965) 1341–1362, https://doi.org/ 10.1002/app.1965.070090413. [30] G. Jonsson, C.E. Boesen, Water and solute transport through cellulose acetate reverse osmosis membranes, Desalination 17 (1975) 145–165, https://doi.org/ 10.1016/S0011-9164(00)84054-0. [31] Z.V.P. Murthy, S.K. Gupta, Estimation of mass transfer coefficient using a combined nonlinear membrane transport and film theory model, Desalination 109 (1997) 39–49, https://doi.org/10.1016/S0011-9164(97)00051-9. [32] O. Nir, O. Lahav, Coupling mass transport and chemical equilibrium models for improving the prediction of SWRO permeate boron concentrations, Desalination 310 (2013) 87–92, https://doi.org/10.1016/j.desal.2012.09.001. [33] M. Taniguchi, M. Kurihara, S. Kimura, Boron reduction performance of reverse osmosis seawater desalination process, J. Membr. Sci. 183 (2001) 259–267, https://doi.org/10.1016/S0376-7388(00)00596-2. [34] S. Agashichev, E. Osman, Low pressure RO for boron elimination: impact of pH on the degree of rejection of boron and monovalent ions, Desalin. Water Treat. 57 (2016) 4701–4707, https://doi.org/10.1080/19443994.2014.995138. [35] M.F. Chillón Arias, L. Valero i Bru, D. Prats Rico, P. Varó Galvañ, Approximate cost of the elimination of boron in desalinated water by reverse osmosis and ion exchange resins, Desalination 273 (2011) 421–427, https://doi.org/10.1016/j. desal.2011.01.072. [36] J. Kim, H. Hyung, M. Wilf, J.-S. Park, J. Brown, Boron rejection by reverse osmosis membranes: national reconnaissance and mechanism study, in: Desalin. Water Purif. Res. Dev. Progr. Rep. No. 127, 2009, p. 140. https://www.usbr.gov/research /AWT/reportpdfs/report127.pdf. [37] G. Schock, A. Miquel, Mass transfer and pressure loss in spiral wound modules, Desalination 64 (1987) 339–352, https://doi.org/10.1016/0011-9164(87)90107X. [38] L. Putić, S. Alnouri, V. Stijepović, J. Stajić-Trošić, A. Grujić, M. Stijepović, A universal transportation model for reverse osmosis systems, Comput. Chem. Eng. 148 (2021), https://doi.org/10.1016/j.compchemeng.2021.107264. [39] S. Lee, J. Kim, C.H. Lee, Analysis of CaSO4 scale formation mechanism in various nanofiltration modules, J. Membr. Sci. 163 (1999) 63–74, https://doi.org/ 10.1016/S0376-7388(99)00156-8. [40] S.A. Avlonitis, M. Pappas, K. Moutesidis, A unified model for the detailed investigation of membrane modules and RO plants performance, Desalination 203 (2007) 218–228, https://doi.org/10.1016/j.desal.2006.04.009. [41] E. Cussler, Diffusion: Mass Transfer in Fluid Systems, 3rd, Cambr ed., University, Cambridge, 1984. [42] K.S. Spiegler, O. Kedem, Thermodynamics of hyperfiltration (reverse osmosis): criteria for efficient membranes, Desalination 1 (1966) 311–326, https://doi.org/ 10.1016/S0011-9164(00)80018-1. [43] C.L. Ritt, T. Stassin, D.M. Davenport, R.M. DuChanois, I. Nulens, Z. Yang, A. BenZvi, N. Segev-Mark, M. Elimelech, C.Y. Tang, G.Z. Ramon, I.F.J. Vankelecom, R. Verbeke, The open membrane database: synthesis–structure–performance relationships of reverse osmosis membranes, J. Membr. Sci. 641 (2022), https:// doi.org/10.1016/j.memsci.2021.119927. [44] X. Chen, C. Boo, N.Y. Yip, Influence of solute molecular diameter on permeabilityselectivity tradeoff of thin-film composite polyamide membranes in aqueous separations, Water Res. 201 (2021) 117311, https://doi.org/10.1016/j. watres.2021.117311. [45] P.M. Biesheuvel, J.E. Dykstra, S. Porada, M. Elimelech, New parametrization method for salt permeability of reverse osmosis desalination membranes, J. Membr. Sci. Lett. 2 (2022) 100010, https://doi.org/10.1016/j. memlet.2021.100010. [46] H. Hyung, J.H. Kim, A mechanistic study on boron rejection by sea water reverse osmosis membranes, J. Membr. Sci. 286 (2006) 269–278, https://doi.org/ 10.1016/j.memsci.2006.09.043. [47] M. Taniguchi, S. Kimura, Estimation of transport parameters of RO membranes for seawater desalination, AIChE J 46 (2000) 1967–1973, https://doi.org/10.1002/ aic.690461009. [48] A guide to Rosa 9.0, Dow Chemical Company, USA, (2016). [49] S.A. Avlonitis, Optimization of the design and operation of seawater RO desalination plants, Sep. Sci. Technol. 40 (2005) 2663–2678, https://doi.org/ 10.1080/01496390500283415. [50] V. Geraldes, N.E. Pereira, M.N. De Pinho, Simulation and optimization of mediumsized seawater reverse osmosis processes with spiral-wound modules, Ind. Eng. Chem. Res. 44 (2005) 1897–1905, https://doi.org/10.1021/ie049357s. [51] K. Rahmawati, N. Ghaffour, C. Aubry, G.L. Amy, Boron removal efficiency from Red Sea water using different SWRO/BWRO membranes, J. Membr. Sci. 423–424 (2012) 522–529, https://doi.org/10.1016/j.memsci.2012.09.004. [52] P.V.X. Hung, S.H. Cho, S.H. Moon, Prediction of boron transport through seawater reverse osmosis membranes using solution-diffusion model, Desalination 247 (2009) 33–44, https://doi.org/10.1016/j.desal.2008.12.010. [53] Y. Al Sunbul, Boron Removal From Seawater by Thin-film Composite Reverse Osmosis Membranes, 2018, pp. 33–48. https://repository.kaust.edu.sa/bitst ream/handle/10754/627887/Yasmeen_Al_Sunbul_Thesis.docxFinal.pdf?sequ ence=1&isAllowed=y. 15