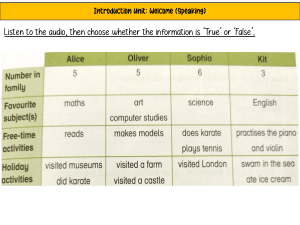

AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR MODEL FA2100 CVR COCKPIT VOICE RECORDER RECORDER PART NUMBERS: 2100−1010−00 2100−1020−02 2100−1025−12 2100−1027−02 2100−1225−24 2100−1010−50 2100−1010−51 2100−1020−50 2100−1020−51 2100−1025−22 2100−1025−24 2100−1220−00 2100−1220−02 2100−1226−02 2100−1227−02 NOTE: For FA2100CVR P/N: 2100−1020−90/−91/−93 Contact L−3AR Product Support 2100−1020−00 2100−1025−02 2100−1026−02 2100−1225−22 2100−1925−22 COMPONENT MAINTENANCE MANUAL WITH ILLUSTRATED PARTS LIST P/N: 165E1689−00 IN ACCORDANCE WITH FAA TSO−C123a FAA TSO−C123b EUROCAE ED−56A EUROCAE ED−112 ARINC CHARACTERISTIC NO. 557 ARINC CHARACTERISTIC NO. 757, 757A VENDOR CODE: 06141 WARNING: THIS TECHNICAL DATA IS CONTROLLED UNDER THE EXPORT ADMINISTRATION REGULATIONS (EAR) ECCN 7E994, AND MAY NOT BE EXPORTED TO A FOREIGN PERSON, EITHER IN THE U.S. OR ABROAD, WITHOUT A LICENSE OR EXCEPTION FROM THE U.S. DEPARTMENT OF COMMERCE. DISTRIBUTION STATEMENT: THIS DOCUMENT CONTAINS L-3 AVIATION RECORDERS PRIVILEGED INFORMATION AND MUST NOT, WITHOUT THE PRIOR WRITTEN CONSENT OF L-3 AVIATION RECORDERS, BE USED OR REPRODUCED IN WHOLE OR IN PART, OR COMMUNICATED TO ANY PERSON EXCEPT AS AUTHORIZED BY L-3 AVIATION RECORDERS. This manual contains date sensitive information. To verify the latest revision level of this manual, visit our document download site at http://www.L-3ar.net. 23−70−04 Rev. 15 Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Model FA2100 CVR Rev. 15 Apr. 14/16 ECopyright 2016 by L-3 Communications. All rights reserved. No part of this manual may be reproduced or utilized in any form or by any means, electronic or mechanical, including photocopying, recording, or by information storage and retrieval system, without permission in writing. Inquiries should be addressed to: L-3 Communications Aviation Recorders Publications Vendor Code: 06141 P. O. Box 3041 Sarasota, Florida 34230 Phone: (941) 371–0811 FAX: (941) 377–5591 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Title Rev. 15 Page ii Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR GENERAL This product and related documentation must be reviewed for familiarization with safety markings and instructions before operation. This instrument was constructed in an ESD (electro–static discharge) protected environment. This is because most of the semiconductor devices used in this instrument are susceptible to damage by static discharge. Depending on the magnitude of the charge, device substrates can be punctured or destroyed by contact or mere proximity of a static charge. The results can cause degradation of device performance, early failure, or immediate destruction. These charges are generated in numerous ways such as simple contact, separation of materials, and normal motions of persons working with static sensitive devices. When handling or servicing equipment containing static sensitive devices, adequate precautions must be taken to prevent device damage or destruction. Only those who are thoroughly familiar with industry accepted techniques for handling static sensitive devices should attempt to service circuitry with these devices. In all instances, measures must be taken to prevent static charge build–up on work surfaces and persons handling the devices. BEFORE APPLYING POWER Verify that the product is set to match the available line voltage and the correct fuse is installed.. Servicing instructions are for use by service–trained personnel only. To avoid dangerous electric shock, do not perform any servicing unless qualified to do so. Adjustments described in the manual are performed with power supplied to the instrument while protective covers are removed. Energy available at many points may, if contacted, result in personal injury. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Title Rev. Rev. 15 14 Page Page iii iii Apr. 14/16 Jul. 13/15 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR THIS PAGE IS INTENTIONALLY LEFT BLANK Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Title Rev. 15 Page iv Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR RECORD OF HIGHLIGHTS Issue Revision Date of Change Comments Revision 15 Apr. 14/16 Page headers updated. Updated unit weights. Added obsolete unit notes. Removed A860, Calibrated Sound Source, and ROC/5. Added PI/2. Removed Auto Test section. Updated Software tables. Revision 14 Jul. 13/15 Updated to include legal reference in footer. Moved legal statements from inside front cover to front cover. Removed 2100−1020−91, 2100−1020−93, and 2100−1020−90. Added 2100−1220−00, 2100−1220−02, 2100−1225−22, 2100−1226−02, 2100−1225−24, 2100−1227−02, and 2100−1925−22. Added 90 Day ULB. Revision 13 Dec. 09/13 Assembly, Dissassembly, and IPL updated to reflect MOD DOT 13. ROSE/ROC/ADLP version numbers updated. Software checksums updated. Model configuration tables added for clarity. Automatic Test Section revised Revision 12 Jul. 03/13 Corrected page number errors and updated the LOEP and Table of Contents. Revision 11 May 21/13 Added automatic testing section. Added p/n 2100−1027−02. Revised IPL. Revision 10 Jun. 15/12 Added configuration Updated Numerical Parts Index to reflect changes in service bulletins. Changed output levels for PI MOD DOT #8 Updated the IPL to reflect p/n 2100−1025−24. Revision 09 Apr. 30/10 Added TSO−C123b. Added Onboard Maintenance System interface and CVR Datalink Input Interface descriptions. Added software FDP checksum list for P/Ns 2100−1025/6−XX. updated ROSE software to 4.X Revision 08 Jul. 30/09 Revised set up figures with Support Equipment in both Test and Special tools sections.. Updated procedures in Section 200 Automatic Testing. added new software for the CVR P/N 2100−1025−22 and 2100−1026−02 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. 23–70–04 Highlights Rev. 15 Page v Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR RECORD OF HIGHLIGHTS (Continued) Issue Revision Date of Change Comments Revision 07 Dec. 01/08 Updated for Revision. Added SB011, SB012, SB013, SB014, SB015, SB 016. Changed the List of Effective Pages to reflect the Revision 07, added divider to Table of Contents. Added reference to ROC/6, updated date for Autotest confirmation. Added Beacon Test note, changed content per SB013, corrected reference to Data Link (ATC) Interface. Added Beacon Test note, added Acquisition Processor configuration, added reference to ROC/6. Updated part numbers, corrected test setup diagram, added RIU power cautions, verified ROC/6 part list. Added configuration. Updated Test Equipment lists, corrected test diagram. Updated Numerical Parts Index to reflect changes in service bulletins. Updated the IPL to reflect p/n 21001026−02. Revision 06 May 01/07 Added new Section 200, Automatic Testing for operational testing of CVR to include the ROC6 /w CATS software. Revised Disassembly & Assembly sections to include p/n’s: 2100−1025−12 & −22, Audio Compressor and Crash Survivable Memory Unit. Revised Description Section for new p/n: 2100−1025−12 & −22, Audio Compressor and Crash Survivable Memory Unit. Updated Test Procedures and Checksum Information for Revisions 5 software and ROC6 /w CATS software. Revised Figure 104 to include all Acquistion Processor configurations. Added new Table 105, CVR fault code corrective actions. Added ROC6 /w Cats software to Special Tools and Test Equipment Section. Updated the IPL to reflect p/n: 2100−1025−12 & −22 CVR, Audio Compressor and Crash Survivable Memory Unit. This includes all Temporary Revisions, including TR6 and Service Bulletins SB008, SB009 and SB010. Revised Description and Test Procedures to include pre and post MOD−DOT #7 units. Revised beacon battery replacement date. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. 23–70–04 Highlights Rev. 15 Page vi Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR RECORD OF HIGHLIGHTS (Continued) Issue Revision Date of Change Comments Revision 05 Oct. 01/04 Revised Disassembly & Assembly sections to include p/n: 2100−1025−02 and associated parts. Added OMS and Data Link information in the Description Section for p/n: 2100−1025−02. Updated Test Procedures and Checksum Information for Revision 4 software. Added Audio Data Link Player Software information to Special Tools and Test Equipment Section. Updated the IPL to reflect p/n: 2100−1025−02 and associated parts, along with new Acquisition Processor Board. Revision 03 Mar. 01/01 Included GACVR changes: All GACVR are DC only w/ RTV. Incorporated 24−month cleaning requirement for Underwater Locator Device. Added new CVR label and change of location. Added 2100−1020−90 version. Revision 04 Jan. 01/03 Revised Disassembly & Assembly sections to include the moisture resistant seals introduced in SB004. Identified an approved ATA300 shipping container in the Assembly section. Added the CICC/2 upgraded cable assembly to the Test & Troubleshooting sections. Updated the IPL to reflect these additions. Added corrections & comments from Boeing Supplier Data Transmittal CD01−0348. Revision 02 June 01/00 Added 2100−1020−93 configuration and S161 control unit information. Revision 01 Feb. 01/00 Includes changes to the IPL Section 1000 to incorporate a new Audio Compressor PWA for FSK capability. Added the FA2100 GACVRs to the manual. Incorporated the Acquisition Processor, p/n: 205E1931−00, turbo PWA changes along with the Revision 01 Software changes. Nov. 01/98 Initial issue of CMM. Includes all sections, Pre ATA100. Includes: FA2100CVR - FSB001. Initial Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. 23–70–04 Highlights Rev. 15 Page vii Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR THIS PAGE IS INTENTIONALLY LEFT BLANK Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. 23–70–04 Highlights Rev. 15 Page viii Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR HIGHLIGHTS REVISION 15 DATED Apr. 14, 2016 Pages which have been added or revised are outlined below, together with the highlights of Revision 15, dated Apr. 14, 2016. Section Page Description Title All Page headers updated. List of FSB’s All Page headers updated. Service Bulletin 023 added. Front Matter All Page headers updated. Introduction All Page headers updated. Removed A860. Description & Operation All Page headers updated. Updated unit weights. Added obsolete notes. Removed A860. Testing & Fault Isolation All Page headers updated. Removed A860. Updated Software tables. Automatic Testing All Page headers updated. Removed section. Disassembly All Page headers updated. ULB information updated. Cleaning All Page headers updated. Check All Page headers updated. Repair All Page headers updated. Assembly All Page headers updated. ULB information updated. Fit and Clear- All ances Page headers updated. Special Tools All and Test Equipment Page headers updated. Removed A860, Calibrated Sound Source, and ROC/5. Added PI/2. Illustrated Parts All List and Schematic Diagrams Page headers updated. Updated ULB information. Added obsolete notes. New CSMU assemblies added. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. 23–70–04 Highlights Rev. 15 Page ix Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR HIGHLIGHTS REVISION 14 DATED Jul. 13, 2015 Pages which have been added or revised are outlined below, together with the highlights of Revision 14, dated Jul. 14, 2015. Section Page Description Title All Updated to include legal reference in footer. Moved legal statements from inside front cover to front cover. Removed 2100−1020−91, 2100−1020−93, and 2100−1020−90. Added 2100−1220−00, 2100−1220−02, 2100−1225−22, 2100−1226−02, 2100−1225−24, 2100−1227−02, and 2100−1925−22. List of FSB’s All Updated to include legal reference in footer. Added Service Bulletins 21 and 22. Front Matter All Updated to include legal reference in footer. Updated to reflect Rev. 14 changes. Introduction All Updated to include legal reference in footer. Added 2100−1220−00, 2100−1220−02, 2100−1225−22, 2100−1226−02, 2100−1225−24, 2100−1227−02, and 2100−1925−22. Added 90 Day ULB. Description & Operation All Updated to include legal reference in footer. Added 2100−1220−00, 2100−1220−02, 2100−1225−22, 2100−1226−02, 2100−1225−24, 2100−1227−02, and 2100−1925−22. Added 90 Day ULB. Testing & Fault Isolation All Updated to include legal reference in footer. Added 2100−1220−00, 2100−1220−02, 2100−1225−22, 2100−1226−02, 2100−1225−24, 2100−1227−02, and 2100−1925−22. Added 90 Day ULB. Automatic Testing All Updated to include legal reference in footer. Disassembly All Updated to include legal reference in footer. Added 90 Day ULB. Cleaning All Updated to include legal reference in footer. Added 90 Day ULB. Check All Updated to include legal reference in footer. Added 90 Day ULB. Repair All Updated to include legal reference in footer. Assembly All Updated to include legal reference in footer. Added 90 Day ULB. Fit and Clear- All ances Updated to include legal reference in footer. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. 23–70–04 Highlights Rev. 15 Page x Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Special Tools All and Test Equipment Updated to include legal reference in footer. Illustrated Parts All List and Schematic Diagrams Updated to include legal reference in footer. Removed 2100−1020−91, 2100−1020−93, and 2100−1020−90. Added 2100−1220−00, 2100−1220−02, 2100−1225−22, 2100−1226−02, 2100−1225−24, 2100−1227−02, and 2100−1925−22. Added 90 Day ULB. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. 23–70–04 Highlights Rev. 15 Page xi Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR HIGHLIGHTS REVISION 13 DATED December 9, 2013 Pages which have been added or revised are outlined below, together with the highlights of Revision 13, dated December 9, 2013. Section Page Description Front Matter LOEP & TOC Changed the List of Effective Pages to reflect Revision 13 changes. Changed the Table of Contents to reflect the Revision 13 changes. Introduction 3,5 Removed ROC/6 reference. Added Datalink reference. Description & Operation 2,4,17,31,36,38 Part number matrix and block diagram updated. ROSE version updated. Model configuration tables added. Testing & Fault 105,142-145,147- ROSE version updated. ADLP added. Software and directory labels Isolation 150 updated. Updated setup diagram. Software checksums updated. Automatic Testing 201-209,211-212, Reformatted section, updated figure labels, removed redundant 220-255,264-269, steps, corrected test sequences, and streamlined procedure. 271-278 Disassembly 304-310,312 Assembly 701,703-704,708- Updated for differences in MOD DOT 6 and MOD DOT 13. 711,716-721 Updated for differences in MOD DOT 6 and MOD DOT 13. Special Tools 902-904,918,928 and Test Equipment Updated software versions and optional speakers. Illustrated 1005-1009,1011Parts List and 1012,1014,1016Schematic 1018,1021-1023 Diagrams Updated for differences in MOD DOT 13. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. 23–70–04 Highlights Rev. 15 Page xii Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR HIGHLIGHTS REVISION 12 DATED July 3, 2013 Pages which have been added or revised are outlined below, together with the highlights of Revision 12, dated July 3, 2013. Section Page Description Front Matter LOEP & TOC Changed the List of Effective Pages to reflect Revision 12 changes. Changed the Table of Contents to reflect the Revision 12 changes. Automatic Test 201−290 Reformatted section to include figure labels and removed redundant steps. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. 23–70–04 Highlights Rev. 15 Page xiii Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR HIGHLIGHTS REVISION 11 DATED May 21, 2013 Pages which have been added or revised are outlined below, together with the highlights of Revision 11, dated May 21, 2013. Section Page Description Title i Added part number 2100−1027−02 (ARINC 757A compliant) to cover page. List of FSB’s xxiii Updated for FSB019 (23−70−04−19) and FSB020 (23−70−04−20) Front Matter LOEP & TOC Changed the List of Effective Pages to reflect Revision 11 changes. Changed the Table of Contents to reflect the Revision 11 changes. Introduction 1 Added part number 2100−1027−02 (ARINC 757A compliant). Description & Operation Section 1, 2, 4, 6, 8, 9, 10, 12, 13−16, 21, 22, 23, 25, 29, 30−34, 35, 36, 43, 48−56, 64, 67 Added part number 2100−1027−02 (ARINC 757A compliant). Added NAND memory to part number matrix. Adds description of PI/2. Added description of acquisition processor 205E2502−34. Removed description of FA2100 CVR p/n: S2100−1020−91 Testing & Fault Isolation Section 101, 102, 140−145, 148, 149, 151, 152 Added notes about ROC/6, ROC/6 and ROC/7 concerning compatibility with CATS 2.0 Added note about return−to−service procedure. Modified Table 105. Added instruction concerning matching part number and check sum. Modified Table 106 and Table 107 Automatic Test 201−288 Added new section describing the automatic testing procedure. Special Tools 903−905, and Test Equip- 931, 932 ment Section Updated Table 901 and Table 902. Revised hardware requirements for ADLP player software. Illustrated Parts 1004, List 1009−1020 Updated the Configuration Matrix to include p/n 2100−1027−02. Updated the drawings in the IPL. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. 23–70–04 Highlights Rev. 15 Page xiv Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR HIGHLIGHTS REVISION 10 DATED Jun. 15, 2012 Pages which have been added or revised are outlined below, together with the highlights of Revision 10, dated Jun. 15, 2012. Section Page Description List of FSB’s n/a Front Matter xix − xxxiv Changed the List of Effective Pages to reflect the Revision 10 changes. Changed the Table of Contents to reflect the Revision 10 changes. Testing 118−120 Updated procedure to accommodate PI MOD DOT #8 Illustrated Parts n/a List and Schematic Diagrams Added 2100−1025−24 configuration Added 742E1619−03 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. 23–70–04 Highlights Rev. 15 Page xv Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR HIGHLIGHTS REVISION 09 DATED Apr. 30, 2010 Pages which have been added or revised are outlined below, together with the highlights of Revision 09, dated Apr. 30, 2010. Section Page Description Title i − ii List of FSB’s n/a Front Matter xix − xxxiv Changed the List of Effective Pages to reflect the Revision 09 changes. Changed the Table of Contents to reflect the Revision 09 changes. Introduction 2, 5, 6 Added Rose 4.0. Updated L−3 Address. Updated shop verication dates. Description & Operation 9, 19 − 21, 45, 54−66 Added note on test tones for P/N 2100−1025/6−02. Added BIT and Fault Detection paragraph. Added TSO C123b. Testing & Fault Isolation 105, 150 Revised P/N for the Variac. Added Table 107 Software FDP checksum. Added Section 9. Onboard Maintenance System interface and Section 10 CVR Datalink Input Interface. Automatic Testing 233 Added Rose 4.0 Disassembly n/a Assembly n/a Updated for Revision 9. Added TSO C123b. Fit and Clear- n/a ances Special Tools n/a and Test Equipment Illustrated Parts 1017 List and Schematic Diagrams Corrected Effective codes for 165B and 165C Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. 23–70–04 Highlights Rev. 15 Page xvi Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR HIGHLIGHTS REVISION 08 DATED Jul. 30, 2009 Pages which have been added or revised are outlined below, together with the highlights of Revision 08, dated Jul. 30, 2009 Section Page Title i − ii List of FSB’s n/a Front Matter xix − xxxiv Introduction n/a Description & Operation n/a Testing & Fault Isolation 143−146, 150 Description Updated for Revision 8. Changed the List of Effective Pages to reflect the Revision 08 changes. Changed the Table of Contents to reflect the Revision 08 changes. Added ROC/6 to note. Revised Figures 105 and 106 for set−up with support equipment. Updated Table 106 with new software P/N’s for the CVR P/N 2100−1025−22 and 2100−1026−02. Added note for the CICC/3 Automatic Testing 201, 203, 207, Added Caution on power input select switch. Revised Figure 201 212, 213, 216, showing the back of the ROC/6. Updated and added to Section 3, the 218, 219, 221 CATS auto test procedures Disassembly Assembly Fit and Clearances Special Tools 902, 918, 919, Revised Table 901 in the ROC/5and ROC/6 Lists. Revised Figures and Test Equip- 921, 926 911 (Sheets 1 and 2) , 913 and 916 for set−up with support equipment ment. Illustrated Parts 1005, 1006, List and Schem- 1010, 1012− atic Diagrams 1014 Corrected stand−offs effective code per Revision 1 of Service Bulletin 15. Change the callouts for the Front Panel Assembly. Added new PWA’s 205E2502−24 and 205E3977−29 for the 2100−1026−02 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. 23–70–04 Highlights Rev. 15 Page xvii Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR HIGHLIGHTS REVISION 07 DATED DECEMBER 01, 2008 Pages which have been added or revised are outlined below, together with the highlights of Revision 07, dated December 01, 2008 Section Page Description Title i − ii Updated for Revision. List of FSB’s 1 Added SB011, SB012, SB013, SB014, SB015, SB 016. Front Matter xix−xxii xxii, xxxvi Changed the List of Effective Pages to reflect the Revision 07, added divider to Table of Contents. Introduction 1, 5, 6 Added p/n: 2100−1026−02. Added reference to ROC/6, updated date for Autotest confirmation. Description & Operation 1−4, 10, 12, 13, 15, 16 19, 20, 22, 23, 27−29, 31−35, 41, 45−47,49−52 Added Beacon Test note, changed content per SB013, corrected reference to Data Link (ATC) Interface. Added RIPs monitoring status and p/n: 2100−1026−02. Removed p/n: 2100−1020−91/93. Testing & Fault Isolation 105−107, 114, 126, 131, 137, 148, 150 Added Beacon Test note, added Acquisition Processor configuration, added reference to ROC/6. Updated Software Checksums. Added p/n: 2100−1026−02. Removed p/n: 2100−1020−91/93 Automatic Testing 201, 203, 205, Updated part numbers, corrected test setup diagram, added RIU 216 power cautions, verified ROC/6 part list. Revised the Auto testing procedure to separate tests using DC, AC or DC and AC power. Disassembly 305, 308, 309 Added new Capacitor bracket configuration and new part. Removed p/n: 2100−1020−91/93. Assembly 705−707, 709, 711 Added new Capacitor bracket configuration and new parts. Removed p/n: 2100−1020−91/93. Fit and Clearances Special Tools 902−904, and Test Equip- 926, 932 ment Illustrated Parts 1004−1012, List and Schem- 1014−1018, atic Diagrams 1020 Removed p/n: 2100−1020−93 in Audio output. 913, Updated Test Equipment lists, corrected test diagram. Added new CVR download Cable p/n: 17TES0078. Updated Numerical Parts Index to reflect changes in service bulletins and added new CVR p/n: 2100−1026−02. Removed p/n: 2100−1020−91/93. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. 23–70–04 Highlights Rev. 15 Page xviii Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR HIGHLIGHTS REVISION 06 DATED May 01, 2007 Pages which have been added or revised are outlined below, together with the highlights of Revision 06, dated May 01/2007. Section Page Description Title i − ii Updated for Revision. Corrected part numbers on title page (editoral correction), FA is part of the model number and not part of the P/N. Added “EUROCAE ED−112”. Revised Export Control Statement IAW CTR 760 Rev. R. List of FSB’s 1 Added SB008, SB009 and SB010. Front Matter xix−xxii xxii−xxxiv Changed the List of Effective Pages to reflect the Revision 06 changes. Changed the Table of Contents to reflect the Revision 06 changes. Introduction 1−4, 6, 7 Added Paragraph 8 “Part Number Formatting”. Added new items to the list of acronyms and abbreviations. Added note: verify CMM information when developing other documentation. Description & Operation 1−4, 6−16,18− 20, 22, 23 27, 29, 31, 32, 35, 38, 44−49 Added “refer to Figure 6, Audio block diagram”. Updated new Audio Compressor and Crash Survivable Memory Unit (CSMU) p/ns. Changed 2100−1025−02 to 2100− 1025−( ) or− XX. Added “EUROCAE ED−112”. Revised text for Per and Post MOD−DOT #7 configurations of P/N 2100−1020−XX. Revised beacon battery replacement date. Testing & Fault Isolation 101−103, 105−107, 110−112, 115−120, 123, 125−132, 139−146, 148−150 Changed 2100−1025−02 to 2100−1025−( ) or− XX. Updated Test Procedures and Checksum Information for Revsions 5 software. Revised testing for Pre and Post MOD−DOT #7 configurations of P/N 2100−1020−XX. Revised Figure 104, Acquisition Processor PWA (AP) Test Point Locations to included all AP configurations. Added new Table 105, CVR fault code corrective actions. Automatic Testing 200−216 Added new Section 200 to the CMM. Operational level testing the CVR using Read-Out Center/6 (ROC/6) Test Station with CVR Automated Test Station (CATS) software. Disassembly 302−309 Updated procedures and drawings to include new Audio Compressor board and Crash Survivable Memory Unit (CSMU) for the FA2100 CVR. Changed 2100−1025−02 to 2100−1025−( ) or− XX. Revised beacon battery replacement date. Cleaning 402, 403 Updated Figure 401 to include new CSMU p/n callouts. Revised beacon battery replacement date. Check 502 Revised beacon battery replacement date. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. 23–70–04 Highlights Rev. 15 Page xix Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR HIGHLIGHTS REVISION 05 DATED OCT. 01, 2004 Pages which have been added or revised are outlined below, together with the highlights of Revision 05, dated Oct. 01/2004. Section Page Description Title 1−2 Updated for Revision. List of FSB’s 1 Added SB006 and SB007 Front Matter xv-xvii xix-xxviii Changed the List of Effective Pages to reflect the Revision 05 changes. Changed the Table of Contents to reflect the Revision 05 changes. Introduction 1 Updated to include p/n: 2100−1025−02. Description & Operation 4, 7−8, 10−16, 18, 22−23, 32−33 Added information for the 2100−1025−02. Updated Figure 3. FA2100 Block Diagram to include OMS and Data Link. Updated Figure 5. FA2100 Audio Monitoring Scheme to include the 2100−1025−02, 2−hour HQ only recorder. Updated Figure 6. FA2100 Recording Schemes to include the 2100−1025−02.Updated Table 1. FA2100 Recording Specifications to include the 2100−1025−02. Added OMS and Data link information. Added Control Unit information on the S161−1390−00. Updated Figure 8. Interwiring Diagram to include OMS and Data LInk pins. Testing & Fault Isolation 101, 105, 112 114−118, 122, 124−127, 141−142 Updated test section/procedure to include p/n: 2100−1025−02, 2−hour HQ only recorder. Updated FA2100 CVR test bench setup requirements and Table 1. Recommeded Standard Test Equipment. Added Data Link Check to Table 102. Operational Test Procedure. Updated Table 103. Test Procedure Data Record Chart to include p/n: 2100−1025−02. Updated Table 105. FA2100 CVR Software Checksums for Revision 4 software. Disassembly 302−305, 307−309 Updated Disassembly procedures and drawings to include p/n: 2100−1025−02 and associated parts. Cleaning 403 Updated Figure 401. to include parts for the 2100−1025−02 CVR. Assembly 702−709, 711−715 Updated Assembly procedures and drawings to include p/n: 2100−1025−02 and associated parts. Fits & Clearances 804−805 Updated Figure 801. FA2100 CVR O&D drawing to include p/n: 2100−1025−02. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. 23–70–04 Highlights Rev. 15 Page xx Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Special Tools and Test Equipment 902, 914, 924−926 Illustrated Parts 1004−1015 List & Schematic Diagrams Updated Software Library Disk information. Modified Figure 910 CVR Menu Structures to include p/n: 2100−1025−02. Added Audio Data Link Player Software information. Updated the Configuration Matrix, Numerical Index, Figure 1., and the IPL to include p/n: 2100−1025−02 and associated parts. Added new Acquistion Processor board for the FA2100 CVR. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. 23–70–04 Highlights Rev. 15 Page xxi Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR HIGHLIGHTS REVISION 04 DATED JAN. 01, 2003 Pages which have been added or revised are outlined below, together with the highlights of Revision 04, dated Feb. 01/2003. Section Page Description Title 1−2 Updated for Revision. List of FSB’s 1 Added SB003, SB004, and SB005 Front Matter 1-4 1-8 Changed the List of Effective Pages to reflect the Revision 04 changes. Changed the Table of Contents to reflect the Revision 04 changes. Introduction 4-5 Added Document Verification Section. Description & Operation 1-6, 8, 11-12, 15-16, 18-20, 22, 24-26, 37 Added S161, S261, S162, S160 & S056 Control Units, Preamplifier, and Microphone information. Identified Benthos as new ULB vendor for ELP−362D beacon. Added channel sensitivity levels and more RSE signal detail. Testing & Fault Isolation 101-103, 105-106, 112, 114, 116 − 123, 136-142. Corrected testing procedural errors. Incorporated CICC/2 information for Uploading Software changes for 2100−1010−( ) and added 2100−1020−90 along with new checksums in Table 105 for SW Rev. 02 Per SB005. Disassembly 302-309 Corrected nomenclature inconsistancies with IPL. Changed removal procedure for Acquisition Processor PWA. Cleaning 402-403 Changed beacon manufacturer information. Check 501-502 Changed beacon manufacturer information. Assembly 701-716 Modified procedure to include installation of the moisture resistant seals for the CSMU and Chassis Cover per SB004 (MOD−DOT#4). Added shipping container information. Fits & Clearances 802 Added torque values for the chassis, Aircraft Interface, Acquisition Processor boards. RSE input impedance value added. Special Tools and Test Equipment 901-904, 917-923 911, Added S161, S261, S162, S160 & S056 Control Units, Preamplifier, and Microphone information. Updated recorder software revisions. Added CICC & CICC/2 cable information. Illustrated Parts 1001, Added abbreviations. Corrected Fig. 1 call-outs. Added moisture reList & 1005-1009, sistant seals and sealing screws for the CSMU and chassis cover. Schematic 1011, 1013-1015 Added new Audio Compressor PWA & shipment kit. Diagrams Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. 23–70–04 Highlights Rev. 15 Page xxii Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR HIGHLIGHTS REVISION 03 DATED MAR. 01, 2001 Pages which have been added or revised are outlined below, together with the highlights of Revision 03, dated Mar. 01/2001. Section Page Description Title 1−2 Updated for Revision. Front Matter LOEP & TOC Changed the List of Effective Pages to reflect the Revision 03 changes. Changed the Table of Contents to reflect the Revision 03 changes. Description & Operation Section 1−5, 13, 19−22, Incorporated new label and updated label position. Updated Part 24 Number Matrix. Corrected ULD cleaning requirements. Incorporated all GACVR’s are DC only. Added −90 version to Figure 3. Updated Aircraft Interface PWA used in GACVRs. Testing & Fault Isolation Section 108, 110, 112, 113, 115−118, 120, 138, 140 Incorporated new label and updated label position. Incorporated all GACVR’s are DC only. Incorporated Software changes for 2100−1010−( ) and added 2100−1020−90 along with new checksums in Table 105. Disassembly Section 302 Corrected ULD cleaning requirements. Cleaning Section 402 Corrected ULD cleaning requirements. Assembly Section 709, 710 Added steps and figure to include the assembly of the −99 version (customer supplied ULD). Fits & Clearances Section 804, 805 Incorporated new label and updated label position. Special Tools and Test Equipment Section 902, 911, 915 Updated recorder software revisions. Incorporated new label and updated label position. Illustrated Parts 1004 − 1014 List & Schematic Diagrams Updated configuration matrix to add that all GACVRs are DC only, and to incluse the−90 configuration. Updated numerical index and part number list to include 2100−1020−90. Incorporated new label and updated label position. Updated item numbers for GACVRs to reflect DC only along with GACVR Aircraft Interface PWA 205E−1763−01. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. 23–70–04 Highlights Rev. 15 Page xxiii Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR HIGHLIGHTS REVISION 02 DATED JUNE 01, 2000 Pages which have been added or revised are outlined below, together with the highlights of Revision 02, dated June 01/2000. Section Page Description Title 1−2 Updated for Revision. Front Matter LOEP, TOC Changed the List of Effective Pages & Table of Contents to reflect the Revision 02 changes. Introduction 4 Updated to reflect multiple configurations for the FA2100. Description & Operation Section 1−6, 8, 12−13, 15, 18−19, 21−22, 24−29, 37 Updated to include −93 configuration. Updated manufacturer information for ULDs. Updated to include S161 Control Unit. Updated interwiring diagrams to differentiate GACVR wiring. Testing & Fault Isolation Section 101−107, 111−113, 115, 122−123, 126, 134, 136−137, 140 Updated to include S161 Control Unit. Updated to include −93 configuration. Updated ULD test procedure and manufacturer information. Disassembly Section 302−303, 306−307 Updated information for ULDs. Updated the beacon removal procedure. Added IPL Tag for 205E1849−04 Audio Compressor PWA. Cleaning Section 402−403 Updated cleaning and manufacturer information for ULD. Check Section 502 Updated manufacturer information for ULDs. Assembly Section 705, 707−708 Added IPL Tag for Audio Compressor PWA. Updated assembly and installation procedure for ULD. Fits & Clearances Section 802 Updated audio output level to reflect −93 configuration. Special Tools and Test Equipment Section 901−903, 906, 910, 915 Updated to include Model S161 Control Unit. Illustrated Parts 1004, 1006, List & 1008 − 1014 Schematic Diagrams Updated configuration matrix to include −93 configuration. Updated numerical index and part number list to include 205E1849−04 Audio Compressor PWA. Updated numerical index and part number list to reflect shift in item numbers for all FA2100 CVR models. Updated numerical index to include ULDs. Updated item numbers for Audio Compressor PWA and ULDs. Updated include correct RTCA / DO−178B level. Updated part number list to reflect FSB002. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. 23–70–04 Highlights Rev. 15 Page xxiv Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR HIGHLIGHTS REVISION 01 DATED FEB. 01, 2000 Pages which have been added or revised are outlined below, together with the highlights of Revision 01, dated Feb. 01/2000. Section Page Description Title 1−2 Updated for the Revision and the Copyright year. List of FSB’s 1 Updated for FSB002 (23−70−04−02). Front Matter LOEP & TOC Changed the List of Effective Pages to reflect Revision 01 changes. Changed the Table of Contents to reflect the Revision 01 changes. Introduction 1 Clarified the cockpit voice and area microphone statement. Description & Operation Section 2−3, 5−13, 16−21, 24, 27, 29, 35, 36, 40 Updated number of CVR configurations. Updated and changed the order of several system component descriptions. Updated CVR recording schemes figure. Added Figure 6 GACVR Fault Circuit for Pin 23. Removed microphone information. Updated Interwiring diagrams. Added GMT and Rotor Speed to ARINC 557/757 Aircraft interface Signals table. Introduced the 205E1849−( ) Audio Compressor boards. Introduced the 205E1931−00 Acquisition Processor board. Testing & Fault Isolation Section 101−140, Added the GACVR Fault Circuitry for Pin 23. Modified testing procedure for GACVRs, p/ns: 2100−1010−51 and 2100−1020−51. Updated the Acquisition Processor test point locations. Added new CVR software upload procedure along with Rose utility software upload procedure. Added Table 105 CVR Software Checksums. Disassembly Section 303−309 Added steps necessary to disassemble the GACVRs, p/ns: 2100−1010−51 & 2100−1020−51. Updated part item numbers. Cleaning Section Page: 403 Updated part item numbers. Assembly Section 701−709 Added 2 new items to the Required Assembly Materials table. Added steps necessary to assemble the GACVRs, p/ns: 2100−1010−51 & 2100−1020−51. Updated part item numbers. Fits & Clearances Section 801−802, 804−806 Updated Physical and Electrical Characteristics. Add CSMU torque requirements. Updated O&D drawing. Special Tools 901− 902, and Test Equip- 907, ment Section 909−910, 912−916 Updated Table 901. Updated S150/CAM test Panel Cable Assembly description and wiring diagram. Added requirements for Acquisition Processor replacement. Updated Portable Interface figure and menu structures. Illustrated Parts 1004−1014 List Update the Configuration Matrix. Updated the Numerical Index. Added the new Audio Compressor PWA for FSK capability. Added the FA2100 GACVRs to the IPL. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. 23–70–04 Highlights Rev. 15 Page xxv Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR THIS PAGE IS INTENTIONALLY LEFT BLANK Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. 23–70–04 Highlights Rev. 15 Page xxvi Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR RECORD OF REVISIONS REV. INSERTION NO. DATE BY 15 Apr. 14/16 JG 14 Jul. 13/15 JG 13 Dec. 09/13 JG 12 Jul. 03/13 JG 11 May 21/13 DN 10 Jun. 15/12 JM 09 Apr. 30/10 GM 08 Jul. 30/09 GM 07 Dec. 01/08 GM 06 May 01/07 GM 05 Oct. 01/04 GW 04 Jan. 01/03 JG 03 Mar. 01/01 GW 02 Jun. 01/00 JG 01 Feb. 01/00 GW REV. NO. INSERTION DATE BY REV. NO Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. INSERTION DATE BY 23–70–04 Record of Revisions Rev. 15 Page xxvii Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR THIS PAGE IS INTENTIONALLY LEFT BLANK Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Record of Revisions Rev. 15 Page xxviii Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR SERVICE BULLETIN LIST SERVICE BULLETIN DATE EFFECTIVITY DESCRIPTION FA2100 CVR FSB001 23−70−04−01 Sep. 08/98 P/N: 2100-1010-00 Modification of Aircraft Interface PWA, P/N: 2100-1020-00 p/n: 205E1593-00 to prevent erroneous test tone activation due excessive noise environment. MOD-DOT #1 FA2100 CVR FSB002 23−70−04−02 Apr. 30/00 FA2100 CVR FSB003 23−70−04−03 Aug. 15/01 P/N: 2100-1020-02 Modified Audio Compressor PWA, p/n: P/N: 2100-1020-98 205E1849−03 to ensure compatibility with FA2100 CVR FSB004 Rev. 01 23−70−04−04 Sep. 15/01 P/N: 2100-1010-( ) Introduce Moisture Resistant Seals & self− P/N: 2100-1020-( ) sealing Chassis Cover & CSMU screws to protect against excessive moisture intrusion. Sep. 30/02 MOD-DOT #4. FA2100 CVR FSB005 23−70−04−05 Apr. 16/02 FA2100 CVR FSB006 23−70−04−06 Sep. 22/04 P/N: 2100-1020-( ) P/N: 2100-1020-( ) FA2100 CVR FSB007 23−70−04−07 Sep. 09/04 P/N: 2100-1010-( ) This modification upgrades the recorder unit P/N: 2100-1020-( ) software to Software Revision 04. FA2100 CVR FSB008 23−70−04−08 Dec. 15/05 P/N: 2100-1010-( ) Introduction of Turbo Acquisition Processor P/N: 2100-1020-( ) PWA, p/n: 205E1931−00, and the reworked 205E1591−01, and Software Revision 01. MOD-DOT #2 ARINC−429 GMT on Boeing 747−400s. MOD-DOT #3 P/N: 2100-1010-00 Corrects Software Download problem with 2100-1010-50/−51 30−min. recorders. Software Revision 02. This modification includes replacing the existing Acquisition Processor PWAs, p/n: 205E1591−00 or 205E1931−00 with a replacement Acquisition Processor PWA, p/n: 205E2502−10 or 205E2502−11. MOD−DOT #5. P/N: 2100-1020-( ) This modification includes replacing the existP/N: 2100-1020-( ) ing Crash Survivable Memory Unit (CMSU), p/n: 253E1568−00, 253E1568−01, 253E1568−07, or 253E1568−07 with a replacement Crash Survivable Memory Unit (CMSU), p/n: 253E1568−38, 253E1568−39, 253E1568−40 or 253E1568−41. MOD−DOT #6. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Service Bulletin Rev. 15 Page xxix Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR SERVICE BULLETIN LIST FA2100 CVR FSB009 23−70−04−09 Dec. 15/05 P/N: 2100-1020-( ) P/N: 2100-1020-( ) This modification includes replacing the existing Audio Compressor PWA, p/n: 205E1596−00, 205E1849−00, 205E1849−10, 205E1849−02, 205E1849−03, 205E1849−13, 205E1849−04 or 205E1849−14 with a replacement Audio Compressor PWA, p/n: 205E3977−10, 205E3977−12, 205E3977−13 or 205E3977−14 MOD−DOT #7. FA2100 CVR FSB010 23−70−04−10 Dec. 15/05 P/N: 2100-1020-( ) P/N: 2100-1020-( ) This modification upgrades the recorder unit software to Software Revision 05. FA2100 CVR FSB011 23−70−04−11 Sep. 20/07 P/N: 2100-1025−02 This modification upgrades the recorder unit software to Software Revision 03. FA2100 CVR FSB012 23−70−04−12 Oct. 17/07 Factory modification to track internal production processes for new recorders MOD−DOT #8 FA2100 CVR FSB013 23−70−04−13 Dec. 14/07 P/N: 2100-1010−5() P/N: 2100-1020−5() Introducing a replacement Acquisition Processor PWA, p/n 205E2502−52, with a coating that protects conductive surfaces from condensation. MOD−DOT #9 FA2100 CVR FSB014 23−70−04−14 Nov.. 26/07 P/N: 2100-1025−02 This modification upgrades the recorder unit software to Software Revision 04. FA2100 CVR FSB015 23−70−04−15 Sep. 01/08 P/N: P/N: P/N: P/N: P/N: P/N: P/N: P/N: P/N: P/N: P/N: P/N: Replacing the previous Aircraft Interface (AI) PWA, Acquisition Processor (AP) PWA, Audio Compressor PWA, and AP to AI W001 ribbon cables with the new Aircraft Interface PWA, and AP to AI W001 ribbon cables MOD−DOT #10 FA2100 CVR FSB016 23−70−04−16 Sep. 04/08 P/N: 2100−1010−( ) P/N: 2100−102X−( ) P/N: 2100-1010-( ) P/N: 2100-1020-( ) P/N: 2100-1025-( ) 2100−1010−00 2100−1010−50 2100−1010−51 2100−1020−00 2100−1020−02 2100−1020−50 2100−1020−51 2100−1020−90 2100−1020−91 2100−1020−93 2100−1020−98 2100−1020−99 Installation of the Capacitor Support Bracket MOD−DOT #11 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Service Bulletin Rev. 15 Page xxx Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR SERVICE BULLETIN LIST FA2100 CVR FSB017 23−70−04−17 Nov. 09/10 P/N: 2100−1010−( ) P/N: 2100−102X−( ) Introduction of Improved Storage Capacitor MOD−DOT #13 FA2100 CVR FSB018 23−70−04−18 Jan. 14/11 P/N: P/N: P/N: P/N: P/N: P/N: P/N: P/N: P/N: P/N: Replacement of Non−Conforming Hardware MOD−DOT N/A FA2100 CVR FSB019 23−70−04−19 Feb. 13/13 NAND Memory change NAND Memory change Introduction of New Crash Survivable Memory Unit (CSMU) MOD−DOT 14 FA2100 CVR FSB020 23−70−04−020 Jan. 10/13 Released Intro of SW Rev 06 Introduction Software Revision 06 FA2100 CVR FSB021 23−70−04−021 Jan. 22/14 All P/Ns Introduction Software Revision (Various) FA2100 CVR FSB022 23−70−04−022 Jul. 01/15 Introduction of the new 90−Day Beacon MOD−DOT 15 FA2100 CVR FSB023 23−70−04−023 Mar. 22/16 P/N: 2100−1020−00 2100−1020−02 2100−1020−50 2100−1020−51 2100−1020−90 2100−1020−93 2100−1020−98 2100−1020−99 2100−1025−22 2100−1220−00 2100−1220−02 2100−1225−22 2100−1225−24 2100−1925−22 2100−1010−00 2100−1010−51 2100−1020−00 2100−1020−02 2100−1020−51 2100−1025−02 2100−1025−12 2100−1025−22 2100−1026−02 2100−2043−01 All P/Ns Introduction Software Revision (Various) New CSMU Part Number Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Service Bulletin Rev. 15 Page xxxi Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR THIS PAGE IS INTENTIONALLY LEFT BLANK Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Service Bulletin Rev. 15 Page xxxii Apr. 14/16 AVIATION RECORDERS L–3 COMMUNICATIONS, AVIATION RECORDERS FIELD SERVICE BULLETIN / SERVICE INFORMATION LETTER EXPORT CONTROL STATEMENT The technical information about recorder products/software are being exported from the United States in accordance with the Export Administration Regulations ECCN 9E991, No License Required. Diversion contrary to U.S. law is prohibited. In accordance with U.S. Law (31 CFR Part 746, and Supplement No.1 to Part 774, and CFR Part 550) resale/re–export or transfer to the countries identified therein is prohibited without the prior written consent of the U.S. Department of Commerce. HTSUS, Sch. B: 4901.10.0040, 4901.10.0000 LIMITED RIGHTS LEGEND Notice to persons receiving this document and/or data: This document and/or data contains information in which L–3 Communications Corporation, Aviation Recorders Division, has a protectable interest and is subject to change without notice. The use, duplication, and/or disclosure, by persons receiving this document and/or data may be subject to restrictions. No part of this document and/or data contained herein may be reproduced and/ or used in any form to design, manufacture, and/or test, anything without written permission from L–3 Communications Corporation, Aviation Recorders Division. The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS 100 Cattlemen Rd., Sarasota, FL 34232 Telephone: 941-371-0811 Facsimile: 941-377-5591 SERVICE BULLETIN MODEL FA2100 COCKPIT VOICE AND DATA RECORDER INTRODUCTION OF SOFTWARE REVISION 07 & 08 Date: May 02, 2013 I. BULLETIN NO. FA2100CVDR SB017 R1 PLANNING INFORMATION A. Effectivity L−3 Communications, Aviation Recorders, Model FA2100 Cockpit Voice & Data Recorder, Part Numbers: 2100−3083−00, 2100−3083−10, and 2100−3083−50. All affected FA2100CVDR part numbers manufactured after November 2012 will have this modification incorporated. The table below identifies the beginning serial numbers for this production cut-in. Table 1. Serial Number Effectivity Beginning Serial Number Part Number New Software Version Audio Compressor PWA P/N 2100−3083−00 000840345 and greater 840E2261−07 205E3977−19 2100−3083−10 000849079 and greater 840E3565−08 205E3977−19 2100−3083−50 000846290 and greater 840E3555−07 205E3977−25 B. Concurrent Requirements None. C. Reason A product improvement has been made to the CVDR which enhances the software. The improvement minimizes the effects of external cockpit noise through the recorder’s audio input, providing a reliable Push−to−Test function. This is a Product Improvement that is recommended for existing recorders in the field. D. Description This modification upgrades the recorder unit software and Audio Compressor PWA per Table 1. 23‐70‐07-017 R1 Page 1 of 11 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS 100 Cattlemen Rd., Sarasota, FL 24232 Telephone: 941-371-0811 Facsimile: 941-377-5591 SERVICE BULLETIN FA2100CVDR E. BULLETIN NO. FA2100CVDR SB017 R1 Compliance This is a recommended modification for units in the field and may be incorporated the next time the recorder is in the shop. F. Approval This service bulletin contains no modification information that revises the approved configuration and therefore does not require governmental or other regulatory agency approval. Operators are not required to apply for modification approval for this change as it does not affect the form, fit, or function of the top level LRU, nor the FA2100CVDR TSO. G. Manpower 3.0 hours with testing. H. Weight and Balance Not affected. I. Electrical Load Data Not changed. J. Software Accomplishment Summary Model FA2100CVR Document No: 818−E1436−20, Revision: K K. Reference L−3AR Notifications of Change: NOC #15224 L−3AR Engineering Change Orders: ECO #15323 L. Other Publications Affected Model FA2100 Cockpit Voice and Flight Data Recorder Component Maintenance Manual, (23–70–07), P/N 165E1690−00. 23‐70‐07-017 R1 Page 2 of 11 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS 100 Cattlemen Rd., Sarasota, FL 24232 Telephone: 941-371-0811 Facsimile: 941-377-5591 SERVICE BULLETIN FA2100CVDR II. BULLETIN NO. FA2100CVDR SB017 R1 MATERIAL INFORMATION A. Material Price and Availability This modification can be completed in one of the following ways: 1) An L-3AR Product Support Engineer can provide on−site support; or 2) The FA2100CVDR may be shipped to the L-3AR repair station; or 3) In the field by Operators or Authorized Repair Facilities that have the necessary Model FA2100CVDR test equipment and factory training. For the 2100−3083−00/−10, the current 205E3997−17 Audio Compression Circuit Board must be sent to the Factory Repair Station for exchange. Customers will be sent P/N 205E3997−19, ready for installation into the CVDR. Customers must specify their request for the new part number on the Repair/ Exchange order. For the 2100−3083−50, the current 205E3997−22 Audio Compression Circuit Board must be sent to the Factory Repair Station for exchange. Customers will be sent P/N 205E3997−25, ready for installation into the CVDR. Customers must specify their request for the new part number on the Repair/Exchange order. The Software Revision is ordered through L-3AR Sales; see Table 2 below for specific part numbers. One Software CD may be utilized on multiple CVDRs with the same part number. The Software CD part number must match the software part number located on the CVDR name label. Software Revision 07 and 08 available from L-3AR Sales: L-3 Communications Aviation Recorders P.O. Box 3041 Sarasota, FL 34230–3041 USA Telephone: (941) 371–0811 Fax: (941) 377–5591 SITA: SRQLFCR 23‐70‐07-017 R1 Page 3 of 11 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS 100 Cattlemen Rd., Sarasota, FL 24232 Telephone: 941-371-0811 Facsimile: 941-377-5591 SERVICE BULLETIN FA2100CVDR BULLETIN NO. FA2100CVDR SB017 R1 Table 2. Material Information/Pricing List Keyword Quantity Part Number Price U.S.D. Delivery 2100-3083−00 Recorder Software 1 ea. 840E2261−07 250 30 Days 2100-3083−10 Recorder Software 1 ea. 840E3565−08 250 30 Days 2100-3083−50 Recorder Software 1 ea. 840E3555−07 250 30 Days CICC Loader Utility Software Ver. 3.0 1 ea. 883E1893-12 No Charge 30 Days CICC Interface Utility Software Ver. 3.7 1 ea. 883E1827-18 No Charge 30 Days For 2100-3083-00/-10, Audio Com­ pression Circuit Board 1 ea. 205E3977-19 1,746 New 90 Days For 2100-3083-00/-10, Audio Com­ pression Circuit Board 1 ea. 205E3977-19 1,222 Exchange 30 Days For 2100-3083-50, Audio Compres­ sion Circuit Board 1 ea. 205E3977-25 1,746 New 90 Days For 2100-3083-50, Audio Compres­ sion Circuit Board 1 ea. 205E3977-25 1,222 Exchange 30 Days B. Tooling For those ROC/6 and ROC/7 test stations operating Microsoft XP and with the internal 17TES0046 RECORDER INTERFACE ADAPTER circuit board, L−3AR recommends an update to the Recorder Interface. ROC/6 and ROC/7 users should remove the 17TES0046 circuit board, and obtain the 17TES0076 USB RECORDER INTERFACE. See the illustration in Figure 1 for more detail. ROSE software version 4.0 (or higher) is required for all applications of the 17TES0076 USB RECORDER INTERFACE. The 17TES0057 CVDR RECORDER INTERFACE CABLE connects between the CVDR and the 17TES0076 USB RECORDER INTERFACE, and is included with the 17TES0400 ROC/6 or the 17TES0700 ROC/7 test station. 23‐70‐07-017 R1 Page 4 of 11 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS 100 Cattlemen Rd., Sarasota, FL 24232 Telephone: 941-371-0811 Facsimile: 941-377-5591 SERVICE BULLETIN FA2100CVDR BULLETIN NO. FA2100CVDR SB017 R1 Table 3. Required Tooling and Availability Keyword Quantity Part Number Price U.S.D. Delivery Read Out Center 7 (ROC/7) 1 ea. 17TES0700 48,000 90 Days Read Out Center 6 (ROC/6) 1 ea. 17TES0400 N/A 90 Days CVDR Recorder Interface (RI) Cable Assembly 1 ea. 17TES0057 2,243 90 Days USB Recorder Interface 1 ea. 17TES0076 2,060 90 Days 23‐70‐07-017 R1 Page 5 of 11 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS 100 Cattlemen Rd., Sarasota, FL 24232 Telephone: 941-371-0811 Facsimile: 941-377-5591 SERVICE BULLETIN FA2100CVDR BULLETIN NO. FA2100CVDR SB017 R1 Power Input Select AC INPUT CICC LOADER SOFTWARE (CDROM) CICC INTERFACE SOFTWARE (CDROM) TO ENHANCED PARALLEL PORT (EPP) RECORDER USB FDAU SIMULATOR (RUFS) (RI) ADAPTER 17TES0076 FA2100CVDR RECORDER INTERFACE (RI) CABLE ASSY. 17TES0057 RECORDER SOFTWARE (CDROM) READ-OUT CENTER /6 or /7 17TES0400 or 17TES0700 FA2100 COMPUTER INTERFACE COMMUNICATIONS CABLE CICC/2 17TES0070 and 17TES0072 DC INPUT CVDR The 17TES0058 cable assembly must only be attached during an upload process and FA2100 SOFTWARE UPLOAD not used when downloading data or CABLE ASSEMBLY 17TES0058 getting recorder status. Typical Bench Setup For FA2100CVDR Recorder and ROC/6 and ROC/7 Figure 1. 23‐70‐07-017 R1 Page 6 of 11 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS 100 Cattlemen Rd., Sarasota, FL 24232 Telephone: 941-371-0811 Facsimile: 941-377-5591 SERVICE BULLETIN FA2100CVDR BULLETIN NO. FA2100CVDR SB017 R1 III. ACCOMPLISHMENT INSTRUCTIONS CAUTION: A. ELECTROSTATIC DISCHARGE (ESD) WARNING: Since the FA2100CVDR contains electrostatic sensitive devices, it must be modified at a workstation equipped for such devices. Before handling printed wiring assemblies, ensure that proper personal ESD grounding techniques are used. Installing CICC Loader and CICC Interface Utility Programs into the ROC/6 or ROC/7. The CICC Loader and CICC Interface utility executable programs are needed to upload the recorder software and to verify that the upload process has been achieved without any errors. To load these programs onto the ROC perform the following steps: (1) Turn ON the power to the ROC. (2) Insert the CICC Loader CDROM into the ROC. (3) At the Windows desktop, shut down the Recorder Interface (RI) by right clicking on the RI Icon in the Windows System Tray at the bottom right of the screen. Select “shutdown.” (4) To install the CICC Loader from the Windows Start Menu, use the Browse button to locate the setup.exe file on the CDROM and click the OK button. (5) Follow the instructions on the Install Wizard and accept all defaults. The Install Wizard will create a folder located at c:\Program Files\L-3 Com\CICC Loader. Left click and hold the CICC Loader (CICCLdr) icon and drag it on to the desktop to create a short-cut. (6) Insert the CICC Interface CDROM. Use the Browse button to locate the setup.exe file on the CDROM and click the OK button. (7) Follow the instructions on the Install Wizard and accept all defaults. The Install Wizard will create a folder located at c:\Program Files\L-3 Com\CICC Interface. Left click and hold the CICC Interface (CICCIfc) Icon and drag it on to the desktop to create a short-cut. 23‐70‐07-017 R1 Page 7 of 11 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS 100 Cattlemen Rd., Sarasota, FL 24232 Telephone: 941-371-0811 Facsimile: 941-377-5591 SERVICE BULLETIN FA2100CVDR B. BULLETIN NO. FA2100CVDR SB017 R1 FA2100 Software Upload Procedure (1) Connect the J1A rear connector of the FA2100CVDR to the ROC/6 or ROC/7 using the Recorder Interface (RI) Cable Assy, P/N 17TES0057. (2) Connect either 115 Vac/400 Hz, or +28 Vdc to the pig−tail connections of the Recorder Interface (RI) Cable Assy. (Do Not connect both power input types at the same time). (3) Connect the Computer Interface Communications Cable/2 (CICC/2), P/N17TES0070 and 17TES0072, to the EPP port of the ROC/6 or ROC/7. (4) Connect the FA2100 Software Upload Cable Assembly, P/N 17TES0058, to the FA2100 Recorder front panel GSE connector and the opposite end to the Computer Interface Communications Cable/2 (CICC/2) Interface Cable P/N: 17TES0072. (5) Apply power to the FA2100CVDR Recorder under test. (6) Turn ON the power to the ROC. (7) Shut down the Recorder Interface (RI) by right clicking on the RI Icon in the Windows System Tray at the bottom right of the screen. Select “shutdown.” NOTE: You can not use RI and CICC Loader at the same time. (8) Note the FDP & SMP version and checksum values listed on the label of the FA2100CVDR Software Distribution CD. (9) Insert the FA2100CVDR Software Distribution CD into the ROC. (10) From the Windows desktop double click on the CICC Loader Icon. (11) When the CICC Loader window appears, refer to Figure 2, select the Browse button at the Load Directory and set the source to “D:\.” (If it is not already present). (12) Select the software load type by choosing the Recorder part number listed that matches the part number found on the recorder identification label. (13) Left click the Load button. 23‐70‐07-017 R1 Page 8 of 11 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS 100 Cattlemen Rd., Sarasota, FL 24232 Telephone: 941-371-0811 Facsimile: 941-377-5591 SERVICE BULLETIN FA2100CVDR BULLETIN NO. FA2100CVDR SB017 R1 (14) Observe the progress window and verify that a status pop−up window appears stating that the FA2100 loaded successfully. Note: If the load procedure was unsuccessful, remove the CD from the D:\ drive, exit the CICC loader program, turn OFF power to the FA2100 CVDR Recorder, and repeat steps (5) − (15). D:\ Figure 2. CICC Loader Window (15) Remove power from the recorder and Exit the CICC Loader utility program. (16) Disconnect the Software Upload Cable 17TES0058 from the FA2100 front panel GSE connector and CICC Cable Assembly. C. To Verify the Software Upload Once the FA2100 software has been loaded, it needs to be verified using the CICC Interface utility program on the ROC/6 or ROC/7 Ground Station: (1) Connect Computer Interface Communications Cable/2 (CICC/2) (P/N: 17TES0072 and 17TES0070) to FA2100CVDR front panel GSE connector. (2) Apply power to the FA2100CVDR Recorder and to the ROC/6 or ROC/7. 23‐70‐07-017 R1 Page 9 of 11 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS 100 Cattlemen Rd., Sarasota, FL 24232 Telephone: 941-371-0811 Facsimile: 941-377-5591 SERVICE BULLETIN FA2100CVDR BULLETIN NO. FA2100CVDR SB017 R1 (3) At the Windows desktop, shut down the Recorder Interface (RI) if not already shutdown from previous steps by right clicking on the RI Icon in the Windows System Icon Tray at the bottom right of the screen. Select “shutdown.” (4) Also shut down the FTP program by right clicking on the FTP Icon in the Windows System Tray at the bottom right of the screen. Select “Exit”. (5) From the Windows desktop, activate the CICC Interface utility program by double−clicking on the CICCIfc Icon. (6) From the CICC Interface Menu, select the “Version” Command from the list and left click the “Send” Command button. Observe that a pop-up window appears showing the recorder software Part Number and SMP & FDP Checksums. (7) Match the listed SW Part Number and SMP & FDP Checksums with the ones listed on the recorder software CD. (8) Left click the OK button and left click the “Exit” button on the CICC Loader Menu to exit the utility and return to the Windows desktop. (9) Once the Software upload versions are validated, perform a full Return To Service test procedure as listed in Sections 100 & 200 of the FA2100CVDR CMM, ATA 23−70−07, P/N 165E1690−00. D. Modification Information Incorporation of this Field Service Bulletin will be identified by marking in the software revision section of the recorder’s name plate with black paint. 23‐70‐07-017 R1 Page 10 of 11 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS 100 Cattlemen Rd., Sarasota, FL 24232 Telephone: 941-371-0811 Facsimile: 941-377-5591 SERVICE BULLETIN FA2100CVDR BULLETIN NO. FA2100CVDR SB017 R1 Table 4. Software Revision Marking Software Revision Recorder E. 2100−3083−00 07 2100−3083−10 08 2100−3083−50 07 Material Information Table 5. Material Information/Pricing List Keyword Quantity Part Number Price U.S.D. Delivery 2100-3083−00 Recorder Software 1 ea. 840E2261−07 250 30 Days 2100-3083−10 Recorder Software 1 ea. 840E3565−08 250 30 Days 2100-3083−50 Recorder Software 1 ea. 840E3555−07 250 30 Days CICC Loader Utility Software Ver. 3.0 1 ea. 883E1893-12 No Charge 30 Days CICC Interface Utility Software Ver. 3.7 1 ea. 883E1827-18 No Charge 30 Days For 2100-3083-00/-10, Audio Com­ pression Circuit Board 1 ea. 205E3977-19 1,746 New 90 Days For 2100-3083-00/-10, Audio Com­ pression Circuit Board 1 ea. 205E3977-19 1,222 Exchange 30 Days For 2100-3083-50, Audio Compres­ sion Circuit Board 1 ea. 205E3977-25 1,746 New 90 Days For 2100-3083-50, Audio Compres­ sion Circuit Board 1 ea. 205E3977-25 1,222 Exchange 30 Days L‐3 Communications, Aviation Recorders David D. Dowding Product Support Manager SB Issue Date: November 12, 2012 SB Revision : May 3, 2013 23‐70‐07-017 R1 Page 11 of 11 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS L–3 COMMUNICATIONS, AVIATION RECORDERS FIELD SERVICE BULLETIN / SERVICE INFORMATION LETTER EXPORT CONTROL STATEMENT The technical information about recorder products/software are being exported from the United States in accordance with the Export Administration Regulations ECCN 9E991, No License Required. Diversion contrary to U.S. law is prohibited. In accordance with U.S. Law (31 CFR Part 746, and Supplement No.1 to Part 774, and CFR Part 550) resale/re–export or transfer to the countries identified therein is prohibited without the prior written consent of the U.S. Department of Commerce. HTSUS, Sch. B: 4901.10.0040, 4901.10.0000 LIMITED RIGHTS LEGEND Notice to persons receiving this document and/or data: This document and/or data contains information in which L–3 Communications Corporation, Aviation Recorders Division, has a protectable interest and is subject to change without notice. The use, duplication, and/or disclosure, by persons receiving this document and/or data may be subject to restrictions. No part of this document and/or data contained herein may be reproduced and/ or used in any form to design, manufacture, and/or test, anything without written permission from L–3 Communications Corporation, Aviation Recorders Division. The document reference is online, please check the correspondence between the online documentation and the printed version. 100 Cattlemen Road, Sarasota, Florida 34232 Telephone: 941−371−0811 Facsimile: 941−377−5591 SERVICE INFORMATION LETTER DATE: March 11, 2015 Letter No. FA2100CVR 037 TO: USERS OF THE MODEL FA2100CVR COCKPIT VOICE RECORDER SUBJECT: NEW CONFORMAL COATING PROCESS FOR ACQUISITION PROCESSOR CIRCUIT CARD ASSEMBLY (CCA) To Whom It May Concern, As of January 2015, all part numbers of L−3 Communications Model FA2100 Cockpit Voice Recorders manufactured will contain a new conformal coating process on the Acquisition Processor CCA. L-3 Communications has introduced this new conformal coating process on all configurations of the Acquisition Processor Circuit Card Assemblies (CCA’s) to improve their moisture resistance and mitigate pending obsolescence of the incumbent coating. As this is a process change only, not affecting any form, fit or function aspects of the Model FA2100 CVR, no external modification identification will be implemented. However, through L-3 AR’s internal serialization and as built manufacturing system, we are tracking all Serial Numbers that have the new process CCA’s incorporated. Sincerely L‐3 Communications, Aviation Recorders Mike Phillips Product Support Manager Issue Date: March 11, 2015 1 of 1 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS L–3 COMMUNICATIONS, AVIATION RECORDERS FIELD SERVICE BULLETIN / SERVICE INFORMATION LETTER EXPORT CONTROL STATEMENT The technical information about recorder products/software are being exported from the United States in accordance with the Export Administration Regulations ECCN 9E991, No License Required. Diversion contrary to U.S. law is prohibited. In accordance with U.S. Law (31 CFR Part 746, and Supplement No.1 to Part 774, and CFR Part 550) resale/re–export or transfer to the countries identified therein is prohibited without the prior written consent of the U.S. Department of Commerce. HTSUS, Sch. B: 4901.10.0040, 4901.10.0000 LIMITED RIGHTS LEGEND Notice to persons receiving this document and/or data: This document and/or data contains information in which L–3 Communications Corporation, Aviation Recorders Division, has a protectable interest and is subject to change without notice. The use, duplication, and/or disclosure, by persons receiving this document and/or data may be subject to restrictions. No part of this document and/or data contained herein may be reproduced and/ or used in any form to design, manufacture, and/or test, anything without written permission from L–3 Communications Corporation, Aviation Recorders Division. The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS 100 Cattlemen Road, Sarasota, Florida 34232 Telephone: 941-371-0811 Facsimile: 941-377-5591 SERVICE BULLETIN PORTABLE INTERFACE (PI) UNIT MOD DOT 9 REQUIRED FOR NAND RECORDERS Date: September 19, 2013 I. BULLETIN NO. PI SB005 Rev. 1 PLANNING INFORMATION A. Effectivity Portable Interface (PI) Unit, manufactured by L-3 Communications, part number 17TES0043. All Portable Interface Units bearing serial number 917791 or higher will have this Service Bulletin incorporated from the factory. B. Reason Portable Interface (PI) Unit Mod Dot 9 is required for compatibility with recorders model number FA2100, FA2200, and FA2300 assembled with the NAND memory. C. Description L−3 Aviation Recorders is now manufacturing model FA2100, FA2200, and FA2300 products with NAND memory devices in the Crash Survivable Memory Unit (CSMU). Recorders equipped with NAND memory can be identified by their Mod Dot status as shown in Table 1. Additionally, NAND recorders will feature the L−3 logo on top of the CSMU as shown in Figure 1. Figure 1 In order to be compatible with the NAND recorders, the 17TES0043 Portable Interface (PI) Unit must contain Mod Dot 9. A modified Portable Interface will still be compatible with older recorders which do not contain NAND memory. PI SB005 R1 Page 1 of 4 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS 100 Cattlemen Road, Sarasota, Florida 34232 Telephone: 941-371-0811 Facsimile: 941-377-5591 SERVICE BULLETIN PORTABLE INTERFACE (PI) UNIT MOD DOT 9 REQUIRED FOR NAND RECORDERS Date: September 19, 2013 BULLETIN NO. PI SB005 Rev. 1 Table 1. Recorder Mod Dot Status with NAND Memory Recorder Type Mod Dot Number CVR Mod Dot 14 CVDR Mod Dot 13 FDR Mod Dot 13 For CVR and CVDR applications with NAND memory, the audio data file extensions in the Portable Interface (PI) Unit have been modified for partial and full audio download. When the NAND CVR is partially downloaded (34 minutes or less), the CVR file extension in the Portable Interface (PI) Unit will be .cvr. When the NAND CVR is fully downloaded (35 minutes or more), the CVR file extensions in the Portable Interface (PI) Unit will be .crr. The file extension for non−modified CVRs (older units with NOR memory), remains as .cvr for all audio downloads. Downloaded files with the .crr extension may be converted into .wav files in the same manner as the .cvr files. The following are three L−3 AR software products that include the file conversion utilities: 1. ROSE (Read Out Support Equipment) software p/n 17TES0321, Version 4.7 and higher. 2. ADLP (Audio Data Link Player) software p/n 17TES0436, Version 3.3 and higher. 3. CVR Audio Utility (CVRUtil.exe), Version 1.1 and higher. Contained on ROSE Utility CD Bundle p/n 883E1894-01. Contact L-3 AR Product Support for details on obtaining the software items listed above. D. Approval This Service Bulletin contains no modification information that revises the approved configuration and therefore does not require governmental or other regulatory agency approval. PI SB005 R1 Page 2 of 4 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS 100 Cattlemen Road, Sarasota, Florida 34232 Telephone: 941-371-0811 Facsimile: 941-377-5591 SERVICE BULLETIN PORTABLE INTERFACE (PI) UNIT MOD DOT 9 REQUIRED FOR NAND RECORDERS Date: September 4, 2013 E. BULLETIN NO. PI SB005 Manpower Not applicable. F. Material Cost and Availability Mod Dot 9 can be installed by L−3AR Product Support Engineers, or at the factory repair station. The cost for the update is $435.00 USD. G. Tooling Not applicable. H. Weight and Balance Not affected. I. Reference Portable Interface (PI) Unit Operator’s Manual, part number 165E1630-00, and ECN−015750. II. MODIFICATION INFORMATION Incorporation of this Service Bulletin shall be identified by marking Modification 9 on the Portable Interface name label as shown in Figure 2. Figure 2 PI SB005 R1 Page 3 of 4 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS 100 Cattlemen Road, Sarasota, Florida 34232 Telephone: 941-371-0811 Facsimile: 941-377-5591 SERVICE BULLETIN PORTABLE INTERFACE (PI) UNIT MOD DOT 9 REQUIRED FOR NAND RECORDERS Date: September 4, 2013 BULLETIN NO. PI SB005 III. MATERIAL INFORMATION L−3 Aviation Recorders will install this Service Bulletin (Portable Interface Mod. Dot 9) for $435. The Portable Interface (PI) Unit must be returned to the Aviation Recorder factory Repair Station for modification. Shipping Address: L−3 Communications Aviation Recorders 100 Cattlemen Road Sarasota, FL 34232 USA Attn: Aviation Recorders Repair Department Tel: (941) 377−5558 L-3 Communications, Aviation Recorders Dave Dowding Product Support Manager SB Issue Date: Rev. 1 Issue Date: Sep. 04, 2013 Sep. 19, 2013 PI SB005 R1 Page 4 of 4 The document reference is online, please check the correspondence between the online documentation and the printed version. The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR LIST OF EFFECTIVE PAGES Section Page Date Section i ii iii iv Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 v vi vii viii Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 ix x xi xii xiii xiv xv xvi xvii xviii xix xx xxi xxii xxiii xxiv xxv xxvi Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Highlights Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 xxvii xxviii Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 xxix xxx xxxi xxxii Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 List of Effective Pages Rev. 15 xxxiii Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 1 2 3 4 5 6 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Description and Operation Service Bulletin List Rev. 15 Rev. 15 Rev. 15 Rev. 15 xxxix xl xli xlii xliii xliv xlv xlvi xlvii xlviii xlix l li lii Introduction Record of Revisions Rev. 15 Rev. 15 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Table of Contents Record of Highlights Rev. 15 Rev. 15 Rev. 15 Rev. 15 Date Rev. 15 xxxiv Rev. 15 xxxv Rev. 15 xxxvi Rev. 15 xxxvii Rev. 15 xxxviii Title Page Rev. 15 Rev. 15 Rev. 15 Rev. 15 Page Apr. 14/16 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 1 2 3 4 5 6 7 8 9 10 11 12 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 23−70−04 List of Effective Pages Rev. 15 Page xxxiii Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR LIST OF EFFECTIVE PAGES (Continued) Section Page Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 Date Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Section Page Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev.11 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Date 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Testing and Troubleshooting Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 23−70−04 List of Effective Pages Rev. 15 Page xxxiv Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR LIST OF EFFECTIVE PAGES (Continued) Section Page Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 145 146 147 148 149 150 151 152 Date Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Section Page Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 153 154 155 156 157 158 159 160 161 162 163 164 165 166 167 168 169 170 171 172 173 174 175 176 177 178 179 180 181 182 183 184 185 186 Date Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Automatic Testing Rev. 15 Rev. 15 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 201 202 Apr. 14/16 Apr. 14/16 23−70−04 List of Effective Pages Rev. 15 Page xxxv Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR LIST OF EFFECTIVE PAGES (Continued) Section Page Date Section Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Disassembly Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 301 302 303 304 305 306 307 308 309 310 311 312 313 314 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Rev. 15 Rev. 15 401 402 Apr. 14/16 Apr. 14/16 Rev. 15 Rev. 15 501 502 Apr. 14/16 Apr. 14/16 Rev. 15 Rev. 15 601 602 Apr. 14/16 Apr. 14/16 701 702 703 704 705 706 707 708 709 710 711 712 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 801 802 803 804 805 806 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Special Tools, Fixtures and Equipment Repair Assembly Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 713 714 715 716 717 718 719 720 721 722 723 724 Date Fits and Clearances Cleaning Check Page Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 901 902 903 904 905 906 907 908 909 910 911 912 913 914 915 916 917 918 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 23−70−04 List of Effective Pages Rev. 15 Page xxxvi Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR LIST OF EFFECTIVE PAGES (Continued) Section Page Rev. 15 Rev. 15 919 920 Date Section Apr. 14/16 Apr. 14/16 Illustrated Parts List Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 1001 1002 1003 1004 1005 1006 1007 1008 1009 1010 1011 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Page Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Rev. 15 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 1012 1013 1014 1015 1016 1017 1018 1019 1020 1021 1022 1023 1024 1025 1026 Date Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 Apr. 14/16 23−70−04 List of Effective Pages Rev. 15 Page xxxvii Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR TABLE OF CONTENTS SUBJECT/DESCRIPTION Page INTRODUCTION 1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2. ACRONYMS AND ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 3. DOCUMENT REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 4. RECORDER DEFINITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 5. MAINTENANCE PHILOSOPHY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 6. COMPONENT MAINTENANCE MANUAL (CMM) DESCRIPTION . . . . . . . . . . . . . . . . . 3 A. FRONT MATTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 B. DESCRIPTION AND OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 C. TESTING AND TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 D. DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 E. CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 F. CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 G. REPAIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 H. ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 I. SPECIAL TOOLS AND TEST FIXTURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 J. ILLUSTRATED PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 7. DOCUMENT VERIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 8. COMPONENT MAINTENANCE MANUAL (CMM) EFFECTIVITY . . . . . . . . . . . . . . . . . 6 9. PART NUMBER FORMATTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 DESCRIPTION AND OPERATION 1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2. FA2100 CONFIGURATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 3. SYSTEM DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 A. Underwater Acoustic Beacon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 B. Circuit Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 C. Power, Control and Monitor Signal Interface Characteristics . . . . . . . . . . . . . . . 5 D. Voice Data Interface Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Table of Contents Rev. 15 Page xxxviii Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR TABLE OF CONTENTS (Cont.) 4. E. Data Recording Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 F. Audio Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 G. Storage Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 H. Data Retrieval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 I. Data Reproduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 J. Built-In-Test (BIT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 K. Crash Survivable Memory Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 L. Crash and Fire Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 M. Control Unit, Microphone & Preamplifier Equipment . . . . . . . . . . . . . . . . . . . . . . 20 N. Remote Microphone Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 O. Ground Support Equipment Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 P. BIT and Fault Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 FA2100 CVR SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 A. Applicable Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 B. Physical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 C. Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 D. Environmental Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 E. Crash and Fire Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 F. CSMU Torque Requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 5. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 6. THEORY OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 A. MODEL FA2100 CVR SYSTEM THEORY OF OPERATION . . . . . . . . . . . . . . . 32 B. Aircraft Interface (AI) PWA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 C. Audio Compressor (AC) PWA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 D. Acquisition Processor (AP) PWA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 7. SOFTWARE CONSIDERATIONS (ALL P/NS EXCEPT 2100−1X25/1X26/1X27−( ) and 2100−1X20−( ) MOD−DOT #7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 A. Store Manager Processor Software Organization . . . . . . . . . . . . . . . . . . . . . . . . 43 B. Software Operating States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44 C. Data Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 D. Fault Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Table of Contents Rev. 15 Page xxxix Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR TABLE OF CONTENTS (Cont.) 8. 9. SOFTWARE CONSIDERATIONS (P/NS: 2100−1X25/1X26/1X27−( ) and 2100−1X20−( ) MOD−DOT#7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 A. Equipment Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 B. Software Partitioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 C. Memory Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 D. Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 E. Push−to−Test (PTT) Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56 F. Bulk Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56 G. Recorder Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57 H. Data downloading (P/N: 2100−1X25/1X26/1X27−( ) only) . . . . . . . . . . . . . . . . . 57 I. CVR RIPS status monitoring (P/N: 2100−1X25−22/−24, 2100−1X26−( ), and 2100−1X27−( ) only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 On board Maintenance System Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 A. Label 350 Status Word Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61 B. Label 354 LRU Identification Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64 C. Label 377 ARINC 429 Equipment Identification Word Output . . . . . . . . . . . . . . 67 D. OMS Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67 10. CVR DATALINK INPUT INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67 A. Data Link Input and Encapsulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68 B. DataLink Heartbeat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70 C. Williamsburg Bit−Oriented Protocol Version Support . . . . . . . . . . . . . . . . . . . . . . 70 D. DataLink Memory Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71 E. DataLink Retrieval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71 TESTING 1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101 2. MAINTENANCE PHILOSOPHY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102 A. Model FA2100CVR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102 B. Model S151/S161, S152/S162, and S251/S261 Control Units . . . . . . . . . . . . . 103 C. MODEL S150/S160 MICROPHONE PREAMPLIFIER MODULES . . . . . . . . . . 103 D. MODEL S055 AND S056 ELECTRET CONDENSER MICROPHONES . . . . . 103 3. MODEL FA2100CVR RECORDER IN-SERVICE CHECKOUT . . . . . . . . . . . . . . . . . . . . 103 4. TEST EQUIPMENT REQUIRED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Table of Contents Rev. 15 Page xl Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR TABLE OF CONTENTS (Cont.) 5. 6. READ−OUT CENTER/6 (ROC/6), WINDOWS XP, AUTO−TESTING . . . . . . . . . . . . . . 106 A. READ−OUT CENTER/6 (ROC/6) Interconnects . . . . . . . . . . . . . . . . . . . . . . . . . . 106 B. READ−OUT CENTER/6 (ROC/6) Sound Card Setup . . . . . . . . . . . . . . . . . . . . . 109 C. READ−OUT CENTER/6 (ROC/6) − CATS AUTOTEST . . . . . . . . . . . . . . . . . . . . 112 D. READ−OUT CENTER/6 (ROC/6) − Autotest Descriptions . . . . . . . . . . . . . . . . . 118 E. ROC/6 − Audio Setup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125 F. ROC/6 − AUDIO DOWNLOAD & PLAYBACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133 READ−OUT CENTER/7 (ROC/7), WINDOWS 7, AUTO−TESTING . . . . . . . . . . . . . . . 135 A. READ−OUT CENTER/7 (ROC/7) Interconnects . . . . . . . . . . . . . . . . . . . . . . . . . . 135 B. READ−OUT CENTER/7 (ROC/7) − Sound Card Setup . . . . . . . . . . . . . . . . . . . . 139 C. READ−OUT CENTER/7 (ROC/7) − CATS Autotest . . . . . . . . . . . . . . . . . . . . . . . 145 D. READ OUT CENTER/7 (ROC/7) − Autotest Descriptions . . . . . . . . . . . . . . . . . . 162 7. READ−OUT CENTER/7 (ROC/7) − AUDIO DOWNLOAD & PLAYBACK . . . . . . . . . . . 170 8. Underwater Locator Beacon Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171 9. MODEL FA2100CVR TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174 10. FA2100CVR SOFTWARE UPLOAD PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178 A. Installing Software Upload Utility and CICC Interface Programs . . . . . . . . . . . . 178 B. To upload the FA2100 Software perform the following steps: . . . . . . . . . . . . . . 181 C. To Verify the Software Upload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182 AUTOMATIC TESTING 1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201 DISASSEMBLY 1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301 2. MODEL FA2100CVR DISASSEMBLY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . 301 A. B. C. Underwater Locator Beacon Removal (See Figure 301 or IPL Figure 1, Item 80) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302 Crash Survivable Memory Unit (CSMU) Removal (See Figure 305 or IPL Figure 1, Item 185) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304 Acquisition Processor (AP) PWA Removal (See Figure 306 or IPL Figure 1, Item 175) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Table of Contents Rev. 15 Page xli Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR TABLE OF CONTENTS (Cont.) D. E. Audio Compressor PWA (AC) Removal (See Figure 307 or IPL Figure 1, Item 155) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309 Aircraft Interface PWA (AI) Removal (See Figure 307 or IPL Figure 1, Item 105) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312 CLEANING 1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401 2. MATERIALS REQUIRED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401 3. CLEANING PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401 A. Printed Wiring Assembly Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 402 B. Connector Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 402 C. Underwater Locator Device (Beacon) Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 402 CHECK 1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 501 2. CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 501 A. Main Recorder Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 501 B. Mechanical Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 501 C. Electrical Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 502 D. Underwater Locator Device (ULD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 502 REPAIR 1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 601 ASSEMBLY 1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 701 2. REQUIRED MATERIALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 701 3. ASSEMBLY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 702 A. General Assembly Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 702 B. Acquisition Processor (AP) PWA Installation (See Figure 701 or IPL Figure 1, Item 175) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 702 Aircraft Interface PWA (AI) Installation (See Figure 703 or IPL Figure 1, Item 105) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 704 C. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Table of Contents Rev. 15 Page xlii Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR TABLE OF CONTENTS (Cont.) D. E. F. G. 4. Audio Compressor PWA (AC) Installation (See Figure 703 or IPL Figure 1, Item 155) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 706 Chassis Cover Installation (See Figure 704 and Figure 706 or IPL Figure 1, Item 20A/B) . . . . . . . . . . . . . . 709 Crash Survivable Memory Unit (CSMU) Installation (See Figure 710 or IPL Figure 1, Item 185) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 714 Underwater Acoustic Beacon Assembly & Installation (See Figure 713 and IPL Figure 1, Item 80) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 721 STORAGE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 723 A. Storage in Original Containers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 723 B. Storage Without Original Containers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 723 C. Shipment Container Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 723 FITS AND CLEARANCES 1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 801 2. SYSTEM SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 801 A. Physical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 801 B. Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 802 C. Environmental Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 802 D. Crash and Fire Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 802 E. Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 802 SPECIAL TOOLS, FIXTURES AND EQUIPMENT 1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 901 2. GROUND SUPPORT EQUIPMENT (GSE) DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . 905 A. Portable Interface Unit, p/n: 17TES0043 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 905 B. FA2100 Software Upload Cable Assembly & Distribution Diskettes . . . . . . . . . 905 C. Audio Data Link Player Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 917 D. CVR Download Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 919 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Table of Contents Rev. 15 Page xliii Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR TABLE OF CONTENTS (Cont.) ILLUSTRATED PARTS LIST 1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1001 2. PURPOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1001 3. ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1001 4. EQUIPMENT DESIGNATOR INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1001 5. NUMERICAL INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1002 6. DETAIL PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1002 7. PART NUMBERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1004 8. MANUFACTURER’S CODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1004 9. L−3 AVIATION RECORDERS (L−3AR) AUTHORIZED PARTS . . . . . . . . . . . . . . . . . . . 1004 10. CONFIGURATION MATRIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1006 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Table of Contents Rev. 15 Page xliv Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR LIST OF FIGURES FIGURE TITLE PAGE 1. Model FA2100 Cockpit Voice Recorder (FA2100CVR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 2. Model FA2100 CVR, (2100-1010-00, 2100-1X20-00/02, 2100-1X25-XX, 2100-1X26-XX and 2100-1X27-XX) Functional System Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 3. Model FA2100 GACVR (2100-1010-50/-51 and 2100-1020-50/-51) Functional System Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 4. Model FA2100 CVR, 30-Minute and 120-Minute Audio Monitor Schemes . . . . . . . . . . . . . . . 9 5. Model FA2100 CVR, 30-Minute and 120-Minute Recording Schemes . . . . . . . . . . . . . . . . . . 13 6. GACVR Fault Circuit for Pin 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 7. Interwiring Diagram, Recorder FA2100 CVR (2100-1010-00, 2100-1X20-00/-02, & 2100-1X25/1X26-XX) . . . . . . . . . . . . . . . . . . 26 8. ARINC 757A Interwiring Diagram, Recorder FA2100 CVR (2100-1X27-XX) . . . . . . . . . . . . 28 9. Interwiring Diagram, Recorder FA2100 GACVR (2100-10X0-50/-51) with Customer−Furnished Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 10. FA2100 CVR Overall Function Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 11. 2–Hr FA2100 CVR (pre MOD−DOT #7) Word Partition Structure Streams . . . . . . . . . . . . . 46 12. 2–Hr FA2100 CVR Memory Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 13. Generic DataLink Message Encapsulation Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69 101. CVR Fault Circuit for Pin 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104 102. ROC/6 w/CVR Automated Test Station Software (CATS) FA2100CVR TEST SETUP . 108 103. Volume Control Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109 104. Line In Input Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110 105. Sound Card Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110 106. Playback Control, Volume Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111 107. CVR Test, Start Toggle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113 108. CVR Test, Warning Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113 109. CVR Test, Instruction Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113 110. CVR Test, Power Consumption Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114 111. CVR Test, Power Consumption Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114 112. CVR Test, Instruction Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114 113. CVR Test, Proceed Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115 114. CVR Test, Instruction Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Table of Contents Rev. 15 Page xlv Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR LIST OF FIGURES (Cont.) 115. CVR Test, Warning Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116 116. CVR Test, Instruction Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116 117. CVR Test, Power Consumption Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117 118. CVR Test, Power Consumption Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117 119. CVR Test, Instruction Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117 120. CVR Test, Proceed Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118 121. Audio Setup Cable Assembly, 17TES0417 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125 122. Audio Reference Level Utility, Warning Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126 123. Audio Reference Level Utility, Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127 124. Audio Reference Level Utility, File Open Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127 125. Audio Reference Level Utility, Play Sound . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128 126. Audio Reference Level Utility, Play Sound . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128 127. Audio Reference Level Utility, Confirmation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129 128. Audio Reference Level Utility, Warning Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129 129. Audio Reference Level Utility, Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130 130. Audio Reference Level Utility, File Open Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130 131. Audio Reference Level Utility, Play Sound . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131 132. Sound Card Input Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131 133. CVR Tester, Update Reference Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132 134. ROC/7 with CVR Automated Test Station Software (CATS 2.0) FA2100CVR TEST SETUP − ROC/7’s DMF: Pre Jul. 2014. . . . . . . . . . . . . . . . . . 137 135. ROC/7 with CVR Automated Test Station Software (CATS 2.0) FA2100CVR TEST SETUP − ROC/7’s DMF: Post Feb. 2015. . . . . . . . . . . . . . . . 138 136. CATS, Channels Control Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139 137. Volume Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140 138. Sound Control, Recording . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140 139. Line−In Properties, Line−In Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141 140. Sound, Playback Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142 141. Speaker Properties, Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143 142. Volume Mixer, Speaker Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144 143. CATS, Connecting Pop-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146 144. CATS, Power Toggle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Table of Contents Rev. 15 Page xlvi Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR LIST OF FIGURES (Cont.) 145. CATS, Start Test Toggle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147 146. CATS, Test Mode and Options Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147 147. CATS, CVDR Test Confirmation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148 148. CATS, CVDR Warning Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148 149. CATS, CVDR Instruction Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149 150. CATS, Power Test Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149 151. CATS, Power Test Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149 152. CATS, CVDR Instruction Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150 153. CATS, CVDR Fault History Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150 154. CATS, CVDR Clear Fault Log Confirmation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151 155. CATS, CVDR Clear Latched Faults and Log Confirmation . . . . . . . . . . . . . . . . . . . . . . . . 151 156. CATS, CVDR Clear Latched Faults and Log Successful . . . . . . . . . . . . . . . . . . . . . . . . . . 151 157. CATS, CVDR Fault History Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152 158. CATS, Continue Test Confirmation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152 159. CATS, Test Results Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153 160. CATS, Connecting Pop-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154 161. CATS, Power Toggle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154 162. CATS, Start Test Toggle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155 163. CATS, Test Mode and Options Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155 164. CATS, CVDR Test Confirmation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156 165. CATS, CVDR Warning Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156 166. CATS, CVDR Instruction Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157 167. CATS, Power Test Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157 168. CATS, Power Test Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157 169. CATS, CVDR Instruction Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158 170. CATS, CVDR Fault History Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158 171. CATS, CVDR Clear Fault Log Confirmation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159 172. CATS, CVDR Clear Fault Log Confirmation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159 173. CATS, CVDR Clear Latched Faults and Log Successful . . . . . . . . . . . . . . . . . . . . . . . . . . 159 174. CATS, CVDR Fault History Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160 175. CATS, Continue Test Confirmation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160 176. CATS, Test Results Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Table of Contents Rev. 15 Page xlvii Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR LIST OF FIGURES (Cont.) 177. Typical Software Upload Setup For FA2100 Recorder with CICC/2 Cable . . . . . . . . . . . 180 301. Underwater Locator Beacon Removal Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303 302. CSMU Memory Sealing Screw Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304 303. CSMU Memory Assembly Removal Diagram (PRE-MOD DOT 6) . . . . . . . . . . . . . . . . . . 305 304. CSMU Memory Assembly Removal Diagram (POST-MOD DOT 6 & PRE-MOD DOT 13) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306 305. CSMU Memory Assembly Removal Diagram (POST-MOD DOT 13) . . . . . . . . . . . . . . . . 307 306. Acquisition Processor PWA Removal Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309 307. Aircraft Interface & Audio Compressor PWA Removal Diagram . . . . . . . . . . . . . . . . . . . . 311 701. Acquisition Processor (AP) Installation Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 703 702. Aircraft Interface & Audio Compressor PWA Installation Diagram (PRE-MOD DOT 6) 707 703. Aircraft Interface & Audio Compressor PWA Installation Diagram (POST MOD DOT 6) 709 704. FA2100CVR Chassis Cover Seal Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 712 705. FA2100 GACVR Chassis RTV Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 713 706. FA2100CVR Chassis Cover Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 714 707. Crash Survivable Memory Unit (CSMU) Seal Application (Pre-MOD DOT 13) . . . . . . . . 715 708. Crash Survivable Memory Unit (CSMU) Seal Application (Post-MOD DOT 13) . . . . . . 716 709. Crash Survivable Memory Unit (CSMU) Seal Application (Post-MOD DOT 13) . . . . . . . 716 710. Crash Survivable Memory Unit (CSMU) Assembly (PRE-MOD DOT 6) . . . . . . . . . . . . . 718 711. Crash Survivable Memory Unit (CSMU) Assembly (POST-MOD DOT 6 & PRE-MOD DOT 13) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 719 712. Crash Survivable Memory Unit (CSMU) Assembly (POST-MOD DOT 13) . . . . . . . . . . . 720 713. Underwater Locator Beacon Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 722 714. Shipping Container, Short Box, p/n: 197E1746-00, part of Shipment Package Kit: p/n: 147E1679-00. . . . . . . . . . . . . . . . . . . . . . . . . . . 724 801. Outline & Dimension Drawing Model FA2100 CVR Recorder P/N: 2100-1010-( ) & 2100-102X-( ) . . . . . . . . . . . 804 901. Portable Interface Unit, p/n: 17TES0043 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 906 902. Portable Interface (PI) Unit, CVR Menu Structures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 908 903. FA2100CVR Software Upload Connections Using Computer Interface & Communications Cable (CICC) . . . . . . . . . . . . . . . . . 909 904. Recorder Interface Cable Assembly P/N: 17TES0057 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 910 905. Computer Interface Communications Cable/2 (CICC/2) P/N: 17TES0070 . . . . . . . . . . . 911 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Table of Contents Rev. 15 Page xlviii Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR LIST OF FIGURES (Cont.) 906. Programmers Adapter Cable Assembly P/N: 17TES0058 . . . . . . . . . . . . . . . . . . . . . . . . . 913 907. ROC/6 w/CVR Automated Test Station Software (CATS) FA2100CVR TEST SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 914 908. Recorder Interface Cable Assembly, 17TES0416 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 915 909. AC 115 VAC/400Hz Power Input Cable Assembly P/N: 17TES0411 . . . . . . . . . . . . . . . . 916 910. DC +28VDC Power Input Cable Assembly P/N: 17TES0412 . . . . . . . . . . . . . . . . . . . . . . 916 911. Audio Setup Cable Assembly, 17TES0417 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 917 912. ULD Test Set-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 917 913. FA2100CVR Download Cable, p/n 17TES0078, Wiring Diagram . . . . . . . . . . . . . . . . . . . 920 1. Model FA2100 Cockpit Voice Recorder PN: 2100-1010-( ) & 2100-1X2X-( ) . . . . . . . . . . 1011 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Table of Contents Rev. 15 Page xlix Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR LIST OF TABLES TABLE TITLE PAGE 1. Shop Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 2. FA2100 CVR Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 1 Model FA2100 CVR Recording Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 2. Aircraft Interface (AI) PWA Current Configuration Where Used . . . . . . . . . . . . . . . . . . . . . . . . 33 3. ARINC 557/757/757A Aircraft Interface Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 4. Aircraft Interface PWA to Audio Compressor PWA Interface Signals . . . . . . . . . . . . . . . . . . . 36 5. Aircraft Interface PWA to Acquisition Processor PWA Interface Signals . . . . . . . . . . . . . . . . 37 6. Audio Compressor (AC) PWA Current Configuration Where Used . . . . . . . . . . . . . . . . . . . . . 39 7. Acquisition Processor (AP) PWA Current Configuration Where Used . . . . . . . . . . . . . . . . . . 41 8. Fault Processing Event Types and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52 9. P/N 2100−1X25/1X26/1X27−( ) Software Fault Warning Failures . . . . . . . . . . . . . . . . . . . . . . 55 10. CVR RIPS Pin Assignment for P/N: 2100−1X25−22/−24 & 2100−1X26/1X27−( ) . . . . . . . 58 11. CVR OMS Output Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 12. CVR Pins Assigned to RIPS Status Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61 13. CVR Label 350 Output Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61 14. CVR Fault Reporting Interactions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62 15. CVR Status Word Fault Reporting Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63 101. 17TES0400 READOUT CENTER/6 (ROC/6) − Parts List . . . . . . . . . . . . . . . . . . . . . . . . . 134 102. 17TES0700 READOUT CENTER/7 (ROC/7) − Parts List . . . . . . . . . . . . . . . . . . . . . . . . . 171 103. Underwater Locator Beacon Test Using L−3AR Test Set P/N: 17TES0015 . . . . . . . . . . 172 104. Underwater Locator Beacon Test Using Test Set P/N: 42A12( ) and 10 Mohm High Impedance Voltmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173 105. FA2100 CVR Fault Code Corrective Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174 106. FA2100CVR Software SMP Checksums . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183 107. FA2100CVR Software FDP Checksums . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185 401. Cleaning Materials Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401 701. Required Assembly Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 701 801. FA2100 CVR Environmental Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 803 901. of Special Tools, Fixtures, and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 901 902. Specification Control Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 918 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Table of Contents Rev. 15 Page l Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR THIS PAGE IS INTENTIONALLY LEFT BLANK Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Table of Contents Rev. 15 Page li Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR INTRODUCTION 1. GENERAL This Component Maintenance Manual (CMM) documents the operation of and suggested maintenance for the Model FA2100 Cockpit Voice Recorder, herein after referred to as the FA2100CVR. The FA2100CVR meets the performance requirements of ED-56A, while complying with the interface requirements of ARINC 557/757 cockpit voice input data including Rotor Speed and GMT interfaces. The only exception is P/N: 2100−1027−02 which complies with the interface requirements of ARINC 757A only. In addition, the FA2100CVR, p/n: 2100−1025/1026/1027−XX, meets the performance requirements of ED−112. The cockpit voice and area microphone channels are lowpass filtered, sampled, digitized, compressed, and stored in solid-state, crash protected memory. This CMM covers both the 30-minute and 2-hour memory storage versions of the FA2100CVR. The FA2100CVR is designed as maintenance-free recorder. No periodic adjustments, calibration, or maintenance is required to maintain this unit. The Model FA2100CVR is considered an “ON CONDITION LRU.” 2. ACRONYMS AND ABBREVIATIONS The following list defines the acronyms and abbreviations used throughout this CMM: AC ADLP ARINC ATA ATC ATE ATR BITE CAA CATS CMM CICC CSMU CVR DC EUROCAE FAA FDAU GA GMT GND GSE IPL Alternating Current Audio and Data Link Playback Aeronautical Radio, Inc. Air Transport Association Air Traffic Control Automated Test Equipment Air Transport Racking Built−In Test Equipment Civil Aviation Authority (United Kingdom) CVR Automatic Test Software Component Maintenance Manual Computer Interface Communication Cable Crash Survivable Memory Unit Cockpit Voice Recorder Direct Current European Organization for Civil Aviation Equipment Federal Aviation Administration Flight Data Acquisition Unit General Aviation Greenwich Mean Time Ground Ground Support Equipment Illustrated Parts List Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Introduction Rev. 15 Page 1 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR LRU MTBF OMS PC PCMCIA PI PWA PWR REC LVL RIU ROC ROSE RSE RTCA RUFS SMT TSO ULB Line Replaceable Unit Mean Time Between Failures Onboard Maintenance System Personal Computer Personal Computer Memory Card International Association (now known as PC Card) Portable Interface printed wiring assembly power Record Level Recorder Interface Unit Read−Out Center Read Out Support Equipment Rotor Speed Encoder Radio Technical Commission for Aeronautics Recorder USB FDAU Simulator Surface Mount Technology Technical Standard Order Underwater Locator Beacon 3. DOCUMENT REQUIREMENTS The following equipment and documents are, or may be, required for on-aircraft installation and check out of the FA2100CVRs: F This Component Maintenance Manual. F Portable Interface Operator’s Manual, Part Number 165E1630–00 F Portable Interface/2 Operator’s Manual, Part Number 165E1630–01 F Installation and Operation Manual, Cockpit Voice Recorder, Model FA2100CVR, Part Number 165E1846-00. F Component Maintenance Manual, ED−56A Control Units, Preamplifier, & Microphone Modules , ATA 23–70–05, Part Number 165E1747-00. F FA2100CVR Audio & Data Link Player Software Operator’s Manual, Part Number 165E3596−00. F Read−Out Support Equipment/Recorder Interface Software Version 3.0 or 4.0 Operator’s Manual, Part Number 165E1696−02 or−03 . 4. RECORDER DEFINITIONS The Model FA2100CVR P/N’s: 2100-1010-( ) and 2100-102X-( ) meet the requirements of ARINC 557/757 with a voice memory storage capacity of 30-minutes and 2-hours, respectively with the exception of 2100−1027−02 meets the ARINC 757A requirement. A Rotor Speed Encoder (RSE) and Greenwich Mean Time (GMT) interface is provided. For all part numbers, an On-Board Maintenance (OMS) interface is implemented in hardware, Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Introduction Rev. 15 Page 2 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR however only the FA2100CVR P/Ns:2100−1025/1026/1027−XX, supports OMS in software. Only FA2100 CVR P/N: 2100−1025/1026/1027−XX, supports RIPS Monitoring status and Datalink. 5. MAINTENANCE PHILOSOPHY The Model FA2100 Solid-State CVR Recorder is considered an “ON CONDITION LRU” and is designed as maintenance-free unit which makes extensive use of surface mount technology (SMT). The repair of printed wiring assemblies (PWAs) containing SMT devices requires specialized factory equipment, training, and techniques, therefore, such PWAs are not field-repairable while the unit is under the warranty period. As a result, during the unit’s warranty period, the FA2100’s CVR maintenance philosophy is replacement of failed level 2 assemblies. The field replaceable assemblies identified for the FA2100CVR are the Aircraft Interface PWA, the Audio Compressor PWA, the Acquisition Processor PWA, and the Crash Survivable Memory Unit (CSMU). When it has been determined that one or more of these assemblies is faulty, the assembly(ies) should be removed and returned to L-3 Aviation Recorders for repair or replacement. Attempts to repair any discrete components of these assemblies will void the warranty. 6. COMPONENT MAINTENANCE MANUAL (CMM) DESCRIPTION This CMM consists of a single volume. The manual conforms to the intent and form of Air Transport Association of America (ATA) Specification 100. The manual is written for an audience of operators and both intermediate− and depot−Level maintenance technicians. Functional, electrical and mechanical aspects of the Model FA2100CVR are documented; that is, description, specifications, operation, testing, removal and replacement, etc. are contained in this manual. The CMM content is summarized as follows: A. FRONT MATTER Front Matter material consists of a title page, service bulletin list, record of revisions, record of changes, list of effective pages, table of contents, and this introduction. B. DESCRIPTION AND OPERATION This section contains the description and operation information for the Model FA2100 Cockpit Voice Recorder. Line art is used to illustrate the unit, its interconnections and functionality. This section also contains the Model FA2100CVR Theory of Operation. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Introduction Rev. 15 Page 3 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR C. TESTING AND TROUBLESHOOTING Sections 100 and 200 contains specific checks and tests required to determine the operational condition of a unit that has been removed from service. Also included in the section are tables of required test equipment, test set-up data, procedures, and test parameters. Troubleshooting data is presented in a tabular form with each entry related to a specific test and fault isolation task. Fault isolation is provided to a Level-2 maintenance, or circuit board removal and replacement level. No calibration of circuit boards within the Model FA2100CVR is required. The Model FA2100 Solid-State Cockpit Voice Recorder is considered an “ON CONDITION LRU”. D. DISASSEMBLY This section provides all the information required to completely disassemble the FA2100CVR to its Lowest Replaceable Unit (LRU) defined by the maintenance philosophy as the circuit board assemblies. The steps of each procedure are coordinated with the TESTING AND TROUBLESHOOTING Section. Access to subassemblies within the FA2100CVR is described such that there is minimal disturbance to other subassemblies. Each major disassembly task is accompanied with a line art exploded-view of the subassembly area which is cross referenced to the applicable Illustrated Parts List (IPL) drawing for ordering replacement parts. E. CLEANING This section contains a listing of all required cleaning materials, procedures for cleaning material use, and applicable warnings and cautions related to the use of prescribed cleaning solvents. F. CHECK This section contains the check procedures that may be required during shop maintenance. It covers Mechanical Inspection, Electrical Inspection and ULD Inspection procedures. G. REPAIR This section contains the Model FA2100CVR maintenance philosophy, which provides for Level-2 removal and replacement of failed circuit board assemblies only. H. ASSEMBLY This section contains detailed step-by-step procedures describing the complete assembly of the Model FA2100 Solid-State Cockpit Voice Recorder. Each major as- Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Introduction Rev. 15 Page 4 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR sembly procedure is accompanied with a line art exploded-view of the subassembly area which is cross referenced to the applicable Illustrated Parts List (IPL) drawing for ordering replacement parts. I. SPECIAL TOOLS AND TEST FIXTURES This section provides a listing of all required tools, fixtures, and equipment which are not common maintenance tools. It also provides a description of the Portable Interface (PI) used to download voice data from the recorder. It also provides a description of the Read−Out Center (ROC)/CVR Automated Test Station (CATS) as used with the Recorder Interface Unit (RIU) to test and download from the FA2100CVR. J. ILLUSTRATED PARTS LIST This section contains parts location diagrams and parts listings for all versions of the Model FA2100 CVR, p/n: 2100-1010-( ) (30-minute) and p/n: 2100-102X-( ) (2-hour) currently produced. 7. DOCUMENT VERIFICATION All CMM drawings, illustrations, wiring diagrams, and block diagrams were validated against existing engineering source material. All Testing & Fault Isolation, Disassembly and Assembly procedures have been verified against the actual performance of the unit under test conditions as indicated in Table 1 below. Table 1 identifies the sections of the CMM that underwent a Shop Verification process and the date of the verification. In addition, a Component Maintenance Manual Verification Report that identifies the technician who performed the procedure and Engineer/ Technical Writer who verified the procedure along with a Quality Assurance Engineer approval signature is kept on file with the CMM sign off release form. For a copy of the Component Maintenance Manual Verification Report for this version of the CMM, please address inquiries to the following: L-3 Aviation Recorders Publications 100 Cattlemen Rd. Sarasota, Florida 34230 Phone: (941) 371–0811 FAX: (941) 377–5591 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Introduction Rev. 15 Page 5 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Table 1. Shop Verification Procedure Chapter Date of Verification Testing & Fault Isolation 100 Mar. 25/13 Automatic Testing 200 Mar. 25/13 Disassembly 300 Mar. 18/13 Assembly 700 Mar. 18/13 Note: Contact L-3 Aviation Recorders, to verify this date sensitive information when using this manual to develop other documentation. The L−3AR Publication index may be located at www.L−3.com or L−3ar.net. 8. COMPONENT MAINTENANCE MANUAL (CMM) EFFECTIVITY Effectivity of the CMM is based on effectivity dates and product serial number. Effectivity of the manual is identified by a list of effective pages in the front of the manual. 9. PART NUMBER FORMATTING L−3AR does not delineate its part numbers by special characters, such as the “−” dash character. L−3AR considers its part numbers with or without the use of special characters to be the same, for example, there is no difference between part number 266−E0305−00, 266E0305−00, or 266E030500. To be in compliance with ARINC Specifications 100 and 200 the part numbers listed in this manual use the following format: 266E0305−00. L−3AR typically identifies its part numbers on other documents such as internal engineering drawings, purchase orders, component labels, shipping orders, Form 8130’s, and certification documents with the format: 266−E0305−00. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Introduction Rev. 15 Page 6 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR DESCRIPTION AND OPERATION 1. GENERAL This Component Maintenance Manual describes the Model FA2100/757A, Cockpit Voice Recorder, FA2100CVR, p/n’s: 2100-1010-( ), 2100-102X-( ), and 2100-122X-( ). The FA2100CVR is a highly reliable recorder that is designed to meet the performance requirements of ED-56A or ED−112 and to accept requirements of ARINC 557/757A Characteristics including Rotor Speed Encoder (RSE) and Greenwich Mean Time (GMT) interface. The FA2100 CVR recorder is designed as a maintenance free recorder. There is no periodic or scheduled maintenance required for this recorder. It is considered an “install and forget it box.” NOTE: The CVDR has a time−in−can circuit that is used to date/ time stamp the downloaded voice or flight data files. This is not a function of the readout time displayed for voice or data. The GMT inputs are the true time of the recording. Data can also be displayed during readout as relative time, based on file size. If the file date time stamp is not displaying the proper time of the download, this is not a fault condition that will impede the normal recording operation of the recorder. The unit should not be pulled from service for a faulty time in a can date/time stamp error. This condition should be noted and fixed at the next shop visit. The FA2100CVR Recorder is an ARINC 404, 1/2 ATR short box which performs the cockpit voice recorder function of an ED-56A, or in the case of 2100−1X25/1X27−XX, ED112, compliant Recorder. The FA2100CVR uses solid state Flash Memory technology as the recording medium with two recording capabilities available p/n: 2100-1010-( ) for 30-minutes, or p/n: 2100-1X2X-( ) for 2-hours. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 1 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR HARDWARE AND SOFTWARE MODIFICATIONS CSMU ULD GSE CONNECTOR (BEHIND DUST COVER) Figure 1. Model FA2100 Cockpit Voice Recorder (FA2100CVR) 2. FA2100 CONFIGURATIONS The current configurations of the FA2100CVR’s are listed in Table 2 below, and with its specific part number in the IPL Section Figure 1, Item 1A through Item 1AB. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 2 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Table 2. FA2100 CVR Descriptions Part Number Description Weight! (lbs) Figure Reference 2100-1010-00 ARINC 757, 30 MIN. CVR, 1/2 ATR SHORT * 10.0.5 Figure 1 2100-1010-50 ARINC 757, 30 MIN. GA CVR, 1/2 ATR SHORT, 28 VDC ONLY * 9.5.5 Figure 1 2100-1010-51 ARINC 757, 30 MIN. GA CVR, 1/2 ATR SHORT, TITANIUM CSMU W/ RTV, 28 VDC ONLY * 7.7.5 Figure 1 2100-1020-00 ARINC 757, 2−HR. CVR, 1/2 ATR SHORT 10.6 max. Figure 1 2100-1020-02 ARINC 757, 2−HR. CVR W/ FSK 10.6 max. Figure 1 2100-1020-50 ARINC 757, 2−HR. GA CVR, 1/2 ATR SHORT, 28 VDC ONLY * 9.5.5 Figure 1 2100-1020-51 ARINC 757, 2−HR. GA CVR, 1/2 ATR SHORT, TITANIUM CSMU W/ RTV, 28 VDC ONLY 8.3 max. Figure 1 2100-1025-02 ARINC 757, 2−HR. CVR W/ OMS, 4 CHANNEL HIGH QUALITY 10.6 max. Figure 1 2100-1025-12 ARINC 757, 2−HR. CVR W/ OMS, 4 CHANNEL HIGH QUALITY (CYRILLIC) 10.6 max. Figure 1 2100-1025-22 ARINC 757, 2−HR. CVR W/ OMS, 4 CHANNEL HIGH QUALITY W/ RIPS 10.6 max. Figure 1 2100-1025-24 ARINC 757, 2−HR. CVR W/ OMS, 4 CHANNEL HIGH QUALITY W/ RIPS S/W 10.6 max. Figure 1 2100-1026-02 ARINC 757, 2−HR. CVR W/ OMS, 4 CHANNEL HIGH QUALITY W/ RIPS 10.6 max. Figure 1 2100-1027-02 ARINC 757, 2−HR. CVR W/ OMS, 4 CHANNEL HIGH QUALITY W/ RIPS 10.6 max. Figure 1 2100-1220-00 ARINC 757, 2−HR. CVR, 1/2 ATR SHORT, 90−DAY BEACON 10.6 max. Figure 1 2100-1220-02 ARINC 757, 2−HR. CVR W/ FSK, 90−DAY BEACON 10.6 max. Figure 1 2100-1225-22 ARINC 757, 2−HR. CVR W/ OMS, 4 CHANNEL HIGH QUALITY W/ RIPS, 90−DAY BEACON 10.6 max. Figure 1 2100-1225-24 ARINC 757, 2−HR. CVR W/ OMS, 4 CHANNEL HIGH QUALITY W/ RIPS S/W, 90−DAY BEACON 10.6 max. Figure 1 2100-1226-02 ARINC 757, 2−HR. CVR W/ OMS, 4 CHANNEL HIGH QUALITY W/ RIPS, 90−DAY BEACON 10.1.5 Figure 1 2100-1227-02 ARINC 757, 2−HR. CVR W/ OMS, 4 CHANNEL HIGH QUALITY W/ RIPS, 90−DAY BEACON 10.1.5 Figure 1 2100-1925-22 ARINC 757, 2−HR. CVR W/ OMS, 4 CHANNEL HIGH QUALITY, 90−DAY BEACON 10.6 max. Figure 1 * Obsolete models. The standard configurations provide for a 600−ohm audio output monitor to an associated Control. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 3 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 3. SYSTEM DESCRIPTION Refer to Figure 2. The Model FA2100 Cockpit Voice Recorder System consists of the recorder and an externally mounted control unit or externally mounted preamplifier with remote microphone. Interconnection between the recorder and the control unit is accomplished using aircraft wiring. The FA2100 CVR is connected to the aircraft wiring via a 57-pin, DPXB-style connector. The Aircraft Interface PWA provides for all input and output signals. The Model FA2100CVR is housed in a 1/2-ATR, Short, ARINC 404A-style case. It has an aluminum chassis cover painted international orange with two reflective stripes located on a stainless steel or titanium Crash Survivable Memory Unit (CSMU). The recorder weighs a maximum of 10.6-pounds with an underwater locator device mounted on the front of the CSMU. The FA2100CVR does not require external shock mounting. The Model FA2100CVR consists of an Underwater Locating Device, chassis and front panel, four internal level-2 replaceable assemblies: the Aircraft Interface PWA, Audio Compressor PWA, Acquisition Processor PWA, and the Crash Survivable Memory Unit (CSMU) which contains the solid-state flash memory used as the recording medium. A. Underwater Acoustic Beacon The Model FA2100 FDR has an underwater acoustic beacon mount located on its front panel which also acts as the recorders carrying handle. The ULB mount will accept either a 30−day or a 90−day underwater locator beacon. The ULB meets or exceeds the requirements of the Federal Aviation Administration technical standard order TSOC121 for 30−day beacons, or TSO−C121b for 90−day beacons. FAA TSO−C121 will be revoked as of March 1, 2015. After this date, the manufacture of 30−day beacons in accordance with TSO−C121 will be prohibited. 30−day beacons already in service may still be used, and a kit is available for battery replacement. A 90−day beacon conversion kit is also available for the retrofit of a 90 day beacon to an existing recorder. All new recorder production will incorporate the 90−day underwater locator beacon. The beacon is located on the front panel for ease of reading the battery replacement date and for quick removal and replacement of the beacon. The ULB is equipped with a battery that has an expected life of six years. The ULB requires cleaning and functional testing every 24−months. The batteries in the beacons are field serviceable and and may be ordered from L−3AR. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 4 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR B. Circuit Boards The FA2100CVR electronics contain all the necessary power supplies and circuitry to input, record, monitor and playback data. In addition, circuitry to perform self– test functions and provide signals to the appropriate status indicators is also integrated into the FA2100CVR electronics. The removable circuit boards include the Aircraft Interface PWA, Audio Compressor PWA, and Acquisition Processor PWA. C. Power, Control and Monitor Signal Interface Characteristics Input power may be 115 Vac, 400 Hz or 28 Vdc (PN 2100−10X0−5X units are 28 Vdc only). At normal power level, an interruption equal to or less than 200 milliseconds will not affect the Model FA2100CVR’s function. Upon application or re-application, or normal, abnormal, or emergency power, the FA2100CVR will begin storing data in memory within 250 milliseconds. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 5 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR COCKPIT AREA MICROPHONE (CAM) * MONITOR AUDIO TO HEADSET JACK ERASE A ERASE C CONTROL UNIT AIRCRAFT WIRING INTERLOCKS (LANDING GEAR MUST BE DOWN AND BRAKE LOCKED TO ALLOW MEMORY TO BE ERASED) PUSH TO TEST GEAR AREA MICROPHONE BRAKE +18 VDC OPERATING POWER 28 VDC OR 115 VAC 400 Hz 2 RECORD ON +5 V FOR LIGHTED PANEL CHANNEL 4 2 CHANNEL 3 PILOT AUDIO FA2100 CVR AUDIO OUT 2 2 CHANNEL 2 CO‐PILOT AUDIO +18 VDC 2 SPARE AUDIO (TO 3RD CREW MEMBER OR PA SYSTEM) 2 CHANNEL 1 TEST INDICATOR 2 2 GMT_IN_B (429) AIRCRAFT INTERFACE PWA GMT_IN_A (429) ROTOR_SPEED_IN_HI ROTOR_SPEED_IN_LO **OMS IN A **OMS IN B **DATA LINK IN A 429 **DATA LINK IN B 429 ***RIPS FAULT INPUT ***RIPS MAINTENANCE INPUT ***RIPS PRESENT INPUT STOP RECORDING/ ***RIPS ACTIVE INPUT CHASSIS GROUND * S055 Mics have 4 Lines to the C.U. CVR FAULT TO AIRCRAFT FAULT MONITORING SYSTEM **OMS OUTPUT A 429 **OMS OUTPUT B 429 **DATA LINK VALID AUDIO COMPRESSOR PWA ACQUISITION PROCESSOR PWA GSE OUTPUT TO GROUND STATION TEST EQUIPMENT S056 MICS have 3 Lines to the C.U. For GA versions refer to Figure 4. ** OMS & Data Link are applicable to the 2100‐1025‐XX, ‐1026‐XX, and ‐1027‐XX only. *** RIPS Status Monitoring. 2100-1025-22/-24 CSMU (Crash Survivable Memory Unit) ASSEMBLY (CRASH PROTECTED SOLID STATE MEMORY) & 2100-1026-XX only. Figure 2. Model FA2100 CVR, (2100‐1010‐00, 2100‐1X20‐00/02, 2100‐1X25‐XX, 2100‐1X26‐XX and 2100‐1X27‐XX) Functional System Block Diagram Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 6 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 2 ERASE A ERASE C AIRCRAFT WIRING INTERLOCKS (LANDING GEAR MUST BE DOWN AND BRAKE LOCKED TO ALLOW MEMORY TO BE ERASED) PUSH TO TEST GEAR COCKPIT AREA MICROPHONE (CAM) BRAKE 3 3 RECORD ON CHANNEL 4 FA2100 GACVR 3 CHANNEL 3 PILOT AUDIO AUDIO OUT 2 2 CHANNEL 2 CO‐PILOT AUDIO 2 SPARE AUDIO (TO 3RD CREW MEMBER OR PA SYSTEM) TEST INDICATOR CHANNEL 1 2 2 CVR FAULT AIRCRAFT INTERFACE PWA GMT_IN_B (429) GMT_IN_A (429) ROTOR_SPEED_IN_HI TO AIRCRAFT FAULT MONITORING SYSTEM ROTOR_SPEED_IN_LO (Input Z = 100 Kohms) 1 28 VDC ATTENUATION 4 STOP RECORDING CHASSIS GROUND 1 2 All GACVR's operate only with a 28Vdc input source. Used for GA versions only. The GA versions do not use a control unit; however, the other input and output signals indi­ cated are still utilized allowing for an optional customer fur­ nished control panel. AUDIO COMPRESSOR PWA ACQUISITION PROCESSOR PWA CSMU (Crash Survivable Memory Unit) ASSEMBLY (CRASH PROTECTED SOLID STATE MEMORY) GSE OUTPUT 3 TO GROUND STATION TEST EQUIPMENT All GACVR's only use the Model S056 Remote Mic. Figure 3. Model FA2100 GACVR (2100‐1010‐50/‐51 and 2100‐1020‐50/‐51) Functional System Block Diagram Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 7 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (1) Stop Recording Command Assertion of the “Stop Recording” command stops the FA2100 CVR recording within ten minutes. Removal of the “Stop Recording” command or “Push-To-Test” resumes the recording. If the recording is resumed due to the “Push-To-Test” function being activated, the recording will again cease within 10 minutes if the “Stop Recording” signal is still active. (2) Control Unit Operating Power and Monitor Audio Signals The FA2100 CVR provides the control unit with +18 Vdc operating power, monitor audio to the headset jack, and a TEST indicator signal. Refer to Figure 4, an Audio Output channel for test monitoring provides a combination of four High Quality (for 30-minute recorders) or two Standard Quality (for 120-minute recorders and 2100−1020−XX pre MOD−DOT #7) or four High Quality (for P/N: 2100−1X25/1X26/1X27−XX and 2100−1X20−XX MOD−DOT #7) reprocessed ADPCM data channels. This monitored Audio Output signal is accessible at the front panel of the control unit via a 600-ohm headset. The monitor audio signal has a reference input level of 2.55 Vrms into 600 ohms applied to one input channel. In the 2100-1010-( ), 30-minute recorders, the monitored Audio Output signal to the control unit is developed by summing together the High Quality Voice for Channels 1, 2, 3, and the Cockpit Area Microphone (CAM) Channel 4. In the 2100-1020-( ) pre MOD−DOT #7, 120-minute recorders, the Audio Output signal consists of the same High Quality Voice and CAM channels and Test signal as found in the 30-minute recorder, in addition to a Standard Quality Voice and Standard Quality CAM output for up to 120 minutes. In the 2100−1X25/1X26/1X27−( ) and 2100−1X20−( ) MOD−DOT #7 the monitored audio is a combination of Channel 1 through Channel 4 High Quality audio. There are no Standard Quality audio channels in the full 2−hour High Quality Recorder. This monitored Audio Output is the Adaptive Differential Pulse Code Modulated (ADPCM) digital data which is reprocessed back to PCM and converted from digital to analog audio prior to being recorded into flash memory. It should not to be confused with the downloaded digital audio retrieved from memory with the Portable Interface Unit, from the front panel ATE connector. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 8 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 3rd Crew Member/ Spare Audio CH 1 CH 1 (HQ) (150‐3500 Hz) Co‐Pilot Audio CH 2 HQ CH1 , HQ CH2, HQ CH3 , HQ CAM CH 2 (HQ) (150‐3500 Hz) Pilot Audio CH 3 CH 3 (HQ) (150‐3500 Hz) Cockpit Area Mic (CAM) Audio CH 4 AUDIO OUT TO CONTROL UNIT HEADSET JACK ERASE CH 4 (HQ) (150‐6000 Hz) PUSH‐TO‐TEST 620 Hz - 660 Hz BULK ERASE 400 Hz ERASE “A” + “C” FA2100 CVR P/N 2100–1010–XX, 30‐Minute Audio Monitor Scheme CH1 (SQ) CH2 (SQ) CH3 (SQ) SQV CAM (SQ) 3rd Crew Member/ Spare Audio CH 1 Co‐Pilot Audio CH 2 Pilot Audio CH 3 Cockpit Area Mic (CAM) Audio CH 4 PUSH‐TO‐TEST CH 1 (150‐3500 Hz) CH1 (HQ) CH 2 (HQ) (150‐3500 Hz) CH 2 (HQ) CH 3 (HQ) (150‐3500 Hz) CH 3 (HQ) CH 4 (HQ) (150‐6000 Hz) SQV SQC HQ CH1 , HQ CH2, HQ CH3 , HQ CAM TEST AUDIO OUT TO CONTROL UNIT HEADSET JACK ERASE CAM (HQ) 620 Hz - 660 Hz BULK ERASE 400 Hz ERASE “A” + “C” FA2100 CVR P/N 2100-1020-XX, 120‐Minute (pre MOD-DOT #7) Audio Monitor Scheme Legend: CAM – Cockpit Area Microphone CH – Channel HQ – High Quality SQ – Standard Quality Figure 4. (Sheet 1 of 2) Model FA2100 CVR, 30‐Minute and 120‐Minute Audio Monitor Schemes Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 9 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 3rd Crew Member/ Spare Audio CH 1 Co‐Pilot Audio CH 2 Pilot Audio CH 3 Cockpit Area Mic (CAM) Audio CH 4 PUSH‐TO‐TEST CH 1 (150‐3500 Hz) CH1 (HQ) CH 2 (HQ) (150‐3500 Hz) CH 2 (HQ) CH 3 (HQ) (150‐3500 Hz) CH 3 (HQ) CH 4 (HQ) (150‐6000 Hz) HQ CH1 , HQ CH2, HQ CH3 , HQ CAM TEST AUDIO OUT TO CONTROL UNIT HEADSET JACK ERASE CAM (HQ) 620 Hz - 660 Hz BULK ERASE 400 Hz ERASE “A” + “C” FA2100 CVR P/N 2100-1X25/1X26/1X27-XX and 2100-1X20-XX (MOD-DOT #7) 120‐Minute Audio Monitor Scheme Legend: CAM – Cockpit Area Microphone CH – Channel HQ – High Quality Figure 4. (Sheet 2 of 2) Model FA2100 CVR, 30‐Minute and 120‐Minute Audio Monitor Schemes (3) Control Unit Test and Bulk Erase Signals The indicator signal is used to drive the TEST indicator in the Model S151/S161, Model S152/S162, and Model S251/S261 Control Units. Refer to the Component Maintenance Manual, ED−56A Control Units, Preamplifier, & Microphone Modules , ATA 23–70–05, Part Number 165E1747-00. The +18 Vdc is a short-circuit protected 30 mA line. All control units provide the FA2100 CVR with three control signals: Erase “A”, Erase “C”, and Push-To-Test. The Erase “A” and Erase “C” signals are used to initiate a bulk erasure of the crash protected solid-state memory. The ERASE pushbutton must be pressed for more than two seconds and then released to initiate the bulk erase function. Landing gear and brake interlocks are provided in the aircraft wiring to prevent memory erasures during flight conditions. The Bulk Erase function will not be activated if Voice Erase “A” is grounded or connected to Voice Erase “C” for 0.5 seconds or less. The function will be activated if Voice Erase “A” is connected to Voice Erase “C” for 2 seconds or more then grounded. The Push-To-Test signal is activated when the TEST pushbutton on the associated control unit is pressed. During this time, a 620 Hz to 660 Hz signal is generated Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 10 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR within the FA2100 which is used to test the circuitry of all the audio channels. In a successful test, the FA2100 Recorder provides a TEST INDICATOR signal which lights the green TEST indicator mounted on the front panel of the S151/S161, S152/S162, and S251/261 Control Units. D. NOTE: For all P/N: 2100−1025−02/−22/−24, 2100−1X26−02, 2100−1X27−02, no test tone will be heard and the Monitor Output will be muted during the test. After the test, if the −Test Good− tone is not heard, then the 2100CVR has failed and the test. Monitor Output will resumes in both a passed and failed test. NOTE: The Model 2100−1X25−XX, when used with the S161−1390−01 Control Unit, does not have a LED test indicator present. However, the audible test tone is still present. Voice Data Interface Characteristics The FA2100 CVR is used in an ARINC 557/757A configuration, with interface to the aircraft provided through a 57-pin DPXB rear panel connector. The Reference Signal, as required by ED-56A & ED−112, is defined as an input signal with a frequency of 1 kHz at an input level of 3 Vrms for Channels 1, 2, and 3, and 2 Vrms for Channel 4. The Audio input sensitivity level is .05 Vrms − 3 Vrms for Channels 1, 2, and 3, and .02 − 2 Vrms for Channel 4. The Model FA2100 CVR provides for four audio inputs which are connected as follows: Channel 1 – Cockpit Spare Audio Input (3rd crew member − CAA) Channel 2 – Co-Pilot’s Audio, Boom, Mask, and Hand-Held Microphone Input Channel 3 – Pilot’s Audio, Boom, Mask and Hand-Held Microphone Input Channel 4 – Cockpit Area Microphone (CAM) Input These audio signals are applied through the rear connector to the Aircraft Interface PWA, then are digitally converted into 16−Bit words, compressed and stored in memory. Refer to Paragraph 5 for detailed pin-outs of the rear interface connector. In the −02 FSK version of the FA2100 CVR, CH 1 or CH 3 may have an FSK GMT input applied along with the standard audio signal. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 11 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR E. Data Recording Storage Refer to Figure 5 for a diagram of the FA2100CVR recording schemes used in the 30-minute and 120-minute recorders and Table 1 for a breakdown of the recording durations for each of the High Quality and Standard Quality combined channels. The audio received from the cockpit area microphone (CAM) is applied to the CAM input channel (CH4). The recorded CAM audio has a bandwidth of 150 to 6000 Hertz. The other three channels receive audio from the pilot audio selectors and have a bandwidth of 150 to 3500 Hertz. The spare audio input applied to Channel 1 may be from a third crew member or PA system. The four audio input signals are applied to separate input circuits located on the Audio Compressor PWA for amplification and shaping with equalization performed as necessary. These four streams are then converted to a digital pulse code modulation (PCM) 16-Bit word format on the Audio Compressor PWA and then routed to the Acquisition Processor PWA. The PCM data for each channel is then encoded for storage using an adaptive differential pulse code modulation (ADPCM) processor. These four streams are recorded as high quality (HQ) audio for a 30-minute duration. In the case of P/N: 2100−1X25/1X26/1X27−XX and 2100−1X20−XX MOD− DOT #7, these HQ Channels are recorded for 120−minutes. The rate of the data stream recorded varies with the type of audio as follows: F 24 kbps for CH 1, 2, and 3 HQV F 48 kbps for CH 4 HQC In the 120−minute FA2100CVR (2100−1020−XX pre MOD−DOT #7), three of these audio streams (pilot, co-pilot, and spare CH1, 2, and 3) are combined to provide a fifth audio stream, designated Standard Quality Voice (SQV), to be recorded in standard quality audio. In the 120-minute FA2100CVR version (2100−1020−XX pre MOD−DOT #7), a sixth audio stream is formed using using the Standard Quality Cockpit Area Microphone (SQC) input. All six digital-encoded ADPCM signals are applied to the CSMU for storage in the solid-state flash memory. In this case, the rate of the data stream recorded varies with the type of audio as follows: F 24 kbps for CH 1, 2, and 3 HQV F 48 kbps for CH 4 HQC (CAM) F 16 kbps for SQV and SQC (CAM) In both versions of the Model FA2100CVR, the four primary audio streams are always recorded as high quality audio (HQV) for 30 minutes. In the 120-minute Model (2100−1020−XX pre MOD−DOT #7), the Standard Quality Voice (SQV) and Cockpit Area Microphone channels (SQC) are recorded for a minimum of 120 minutes. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 12 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (CSMU) FLASH MEMORY 3rd Crew Member/ Spare Audio CH1 CH 1 (HQV) (150‐3500 Hz) Co‐Pilot Audio CH2 CH 2 (HQV) (150‐3500 Hz) Pilot Audio CH3 CH 3 (HQV) (150‐3500 Hz) CH 1 (24 kbps) 30 minutes CH 2 (24 kbps) 30 minutes CH 3 (24 kbps) 30 minutes CH 4 (HQC) (150‐6000 Hz) Cockpit Area Mic (CAM) Audio CH 4 CH 4 (48 kbps) 30 minutes Low Speed ARINC 429 GMT (12.5 kbps) 429 GMT Time Code GMT (2 Wds per 1 Sec.) RSE (7‐6000 Hz) Rotor Speed RSE (2 Wds per 1/2 Sec FA2100 CVR P/N 2100–1010–XX, 30‐Minute Recording Scheme (CSMU) FLASH MEMORY 3rd Crew Member/ Spare Audio CH1 CH 1 (HQV) (150‐3500 Hz) Co‐Pilot Audio CH2 CH 2 (HQV) (150‐3500 Hz) Pilot Audio CH3 CH 3 (HQV) (150‐3500 Hz) Cockpit Area Mic (CAM) Audio CH 4 CH 1 (24 kbps) 30 minutes CH 2 (24 kbps) 30 minutes CH 3 (24 kbps) 30 minutes CH 4 (HQC) (150‐6000 Hz) CH 4 (48 kbps) 30 minutes 429 GMT Time Code CH1 + CH2 + CH3 Low Speed ARINC 429 GMT (12.5 kbps) GMT (2 Wds per 1 Sec.) 120 minutes RSE (7‐6000 Hz) Rotor Speed Internal Channel (SQV) (16 kbps) 120 minutes RSE (2 Wds per 1/2 Sec) 120 minutes CAM FA2100 CVR Internal Channel (SQC) (16 kbps) 120 minutes P/N 2100-1020-XX (pre MOD-DOT #7) 120‐Minute Recording Scheme Legend: CAM – Cockpit Area Microphone CH – Channel HQ – High Quality SQ – Standard Quality Figure 5. (Sheet 1 of 2) Model FA2100 CVR, 30-Minute and 120-Minute Recording Schemes Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 13 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (CSMU) FLASH MEMORY 3rd Crew Member/ Spare Audio CH1 CH 1 (HQV) (150‐3500 Hz) Co‐Pilot Audio CH2 CH 2 (HQV) (150‐3500 Hz) Pilot Audio CH3 CH 3 (HQV) (150‐3500 Hz) Cockpit Area Mic (CAM) Audio CH 4 429 GMT Time Code Rotor Speed CH 4 (HQC) (150‐6000 Hz) Low Speed ARINC 429 GMT (12.5 kbps) RSE (7‐6000 Hz) CH 1 (24 kbps) 120 minutes CH 2 (24 kbps) 120 minutes CH 3 (24 kbps) 120 minutes CH 4 (48 kbps) 120 minutes GMT (2 Wds per 1 Sec.) 120 minutes RSE (2 Wds per 1/2 Sec) 120 minutes Data Link* Data Link 120 minutes OMS* OMS 120 minutes FA2100 CVR P/N 2100-1X25/1X26/1X27-XX and 1200-1X20-XX (MOD-DOT #7) 120‐Minute Recording Scheme Legend: CAM – Cockpit Area Microphone CH – Channel HQ – High Quality OMS − On board Maintenance System* * P/N 2100−1025/1026−XX only Figure 5. (Sheet 2 of 2) Model FA2100 CVR, 30-Minute and 120-Minute Recording Schemes (1) Output Audio Quality The FA2100CVR’s audio quality meets or exceeds the audio quality specified in Chapter 3 of ED–56A and Part I of ED−112. Specifically, the Reference Signal is 1-kHz at 3 Vrms for the voice channels, and 1-kHz at 2 Vrms for the CAM channel. The signal-to-noise plus distortion ratio (SINAD) of this signal when reproduced exceeds 24 dB (6 percent distortion) for the most recent 30 minutes of recording and exceeds 20 dB (10 percent distortion) otherwise. NOTE: Refer to Table 3.1 of ED–56A and I−3.1 of ED−112 for other applicable audio quality specifications including the Speech Transmission Index requirement for various channels and segments of recording. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 14 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Table 1 Model FA2100 CVR Recording Specifications Cockpit Audio Inputs Model FA2100 Part Number Channel 1 Channel 2 Combined Channels Channel 3 Channel 4 Combined Audio SQ CAM–SQ 3rd Crew Member/ Spare Audio Input for High Quality Recording Co-Pilot Audio Input for High Quality Recording Pilot Audio Input for High Quality Recording Cockpit Area Microphone (CAM) Input for High Quality Recording Summation of CH 1, 2, & 3 audio inputs for Standard Quality Recording Standard Quality Recording of Cockpit Area Microphone (CAM) (CH 4) Input 2100–1010–XX 30 minutes 30 minutes 30 minutes 30 minutes Not available Not available 2100–1020–XX pre MOD−DOT # 7 30 minutes 30 minutes 30 minutes 30 minutes 120 minutes 120 minutes 2100–1X20–XX MOD−DOT # 7 120 minutes 120 minutes 120 minutes 120 minutes Not available Not available 2100–1X25–XX 2100–1X26–XX 2100–1X27–XX 120 minutes 120 minutes 120 minutes 120 minutes Not available Not available NOTE: All of the times indicated in the above chart are minimum recording times. (2) GMT/FSK Output Signals In addition to the voice channel inputs, in the 2100−1010−( ) and 2100−1X2X−( ) configurations, GMT is applied as low speed (12.5 kbps) ARINC-429 to pins 25 and 26; with the exception of 2100−1X20−02 configurations (FSK option). In the 2100−1X20−02 version, GMT may either be applied as low speed ARINC 429, or alternatively as an FSK signal combined with the audio input on either Channel 1 or Channel 3. (3) Rotor Speed Signals Rotor Speed Encoded (RSE) input signals are applied to the rear connector pins 48 and 49 as an analog frequency varying between 7−6000 Hz. The input impedance of the RSE signal is 100 Kohms. The GMT/RSE input signals are then digitally converted and compressed in the Acquisition Processor PWA. This data is then stored in a memory partition separate from the Audio data. In the case of the 30-minute Model FA2100 CVR, p/n: 2100–1010–( ), 30 minutes of GMT/RSE data is stored. In the case of the 120-minute Model FA2100 CVR, p/n: 2100–1X2X–( ), a full 120 minutes of GMT/RSE data is stored. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 15 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR The Rotor Speed input is recorded as two words every 1/2 second. Rotor Speed Word 1 (8-bits) provides the number of 400-Hz reference pulses counted during the sample period. Word 2 (12-bits) contains the integer number of rotor pulse cycles counted during the sample period. The average rotor pulse frequency is determined from the word values with better than 1% accuracy using the following formula: Rotor Pulse Frequency = (400 Hz) x (Rotor Pulse Count) / (Reference Count), or Rotor Pulse Frequency = 400 x Word 2 / Word 1. For displaying rotor speed the user must be able to select the display to be frequency or calculated revolutions per minute (RPM). To allow the conversion from frequency to RPM the user must provide a matching frequency to RPM ratio. For example, 6 kHz = 300 RPM. To determine the calculated RPM use the following formula: RPM = Rotor Pulse Frequency x (Rotor RPM/Tach Frequency). In the case of helicopter installations of the FA2100CVR, the Bulk Erase function is inhibited until the rotors stop. (4) On board Maintenance System (OMS) The OMS input signals are applied to the rear connector pins 39 and 40 as a low speed ARINC 429 signal. The OMS output signal is sent out on pins 50 and 51 as a high speed ARINC 429 signal, along with the Data Link output signal. The Recorder records the FA2100 CVR OMS status word only, but is also used to send status messages to the aircraft’s OMS computer. Basically, there are two modes for sending messages to the OMS computer, Normal and Interactive. When the aircraft’s recorder is in Normal mode, the CVR sends a status message to the OMS computer four times per second. When the recorder is in Interactive mode, the OMS computer can request the status of the recorder through a series of menus. The OMS feature can be found on the FA2100 CVR p/n: 2100−1X25/1X26/1X27−( ) only. (5) Data Link The Data Link input signals are applied to the rear connector pins 33 and 34 as a high speed ARINC 429 signal. The Data Link output signal is sent out on pins 50 and 51 as a high speed ARINC 429 signal, along with the OMS output signal. The Data Link Valid input signal is applied to pin 56. The Data Link Valid input signal notifies the recorder to expect Data Link input signals. When the Data Link system is energized, it sends an Aloha response message to the recorder. If the recorder is in place and operational, the recorder records the Aloha response message and returns a response message to inform the Data Link Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 16 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR system that the recorder is in place and operational. Once the Data Link system receives a response from the recorder, it will send all messages received by the Data Link system to the recorder to be stored in the CSMU. If the recorder is not in installed or not operational, the Data Link system will continue to send Aloha messages until the recorder’s status changes. The Data Link feature can be found on the FA2100 CVR p/n: 2100−1X25/1X26/1X27−( ) only. For p/n 2100−1X25/1X26/1X27−XX CVRs, the Audio and Data Link Playback (ADPL) software may be used to download and analyze the audio data. Refer to the FA2100CVR Audio and Data Link Player Software Operator’s Manual, Part Number 165E3596−00. F. Audio Monitoring For TSO compliant FA2100CVRs mounted in the aircraft, previously recorded data cannot be monitored from the FA2100CVR. This is a security feature implemented to protect the rights of pilots and other flight crew members. The Cockpit Area Microphone (CAM), pilot, co-pilot, and spare audio can be monitored during recording using a headset plugged into the 1/4-inch, 600-ohm phone jack mounted on the front panel of the associated control unit. G. Storage Capacity The Model FA2100CVR storage media is designated as the Crash Survivable Memory Unit (CSMU). The CSMU in the Model FA2100, p/n 2100–1010–( ), contains flash memory with enough storage capacity to allow continuous recording of the four high quality audio channels for a minimum of 30 minutes. The CSMU Flash memory in the Model FA2100, p/n 2100–1020–( ) pre MOD−DOT #7, provides enough storage capacity to allow continuous recording of the four high quality audio channels for a minimum of 30 minutes, and the standard quality combined and cockpit microphone channels for a minimum of 120 minutes. The CSMU Flash memory in the Model FA2100, p/n 2100–1X25/1X26/1X27–( ) and p/n 2100−1X20−( ) post MOD− DOT #7, provides enough storage capacity to allow continuous recording of the four high quality audio channels for a minimum of 120 minutes. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 17 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR H. Data Retrieval Incorporated into the FA2100CVR aircraft installation is a “Record On” jumper. During bench test of the FA2100CVR, removal of the jumper disables the record function of the recorder, thereby allowing playback of the recorded data. While in the Playback mode, replaying of recorded data is controlled by the Portable Interface (PI) Unit p/n: 17TES0043 or Portable Interface/2 (PI/2) Unit P/N: 17TES0062. Detailed operation of the PI is contained in the PI Operation Manual, P/N: 165E1630−00 or PI/2 Operation Manual, P/N: 16521630−01. To retrieve data from the recorder, the recorder must be removed from the aircraft, connected to appropriate AC or DC power (DC power only for FA2100CVR Models 2100−1010−5X and 2100−1020−5X), and the Portable Interface Unit (PI) p/n: 17TES0043 or Portable Interface/2 (PI/2) Unit P/N: 17TES0062 must be connected to the recorder’s front panel GSE connector. The PI or PI/2 Unit allows a user to replay, using a 600-ohm headset and a 600−ohm boomset microphone headset in the case of the 2100−1X25/1X26/1X27−( ) model, any one of the high quality audio channels, or the cockpit area microphone channel. The PI or PI/2 Unit also has the capability to search through the stored data using the fast forward and fast reverse command keys. The fidelity of the FA2100CVR audio data output at the PI or PI/2 Unit is such that its internal speaker allows quality analysis of the recorded data. The PI or PI/2 Unit also simplifies connection to standard commercial recording equipment for duplicating any of the monitored audio streams. Additionally, the audio data can be down-loaded through the GSE connector, stored on Type III PCMICA portable hard disks inserted in the PI Unit for later playback. The Portable Interface Unit must have MOD-DOT 1 and the FA2100CVR must have MOD-DOT 2 for Audio data downloading capability to be activated. For the PI/2 refer to the PI/2 Operation Manual, P/N: 16521630−01on how audio data can be downloaded and the different ways to store data. For operators using Rose 4.0 or higher software on a ROC or RAU, audio data along with the flight data may be downloaded directly from a CVR and played back through Rose. The audio and flight data will be time synchronized through the Rose software. Refer to the Read−Out Support Equipment/Recorder Interface Software Version 4.0 or Higher Operator’s Manual, Part Number 165E1696−03. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 18 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR I. Data Reproduction A standard cassette, reel-to-reel tape, or digital audio tape recorder can be used to produce a high fidelity copy of the Model FA2100CVR recorded data. To do so, the inputs of the copy recorder are connected to any one of the output RCA phono jacks located on the Portable Interface (PI) Unit’s PI Audio Read-out Cable, p/n 17TES0051. Depending upon the type of recorder used for copying, the FA2100CVR audio can be copied one channel at a time, or all individual channels can be copied simultaneously. Reconstructed GMT/RSE output signals may also be reproduced using the PI’s Aux Read-out Cable, p/n: 17TES0052. J. Built-In-Test (BIT) A continuous Built-In-Test (BIT) capability is provided at power up to establish and monitor the mission fitness of the hardware. The built-in-test feature has been designed to perform a continuous test of all bits within the solid-state memory located in the Crash Survivable Memory Unit (CSMU). An additional built-in-test is initiated by pressing a green TEST pushbutton located on the front panel of the control unit (Models S151/S161, S152/S162 or S251/S261). A green TEST indicator is located on the front panel of the Model S151/S161/S152/S162 and S251/S261 Control Units to indicate successful completion of the manual test. (Note: The S161−1390−01 Control Unit does not have a LED Test Indicator.) The TEST pushbutton is used to generate the 620- to 660-Hertz test tone used for unit verification. This test tone is developed on the Audio Compressor PWA and applied to each channel individually where it is processed, stored in memory, read from memory, and checked for expected frequency and amplitude. In the GACVR, a continuous Bite Status Output or Recorder Fault is indicated on pin 23. A ground at pin 23 represents a no fault, while an open indicates a fault or that a CVR is not installed. The CVR test indicator wires, pins 15 and 16 (1mA) may be omitted in installations where ARINC 557 compatibility is not needed. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 19 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR CVR FAULT LIGHT REAL TIME OPEN = FAULT GND = NO FAULT ANNUNCIATOR PANEL CVR 23 RELAY +V ENERGIZE = OPEN (NO CVR FAULT) DE-ENGERIZED = GRN (CVR FAULT) Figure 6. GACVR Fault Circuit for Pin 23 K. Crash Survivable Memory Unit The Crash Survivable Memory Unit (CSMU) is the environmentally hardened memory storage assembly of the Model FA2100. Electrical interface to the CSMU is made by the Acquisition Processor PWA via a single 16-contact connector at connector J1. L. Crash and Fire Protection The Crash Survivable Memory Unit (CSMU) construction enables the Model FA2100CVR to meet or exceed the rigorous crash protection requirements of EUROCAE ED–56A, ED−112 and TSO-123a. M. Control Unit, Microphone & Preamplifier Equipment Refer to Aviation Recorders ED-56A Compliant Control Unit, Preamplifier and Microphone CMM, ATA No. 23-70-05, Part Number 165E1747-00, for more detailed information of these ancillary recorder components. A Control Unit or Preamplifier is a required component of a CVR installation and functions as the FA2100CVR cockpit user interface; however, this is not required for GACVR recorders. Control Units contain a preamplifier for interfacing the cockpit area microphone with the CVR, and provide a means for activating the test function, by pressing a green TEST push button and observing an green TEST indicator. Bulk erasure of the FA2100CVR storage media is also accomplished by pressing the Control Unit’s red ERASE push button. All Control Units contain a headset jack for verifying system operation. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 20 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR The Model S151/S161, Model S152/S162, and the Model S251/S261 Control Units are for use in FA2100CVR System installations that comply with ARINC Characteristic 757, TSO−C123a and EUROCAE ED–56A. The Model S151/S161, and Model S251/S261 Control Units house the Microphone Preamplifier PWA, and the TEST and Bulk ERASE switches. The S151/S251 Control Units are used with remote microphone Model S055, whereas the S161/S261 Control Units are used with the remote microphone Model S056. The Model S152/S162 contains a built-in electret condenser-type microphone, Microphone Preamplifier PWA, and TEST and Bulk ERASE switches. All three of these Control Units also contain a TEST indicator lamp and a 600-ohm HEADSET jack, with the exception of the Model S161 Control Unit P/N: S161−1390−01, which does not have a test lamp. The Model S150/S160 Preamplifiers are available for FA2100CVR System installations that do not require a Control Unit but that are required to comply with TSO− C123a and EUROCAE ED–56A. However, because ARINC Characteristic 757 does not address microphone preamplifiers, the Model S150/S160 Preamplifiers are not considered ARINC 557/757 compliant. The S150/S160 provides the same preamplifier circuit for the cockpit area microphone as the Model S151/S161, Model S152/S162, and Model S251/S261 Control Units. The FA2100CVR is compatible with installations using the Model A151B and A152B Control Units; however, such installations do not comply with EUROCAE ED–56A. The Model A151B houses the Microphone Preamplifier PWA, and the TEST and Bulk ERASE switches. This Control Unit is used with an externally-mounted condenser microphone (Model A055B). The Model A152B contains a built-in condenser microphone, Microphone Preamplifier PWA, and TEST and Bulk ERASE switches. Both the A151B and A152B Control Units contain an analog TEST meter compatible with the FA2100CVR. N. Remote Microphone Module The Model S055/S056 Remote Microphone Modules are available to complete a TSO−C123a and ED–56A-compatible installation. The Model S055 Microphone is required with the S151 and S251 Control Units, and with the S150 Preamplifier Module. The Model S056 Microphone is required with the S161 and S261, and with the S160 Preamplifier Module. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 21 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR O. Ground Support Equipment Interface The interface to the Ground Support Equipment (GSE) is via a bi-directional highspeed serial link available at the front-panel GSE connector. A facility for retrieving the stored data from the CSMU to Ground Support Equipment, GSE, is provided for high-speed downloading of the voice data. The GSE Interface serves two purposes: P. (1) As a connector for use with portable or bench test equipment for recorder checkout. (2) As a connector for use in downloading data into a storage device while on the aircraft or bench. BIT and Fault Detection The FA2100 incorporates multiple overlapping methods of built−in−test (BIT) to ensure proper reporting of the recorder faults. At the most basic level the fault driver outputs default to the FAULT state (even with no power applied to the recorder) and must be actively cleared by a properly operating Store Manager Processor (SMP) as the recorder powers up. Next, a watchdog circuit monitors the operation of the SMP and associated circuitry. This assures that a fault is asserted in the event of a processor failure (including partial failures such as arithmetic errors, inordinate increments, and logic errors.) The watchdog circuit will also be activated in the event of a failure of the SMP’s program Flash memory. If the SMP is operating properly it performs the task of monitoring the above listed faults in the other FA2100 processors. It detects errors in the Flight Data Processor (FDP) and Audio Compressor Processor (ACP) by checking for protocol errors and unexpected data values. The SMP checks the non−volatile random access memory (NVRAM) for operation and data integrity using a cyclic redundancy check (CRC) on the contents. A failure to read or write this device properly will be flagged by a CRC mismatch and a BIT fault will be asserted. Finally, the SMP verifies the function of the crash−survivable memory unit (CSMU) by performing a read after each write to ensure the data written to CSMU can be retrieved. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 22 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR In summary each processor, RAM and programmable memory device in the FA2100 is monitored by BIT. They are checked at power−up and continuously monitored during operation of the recorder. Failures are reported using the FAULT output signals. 4. FA2100 CVR SPECIFICATIONS Specifications for the Model FA2100CVR have been developed in close coordination with Aerospace Industry regulatory agencies. As such, the FA2100CVR meets or exceeds the requirements of technical standard order TSO–C123a, TSO–C123b, EUROCAE ED–55, EUROCAE ED–56A, and EUROCAE ED−112. A. Applicable Documents The following documents form a part of, or are referenced, within this CMM: (1) TSO–C123a Federal Aviation Agency Technical Standard Order TSO–C123a Technical Standard Order for Cockpit Voice Recorder Systems. Federal Aviation Agency Technical Standard Order TSO–C123b Technical Standard Order for Cockpit Voice Recorder Equipment. (1) TSO–C123b (2) EUROCAE MOPS ED–55 European Organization for Civil Aviation Electronics Minimum Operational Performance Specification for Flight Data Recorder Systems (3) EUROCAE MOPS ED–56A European Organization for Civil Aviation Electronics Minimum Operational Performance Specification for CVR Systems, December 1993 (4) EUROCAE MOPS ED–112 European Organization for Civil Aviation Electronics Minimum Operational Performance Specification for Crash Protected Airborne Recorder Systems, March 2003 (5) ARINC 404A Air Transport Equipment Cases and Racking Characteristic (6) ARINC Report 604–1 Guidance for Design and Use of Built-In-Test-Equipment (7) ARINC Report 624 Design Guidance for On-board Maintenance System (8) ARINC Characteristic 557 (9) ARINC Characteristic 757 (10) ARINC Characteristic 757A Cockpit Voice Recorder Cockpit Voice Recorder Cockpit Voice Recorder (11) ARINC Characteristic 777−1 Recorder Independent Power Supply (RIPS) Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 23 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (12) RTCA DO–160C Environmental Conditions and Test Procedures for Airborne Equipment (13) RTCA DO–178B Software Considerations in Airborne Systems and Equipment Certification to Level D The Model FA2100CVR meets the performance requirements of ED-56A, chapters 2, 3, 4, and 5, ED–55 chapter 7 and ED−112, chapter 2, and Part I, while conforming to the input interface required in ARINC 557/757/757A. When the software detects a fault a CVR FAULT will be asserted immediately with no artificial delay. B. Physical Characteristics For specific physical characteristic, refer to Section 800, Fits and Clearances. C. Electrical Characteristics For specific electrical characteristics, refer to Section 800, Fits and Clearances. D. Environmental Characteristics For specific environmental characteristics, refer to Section 800, Fits and Clearances. E. Crash and Fire Protection For specific crash and fire protection specifications, refer to Section 800, Fits and Clearances. F. CSMU Torque Requirement For specific CSMU torque requirements, refer to Section 800, Fits and Clearances. 5. INSTALLATION The information provided in this section is for general knowledge use only. For authorized detailed installation instructions, refer to the Model FA2100CVR Installation and Operation Instruction Manual, p/n: 165E1846-00. The Model FA2100CVR is an environmentally hardened unit housed in an ARINC 404A 1/2-ATR short box painted international orange. The FA2100 does not require external shock mounting for installation into the aircraft. However, the Model FA2100CVR requires mounting in an approved mount system for installation into the aircraft. FA2100CVR Mount, Part Number 178E0919–00, is a mount used for this purpose. The FA2100CVR is fully compatible with ARINC Specification 757 and is directly interchangeable with all existing cockpit voice recorder installations. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 24 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR The FA2100CVR is connected to its control unit or preamplifier module by means of the aircraft wiring. Refer to Figure 7 and Figure 9 for the Standard ARINC−757 and GACVR Interface Wiring Diagrams used when installing the FA2100CVR into an aircraft. The Control Unit & Microphone information can be found in CMM, ATA No. 23−70−05, p/n: 165E1747−00 for ED−56A installations or the FA2100CVR Installation & Operation manual, p/n: 165E1846−00. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 25 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR STANDARD INTERWIRING PER ARINC SPEC 757 1A TO 115 Vac HOT (400Hz) TO AC COLD *5 TO C.U. GND *1, 2, 7 *3 OR *4 5A TO 28 Vdc *7 PUSH TO TEST *14 C *3 ERASE (MOMENTARY PUSH BUTTON) NC *8 NO TO ANNUNCIATOR PANEL FROM CAPTAIN'S CLOCK *10 SPARE MICROPHONE −TO 3RD CREW MEMBER OR PA SYSTEM *9, 11 TO CO-PILOT MICROPHONE *10 TO PILOT MICROPHONE *16 *9, 11 AREA MICROPHONE FROM ROTOR SPEED SENSOR *3, 6 * Refer to Notes for Figure 7. BRAKE GEAR BULK ERASE INTERLOCK (TYPICAL) OPEN = IN FLIGHT CLOSED = WEIGHT ON WHEELS For GACVR versions refer to Figure 9. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 115 Vac, 400 Hz (HOT) 115 Vac, 400 Hz (COLD) AUDIO OUT LO AUDIO OUT HI RECORD ON B RECORD ON A +28 Vdc POWER IN STOP RECORDING /RIPS ACTIVE INPUT *7 PUSH_TO_TEST PREAMP POWER OUT PREAMP GND POWER OUT HOT TEST INDICATOR + TEST INDICATOR – CHASSIS GROUND CVR FAULT OUT *8 GMT IN B (429) LO *12 GMT IN A (429) HI *7 RIPS FAULT INPUT CHANNEL 1 AUDIO IN LO DATA LINK FAULT *15 CHANNEL 1 AUDIO IN HI DATA LINK IN (429) B *15 DATA LINK IN (429) A CHANNEL 2 AUDIO IN LO CHANNEL 2 AUDIO IN HI RIPS MAINTENANCE IN­ *7 PUT OMS IN (429) B *15 OMS IN (429) A CHANNEL 3 AUDIO IN LO RIPS PRESENT INPUT *7 CHANNEL 3 AUDIO IN HI CVR REPLAY INHIBIT/FDR INHIBIT CHANNEL 4 AUDIO IN LO CHANNEL 4 AUDIO IN HI ROTOR SPEED IN LO *15 ROTOR SPEED IN HI DATA LINK V1/OMS B OUT DATA LINK V1/OMS A OUT *13 VOICE ERASE A DATA LINK VALID VOICE ERASE C *15 Wiring for all CVR's except for 2100-1025-XX and 2100-1026-XX, are compliant to ARINC 757-3. Figure 7. Interwiring Diagram, Recorder FA2100 CVR (2100-1010-00, 2100-1X20-00/-02, & 2100-1X25/1X26-XX) Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 26 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Notes for Figure 7: 1. Recommended minimum wire size is #22: #24 is electrically permissible except for power leads, where #18 wire is desirable on long-runs (pins 2, 3, 9, & 17). Wire resistance should not exceed 1 ohm for power leads and should not exceed 5 ohms for signal leads. All wiring should be MIL–W–22759 or MIL–C–27500. 2. Only one power source to be wired per aircraft. If 115 Vac, 400 Hz is supplied, connection is to be made to pins 2 & 3. If 28 Vdc is supplied, connection is to be made to pin 9. Shorting pins 1 & 2 is optional. 3. Recorder ground connection to be within 1 foot of pin 17, heavy gauge wire. Shields to be grounded at the recorder using short connections. Pin 17 is used as a +28vdc return. Control unit may be grounded in the cockpit to a chassis ground. 4. Jumper in aircraft connector. Without this jumper, the unit will not record or erase previously recorded information, bulk erase will not activate, and test will indicate NO–GO. 5. Pin 3 is not a DC return and is not grounded in the recorder. (see Note 3) 6. Twisted shielded cable. Shields to be grounded at the airframe using short connections. Tie shields to existing single point GND use for Pin 17. (see Note 3) 7. Using the the Stop Recording function, the grounded pin 10 terminates recording within 10 minutes. When using the RIPS Active function the CVR has a backup power source or RIPS available, pins 10, 29, 38 and 42 will be used for the RIPS Status Monitoring. 8. BITE status output: ground = no fault, open = fault or CVR not installed. 9. Audio input 3 Vrms maximum. 10. In 2100−1010−( ) and 2100−1X20−( ) configurations GMT is inputted as low speed (12.5 kbps) ARINC 429 to pins 25 and 26; with the exception of 2100−1X20−02 configurations (FSK option). In the −02 versions, GMT is input either as an FSK signal combined with the audio input signals on either Channel 1 or Channel 3, or as an ARINC 429 input on pins 25 and 26. This recorder has Auto−Sense and will process the GMT input type. 11. The Control Unit & Microphone information can be found in CMM, ATA No. 23−70−05, p/n: 165E1747−00 for ED−56A installations or the FA2100CVR Installation & Operation manual, p/n: 165E1846−00. 12. The 205E1849−( ) and 205E3977−( ) Audio Compressor cards provide for both ARINC 429 Label150 (1 sec resolution) and 125 (0.1 min. resolution) Low Speed GMT inputs. 13. If no Erase function is desired, ground “ERASE A” on pin 55 and leave open “ERASE C” on pin 57. 14. Test Indicator +/− lines (pins 15 & 16) only provide +28 Vdc, 1ma output to illuminate the Control Unit TEST lamp. (This is not sufficient to light an external annunciator lamp). 15. Data Link and OMS input and output signals are applicable only to p/n: 2100−1X25−( ). Data Link wiring is in accordance with ARINC 757−4, paragraph 3.9. 16. Pin 44 may be used to inhibit audio replay when pins 7 and 8 are not jumpered and is applicable only to p/n: 2100−1X25−( ). For further details , refer to ARINC 757−4, Attachment 6, Item 21. (see Note 4) Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 27 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR STANDARD INTERWIRING PER ARINC SPEC 757A (Data Link wiring IAW ARINC Spec 757A Paragraph 3.9) VOICE RECORDER UNIT (2100−1027−02 wiring shown for reference) 1 AMP TO 115 VAC, 400 HZ TO AC COLD 2, 8 5 OR TO DC POWER IN 28 VDC 5 AMPS 3 28 VDC RETURN 4 CONTROL UNIT PUSH TO TEST PREAMP PWR GND PREAMP PWR HOT (+18 VDC REG) CHASSIS GND VOICE ERASE ”A” VOICE ERASE ”C” OUTPUT LO OUTPUT HI MIC INPUT LO MIC INPUT HI MIC BIAS AUDIO MONITOR LO AUDIO MONITOR HI 15 15 LIGHTING COMMON LIGHTING 28V 8 A B C D E F G H J K L M N P R S T U V W X Y Z a b c d e f g h i j k m n p q r s 9 3 TO ANNUNCIATOR OR MAINT. COMPUTER FROM CAPTAIN’S CLOCK SPARE MICROPHONE TO 3RD CREW MEMBER OR PA SYSTEM 10, 11 TO COPILOT MICROPHONE 10 TO PILOT MICROPHONE 10, 11 6 COCKPIT AREA MICROPHONE FROM ROTOR SPEED SENSOR t 3, 7 MICROPHONE MIC BIAS (WHITE) MIC HIGH (BLACK) MIC LOW (SHEILD)) 13 BRAKE GEAR 1 115 VAC POWER IN COLD 5 2 115 VAC POWER IN HOT 28 VDC RETURN/SIGNAL GROUND 3 4 5 AUDIO OUT LO AUDIO OUT HI 6 RECORD ON B 7 RECORD ON A 8 9 +28 VDC POWER IN 10 STOP RECORDING/RIPS ACTIVE INPUT 11 12 PUSH TO TEST 13 PREAMP PWR OUT GND 14 PREAMP PWR OUT HOT (+18 VDC REG) 15 16 17 CHASSIS GND 3 18 19 20 21 22 23 CVR FAULT 24 25 GMT IN B (ARINC 429) LO 12 26 GMT IN A (ARINC 429) HI 27 28 16 29 RIPS FAULT INPUT 30 CHANNEL 1 LO INPUT CHANNEL 31 DATA LINK FAULT 1 32 CHANNEL 1 HI 33 DATA LINK IN (429) B 14 34 DATA LINK IN (429) A 35 CHANNEL 2 LO INPUT CHANNEL 36 2 37 CHANNEL 2 HI RIPS MAINTENANCE INPUT 38 OMS IN (429) B 39 14 OMS IN (429) A 40 41 CHANNEL 3 LO INPUT 42 RIPS PRESENT INPUT CHANNEL 3 43 CHANNEL 3 HI RES - CVR REPLAY INHIBIT/ 17 44 PLAYBACK INHIBIT 45 CHANNEL 4 LO INPUT CHANNEL 46 4 47 CHANNEL 4 HI 48 ROTOR SPEED IN LO 49 ROTOR SPEED IN HI 50 DATA LINK V1/OMS B OUT 14 51 DATA LINK V1/OMS A OUT 52 53 54 VOICE ERASE ”A” 55 56 DATA LINK VALID 14 57 VOICE ERASE ”C” BULK ERASE INTERLOCK (TYPICAL) Figure 8. ARINC 757A Interwiring Diagram, Recorder FA2100 CVR (2100-1X27-XX) Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 28 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Notes for Figure 9: 1. Recommended minimum wire size is #22; however, wire size #24 is electrically permissible except for long−run power leads where #18 wire is recommended (pins 3, 9, & 17). Wire resistance should not exceed 1 ohm for DC power leads and should not exceed 5 ohms for other leads. All wiring should be MIL−W−22759 or MIL−C−27500. 2. If 115 VAC, 400 Hz is supplied, connection is to be made to pins 2 & 1. If 28 VDC is supplied, connection is to be made to pins 9 and 3. 3. Recorder Chassis ground connection to be within 1 foot of pin 17, with heavy gauge wire. Shields to be grounded at the recorder using short connections. Note that Pin 3 is used as +28 VDC return. Control unit may be grounded in the cockpit to a local chassis ground. 4. Record enable jumper in aircraft connector. Without this jumper, the unit will not record or erase previously recorded information, bulk erase will not activate, and test will indicate NO-GO. 5. Pin 3 is used for DC power return and is not connected to chassis ground within the recorder. (see Note 3). Pin 1 is used for AC power return and is not connected to chassis ground within the recorder. All power input and return pins (2 & 1, 9 & 3), are galvanically insulated from the conductive chassis ground connection. 6. The Control Unit pre-amp attenuation program pins are not used. 7. Twisted shielded cable. Shields to be grounded at the airframe using short connections. Tie shields to existing single point GND used for Pin 17. (see Note 3) 8. If the power source has battery back-up, a means for terminating recording after a crash should be included in the aircraft wiring. Grounding pin 10 terminates recording within 10 minutes. 9. BITE status output: ground = no fault, open = fault or CVR not installed. 10. Audio input .05 Vrms − 3 Vrms maximum. (1Vrms nominal). 11. Per FAA Action Notice A8300.56 dated Jan. 24, 1990, the wiring to Channels 1 and 3 may be transposed; that is, Channel 1 will be Pilot and Channel 3 will be Third Crew Member or PA System. 12. In the Model 2100−1X27−( ) configurations GMT is inputted as low speed (12.5 kbps) ARINC-429 to pins 25 and 26. In addition, the −02 versions can also accept GMT as an FSK signal combined with the audio input signals on either Channel 1 or Channel 3. In all CVR configurations, the recorder accepts both label 150 (1 sec resolution) and label 125 (0.1 min. resolution) for 429 GMT inputs. If both are present, label 150 will be used. Any FSK input will be used only if there is no valid ARINC 429 GMT input. 13. External microphone connections to control unit. 14. Data Link and OMS input and output signals are applicable to p/n: 2100−1X27−( ). When data link valid (pin 56) is grounded and data link communications (pins 32 and 34) are receiving data, then ARINC−429 label 350/352 Bit 16 will be set at zero = good 15. Control Unit front panel illumination control. 16. Data Link Fault = Open/Ground discrete, Asserted is Open. 17. Pin 44 may be used to inhibit audio download when pins 7 and 8 are not jumpered and is applicable to p/n: 2100-1X27-( ). Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 29 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR STANDARD INTERWIRING FOR GACVR INSTALLATIONS 6 TO DC POWER IN 28 VDC 5 AMPS 3 CONTROL PANEL* AUDIO JACK LO AUDIO JACK HI 6 PUSH TO TEST NC ERASE C (MOMENTARY PUSH BUTTON) 8 2, 4 NO TO ANNUNCIATOR PANEL TEST LAMP 28 V, 40 mA INCANDESCENT FROM CAPTAIN'S CLOCK 10 TO 3RD CREW MEMBER OR PA SYSTEM 5, 7, 9 TO COPILOT 5, 7 TO PILOT 5, 7, 9 MODEL S056 MICROPHONE FROM ROTOR SPEED SENSOR 2, 5 MIC BIAS (WHITE) MIC LO MIC HI (BLACK) * Optional Control Panel is custom­ er-furnished. Refer to Notes on the Following Page. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 AUDIO OUT LO AUDIO OUT HI RECORD ON B RECORD ON A +28 VDC POWER IN STOP RECORDING ATTENUATION COMMON PUSH TO TEST PREAMP PWR OUT GND PREAMP PWR OUT HOT (+18 VDC REG TEST INDICATOR – (TEST LAMP Return) CHASSIS GND 6dB ATTENUATION 12dB ATTENUATION 24dB ATTENUATION CVR FAULT 10, 11 GMT IN B (429) LO GMT IN A (429) HI CHANNEL 1 LO CHANNEL 1 HI CHANNEL 2 LO CHANNEL 2 HI INPUT CHANNEL 1 INPUT CHANNEL 2 CHANNEL 3 LO CHANNEL 3 HI TEST LAMP INPUT CHANNEL 3 ROTOR SPEED IN LO ROTOR SPEED IN HI MIC. SUPPLY MIC. GND (SHIELD) MIC. IN INPUT CHANNEL 4 VOICE ERASE ”A” VOICE ERASE ”C” GEAR BULK ERASE INTERLOCK (TYPICAL) OPEN = IN FLIGHT CLOSED = WEIGHT ON WHEELS Figure 9. Interwiring Diagram, Recorder FA2100 GACVR (2100-10X0-50/-51) with Customer−Furnished Control Panel Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 30 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Notes for Figure 9 1. Recommended minimum wire size is #22; however, wire size #24 is electrically permissible except for long-run power leads where #18 wire is recommended (pins 9 & 17). Wire resistance should not exceed 1 ohm for power leads and should not exceed 5 ohms for signal leads. All wiring should be MIL–W–22759 or MIL–C–27500. 2. Single point ground. 3. Jumper in aircraft connector. Without this jumper, the unit will not record or erase previously recorded information, bulk erase will not activate, and test will indicate NO-GO. 4. Ground connection to be within 1 foot of pin 17. Shields to be grounded at the recorder using short wires. Pin 17 is used as a dc return. 5. Twisted shielded cable. Shields to be grounded at the airframe using short connections. Tie shields to existing single point GND use for Pin 17. (see Note 4). 6. If the power source has battery back-up, a means for terminating recording after a crash should be included in the aircraft wiring. Grounding pin 10 terminates recording within 10 minutes. 7. Audio input 3V rms maximum. 8. Wiring shown for fixed attenuation of 18 dB. 9. Per FAA Action Notice A8300.56 dated Jan. 24, 1990, the wiring to Channels 1 and 3 may be transposed; that is, Channel 1 will be Pilot and Channel 3 will be Third Crew Member or PA System. 10. If the Solid State GACVR replaces an existing tape-based GA100 Cockpit Voice Recorder installation, the Test Lamp wire connected to pin 23 in the connector that mates with the GACVR’s J1 connector must be moved to pin 44 with the return connected to pin 16. 11. BITE status output: ground = no fault, open = fault or CVR not installed. 12. The Control Unit & Microphone information can be found in CMM, ATA No. 23−70−05, p/n: 165E1747−00 for ED−56A installations or the FA2100GACVR Installation & Operation manual, p/n: 165E1848−00. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 31 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 6. THEORY OF OPERATION The theory of operation provided for the Model FA2100CVR describes the function of the recorder both at the system level, PWA level and software operational level. System level theory of operation describes the general operation of the system as a whole. Refer to the Model FA2100CVR System Block Diagram during the following discussion. The theory of operation for each PWA describes the electrical circuitry of the major functional groupings contained on the individual PWAs. The software level theory describes the modes of operation of the recorder software. A. MODEL FA2100 CVR SYSTEM THEORY OF OPERATION The ARINC 557/757/757A, Model FA2100CVR consists of four subassemblies, the Aircraft Interface Printed Wiring Assembly (PWA), the Audio Compressor PWA, the Acquisition Processor PWA, and Crash Survivable Memory Unit (CSMU). The recorder interfaces with the aircraft’s cockpit recorder control unit and microphone through the rear panel connector J1 and with the Ground Station Equipment through the front panel GSE connector. The descriptions and block diagrams of these subassemblies are provided in this section to support level two maintenance coverage of this unit. Rear J1 Aircraft Signals & Power Front Aircraft Interface (AI) Analog Audio Signals Audio Compressor (AC) TDM Crash Survivable Memory Unit Processor (CSMU) – ADPCM Encoding – GMT Merging – Signal Conditioning – Power Supply Power Signals Acquisition Processor (AP) HSS – CVR Control – Fault Processing – Logic Power Supply – Digitized Audio Storage TDM/HSS GSE –> PI Figure 10. FA2100 CVR Overall Function Block Diagram Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 32 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR B. Aircraft Interface (AI) PWA The Aircraft Interface (AI) PWA mounts within the rear of the Cockpit Voice Recorder chassis and provides the interface between the aircraft and the Cockpit Voice Recorder’s Audio Compressor (AC) and Acquisition Processor (AP) functions. The Aircraft Interface PWA also includes the storage power supply and provides RF filtering and lightning protection for all input and output signals that interface with the aircraft. Input and output signal conditioning is also provided for some signals. Table 2. Aircraft Interface (AI) PWA Current Configuration Where Used Aircraft Interface PWA P/N 205E250305 205E250301 205E250308 205E176311 Model Effectivity 2100−1010−00 2100−1020−00 2100−1020−02 2100−1220−00 2100−1220−02 2100−1025−02 2100−1025−12 2100−1025−22 2100−1025−24 2100−1026−02 2100−1225−22 2100−1225−24 2100−1226−02 2100−1027−02 2100−1227−02 Notes Data Link On−board Maintenance System (OMS) 2100−1010−50 2100−1010−51 2100−1020−50 2100−1020−51 Specifically, the Aircraft Interface RF Barrier function provides RF suppression on all input and output signals needed to meet the requirements of RTCA/DO-160C Sections 20 and 21; while it provides for lightning protection on all input and output signals needed to meet the requirements of RTCA/DO–160C Section 22. The ARINC 557/757A Aircraft Interface provides input signal conditioning for: Audio Channel Inputs Push-To-Test Voice Erase Record Stop Recording Rotor Speed GMT *Datal Link *OMS Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 33 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR * Only for P/N 205E2503−01 and 205E1763−08. The ARINC 557/757 Aircraft Interface provides output signal conditioning for: CVR Fault Audio Out for Monitoring at the Control Unit headset. Data Link and OMS (Only for P/N: 205E2503−01 and 205E1763−08) The Aircraft Interface also includes the storage supply portion of the power supply. This supply conditions the applied ac or dc input power and charges the 39 Vdc storage capacitor to provide the energy required to operate the Cockpit Voice Recorder during power outages up to 200 milliseconds in duration. (1) ARINC 557/757/757A Aircraft Interface Signals to Aircraft Interface PWA Table 3 lists the ARINC 557/757/757A aircraft interfaces to the FA2100CVR Aircraft Interface PWA. Table 3. ARINC 557/757/757A Aircraft Interface Signals Signal Name 115 AC IN (HOT, COLD) AUDIO OUT (HI, LO) RECORD ON (A, B) 28 VDC POWER IN STOP RECORDING PUSH TO TEST PRE AMP PWR OUT (HOT, GND) TEST INDICATOR (P,N) CHASSIS GND CVR FAULT OUT Description Ac input power as defined in RTCA/DO–160C, Section 16. Combined high quality voice and CAM channels to provide audio monitor output. With the reference signal applied to one channel, the output level is 2.45 Vrms$30% into a 600 ohm load (350−400 mVrms into an 8 ohm load for the −93 configuration). CVR is in Record Mode when A and B are jumpered. A is grounded internally. DC input power as defined in RTCA/DO–160C, Section 16. Recorder stops recording voice and flight data within 10 minutes after this pin is grounded. Recording resumes when ground is removed. A ground of this input initiates the BIT test tone sequence. +18 $2 Vdc output for control unit. Maximum operating current is 25 ma. Short circuit limited at approximately 30 ma. Provides 1 ma output into 100 ohms if the PUSH TO TEST function passed (+12 V $5% through 11.94 kohms $1%). TEST INDICATOR N is grounded internally. (Not used in GACVR models.) Chassis, power, and signal ground. CVR fault output signal. Open indicates fault, ground indicates no fault. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 34 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Table 3. (Cont.) ARINC 557/757/757A Aircraft Interface Signals Signal Name GMT IN (A, B) (429) CHANNEL 1 AUDIO IN (HI, LO) CHANNEL 2 AUDIO IN (HI, LO) CHANNEL 3 AUDIO IN (HI, LO) CHANNEL 4 AUDIO IN (HI, LO) ROTOR SPEED IN (HI, LO) VOICE ERASE (A, C) *Data Link In (A,B) Out (A,B) *OMS In (A,B) Out (A,B) Description GMT input signal. ARINC 429 format. Low Speed (12.5 kbps). The 205E1849−00 and 205E1849−03 Audio Compressor cards provide both 150 (1 sec resolution) and 125 (0.1 min. resolution) for 429 GMT inputs. 3rd crew member or extra audio input. Reference signal is 1 kHz at 3 Vrms. Input impedance is greater than 10 kohms. Co–pilot’s audio input. Reference signal is 1 kHz at 3 Vrms. Input impedance is greater than 10 kohms. Pilot’s audio input. Reference signal is 1 kHz at 3 Vrms. Input impedance is greater than 10 kohms. CAM audio input. Reference signal is 1 kHz at 2 Vrms. Input impedance is greater than 10 kohms. Rotor speed input data as defined in ARINC 557/757. 7−6000 Hz Analog Frequency Input. No Bulk Erase if “A” is grounded or connected to “C” for less than 0.5 seconds. Bulk Erase occurs if “A” is connected to “C” for 2 or more seconds and then grounded. ARINC 429, Labels 156 & 157, Message for displaying ATC Data Link messaging IAW Williamsburg V3 protocol On−board Maintenance System, ARINC−429, Label 350, For monitoring recorder system status including, CVR, CMC Bus, Control Unit, FDR, and Data Link. * Only used in 2100−1X25/1X26/1X27−( ) Models of CVR. (2) ARINC 557/757/757A Aircraft Interface Signals Between Aircraft Interface and Audio Compressor PWAs Table 4 lists the signal interfaces between the FA2100 Aircraft Interface PWA and Audio Compressor PWA. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 35 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Table 4. Aircraft Interface PWA to Audio Compressor PWA Interface Signals Signal Name CH 1 IN HI CH 2 IN HI CH 3 IN HI CH 4 IN HI CH IN RTN STOP L RECORD L TEST L AUDIO OUT AUDIO OUT RTN TEST GOOD L VOICE ERASE L ROTOR SPEED IN CVR FAULT L GMT IN (A, B) PREAMP PWR FAIL L Description Single ended, Channel 1 audio output to Audio Compressor. Signal level is 2 Vrms $10% with reference signal applied to CVR Channel 1 input. Single ended, Channel 2 audio output to Audio Compressor. Signal level is 2 Vrms $10% with reference signal applied to CVR Channel 2 input. Single ended, Channel 3 audio output to Audio Compressor. Signal level is 2 Vrms $10% with reference signal applied to CVR Channel 3 input. Single ended, Channel 4 audio output to Audio Compressor. Signal level is 1.33 Vrms $10% with reference signal applied to CVR Channel 4 input. Return signal for channel 1, 2, 3, and 4 audio signals. Not connected to ground on Aircraft Interface. Conditioned STOP RECORDING signal output. +5 V through 10 kohms for not asserted. Less than 0.4 V sinking 3.5 ma when asserted. Conditioned RECORD ON signal output. +5 V through 15 kohms when not asserted. Ground through 10 kohms when asserted. Conditioned PUSH TO TEST signal output. +5 V through 10 kohms for not asserted. Less than 0.4 V sinking 3.5 ma when asserted. Audio monitor data input from Audio Compressor. Signal level is 2.55 Vrms $30% into 622 ohms when Reference Signal is applied to one CVR audio input. Return signal for AUDIO OUT. Grounded on Audio Compressor and Aircraft Interface. Push-to-test BIT result input from Audio Compressor. Low indicates test passed. DS1 on the Audio Compressor Board. Conditioned voice erase signal output. +5 V through 10 kohms when high. Less than 0.4 V sinking 3.5 ma when low. Single ended rotor speed signal output. In phase with ROTOR SPEED IN HI. +5 V through 10 kohms when high. Less than 0.4 V sinking 3.5 ma when low. CVR fault indicator input from Audio Compressor. Low indicates fault. DS2 on the Audio Compressor Board. Provides conditioned, differential GMT input signal to Audio Compressor. Preamp power fail indication output to Audio Compressor. High is +5V from 10 kohms and indicates no fault. When preamp power is less than +15 V output goes low and sinks 3.5 ma at less than 0.4 V. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 36 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (3) ARINC 557/757A Aircraft Interface Signals Table 5 lists the signal interfaces between the FA2100 Aircraft Interface PWA and Acquisition Processor PWA. Table 5. Aircraft Interface PWA to Acquisition Processor PWA Interface Signals Signal Name 39VDC 39VDC RTN +5VDC +12VDC −12VDC PREAMP PWR (+18VDC) +15VDC + 5VDC (S) Data Link & OMS* * Used with 2100− 1025/1026/ 1027−XX only C. Description 36.6 $2 volt dc output provides up to 16 watts, maximum, to the main power supply. Up to an additional 4 watts can be supplied to external test equipment with nominal input voltages and room temperature. Return path for 39 Vdc current. Tied to ground on both PWAs. +5 volt input from main power supply. Required tolerance is $5%. Current required is less than 40 ma. +12 volt input from main power supply. Required tolerance is $10%. Current required is not more than 35 ma. –12 volt input from main power supply. Required tolerance is $10%. Current required is not more than 25 ma. +18 volt input from the main power supply, current limited on Acquisition Processor. Required tolerance is $2 volts. Current requirement is less than 25 ma. +15 volt output made from Storage Supply input voltage. Tracks the unregulated input below about 15 volts and then regulates at that level. +18VDC of the main supply is diode coupled to this signal and provides the power after the main supply is running. Maximum current required by Aircraft Interface is 20 ma. The Aircraft Interface can supply 100 ma to the Acquisition Processor until the main supply starts running. +5 $0.1 volt output made by Storage Supply to provide power to the main power supply control circuits. The external current must be less than 10 ma. Inputs (A, B) − Conditioned, differential Data Link/OMS input to AP PWA [only used with 205E2502−10/11 AP boards. (MOD−DOT 5 Units.)] Outputs (A, B) − Data Link/OMS output signal for Acquisition Processor, which drives the ARINC−429 output buffer. Audio Compressor (AC) PWA The Audio Compressor (AC) provides a data interface between the Aircraft Interface (AI) and the Acquisition Processor (AP). The AC digitizes, compresses, and packages four audio channels for subsequent processing by the AP. The AC provides interfaces between the AI and the AP for Greenwich Mean Time (GMT) Data, Rotor Speed (RSE) Data, and Discrete Data. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 37 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR The Audio Compressor PWA receives conditioned audio, GMT, rotor speed, and discrete command/control data from the AI concurrently. Audio and ARINC 429 input data are processed by the AC and formatted into 16–bit wide words for serial Time Division Multiplexed (TDM) Bus transmission to the AP. Discrete data from the AI are consolidated into word format prior to TDM transmission. Discrete data received over the TDM Bus from the Acquisition Processor provide the Audio Compressor with Built–In Test (BIT) control and with BIT fault status; fault status data are output to the Aircraft interface PWA. Additionally, audio data reprocessed on the Audio Compressor are output to the Aircraft Interface for audio monitoring. Power/ground and a master reset for the Audio Compressor are derived from the Acquisition Processor PWA. The Audio Compressor PWA interfaces with the Aircraft Interface and the Acquisition Processor. The AC/AI interface comprises four audio input channels: an audio monitoring output channel, a serial ARINC 429 GMT data input channel, and inputs for rotor speed frequency and discrete control data. The AC/AP Interface consists of a serial TDM bus, a master clock signal, a master reset, a test mode control bit, and power/ground interconnections. The information transmitted by the AC over the serial TDM bus includes audio, GMT, rotor speed, and discrete data. Information received by the AC over the serial TDM bus includes discrete data for status and control. The AI/AC Interface includes the Audio Interface, the GMT Interface, the Rotor Speed Interface, and the Discrete Data Interface. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 38 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Table 6. Audio Compressor (AC) PWA Current Configuration Where Used Audio Compressor PWA P/N 205E397720 205E397723 205E397717 205E397729 205E397737 205E397722 (1) Model Effectivity 2100−1010−00 2100−1020−00 2100−1220−00 2100−1020−02 2100−1220−02 2100−1025−02 2100−1025−12 2100−1025−22 2100−1025−24 2100−1225−22 2100−1225−24 2100−1026−02 2100−1226−02 2100−1027−02 2100−1227−02 2100−1010−50 2100−1010−51 2100−1020−50 2100−1020−51 Notes FSK Function 2−hour Voice 2−hour Voice AGC Function Audio Interface The Audio Interface consists of four audio input channels. Input Channels 1–3 correspond to one of three crew member voice inputs. The ED–56A and ED−112 reference voltage input to the AC for Channels 1–3 is 2.0 Vrms into a 10 kohm load and a specified bandwidth of 150–3500 Hz. Input Channel 4 corresponds to the Cockpit Area Microphone (CAM) audio input. This channel has an ED–56A and ED−112 reference voltage input of 1.33 Vrms input into a 10–kohm load with a specified bandwidth of 150–6000 Hz. An audio channel return ground is included in this interface. Attenuated microphone (AMIC_IN) is received for the Aircraft Interface. (2) ARINC 429 GMT Interface The ARINC 429 GMT Interface is responsible for receiving serial TTL/CMOS ARINC 429 Low Speed (12.5 kbps) data from the Aircraft Interface PWA. (3) Rotor Speed Interface The Rotor Speed Interface consists of a single input representing rotor speed frequency ranging from 7 to 6000 Hz with measurement error less than 2%. The output signal is 0 – 5 V, with a 10–kohm pull–up resistor on an open collector output. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 39 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (4) Discrete Data Interface The Discrete Data Interface includes Aircraft Interface output signals: RECORD L, TEST L, VOICE ERASE L, STOP L, and PREAMP PWR FAIL L. Each output signal is 0 – 5 V, with a 10–kohm pull–up resistor on an open collector output. The Discrete Data Interface Audio Compressor output signals are CVR FAULT L and TEST GOOD L. (5) Audio Monitor Interface An audio output channel for test monitoring provides a combination of six reprocessed Adaptive Differential Pulse Code Modulations (ADPCM) data channels, with or without a 640 Hz test tone, or a 400 Hz tone indicating bulk erase to a listener. The output level is 2.55 Vrms into a 622–ohm load with respect to any input reference level. An audio return ground is included in this interface. (6) Audio Compressor/Acquisition Processor Interface The AC/AP Interface includes the following signals: (a) Serial TDM Bus signals TCLK, TFRM, TADD, and TDAT (b) Master Clock Input F8.192 MHz (c) Master Reset AC RESET L (d) BIT Control Input TEST MODE L (e) Power/Ground Signals V5N, V5P, and GND The TCLK and TFRM signals are generated by the Acquisition Processor and provide bit and TDM frame synchronization, respectively. TADD and TDAT are bidirectional signals; receiver specific port identification is furnished by TADD bits [7...0], and the data associated with the targeted receiver occur as TDAT bits [15...0]. D. Acquisition Processor (AP) PWA The Acquisition Processor PWA performs data management of audio data as a Cockpit Voice Recorder (CVR). It also provides various command and control functions for the recorder, as well as power management. The Acquisition Processor PWA actually consists of two separate processors: the Store Manager Processor (SMP) and the Flight Data Processor (FDP). However, in the FA2100 CVR configuration the SMP is the only processor functioning, with the exception of p/n: 205E2502−14 since the Data Link signals utilize the FDP proces- Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 40 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR sor. The Store Manager Processor gathers audio data from the Audio Compressor, packetizes the data, and saves the data into the flash memory contained in the Crash Survivable Memory Unit (CSMU). Table 7. Acquisition Processor (AP) PWA Current Configuration Where Used Acquisition Processor PWA P/N 205E250221 205E250214 205E250224 205E250234 205E250238 Model Effectivity Notes 2100−1010−00 2100−1020−00 2100−1020−02 2100−1220−00 2100−1220−02 2100−1025−02 2100−1025−12 2100−1025−22 2100−1025−24 2100−1225−22 2100−1225−24 2100−1026−02 2100−1226−02 2100−1027−02 2100−1227−02 2100−1010−50 2100−1010−51 2100−1020−50 2100−1020−51 Compatible with 3V Intel Memory Data Link Compatible with 3V Intel Memory The Acquisition Processor interfaces with three internal functional modules: Aircraft Interface, Audio Compressor, and CSMU. Additionally, is an external interface to the Ground Support Equipment (GSE). (1) Aircraft Interface The Aircraft Interface (AI) Interface involves the following external power inputs and outputs: (2) (a) External power input +39 Vdc storage supply, +15 V, and +5 V (storage) from the Aircraft Interface PWA. (b) External power output +18 V preamp power, +5 V, and $12 V to the Aircraft Interface PWA. Audio Compressor The Audio Compressor (AC) Interface consists mainly of the Time Division Multiplexing (TDM) bus. Audio data is transmitted by the AC via the TDM bus to the Store Manager Processor (SMP). Additionally, an 8.192 MHz clock is output to the AC to be used as the time base for audio sampling. AC Reset and Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 41 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Test mode as well as operating voltages of $5 V are also routed through this interface. (3) Crash Survivable Memory Unit The Crash Survivable Memory Unit (CSMU) Interface consists mainly of the buffered high speed serial bus of the SMP. Command and data messages are transmitted by the Acquisition Processor (AP) to the CSMU. These messages involve the various data types to be stored in the flash memory of the CSMU. The CSMU transmits data messages to the AP only in response to commands issued by the AP. Additionally, +5 V and +12 V power for the CSMU and CSMU reset are routed through this interface. (4) Ground Support Equipment Interface The Ground Support Equipment (GSE) Interface consists of the buffered TDM bus, the multiplexed/buffered high–speed serial buses, multiplexer control input, test mode control input, program flash power/control input, and 39 Vdc current limited (GSE pwr, 4–watt available), and +5 V (prgm vpp ap). This interface allows external equipment to monitor microprocessor data transfers within the recorder, copy the contents of flash memory from the CSMU, download/ upload application software to/from the SMP, and perform functional testing of the recorders. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 42 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 7. SOFTWARE CONSIDERATIONS (ALL P/NS EXCEPT 2100−1X25/1X26/1X27−( ) and 2100−1X20−( ) MOD−DOT #7) Two sets of software run on the FA2100CVR Recorder. One is the high–level system software and the other is the low–level processor software. The high–level software consists of a real–time embedded operating system that controls several tasks. Each task is dedicated to a certain function, such as the recorder controller task. The main purpose of the system software is to process commands received on the front panel GSE interface and to coordinate the storing of flight data and voice data. The low–level software is dedicated to the data processing module. The main purpose of this software is to help the hardware to process the audio data. This software is self–contained and runs separately from the system software. As defined in RTCA/DO–178B, the Criticality Category of the Model FA2100CVR is classified as Minor. Accordingly, the software in the FA2100 CVR will comply with the Level D requirements of RTCA/DO–178B. A. Store Manager Processor Software Organization The SMP software is organized as a multi−tasking environment with individual modules executing as tasks under control of an operating system kernel. The kernel provides preemptive, priority based multi−tasking of the various modules which satisfy the CVR functionality. The kernel also includes an intertask communications facility which allows the tasks to transmit and receive data. The modules which run as tasks under software kernel include: F CVR Executive F Flash Manager F NVRAM Manager F Fault Manager F Mode Executive F Audio Channelizer F Audio Reconstructer The SMP software also includes interrupt service routines for the timer, TDM transmit, and TDM receive interrupt handling. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 43 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR B. Software Operating States The FA2100 CVR software operates in several states which include initialization, recording, power down, data playback, bulk erase, and push to test. Of these states, the CVR operates in the record state for most of its power on time. Each of the states will be discussed in the following sections. (1) Initialization State The SMP goes through the initialization sequence when reset is asserted as a result of power up or watchdog timeout. The power up hardware reset interrupt is connected directly to the SMP. Initialization consists of setting up the run time environment and starting the software kernel. After the software kernel is initialized, all of the required SMP tasks needed for CVR operation are started. These include the Mode Executive, CVR Executive, NVRAM Manager, Flash Manager, Fault Manager, Audio Channelizer, and Audio Reconstructer. The Mode Executive provides the interface to the GSE if it is connected to the recorder. It controls whether the CVR will progress into the record state or playback state for recovery of recorded audio. The CVR Executive processes the input digital audio channel data and manages the actual record or playback operations. The Flash Manager acts as a server task supporting all accesses to the crash protected flash memory devices. Likewise, the NVRAM Manager task provides a similar interface function to the non−volatile RAM used for memory index and configuration information storage. The Fault Manager provides common processing for all fault conditions and notable events that are detected by the other software tasks. The Audio Channelizer task “demultiplexes” mixed audio data from the TDM bus interface and builds packets of channel specific audio data for storage in the CSMU. The Audio Reconstructer task processes the individual audio channel streams, either in real time (using the read−after write CSMU data) or as part of the audio data playback state back into a single stream for transmission to the GSE via the TDM bus. Once all the SMP tasks are running, record state initialization is controlled by the CVR Executive task. It retrieves the record−location indices from NVRAM, then performs a CRC and additional validation steps. If the indices cannot be validated, the CSMU memory is scanned to find an appropriate record starting point as evidenced by an erase gap. In the case where no erase gap can be Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 44 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR found, the indices are set to a pre−determined top of memory location. Once the indices are restored, the CVR is ready to transition to the record state. (2) Record State Figure 11 shows the word partition structure for the 2-Hr FA2100CVR, refer to this figure for the following description. Once the FA2100CVR has been initialized, recording will commence with the first digitized audio data received from the Audio Compressor board. The CVR Executive task enables the TDM receive routine to begin collecting data form the Audio Compressor stream sent over the TDM bus. The SMP software is responsible for all of the processing needed to format the received audio data streams into a form ready for storage into the CSMU. The complete sequential process is described in the steps below: (a) The TDM interrupt handler receives the audio data stream from the Audio Compressor hardware and buffers it into 8 ms blocks of data. Each of these blocks contains four, 2 ms frames of interleaved digital samples of the HQV, HQC, SQV, and SQC audio channels. Each 2 ms frame also contains samples of GMT, rotor speed, and discrete inputs (push−to−test, bulk erase). (b) The 8 ms blocks of audio data are split by the Audio Channelizer task. This task “demultiplexes” the audio sample stream into the individual streams that will be stored in the CSMU. The Audio Channelizer builds 36 word packets of data for each of the four stream types, HQV, HQC, SQV, and SQC, along with 36 word packets of “special” data (GMT, rotor speed, discretes). As each packet is filled, it is forwarded to the CVR Executive task. Special packets containing GMT and rotor speed data are also built and forwarded. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 45 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR HQV HQC 36‐Wd HQV SF SQV SQV HQV SF HQC SF HQC HQV HQC HQC HQV HQC HQV SF X SQC SQC SF SQC SQV SQC SF SQC SPCL SQC SF SQV HQC SF HQV SQV SQC SQC SQV SF HQV SQV 36‐Wd SF SQV HQC HQV SF SQV HQC SF SQC 36‐Wd SF HQC HQV HQV 36‐Wd HQC SQC SQV SQC SF HQV SQV HQC SF HQV SF HQC SQV SQV HQV SF HQV SQC SQC SF SQV SQC SQC SF SQV HQV HQV HQV HQV (9) 36‐Word Frames per 72‐ms Superframe HQC (6) 36‐Word Frames per 72‐ms Superframe SF SQC SQV SQC SF X SPCL SQV Special Frame Rotor Speed, GMT, (2) 36‐Word Frames per 72‐ms Superframe Discretes, FDR + Sync Mark (1) 36‐Word Special Frame per 4 Superframes SQC SQC (2) 36‐Word Frames per 72‐ms Superframe * Block headers & Block boundaries Not Shown Figure 11. 2–Hr FA2100 CVR (pre MOD−DOT #7) Word Partition Structure Streams Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 46 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (c) The CVR Executive manages the storage of received channel specific audio data packets to the CSMU. The CVR Executive examines the packet, determines which memory partition should be addressed, and sends the complete packet to the Flash Manager for storage in the CSMU. The CVR Executive task also manages the erase look−ahead function to insure that there is always a new erased block of flash memory available for impending memory write operations. (d) The Flash Manager stores the packet in the CSMU and performs a read− after−write for each word stored. The read−after−write data packet along with error count is returned to the CVR Executive. (e) The CVR Executive checks for any CSMU access errors, logs error as appropriate, and sends the 36 word read−after−write packet to the Audio Reconstructer task. (f) The Audio Reconstructer task accumulates the channel specific audio data packets and multiplexes them into the 2 ms. audio data frame format. The reconstructed audio stream is transmitted via the TDM bus to the GSE connector. If attached, this allows the GSE to monitor real time audio that has been completely processed through the CSMU. While in the record state, the Mode Executive monitors the delayed shutdown input to the CVR. If asserted, and held, this will cause the Mode Executive to start a shutdown timer. If the timeout occurs (within 10 minutes), Mode Executive will set a shutdown flag which is polled by the CVR Executive. This results in a shutdown of record operation until the delayed shutdown input is de-asserted, or the timer is reset by an assertion of the “push−to−test” input. (3) Power Down State Power down is initiated when the hardware detects an imminent power failure. The hardware design is such that a power fail signal will be provided to the SMP at least 50 milliseconds before reset will occur. This input to the SMP is detected by the CVR executive task. This task then proceeds to effect an orderly shutdown of record operations within the CVR. The shutdown sequence is as follows: (a) After sensing the power fail input, the CVR executive sends a “stop recording” message to the Audio Channelizer task. The Audio Compressor hardware is disabled to stop the flow of audio data into the SMP. The CVR executive then starts a timer while waiting for the Audio Channelizer task to respond to the shutdown message. During this time, all processed audio data will continue to be received from the Audio Channelizer and sent to crash protected flash memory as in normal record mode. The Au- Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 47 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR dio Reconstructer task is also shutdown to free resources and CPU bandwidth. (b) The Audio Channelizer task receives the shutdown message, but continues to process any 8 ms blocks of audio data that may be in its input queue. (c) When it has processed all pending data, the Audio Channelizer zero fills any remaining partial 36 work channel specific packets. The last packets are sent to the CVR Executive along with a “shutdown complete” indication. (d) Upon receiving the shutdown complete indicator from the Audio Channelizer task, the CVR executive knows that it has processed the last of the audio channel packets. Record position indices are then stored in NVRAM (via the NVRAM manager task). If the “shutdown complete” indication is not received from the Audio Channelizer task within the prescribed timeout limit, the CVR Executive will proceed with the shutdown sequence. This prevents an Audio Channelizer anomaly from inhibiting an orderly storage of pointer indices and other data before the power fail reset occurs. (e) (4) After the NVRAM values have been updated, the CVR executive enters an idle loop waiting for power to drop. If the power fail indicator relents, the CVR executive will perform a re-initialization and re-enter the record state. Data Playback State Data Playback state is enabled when the SMP Mode Executive task detects a playback request command from the GSE via the TDM bus. Playback of audio data is inhibited if the recorder is installed in an aircraft through sensing of the record bias input signal. Requests for audio data playback from the GSE are forwarded to the CVR Executive task. The CVR Executive will calculate the physical memory indices for the playback start point based on playback positioning commands (rewind, forward, fast rewind, fast forward) received from the GSE. Audio data output starts when the “play” command is received. At that point, the CVR Executive will start to retrieve 36 word packets of channel specific audio data from the appropriate memory partitions. The packets are passed to the Audio Reconstructer task which, in turn, multiplexes the 2 ms. frames of audio data and transmits it to the GSE over the TDM bus. This process continues until the end of the recording is reached or a stop command is received from the GSE. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 48 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (5) Bulk Erase State The bulk erase operation is initiated by assertion of the bulk erase discrete input to the recorder. After this input has been detected by the Mode Executive task for at least two seconds (usually by depressing a push button on the control unit in the cockpit), the bulk erase command is sent to the CVR Executive. The CVR Executive task will cycle through each erase block in the CSMU and set the bulked erased flag which is part of the eight word block header. The CVR Executive will prevent the playback of any CSMU memory block which has been marked as bulk erased. The bulk erase flag in each block is reset during normal record state operation. During the bulk erase operation the CVR Executive controls a 400 Hz tone which is inserted on the monitor audio channel to confirm bulk erase state operation. (6) Push to Test State The built in test capability includes the push to test state which is initiated and controlled by the push to test discrete input to the CVR. Assertion of the push to test input (usually by depressing a push button on the control unit in the cockpit) is detected by the Mode Executive task. Once this input is detected, the Mode Executive will start the test sequence which takes about two seconds to complete. A 640 Hz analog tone of about 200 ms duration is inserted sequentially into each of the audio input channels and recorded. The tone is detected on the Audio Compressor board in the monitored audio channel. Proper detection is checked by the Mode Executive and, if detected correctly on all inputs, and no other fault condition exists, a “good” or “passed” indication is asserted and held for about one second. Such an indication is usually displayed on the control panel in the cockpit. C. Data Structures The primary data structure utilized in the FA2100 CVR is the organization of the crash protected flash memory contained in the CSMU. The partitioning of the 2-Mwords chips (32 Mb) of the CSMU memory provides for the physical separation of the individual audio partitions needed for the storage of the HQV, HQC, SQV, and SQC channels (per ED−56A). Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 49 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR The memory model for the two hour CVR is physically constructed as illustrated in Figure 12. There are a total of 15 X 32 Mb memory devices allocated to the four partitions as shown. The 30 minute CVR contains a total of 7 X 32 Mb memory devices allocated to just the first two partitions, for the HQV and HQC channels. Due to the amount of sampling required for high quality channels, it takes almost as many memory devices for 30 minutes of high quality recording as it does for 120 minutes of standard quality recording. For 30 minute recorders the total amount of physical memory capacity is 24 megabytes. For 120 minute recorders the memory capacity is 60 megabytes. 2M Words 2M Words 2M Words 2M Words 2M Words 2M Words 2M Words 2M Words 2M Words 2M Words 2M Words 2M Words 2M Words 2M Words HQV = High Quality Voice HQC = High Quality CAM SQV = Standard Quality Voice SQC = Standard Quality CAM 2M Words HQV = 4 Chips 30 Min. HQC = 3 Chips 30 Min. SQV = 4 Chips 120 Min. SQC = 4 Chips 120 Min. NOTE: This representation does not include p/n: 2100-1025-( ), which is a 2-hour HQ only recorder. Figure 12. 2–Hr FA2100 CVR Memory Structure Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 50 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Each 32 Mb flash memory device in the CSMU contains 2 Mwords (16 bits per word) of storage capacity. This 2 Mwords consists of 64 “Erase” Blocks which are each 32 Kwords long. An erase block is the smallest physical block of a flash memory device that can be erased at one time. The FA2100 CVR software partitions each 32 Mb Erase Block into an eight word header followed by 910 logical packets of 36 words each. These packets are the fundamental units which are built and stored into the CSMU. The header data includes partition, channel, block number and other information that can be used to re-align and re-assemble the physical memory devices should they become detached from the printed wiring board during impact. D. Fault Processing The Model FA2100 CVR software monitors virtually every internal data transaction for anomalies. This includes all messaging between tasks, SMP to CSMU, and SMP to GSE. The digitized audio data input stream from the Audio Compressor board is also monitored for integrity. The software also monitors itself for illegal or unexpected operations. Fault information is stored in the NVRAM fault history log. The log can contain about 275 entries. Of these, the first 255 entries are considered as “primary” events. If this portion of the log fills, the remaining 20 “secondary” entries are used and overwritten as required. The log records the power up sequence number and the following information for each event: F time (in seconds) from last power up F event class F task ID of event source F type of event F specific event code F event count (within this power up sequence) The event class identifies the severity of the event detected. This allows the fault log to be used for recording non−fault conditions that may help in determining subsequent failure modes. The event classes reported by the software are: F EV − No fault, event recording only F NN − Fault, not latched, not fatal F LN − Fault, latched, not fatal F LF − Fault, latched fatal Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 51 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Any detected fault condition asserts the fault output from the CVR. Some faults are “latched’ meaning that the fault indication will continue to be asserted (regardless of power cycling) until it is cleared by maintenance action. Other faults may relent, allowing normal CVR operation to continue. In such a case, the fault condition is not “latched“ and the fault output from the CVR will be de−asserted. Of the latched faults, some may be severe enough to halt and then restart recorder operation. Such faults are considered fatal. Any active or latched fault condition is also reported by a “not passed” indication in response to the push−to−test command. The task ID indicates which module within the software organization detected the reported condition. The “type of event“ field categorizes the general nature of the fault conditions. Reported categories include: Table 8. Fault Processing Event Types and Descriptions Type of Event Description Internal Faults illegal or unexpected software errors CSMU flash memory errors flash memory write or erase errors BITE errors detected power supply faults Communications errors illegal or unexpected GSE messages While fault conditions are detected throughout the CVR software modules, the conditions are all reported and logged through the Fault Manager task which executes on the SMP. It provides the common interface for fault output control and fault history log management. The fault history log is accessed via GSE commands for downloading and analysis of the fault log entries. Likewise, the latched fault condition and the fault log itself are cleared by GSE commands by using the Portable Interface Unit. Refer to the Testing and Troubleshooting, Section 100, for the corrective action to be taken if any of these fault codes should appear in the status report. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 52 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 8. SOFTWARE CONSIDERATIONS (P/NS: 2100−1X25/1X26/1X27−( ) and 2100−1X20−( ) MOD−DOT#7) A. Equipment Environment The hardware environment for the 2100−1X25/1X26/1X27−( ) and 2100−1X20−( ) MOD−DOT #7 Solid State Cockpit Voice Recorder is composed of a pair of TMS320C50 Digital Signal Processors (DSPs), an external program memory for each DSP that contains the executable program code, one external NVRAM for non−crash critical data storage and a flash memory array located in a Crash Survivable Memory Unit (CSMU). In addition there are external interfaces attached to each DSP to allow external communication for testing purposes, interfaces to allow the system to gather data for storage, and interfaces used to send and receive external control/state information. B. Software Partitioning Software for the Model FA2100 Solid State Flight Recorders will be partitioned into two parts. This is to accommodate the use of two DSPs. One DSP, called the Flight Data Processor (FDP), is responsible for the collection, processing, and forwarding of Data Link messages. The other processor, called the Storage Management Processor (SMP), is responsible for the collection of audio data, the management of the CSMU, and other ancillary functions. Communication between the two processors will be over the device−specific TDM (time division multiplexing) serial link. C. Memory Requirements The memory requirements for the Model FA2100 Cockpit Voice Recorders varies depending on the specifics of the part number produced. The types of memory present in the recorders are: RAM, which is built into the DSP chip; ROM, containing the program image; NVRAM, which is used to store fault and start−up information; and Flash memory within the CSMU, that is used to store Data Link and audio data. Each DSP has a total of 10k words of built−in RAM. Each DSP has access to 64k of ROM for the executable program image. The system contains one NVRAM with a minimum of 2k words being required. D. Interfaces The system level inputs dedicated to the CVR functions are: F Audio Data Input F Audio Frame Synch Input F Bulk Erase Input F Channel Tone Select Output Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 53 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR F Channel Monitor/Test Select Output F CVR Fault Output F GMT Input F Push−To−Test Input F Record On Input F Rotor Speed Input F Stop Record Input F Test Good Output The system level interfaces used by all configurations are: F Power In F Power Return F GSE Input F GSE Output Data Link interfaces (P/N 2100−1X25/1X26/1X27−( ) only) are: F Data Link Input F Data Link/OMS Output F Data Link Valid F CVR Indent Pin (1) On−Board Maintenance System (OMS) Interface (P/N 2100−1X25/1X26/1X27−( ) only) The CVR is identified as a BITE Standard A equipment so as to be portable to other AIRBUS programs. The CVR interfaces with the OMS through a system BITE such that the CVR will pass fault information to the OMS (via SCI) and receive test request based on two ARINC 429 buses (as per a BITE Type 1 principle): (2) F Use of one ARINC 429 High Speed (HS) output bus for continuous fault reporting by means of the CVR output pins 50/51 (Data Link / OMS Out). F Use of one ARINC 429 Low Speed (LS) input bus for test request by means of CVR input pins 39/40 (OMS IN). Fault Warning System (FWS) Interface As per ARINC 757A, the CVR transmits its status at a 1 Hz rate. The status is transmitted on Label 350 per ARINC 429 in the format depicted in Attachment 19 of ARINC 757A (CVR STATUS WORD). Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 54 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR The fault signal is indicated for any of the following (as per ED112 §2−1.4.2): F failure of the audio or digital interface and processing equipment. F failure of the recording medium and/or drive mechanism. F failure of the recorder to store the information in the storage medium as shown by checks fo the recorded material including, if reasonably practicable, correct correspondence with the inputs. The following list explains system failures intended to be displayed with the message: “CVR SYSTEM FAULT” Table 9. P/N 2100−1X25/1X26/1X27−( ) Software Fault Warning Failures SSCVR label 350 bit 11 Failure of the audio circuit CVR CU label 350 bit 13 DataLink Recording label 350 bit 16 Control Unit loads Its powFailure of the recording er supply below 15.5 Volts. medium Failure of the recording medium Failure of the recorder to store Information In the storage medium Insufficient audio or UTC time record duration CVR Inhibited (pin 10 activated) (3) Failure of the recorder to store Information In the storage medium Insufficient datalink record duration CVR Inhibited (pin 10 activated) Data Link (ATC) Interface (p/ns: 2100−1X25/1X26/1X27−( ) only) The FA2100CVR, p/n: 2100−1X25/1X26/1X27−( ) only can interface with the Data Link Systems from other aircraft programs (ATSU on SA/LR or even CMU). The FA2100CVR is designed to support V3 Williamsburg Protocol high and V1 Williamsburg hardware provision. The “data link recording” information status is taken into account by the A429 CVR output through the label 350 bit 16. (0 = ok and 1=failure), as per ARINC 757. The CVR receives all data link messages on pins 33/34 (DATALINK IN 429) as per ARINC 757 characteristics. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 55 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR E. Push−to−Test (PTT) Functionality The Push−to−Test functionality (already implemented on existing aircraft and standardized in ARINC 757A specification) is used to provide the flight crew with the ability to quickly confirm good serviceability of the CVR before flight as required by the applicable regulation. Upon test activation, the CVR tests the front end audio inputs (each of the four audios inputs channels) and initiates Built−In−Test functions of the CVR. When used with the FA2100CVR, p/n: 2100−1X25−( ) and the S161−1390−01 control unit, the push−to−test action must be a minimum of one (1) second. During the test, the monitor output (pin 5/6) will be muted (no sound). If the test passes, a .5 second 600−660 Hz tone is activated on the monitor output. For a failure the output remains muted. Upon initiation of the Push−To−Test (PTT) function, the CVR sends status indication on dedicated outputs, particularly on CVR fault discrete output pin 23 (not used) and on label 350 (CVR STATUS WORD bit 11 on pins 50/51). CVR Test activation (PTT switch) is allowed at any time during the flight so that the crew can re−initiate the test after a fault is detected in the hope of recovering the recorder (test is specified to act as a reset of the recorder). F. Bulk Erase As per ARINC 757A, the CVR provides a Bulk erase function. In order to ensure reliable operation, the function is inhibited to prevent inadvertent or untimely erasure while the aircraft is capable of moving under its own power. In addition to the means already provided at A/C level (interlock devices monitored with the aircraft on− ground information and effective park brake locked), the CVR provides a timed interlock for erase. The erase starts by connecting CVR pin 55 to pin 57 for a minimum of 2 seconds and then connecting pin 55 to ground (pin17) before erasing the previously recorded data. This action is initiated by pressing the Bulk Erase push−button on the applicable Control Unit. The erase is indicated by a 400Hz tone activated during the erase process on Control Unit Headphone or Boomset to validate bulk erasure. The erasure is activated once per depression (no cycling). As per ED112 IV−2.2.3 (Data Link part), recorded digital messages shall not be erased, re−written or altered during the process of downloading. In addition, also per ED112 IV−2.1.12 (Data Link part), no means for the erasure of the record shall be provided in the recorder, except for the overwriting of the oldest data by new information. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 56 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR G. Recorder Synchronization The FA2100CVR equipment is designed to be able to record time code from an ARINC 429 in priority and later FSK source (the frequencies used are 3607Hz +/− 30Hz and 4193Hz +/− 30Hz), depending on the source used on the aircraft. For Models FA2100CVR, p/n: 2100−1X20−02/2100−1X25−( ), 2100−1X26−( ), and 2100−1X27−( ) the recorder automatically detects which source is received, acquires the time data, and stores it into memory. The A429 clock refresh time is to one (1) second; if after this time, the CVR is capable of acquiring and to recording the FSK Frequency necessary for synchronization. The ARINC GMT word (either label 125 UTC BCD or 150 UTC BNR) is transmitted at a rate of one (1) second, the FA2100CVR recorder is designed to recognize and record GMT word sent at this transmit rate. The CVR is capable of recording both label 150 or 125 with a priority for Label 150 if both labels are present. The CVR equipment contains an internal time reference in the event FSK or ARINC 429 time reference is not available. Label 350, Bit 17 indicates the status of the clock as the following: 0=ok and 1=failure. H. Data downloading (P/N: 2100−1X25/1X26/1X27−( ) only) It is possible to download the Data Link message data from the crash protected medium, while the recorder is installed on the aircraft (as per ED112 Part IV § IV−2.2.3). The L−3AR Portable Interface, 17TES0043 PI/1; 17TES0062 PI/2, provides a means to download the Data Link message data at the CVR on-aircraft so that an operator can easily and quickly download previously recorded Data Link information without removing the recorder from its mounting. The downloading may be performed by means a ground PC personal computer on and in laboratory with the L−3AR Audio Data Link Playback software, ADLP software. Refer to the L−3AR Audio Data Link Player Operators manual, p/n: 165E3596−01 for more details. For operators using ROSE 4.0 or higher software on a ROC or RAU, audio data along with the flight data may be downloaded directly from a CVR and played back through ROSE. The audio and flight data will be time synchronized through the ROSE software. Refer to the Read−Out Support Equipment/Recorder Interface Software Version 4.0 or Higher Operator’s Manual, Part Number 165E1696−03. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 57 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR I. CVR RIPS status monitoring (P/N: 2100−1X25−22/−24, 2100−1X26−( ), and 2100−1X27−( ) only) The Recorder Independent Power Supply (RIPS) is an ON−CONDITION LRU designed to provide 10 minutes CVR backup power as per ARINC Characteristic 777−1. The CVR RIPS status monitoring provides a way to monitor the function status of RIPS within the CVR. There is no change in CVR hardware except for the pin assignments to the rear connector. Listed in Table 7 are the difference in the pin assignments of the CVR rear connector for both prior to RIPS and RIPS installation. RIPS status will be received and transmitted using Fault Warning Label 350, Label 351 and Label 352 as part of the OMS. RIPS status will also be stored within the CSMU memory and the data will be able to be retrieved using the existing support equipment for analysis. Table 10. CVR RIPS Pin Assignment for P/N: 2100−1X25−22/−24 & 2100−1X26/1X27−( ) Pin Number 10 29 38 42 (1) Pre RIPS Pin Assignment CVR Stop Recording FDR Rate A FDR Rate B CVR Ident Pin Program RIPS Pin Assignment RIPS Active Input RIPS Fault Input RIPS Maintenance Input RIPS Present Pin Program RIPS Active The CVR will use Pin 10 to receive the RIPS Active Status Discrete output. In addition to reporting the RIPS Active status on this input, the assertion of this input will start the CVR Stop Recording10 minute timer in order to retain this standard CVR functionality. Since the RIPS is only active for up to 10 minutes maximum, the function will be correct if either the RIPS or the CVR shuts down first. This status will be received and transmitted in the Label 350, Label 351, and new Label 352 outputs as follows: RIPS Active Status CVR Discrete input (Pin 10) SSCVR Label 350 SSCVR Label 351 and 352(Bit 21) (Bit 12) Not active Open 0 1 Active Ground 1 0 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 58 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (2) RIPS Fault The CVR will use Pin 29 to receive the RIPS Failure Status Discrete output. This discrete input is presently assigned in ARINC 757A as FDR Rate A for combination recorder applications. This discrete input is not presently utilized by the pre RIPS CVR software. This RIPS status will be received and transmitted in the Label 350, Label 351, and new Label 352 outputs as follows: (3) RIPS Failure Status CVR Discrete input (Pin 29) SSCVR Label 350 SSCVR Label 351 and 352(Bit 15) (Bit 18) Not Failure Ground 0 1 Fault Open 1 0 RIPS Maintenance The CVR will use Pin 38 to receive the RIPS Maintenance Status Discrete output. This discrete input is presently assigned in ARINC 757A as FDR Rate B for combination recorder applications. This discrete input is not presently utilized by the pre RIPS CVR software. This RIPS status will be received and transmitted in the Label 350, Label 351, and new Label 352 outputs as follows: (4) RIPS Maintenance Status CVR Discrete input (Pin 38) SSCVR Label 350 SSCVR Label 351 and 352(Bit 20) (Bit 19) No Maintenance required Open 0 1 Maintenance required Ground 1 0 RIPS Present Use of CVR Pin 42, ”CVR Ident” is being used for the RIPS Present Pin Program. Since we do not anticipate more than one CVR installed on any current aircraft type, the CVR Ident will be defaulted to the first CVR installed (0) in the software for BITE reporting purposes instead of reading this through Pin 42. This will free Pin 42 for use as the RIPS Present Pin Program. The status of this discrete input will be used to modulate the Label 350, Label 351, and Label 352 reporting of RIPS status. If RIPS is not present, then all of the associated RIPS status bits (Fault, Maintenance, Active, and Present) will be set to zero (0) in the Label 350/352 output. Likewise, RIPS Fault and RIPS Maintenance will default to zero (0) in the Label 351 output if the RIPS is not present. If the RIPS is not present, then any reference to RIPS in the Interactive OMS output pages will be suppressed. However, in the case where the CVR is re- Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 59 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR moved from an aircraft with RIPS and re−installed on an aircraft without RIPS, it is possible that previous flight leg RIPS fault information, stored in the CVR fault log while installed on the aircraft with RIPS, will be displayed. This is not considered a likely event since when a CVR is removed from an aircraft it is required to pass a ”return to service” test performed on a repair bench, before re− installation. This procedure usually includes clearing the fault log that may have had RIPS faults recorded. This RIPS Present status will be received and transmitted in the Label 350, Label 351, and new Label 352 outputs as follows: RIPS Presence CVR Discrete inStatus put (Pin 42) SSCVR Label 350 SSCVR Label 351 and 352 (Bit 22) (Bit 20) Not present Open 0 1 Present Ground 1 0 For more information on the RIPS, see P/N:165E4900−00, Installation and Operation Instruction Manual for Recorder Independent Power Supply (RIPS). 9. On board Maintenance System Interface The 2100−1025−22/−24 CVR includes an ARINC 429, high speed, On board Maintenance System (OMS) output interface (Pins 50/51) and an ARINC 429, low speed, OMS input interface (Pins 39/40). The OMS input interface is only used for OMS heartbeat detection and is discussed further in section 1.4 below. The OMS output interface is used for transmission of CVR status information to a Centralized Maintenance Computer (CMC). The OMS outputs are listed in Table 1.1. Table 11. CVR OMS Output Words Label 350 354 377 Parameter Format CVR Status Word BNR LRU identification (P/N and S/N) ISO 5 ARINC 429 equipment identification BCD Rate 1s 0.5 s 1s The Label 350 status word can be used to supplement or replace the discrete status outputs that are otherwise available from the CVR (e.g. CVR Fault discrete, DataLink Fault Discrete, and Test Good Indicator). The CVR software provides the Label 350 status output word, per ARINC 757A, once per second. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 60 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR As an additional capability, this CVR also monitors the status of an attached Recorder Independent Power Supply, if present, and includes that status with the OMS output reporting. The RIPS status is monitored using the CVR input pins listed in Table 1.2: Table 12. CVR Pins Assigned to RIPS Status Monitoring Pin Number 10 29 38 42 A. RIPS Monitoring Function State CVR Stop Recording / RIPS Active Open = Not Active Closed = RIPS Active or Stop Recording RIPS Fault Open = RIPS Fault Ground = RIPS OK RIPS Maintenance Open = No RIPS Maintenance Needed Ground = RIPS Maintenance Required RIPS Present Pin Program Open = No RIPS Installed Ground = RIPS Present If the RIPS is not present, then the CVR will not monitor the RIPS status inputs, and they will not be reported (default to “0’’ in Label 350 output). Label 350 Status Word Output The CVR will report status using Label 350 on the OMS ARINC 429 output word as shown in Table 1.3 below: Table 13. CVR Label 350 Output Format BIT N° FUNCTION STATUS 1­8 Label 350 9­10 SDI 1 2 1 1 10 9 0 0 0 1 1 0 1 1 0: OK 11 12 13 14 15 16 17 18 CVR Audio Recording Failure CMC Bus Status CVR Control Unit Failure FDR Status (not used) RIPS Fault Status (pin 29) CVR DataLink Recording Failure Clock Status Data Link Input Interface 0: OK 3 1 4 0 5 1 6 0 7 0 8 0 Normal (CVR1) Not used (CVR2) Not used Not used 1 : Failure 0: OK 1 : Failure 0: OK 1 : Failure 0: OK 1 : Failure 1 : RIPS Fault 0: OK 1 : Failure 0: OK 1 : Failure 0: OK 1 : Failure Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 61 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 19 20 21 22 23­29 30­31 CVR Recording Failure (Record Enable) RIPS Maintenance Status (Battery) (pin 38) RIPS Active Status (pin 10) RIPS Presence Status (Pin 42) Spare SSM 350 0: OK 1 : Failure 0: No Maint. 1 : Maint. Req. 0: Not Active 1 : RIPS Active 0: Not Pres. 1 : RIPS Present 32 Parity In general, the Label 350 Status Word bits operate as outlined in ARINC 757−4, Attachment 20. There is some interaction among the status bits in Label 350 with regard to Bit 11 (CVR Status), the CVR Fault Status discrete output, and with the results of the CVR Push−to−Test function. These interactions are summarized in Table 1.4 below: 31 1 1 0 0 30 1 Normal Operation (NO) 0 Functional Test (FT) 1 Non Computed Data (Not Used) 0 Fault Warning (Not Used) Table 14. CVR Fault Reporting Interactions L350 BIT N° 11 12 13 14 15 16 17 18 19 20 21 22 FUNCTION CVR Status (Audio Recording Failure) CMC Bus Status (OMS Input) CVR Control Unit Failure FDR Status (not used) RIPS Fault Status (Pin 29) CVR DataLink Recording Failure Clock Status Data Link Input Interface CVR Record Enable (Pins 7/8) RIPS Maintenance Status (Battery) (Pin 38) RIPS Active Status (Pin 10) RIPS Presence Status (Pin 42) REPORTED WITH L350 BIT 11 REPORTED WITH PUSH TO TEST YES YES REPORTED WITH CVR FAULT DIS­ CRETE YES NO YES NO NO NO NO NO NO NO NO YES NO NO NO NO NO YES NO NO YES NO NO NO NO NO YES NO NO NO NO NO NO NO It is important to note that certain CVR faults can only be detected through the “Push−to−Test” function. This commanded BITE provides the only test of the CVR audio input circuits. During the Push−to−Test operation, the CVR generates a test tone and sequentially injects it into each of the four audio input channels. A CVR fault will be asserted if the tone amplitude or frequency is not correctly detected. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 62 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Like any other internal CVR fault, this audio circuit failure will be reported using: the Label 350 output Bit 11, the CVR Fault Status discrete output, and the Push−to−Test results. If an audio input circuit failure occurs after a successful Push−to−Test operation, it will not be detected, or reported, until the next Push−to−Test is initiated. This audio input circuit failure is the only fault that would not otherwise be detected and reported by the CVR continuous BITE. Push−to−Test results are reported, during the test, using the CVR Test Indicator output (Pins 15/16) which is usually connected to an indicator lamp or meter on the CVR Control Unit. In addition, CVR failures reported through the Push−to−Test operation will be indicated by muting of the CVR Monitor Audio output (Pins 5/6). The fault criteria used to determine the reporting status associated with the CVR Label 350 Status Word bits are summarized in Table 1.5. Table 15. CVR Status Word Fault Reporting Criteria L350 BIT N° 11 FUNCTION FAILURE CRITERIA CVR Status (Audio Recording Failure) Any internal CVR failure that prevents correct recording of the audio inputs (including CU failure and Push−to−Test audio input circuit failure). May relent depending on fault severity. Loss of OMS input Heartbeat (valid Label 227 input) for more than 3 seconds. Relents if OMS Heartbeat is restored. Loss of 18 VDC Control Unit supply voltage. Relents if voltage level returns. Always reported as “Failed” in CVR only recorder. RIPS Fault as reported on pin 29 input (if present). Any internal CVR failure that prevents correct recording of the DataLink input. Loss of the ARINC 429 GMT input (Label 125 or 150) for more than 40 seconds. Relents if clock input is restored. Loss of the DataLink Heartbeat (valid Label 270) for more than 3 seconds (only if DataLink Valid, Pin 56, is asserted). Relents if DataLink Heartbeat is restored or DataLink Valid removed. Or Presence of DataLink Heartbeat (valid Label 270) if DataLink Valid, Pin 56, is not asserted. Relents if DataLink Valid is asserted or DataLink Heartbeat is removed. 12 CMC Bus Status (OMS Input) 13 CVR Control Unit Failure 14 15 16 17 FDR Status (not used) RIPS Fault Status (Pin 29) CVR DataLink Recording Failure Clock Status 18 Data Link Input Interface Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 63 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 19 CVR Record Enable (Pins 7/8) RIPS Maintenance Status (Battery) (Pin 38) RIPS Active Status (Pin 10) 20 21 22 RIPS Presence Status (Pin 42) CVR “Record Enable” jumper status (pins 7/8). RIPS Maintenance Status as reported on pin 38 input (if present). RIPS Active Status as reported on pin 10 input (if present). RIPS Presence as reported on pin 42 input. Any and all faults detected by the CVR, even if they relent, are recorded in a non−volatile fault log memory. This fault log can be retrieved using appropriate ground support equipment for review and analysis. B. Label 354 LRU Identification Output The CVR LRU IDENTIFICATION consists of multiple ARINC 429 words for the transmission of the CVR part number and serial number. The group of eleven ARINC 429 words defined below is transmitted twice per second. a. Start of Transmission Word Bit No 1­8 9­16 17­24 25­31 32 Function Label 354 Number of words in transmission (11) Not used STX Parity Status 11101100 00001011 00000000 00000010 b. LRU Name Bit No 1­8 9­15 16 17­23 24 25­31 32 Function Label 354 ‘C’ Not used ‘V’ Not used ‘R’ Parity Status 11101100 1000011 0 1010110 0 1010010 c. End of LRU Name, Start of Part Number Bit No 1­8 9­15 16 17­23 Function Label 354 Carriage return Not used First character of part number Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. Status 11101100 0001101 0 23–70–04 Description and Operation Rev. 15 Page 64 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 24 25­31 32 Not used Second character of part number Parity 0 d. Part Number (continued) Bit No 1­8 9­15 16 17­23 24 25­31 32 Function Label 354 Third character of part number Not used Fourth character of part number Not used Fifth character of part number Parity Status 11101100 0 0 e. Part Number (continued) Bit No 1­8 9­15 16 Function Label 354 Sixth character of part number Not used 17­23 24 25­31 32 Seventh character of part number Not used Eighth character of part number Parity f. Status 11101100 0 0 Part Number (continued) Bit No 1­8 9­15 16 17­23 24 25­31 32 Function Label 354 Ninth character of part number Not used Tenth character of part number Not used Eleventh character of part number Parity Status 11101100 0 0 g. End of Part Number, Start of Serial Number Bit No 1­8 9­15 16 17­23 24 25­31 32 Function Label 354 Twelfth character of part number Not used Carriage return Not used First character of serial number Parity Status 11101100 0 0001101 0 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 65 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR h. Serial Number (continued) Bit No 1­8 9­15 16 17­23 24 25­31 32 i. Status 11101100 0 0 Serial Number (continued) Bit No 1­8 9­15 16 17­23 24 25­31 j. Function Label 354 Second character of serial number Not used Third character of serial number Not used Fourth character of serial number Parity Function Label 354 Fifth character of serial number Not used Sixth character of serial number Not used Seventh character of serial number Status 11101100 0 0 Serial Number (continued) Bit No 1­8 9­15 16 17­23 24­31 32 Function Label 354 Eighth character of serial number Not used Ninth character of serial number Not used Parity Status 11101100 0 00000000 k. End of Transmission Word Bit No 1­8 9­24 25­31 32 Function Label 354 Not used EOT Parity Status 11101100 0000000000000000 0000100 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 66 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR C. Label 377 ARINC 429 Equipment Identification Word Output The CVR outputs a Label 377 equipment identification word on the OMS bus once per second. The word structure is defined below: Bit No 1­8 9­10 11­18 19­29 30­31 32 D. Function Label 377 SDI Equipment ID (CVR = 0x57) Not Used SSM Parity Status 11111111 00 11101010 00 OMS Input For the purpose of reporting the OMS input bus status in the Label 350 CVR Status Word output, the CVR expects a valid OMS input “heartbeat” once per second on the low speed OMS ARINC 429 input. The heartbeat is detected through the presence of a valid Label 227 input (including good parity) to the CVR. This Label 227 is used only for heartbeat detection and is not otherwise processed by the CVR. If the heartbeat is not detected during three consecutive seconds, the CVR will report the CMS Bus (OMS input) status as “failed” in the Label 350 CVR Status Word output. If the OMS input bus is not connected, then the associated Label 350 Status Word bit 12 can be ignored. 10. CVR DATALINK INPUT INTERFACE The FA2100 CVR, part numbers 2100−1X25−02/−22/−24 and 2100−1X26−02, was developed specifically to satisfy recent requirements for Controller Pilot DataLink Communications (CPDLC or “DataLink”) recording in addition to the two hour audio recording capability. The DataLink recording function of the CVR is generally compatible with ARINC 429, ARINC /757A, ARINC 758, and ARINC 619. The interface is characterized by the following specifications: F Single, ARINC 429, High Speed, physical layer input interface (Pins 33/34) F Williamsburg Version 3, Bit−Oriented Protocol for link layer interface F Includes support for ALOHA exchange (but not required) F Records all System Address Label (SAL) 157 and/or 156 full word inputs F Recording of all Label 270 and Label 276 DataLink status word inputs F Recording of all Label 350 CVR OMS status word outputs F 32 Mbytes of crash survivable memory reserved for DataLink message recording Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 67 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR F DataLink Valid Discrete input (Pin 56) F DataLink Fault Discrete output (Pin 31) All Label 270, 276, 157, and 156 words input on the CVR DataLink interface will be recorded to crash protected memory regardless of the parity (good or bad). Likewise, these inputs, if present, will be recorded regardless of the state of the DataLink Valid discrete input (Pin 56). A. Data Link Input and Encapsulation It is generally recognized that the Williamsburg Version 3 CVR input will utilize only Command frames containing the encapsulated DataLink message information. These Command frames then include the ARINC 619 formatting which provides the Network layer interface. However, the FA2100CVR records data at the link layer interface level and is unaffected by any link layer, or above, data content. This means that the CVR will record all 32 bits of each and every SAL 157 or 156 word received on the DataLink input. As a result, the CVR will not be impacted by any changes or additions to the approved DataLink message set. Likewise, the CVR DataLink recording function is not affected by the ARINC 619 General Format Identifier (GFI) coding or by the Extended GFI header encoding currently defined for message encapsulation. This technique provides the maximum flexibility in DataLink recording without the need for future CVR changes as the approved message set or associated encapsulation protocols continue to evolve. A generic DataLink encapsulation structure is illustrated in Figure 2.1 below. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 68 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Williamsburg V3 protocol payload protocol ARINC 619 Header payload Common Header Header Payload = one of the following styles CPDLC 0 Header Length ASCII or Unaligned PER Message ADS−C 1 Header Length ASCII or Bit Encoded Message AFN, ARINC 623 DC and ARINC 623 OC 2,3,5 Length ASCII Message ARINC 623 ATIS & Display Server 4,6 Area Length ASCII Message Figure 13. Generic DataLink Message Encapsulation Structure As indicated in Section 1 above, the FA2100 DataLink CVR also includes an ARINC 429 OMS output interface (Pins 50/51) that provides a Label 350 CVR status word output once per second. This word, in its entirety, along with any DataLink Label 270 or 276 input status words are also recorded as part of the DataLink stream. This provides a complete representation of the CVR DataLink input, and overall CVR status, within the recorded DataLink stream. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 69 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR B. DataLink Heartbeat In addition to providing the originating system status (e.g. CMU), the Label 270 input word is also used for DataLink “heartbeat” detection by the CVR. A valid Label 270 input (including good parity) must be received once per second by the CVR. If this heartbeat is not detected for 40 consecutive seconds for the 2100−1025−02, 2100−1X26−02, 2100−1X27−02 or three consecutive seconds for the 2100−1X25−22/−24, and the DataLink Valid discrete input (Pin 56) is asserted, a DataLink Interface fault will be asserted (as reported in the Label 350 CVR Status Word output). Likewise, a DataLink Interface fault will also be reported if the Label 270 heartbeat is detected, and DataLink Valid (Pin 56) is not asserted. C. Williamsburg Bit−Oriented Protocol Version Support It should be noted that the FA2100 CVR does not currently support Williamsburg Version 1 protocol or a low speed ARINC 429 interface for input of DataLink information. However, the CVR does support the Williamsburg ALOHA exchange, even though it is not required for Williamsburg Version 3 DataLink input. In the event that the CVR receives a valid ALO input on the SAL Label 157 (or 156), it will respond with a valid Label 304 ALR output indicating support for the Version 3 protocol. The format of the Label 157 or 156 ALO input is as follows: Label 157 0r 156 ALO Input Bit No Function Status 1-8 System Address Label 157 or 156 01101111 or 01101110 9-24 Don’t Care (not used by CVR) xxxxxxxxxxxxxxxx 25-28 ALO 1110 29-31 Protocol 001 32 Parity The format of the Label 304 ALR response word from the CVR, indicating support for Version 3 only, is shown below. CVR Label 304 ALR Output (in response to ALO input) Bit No Function Status 1­8 System Address Label 304 11000100 9­12 Version Supported (3) 1100 13­24 Reserved 000000000000 25­28 ALR 0001 29­31 Protocol 001 32 Parity As noted above, this ALOHA exchange is not necessary to initiate Williamsburg Version 3 DataLink input to the CVR. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 70 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR D. DataLink Memory Capacity The CVR is currently configured with 32 Mbytes of dedicated DataLink recording memory. This provides for a recording duration far in excess of the existing two hour requirement. E. DataLink Retrieval Recorded DataLink information is retrieved from the CVR in much the same way as audio data. All, or a portion, of the DataLink recording can be downloaded from the CVR using Ground Support Equipment supplied by L−3, Aviation Recorders. The Portable Interface can be used to download the DataLink recording to a PCMCIA memory card. The DataLink recording can also be downloaded using the CICC/2 or CICC/3 interface cable connected to a PC. The downloaded DataLink file can then be displayed using the Audio DataLink Playback software utility. can also output the recorded DataLink stream as a Hex ASCII file or Binary ASCII file for more extended user processing and display. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 71 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR THIS PAGE IS INTENTIONALLY LEFT BLANK Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Description and Operation Rev. 15 Page 72 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR TESTING 1. GENERAL NOTE: The 17TES0400 ROC/6 was manufactured from 2006 to 2011. Support for the PC operating system (Microsoft Windows XP) has been discontinued by Microsoft. L−3AR continues to provide technical support and repair; however operators are encouraged to upgrade to the current production 17TES0700 ROC/7. Technical support and documentation for the ROC/6 will not be available beyond revision 14 of this CMM. NOTE: The ROC/6 and ROC/7 will be referred to as “ROC” when the context and information apply equally to both of them. NOTE: If using the ROC/6, begin the testing procedure with Section 2. If using the ROC/7, begin the testing procedure with Section 3. NOTE: ROC/5 and ROC/6 will not run CATS 2.0 and higher. Auto Testing Part Numbers 2100−1X25−XX, 2100−1X26−XX and 2100−1X27−XX require the ROC/7 and CATS 2.0. This section provides operational level testing procedures for the Model FA2100 Cockpit Voice Recorder when using the CVR Automated Test Station (CATS) software, p/n: 17TES0420. The CATS software v1.0 or 1.1 is contained on the L−3AR Read-Out Center/6 (ROC/6), p/n: 17TES0400 and is used in conjunction with the L−3AR Recorder Interface Unit (RIU), p/n: 17TES0410. The CATS software v2.0 or higher is contained on the L−3AR Read-Out Center/7 (ROC/7), p/n: 17TES0700 and is used in conjunction with the L−3AR Recorder Interface Unit (RIU), p/n: 17TES0710. Associated Model S151/S161, S152/S162, and S251/S261 Control Units, S150/S160 Microphone Preamplifier Module, and S055 Remote Microphone testing and troubleshooting procedures are located in the ED-56A Control Unit and Microphone CMM, p/n: 165E1747- 00. Testing for the Model FA2100CVR is based upon an automated operational test procedure. The automated test procedure may serve as an acceptance criteria for the unit, as well as provide pointers to probable malfunctioning assemblies in the event that the unit is Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 101 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR not functioning properly. For troubleshooting failures, refer to Section 100, Paragraph 7. To upload the FA2100CVR software, use the ROC/6 without the RIU or an compatible PC. Refer to Section 100, Paragraph 8. 2. MAINTENANCE PHILOSOPHY A. Model FA2100CVR NOTE: L-3AR Repair Station has been given authority by L-3AR Factory to perform board and memory module level, disassembly, repair, assembly and return−to−service testing using factory procedures for all FA2100 CVRs. L-3AR Repair Station is the only authorized Repair Station to use the L−3AR factory procedures, all other repair stations must use the return−to−service testing procedure in this CMM. The EUROCAE ED−56A and ED−112 compliant Model FA2100CVR has been designed as a maintenance-free unit. The Model FA2100CVR is considered an “ON CONDITION LRU.” Each of its printed wiring assemblies (PWAs) makes extensive use of surface mount technology (SMT). The repair of a PWA containing SMT devices requires specialized training and factory equipment, along with special troubleshooting and soldering techniques; therefore, L-3 Communications, Aviation Recorders has deemed that PWAs containing SMT devices are not to be repaired in the field. As a result, the Model FA2100CVR’s maintenance philosophy is to level-2 board replacement. The FA2100CVR, has four field replaceable assemblies: (1) the Aircraft Interface PWA, which contains the power and input circuits; (2) the Audio Compressor PWA, which conditions the audio streams into digital formats for recording; (3) the Acquisition Processor PWA, which contains the processing and control circuits; and (4) the Crash Survivable Memory Unit (CSMU), which is used to digitally store and crash protect the cockpit voice communications. When it has been determined that an assembly is faulty, it should be removed from service, properly packaged, and returned to L3 Communications, Aviation Recorders for repair or replacement. No troubleshooting procedure is provided for any of these assemblies. Attempting field repair on any of these assemblies will void their warranty. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 102 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR B. Model S151/S161, S152/S162, and S251/S261 Control Units The Model S151/S161, S152/S162, and S251/S261 Control Units have been designed for use with the Model FA2100CVR’s in ED−56A compatible systems and contain a Microphone Preamplifier PWA manufactured with SMT devices. Refer to ED-56A Control Unit and Microphone CMM, p/n: 165E1747-00 for detail Testing Procedures for these units. C. MODEL S150/S160 MICROPHONE PREAMPLIFIER MODULES The Model S150/S160 Preamplifiers have also been designed for use with the Model FA2100CVR’s in ED−56A compatible systems that do not require a control unit. Refer to ED-56A Control Unit and Microphone CMM, p/n: 165E1747-00 for detail Testing Procedures for these units. D. MODEL S055 AND S056 ELECTRET CONDENSER MICROPHONES The Model S055 and Model S056 Microphones have also been designed for use with the Model FA2100CVR’s in ED−56A compatible systems. Refer to ED-56A Control Unit and Microphone CMM, p/n: 165E1747-00 for detail Testing Procedures for these units. 3. MODEL FA2100CVR RECORDER IN-SERVICE CHECKOUT A continuous Built-In-Test (BIT) capability is provided at power up to establish and monitor the mission fitness of the hardware. The built-in-test feature has been designed to perform a continuous test of all bits within the solid-state memory located in the Crash Survivable Memory Unit (CSMU). Any faults with the unit are stored in non−volatile RAM as a fault history log to aid in troubleshooting. An additional built-in-test is initiated by pressing a green TEST pushbutton located on the front panel of the control units (Model S151/S161 or Model S251/S261). A green TEST indicator is located on the front panel of the Model S151/S161 and Model S251/S261 Control Units to indicate successful completion of the manual test. The TEST pushbutton is used to generate the 620- to 660-Hertz test tone used for unit verification. This test tone is developed on the Audio Compressor PWA and applied to each channel individually where it is processed, stored in memory, read from memory, and checked for expected frequency and amplitude. The Model FA2100CVR’s built-in-test (BIT) philosophy is in accordance with guidelines set forth in ARINC Reports 604−1 and 624. Activating the BIT test is sufficient to determine the mission readiness of the Model FA2100 Cockpit Voice Recorder System. This operational test is performed as a pre-flight functional checkout of the Model FA2100CVR and is activated using front panel controls on its associated control unit. In the GACVR, a continuous Bite Status Output or Recorder Fault is indicated on pin 23. A ground at pin 23 represents a no fault, while an open equals fault or CVR not installed. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 103 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR The CVR test indicator wires, pins 15 and 16 (1mA) may be omitted in installations where ARINC 557 compatibility is not needed. CVR FAULT LIGHT REAL TIME OPEN = FAULT GND = NO FAULT ANNUNCIATOR PANEL CVR 23 RELAY +V ENERGIZE = OPEN (NO CVR FAULT) DE-ENERGIZED = GRN (CVR FAULT) Figure 101. CVR Fault Circuit for Pin 23 To checkout the operation of the Model FA2100CVR, its associated control unit, microphone preamplifier PWA, and cockpit area microphone, connect a headset to the control unit and, at a distance of approximately 6-inches, speak into the microphone at a normal voice level. You should be able to hear your words without any significant distortion. Bulk erasure of the Model FA2100CVR storage medium is accomplished using the associated control unit red ERASE pushbutton switch. Aircraft wiring interlocks must be set (that is, landing gear must be down and brakes locked) to allow the CSMU (solid-state flash memory) to be erased. To erase the information stored in the flash memory, press the ERASE pushbutton for more than 2 seconds and release. A 400-Hertz tone should be heard via the headset for less than 10 seconds. Should a problem be detected with the Model FA2100CVR and its associated control unit, remove the units from the aircraft. To determine the fault, place the units on the test bench for complete testing as listed in the procedures in the Testing Section. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 104 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 4. TEST EQUIPMENT REQUIRED The Model FA2100CVR has been designed as a direct line replaceable unit (LRU) for the existing Cockpit Voice Recorders, Models A100, A100A, A100S and A200S. As such, the Model FA2100CVR is to be tested using the same special test equipment built for the earlier model recorders with the exception of the Model A860 Test Panel which is no longer supported. The special test equipment required for use at a FA2100CVR test bench setup consists of the following units: L-3AR Read-Out Center/6 (ROC/6) P/N17TES0400 L-3AR Read-Out Center/7 (ROC/7) P/N17TES0700 CVR Automated Test Station Software (CATS) P/N 17TES0420 L−3AR Beacon Test Set P/N 17TES0015 Dukane Beacon Test Set Dukane 42A12( ) 10 Mohm High Impedance Voltmeter Commercially Available Audio Data Link Player (ADLP) Software P/N 17TES0423 (ADLP Software is only required for FA2100CVR P/N: 2100−1X25/1X26/1X27−( ) for playback only, CATS 2.0+ for Return to Service.) Note: The Dukane Beacon Test Set may be used as an alternate to the L−3AR Beacon Test Set, and must be purchased directly from Dukane. A 10 Mohm high impedance voltmeter is required when using the test equipment below, but it is not included in the test set. For additional information on the special test equipment, refer to the Special Tools And Test Fixtures Section 900. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 105 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 5. READ−OUT CENTER/6 (ROC/6), WINDOWS XP, AUTO−TESTING This section provides instructions for connecting the Recorder Interface Unit to the ROC/6 and FA2100CVR under test. Refer to Figure 201 for the ROC/6 w/CVR Automated Test Station Software (CATS) FA2100CVR test setup diagram. NOTE: The 17TES0400 ROC/6 was manufactured from 2006 to 2011. Support for the PC operating system (Microsoft Windows XP) has been discontinued by Microsoft. L−3AR continues to provide technical support and repair; however operators are encouraged to upgrade to the current production 17TES0700 ROC/7. Technical support and documentation for the ROC/6 will not be available beyond revision 14 of this CMM. CAUTION:Before proceeding, ensure that the power input select switch on the ROC/6 is in the proper electrical setting: 115 Vac or 230 Vac. If power input select switch is not in the proper setting, this will lead to failure in the ROC/6. A. READ−OUT CENTER/6 (ROC/6) Interconnects CAUTION:Make certain that all power is turned off before attaching cables. Failure to turn off power before attaching cables will result in immediate and serious damage to the unit. CAUTION:Only connect DC OR AC input voltage. Do not connect both input voltages at the same time. (1) Connect input power as detailed below, depending on the type of input power used. (a) For DC power, connect the DC power cable (17TES0412) from the DC Power connector (J8) on the rear of the RIU to a DC power supply that can generate 28 Volts 1 Amp. (b) For AC power, connect the AC power cable (17TES0411) from the AC Power connector (J7) into a watt meter that handles 115Vac, 400 Hz. Plug the watt meter into a 115 Vac 400Hz AC power supply (2) Plug the cable (17TES0416 for ROC/6) into the rear of the recorder to be tested. Plug the SCSI connector into “Rear Connector Intfc” (J1) and plug the blue connector into the blue “AC RCDR Power Test” (J9) connector. Both of these connectors are on the RIU front panel. (3) Connect the cable (17TES0072) between the recorder front ATE connector and the connector on the front of the RIU labeled “GSE Intfc” (J2). (4) Connect the USB Interface cable (17TES0415) between the RIU rear panel connector (J4) and a USB connector on the ROC/6. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 106 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR NOTE: Note: Make the following audio connections from the RIU to Sound Blaster sound card. Note that the sound card is located in an expansion slot not on the motherboard. (5) Attach the RIU Sound Card In (SND IN (J3)) cable to the Sound Card Line−In (or Microphone−In) which is the blue connector. (6) Attach the RIU Sound Card Out (SND OUT (J5)) cable to the Sound Card Line−Out which is the green connector. (7) Connect the DIN CABLE from the speakers to the middle Speaker Out (SPKRS OUT (J6)) connector on the front panel of the RIU. (8) After all connections are made to the RIU, apply power to the RIU. This can be either 28 Vdc or 115 Vac, 400 Hz. (9) Apply power to the PC or ROC/6 and observe that the PC boots to the Windows desktop. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 107 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR CVR AUTOMATED TEST SOFTWARE (CATS) 17TES0420 J4 USB 4‐PIN RIU UNIVERSAL SERIAL BUS INTERFACE 17TES0415 POWER INPUT SELECT RIU DC POWER INPUT 17TES0412 (DC)- J8 RIU AC POWER INPUT 17TES0411 (AC)- J7 DC AC 5A 1A RECORDER INTERFACE UNIT (RIU) J4 17TES0410 USB R-SPKR * GREEN REAR CONNECTOR INTFC GSE INTFC J9 RCDR AC PWR TEST J1 SPKRS SND OUT OUT BLUE SOUND CARD DC RED LIGHT YELLOW LIGHT AC SND IN J2 J6 J5 J3 L-SPKR * SND OUT - GREEN 17TES0413 SND IN - BLUE 17TES0413 J6 RIU AUDIO OUTPUT (SPKRS) ROC/6 17TES0400 FA2100 SOFTWARE UPLOAD CABLE ASSEMBLY 17TES0058 (use for software uploading only) RECORDER INTERFACE CABLE ASSY. 17TES0416 (FA2100‐CICC/2) COMPUTER INTERFACE COMMUNICATIONS CABLE ASSY. 17TES0072 * Note: Speakers are optional and not incld with ROC/6 To order speakers from L-3AR use: p/n: 17TES0425 (110V) or 17TES00426 (220V). FA2100 CVR RECORDER Figure 102. ROC/6 w/CVR Automated Test Station Software (CATS) FA2100CVR TEST SETUP Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 108 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR B. READ−OUT CENTER/6 (ROC/6) Sound Card Setup (1) Double−click the CATS (CVR Tester) icon on the ROC/6 to start the software then follow this procedure. (2) Click the Speaker button (Volume Control) to display the Playback Control menu. (3) Click on the Options pull down and then click on Properties. (4) Click the Recording radio button. (5) Select the Line−In check box. (all other boxes should not be checked) (6) Click Ok. Figure 103. Volume Control Properties (7) At the Record Control menu under Line−In check the Select box (8) Move the Line−In “Volume” control to full volume. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 109 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 104. Line In Input Level (9) Click on the Options pull down and then click on Properties. (10) Select the Playback radio button. (11) Select the following check boxes: Play Control, Wave and Line−In. All other boxes should not be checked. (12) Click Ok. Figure 105. Sound Card Properties Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 110 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (13) Move the Playback and the Wave Volume Controls to full volume and check the Mute box on the Line in (Mute should not be checked for all others). Figure 106. Playback Control, Volume Levels (14) Close the Play Control menu by clicking on the “X” in the upper right corner. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 111 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR C. READ−OUT CENTER/6 (ROC/6) − CATS AUTOTEST CAUTION:Ensure power is removed from the the RIU before proceeding. If the cable, p/n: 17TES0416 is connected to rear of the unit with the power applied to the RIU, the RIU may be damaged. CAUTION:Only connect DC OR AC input voltage. Do not connect both input voltages at the same time. Connecting both types of input voltages simultaneously will result in damage to the RIU. NOTE: The autotest can be performed using DC or AC applied to the RIU. When autotesting using DC power, proceed to CATS Autotest using DC power paragraph C.(1). when autotesting using AC power, proceed to CATS Autotest using AC power paragraph C.(2). (1) CATS Autotest using DC Power To perform the CATS Autotest using DC power only, follow the procedures below: (a) Ensure that the RIU has no power applied. Connect a CVR to the RIU using the cable, p/n:17TES0416 for the recorder rear connector and cable , p/n:17TES0072 for the recorder front connector. (b) Setup an in line RMS multimeter. Set to DC amps (c) Apply power to the RIU using 28 Vdc. (d) If the CATS test page is not shown, Click the L−3 CVR Test Icon on the Window desktop. Click the Ok button on the Monitor Audio Channel Pop− up menu. (e) From the pull down menu, click on Power at the top of the window and select Recorder Interface Reset. NOTE: This will load the Altera chip in the RIU unit. Observe the “connecting to recorder” status window appears. (f) From the pull down menu, click on Power => DC Power On. NOTE: Observe the “connecting to recorder” status window appears. (g) Verify that the DC LED on the front of the RIU is on. (h) Click on the Information tab in the test section of the menu. (i) Enter appropriate information into Department, Part Number and Serial Number fields. (j) From the pull down menu , click on Test=>Test Mode => Return−to−Service Test. Ensure that the Return−to−Service is checked. (k) From the pull down menu, click on Test=>Start Test. NOTE: Follow the instructions below as it appears presented by the software. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 112 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (l) Read and click on Yes. Figure 107. CVR Test, Start Toggle (m) Read and click on OK. Figure 108. CVR Test, Warning Message (n) Remove front cable and click on OK. Figure 109. CVR Test, Instruction Message (o) Enter in the current value in amps (typically .17) in window and click on OK. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 113 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 110. CVR Test, Power Consumption Entry (p) Verify that the DC LED on the front of the RIU is on. (q) Enter the current value in amps (typically .52) in window and click on OK. Figure 111. CVR Test, Power Consumption Entry (r) Connect the recorder front cable and click on OK. Figure 112. CVR Test, Instruction Message (s) Verify that the DC LED on the front of the RIU is on. (t) Observe the Fault History Log window appears. Select Print if you want to save the fault history or Close to continue. (u) Click on Yes. The autotest will now proceed in completing the autotest which will take approximately 30 minutes or less. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 114 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 113. CVR Test, Proceed Message (v) At the end of the test, save the report by selecting File => Test Report => Save Report. NOTE: The test report is named with the part number of the Unit Under Test and the serial number provided in the Information section of the test. The test report is located in the following default location: C:\Program Files\L−3Com\CVR Tester\Reports. This file is in an ASCII text file format. (w) If the autotest is successful, clear the fault history log by the pull down menu, click on Test=>Clear Fault History. (2) ROC/6 − CATS Autotest using AC Power To perform the CATS Autotest using AC power only, follow the procedures below: (a) Ensure that the RIU has no power applied. Power is removed. Connect a CVR to the RIU using the 17TES0416 for the recorder rear connector and 17TES0072 for the recorder front connector. (b) Setup an in line RMS multimeter. Set to AC amps (c) Apply power to the RIU using 115Vac. (d) If the CATS test page is not shown, Click the L−3 CVR Test Icon on the Window desktop. Click the OK button on the Monitor Audio Channel Pop− up menu. (e) From the pull down menu, click on Power at the top of the window and select Recorder Interface Reset. NOTE: This will load the Altera chip in the RIU unit. Observe the “connecting to recorder” status window appears. (f) From the pull down menu, click on Power => AC Power On. NOTE: Observe the “connecting to recorder” status window appears. (g) Verify that the AC LED on the front of the RIU is on. (h) Click on the Information tab in the test section of the menu. (i) Enter appropriate information into Department, Part Number and Serial Number fields. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 115 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (j) From the pull down menu , click on Test=> Test Mode=> Return−to−Service Test. Ensure that the Return−to−Service is checked. (k) From the pull down menu, click on Test=>Start Test. (l) Follow the instructions below as it appears presented by the software. (m) Read and click on Yes. Figure 114. CVR Test, Instruction Message (n) Read and click on OK. Figure 115. CVR Test, Warning Message (o) Remove front cable and click on OK. Figure 116. CVR Test, Instruction Message (p) Enter in the current value in amps (typically .085) in window and click on OK. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 116 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 117. CVR Test, Power Consumption Entry (q) Verify that the AC LED on the front of the RIU is on. (r) Enter the current value in amps (typically .21) in window and click on OK. Figure 118. CVR Test, Power Consumption Entry (s) Connect the recorder front cable and click on OK. Figure 119. CVR Test, Instruction Message (t) Verify that the AC LED on the front of the RIU is on. (u) Observe the Fault History Log window appears. Select Print if you want to save the fault history or Close to continue. (v) Click on Yes. The autotest will now proceed in completing the autotest which will take approximately 30 minutes or less. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 117 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 120. CVR Test, Proceed Message (w) At the end of the test, save the report by selecting File => Test Report => Save Report. NOTE: The test report is named with the part number of the Unit Under Test and the serial number provided in the Information section of the test. The test report is located in the following default location: C:\Program Files\L−3Com\CVR Tester\Reports. This file is in an ASCII text file format. (x) D. If the autotest is successful, clear the fault history log by the pull down menu, click on Test=>Clear Fault History. READ−OUT CENTER/6 (ROC/6) − Autotest Descriptions The following provides detailed descriptions of the test performed during the autotest function. (1) Power Test Prompts the user for AC/DC power usage as in the following AC example: Please remove the front panel cable from the recorder now and click the ”OK” button. Please enter the AC power consumption (in amps or watts) Please enter the AC power consumption (in amps or watts) Please connect the recorder front panel cable and press the ”OK” button. Example report message(s): 08:02:13 PASSED Power(AC) (Expected <= 12 watts) Results = (12 watts − 4 watts) = 8 watts 08:02:23 PASSED Power(DC) (Expected <= 11 watts) Results = (12.375 watts – 2.2 watts) = 10.175 watts Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 118 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (2) Fault Log Displays the current recorder fault log for user review and prompts the user: Continue CVR Tests? Example report message(s): 08:02:32 PASSED Fault History (3) Bulk Erase Part 1 – record audio out and verify 400 Hz bulk erase tone. Part 2 – record audio out and verify absence of bulk erase tone during rotor data output. Part 3 – record audio out and verify absence of bulk erase with recording disabled. Example report message(s): 08:02:42 PASSED Bulk Erase #1 (Expected 400 Hz) Results = 400.0 Hz 08:02:50 PASSED Bulk Erase #2 with active Rotor Speed (Expected <> 400 Hz) Results = 123.0 Hz 08:02:58 PASSED Bulk Erase #3 with No Recording (Expected <> 400 Hz) Results = 3334.6 Hz (4) Test Tone Enable push to test and verify push to test indicator is set. Example report message(s): 08:03:06 PASSED Test Tone (Expected Push−To−Test indicator) Results = Push−To−Test indicator set (5) GMT 429 Record simulated GMT−429 data (label 125 first and label 150 second) and verify 10 good patterns are recorded for each label. Example report message(s): 08:03:22 PASSED GMT 429 (Label 125) (Expected 10 patterns) Results = 10 good patterns08:03:42 PASSED GMT 429 (Label 150) (Expected 10 patterns) Results = 10 good patterns Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 119 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (6) Rotor Speed Part 1 – Record simulated 6000 Hz rotor speed data and verify data is within 2% of sent frequency. Part 2 – Record simulated 7 Hz rotor speed data and verify data is within 2% of sent frequency. Example report message(s): 08:03:52 PASSED Rotor Speed 6000 Hz (Expected 4 patterns > 5880.0 Hz < 6120.0 Hz) Results = 5998.0 Hz, 6026.4 Hz, 6026.4 Hz, 6026.4 Hz 08:04:03 PASSED Rotor Speed 7 Hz (Expected 4 patterns > 6.9 Hz < 7.1 Hz) Results = 7.0 Hz, 7.0 Hz, 7.0 Hz, 7.0 Hz (7) Channel Balance Record simulated 1000 Hz ½ reference level data for each channel 1,2,3 and 4 and verify amplitude all within 3 dB. Record simulated 1000 Hz 1/10 reference level data for each channel 1,2,3 and 4 and verify amplitude all within 3 dB. Example report message(s): 08:04:52 PASSED Channel Bal 1000 Hz 0.5 ref (All within 3 dB) Results = HQ1 5.2 /HQ2 5.3 /HQ3 5.1 /HQC 5.1 /SQV1 5.0 /SQV2 5.4 /SQV3 5.4 /SQC 5.5 dBV 08:05:40 PASSED Channel Bal 1000 Hz 0.1 ref (All within 3 dB) Results = HQ1 −8.3 /HQ2 −8.2 /HQ3 −8.4 /HQC −9.4 /SQV1 −8.0 /SQV2 −8.1 /SQV3 −8.1 /SQC −9.1 dBV (8) Frequency Response Record simulated 150 Hz ½ reference data for each channel 1,2,3 and 4. Record simulated 1000 Hz ½ reference data for each channel 1,2,3 and 4. Record simulated 3500 Hz ½ reference data for each channel 1,2,3 and 4. Record simulated 5000 Hz ½ reference data for channel 4. Record simulated 6000 Hz ½ reference data for channel 4. Verify amplitude all within 6 dB. Example report message(s): 08:06:28 Frequency Resp 150 Hz 0.5 ref Results = HQ1 3.6 /HQ2 3.8 /HQ3 3.5 /HQC 1.4 /SQV1 3.9 /SQV2 3.9 /SQV3 3.9 /SQC 3.9 dBV Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 120 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 08:07:15 Frequency Resp 1000 Hz 0.5 ref Results = HQ1 5.2 /HQ2 5.3 /HQ3 5.1 /HQC 5.1 /SQV1 5.4 /SQV2 5.4 /SQV3 5.4 /SQC 5.4 dBV 08:08:02 Frequency Resp 3500 Hz 0.5 ref Results = HQ1 3.3 /HQ2 2.9 /HQ3 2.5 /HQC 5.1 /SQV1 3.7 /SQV2 3.7 /SQV3 3.8 /SQC 3.5 dBV 08:08:12 Frequency Resp 5000 Hz 0.5 ref Results = HQC 4.9 dBV 08:08:23 Frequency Resp 6000 Hz 0.5 ref Results = HQC 4.9 dBV 08:08:23 PASSED Frequency Resp (All within 6 dB) (9) Signal to Noise and Distortion Record simulated data at each of the following frequencies once at 0 reference level and again at 1/10 reference). Frequencies for HQ1, HQ2, HQ3, HQCAM, SQV1, and SQCAM are: 206, 282, 386, 529, 724, 993, 1360, 1864, 2554 and 3500 Hz. Frequencies for HQCAM and SQCAM are: 217, 314, 454, 656, 949, 1372, 1984 and 2869 Hz. Frequencies for HQCAM only are: 4148 and 6000 Hz. Verify HQ > 24.0 dB and SQ > 20.0 dB. Example report message(s): 08:09:38 PASSED SN+D 150 Hz 1.0 ref (Expected HQ > 24.0 dB SQ > 20.0 dB) Results = HQ1 35.0 /HQ2 34.6 /HQ3 35.3 /HQC 36.9 /SQV1 32.1 /SQV2 31.6 /SQV3 32.0 /SQC 31.6 dB 08:35:07 PASSED SN+D 150 Hz 1.0 ref (Expected HQC > 24.0 dB SQC > 20.0 dB) Results = HQC 30.7 /SQC 25.9 dB (10) Crosstalk Audio Record simulated 1000 Hz data for each channel 1,2,3 and 4 and calculate difference between driven and non−driven channels. Verify difference is less than −40 dB. Example report message(s): 08:41:34 PASSED Crosstalk (Audio) 1000 Hz 1.0 ref (Expected Driven − Non− Driven < −40 dB) Results = HQ1 11.2 /HQ2 −101.0 /HQ3 −109.9 /HQC −128.1 /SQV 11.4 /SQC −84.4 dBV 08:41:49 PASSED Crosstalk (Audio) 1000 Hz 1.0 ref (Expected Driven − Non− Driven < −40 dB) Results = HQ1 −101.3 /HQ2 11.2 /HQ3 −115.3 /HQC −107.5 /SQV 11.4 /SQC −72.3 dBV Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 121 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 08:42:04 PASSED Crosstalk (Audio) 1000 Hz 1.0 ref (Expected Driven − Non− Driven < −40 dB) Results = HQ1 −304.8 /HQ2 −127.4 /HQ3 11.1 /HQC −104.4 /SQV 11.4 /SQC −72.0 dBV 08:42:19 PASSED Crosstalk (Audio) 1000 Hz 1.0 ref (Expected Driven − Non− Driven < −40 dB) Results = HQ1 −304.9 /HQ2 −304.9 /HQ3 −111.7 /HQC 11.1 /SQV −72.4 /SQC 11.4 dBV (11) Crosstalk Data NOTE: Test for combination recorders where both flight data and voice data are being recorded. Perform a Channel Balance to determine and store results for each channel 1,2,3 and 4. Record 6000 Hz simulated rotor data and simulated GMT 429 and calculate channel results minus channel balance results. Verify difference is less than −34 dB Example report message(s): 08:43:07 PASSED Channel Bal 1000 Hz 1.0 ref (All within 3 dB) Results = HQ1 11.2 /HQ2 11.2 /HQ3 11.0 /HQC 11.1 /SQV1 11.0 /SQV2 11.3 /SQV3 11.4 /SQC 11.5 dBV 08:43:23 PASSED Crosstalk (Data) 6000 Hz 1.0 ref (Expected Crosstalk − Channel Bal < −34 dB) Results = HQ1 −304.9 /HQ2 −125.7 /HQ3 −304.8 /HQC −49.8 /SQV −83.4 /SQC −82.8 dB (12) Audio Out Monitor Record simulated 1000 Hz data for each channel 1,2,3 and 4 and verify amplitudes by part number: Part# 2100−10X0 = 2.45 +/−20% Audio Out level (VRMS) Part# 2100−30X3−00 = 2.45 +/−20% Audio Out level (VRMS) Part# S200−XXX−XX = 4.6 − 8.4 Audio Out level (VRMS) Example report message(s): 08:45:17 PASSED Audio Out Monitor 1000 Hz (Expected 0.358 +/−20 percent VRMS) Results = HQ1 0.322 /HQ2 0.323 /HQ3 0.321 /HQC 0.319 VRMS Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 122 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (13) Signal To No Signal Record simulated 1000 Hz data for each channel 1,2,3 and 4 and store results then record no data for channels 1,2,3 and 4 and compare differences between signal data results and no signal data results. Verify difference is less than −48 dB. Example report message(s): 08:47:12 PASSED Sig To No Sig 0 Hz 1.0 ref (Expected HQ < −48 dB SQ < −40 dB) Results = HQ1 −304.9 /HQ2 −122.6 /HQ3 −108.4 /HQC −115.4 /SQV1 −82.7 /SQV2 −82.2 /SQV3 −80.7 /SQC −85.0 dB (14) Shutdown Part 1 – enable delayed shutdown. Part 2 – verify shutdown is detected (CVR fault set) after > 9 and < 10 minutes. Part 3 – verify shutdown is terminated following a push to test and recording is resumed. Example report message(s): 08:47:13 PASSED Shutdown Initialization (Shutdown issued − Please wait 9−10 minutes...) 08:56:14 PASSED Shutdown CVR Fault (Expected CVR fault to occur) Result = CVR Fault 08:56:27 PASSED Shutdown Push−to−Test (Expected 1000 Hz frequency) Results = 999.9 Hz (15) Capacitor Power off recorder and verify recorder is still powered after 200 milliseconds but not powered after 2 seconds. Example report message(s): 08:56:32 PASSED Capacitor − GSE powered after 200 milliseconds but not after 2 seconds Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 123 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (16) FSK Time (V1.1 BETA) Cycle power to recorder to reset for FSK input then record simulated 16000 sps FSK data and then simulated GMT 429 data (label 150) first with channel 1 output and again with channel 3 output. Verify 9 good FSK data patterns and a switch to 9 good GMT 429 data patterns for each channel 1 and channel 3. Example report message(s): 14:50:07 PASSED FSK Time HQ1 (Playback)(Expected 9 patterns) Results = 9 good patterns 14:50:07 PASSED FSK Time HQ1 (GMT Switch) (Expected 9 patterns) Results = 9 good patterns 14:50:53 PASSED FSK Time HQ3 (Playback)(Expected 9 patterns) Results = 9 good patterns 14:50:53 PASSED FSK Time HQ3 (GMT Switch) (Expected 9 patterns) Results = 9 good patterns Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 124 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR E. ROC/6 − Audio Setup Procedure NOTE: L−3AR recommends that an Audio Setup check be performed every two years, or if the Sound Blaster Audio card is replaced on the ROC/6−CATS RIU System. The Sound Blaster Audio Card in the ROC/6 must be set up to ensure that the proper reference voltage levels of the audio test signals are sent to the RIU for testing the FA2100CVR. The Audio Setup is only required when the RIU or Sound Blaster Audio Adapter card is removed or replace by a new one or when the autotest results indicate that the Audio Adapter Card is not outputting the proper signal levels. Indication of this is when a known good CVR is failing all of the the autotest audio test functions. The audio setup process requires the use of the Audio Setup Cable Assembly, p/n: 17TES0417, refer to Figure 121. LOOP BACK CONNECTOR Figure 121. Audio Setup Cable Assembly, 17TES0417 NOTE: (1) Selections on the toggle switches of the Audio Setup Cable Assembly, pn 17TES0417, override channel selections made in the CATS software. For example, if the user selects channels 1,2,3,4 in the Audio Reference Setup Utility, but selects CH1 on the cable toggle switches, the Audio Reference Level will be calculated for Channel 1. Reference values calculated for Channel 1 are functionally equivalent to reference values for channels 2−3. Sound Card Input/Output Setup CAUTION: Remove power from the the RIU before proceeding. If the connector is disconnected with power applied to the RIU, the RIU may be damaged. (a) Attach the loop−back connector of the Audio Setup Cable, p/n: 17TES0417, to the Recorder Interface cable, p/n: 17TES0416, coming from the RIU. Connect the Audio Setup Cable, p/n 17TES0417, to multimeter set to “Volts AC”. (b) Ensure that the RIU Sound Card In (SND IN (J3)) cable is connected to the Sound Card Line−In (blue connector). Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 125 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (c) Ensure that the RIU Sound Card Out (SND OUT (J5)) cable is connected to the Sound Card Line−Out (green connector). (d) Apply DC or AC power to the RIU. (e) If the CATS test page is not shown, Click the L−3 CVR Test Icon on the Window desktop. Click the OK button on the Monitor Audio Channel Pop− up menu. (f) From the pull down menu, click on Power at the top of the window and select Recorder Interface Reset. NOTE: This will load the Altera chip in the RIU unit. Observe the “connecting to recorder” status window appears. (g) From the pull down menu, click on Power => DC Power On or AC Power On. NOTE: Observe the “connecting to recorder” status window appears. (2) (h) Verify that the DC LED or AC LED on the front of the RIU is on. (i) Click the Speaker button (Volume Control) to display the Playback Control menu. (j) Please refer to and perform steps (2) through (14) of Section 5.B. “Read-Out Center/7 (ROC/7) - Sound Card Setup.” Part 1 – Sound Card Output Adjustment (a) Select Utilities => Audio Reference Level Utility to run the Audio Reference Utility from the CVR Tester menu. At the CVR Tester Pop−up menu, select the OK button Figure 122. Audio Reference Level Utility, Warning Message (b) Select Channel 1 check box ion the Audio Reference Level Menu. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 126 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 123. Audio Reference Level Utility, Menu (c) Load 1000Hz full amplitude .wav file by selecting File => Open File on the Audio Reference Utility. Select Setup_1000Hz.wav. and click on Open. Figure 124. Audio Reference Level Utility, File Open Menu (d) Ensure the MultiMeter is connected to the Audio Setup Loop−back cable. Set the toggle switches to the following settings: (Switch Settings: Channel 1 and No Audio Out). (e) At the Audio Reference Level menu, ensure that the Channel 1 check box is selected. Select Sound => Play Sound to output the 1000 Hz wave file to the sound card. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 127 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 125. Audio Reference Level Utility, Play Sound (f) Adjust the Audio Reference Level menu volume slider so that the meter reads 3 Volts RMS or as close as possible to this voltage (without going over 3 Volts RMS). (g) From the Audio Reference Level Menu select Sound => Stop Play to stop audio output to the sound card. (h) Set the toggle switches on the loop−back connector to the following settings: (Switch Settings: Channel 4 and No Audio Out). (i) At the Audio Reference Level menu, ensure that the Channel 4 check box is selected and Channel 1 is deselected. Select Sound => Play Sound to output the 1000 Hz wave file to the sound card. Figure 126. Audio Reference Level Utility, Play Sound (j) Adjust the Audio Reference Level menu volume slider so that the meter reads 2 Volts RMS or as close as possible to this voltage (without going over 2 Volts RMS). (k) From the Audio Reference Level menu select Sound => Stop Play to stop audio output to the sound card. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 128 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (l) Select Store Result =>Output Results. A pop−up window will appear displaying the current REFERENCE, and the new VOICE VOLUME and CAM VOLUME values. Figure 127. Audio Reference Level Utility, Confirmation (m) Select Yes to update the Setup reference level file with the values displayed, or select No to cancel the update of the Setup reference level file. (n) NOTE: (3) Close the Audio Reference Level menu by selecting the Close button. The Audio Reference Utility volume value is used to define the VOICE VOLUME for channels 1,2,3 and the CAM VOLUME for channel 4, for output to the recorder during CVR tests. Part 2 – Sound Card Input Adjustment (a) Set the toggle switches on the Loop−Back Connector to the following settings: (Switch Settings: Channel 1 and Audio Out). (b) Select Utilities => Audio Reference Level Utility to run the Audio Reference Utility from the CVR Tester menu. At the CVR Tester Pop−up menu, select the OK button Figure 128. Audio Reference Level Utility, Warning Message (c) Select Channel 1 check box ion the Audio Reference Level Menu. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 129 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 129. Audio Reference Level Utility, Menu (d) Load 1000Hz full amplitude .wav file by selecting File => Open File on the Audio Reference Utility. Select Setup_1000Hz.wav. and click on Open. Figure 130. Audio Reference Level Utility, File Open Menu (e) From the menu bar under Utilities, select Audio Reference Utility. Select the check box next to Channel 1 and deselect Channel 4 check box. Select Sound => Play Sound to output the 1000 Hz wave file to the sound card. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 130 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 131. Audio Reference Level Utility, Play Sound (f) Adjust the Audio Reference Level volume slider so that the meter reads 2.45 Volts RMS or as close as possible to this voltage. (g) From the Audio Reference Level menu select Sound => Record Sound to record the input sound. (h) From the Audio Reference Level menu select Sound => Stop Record to stop recording. (i) From the Audio Reference Level menu select Sound => Stop Play to stop audio output from the sound card. (j) From the Audio Reference Level menu select Store Results => Input Results to calculate and display the REFERENCE value or Correction Factor (CF). Figure 132. Sound Card Input Results (k) Click OK to continue with the update or Cancel to stop the update. Following an OK click a pop−up window will appear displaying the new REFERENCE, and current VOICE VOLUME and CAM VOLUME values. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 131 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 133. CVR Tester, Update Reference Level (l) Select Yes to update the audio setup reference level file with the values displayed, or select No to cancel the update of the audio setup reference level file. (m) Close the Audio Reference Level menu by selecting the Close button. (n) Remove power from the RIU CAUTION: Remove power from the the RIU before proceeding to the next step. If the connector is disconnected with power applied to the RIU, the RIU may be damaged. (o) Remove the Audio Setup Loop−Back Connector, p/n: 17TES0417. NOTE: This reference value will be used to adjust the audio voltages read from the audio output of a 600 ohm recorder during CVR tests. For example, if 1.952 Volts RMS is read from the sound card then Correction Factor = 2.45 VRMS / 1.952 VRMS. If the Volts RMS value read is less than 1 Volt RMS then and error message will be displayed. In this case, verify that all of the cables are working and are installed correctly. NOTE: The setup reference level file is named ri_Ref_Level.txt and is located in the CVR Tester local subdirectory. Sample ri_Ref_Level.txt file: ; RI Sound Card reference level ; ; REFERENCE value equals 2.45 VRMS / X VRMS read from sound card. ; Example: 1.255 VRMS REFERENCE = (2.45 VRMS/ 1.952 VRMS read from sound ; card) ; VOICE VOLUME value for Full Reference or 3 Volts RMS input to recorder ; CAM VOLUME value for Full Reference or 2 Volts RMS input to recorder REFERENCE = 1.255 VOICE VOLUME = 9509 CAM VOLUME = 6168 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 132 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR F. ROC/6 − AUDIO DOWNLOAD & PLAYBACK NOTE: ROSE 4.0 or higher on a ROC or RAU is recommended to download directly from a CVR and convert audio into a .WAV for playback. Refer to the Read-Out Support Equipment / Recorder Interface Software version 4.0 or Higher Operator’s Manual, p/n 165E1696-03, to Retrieve Flight Data and / or Audio Data from a Recorder. NOTE: When decompressing Standard Quality Audio from a 2−Hr. FA2100CVR, p/n: 2100−1020−XX, pre Hardware MOD−DOT #7, you must have the RIU powered and the Altera chip reset using the Power −> RIU Interface Reset command. This is required because hardware inside the RIU is used for converting of the 2−bit compressed Standard Quality Combined (SQV) and Standard Quality CAM (SQC) channels. This is not a requirement for the High Quality Channels (HQV & HQC) because this 3−bit compression is converted using the CATS software. The FA2100CVRs that have Hardware MOD−DOT #7 installed have full two hour High−Quality for all four audio channels as does all 30−Minute FA2100CVRs. (1) Click on the Copy button. Set the File Name to Filename.cvr (the system will use a default file name with the part number of the recorder and serial number that was entered in the information fields of the test section). (2) Click on the Save button. (3) Select either Full Audio Data Download or Copy data from last XX Hrs. XX Min. Click OK. Copying of the data will start. (4) When the “Copy Data is Complete” box is shown click on Yes. On the Decompression Options menu select HQV1 through HQV3 and HQC. If using an FA2100CVR, p/n: 2100−1020−XX, pre MOD−DOT #7 unit also select the Standard Quality Audio data SQV & SQC. Click OK. (5) Click on the Microphone button. Select the Left Channel to be HQV1 and the Right Channel to be HQC. Click OK to exit the dialog box. (6) Click on the Play button. Confirm that the display changes and that the speakers output the audio. Click on the Stop button when satisfied that the data is being played back properly. (7) Click on File => Exit to leave CVR Tester. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 133 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Table 101. 17TES0400 Part Number READOUT CENTER/6 (ROC/6) − Parts List Description Mfg. 17TES0400 Read-Out Center/6 − Full CVR/FDR Configuration (The following items are included with the ROC/6). L-3 Com 17TES0410 Recorder Interface Unit (RIU) L-3 Com 17TES0411 Cable, RIU to AC Power In L-3 Com 17TES0412 Cable, RIU to DC Power In L-3 Com 17TES0413 Cable, RIU to Sound Card (2ea.) L-3 Com 17TES0415 Cable, RIU to USB L-3 Com 17TES0416 Cable, RIU to CVR L-3 Com 17TES0417 Cable Assembly, Audio Setup L-3 Com 17TES0420 CATS Software, FA2100 L-3 Com 17TES0070 CICC/2 Assembly L-3 Com 17TES0072 Cable Assembly, FA2100−CICC/2 L-3 Com 17TES0321 Read-Out System Equipment Software (ROSE 4.X) L-3 Com 17TES0058 FA2100 Software Upload Cable Assembly L-3 Com 883E4557−00 CD, Soundblaster Audigy Obsolete w/ROC−7s mnf. After 07/14. 17TES0076 RUFS Recorder Interface, USB L-3 Com 17TES0425 Speakers (2), 110 Vac (U.S. − Standard) Optional 17TES0426 Speakers (2), 220 Vac (Non−U.S. − Standard) Optional Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 134 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 6. READ−OUT CENTER/7 (ROC/7), WINDOWS 7, AUTO−TESTING This section provides instructions for connecting the Recorder Interface Unit to the ROC and FA2100 under test. Refer to Figure 134 for the ROC/7 w/CVR Automated Test Station Software (CATS) FA2100CVR test setup diagram. CAUTION:Before proceeding, ensure that the power input select switch on the ROC is in the proper electrical setting: 115 Vac or 230 Vac. If power input select switch is not in the proper setting, this will cause failure or damage in the units. A. READ−OUT CENTER/7 (ROC/7) Interconnects CAUTION:Make certain that all power is turned off before attaching cables. Failure to turn off power before attaching cables will result in immediate and serious damage to the unit. CAUTION:Only connect DC OR AC input voltage. Do not connect both input voltages at the same time. (1) Connect input power as detailed below, depending on the type of input power used. (a) For DC power, connect the DC power cable (17TES0412) from the DC Power connector (J8) on the rear of the RIU to a DC power supply that can generate 28 Volts 1 Amp. (b) For AC power, connect the AC power cable (17TES0411) from the AC Power connector (J7) into a watt meter that handles 115Vac, 400 Hz. Plug the watt meter into a 115 Vac 400Hz AC power supply (2) Plug the cable (17TES0418 for ROC/7) into the rear of the recorder to be tested. Plug the SCSI connector into “Rear Connector Intfc” (J1) and plug the blue connector into the blue “AC RCDR Power Test” (J9) connector. Both of these connectors are on the RIU front panel. (3) Connect the cable (17TES0072) between the recorder front ATE connector and the connector on the front of the RIU labeled “GSE Intfc” (J2). (4) Connect the USB Interface cable (17TES0415) between the RIU rear panel connector (J4) and a USB connector on the ROC. NOTE: Make the following audio connections from the RIU to Sound Blaster sound card or to the motherboard sound system depending on the serial number of the ROC/7. Newer ROC/7 manufactured after Jun. 2014 do not contain the Sound Blaster auxiliary card. (5) Attach the RIU Sound Card In (SND IN (J3)) cable 17TES0413 to the Sound Card Line−In (or Microphone−In) which is the blue connector. (6) Attach the RIU Sound Card Out (SND OUT (J5)) 17TES0413 cable to the Sound Card Line−Out which is the green connector. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 135 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (7) Connect the DIN CABLE from the speakers to the middle Speaker Out (SPKRS OUT (J6)) connector on the front panel of the RIU. (8) After all connections are made to the RIU, apply power to the RIU. This can be either 28 Vdc or 115 Vac, 400 Hz. (9) Apply power to the PC; the ROC and observe that the PC boots to the Windows desktop. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 136 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR CVR AUTOMATED TEST SOFTWARE (CATS 2.0) 17TES0420 J4 USB 4‐PIN RIU UNIVERSAL SERIAL BUS INTERFACE 17TES0415 POWER INPUT SELECT RIU DC POWER INPUT 17TES0412 (DC)- J8 RIU AC POWER INPUT 17TES0411 (AC)- J7 DC AC 5A 1A RECORDER INTERFACE UNIT (RIU) 17TES0710 R-SPKR * J4 USB GREEN REAR CONNECTOR INTFC GSE INTFC SND SPKRS OUT OUT SND PWR IND IN J5 BLUE J9 RCDR AC PWR TEST J1 SOUND CARD DC RED LIGHT YELLOW LIGHT AC J2 J3 J6 SND OUT - GREEN 17TES0413 SND IN - BLUE 17TES0413 L-SPKR * J6 RIU AUDIO OUTPUT (SPKRS) ROC/7 17TES0700 FA2100 SOFTWARE UPLOAD CABLE ASSEMBLY 17TES0058 (use for software uploading only) RECORDER INTERFACE CABLE ASSY. 17TES0418 (FA2100‐CICC/2) COMPUTER INTERFACE COMMUNICATIONS CABLE ASSY. 17TES0072 * Note: Speakers are optional for ROC/7. To order speakers from L-3AR use: p/n: 17TES0425 (110V) or 17TES0426 (220V) CVR RECORDER Figure 134. ROC/7 with CVR Automated Test Station Software (CATS 2.0) FA2100CVR TEST SETUP − ROC/7’s DMF: Pre Jul. 2014. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 137 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR CVR AUTOMATED TEST SOFTWARE (CATS 2.0) 17TES0420 J4 USB 4‐PIN RIU UNIVERSAL SERIAL BUS INTERFACE 17TES0415 POWER INPUT SELECT RIU DC POWER INPUT 17TES0412 (DC)- J8 RIU AC POWER INPUT 17TES0411 (AC)- J7 DC AC 5A 1A RECORDER INTERFACE UNIT (RIU) 17TES0710 GREEN R-SPKR * J4 USB REAR CONNECTOR INTFC GSE INTFC SND SPKRS OUT SND OUT J1 DC PWR IND IN SND OUT - GREEN 17TES0413 RED LIGHT YELLOW LIGHT AC J5 BLUE J9 RCDR AC PWR TEST J2 J6 J3 ROC/7 17TES0700 SND IN - BLUE 17TES0413 FA2100 SOFTWARE UPLOAD CABLE ASSEMBLY 17TES0058 (use for software uploading only) L-SPKR * J6 RIU AUDIO OUTPUT (SPKRS) RECORDER INTERFACE CABLE ASSY. 17TES0418 (FA2100‐CICC/2) COMPUTER INTERFACE COMMUNICATIONS CABLE ASSY. 17TES0072 * Note: Speakers are optional for ROC/7. To order speakers from L-3AR use: p/n: 17TES0425 (110V) or 17TES0426 (220V) CVR RECORDER Figure 135. ROC/7 with CVR Automated Test Station Software (CATS 2.0) FA2100CVR TEST SETUP − ROC/7’s DMF: Post Feb. 2015. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 138 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR B. READ−OUT CENTER/7 (ROC/7) − Sound Card Setup (1) Double−click the CVDR Test icon on the ROC to start the software. The application will launch with the Channels control screen displayed, as illustrated in Figure 136. Figure 136. CATS, Channels Control Screen (2) In the Channels control screen, click OK. The Channels control screen will disappear. (3) Click the Volume control icon (it is the icon that looks like a speaker). The Volume Mixer − Speakers (SB Audigy) control displays, see Figure 137. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 139 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 137. Volume Control (4) Under Applications, click Sound Systems, then click the Recording tab. This will display the Sound control window illustrated on the following page. Figure 138. Sound Control, Recording (5) Select the Recording tab. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 140 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (6) Highlight and select Line−in. (7) Click on Properties. Figure 139. Line−In Properties, Line−In Level (8) Select the Levels tab. (9) Make sure that the Line−In level is set at 100 (move the Line−In slider to maximum.) (c) Click on OK. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 141 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 140. Sound, Playback Devices (10) Click on the Playback tab. (11) Highlight Speakers. (12) Click on Properties. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 142 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 141. Speaker Properties, Levels (13) Select the Levels tab. (14) Make sure Playback Control is set at 100. (move the Playback Control slider to its maximum setting) (15) Make sure that the four remaining controls, Microphone, Line−In, Auxiliary, and S/PDIF−In are all muted. Volume slider levels do not need modification since these input volumes have been muted. (16) Click OK. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 143 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 142. Volume Mixer, Speaker Levels (17) In the Volume Mixer, make sure both sliders are all the way up. (18) Close the Volume Mixer. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 144 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR C. READ−OUT CENTER/7 (ROC/7) − CATS Autotest CAUTION:Ensure power is removed from the the RIU before proceeding. If the cable, p/n: 17TES0418 is connected to rear of the unit with the power applied to the RIU, the RIU may be damaged. CAUTION:Only connect DC OR AC input voltage. Do not connect both input voltages at the same time. Connecting both types of input voltages simultaneously will result in damage to the RIU. NOTE: The autotest can be performed using DC or AC applied to the RIU. When autotesting using DC power, proceed to CATS Autotest using DC power paragraph C.(1). when autotesting using AC power, proceed to CATS Autotest using AC power paragraph C.(2). When autotesting using both DC and AC power,to CATS Autotest using AC and DC power paragraph C.(2). (1) ROC/7 − CATS Autotest using DC power To perform the CATS Autotest using DC power only, follow the procedures below: NOTE: (a) Ensure that the RIU has no power applied, power is removed if not already done. Connect a CVR to the RIU using the cable, p/n:17TES0418 (ROC/7) for the recorder rear connector and cable, p/n:17TES0072 for the recorder front connector. (b) If the power supply does not include a built−in multimeter, set up an inline RMS multimeter. Set to DC amps (c) Apply power to the RIU using 28 Vdc. (d) If the CATS test page is not shown, click the L-3 CVDR Test icon on the Windows desktop. (e) Click the Ok button on the Monitor Audio Channel pop-up menu. (f) From the Menu bar, click on Power and select Recorder Interface Reset from the drop down menus. This will load the Altera chip in the RIU unit. Observe the “connecting to the recorder” status window appears. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 145 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Observe Figure 143. CATS, Connecting Pop-Up (g) On the tool bar, select Power. Figure 144. CATS, Power Toggle NOTE: When DC power is applied verify the appropriate LED is lit up on the RIU. (h) Click on the Information tab in the Test section of the menu. (i) Enter appropriate information into Department, Part Number, and Serial Number fields. (j) On the tool bar, select Start Test. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 146 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 145. CATS, Start Test Toggle (k) In the “Test Mode and Options” dialog box, select either Return−to−Service or Selectable Test Options, then click on OK. Figure 146. CATS, Test Mode and Options Screen NOTE: If a full return to service test is not desired then select the “Selectable Test Options” radio button and choose the test options desired. Figure 147 will appear as confirmation. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 147 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR NOTE: Figure 147 is only displayed if “Selectable Test Option” is chosen from the CATS, Test Mode and Options Screen. Figure 147. CATS, CVDR Test Confirmation NOTE: Follow the instructions displayed in the confirmation window. (l) Read and click on Yes. Figure 148. CATS, CVDR Warning Message (m) Remove front cable and click on OK. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 148 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 149. CATS, CVDR Instruction Window (n) Read the current DC amps value from the built-in multimeter on the power supply or from the inline RMS multimeter. And enter in the value in amps in window and click on OK. Figure 150. CATS, Power Test Input (o) Read the current DC amps value from the built-in multimeter on the power supply or from the inline RMS multimeter. And enter in the value in amps in window and click on OK. Figure 151. CATS, Power Test Input (p) Connect the recorder front cable and click on OK. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 149 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 152. CATS, CVDR Instruction Window (q) Observe the Fault History Log window appears. Select Print if you want to save the fault history or Close to continue. Figure 153. CATS, CVDR Fault History Log (r) Click on Yes on the dialog box to clear the fault logs. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 150 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 154. CATS, CVDR Clear Fault Log Confirmation (s) Click on Yes on the dialog box to clear the latched faults and fault history log. Figure 155. CATS, CVDR Clear Latched Faults and Log Confirmation (t) Click on Ok. Figure 156. CATS, CVDR Clear Latched Faults and Log Successful (u) Observe the Fault History Log window appears. Select Print if you want to save the fault history or Close to continue. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 151 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 157. CATS, CVDR Fault History Log (v) Click on Yes. The autotest will now proceed in completing the autotest which will take approximately 30 minutes or less. Figure 158. CATS, Continue Test Confirmation (w) At the end of the test, save the report by selecting File => Test Report => Save Report. NOTE: The test report is named with the part number of the Unit Under Test and the serial number provided in the Information section of the test. The test report is located in the following default location: C:\Program Files\L−3Com\CVRTester\Reports. This file is in an ASCII text file format. (x) If the autotest is successful, clear the fault history log by the pull down menu, click on Test=>Clear Fault History. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 152 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 159. CATS, Test Results Screen CAUTION:Ensure power is removed from the the RIU before proceeding. If the cable, p/n: 17TES0418 is connected to rear of the unit with the power applied to the RIU, the RIU may be damaged. CAUTION:Only connect DC OR AC input voltage. Do not connect both input voltages at the same time. Connecting both types of input voltages simultaneously will result in damage to the RIU. (2) ROC/7 − CATS Autotest using AC power To perform the CATS Autotest using AC power only, follow the procedures below: (a) Ensure that the RIU has no power applied, power is removed. If not already done. Connect a CVR to the RIU using the cable, p/n:17TES0418 (ROC/7) for the recorder rear connector and cable , p/n:17TES0072 for the recorder front connector. (b) If the power supply does not include a built−in multimeter, set up an inline RMS multimeter. Set to AC amps (c) Apply power to the RIU using 115 Vac, 400Hz. (d) If the CATS test page is not shown, Click the L-3 CVDR Test Icon on the Window desktop. (e) Click the Ok button on the Monitor Audio Channel Pop-up menu. (f) From the Menu Bar, click on Power and select Recorder Interface Reset from the drop down menus. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 153 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Observe Figure 160. CATS, Connecting Pop-Up (g) NOTE: From the menu bar, select Power ==> Recorder Interface Reset. This will load the Altera chip in the RIU unit. Observe the “connecting to the recorder” status window appears. (h) On the tool bar, select Power. Figure 161. CATS, Power Toggle NOTE: When AC power is applied verify the appropriate LED is lit up on the RIU. (i) Click on the Information tab in the test section of the menu. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 154 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (j) Enter appropriate information into Department, Part Number and Serial Number fields. (k) On the tool bar, select Start Test. Figure 162. CATS, Start Test Toggle (l) In the “Test Mode and Options” dialog box, select either Return-to-Service or Selectable Test Options, and then click on OK. Figure 163. CATS, Test Mode and Options Screen Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 155 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR NOTE: If a full return to service test is not desired then select the “Selectable Test Options” radio button and choose the test options desired. NOTE: Figure 164 is only displayed if you select “Selectable Test Option” from the CATS, Test Mode and Options Screen. Figure 164. CATS, CVDR Test Confirmation NOTE: Follow the instructions in Figure 165 as displayed by the software. (m) Read and click on Yes. Figure 165. CATS, CVDR Warning Message (n) Remove front cable and click on OK. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 156 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 166. CATS, CVDR Instruction Window (o) Read the current AC amps value from the built-in multimeter on the power supply or from the inline RMS multimeter. And enter in the value in amps in window and click on OK. Figure 167. CATS, Power Test Input (p) Read the current AC amps value from the built-in multimeter on the power supply or from the inline RMS multimeter. And enter in the value in amps in window and click on OK. Figure 168. CATS, Power Test Input (q) Connect the recorder front cable and click on OK. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 157 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 169. CATS, CVDR Instruction Window (r) Observe the Fault History Log window appears. Select Print if you want to save the fault history or Close to continue. Figure 170. CATS, CVDR Fault History Log (s) Click on Yes on the dialog box to clear the fault logs. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 158 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 171. CATS, CVDR Clear Fault Log Confirmation (t) Click on Yes on the dialog box to clear the latched faults and fault history log. Figure 172. CATS, CVDR Clear Fault Log Confirmation (u) Click on Ok. Figure 173. CATS, CVDR Clear Latched Faults and Log Successful (v) Observe the Fault History Log window appears. Select Print if you want to save the fault history or Close to continue. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 159 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 174. CATS, CVDR Fault History Log (w) Click on Yes. The autotest will now proceed in completing the autotest which will take approximately 30 minutes or less. Figure 175. CATS, Continue Test Confirmation (x) At the end of the test, save the report by selecting File => Test Report => Save Report. NOTE: The test report is named with the part number of the Unit Under Test and the serial number provided in the Information section of the test. The test report is located in the following default location: C:\Program Files\L−3Com\CVRTester\Reports. This file is in an ASCII text file format. (y) If the autotest is successful, clear the fault history log by the pull down menu, click on Test=>Clear Fault History. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 160 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 176. CATS, Test Results Screen Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 161 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR D. READ OUT CENTER/7 (ROC/7) − Autotest Descriptions The following provides detailed descriptions of the test performed during the autotest function. (1) Power Test Test Prompts the user for AC/DC power usage as in the following AC example: Please remove the front panel cable from the recorder now and click ”OK”. Please enter the AC power consumption (in amps or watts) Please enter the AC power consumption (in amps or watts) Please connect the recorder front panel cable and press the ”OK” button. Example report message(s): 08:02:13 PASSED Power(AC) (Expected <= 12 watts) Results = (12 watts − 4 watts) = 8 watts 08:02:23 PASSED Power(DC) (Expected <= 11 watts) Results = (12.375 watts – 2.2 watts) = 10.175 watts (2) Fault Log Displays the current recorder fault log for user review and prompts the user: “Clear fault log?” Select “yes” when testing the FA2100 recorder and the full fault log is NOT to be written to the test report. Continue CVDR Tests? Select “yes” to continue or “no” to stop testing. Example report message(s) 08:02:32 PASSED Fault History (3) Bulk Erase Part 1 – record audio out and verify 400 Hz bulk erase tone. Part 2 – record audio out and verify absence of bulk erase tone during rotor data output. Part 3 – record audio out and verify absence of bulk erase with recording disabled. Example report message(s): 08:02:42 PASSED Bulk Erase #1 (Expected 400 Hz) Results = 400.0 Hz 08:02:50 PASSED Bulk Erase #2 with active Rotor Speed (Expected <> 400 Hz) Results = 123.0 Hz Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 162 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 08:02:58 PASSED Bulk Erase #3 with No Recording (Expected <> 400 Hz) Results = 3334.6 Hz (4) Test Tone Enable push to test and verify push to test indicator is set. Example report message(s): 08:03:06 PASSED Test Tone (Expected Push−To−Test indicator) Results = Push−To−Test indicator set (5) GMT 429 Record simulated GMT−429 data (label 125 first and label 150 second) and verify 10 good patterns are recorded for each label. Example report message(s): 08:03:22 PASSED GMT 429 (Label 125) (Expected 10 patterns) Results = 10 good patterns 08:03:42 PASSED GMT 429 (Label 150) (Expected 10 patterns) Results = 10 good patterns (6) Rotor Speed Part 1 – Record simulated 6000 Hz rotor speed data and verify data is within 2% of sent frequency. Part 2 – Record simulated 7 Hz rotor speed data and verify data is within 2% of sent frequency. Example report message(s): 08:03:52 PASSED Rotor Speed 6000 Hz (Expected 4 patterns > 5880.0 Hz < 6120.0 Hz) Results = 5998.0 Hz, 6026.4 Hz, 6026.4 Hz, 6026.4 Hz 08:04:03 PASSED Rotor Speed 7 Hz (Expected 4 patterns > 6.9 Hz < 7.1 Hz) Results = 7.0 Hz, 7.0 Hz, 7.0 Hz, 7.0 Hz (7) Channel Balance Record simulated 1000 Hz ½ reference level data for each channel 1,2,3 and 4 and verify amplitude all within 3 dB. Record simulated 1000 Hz 1/10 reference level data for each channel 1,2,3 and 4 and verify amplitude all within 3 dB. Example report message(s): 08:04:52 PASSED Channel Bal 1000 Hz 0.5 ref (All within 3 dB except HQC) Results = HQ1 5.2 /HQ2 5.3 /HQ3 5.1 /HQC 5.1 /SQV1 5.0 /SQV2 5.4 /SQV3 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 163 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 5.4 /SQC −56.6 dBV 08:05:40 PASSED Channel Bal 1000 Hz 0.1 ref (All within 3 dB except HQC) Results = HQ1 −8.3 /HQ2 −8.2 /HQ3 −8.4 /HQC −9.4 /SQV1 −8.0 /SQV2 −8.1 /SQV3 −8.1 /SQC −293.8 dBV (8) Frequency Response Record simulated 150 Hz ½ reference data for each channel 1,2,3 and 4. Record simulated 1000 Hz ½ reference data for each channel 1,2,3 and 4. Record simulated 3500 Hz ½ reference data for each channel 1,2,3 and 4. Record simulated 5000 Hz ½ reference data for channel 4. Record simulated 6000 Hz ½ reference data for channel 4. Verify amplitude all within 6 dB. Example report message(s): 08:06:28 Frequency Resp 150 Hz 0.5 ref Results = HQ1 3.6 /HQ2 3.8 /HQ3 3.5 /HQC 1.4 /SQV1 3.9 /SQV2 3.9 /SQV3 3.9 /SQC 3.9 dBV 08:07:15 Frequency Resp 1000 Hz 0.5 ref Results = HQ1 5.2 /HQ2 5.3 /HQ3 5.1 /HQC 5.1 /SQV1 5.4 /SQV2 5.4 /SQV3 5.4 /SQC 5.4 dBV 08:08:02 Frequency Resp 3500 Hz 0.5 ref Results = HQ1 3.3 /HQ2 2.9 /HQ3 2.5 /HQC 5.1 /SQV1 3.7 /SQV2 3.7 /SQV3 3.8 /SQC 3.5 dBV 08:08:12 Frequency Resp 5000 Hz 0.5 ref Results = HQC 4.9 dBV 08:08:23 Frequency Resp 6000 Hz 0.5 ref Results = HQC 4.9 dBV 08:08:23 PASSED Frequency Resp (All within 6 dB) (9) Signal to Noise and Distortion Record simulated data at each of the following frequencies once at 1.0 reference level and again at 1/10 reference). Verify HQ data is > 24.0 dB and SQ data is > 20.0 dB. Return To Service Frequencies: Frequencies for HQ1, HQ2, HQ3, HQCAM, SQV1, and SQCAM are: 150, 1000 and 3500 Hz. Frequencies for HQCAM only are: 5000 and 6000 Hz. Selectable Test Options Frequencies: Frequencies for HQ1, HQ2, HQ3, HQCAM, SQV1, and SQCAM are: 150, 200, 250, 315, 400, 500, 630, 800, 1000, 1250, 1600, 2000, 2500 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 164 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR and 3500 Hz. Frequencies for HQCAM and SQCAM only is 3150 Hz. Frequencies for HQCAM only are: 4148 and 6000 Hz. Example Return to Service report message(s): 11:24:20 PASSED SN+D 150 Hz 1.0 ref (Expected HQ > 24.0 dB SQ > 20.0 dB) Results = HQ1 34.6 /HQ2 34.4 /HQ3 34.8 /HQC 36.4 /SQV1 30.9 /SQV2 31.0 /SQV3 30.6 /SQC 31.4 dB 11:26:44 PASSED SN+D 1000 Hz 1.0 ref (Expected HQ > 24.0 dB SQ > 20.0 dB) Results = HQ1 27.0 /HQ2 26.9 /HQ3 26.7 /HQC 32.4 /SQV1 23.3 /SQV2 23.0 /SQV3 23.3 /SQC 23.3 dB 11:29:09 PASSED SN+D 3500 Hz 1.0 ref (Expected HQ > 24.0 dB SQ > 20.0 dB) Results = HQ1 30.6 /HQ2 30.2 /HQ3 30.4 /HQC 30.3 /SQV1 25.0 /SQV2 25.2 /SQV3 24.9 /SQC 25.5 dB 11:30:35 PASSED SN+D 5000 Hz 1.0 ref (Expected HQC > 24.0 dB) Results = HQC 30.6 dB 11:31:07 PASSED SN+D 6000 Hz 1.0 ref (Expected HQC > 24.0 dB) Results = HQC 27.7 dB NOTE: Running the Signal to Noise and Distortion test in the Selectable Test mode will perform additional tests at 200, 250, 315, 400, 500, 630, 800, 1250, 1600, 2000, 3150 and 4000 Hz. (10) Crosstalk Audio Record simulated 1000 Hz data for each channel 1,2,3 & 4 and calculate difference between driven and non−driven channels. Verify difference is less than −40 dB. Example report message(s): 08:41:34 PASSED Crosstalk (Audio) 1000 Hz 1.0 ref (Expected Driven − Non− Driven < −40 dB) Results = HQ1 11.2 /HQ2 −101.0 /HQ3 −109.9 /HQC −128.1 /SQV 11.4 /SQC −84.4 dBV 08:41:49 PASSED Crosstalk (Audio) 1000 Hz 1.0 ref (Expected Driven − Non− Driven < −40 dB) Results = HQ1 −101.3 /HQ2 11.2 /HQ3 −115.3 /HQC −107.5 /SQV 11.4 /SQC −72.3 dBV 08:42:04 PASSED Crosstalk (Audio) 1000 Hz 1.0 ref (Expected Driven − Non− Driven < −40 dB) Results = HQ1 −304.8 /HQ2 −127.4 /HQ3 11.1 /HQC −104.4 /SQV 11.4 /SQC −72.0 dBV Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 165 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 08:42:19 PASSED Crosstalk (Audio) 1000 Hz 1.0 ref (Expected Driven − Non− Driven < −40 dB) Results = HQ1 −304.9 /HQ2 −304.9 /HQ3 −111.7 /HQC 11.1 /SQV −72.4 /SQC 11.4 dBV (11) Crosstalk Data This is a test for CVDR recorders where both flight data and voice data are being recorded. A Channel Balance is performed prior to the cross talk data test to determine and store results for each channel 1,2,3 and 4. Record 6000 Hz simulated rotor data and simulated GMT 429 and calculate channel results minus channel balance results. Verify difference is less than −34 dB Example report message(s): 08:43:07 PASSED Channel Bal 1000 Hz 1.0 ref (All within 3 dB) Results = HQ1 11.2 /HQ2 11.2 /HQ3 11.0 /HQC 11.1 /SQV1 11.0 /SQV2 11.3 /SQV3 11.4 /SQC 11.5 dBV 08:43:23 PASSED Crosstalk (Data) 6000 Hz 1.0 ref (Expected Crosstalk − Channel Bal < −34 dB) Results = HQ1 −304.9 /HQ2 −125.7 /HQ3 −304.8 /HQC −49.8 /SQV −83.4 /SQC −82.8 dB (12) FSK Time This test cycles power to recorder to reset for FSK input then records simulated 16000 sps FSK data and then simulated GMT 429 data (label 150) first with channel 1 output and again with channel 3 output. It verifies 9 good FSK data patterns and a switch to 9 good GMT 429 data patterns for each channel 1 and channel 3. Example report message(s): 14:50:07 PASSED FSK Time HQ1 (Playback)(Expected 9 patterns) Results = 9 good patterns 14:50:07 PASSED FSK Time HQ1 (GMT Switch) (Expected 9 patterns) Results = 9 good patterns 14:50:53 PASSED FSK Time HQ3 (Playback)(Expected 9 patterns) Results = 9 good patterns 14:50:53 PASSED FSK Time HQ3 (GMT Switch) (Expected 9 patterns) Results = 9 good patterns Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 166 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (13) Audio Out Monitor Record simulated 1000 Hz data for each channel 1,2,3 and 4 and verify amplitudes by part number: Example report message(s): 08:26:43 PASSED Audio Out Monitor 1000 Hz (Expected 2.45 +/−20 percent VRMS) Results = HQ1 2.319 /HQ2 2.338 /HQ3 2.317 /HQC 2.355 VRMS (14) Signal To No Signal Record simulated 1000 Hz data for each channel 1,2,3 and 4 and store results; then record no data for channels 1,2,3 and 4 and compare differences between signal data results and no signal data results. Verify difference is less than −48 dB. Example report message(s): 08:47:12 PASSED Sig To No Sig 0 Hz 1.0 ref (Expected HQ < −48 dB SQ < −40 dB) Results = HQ1 −304.9 /HQ2 −122.6 /HQ3 −108.4 /HQC −115.4 /SQV1 −82.7 /SQV2 −82.2 /SQV3 −80.7 /SQC −85.0 dB (15) Shutdown Remove recorder power and verify recorder continues to operate for > 9 and < 10 minutes after power is removed and shutdown is terminated following a push to test. Part 1 – enable delayed shutdown. Part 2 – verify shutdown is detected (CVR fault set) after > 9 and < 10 minutes. Part 3 – verify shutdown is terminated following a push to test and recording is resumed. Example report message(s): 08:47:13 PASSED Shutdown Initialization (Shutdown issued − Please wait 9−10 minutes) 08:56:14 PASSED Shutdown CVDR Fault (Expected CVDR fault to occur) Result = CVDR Fault 08:56:27 PASSED Shutdown Push−to−Test (Expected 1000 Hz frequency) Results = 999.9 Hz Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 167 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (16) Capacitor Power off recorder and verify recorder is still powered after 200 milliseconds but not powered after 2 seconds. Example report message(s): 08:56:32 PASSED Capacitor − GSE powered after 200 milliseconds but not after 2 seconds (17) Data Link Record simulated data link messages and verify 10 good data link messages. Example report message(s): 08:58:00 PASSED DLR (Expected 10 patterns) Results = 10 good patterns NOTE: If the L−3 DL_RTS software utility was previously used to write an incrementing patterns into recorder memory then the Data Link test will fail until this incrementing pattern is overwritten with simulated data link messages. (18) OMS Read the OMS status words and verify CVR fault status and CVR part number and serial number. Example report message(s): 08:59:00 PASSED OMS Part 1 (Expected OMS Status to match) 08:59:10 PASSED OMS Part 2 (Expected OMS Part and Serial Numbers to match) Results = pn2100−1025−22 sn000000000 (19) RIPS Clear the FA2100 fault log and existing faults that might prevent RIPS test success. Remove FA2100 recorder power and verify the recorder continues to operate for over 9 minutes after power is removed. Example report message(s): 09:00:02 RIPS Initialization (Power has been removed. Please wait 9 minutes) 09:09:15 PASSED RIPS (Expected no CVR Fault for over 9 minutes) Results = No CVR Fault after power removed for over 9 minutes (20) FRED Verify FA2100 Flight Recorder Electronic Documentation (FRED) file exists or can be written. Example report message(s): 09:09:30 PASSED FRED – Engineering Units File CRC Verified Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 168 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (21) FDR Clear the FA2100 fault log and existing faults that might prevent FDR test success. Record simulated flight data and verify good flight data was recorded. Example report message(s): 09:11:00 PASSED FDR Test Results = 1 minute(s) of good data NOTE: The Data Link test, OMS test and FDR tests requires a CATS V2 RIU and rear panel cable. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 169 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 7. READ−OUT CENTER/7 (ROC/7) − AUDIO DOWNLOAD & PLAYBACK NOTE: ROSE 4.0 or higher on a ROC or RAU is recommended to download directly from a CVR and convert audio into a .WAV for playback. Refer to the Read-Out Support Equipment / Recorder Interface Software version 4.0 or Higher Operator’s Manual, p/n 165E1696-03, to Retrieve Flight Data and / or Audio Data from a Recorder. NOTE: When decompressing Standard Quality Audio from a 2−Hr. FA2100CVR, p/n: 2100−1020−XX, pre Hardware MOD−DOT #7, you must have the RIU powered and the Altera chip reset using the Power −> RIU Interface Reset command. This is required because hardware inside the RIU is used for converting of the 2−bit compressed Standard Quality Combined (SQV) and Standard Quality CAM (SQC) channels. This is not a requirement for the High Quality Channels (HQV & HQC) because this 3−bit compression is converted using the CATS software. The FA2100CVRs that have Hardware MOD−DOT #7 installed have full two hour High−Quality for all four audio channels as does all 30−Minute FA2100CVRs. (1) Click on the Copy button. Set the File Name to Filename.cvdr (the system will use a default file name with the part number of the recorder and serial number that was entered in the information fields of the test section). (2) Click on the Save button. (3) Select either Full Audio Data Download or Copy data from last XX Hrs. XX Mins. Click OK. Copying of the data will start. (4) When the “Copy Data is Complete” box is shown click on Yes. On the Decompression Options menu select HQV1 through HQV3 and HQC. If using an FA2100CVDR, p/n: 2100−1020−XX, pre MOD−DOT #7 unit also select the Standard Quality Audio data SQV & SQC. Click OK. (5) Click on the Microphone button. Select the Left Channel to be HQV1 and the Right Channel to be HQC. Click OK to exit the dialog box. (6) Click on the Play button. Confirm that the display changes and that the speakers output the audio. Click on the Stop button when satisfied that the data is being played back properly. (7) Click on File => Exit to leave CVR Tester. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 170 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Table 102. 17TES0700 Part Number READOUT CENTER/7 (ROC/7) − Parts List Description Mfg. 17TES0700 Read-Out Center/7 − Full CVDR/FDR Configuration (The following items are included with the ROC/7). L-3 Com 17TES0710 Recorder Interface Unit (RIU) L-3 Com 17TES0411 Cable, RIU to AC Power In L-3 Com 17TES0412 Cable, RIU to DC Power In L-3 Com 17TES0413 Cable, RIU to Sound Card (2 ea.) L-3 Com 17TES0415 Cable, RIU to USB L-3 Com 17TES0417 Cable Assembly, Audio Setup L-3 Com 17TES0418 Cable, RIU to CVR L-3 Com 17TES0420 CATS Software, FA2100, V. 2.0 L-3 Com 17TES0070 CICC/2 Assembly L-3 Com 17TES0072 Cable Assembly, FA2100−CICC/2 (2 ea.) L-3 Com 17TES0042 Cable Assembly, Recorder Interface L−3 Com 17TES0057 Cable Assembly, CVDR Interface L−3 Com 17TES0071 Cable Assembly, F1000−CICC/2 L−3 Com 17TES0321 Read-Out System Equipment Software (ROSE 4.5) L-3 Com 17TES0058 FA2100 Software Upload Cable Assembly L-3 Com 883E4557−00 CD, Soundblaster Audigy L-3 Com 17TES0076 RUFS Recorder Interface, USB L−3 Com 17TES0425 Speakers (2), 110 Vac (U.S. − Standard) Optional 17TES0426 Speakers (2), 220 Vac (Non−U.S. − Standard) Optional 8. Underwater Locator Beacon Testing Recommended Method to Test the 90-Day Underwater Locator Beacon The 17TES0015 is a battery operated heterodyne type receiver that operates at an ultrasonic frequency of 37.5 kHz. The test set is a self-contained, hand held functional tester for testing 90−Day and 30−Day Underwater Locator Beacons. Use the internal microphone and loudspeaker to perform an operational test on a beacon without removing it from the recorder’s CSMU Mount. The test set can also be used to perform a voltage measurement for testing the replacement battery within a Beacon. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 171 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Table 103. Underwater Locator Beacon Test Using L−3AR Test Set P/N: 17TES0015 PROCEDURE This test should be performed after the 90−Day Beacon is installed. It verifies the proper operation of the Beacon after mounting on the CSMU. 1) Turn the test set ON using the small slide switch located on the left side of the housing. 2) If the display reads LB, the test set battery voltage has fallen below the level required for operation, and the 9−Volt battery should be replaced. 3) To test the Beacon battery voltage, attach the test probe clip to the Beacon case. The clip has a spring action that will allow it to slip over the housing on the Beacon. Place the tip of the probe in contact with the metal pad at the center of the water switch. 4) Read the battery voltage from the test set display. If the battery voltage is at or above 2.97 volts, the battery is operable. If the battery voltage is below 2.97 volts, remove the Beacon from service. 5) To perform an operational test of the Beacon, place the probes on the Beacon as described above and press the red button on the test set (the display will be blank during this operation). 6) If the Beacon is operating properly, a pinging sound will be audible from the test set speakers. If hearing is difficult due to background noise, repeat the test in a quieter area. 7) Turn off the test set, and remove the Beacon from the test probe clip. 8) If required, record the Beacon’s serial number and expiration date on the appropriate recorder data record. Alternate Method to Test the 90-Day Underwater Locator Beacon Note that using this method requires the use of a 10 Mohm impedance voltmeter that is not included in the test set. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 172 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Table 104. Underwater Locator Beacon Test Using Test Set P/N: 42A12( ) and 10 Mohm High Impedance Voltmeter PROCEDURE This test should be performed after the 90−Day Beacon is installed. It verifies the proper operation of the Underwater Locator Beacon after mounting on the CSMU. 1) To test the Beacon battery voltage, place the negative lead of the high impedance voltmeter on the metal pad at the center of the water switch and the positive lead on the Beacon case. 2) Measure the battery voltage. If the battery voltage is at or above 2.97 volts, the battery is operable. If the battery voltage is below 2.97 volts, remove the Beacon from service. 3) To perform an operational test of the Beacon, turn on the test set by rotating the front panel GAIN control clockwise until it clicks. 4) On the front panel of the test set, set the INT.-EXT. switch to INT. 5) Rotate TUNING control to a setting between 35 and 40 kHz. 6) Use a metal braid, or other flexible metal conductor, to temporarily short the metal pad at the center of the water switch to the Beacon case, and activate the unit. 7) Make sure that the test set’s microphone and the Beacon are in close proximity of each other with unobstructed, line−of−sight between them. This will ensure that the test set will detect the proper output of the Beacon. 8) If the Underwater Locator Beacon is functioning properly, it will emit inaudible, ultrasonic sound waves that the test set will receive and reproduce as repetitive beeps through the test set’s speakers. 9) Remove the metal conductor to stop the short and turn off the test set. 10) If required, record the Beacon’s serial number and expiration date on the appropriate recorder data record. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 173 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 9. MODEL FA2100CVR TROUBLESHOOTING WARNING: VOLTAGES CAPABLE OF FATAL INJURY ARE PRESENT AT THE RECORDER INPUT CONNECTOR. ONLY QUALIFIED MAINTENANCE TECHNICIANS SHOULD PERFORM THE FOLLOWING MAINTENANCE. CAUTION: THE FA2100CVR’s PRINTED WIRING ASSEMBLIES (PWA) CONTAIN DEVICES SENSITIVE TO ELECTROSTATIC DISCHARGE (ESD). PERSONNEL HANDLING A PRINTED WIRING BOARD SHOULD COMPLY WITH PROPER ESD HANDLING PROCEDURES. FAILURE TO DO SO MAY RESULT IN DAMAGE TO THE ESD SENSITIVE DEVICES RENDERING THE PRINTED WIRING BOARD USELESS. PRIOR TO HANDLING A PRINTED WIRING BOARD, ENSURE PROPER PERSONNEL GROUNDING TECHNIQUES ARE USED. ALSO, ENSURE THAT ALL PRINTED WIRING ASSEMBLIES BOARDS ARE PLACED INTO STATIC SHIELDING CONDUCTIVE BAGS WHEN HANDLING OR STORING. Table 105. FA2100 CVR Fault Code Corrective Actions Failure Mode Corrective Action cde0 An invalid partition map was found 1) Remove Memory. 09d7 The SMP Check timed out 1) ck cables. waiting for audio 2) If fault codes persist, then remove and replace channelizer to shutdown. Audio Compressor PWA, p/ns: 205E3977-( ). 3) Run autotest & recheck recorder status. Fault Code 4) Remove and replace Acquisition Processor PWA, PN: 205E2502‐( ). 89d2 Next power−up will generate a CVR Bad Indices (latched fault). 690X, 89d2, Power supply failure 0X0855 combined with CVR bad indices and read after write errors 6900 18v Power Supply Failure 1) Remove and replace Acquisition Processor PWA, PN: 205E2502‐( ). 2) Run autotest & recheck recorder status. 3) If fault codes still present in status report, then return the recorder to factory for repair. 1) Remove and replace Acquisition Processor PWA, PN: 205E2502‐( ). 2) Run autotest & recheck recorder status. 3) If fault codes still present in status report, then return the recorder to factory for repair. 6901, 6902, BITE Error: Negative 12 & 6904 5 volt & 5 Volt (VCC) power supply failure 6901 Negative 12 volt power supply failure. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 174 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Table 105. FA2100 CVR Fault Code Corrective Actions (Continued) Fault Code Failure Mode 6902 Negative 5 volt power supply failure. 6903 12 volt (VPP) power supply failure 51d9 An underflow occurred in the TDM high priority queue. Corrective Action see previous page 1) Remove and replace Acquisition Processor PWA, PN: 205E3977-XX‐( ). 2) Run autotest & recheck recorder status. 3) If fault codes still present in status report, then return the recorder to factory for repair. 1) Remove and replace Audio Compressor PWA, 51d9, 85da, TDM Hi−Priority PN: 205E3977‐( ). d9c6, 89d7 Underflow, TDM AC RX Overflow, CVR Audio 2) Run autotest & recheck recorder status. Packet Timeout, CVR Bad 3) If fault codes still present in status report, then Indices, Audio Packet return the recorder to factory for repair. Shutdown Timeout. 59db System Error: CVR test failed. Test tone failed 1) Remove and replace Audio Compressor PWA, PN: 205E3977‐( ). 2) Run autotest & recheck recorder status. 3) If fault codes still present in status report, then return the recorder to factory for repair. 1) Remove and replace Acquisition Processor PWA, 85da, 51d9, 85da: An overflow PN: 205E2502‐( ). 0855, 6900 occurred in the audio channelizer receive buffer. 2) Run autotest & recheck recorder status. 3) If fault codes still present in status report, then 51d9: An underflow return the recorder to factory for repair. occurred in the TDM high priority queue. 0855: A CVR flash memory read−after−write error occurred. 6900: 18 volt power supply failed. 85da An overflow occurred in the audio channelizer receive buffer. 1) Remove and replace CSMU, p/n: 253E3977‐( ). 2) Run autotest & recheck recorder status. 3) If fault codes still present in status report, then return the recorder to factory for repair. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 175 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Table 105. FA2100 CVR Fault Code Corrective Actions (Continued) Fault Code Failure Mode Corrective Action 885e The total number of CVR errors exceeded the allowable threshold. 8850, 0855 Flash Error: A flesh memory read−after−write error occurred 1) Run Memory test. 2) If fault codes persist, then remove and replace CSMU, p/n: 253E1568‐( ). 3) Run autotest & recheck recorder status. 89d1 The non volatile memory contains bad CRC. 89d1 The non−volatile memory on the CVR has a bad CRC −This problem is usually related to a bad chip on the Acquisition Processor. 89d2 The non volatile memory contains bad indices. 89d2, 09d4 89d2: System Error: The non−volatile memory on the CVR contains bad indices. 4) If fault codes still present in status report, then return the recorder to factory for repair. 1) Remove and replace Acquisition Processor PWA, p/n: 205E2502‐XX. 2) Run autotest & recheck recorder status. 3) If fault codes still present in status report, then return the recorder to factory for repair. 09d4: System Error : The CVR had to wait for a flash memory block to erase. 89d6 89d6, 09d7 System Error: The SMP timed out waiting for an audio packet to arrive 89d6: System Error: The SMP timed out waiting for an audio packet to arrive. 09d7: System Error: The SMP timed out waiting for audio channelizer to shutdown. 89d6, 6901, System Error: The SMP 6902, 6904 timed out waiting for an audio packet to arrive. 690X: BITE Errors: power supply failures. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 176 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Table 105. FA2100 CVR Fault Code Corrective Actions (Continued) Fault Code Failure Mode Corrective Action 89d7 The SMP timed out waiting for audio channelizer to shutdown. 1) Remove and replace Acquisition Processor PWA, p/n: 205E3977‐XX. 2) Run autotest & recheck recorder status. 3) If fault codes still present in status report, then return the recorder to factory for repair. 8453 1) Remove and replace CSMU, p/n: 253E1568‐( ). Read After Write Errors, Too Long Erase Event and 2) Run autotest & recheck recorder status. Error. 3) If fault codes still present, remove and replace Acquisition Processor PWA, p/n: 205E2502-( ). The unit took too long to 4) Run autotest & recheck recorder status. erase. 5) If fault codes still present in status report, then return the recorder to factory for repair. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 177 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 10. FA2100CVR SOFTWARE UPLOAD PROCEDURE Computer Interface Communications Cable/2 (CICC/2) is shown in Figure 177. In the event that the original Acquisition Processor (AP) PWA, p/n: 205E1591−00 or 205E1931−00, is required to be replaced in the FA2100CVR, it will be replaced with the Acquisition Processor PWA, p/n 205E2502−11, or −14 in the case of the 2100−1025−( ), and the software that is required to be loaded onto this PWA. To load the software, use the FA2100 Software Upload cable assembly, p/n: 17TES0058 and the FA2100 Software Upload Utility software. The Upload Utility software contains a CICCLDR executable file and a CICCIFC executable file. The CICCLDR and CICCIFC executable files are found on the FA2100 Utility Bundle CD p/n 883E1894−01. NOTE: The CICC/3 with ethernet (P/N 17TES0075) cannot be used to upload FA2100CVR software. The Software Upload cable assembly is connected between the front panel GSE connector of the FA2100 and the CICC/2 Cable assembly, which includes the Computer Interface Communications Cable/2 (p/n: 17TES0070) and the FA2100 to CICC/2 cable (p/n: 17TES0072). The software upload procedure is also necessary when replacing a faulty Turbo Acquisition Processor PWA, p/n: 205E2502−10/−11 with a known good AP board from the factory, since the factory spare PWA’s are shipped without the recorder firmware preloaded. The specific recorder software for either the 2100-1010-( ) 2100-1020-( ) or the 2100−1025−( ) CVRs will be loaded from the FA2100CVR Software Distribution CD. Once installed, a Windows-98/XP short-cut icon linking to the CICCLDR.exe may be placed on the desktop. To upload the recorder software perform the following procedure: NOTE: A. After installing CICC loader and/or interface on Windows 7, you must set the properties of CiccLDR.exe and/or the Ciccldr.exe to run in compatibility mode of “Windows 98/Windows Me.” Installing Software Upload Utility and CICC Interface Programs NOTE: The Software Upload Utility and the CICC Interface Programs may be loaded onto a ROC/5, ROC/6, ROC/7, RAU, or any PC. Reference to any of these units is herein referred to as PC. The Software Upload utility and Interface executable programs are contained on the CICC Utility Bundle CD. To load these programs onto a PC perform the following steps: Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 178 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (1) Turn ON the power to the PC. (2) Insert the FA2100 Utility Bundle CD 883E1894−01 into the PC. When ask to select, Click on the “Open folder to view files using Windows Explorer” . (3) To install the Upload utility from the CD, click open the CICCLdr folder and then click on the “Setup” file. (4) Follow the instructions on the Install Wizard and accept all defaults. The Install Wizard will create a folder and Icons within. To check the version level of the program right−click on the CICCLdr Icon select Properties −> Version and verify that the version level is 3.0. Left click and hold the CICCLdr Icon and drag it on to the desktop. There it will remain as a shortcut. NOTE: Note: older versions of the CICCIfc.exe program distributed with ROSE 3.1 or lower will not work with the updated CICC/2 Interface. Newer versions of the software are backward compatible and will work with the original CICC Interface. (5) To load the Interface program and to verify the upload process, perform the following: Open up the the FA2100 Utility Bundle CD. To install the Interface utility, click open the CICCIfc folder and then click on the “Setup” file. (6) Follow the instructions on the Install Wizard and accept all defaults. The Install Wizard will create a folder and Icons within. To check the version level of the program right−click on the CICCIfc Icon select Properties −> Version and verify that the version level is 3.7. Left click and hold the CICCIfc Icon and drag it on to the desktop. There it will remain as a shortcut. Remove the CD from the PC. (7) Exit from Windows by selecting the START button and Shut Down. When prompted that it is safe, turn OFF the power to the PC. (Note: Newer PCs may automatically remove power without having to press the power switch.) Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 179 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR ROSE/RI SOFTWARE 17TES0321 (CDROM) Power Input Select FA2100 SOFTWARE DISTRIBUTION DISK 840‐EXXX‐XX Note: Firmware Distribution Diskette P/N will match the FA2100 Software Part Number located on the recorder 's Name Plate Label. TO ENHANCED PARALLEL PORT (EPP) RECORDER USB FDAU SIMULATOR (RUFS) (RI) ADAPTER 17TES0076 CICC/2 COMPUTER INTERFACE COMMUNICATIONS CABLE/2 17TES0070 FA2100 TO CICC/2 COMPUTER INTERFACE COMMUNICATIONS CABLE 17TES0072 RECORDER INTERFACE (RI) CABLE ASSY. 17TES0057 READ-OUT CENTER/5, /6 or /7 17TES0300/17TES0400/17TES0700 AC INPUT FA2100 SOFTWARE UPLOAD (BOOTLOAD) CABLE ASSEMBLY 17TES0058 (use for software uploading only) DC INPUT Note: RI = Recorder Interface. ROSE = Read‐Out Support Equipment. ROC = Read‐Out Center (ROC/5, /6 or /7) Note: The ROC rear connections shown in this diagram are for general reference and may not reflect the exact connector location or configuration your ROC system computer. Note: The 17TES0058 cable assembly should only be attached during upload process. Not used when downloading data or getting recorder status. FA2100 CVR RECORDER Figure 177. Typical Software Upload Setup For FA2100 Recorder with CICC/2 Cable Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 180 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR B. To upload the FA2100 Software perform the following steps: (1) If using the CICC/2 Cable refer to Figure 177 and perform the following steps: (a) Connect the FA2100 Software Upload Cable Assembly (p/n: 17TES0058) to the FA2100 Recorder front panel GSE connector and the opposite end to the FA2100 to Computer Interface Communications Cable/2 (CICC/2), (p/n: 17TES0072). (b) Connect the opposite end of the FA2100 to CICC/2 cable to the CICC/2 (p/n: 17TES0070). (c) Connect the opposite end of the CICC/2 to the PC EPP parallel connector. CAUTION: NOTE: (2) Do not connect both DC and AC input voltages simultaneously or dam age to the recorder will result. Both the Computer Interface Communications Cable/2, p/n: 17TES0070, and the FA2100 to Computer Interface Communications Cable/2, p/n: 17TES0072, are required to upload FA2100 software to the recorder when using the CICC/2. At the FA2100 J1A connector, use the Recorder Interface (RI) Cable Assy, P/N 17TES0057, to connect either 115 Vac/400 Hz, or +28 Vdc to the pig−tail connectors. Alternatively, +28Vdc power may be directly applied to J1A−9 and Ground to J1A−17, or connect 115Vac, 400Hz to J1A pins 2 & 3. (3) Apply power to the FA2100CVR Recorder. (4) Note the SMP version and checksum value listed on the label of the FA2100 CD and ensure that the software part number is the software needed to be loaded into the FA2100CVR recorder. If the FA2100 Software CD is unavailable, refer to Table 106. (5) Turn ON the power to the PC, RAU or ROC/5−ROC/6 −ROC/7 Ground Station. NOTE: If using a PC, proceed to step (8). If using an RAU or ROC/5 Ground Station, perform steps (6) and (7) prior to performing step (8). (6) At the Windows 98 or XP desktop shut down the Recorder Interface (RI) by right clicking on the RI Icon in the Windows System Tray at the bottom right of the screen. Select “shutdown.” (7) At the Windows 98 or XP desktop also shut down the FTP protocol program by right clicking on the FTP Icon in the Windows System Tray at the bottom right of the screen. Select “Exit”. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 181 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (8) Insert the FA2100 CD into the PC, RAU, or ROC/5−ROC/6−ROC−7 Ground Station system CD. (9) From the Windows 98 or XP desktop, activate the (put in new PC & SW) CICC Loader utility program by double−clicking on the CICCLdr Icon. (10) When the CICC Loader window appears select the Browse button at the Load Directory and set the source to “D:\.” (If it is not already present). (11) Select the software load type by choosing the Recorder part number listed that matches the part number found on the recorder identification label. (12) Left click the Load button. (13) Observe the progress window and verify that a status pop−up window appears stating that the FA2100 loaded successfully. Note: if the load procedure was unsuccessful, recycle power to the FA2100CVR and repeat steps (4) − (9). NOTE: If still unsuccessful, make sure that the address of the parallel port specified in the CICCLDR.ini file matches the address of the parallel port connected to the CICC. (14) Turn off power from the recorder and Exit the CICC Loader utility program. (15) Disconnect the 17TES0058 Upload Cable from the FA2100CVR Front Panel ATE connector and the 17TES0072 CICC/2 Cable Assembly. (16) Reconnect the 17TES0072 CICC/2 Cable Assembly to the ATE connector. (17) Proceed to paragraph C. to verify the software upload. C. To Verify the Software Upload Once the FA2100 software has been loaded it needs to be verified using the CICC Interface Software Utility as follows: (1) Apply power to the FA2100CVR Recorder. (2) From the Windows 98 or XP desktop, activate the CICC Interface utility program by double−clicking on the CICCIfc Icon. (3) From the CICC Interface Menu, select the Version Command from the list and left click the Send Command button. Observe that a pop-up window appears showing the recorder software Part Number and SMP Checksum. NOTE: If the “FA2100 Command” window is disabled, make sure that the address of the parallel port specified in the CICCIFC.ini file is that same as the address of the parallel port connected to the CICC. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 182 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (4) Match the listed Software Part Number and SMP Checksum with the one listed on the recorder software distribution CD. If the software distribution CD is unavailable, refer to Table 106 for a list of checksums. (5) Left click the OK button and left click the X button in the upper right corner of the CICC Loader Menu to exit the utility and return to the Windows 98 or XP desktop. (6) Download fault history with PI and verify no faults. (7) Once the Software upload versions are validated, perform a full Return To Service test procedure as listed in Section 100 of this manual. Table 106. FA2100CVR Software SMP Checksums Software P/N Recorder P/N SMP Checksum SMP Ver. 840-E1657-01 2100-1020-00 2100-1020-02 0X5609 6.1 840-E1657-03 2100-1020-00 2100-1020-02 0X67EE 7.4 840-E1657-04 2100-1020-00 2100-1020-02 0X313B 7.5 840-E1657-05 2100-1020-00 2100-1020-02 0XAD9F 7.9 840-E1657-06 2100-1020-00 2100-1020-02 0XA84B 8.7 840-E1657-07 2100-1020-00 2100-1020-02 0XAEF6 8.8 840-E1657-08 2100-1020-00 2100-1020-02 2100-1220-00 2100-1220-02 0XA96F 9.0 840-E1657-09 2100-1020-00 2100-1020-02 2100-1220-00 2100-1220-02 0XC62C 9.1 840-E1658-02 840-E1658-03 840-E1658-04 840-E1658-05 2100-1010-00 2100-1010-00 2100-1010-00 2100-1010-00 0X6B52 0XB9C7 0X8314 0X8F17 6.7 7.4 7.5 840-E1658-06 2100-1010-00 0X89C3 8.7 840-E1658-07 2100-1010-00 0X28E2 8.9 840-E1658-08 2100-1010-00 0X8AE7 9.0 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 7.9 23–70–04 Testing & Fault Isolation Rev. 15 Page 183 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Software P/N Recorder P/N SMP Checksum SMP Ver. 840-E1663-02 2100-1010-50 2100-1010-51 0X6B67 6.7 840-E1663-04 2100-1010-50 2100-1010-51 0X8329 7.5 840-E1663-05 2100-1010-50 2100-1010-51 0X8F2C 7.9 840-E1663-06 2100-1010-50 2100-1010-51 0X89D8 8.7 840-E1664-01 2100-1020-50 2100-1020-51 0X5620 6.1 840-E1664-04 2100-1020-50 2100-1020-51 0X3152 7.5 840-E1664-05 2100-1020-50 2100-1020-51 0XADB6 7.9 840-E1664-06 2100-1020-50 2100-1020-51 0X8A62 8.7 840-E1664-09 2100-1020-50 2100-1020-51 840-E3408-04 2100-1025-12 0XD857 8.1 840-E3408-05 2100-1025-02 0X046A 8.1 840-E4568-06 2100-1025-22 0XD8A2 8.5 840-E4568-09 2100-1025-22 2100-1125-02 0XF168 8.8 840-E4568-10 2100-1025-22 0X8D8E 8.9 840-E4568-11 2100-1025-22 2100-1225-22 0X6118 9.0 840-E4568-12 2100-1025-22 2100-1225-22 2100-1925-22 0X7DD5 9.1 840-E5022-02 2100-1026-02 2100-1026-22 0X6A9D 8.5 840-E5022-03 2100-1026-22 0X6A9E 8.5 840-E5022-04 2100-1026-02 2100-1026-22 0X7152 8.8 840-E5022-05 2100-1026-02 0X6BCB 9.0 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 184 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Software P/N Recorder P/N SMP Checksum SMP Ver. 840-E5022-06 2100-1026-02 2100-1226-02 0X8018 9.0 840-E5634-00 2100-1025-24 0XF6F4 8.7 840-E5634-02 2100-1025-24 0X3D09 8.9 840-E5634-03 2100-1025-24 2100-1225-24 0X9A14 9.0 840-E5634-04 2100-1225-24 0X55D8 9.1 Table 107. FA2100CVR Software FDP Checksums Software P/N Recorder P/N FDP Checksum FDP Ver. 840-E3408-04 2100-1025-02 2100-1025-12 0X44A9 1.8 840-E3408-05 2100-1025-02 2100-1025-12 0X44A9 1.8 840-E4568-06 2100-1025-22 2100-1125-02 0X486D 2.1 840-E4568-09 2100-1025-22 2100-1125-02 0X5E5E 2.3 840-E4568-11 2100-1025-22 2100-1125-02 2100-1225-22 0X5E5E 2.3 840-E4568-12 2100-1025-22 2100-1225-22 2100-1925-22 0XF9F1 2.5 840-E5022-02 2100-1026−02 0X9834 2.1 840-E5022-03 2100-1026−02 0X8190 2.1 840-E5022-04 2100-1026-02 0XEF55 2.3 840-E5022-05 2100-1026-02 0XEF55 2.3 840-E5022-06 2100-1026-02 2100-1226-02 0X8970 2.3 840-E5634-00 2100-1025-24 0X6E00 2.2 840-E5634-02 2100-1025-24 0X3684 2.3 840-E5634-03 2100-1025-24 2100-1225-24 0XA8E3 2.3 840-E5634-04 2100-1225-24 0X7769 2.5 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 185 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR THIS PAGE IS INTENTIONALLY LEFT BLANK Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Testing & Fault Isolation Rev. 15 Page 186 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR AUTOMATIC TESTING 1. GENERAL There are no Automatic Test Procedures for the FA2100 CVR. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Automatic Testing Rev. 15 Page 201 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR THIS PAGE IS INTENTIONALLY LEFT BLANK Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Automatic Testing Rev. 15 Page 202 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR DISASSEMBLY 1. GENERAL This section contains the information required to disassemble the Model FA2100 Cockpit Voice Recorder (FA2100CVR). Access to the major assemblies within the Model FA2100CVR is described such that there is minimal disturbance to other assemblies. Extreme care should be exercised when removing these assemblies. To ensure the warranty coverage of a defective circuit board, it must be returned to the factory for repair or replacement. CAUTION: THE MODEL FA2100’s PRINTED CIRCUIT ASSEMBLIES CONTAIN DEVICES SENSITIVE TO ELECTROSTATIC DISCHARGE (ESD). PERSONNEL HANDLING A PRINTED CIRCUIT BOARD SHOULD COMPLY WITH PROPER ESD HANDLING PROCEDURES; FAILURE TO DO SO MAY RESULT IN DAMAGE TO THE ESD SENSITIVE DEVICES RENDERING THE PRINTED CIRCUIT BOARD USELESS. PRIOR TO HANDLING A PRINTED CIRCUIT BOARD, ENSURE PROPER PERSONNEL GROUNDING TECHNIQUES ARE USED. ALSO, ENSURE THAT ALL CIRCUIT BOARDS ARE PLACED INTO STATIC SHIELDING CONDUCTIVE BAGS WHEN HANDLING OR STORING. ESD WARNING SYMBOL SYMBOL FOR ESD GROUND CONNECTING O 2. MODEL FA2100CVR DISASSEMBLY INSTRUCTIONS Special tools, fixtures, and equipment that are needed to disassemble and repair the Model FA2100CVR are listed in Figure 901. NOTE: Numbers shown in parentheses in the following text and figures are the Illustrated Parts List (IPL) figure number followed by the IPL item number for a particular part; e.g., (1-100) for IPL Figure 1, Item 100. For items listed in the parts list but not illustrated, the item number is preceded by a “-”. In addition to the IPL figure references, each disassembly instruction is accompanied with an illustration showing specific assemblies or subassemblies to which the steps of the procedure are related. The figures in this section contain the same figure/item number references identifying the piece parts of the assembly as in the IPL figures; however, different views of the assemblies may be provided to facilitate disassembly tasks. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Disassembly Rev. 15 Page 301 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR NOTE: A. All attaching parts such as cable assemblies, stand−offs, screws, washers, etc. that are not damaged, should be retained with the chassis for reinstallation with the repaired LRUs. The FA2100CVR replaceable PWAs or modules consist of the Acoustic Beacon, Aircraft Interface PWA, Audio Compressor PWA, Acquisition Processor PWA, and the Crash Survivable Memory Unit (CSMU). Underwater Locator Beacon Removal (See Figure 301 or IPL Figure 1, Item 80) The Underwater Locator Beacon (ULB) is mounted on the Model FA2100’s CSMU front bracket with the beacon water switch facing to the left (refer to Figure 301, (1–80)). The ULB is equipped with a battery that has an expected life the same as the beacon replacement date marked on the beacon label. Upon expiration of expected battery life, contact L-3AR for replacement batteries, installation instructions and re-certification. 30−Day ULB’s already in service may still be used, and a ULB Battery Kit, p/n: 147E0305−00, is available for battery replacement. The 30−Day ULB, p/n: 266E0305−00, is no longer manufactured due to the cancellation of TSO−121 and TSO−121a as of Dec. 1, 2015. A 90−Day ULB Conversion Kit, pn: 068E5542−00, is available for retrofit of a 30−Day ULB to 90−Day beacon to an existing recorder. When converting from a 30−Day ULB to a 90−Day ULB, the L−3AR ULB Conversion Kit, P/N 068E5542−00, must be used. This kit contains the 90−Day ULB and four attaching hex mounting screws. Converted CVR units must be marked with MOD− DOT #15. Refer to FA2100CVR SB022 for more details. NOTE: Once a unit has been changed to a 90−Day ULB, it can not revert to a 30−Day ULB due to the Hardware MOD−DOT marking. NOTE: Refer to the IPL effectivity column, as some specific FA2100CVR Part Numbers are allowed only 90−Day ULBs to be installed. All new recorder production units will incorporate the 90−Day underwater locator beacon, p/n: 266E5542−00. For more information, including the testing and cleaning of the ULB, please see the L−3AR Underwater Locator Beacon CMM, p/n 165E5542−00. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Disassembly Rev. 15 Page 302 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR BEACON REMOVAL PROCEDURE (1) To remove the Underwater Acoustic Beacon (1-80) from the Beacon Mount Bracket (1-70), use a 3/16” Allen hex-wrench, remove the two left 1/4–20, hexcap screws (1-75) that secures the left Beacon Mount Bracket to the CSMU. (2) Loosen the lower right hex−cap screw (1-75) which secures the right Beacon Mount Bracket to the CSMU and holds the beacon in the bracket. (3) The beacon can now be removed from the Beacon Mount Bracket. (4) If the CSMU requires removal, then remove the right beacon bracket mount from the CSMU assembly. Crash Survivable Memory Unit (CSMU) (1‐185) Right Beacon Mount Bracket (1-70) Water Switch Left Beacon Mount Bracket (1-70) 1/4” Hex−cap Screw (1-75) Underwater Acoustic Beacon (1-80) Figure 301. Underwater Locator Beacon Removal Diagram Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Disassembly Rev. 15 Page 303 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR B. Crash Survivable Memory Unit (CSMU) Removal (See Figure 305 or IPL Figure 1, Item 185) The Model FA2100CVRs CSMU is mounted to the top of the recorder chassis by (4) pan-head sealing screws (MOD−DOT 4). It interfaces to the Acquisition Processor PWA through the Memory Interface Cable assembly attached to the Acquisition Processor PWA’s J1 connector. The CSMU is a sealed unit and must be returned to the factory for repair. If replacement of the CSMU is required, proceed with the following procedure: CSMU REMOVAL PROCEDURE (1) Remove the Underwater Acoustic Beacon (1-80) as described in paragraph A. above. (2) Remove the four 1/4–20, 1” pan−head sealing screws (190) that secure the CSMU memory assembly (1-185) to the recorder chassis (1-5). (a) NOTE: For Pre-MOD DOT 13 units only, carefully remove the RTV from around the memory interface cable assembly slot in the chassis. Pan-head sealing screws (1-190) are one time use items that should be discarded when removed and replaced with new screws. 1/4” Pan−Head Sealing Screws (190) (Qty. 4) CSMU Memory Assembly (1‐185) Recorder Chassis (1‐5) Figure 302. CSMU Memory Sealing Screw Removal Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Disassembly Rev. 15 Page 304 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (3) Lift and disconnect the CSMU memory assembly as per the appropriate instructions below. (a) For Pre-MOD DOT 6 units only, carefully tilt the CSMU memory assembly to the left side (same side as cable) to gain access to the J1 connector located on the Acquisition Processor PWA (1-175). Carefully unplug P1 of the Memory Interface Cable Assembly from J1 on the Acquisition Processor PWA. Note the pins of J1 can be easily damaged if handled incorrectly. CSMU Memory Assembly Memory Interface Cable Assembly (1‐185) P1 Acquisition Processor PWA (AP) (1‐175) J1 Recorder Chassis (1‐5) Figure 303. CSMU Memory Assembly Removal Diagram (PRE-MOD DOT 6) (b) For Post-MOD DOT 6 / Pre-MODT DOT 13 units only, carefully tilt the CSMU memory assembly to the left side (same side as cable) to gain access to the J5 connector located on the Acquisition Processor PWA (1-175). Carefully unplug P1 of the Memory Interface Cable Assembly from J5 on the Acquisition Processor PWA. Note the pins of J5 can be easily damaged if handled incorrectly. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Disassembly Rev. 15 Page 305 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Memory Interface Cable Assembly CSMU Memory Assembly (1‐185) P1 Acquisition Processor PWA (AP) (1‐175) Recorder Chassis J5 J1 (1‐5) Figure 304. CSMU Memory Assembly Removal Diagram (POST-MOD DOT 6 & PRE-MOD DOT 13) (c) For Post-MOD DOT 13 units only, carefully lift the CSMU memory assembly directly up without pulling the memory interface cable to gain access to the J5 connector located on the Acquisition Processor PWA (1-175). Carefully unplug P1 of the Memory Interface Cable Assembly from J5 on the Acquisition Processor PWA. Note the pins of J5 can be easily damaged if handled incorrectly. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Disassembly Rev. 15 Page 306 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Memory Interface Cable Assembly CSMU Memory Assembly (1‐185) P1 Acquisition Processor PWA (AP) (1‐175) Recorder Chassis J5 J1 (1‐5) Figure 305. CSMU Memory Assembly Removal Diagram (POST-MOD DOT 13) (4) For GACVR’s, p/ns: 2100−1010−5X and 2100−1020−5X, remove RTV from the bottom of the CSMU and the Chassis at the seating surface for the CSMU memory assembly. (5) Lift the CSMU away from the chassis. NOTE: (6) C. Post-MOD DOT 13 CSMU Memory Assemblies have circuitry located on the bottom (flat) side of the CSMU. Only place the CSMU down oriented so that this circuitry is not underneath the CSMU. Failure to do this will result in damage to the CSMU Memory Assembly. Package CSMU memory assembly and return to L-3 Aviation Recorders for repair. Acquisition Processor (AP) PWA Removal (See Figure 306 or IPL Figure 1, Item 175) The Model FA2100’s Acquisition Processor PWA (1-175) is mounted in the bottom of the recorder chassis just below the CSMU. It provides an interface between the Aircraft Interface PWA through Cable Assembly W001 connected at J2, the Audio Compressor PWA through Cable Assembly W003 connected at J4, and the CSMU via the Memory Interface Cable assembly connected at J1. The Acquisition PWA also provides an interface between the FA2100 Recorder and Ground Support Equipment, GSE, directly through front panel connector J3. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Disassembly Rev. 15 Page 307 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (1) Remove the CSMU memory assembly (1-185) as described in paragraph B. above. (2) To gain full access to the Acquisition Processor PWA (1−175) remove the 10 panhead sealing screws (1-25) and lift chassis cover (1-20) from the recorder chassis. NOTE: Pan-head sealing screws (1-25) are one time use items that should be discarded when removed and replaced with new screws. (3) Disconnect the Aircraft Interface PWA interconnection cable assembly, W001 (1-165), from J2 on the Acquisition Processor PWA. (4) Disconnect the Audio Compressor PWA interconnection cable assembly, W003 (1-165), from J4 on the Acquisition Processor PWA. (5) Remove 8 flat-head screws (1-95) that secure the rear panel assembly (1-90) with attached Aircraft Interface PWA and Audio Compressor PWA into the recorder Chassis (1-5). NOTE: Flat-head screws (1-95) are one time use items that should be discarded when removed and replaced with new screws. (6) Lift the rear panel assembly away from the chassis. (7) Remove 10 pan-head screws (1-180) that secure the Acquisition Processor PWA to the recorder chassis. (8) Carefully slide the Acquisition Processor PWA from the rear of the recorder chassis while observing proper ESD handling techniques. (9) Package Acquisition Processor PWA in a static-resistant container for shipment to the factory for repair. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Disassembly Rev. 15 Page 308 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (1-180) Qty. 10 Acquisition Processor PWA (AP) (1‐175) Chassis Cover Assy (1-20) J3 Rear Panel Assy J5 J1 J4 J2 (1-90) Chassis (1‐5) W003 (1-165) W001 (1-170) Aircraft Interface Audio Compressor PWA (AI) PWA (AC) (1-105) (1-95) Qty. 8 (1-155) Figure 306. Acquisition Processor PWA Removal Diagram D. Audio Compressor PWA (AC) Removal (See Figure 307 or IPL Figure 1, Item 155) The Model FA2100’s Audio Compressor PWA is mounted to the Aircraft Interface PWA located in the rear panel assembly of the recorder chassis. It provides digital conversion and compression of the input audio stream. It interfaces to the Acquisition Processor PWA via interconnect cable assembly W003 through the J2 connec- Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Disassembly Rev. 15 Page 309 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR tor; and to the Aircraft Interface PWA via cable assembly W002 through the J1 connector. (1) Remove the CSMU memory assembly (1-185) as described in paragraph B. above. (2) Remove the 10 pan-head screws (1-25) which secure the chassis cover (1-20) to the recorder chassis (1−5). NOTE: Pan-head sealing screws (1-25) are one time use items that should be discarded when removed and replaced with new screws. (3) If the rear panel assembly has not been removed from the chassis perform steps (4) − (7). If the rear panel assembly has been removed, then skip to step (8). (4) Disconnect the Aircraft Interface PWA interconnection cable assembly, W001 (1-165), from J2 on the Acquisition Processor PWA. (5) Disconnect the Audio Compressor PWA interconnection cable assembly, W003 (1-165), from J4 on the Acquisition Processor PWA. (6) Remove 8 flat-head screws (1-95) that secure the rear panel assembly (1-90) with attached Aircraft Interface PWA and Audio Compressor PWA into the recorder Chassis (1-5). NOTE: Flat-head screws (1-95) are one time use items that should be discarded when removed and replaced with new screws. (7) Lift the rear panel assembly away from the chassis. (8) Disconnect the interconnection cable assembly, W002 (1-170), from J1 on the Audio Compressor PWA (1−155). (9) Disconnect the interconnection cable assembly, W003 (1-165), from J2 on the Audio Compressor PWA. (10) Place the Assembly Support Tool fixture, Table 701: item 5, between the Aircraft Interface PWA (1-105) and the rear panel assembly (1-90). Position the fixture such that the inner part of the “U” shape surrounds the J1A connector. NOTE: This fixture is used to support the Aircraft Interface PWA and prevent damage to the circuit board when removing the two bottom standoff screws that attach to the Audio Compressor PWA. (11) Remove the 4 pan-head screws (1-160) which mount the Audio Compressor PWA (1-155) to the 4 standoffs (1-120) on the Aircraft Interface PWA (1-105). Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Disassembly Rev. 15 Page 310 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (1-141) (1-135) REF (1-20) (1-25) Qty. 10 (1-151) (1-146) (Post MOD DOT 11) Audio Compressor PWA (AC) (1-155) Aircraft Interface PWA (AI) (1-160) Qty. 4 (1-105) A (1-135) (1-140) Qty. 2 BLACK (Bottom - J5) (1-120) Qty. 4 (1-110) Qty. 2 RED (Top - J4) (1-105) (1-115) (1-155) J1 (1-125) Qty. 3 J2 (1-125) W003 (1-165) J2 J3 (1-145) (1-150) Qty. 2 (1-125) W002 Qty. 2 (1-165) (1-90) J3 J5 W001 (1-170) (1-130) Qty. 4 VIEW A J1 Acquisition Processor PWA (AP) (1-95) Qty. 8 (1-175) Figure 307. Aircraft Interface & Audio Compressor PWA Removal Diagram Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Disassembly Rev. 15 Page 311 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (12) Remove the Assembly Support Tool fixture, Table 701: item 5 from under the Aircraft Interface PWA. (13) Carefully lift the Audio Compressor PWA from the rear panel assembly observing proper ESD handling precautions. (14) If the Audio Compressor PWA is the faulty component, then package it in an staticresistant container for shipment to the factory for repair. E. Aircraft Interface PWA (AI) Removal (See Figure 307 or IPL Figure 1, Item 105) The Model FA2100CVR Aircraft Interface PWA is mounted in the rear panel assembly of the recorder chassis. It provides the Cockpit Voice Recorder with an interface to the Aircraft’s power and Cockpit Control Unit, through the rear panel connector, J1A. It also provides operating voltage to the storage capacitor and routes the input voice, GMT and RSE signals to the Audio Compressor PWA. AIRCRAFT INTERFACE PWA REMOVAL PROCEDURE (1) Remove the Audio Compressor PWA (1-155) from the rear panel assembly as detailed in Para. D. above. (2) Disconnect the interconnection cable assembly, W001 (1-165), from J2 and W002 (1−170) from J3 on the Aircraft Interface PWA. Keep these cables for later use. (3) Remove 4 flat-head screws (1-130) that attach the J1A Main connector on the Aircraft Interface PWA to rear panel assembly (1-90). (4) Disconnect the storage capacitor red blade connector (39Vdc Hot) from the top, J4, connector on the Aircraft Interface PWA. (5) Disconnect the storage capacitor black blade connector (39Vdc Return) from the lower, J5, connector on the Aircraft Interface PWA. (6) Remove 3 pan-head screws (1-125) which mount the two upper standoffs (1-110), and center standoff (1-115) between the rear panel assembly and Aircraft Interface PWA. (7) If storage capacitor is faulty, remove it by performing step (8), otherwise, skip step (8). (8) On pre MOD DOT 11, remove two flat-head screws (1-140), flat washers (1-145) and self−locking hex nuts (1-150) that secure the storage capacitor to the top of the rear panel assembly. (9) On post MOD DOT 11, remove two flat-head screws (1-141), from the support capacitor bracket (1−146) that secure the storage capacitor to the top of the rear panel assembly. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Disassembly Rev. 15 Page 312 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (10) Carefully lift the Aircraft Interface PWA from the rear panel assembly observing proper ESD handling precautions. (11) Remove 2 pan-head screws (1-125) which mount the two lower standoffs (1-120) on the Aircraft Interface PWA. (12) Remove the remaining single pan-head screw (1-125) which attaches the center standoff (1-115) to the Aircraft Interface PWA. (13) Using a 3/16” hex wrench, unscrew the four top standoff’s (1-110 & 1-120) on the Aircraft Interface PWA. (14) Save all Aircraft Interface PWA attaching parts for use with replacement Aircraft Interface PWA. (15) Package Aircraft Interface PWA in an static-resistant container for shipment to the factory for repair. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Disassembly Rev. 15 Page 313 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR THIS PAGE IS INTENTIONALLY LEFT BLANK Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Disassembly Rev. 15 Page 314 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR CLEANING 1. GENERAL This section contains a list of all required cleaning materials, general cleaning procedures, applicable cautions and warnings related to the use of any cleaning material, and instructions for cleaning the Model FA2100 CVR major assemblies. 2. MATERIALS REQUIRED Refer to Table Table 401 for a listing of required cleaning materials: Table 401. Cleaning Materials Required NOTE: Material Specification Solvent Soft‐Bristle Brush Cotton Swabs Lint‐Free Cotton Cloth MIL‐PRF‐680 Equivalent substitutes may be used for all cleaning materials. All materials and chemicals may be obtained from any commercial source. 3. CLEANING PROCEDURES WARNINGS: 1) OBSERVE ALL FIRE PRECAUTIONS WHEN USING FLAMMABLE MATERIALS FOR CLEANING PURPOSES. 2) PERFORM OPERATIONS INVOLVING CLEANING SOLVENT IN A WELLVENTILATED AREA. AVOID PROLONGED BREATHING OF VAPORS OR CONTACT WITH SKIN. CAUTION: THE FA2100 CIRCUIT BOARDS ARE SUSCEPTIBLE TO ELECTRO– STATIC DESTRUCTION (ESD). PRIOR TO HANDLING PWAs, ENSURE PROPER PERSONNEL GROUNDING TECHNIQUES ARE USED. ENSURE THAT CARDS ARE PLACED INTO STATIC SHIELDING CONDUCTIVE BAGS WHEN HANDLING OR STORING. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Cleaning Rev. 15 Page 401 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR CAUTION: DO NOT IMMERSE ANY PRINTED WIRING ASSEMBLY MOUNTED ELECTRONIC PARTS IN THE CLEANING SOLVENT; OTHERWISE, CIRCUIT BOARD AND/OR COMPONENT DAMAGE MAY RESULT. A. B. Printed Wiring Assembly Cleaning (1) Remove dust, dirt, and foreign matter from all surfaces, using soft-bristle brush. (2) Wipe finished surfaces and contacts, using a cloth moistened in solvent. Connector Cleaning (1) C. Wipe dust and dirt from connectors, using a lint-free cloth, moistened with solvent. Underwater Locator Device (Beacon) Cleaning All information for the ULB, including the testing and cleaning, is contained in the L−3AR Underwater Locator Beacon CMM, p/n 165E5542−00. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Cleaning Rev. 15 Page 402 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR CHECK 1. GENERAL This section contains the various checks that should be performed on the Model FA2100 Cockpit Voice Recorder during shop maintenance. Check procedures, when required, are written in step-by-step procedures wherever practicable, and include specific methods, techniques, and equipment required. Electrical set up and checks are given in the Testing and Troubleshooting Section 100 of this Component Maintenance Manual. CAUTION: THE FA2100 CIRCUIT BOARDS ARE SUSCEPTIBLE TO ELECTRO– STATIC DESTRUCTION (ESD). PRIOR TO HANDLING PWAs, ENSURE PROPER PERSONNEL GROUNDING TECHNIQUES ARE USED. ENSURE THAT CARDS ARE PLACED INTO STATIC SHIELDING CONDUCTIVE BAGS WHEN HANDLING OR STORING. 2. CHECKS A. B. Main Recorder Assembly (1) Check the general physical integrity of the recorder; i.e. front panel ATE connector pins, Underwater Locator Device (acoustic beacon) and J1A rear panel connector pins. (2) Check that dust cover is serviceable, exhibiting no undue deterioration and is properly painted. Mechanical Inspection (1) Remove the unit dust cover, refer to Section 300 Disassembly Section. (2) Inspect all parts for cracks, distortion, excessive wear, and proper finish. (3) Inspect all cast parts for cracks, especially at bosses, flanges, and other critical areas. (4) Inspect circuit boards and connectors for loose terminals, pins, and screws, and check for cracks in the boards that may have been brought about by environmental conditions. (5) Check all wire leads for broken conductors, burnt or deteriorated installation, and loose connections. (6) Check all flat ribbon cable assemblies and associated connectors for broken conductors, burnt or deteriorated installation, and loose pin connections. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Check Rev. 15 Page 501 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR C. (7) Check the circuit boards for broken parts and bad solder joints. Check for burnt parts. Check the circuit boards for cracks and abrasions. (8) Inspect the nameplate for legibility. (9) Reassemble recorder in accordance with the steps of procedure outlined in Section 700: Assembly. Electrical Inspection Perform all test set-up and testing per instructions given in the Testing and Troubleshooting Section 100 of this Component Maintenance Manual. D. Underwater Locator Device (ULD) All information for the ULB, including the testing and cleaning, is contained in the L−3AR Underwater Locator Beacon CMM, p/n 165E5542−00. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Check Rev. 15 Page 502 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR REPAIR 1. GENERAL This section is intended to contain information required to restore a worn or damaged part to a serviceable condition. However, the Fairchild Model FA2100 Cockpit Voice Recorder is a completely solid-state device that does not contain any electro-mechanical moving parts. The Model FA2100CVR has been designed as maintenance-free unit which makes extensive use of surface mount technology (SMT). The repair of printed wiring assemblies (PWAs) containing SMT components requires specialized factory equipment, training, and techniques, therefore, such PWAs are not field-repairable. Only the L−3AR Repair Station, FAA: LD7R612J; EASA.145.4620 is authorized to repair the FA2100CVR to component level in accordance with L−3AR Factory test, calibration and repair specifications. As a result, the Model FA2100CVR’s maintenance philosophy is replacement of failed assemblies. In the case of the Model FA2100CVR, the replaceable assemblies are the Aircraft Interface PWA, the Audio Compressor PWA, the Acquisition Processor PWA, and the Crash Survivable Memory Unit (CSMU). When it has been determined that one or more of these assemblies is faulty, the faulty assembly(ies) should be removed and returned to the Aviation Recorders factory for repair or replacement. Attempts to repair any of these assemblies will void the warranty. Extreme care should be used when handling these assemblies. CAUTION: THE FA2100 CIRCUIT BOARDS ARE SUSCEPTIBLE TO ELECTRO– STATIC DESTRUCTION (ESD). PRIOR TO HANDLING PWAs, ENSURE PROPER PERSONNEL GROUNDING TECHNIQUES ARE USED. ENSURE THAT CARDS ARE PLACED INTO STATIC SHIELDING CONDUCTIVE BAGS WHEN HANDLING OR STORING. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Repair Rev. 15 Page 601 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR THIS PAGE IS INTENTIONALLY LEFT BLANK Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Repair Rev. 15 Page 602 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR ASSEMBLY 1. GENERAL This section contains procedures describing the assembly of the Model FA2100 Cockpit Voice Recorder as well as storage instructions after assembly. There is no special testing necessary during assembly. However, once assembly is completed, the operational test procedure provided in the Testing and Troubleshooting Section 100 should be performed to verify proper operation of the Recorder. 2. REQUIRED MATERIALS Special equipment required for testing and assembly of the recorder can be found in Table 901 of the Special Tools, Fixtures, and Equipment Section 900 of this CMM. Table 701 provides a list of the common assembly materials used with the FA2100 Cockpit Voice Recorder. Table 701. Required Assembly Materials Item 1. Adhesive Manufacturing and Specification Loctite, Grade E, Purple No. 222 Lock/sealant manufactured by Loctite Corp., 705 N. Mountain Rd., Newington, CT 06111 [V05972] 2. Torque Wrench Local tool supplier Range: 5−6 in/lbs End Range: 75 in/lbs 3. RTV Adhesive Dow Corning RTV 3145 (V71984) L-3 p/n: 0601200006, or equivalent 4. Tape, Polymide MMM (3M) 5413 Use Retain screw CSMU & Beacon Bracket mounting screws (75 in/lbs.); Chassis Cover screws (9-10 in/ lbs; and Rear Panel & AP board screws (5-6 in/ lbs.) Chassis Chassis L-3 p/n: 2529800034, or equivalent 5. Tool, Assembly L-3 p/n: 980E2196-00, or equivalent Support 6. Tool, Seal Align- L-3 p/n: 980E2188-00, or equivalent ment, Short Chassis 7. Tool, Seal L-3 p/n: 980E2189-00, or equivalent Applicator Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. Audio Compressor PWA Installation Chassis Seal Installation Chassis Seal Installation 23–70–04 Assembly Rev. 15 Page 701 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 3. ASSEMBLY INSTRUCTIONS CAUTION: A. THE FA2100 CIRCUIT BOARDS ARE SUSCEPTIBLE TO ELECTRO– STATIC DESTRUCTION (ESD). PRIOR TO HANDLING PWAs, ENSURE PROPER PERSONNEL GROUNDING TECHNIQUES ARE USED. ENSURE THAT CARDS ARE PLACED INTO STATIC SHIELDING CONDUCTIVE BAGS WHEN HANDLING OR STORING. General Assembly Techniques The Model FA2100CVR circuit board components are mounted using Surface Mount Technology (SMT) and also incorporate extensive software programming to functionally configure the logic circuits. Thus, Level-3 repair of these circuit boards requires specialized factory equipment, diagnostic software, training, and techniques; therefore, such boards are not field-repairable while the unit is under warranty. Consequently, in accordance with the accepted Level-2 repair philosophy for the FA2100 CVR, a known defective circuit board assembly shall be returned to the factory for repair or replacement. NOTE: Numbers shown in parentheses in the following text are the Illustrated Parts List (IPL) figure number followed by the IPL item number for a particular part; e.g., (1-115) for IPL Figure 1, Item 115. For items listed in the parts list but not illustrated, the item number is preceded by a “-”. The Assembly procedures begin with the Acquisition Processor PWA installation then continue with the Audio Compressor and Aircraft Interface PWA installation, CSMU installation, and Underwater Acoustic Beacon installation. B. Acquisition Processor (AP) PWA Installation (See Figure 701 or IPL Figure 1, Item 175) This procedure assumes that the Crash Survivable Memory Unit (CSMU) is removed from the chassis and that the rear panel chassis assembly with the Aircraft Interface PWA and Audio Compressor PWA attached is also removed from the recorder chassis. The Model FA2100’s Acquisition Processor (AP) PWA (1-175) is mounted in the bottom of the recorder chassis just below the CSMU. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Rev. 15 Page 702 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (1-180) Qty. 10 Acquisition Processor PWA (AP) (1‐175) Chassis Cover Assy (1-20) J3 Rear Panel Assy J5 J1 J4 J2 (1-90) Chassis (1‐5) W003 (1-165) W001 (1-170) Aircraft Interface Audio Compressor PWA (AI) PWA (AC) (1-105) (1-95) Qty. 8 (1-155) Figure 701. Acquisition Processor (AP) Installation Diagram The Acquisition Processor PWA provides an interface between the Aircraft Interface PWA, through W001 Cable Assembly connected at J2 and the Audio Compressor PWA, through W003 Cable Assembly connected at J4. The Acquisition Processor PWA connects to the CSMU via the Memory Interface Cable assembly connected at J1 (Pre-MOD DOT 6 units) or the J5 (Post-MOD DOT 6 units). The Acquisition Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Rev. 15 Page 703 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Processor PWA also provides an interface between the FA2100CVR and Ground Support Equipment, GSE, directly through front panel GSE connector J3. C. (1) Remove the Acquisition Processor PWA (1-175) from its static-resistant container ensuring that none of the connector contacts are touched and general ESD handling precautions are observed. (2) Slide the Acquisition Processor PWA into the chassis with the GSE (J3) connector toward the front from the rear and position into place. Refer to Figure 701. (3) Apply adhesive, Table 701: item 1, to 10 pan-head screws (1-180) and tighten into place using a torque wrench set at 5-6 in./lbs. to secure the Acquisition Processor PWA to the recorder chassis (1-5). (4) If the Aircraft Interface PWA (1−105) and Audio Compressor PWA (1−155) are not attached to the rear panel assembly (1−90), then perform the steps in paragraph C. and paragraph D. (5) If the Aircraft Interface PWA and Audio Compressor PWA are attached to the rear panel assembly, then continue with paragraph D., Step (9). (6) Since the Acquisition Processor requires specifically configured software to operate, refer to the Test and Troubleshooting Section 100, for detailed procedures on loading the recorder software through the front panel GSE connector. Aircraft Interface PWA (AI) Installation (See Figure 703 or IPL Figure 1, Item 105) The Model FA2100’s Aircraft Interface PWA is mounted in the rear panel assembly of the recorder chassis. It provides the Flight Recorder with an interface to the Aircraft’s power and Flight Data Acquisition Unit, FDAU, through the rear panel connector, J1A. It also provides operating voltage to the storage capacitor and routes the input signals to the Audio Compressor PWA through W002 Cable Assembly connected at J3 and to the Acquisition Processor PWA through the W001 Cable Assembly connected at J2. This procedure assumes that the CSMU is removed from the recorder chassis, that the dust cover is off, the rear panel assembly is detached from the recorder chassis, the Audio Compressor PWA is not attached, and that the Acquisition Processor PWA is installed and secured into the chassis as described in paragraph B. NOTE: Front orientation means toward or facing the front of the unit, whereas rear means toward or facing the rear of the unit. To secure the Aircraft Interface PWA to the rear panel assembly (1-90): Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Rev. 15 Page 704 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (1) For GACVRs, p/n: 2100−1010−51 and 2100−1020−51, verify that the three unused holes on the rear of the chassis (1−5) are filled with RTV. If the unused holes are not filled with RTV, place polymide tape (Table 701: Item 4) over the holes on the inside of the chassis (1−5). (2) Attach the (2) lower short standoffs (1-120) to the front side of the Aircraft Interface PWA using (2) pan−head screws (1-125), inserted from the rear (J1A) side of the board and coated with adhesive, Table 701: item 1. Hand tighten for right now. (3) Using a 3/16” hex wrench attach 2 studded upper standoffs (1-110) inserted from the rear side through the board and attach with the remaining two short standoffs (1-120) from the front side of the Aircraft Interface PWA (1-105). Hand tighten for right now. (4) Attach the center standoff, (1-115) to the rear side of the Aircraft Interface PWA using (1) pan-head screw (1-125) inserted from the front side of the AI PWA and coated with adhesive, Table 701: item 1. (5) Tighten all screws and standoffs attached to a torque value of 5-6 in./lbs. (6) Position the Aircraft Interface PWA into the rear panel assembly such that the J1A mounting holes and upper standoffs are aligned properly. (7) While holding the J1 connector flush with the bottom of the connector opening of the rear panel assembly, insert (4) flat-head screws (1-130) and tighten down in a cross pattern to ensure a proper alignment of the J1 main connector assembly with the rear panel assembly (1-90). Note that these screws do not use adhesive. (8) Insert the (3) pan−head screws (1-125) coated with adhesive, Table 701: item 1, which secure the Aircraft Interface PWA to the rear panel through the standoffs (1-110 & 1-115). Tighten screws to a torque value of 5-6 in./lbs. (9) Connect interconnect cable assembly W001 (1-165) to J2 on the Aircraft Interface PWA. (10) Connect the interconnect cable assembly W002 (1-170) to J3 on the Aircraft Interface PWA. (11) If the storage capacitor assembly was removed earlier, perform step (12), otherwise skip to step (14). (12) On pre MOD DOT 11, secure the storage capacitor assembly (1-135) to the top of the rear panel assembly (1-90) with a pair of flat-head screws (1-140), flat washers (1-145) and hex nuts (1-150). (13) On post MOD DOT 11, Apply thread-locking adhesive, Table 701 item 1 to the two flat-head screws (1-136). Install two flat-head screws to secure the storage Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Rev. 15 Page 705 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR capacitor (1−130) to the top of the rear panel assembly using the support capacitor bracket (1−141). (14) Connect the red blade connector (39 Vdc Hot) to the top, J4, connector on the front side of the Aircraft Interface PWA. (15) Connect the black blade connector (39 Vdc Return) to the lower, J5, connector on the front side of the Aircraft Interface PWA. D. Audio Compressor PWA (AC) Installation (See Figure 703 or IPL Figure 1, Item 155) The Model FA2100’s Audio Compressor PWA is mounted to the Aircraft Interface PWA located in the rear panel assembly of the recorder chassis. It provides digital conversion and compression of the input audio stream. It interfaces to the Acquisition Processor PWA via interconnect cable assembly W003 through the J2 connector; and to the Aircraft Interface PWA via cable assembly W002 through the J1 connector. (1) Ensure that the Aircraft Interface PWA (1-105) is installed into rear panel assembly (1-90) as described in paragraph C. above. (2) Lay the rear panel assembly on its back with the Aircraft Interface PWA facing up. (3) Place the Assembly Support Tool fixture, Table 701: item 5, between the Aircraft Interface PWA (1-105) and the rear panel assembly (1-90). Position the fixture such that the inner part of the “U” shape is around the J1A connector. NOTE: This fixture is used to support the Aircraft Interface PWA and prevent damage to the circuit board when installing the two bottom standoff screws that attach to the Audio Compressor PWA. (4) Secure Audio Compressor PWA (1-155) to the Aircraft Interface PWA standoffs (1-120) using (4) pan-head screws (1-160) coated with adhesive Table 701: item 1. Only hand tighten right now. (5) Tighten the (4) pan-head screws in a cross pattern and torque to a value of 5-6 in./lbs. (6) Remove the Assembly Support Tool fixture, Table 701: item 5 from under the Aircraft Interface PWA. (7) Attach W002 (1−170) from the Aircraft Interface PWA to J1 on the Audio Compressor PWA. (8) Attach W003 (1−165) to J2 on the Audio Compressor PWA. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Rev. 15 Page 706 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (1-141) Qty. 2 (1-25) Qty. 10 (1-135) REF (1-20) Audio Compressor PWA (AC) (1-155) (1-146) (1-160) Qty. 4 Aircraft Interface PWA (AI) Torque Sequence (5‐6 in/lbs) (1-105) A (1-140) Qty. 2 (1-135) 4 (1-120) Qty. 4 (1-110) Qty. 2 (1-146) (Post MOD DOT 11) 2 (1-115) BLACK (Bottom - J5) 1 (1-105) 3 (1-125) Qty. 3 RED (Top - J4) (1-155) J1 J2 W003 (1-165) (1-125) 4 2 J2 J3 1 3 Torque Sequence (5‐6 in/lbs) (1-125) W002 Qty. 2 (1-165) (1-90) W001 (1-170) (1-130) Qty. 4 (1-145) Qty. 2 VIEW A (1-150) Qty. 2 3 2 1 Torque Sequence 9−10 in/lb (Each Side) W003 (1-165) J3 2 J5 (Post MOD DOT 6) 3 J1 1 Acquisition Processor PWA (AP) (1-175) (1-95) Qty. 8 Figure 702. Aircraft Interface & Audio Compressor PWA Installation Diagram (PRE-MOD DOT 6) Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Rev. 15 Page 707 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (1-141) (1-135) REF (1-25) Qty. 10 (1-20) (1-151) (1-146) (Post MOD DOT 11) Audio Compressor PWA (AC) (1-155) Aircraft Interface PWA (AI) (1-105) (1-120) Qty. 4 (1-110) Qty. 2 (1-160) Qty. 4 Torque Sequence (5‐6 in/lbs) (1-135) (1-140) Qty. 2 A BLACK (Bottom - J5) 4 (1-105) (1-115) (1-155) 2 1 (1-125) Qty. 3 J1 J2 3 W003 (1-165) (1-125) J2 J3 (1-145) (1-150) Qty. 2 4 2 3 1 3 Torque Sequence (5‐6 in/lbs) (1-130) Qty. 4 RED (Top - J4) (1-125) W002 Qty. 2 (1-165) (1-90) W001 (1-170) Torque Sequence 9−10 in/lb (Each Side) VIEW A 2 J3 1 2 1 J5 3 J1 Acquisition Processor PWA (AP) (1-95) Qty. 8 (1-175) Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Rev. 15 Page 708 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 703. Aircraft Interface & Audio Compressor PWA Installation Diagram (POST MOD DOT 6) (9) Insert the rear panel assembly with attached Aircraft Interface PWA and Audio Compressor PWA into the recorder chassis (1-5). (10) To secure the rear panel assembly, insert six flat-head screws (1-95) coated with adhesive, Table 701: item 1, three to each side of the rear panel assembly, but do not fully tighten down. NOTE: Flat-head screws (1-95) are one time use items and should be replaced during re-assembly. These screws should not be retained after dis-assembly. (11) Insert two flat-head screws (1-95) coated with adhesive, Table 701: item 1, into the bottom of the chassis and tighten them down using a torque wrench set to 9-10 in./lbs. (12) Hold the rear panel assembly (1-90) securely to the chassis, turn on its side and tighten three screws inserted in Step (10) to 9−10 in./lbs. in the pattern shown in Figure 703. (13) Turn the chassis over to the opposite side and tighten the remaining three screws to 9-10 in./lbs. in the same pattern as shown in Figure 703. (14) Connect the Aircraft Interface PWA W001 Cable Assembly (1-165) to J2 on the Acquisition Processor PWA (1-175). (15) Connect the W003 Cable Assembly (1-165) between J2 on the Audio Compressor PWA and J4 on the Acquisition Processor PWA. (16) Check proper alignment of the rear connector J1A by carefully inserting the FA2100CVR into an SSCVR Mount, Part Number 178E0919–00, (Ref: Model FA2100CVR Installation and Instruction Manual, p/n: 165E1846-00). If alignment is skewed, loosen (8) flat-head screws (1-95) and repeat steps (11) − (13). (17) Secure the Chassis Cover (1−20) as described in Paragraph E. (18) Secure the CSMU (1-185) to the recorder as described in Paragraph F. E. Chassis Cover Installation (See Figure 704 and Figure 706 or IPL Figure 1, Item 20A/B) (1) For GACVR p/ns: 2100−1010−5X and 2100−1020−5X, skip steps (2) − (8) and proceed with step (9), these units do not have the chassis cover seal. (2) If original cover seal material is damaged or seals need to be installed (pre mod−dot #4 units) perform steps (3) − (8), otherwise skip to step (9). Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Rev. 15 Page 709 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (3) Position the chassis cover seal (1-28) into place on the Seal Alignment Tool, Table 701: item 6, (see Figure 704, frame 1). (4) Carefully peel the paper backing from the chassis cover seal (1-28) to end of the alignment tool ensuring that you do not stretch the seal. (5) With the seal placed on the alignment tool with the sticky side up, position the front part of the chassis cover (1-20) down onto the seal and gently press (see Figure 704, frame 2). (6) Carefully turn over the alignment tool with chassis cover and seal so that the rear of the chassis is nearest to you. Carefully, remove the remaining paper backing from the seal ensuring that you do not stretch the seal or that it folds over on itself. (7) Using the Seal Applicator Tool, p/n: 980E2189−00, or equivalent (see Figure 702, frame 3), gently smooth down the chassis cover seal (1−28) to form two 90_ bends at the rear of the chassis cover. (8) Remove the chassis cover with attached seal from the alignment fixture and ensure that the seal screw holes line up with the chassis cover screw holes. (9) Replace the chassis cover (1-20) by inserting the front end of the cover into the alignment grove and inserting ten attaching pan-head sealing-screws (1-25) coated with adhesive Table 701: item 1. NOTE: Pan-head sealing screws (1-25) are one time use items and should be replaced during re-assembly. These screws should not be retained after dis-assembly. (10) To secure the cover to the chassis, tighten down each of the 10 pan-head sealing-screws (1-25) in the pattern shown in Figure 706, torque to a value of 9-10 in./lbs. (11) If needed, apply RTV, DOW Corning, 3145 Adhesive silicone sealant to the two inside corner bend relieves of the chassis cover and to the two front screw heads as indicated in Note 1 and Note 2, Figure 706, respectively. (12) For GACVR p/ns: 2100−1010−5X and 2100−1020−5X, apply RTV (Table 701: Item 3) to the two front screw heads, and the front seam where the chassis cover (1−20B) meets the chassis (1−5), as indicated in Note 1, Figure 705. NOTE: For GACVR p/ns: 2100−1010−5X and 2100−1020−5X, install the CSMU in accordance with Step 13, and then perform Steps 14 through 15. This will ensure that the Chassis Cover will be firmly seated prior to applying RTV around the Chassis Cover to Chassis seam. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Rev. 15 Page 710 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (13) Secure the CSMU (1-185) to the recorder as described in Paragraph F. (14) For GACVR p/ns: 2100−1010−5X and 2100−1020−5X, apply RTV (Table 701: Item 3) to the entire seam where the chassis cover (1−20B) meets the chassis (1−5), as indicated in Note 2, Figure 705. (15) For GACVR p/ns: 2100−1010−5X and 2100−1020−5X, apply RTV (Table 701: Item 3) around the connector, including the three keying holes, and the seam on the back of the CVR, as indicated in Note 3, Figure 705. (16) For GACVR p/ns: 2100−1010−5X and 2100−1020−5X, if the three unused holes on the backside of the chassis (1−5) are not filled with RTV, apply RTV (Table 701: Item 3) to the holes to seal them, as indicated in Note 4, Figure 705. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Rev. 15 Page 711 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 1 ALIGN CHASSIS COVER OVER SEAL & PRESS IN PLACE 2 ALIGN SEAL OVER FIXTURE HOLES REMOVE SEAL BACKING AND SMOOTH OUT 3 PUSH TOOL FIRMLY TO AFFIX SEAL TO SIDE 4 HOLES IN SEAL SHOULD LINE UP WITH HOLES IN CHASSIS COVER ASSEMBLY DO NOT STRETCH SEAL MATERIAL Figure 704. FA2100CVR Chassis Cover Seal Installation Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Rev. 15 Page 712 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Note 1: Apply RTV to Two Front Screw Heads and the front seam where the Chassis Cover meets the Chassis. Note 2: Apply RTV to entire seam, where Chassis Cover meets the Chassis, after the CSMU is installed and tightened. Note: 4 Apply RTV to seal unused holes on backside of Chassis. (if present) Note: 3 Apply RTV to seam on the back of the CVR and around the connector and the (3) keying holes. Figure 705. FA2100 GACVR Chassis RTV Installation Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Rev. 15 Page 713 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 7 8 Torque Sequence (9−10 in./lbs.) 5 6 3 Chassis Cover Seal-Screws (Qty 10) 1 4 2 9 10 Note 1: Apply RTV to two front bend relieves in Chassis Cover Note 2: Apply RTV to Two Front Screw Heads Figure 706. FA2100CVR Chassis Cover Installation F. Crash Survivable Memory Unit (CSMU) Installation (See Figure 710 or IPL Figure 1, Item 185) The Model FA2100’s Crash Survivable Memory Unit, CSMU, is a sealed unit and must not be opened in the field. CSMU is mounted to the top of the recorder chassis by (4) pan-head srews. The CSMU interfaces to the Acquisition Processor Board connector J1 through the Memory Interface Cable assembly. (1) For GACVR p/ns: 2100−1010−5X and 2100−1020−5X, apply RTV (Table 701: Item 3) to the CSMU seating surface on the chassis (1−5). (2) If the CSMU Cover Seal is not installed or has been damaged and needs replacing perform the CSMU Cover Seal installation / replacement below. CSMU COVER SEAL INSTALLATION / REPLACEMENT (PRE−MOD DOT 13) Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Rev. 15 Page 714 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (a) Remove the damaged seal, if necessary, by peeling the seal up from the edge. (b) Ensure that the flat underside surface of the CSMU is clean. CSMU Cover Seal Apply RTV to seal Memory Cable Slit Figure 707. Crash Survivable Memory Unit (CSMU) Seal Application (Pre-MOD DOT 13) (c) Carefully peel the paper backing from the CSMU Cover Seal (1-200) and position seal into place on the CSMU memory assembly (1-185), with the sticky side against the CSMU cover. (See Figure 707.) (d) Smooth the seal down onto the CSMU memory assembly, such that the application is toward the memory interface cable assembly. Carefully work the cable assembly slit in the seal around the memory interface cable assembly. (e) Apply RTV, DOW Corning, 3145 Adhesive silicone sealant between the slit in the CSMU cover seal where memory interface cable assembly passes through the seal as shown in Figure 707. CSMU COVER SEAL INSTALLATION / REPLACEMENT (POST−MOD DOT 13) (a) Disconnect the memory cable from CSMU circuitry by lifting the cable clasp and sliding the cable free. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Rev. 15 Page 715 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Location of memory cable clasp Figure 708. Crash Survivable Memory Unit (CSMU) Seal Application (Post-MOD DOT 13) (b) Secure the loose cable to the side, ensuring that it is away from the bottom of the CSMU. This will keep the cable out of access while applying the new CSMU seal. (c) If necessary remove the damaged seal by peeling the seal up from the edge. Take care to not damage the circuitry affixed to the bottom of the CSMU. (d) Ensure that the flat underside surface of the CSMU is clean. CSMU Cover Seal Apply RTV to seal Memory Cable Slit Figure 709. Crash Survivable Memory Unit (CSMU) Seal Application (Post-MOD DOT 13) (e) Carefully peel the paper backing from the CSMU Cover Seal (1-200) and position seal into place on the CSMU memory assembly (1-185). Place the cut out in the seal around the CSMU circuitry with the notch oriented towards the memory cable. The sticky side of the seal should be against the CSMU cover. (See Figure 709.) (f) Smooth the seal down onto the CSMU memory assembly, such that the application is toward the memory interface cable assembly. Carefully work Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Rev. 15 Page 716 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR the cable assembly slit in the seal around the memory interface cable assembly. (3) (4) (g) Apply RTV, DOW Corning, 3145 Adhesive silicone sealant between the slit in the CSMU cover seal where memory interface cable assembly passes through the seal as shown in Figure 709. (h) Reattach the memory cable to the CSMU circuitry by sliding the end of the cable into the connection slot and pushing the clasp down to secure it. Carefully reconnect the memory interface cable assembly connector from the CSMU to the Acquisition Processor PWA. (a) For Pre-MOD DOT 6 units, the memory interface cable should be connected to J1 on the Acquisition Processor PWA. (b) For Post-MOD DOT 6 units, the memory interface cable should be connected to J5 on the Acquisition Processor PWA. Apply Locktite 222 to the four pan-head sealing-screws (1−190) and insert them into the CSMU cover (1-185). NOTE: Pan-head sealing screws (1-190) are one time use items and should be replaced during re-assembly. These screws should not be retained after dis-assembly. (5) While pushing back on the front of the CSMU, partially tighten the rear two panhead screws. (6) Use a torque-wrench to tighten the four pan-head sealing-screws to 75 in/lbs in the cross pattern, shown in Figure 710, to fully secure the CSMU to the recorder chassis. (7) Apply RTV, DOW Corning, 3145 Adhesive silicone sealant to the memory interface cable assembly tab to seal the slot through the chassis that the cable passes through as shown in Figure 710, Figure 711 and Figure 712. NOTE: (8) The GACVRs, p/ns: 2100−1010−5X and 2100−1020−5X, must be allowed to set for 24 hours to allow the RTV to cure. Install the Underwater Acoustic Beacon as described in the next paragraph. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Rev. 15 Page 717 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 4 Torque Sequence 75 in/lb 1 3 CSMU Mounting Seal-Screws (1−190B) (Qty 4) 2 Note: After attached, apply RTV to seal Memory Cable Slot P1 Crash Survivable Memory Unit (CSMU) (1‐185) Memory Interface Cable Assembly J1 Recorder Chassis Assembly (1-5) Acquisition Processor PWA (AP) (1‐175) Figure 710. Crash Survivable Memory Unit (CSMU) Assembly (PRE-MOD DOT 6) Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Rev. 15 Page 718 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 4 Torque Sequence 75 in/lb 1 3 CSMU Mounting Seal-Screws (1−190B) (Qty 4) 2 Note: Crash Survivable Memory Unit (CSMU) After attached, apply RTV to seal Memory Cable Slot (1‐185) P1 Memory Interface Cable Assembly J5 Recorder Chassis Assembly (1-5) J1 Acquisition Processor PWA (AP) (1‐175) Figure 711. Crash Survivable Memory Unit (CSMU) Assembly (POST-MOD DOT 6 & PRE-MOD DOT 13) Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Rev. 15 Page 719 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 4 Torque Sequence 75 in/lb 1 3 CSMU Mounting Seal-Screws (1−190B) (Qty 4) 2 Note: Crash Survivable Memory Unit (CSMU) After attached, apply RTV to seal Memory Cable Slot (1‐185) P1 Memory Interface Cable Assembly J5 Recorder Chassis Assembly (1-5) J1 Acquisition Processor PWA (AP) (1‐175) Figure 712. Crash Survivable Memory Unit (CSMU) Assembly (POST-MOD DOT 13) Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Rev. 15 Page 720 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR A. Underwater Acoustic Beacon Assembly & Installation (See Figure 713 and IPL Figure 1, Item 80) The Underwater Acoustic Beacon is mounted on the Model FA2100’s CSMU front bracket with the beacon’s water switch facing to the left (refer to Figure 713, 1–80). NOTE: When replacing the 30−day ULB it is recommended that new mounting hex screws (MS 16995-54) are used to ensure a secure connection to the CSMU. NOTE: When replacing the 90−day ULB it is REQUIRED that four new mounting hex screws (L-3AR p/n 2290200424) that are used to secure the ULB brackets to the CSMU. When converting from a 30−Day ULB to a 90−Day ULB, the L−3AR ULB Conversion Kit, P/N 068E5542−00, is recommended. This kit contains the 90−Day ULB and the attaching hex mounting screws. Converted CVR units must be marked with MOD− DOT #15. Refer to FA2100CVR SB022 for more details. NOTE: Once a unit has been changed to a 90−Day ULB, it can not revert to a 30−Day ULB due to the Hardware MOD−DOT marking. NOTE: Refer to the IPL effectivity column, as some specific FA2100CVR Part Numbers that only are allowed only 90−Day ULBs to be installed. NOTE: For complete testing of the ULB and battery replacement procedures, refer to the 90−Day Underwater Locator Beacon CMM, L-3 p/n 165-E5542-00. (1) Insert the Underwater Acoustic Beacon (1-80) into the right and left beacon mount bracket (1-70) with the beacon water switch facing left and replacement date label visible to the front. (2) Apply thread-locking adhesive, Table 701 item1, to four 1/4–20, 1” hex-cap bolts (1-75). (3) Insert and tighten secure the right and left beacon mount bracket (1-70) with beacon to the CSMU. Torque mounting bolts (1-75) in a cross−pattern as shown in Figure 713 to 75 in/lbs. (4) For those units with customer installed beacons, p/n’s: 2100-1020−98 and 2100-1020-99, remove the temporary label which covers the standard identity label. (5) Perform a return-to-service test on the recorder in accordance with Section 100 of this CMM. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Temp. Rev. 16 Page 721 Apr. 15/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Note: - Must use the L-3AR Conversion Kit, PN 068E5542-00 when converting from a 30-Day ULB to a 90-Day ULB. Mark Name Plate Hardware MOD-DOT #15 Underwater Acoustic Beacon (1-80) Crash Survivable Memory Unit (CSMU) Right Beacon Mount Bracket (1-70) Water Switch #2 (1‐185) Left Beacon Mount Bracket (1-70) #4 1/4” Hex Screw (1-75) #1 #3 Cross-Pattern Torquing Sequence (75 in./lbs.) Figure 713. Underwater Locator Beacon Assembly Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Rev. 15 Page 722 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 4. STORAGE INSTRUCTIONS NOTE: A. A Return-To-Service bench test is recommended after storage of more than one year. Refer to Automatic Test Section 200 for specific test and check-out procedures. Storage in Original Containers When possible, the FA2100 Cockpit Voice Recorder should be stored in its original container(s). Provide adequate packing to ensure protection from damage during storage and shipment and ensure that adequate silica gel packages are packed in the container(s) to protect the equipment from moisture. Seal the container(s) to provide a moisture–proof package. B. Storage Without Original Containers If the original container(s) are not available, perform the following procedures to wrap the FA2100CVR system equipment for storage: C. (1) Wrap the recorder unit in plain wrapping paper or newspaper of sufficient thickness to thoroughly cover all sharp corners and protrusions. (2) Enclose the unit in a polyethylene bag (3 mils thick, min.) seal the bag. (3) Place the recorder unit in a suitably sized heavy construction cardboard box surrounded with packing material sufficient to protect it on all sides. Arrange packing material in such a way that the unit is protected and will not move around within the box. (4) Seal box(es) with fiberglass packing tape. (5) Mark boxes clearly as to contents. Shipment Container Kit A shipment package kit, P/N: 147E1679-00, (IPL Item 1−210) may be ordered from Aviation Recorders if the original container(s) are not available. This kit contains the FA2100CVR shipping container, p/n: 197E1746-00, (IPL Item 1−220) shown in Figure 714. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Rev. 15 Page 723 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR NOTES: 1. CONTAINER TO MEET ATA SPEC 300 CATEGORY II. MATERIAL: OUTER SHELL FIBER BOARD TO BE TYPE 1, CLASS 2, PER PPP−8−836 BOUBLE WALL 275 LBS CONSTRUCTION MATERIAL PACKING FOAM (1.50 IN. THICK) 1.8 LBS/ CUBIC FOOT WITH A COMPRESSION SET OF 95%. MATERIAL PACKING FOAM (2.00 IN. THICK) 1.2 LBS/ CUBIC FOOT WITH A COMPRESSION SET OF 40%. FOAM TO BE BONDED TO CARDBOARD. FLUTED SINGLE WALL 200 LBS CONSTRUCTION REF: CONTINOUS STITCHING STAPLE APPROX 1.0 INCH SPACING, DOUBLE STAPLE EACH END (.25 IN SPACING) 8.9 8.9 17.1 8.9 8.9 FOAM BONDED TO INSIDE FLAPS OF CONTAINER FOAM NOT TO EXTEND BEYOND THE CUT EDGE OF THE FLAP SHIPPING CONTAINER, Short Box (1-220) Figure 714. Shipping Container, Short Box, p/n: 197E1746-00, part of Shipment Package Kit: p/n: 147E1679-00. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Assembly Rev. 15 Page 724 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR FITS AND CLEARANCES 1. GENERAL This section provides the FA2100CVR recorder’s specifications and outline and dimensions. Since the recorder uses solid−state memory recording technology, there are no internal fits and clearances or tension values normally associated with older technology electromechanical tape recorder units. The information contained herein is also in the Description/Operation section of this CMM and is presented here for the purpose of quick reference. 2. SYSTEM SPECIFICATIONS The Model FA2100CVR meets the performance requirements of ED-56A, chapters 2, 3, 4, and 5, and 7, ED−112, chapter 2, and Part I, while conforming to the input interface required in ARINC 557/757. When the software detects a fault an CVR FAULT will be asserted immediately with no artificial delay. A. Physical Characteristics (1) Size: (Refer to Figure 801. for the FA2100CVR Outline & Dimension Drawing) Height: Width: Depth: 5.5 inches 4.98 inches 12.6 inches (behind front panel) (2) Weight: 10.0 ($.5) pounds nominal 7.7 ($.5) pounds (p/ns: 2100−1010−51 and 2100−1020−51) (3) Case: 404A–ATR Case, Short. Stainless Steel CSMU Housing, International Orange, Reflective Striping, English/French Markings (4) Main (Rear) Connector: 57–Pin Connector Compatible with ARINC757, p/n: 063E1072–00 (Cannon p/n: DPXBMA–36571–59) (5) Main (Rear) Mating Connector: Crimp: p/n: 063–98–01474 (Cannon p/n: DPXBMA–57–33S- 0001) Solder: p/n 9300–435 (Cannon p/n: DPXB-57-33S-0001) (6) Ground Support Equipment Connector: p/n: 063–98–01962 (AMP p/n: 748481–6) Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Fits and Clearances Rev. 15 Page 801 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR B. C. Electrical Characteristics (1) Power Requirements: 115 Vac @ 400 Hz, or 28 Vdc Only 28 Vdc for GACVRs (p/n’s: 2100−1010−−50/51 and 2100−1020−−50/51) (2) Power Level: 12W max ac, 10.5W max dc (3) Power Factor: .65 (4) Recording Time: 2100-1010-( ) = 30 min. minimum 2100-102X-( ) = 120 min. minimum (5) Input Signal Format: ARINC 557/757 (6) Rotor Speed: Analog Frequency = 7 to 6,000 Hz with input impedance of 100 kohms (7) Audio Output: 2.55 Vrms into 600−ohms Environmental Characteristics Refer to Table 801 for the FA2100 CVR environmental characteristics. D. Crash and Fire Protection The Crash Survivable Memory Unit (CSMU) is designed to fully meet the 5,000 pounds crush test requirement of TSO–123a and provides impact protection for up to 3400 g’s for 6.5 msec. The inner steel casing assembly protects the memory elements from deep sea pressures to 20,000 ft. The FA2100’s crash–protected CVR memory survives ED–56A 5.3.2.d. and ED−112 2−4.2.4 High Temperature Fire for one hour per the requirements of TSO-123a, or ED–56A 5.3.2.e., ED−112 2.4.2.5 Low Temperature Fire for ten hours. Specifically, 1 Hr @ 1100_ C, and 10 Hrs @ 260_ C. E. Torque Requirements The following assembly items have the specified torque requirements: CSMU & Beacon Bracket mounting screws (75 in./lbs.); Chassis Cover screws (9-10 in./lbs.); and Rear Panel, Aircraft Interface & Acquisition Processor attaching screws (5-6 in./lbs.) Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Fits and Clearances Rev. 15 Page 802 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Table 801. FA2100 CVR Environmental Characteristics Conditions Description Temperature & Altitude RTCA/ DO–160C Section 4.0 Ground Survival: Low Temperature High Temperature 4.5.1 4.5.2 (–55_C) (+85_C) Low Temperature Operating High Temperature Short–time Operating High Temperature 4.5.1 4.5.2 4.5.3 (–55_C) (+70_C) (+70_C) Altitude Decompression Overpressure Temperature Variation Humidity Shock: Operational Shock Crash Safety (Impulse) 4.6.1 4.6.2 4.6.3 5.0 6.0 7.0 7.2.2 7.3.1.1 55,000 ft 55,000 ft –15,000 ft Category B Category A (Standard) Crash Safety (Sustained) Vibration (Random) Crash Survival 7.3.2 8.6.2 12 G – 3 seconds Categories C Without Shock Mounts 3400 G – 6.5 MS Categories A2 & F2 6 G – 11 MS 15 G – 11 MS Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Fits and Clearances Rev. 15 Page 803 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR ESD LABEL C COCKPIT VOICE RECORDER MODEL FA2100 B 2.44 .5 B 7.5 A C .5 A 5.4 .1 3.0 .5 FARSIDE LABEL READS: ENREGISTREUR DE VOL NE PAS OUVRIR .2 MAX 12.60 .5 MAX .04 NOTES: 1. RECORDER COLOR IS INTERNATIONAL ORANGE NO. 12197 PER FED-STD-595. FRONT AND SIDE LABELS ARE REFLECTIVE WHITE BACKGROUND WITH BLACK LETTERING. NAMEPLATE IN VIEW A-A HAS LIGHT GRAY BACKGROUND WITH BLACK MARKING. A RUSSIAN TEXT LABEL IS LOCATED ON THE CSMU ON P/N: 2100−1025−12 AS SHOWN IN THE LOWER RIGHT HAND CORNER OF THIS DRAWING 2. ELECTRICAL INTERFACE CONNECTIONS PER APPLICABLE ARINC CHARACTERISTIC. 3. SEE CHART FOR FINAL PART NO. INPUT POWER, AND WEIGHT. POWERS ARE MAXIMUMS AND WEIGHTS ARE NOMINAL WITH .5 LBS TOLERANCE. 4. OVERALL EQUIPMENT SIZE AND MOUNTING SCHEME COMPLY WITH ARINC 404 AND 404A. 5. REAR PANEL CONTAINS HOLES TO MATE WITH GUIDE PINS IN ARINC 404 MOUNTING TRAYS. Figure 801. (Sheet 1 of 2) Outline & Dimension Drawing Model FA2100 CVR Recorder P/N: 2100-1010-( ) & 2100-102X-( ) Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Fits and Clearances Rev. 15 Page 804 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 2.44 .50 REFERENCE ONLY POLARIZING KEYS SHADING DENOTES SOLID KEY AREA 4 .275 A View A B B View J1 CONNECTOR PART NUMBERS: PN 063-E1072-00 (CANNON DPBX-36571-59) MATING CONNECTORS: (CRIMP) PN 063-98-01474 (CANNON DPXBMA-57-33S-0001) (SOLDER) PN 9300-435 (CANNON DPXB-57-33S-0001) 4.88 CRASH SURVIVABLE MEMORY UNIT .04 UNDERWATER LOCATING DEVICE 5.5 .2 GROUND SUPPORT EQUIPMENT CONNECTOR 063-98-01962 (AMP 748481-6) 4.12 4.98 C .04 View C Figure 801. (Sheet 2 of 2) Outline & Dimension Drawing Model FA2100 CVR Recorder P/N: 2100-1010-( ) & 2100-102X-( ) Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Fits and Clearances Rev. 15 Page 805 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR THIS PAGE IS INTENTIONALLY LEFT BLANK Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Fits and Clearances Rev. 15 Page 806 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR SPECIAL TOOLS, FIXTURES AND EQUIPMENT 1. GENERAL This section provides a listing of all required tools, fixtures, and equipment which are not common maintenance tools. Refer to Table 901 for a table listing required FA2100CVR special test equipment. Refer to the following paragraphs for a synopsis of equipment description and purpose. Table 901. Table of Special Tools, Fixtures, and Equipment Portable Interface (PI) Part Number 17TES0043 Description Mfg. Portable Interface (PI) L-3 Com. 17TES0053 PI Memory Card Module (Obsolete) L-3 Com. 17TES0054 PI Memory Card Module L-3 Com. 17TES0051 PI Audio Readout Cable L-3 Com. 17TES0052 PI Aux Readout Cable L-3 Com. Portable Interface/2 (PI/2) Part Number 17TES0062 Description Mfg. Portable Interface (PI/2) L-3 Com. 024E5002-00 USB 2.0 Cable L-3 Com. 147E4785-00 USB Adapter L-3 Com. 253E5106-00 USB Key L-3 Com. 024E5000-00 FA2XXX FDR Interface Cable L-3 Com. FA2100 Software Upload Test Equipment, Cable Assemblies & Software (ROC/6) Part Number 17TES0400 Description Mfg. Read-Out Center/6 − Full CVR/FDR Configuration (The following items are included with the ROC/6) L-3 Com. 17TES0410 Recorder Interface Unit (RIU) L-3 Com. 17TES0411 Cable, RIU to AC Power In L-3 Com. 17TES0412 Cable, RIU to DC Power In L-3 Com. 17TES0413 Cable, RIU to Sound Card (2ea.) L-3 Com. 17TES0414 GSE − Recorder Cable Assy to PC Line In L-3 Com. 23–70–04 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. Special Tools and Test Equipment Rev. 15 Page 901 Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 17TES0415 Cable, RIU to USB L-3 Com. 17TES0416 Cable, RIU to CVR L-3 Com. 17TES0417 Cable Assembly, Audio Setup L-3 Com. 17TES0420 CATS Software, FA2100 L-3 Com. 17TES0070 CICC/2 Assembly Dwg. L-3 Com. 17TES0071 Cable Assembly, F1000−CICC/2 L-3 Com. 17TES0072 Cable Assembly, FA2100−CICC/2 L-3 Com. 17TES0076 Recorder Interface, USB, Top Level L-3 Com. 17TES0321 Read-Out System Equipment Software (ROSE 3.4) L-3 Com. 17TES0057 Recorder Interface Cable Assembly L-3 Com. 17TES0058 FA2100 Software Upload Cable Assembly L-3 Com. 883E4557−00 CD, Soundblaster Audigy L-3 Com. 17TES0425 Speakers (110V) Optional 17TES0426 Speakers (220V) Optional FA2100 Software Upload Test Equipment, Cable Assemblies & Software (ROC/7) Part Number 17TES0700 Description Mfg. Read-Out Center/7 − Full CVR/FDR Configuration (The following items are included with the ROC/7) L-3 Com. 17TES0710 Recorder Interface Unit (RIU) L-3 Com. 17TES0411 Cable, RIU to AC Power In L-3 Com. 17TES0412 Cable, RIU to DC Power In L-3 Com. 17TES0413 Cable, RIU to Sound Card (2ea.) L-3 Com. 17TES0415 Cable, RIU to USB L-3 Com. 17TES0417 Cable Assembly, Audio Setup L-3 Com. 17TES0418 Cable, RIU to CVR L-3 Com. 17TES0420 CATS Software, FA2100, V. 2.0 L-3 Com. 17TES0070 CICC/2 Assembly Dwg. L-3 Com. 17TES0072 Cable Assembly, FA2100−CICC/2 L-3 Com. 17TES0076 (RUFS) Recorder Interface USB, Top Level L-3 Com. 17TES0321 Read-Out System Equipment Software (ROSE 4.5) L-3 Com. 23–70–04 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. Special Tools and Test Equipment Rev. 15 Page 902 Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 17TES0057 Recorder Interface Cable Assembly L-3 Com. 17TES0058 FA2100 Software Upload Cable Assembly L-3 Com. 883E4557−00 CD, Soundblaster Audigy L-3 Com. 17TES0426 Speakers (110V) Optional 17TES0426 Speakers (220V) Optional Note: The FA2100 Software Program P/N, listed below for the specific recorder, is needed to perform the upload function. 23–70–04 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. Special Tools and Test Equipment Rev. 15 Page 903 Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR FA2100 CVR Software Disk Part Number Description Mfg. 840E1658-07 FA2100CVR p/n: 2100-1010-00, 30-Min. Program Software L-3 Com. 840E1657-07 FA2100CVR, p/n: 2100-1020-00 120-Min. Program Software L-3 Com. 840E1663-07 FA2100 GACVR p/n: 2100-1010-50/51, 30-Min. Program Software L-3 Com. 840E1664-07 FA2100 GACVR, p/n: 2100-1020-50/51 120-Min. Program Software L-3 Com. 840E3408−07 FA2100CVR, p/n: 2100-1025-02 120-Min. Data Link L-3 Com. 840E3408−04 FA2100CVR, p/n: 2100-1025-12 CVR 120-Min. Data Link, (Cyrillic Russian Text)) L-3 Com. 840E4568−09 FA2100CVR, p/n: 2100-1025-22 CVR 120-Min. OMS Data Link L-3 Com. 804E4568−06 FA2100CVR, p/n: 2100-1025-24 CVR 120−Min. OMS Data Link, Bombardier Global L-3 Com. TBD FA2100CVR, p/n: 2100-1026-02 CVR 120−Min. OMS Data Link, Airbus L-3 Com. TBD FA2100CVR, p/n: 2100-1027-02 CVR 120−Min. OMS Data Link, Airbus L-3 Com. Note: The ADLP Software is only required for playback of the datalink data. FA2100CVR P/N: 2100−1025−02/−12./−22, 2100−1026−02 and 2100−1027−02. CATS 2.0 or higher is required for Return to Service. Audio Data Link Player (ADLP) Software Part Number 17TES0436 Description Mfg. Audio Data Link Player Software, Version 3 L-3 Com. 23–70–04 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. Special Tools and Test Equipment Rev. 15 Page 904 Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 2. GROUND SUPPORT EQUIPMENT (GSE) DESCRIPTIONS A. Portable Interface Unit, p/n: 17TES0043 Refer to Figure 901 and Figure 902. The Portable Interface (PI) Unit, Part Number 17TES0043, can be used to check the recorder status and download FA2100CVR audio data from the recorder to the PI Memory Module, Part Number 17TES0053, while installed in the aircraft. On the bench, the PI Unit can also be used to monitor audio channels, playback audio data, check the recorder status, clear latch faults and fault history logs. For these procedures, refer to the Portable Interface Unit Operating Manual p/n: 165E1630-00. B. FA2100 Software Upload Cable Assembly & Distribution Diskettes In the event that the Acquisition Processor PWA, p/n: 205E1591-00, p/n 205E1931-00 or p/n: 205E2502-10/-11, requires replacement, the FA2100CVR program software must be loaded into the new board using the FA2100 Software Upload cable assembly, p/n: 17TES0058, the FA2100 Software Utility Bundle Program, p/n: 883E1894−01 which contains the CICCLDR and CICCIFC executable files. The Utility Programs are also found on the ROSE Distribution CD, p/n: 17TES0321. The Software Upload cable assembly is connected between the FA2100 front panel GSE/ATE connector and the Computer Interface and Communications Cable (CICC or CICC/2) cable to an enhanced parallel port of a PC. For the the procedure to install the Software Upload Utility and CICC Interface Programs into the ROC/5 or ROC/6 Ground Station, and the procedure to upload the FA2100 Software into the recorder, refer to Test and Troubleshooting Section, 100, Paragraph 10. 23–70–04 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. Special Tools and Test Equipment Rev. 15 Page 905 Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR CVR: MONITOR PLAYBACK TO RECORDER GSE CONNECTOR STATUS / CONTROL SPECIAL FUNCTIONS GMT/ROTOR FSK AUDIO SELECT DELETE MENU Sarasota, Florida PI AUX READOUT CABLE 17TES0052 PI AUDIO READOUT CABLE 17TES0051 CH 1 HQ SQ 2 3 COMB 4 CAM Figure 901. Portable Interface Unit, p/n: 17TES0043 23–70–04 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. Special Tools and Test Equipment Rev. 15 Page 906 Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR MAIN MENU CVR: MONITOR PLAYBACK MONITOR MENU PLAYBACK MENU CVR PLAYBACK MODE: STOP POSITION: HRS : MIN : SEC ROTOR: __HZ GMT: (PLAY) STATUS / CONTROL (STOP) KEYPAD SPECIAL FUNCTIONS (RWD) (FFWD) STATUS / CONTROL MENU OFF/ON CH 4 ** SQ VOICE CH 1−3 OFF/ON ** SQ CAM CH 4 OFF/ON MODE: NORM UP VOLUME: DOWN PLAYBACK CONTROL MENU VERSION ID: CVR RUN STATUS SET / CLEAR TEST CNDTNS DELETE FILE FROM DISK (A) DISPLAY GMT/ROTOR (B) (C) (D) TRACE MSGS TO FILE HQ CAM CTRL MENU SPECIAL FUNCTIONS MENU FAULT LOG TO FILE OFF/ON OFF/ON OFF/ON RED KEY (END/BEGIN) (F) HQ VOICE CH 1 CH 2 CH 3 CVR SUPER FR #: (1 Sec Samples) CVR PLBK OFFST: 0:00 CVR FAULT STAT: NODAT ** ** HQ VOICE CH 1 OFF/ON CH 2 OFF/ON CH 3 OFF/ON HQ CAM CH 4 OFF/ON SQ VOICE CH 1−3 OFF/ON SQ CAM CH 4 OFF/ON FILE BACK UP VOLUME: VERSION MENU SET / CLEAR TEST CNDTNS MENU CVR FILE CONTROL MENU PORTABLE INTERFACE PI S/W VERSION 1.2 CLEAR LATCHED FAULT FA2100 REV. NO. −OO CLEAR FAULT LOG SMP VERSION: X.X. DOWN CVR FILE CONTROL FILE NAME: XXXX.CVR FILE ID: XXXX (DATE RECORD MADE) 03−APR−1999 (TIME RECORD MADE) 11: 30:10 (HRS :MIN:SEC) (FILE SIZE:) XXXXX Kbytes (RECORD DURATION) HR:MIN:SECS BACK COPY PLAY CVR FAULT : GSE : ON CVR FAULT : GSE : OFF CVR FAULT : GSE :RELEASE SMP CHECK SUM: XXXX (E) CVR COPY MENU FILE ID :_ (11CHAR LIMIT) A B C D E F G H I J K L M N O P Q R S T U V W X Y Z . : − / + _ # & $ @ < > ! 0 1 2 3 4 5 6 7 8 9 CLEAR START COPY TIME REMAINING CVR COPY FOR CVR DATA COPY HR:MIN:SEC ** Note: SQ Voice and SQ CAM are not available for p/n: 2100−1025−02 since it is a two−hour HQ Recorder. START COPY 23–70–04 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. Special Tools and Test Equipment Rev. 15 Page 907 Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR Figure 902. Sheet 1 of 2 Portable Interface (PI) Unit, CVR Menu Structures. (A) (B) FILE DELETION MENU FILE DELETION (FILE NAME): XXXX.CVR (FILE ID): XXXX DATE: 0I−JAN−1999 TIME RECORDED: HRS : MIN : SEC FILE SIZE: XXX Kbytes FILE DURATION: HRS : MIN : SEC BACK DELETE DISPLAY GMT/ROTOR DELETE THIS FILE: ROTOR: XXXX HZ XXXX.CVR GMT:: X:XX::XX ARE YOU SURE? YES NO (F) (C) (E) FAULT LOG TO FILE FILE ID :_ (11 CHAR LIMIT) A B C D E F G H I J K L M N O P Q R S T U V W X Y Z . : − / + _ # & $ @ < > ! 0 1 2 3 4 5 6 7 8 9 FILE PLAYBACK MENU FILE ID : XXXX MODE: PLAY POSITION: 00:00:00 ROTOR: Hz GMT:: X:XX:XX (PLAY) DUMPING FAULT LOG TO: XXXX.FLT KEYPAD (RWD) This halts recording. CLEAR START (STOP) (FFWD) (END/BEGIN) CTRL MENU (D) TRACE MESSAGES FILE ID :_ (11 CHAR LIMIT) A B C D E F G H I J K L M N O P Q R S T U V W X Y Z . : − / + _ # & $ @ < > ! DUMPING TRACE LOG TO: XXXX.TRC Press MENU to end. 0 1 2 3 4 5 6 7 8 9 CLEAR START Note: Data enclosed in parentheses does not appear on the PI menus and is provided in these figures for clarification . Figure 902. Sheet 2 of 2 Portable Interface (PI) Unit, CVR Menu Structures 23–70–04 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. Special Tools and Test Equipment Rev. 15 Page 908 Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR ROSE/RI SOFTWARE 17TES0321 (CDROM) FA2100 SOFTWARE DISTRIBUTION DISK 840‐EXXX‐XX Power Input Select Note: TO ENHANCED PARALLEL PORT LPT‐1 (EPP) RECORDER USB FDAU SIMULATOR (RUFS) (RI) ADAPTER 17TES0076 Firmware Distribution Diskette P/N will match the FA2100 Software Part Number located on the recorder 's Name Plate Label. CICC/2 COMPUTER INTERFACE COMMUNICATIONS CABLE/2 17TES0070 FA2100 TO CICC/2 COMPUTER INTERFACE COMMUNICATIONS CABLE 17TES0072 RECORDER INTERFACE (RI) CABLE ASSY. 17TES0057 READ-OUT CENTER/6 or /7 17TES0400 or 17TES0700 Note: Typical view of the back of the computer. Views may vary depending on the computer AC INPUT FA2100 SOFTWARE UPLOAD (BOOTLOAD) CABLE ASSEMBLY 17TES0058 (use for software uploading only) DC INPUT Note: RI = Recorder Interface. ROSE = Read‐Out Support Equipment. ROC = Read‐Out Center (ROC/5, /6 or /7) Note: The ROC rear connections shown in this diagram are for general reference and may not reflect the exact connector location or configuration your ROC system computer. Note: The 17TES0058 cable assembly should only be attached during upload process. Not used when downloading data or getting recorder status. FA2100 CVR RECORDER Figure 903. FA2100CVR Software Upload Connections Using Computer Interface & Communications Cable (CICC) 23–70–04 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. Special Tools and Test Equipment Rev. 15 Page 909 Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR P2 28VDC 115VAC 36.0 .2 P1A P1 2 3 9 17 18 19 115VAC HOT 115VAC COLD P2 28VDC GND FDR DATA OUT LO * FDR DATA OUT HI * MONITOR WIRE A 23 MONITOR WIRE B * 24 27 28 29 38 22 19 15 14 16 17 FDR DATA IN LO * FDR DATA IN HI * ACID 6 * ACID 7 * 13 12 2 1 * These signal lines are not used with the FA2100CVR, they are used with the Combi Recorder CVDR. Figure 904. Recorder Interface Cable Assembly P/N: 17TES0057 23–70–04 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. Special Tools and Test Equipment Rev. 15 Page 910 Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR CICC/2 PNR 17−TES0070 3.3 + .2 SER XXXXXXXXX MFR 06141 DMF MMYYYY 4.4 + .2 3 fT + 2 IN 1.4 + .2 NOTE: MUST BE USED WITH VER ROSE 3.2/RI 2.0 OR HIGHER SOFTWARE Figure 905. (Sheet 1 of 2) Computer Interface Communications Cable/2 (CICC/2) P/N: 17TES0070 23–70–04 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. Special Tools and Test Equipment Rev. 15 Page 911 Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR P1 − POSITRONICS MC8122D−1038.0 P2 CONN PN AMP 749210−5 SHELL PN AMP 749193−2 10 FT + 3 IN PIN−1 50 PIN CICC/2 P2 − SCSI CONN 26 PIN FA2100 P1 − DB CONN 1 GSS_PWR 2 GSE_PWR GND 2 1 GND TDM_CLK_HI 3 23 SER_D0_RX_HI TDM_CLK_LO 4 24 SER_D0_RX_LO TDM_FRM_HI 5 28 SER_D1_RX_HI TDM_FRM_LO 6 29 SER_D1_RX_LO TDM_ADD_HI 7 17 SER_C0_I0_HI TDM_ADD_LO 8 18 SER_C0_I0_LO 11 12 SER_B0_RX_HI 46 CABLE_0 GND 11 SER_FS_AP_HI 10 SER_FS_AP_LO 19 SER_B0_RX_LO PRGM_VPP_AP 12 PRGM_VPP_SW 13 SER_CLK_HI 14 15 3 4 SER_A0_I0_HI SER_CLK_LO SER_A0_I0_LO SER_DAT_AP_HI 16 15 SER_B1_RX_HI SER_DAT_AP_LO 17 16 SER_B1_RX_LO TDM_DAT_HI 9 19 SER_C1_I0_HI TDM_DAT_LO 18 20 SER_C1_I0_LO SER_DAT_PI_HI 20 9 SER_B0_TX_HI SER_DAT_PI_LO 21 10 SER_B0_TX_LO SER_FS_PI_HI 22 13 SER_B1_TX_HI SER_FS_PI_LO 23 14 SER_B1_TX_LO SEL_SMP/FDP 24 21 SER_D0_TX_HI TEST_MODE_L 25 47 CABLE_1 GSE_PORT_EN 26 48 CABLE_2 49 CABLE_3 NOTE: MUST BE USED WITH VER ROSE 3.2/RI 2.0 OR HIGHER SOFTWARE Figure 905. (Sheet 2 of 2) FA2100 − CICC/2 Interface Cable Assembly P/N: 17TES0072 23–70–04 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. Special Tools and Test Equipment Rev. 15 Page 912 Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR TO PI OR CICC OR CICC/2 INTERFACE TO FA2100 P1 AMP 748747-1 P2 AMP 748640-1 4.0 .5 P1 PIN1 P2 GSS_PWR 1 39VDC_RTN 2 TDM_CLK_HI 3 TDM_CLK_LO 4 TDM_FRM_HI 5 1 2 3 4 5 6 TDM_FRM_LO 6 7 TDM_ADD_HI 7 8 TDM_ADD_LO 8 TDM_DAT_HI 9 TDM_DAT_LO 18 SER_FS_AP_HI 10 SER_FS_AP_LO 19 GND 11 SEL_SMP/FDP 24 12 PRGM_REC_L PIN1 9 18 10 19 11 24 12 PRGM_VPP_SW 13 13 SER_CLK_HI 14 15 16 SER_CLK_LO SER_DAT_AP_HI 14 15 16 SER_DAT_AP_LO 17 20 21 22 SER_DAT_PI_HI SER_DAT_PI_LO SER_FS_PI_HI SER_FS_PI_LO 23 17 20 21 22 23 TEST_MODE_L 25 26 25 GSE_PORT_EN 26 Figure 906. Programmers Adapter Cable Assembly P/N: 17TES0058 23–70–04 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. Special Tools and Test Equipment Rev. 15 Page 913 Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR CVR AUTOMATED TEST SOFTWARE (CATS) 17TES0420 J4 USB 4‐PIN RIU UNIVERSAL SERIAL BUS INTERFACE 17TES0415 POWER INPUT SELECT RIU DC POWER INPUT 17TES0412 (DC)- J8 RIU AC POWER INPUT 17TES0411 (AC)- J7 DC AC 5A 1A RECORDER INTERFACE UNIT (RIU) J4 17TES0410 USB R-SPKR * GREEN REAR CONNECTOR INTFC GSE INTFC J9 RCDR AC PWR TEST J1 SPKRS SND OUT OUT BLUE SOUND CARD DC RED LIGHT YELLOW LIGHT AC SND IN J2 J6 J5 J3 L-SPKR * SND OUT - GREEN 17TES0413 SND IN - BLUE 17TES0413 J6 RIU AUDIO OUTPUT (SPKRS) ROC/6 17TES0400 FA2100 SOFTWARE UPLOAD CABLE ASSEMBLY 17TES0058 (use for software uploading only) RECORDER INTERFACE CABLE ASSY. 17TES0416 (FA2100‐CICC/2) COMPUTER INTERFACE COMMUNICATIONS CABLE ASSY. 17TES0072 * Note: Speakers are optional and not incld with ROC/6 To order speakers from L-3AR use: p/n: 17TES0425 (110V) or 17TES00426 (220V). FA2100 CVR RECORDER Figure 907. ROC/6 w/CVR Automated Test Station Software (CATS) FA2100CVR TEST SETUP 23–70–04 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. Special Tools and Test Equipment Rev. 15 Page 914 Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR P2 P1 P3 120 Signal Name From To 6.0 IN Signal Name From To CHANNEL 1 AUDIO IN LO P1−30 P2−30 PWR IN 115 VAC (HOT) P1−2 P3−1 DATA LINK FAULT P1−31 P2−5 PWR IN 115 VAC (COLD) P1−3 P3−2 CHANNEL 1 AUDIO IN HI P1−32 P2−32 INDICATOR PWR P1−4 P2−22 DATA LINK IN (429) (B) P1−33 P2−34 AUDIO OUT LO P1−5 P2−1 DATA LINK IN (429) (A) P1−34 P2−33 AUDIO OUT HI P1−6 P2−6 CHANNEL 2 AUDIO IN LO P1−35 P2−35 RECORD ENABLE B P1−7 P2−8 FDR STATUS P1−36 P2−20 RECORD ENABLE A P1−8 P2−7 CHANNEL 2 AUDIO IN HI P1−37 P2−37 PWR IN +28 VDC 9HOT0 P1−9 P2−9 FDR WORD RATE B P1−38 P2−38 STOP CVR RECORDING P1−10 P2−10 OMS IN B (AIRBUS ONLY) P1−39 P2−39 PUSH−TO−TEST P1−12 P2−12 OMS IN A (AIRBUS ONLY) P1−40 P2−34 PREAMP PWR OUT GND P1−13 P2−13 CHANNEL 3 AUDIO IN LO P1−41 P2−41 PREAMP PWR OUT HOT P1−14 P2−14 CVR IDENT PIN P1−43 P2−4 RESERVERED TEST IND + P1−15 P2−15 CHANNEL 3 AUDIO IN HI P1−43 P2−43 RESERVERED TEST IND − P1−16 P2−16 CHANNEL 4 AUDIO IN LO P1−45 P2−45 CHASSIS GND−DC RET P1−17 P2−17 FDR MAINTENANCE P1−46 P2−21 FDR DATA OUT B (LO) P1−18 P2−18 CHANNEL 4 AUDIO IN HI P1−47 P2−47 FDR DATA OUT B (HI) P1−19 P2−19 ROTOR SPEED IN (LO) P1−48 P2−48 INT PREAMP ATTEN (−6 dB) P1−20 P2−58 ROTOR SPEED IN (HI) P1−49 P2−49 INT PREAMP ATTEN (−12 dB) P1−21 P2−59 DATA LINK V1 OUT B P1−50 P2−50 INT PREAMP ATTEN (−24 dB) P1−22 P2−60 DATA LINK V1 OUT A P1−51 P2−51 CVR FAULT OUT P1−23 P2−23 VOICE ERASE A P1−55 P2−36 FDR FAULT OUT P1−24 P2−24 DATA LINK VALID P1−56 P2−66 GMT IN (429) (B) P1−25 P2−25 VOICE ERASE A P1−57 P2−57 GMT IN (429) (A) P1−26 P2−26 FDR DATA IN B (LO) P1−27 P2−27 FDR DATA IN B (HI) P1−28 P2−28 FDR WORD RATE A P1−29 P2−29 Figure 908. Recorder Interface Cable Assembly, 17TES0416 23–70–04 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. Special Tools and Test Equipment Rev. 15 Page 915 Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 1 3 2 1 CABLE, PWR, AC 2 LABEL, “115V/400Hz” 3 LABEL, “17−TES0411” Figure 909. AC 115 VAC/400Hz Power Input Cable Assembly P/N: 17TES0411 4 Strip and Tin 144.0 1.0 IN 2X 2.00 .13 IN 2X 1.00 .13 I 2* 5 (See Note) * WIRE CHART BLACK OUTER WHITE INNER 1 3 Note: TRIM SHIELD EVEN WITH OUTER JACKET. APPLY SLEEVING ITEM 5 OVER OUTER JACKET TRANSITION 1 WIRE, # 22, STRD, 2 COND, SHLD 2 CONN, DC PWR PLUG 3 LABEL, “DC POWER” 4 LABEL, “17−TES0412” 5 TBG, 3/16, THERMO−FIT, BLK Figure 910. DC +28VDC Power Input Cable Assembly P/N: 17TES0412 23–70–04 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. Special Tools and Test Equipment Rev. 15 Page 916 Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR LOOP BACK CONNECTOR Figure 911. Audio Setup Cable Assembly, 17TES0417 MICROPHONE SWITCH INT EXT INPUT 35 40 30 45 KHZ TUNNING OFF GAIN BAT. TEST OK AUDIO OUTPUT ULTRASONIC TEST SET MODEL 42A12( ) UNDERWATER LOCATOR DEVICE 42A12( ) ULTRASONIC TEST SET Figure 912. ULD Test Set-Up C. Audio Data Link Player Software The FA2100CVR Audio & Data Link Player (ADLP) software provides a user−friendly interface for initiating audio and data link message retrieval and playback functions for the Model FA2100CVR, part number 2100−1025−( ). It also provides the capability to decompress the data into standard waveform audio files (.wav) for playback using conventional audio media players. 23–70–04 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. Special Tools and Test Equipment Rev. 15 Page 917 Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR All other Model FA2100CVR part numbers can use this utility software to playback the CVR audio data but will not be able to analyze any data link messages since these other CVR part number recorders do not support the recording of data link messages. (1) Hardware Requirements for Audio & Data Link Player Software The ADLP software, p/n: 17TES0436, is designed to operate on an IBM/IBMcompatible computer containing specific required hardware. Assembly is a standard personal computer with tower case; includes the following standard features and may include features not listed hereon. Upgraded features are acceptable. Dual core CPU 2.5 GHz or greater Motherboard with EPP support, compatible with PCMCIA reader (below) Four USB 2.0 connections 4 GB or greater memory 17” SVGA Color LCD Monitor and Graphics Adapter Must support 1024x768 and 1280 x 1024 Samsung SyncMaster 710n is an example of a compliant monitor 300 GB Hard Drive 7200 RPM or better 8x4x32X (or better) CD−RW/DVD−RW 104 Keyboard Windows 7 Professional 32−bit edition OS 2−Button Mouse Ethernet 100 MHz or greater 2nd Ethernet (Intel Pro/100m PCI or equivalent) Audigy sound card PCMCIA Dual Slot PCI installed in 3.5” External Bay Must be compatible with motherboard above Envoy Data EDC−F2PCI is an example of compliant reader (2) System must be CE and suitable for export. (3) Associated user/installation manuals and CDs are to be included with computer. Table 902. Specification Control Drawing Configuration −00 Next Assy No. Used On Audio Data Link Player Software, Version 3 ROC/7 23–70–04 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. Special Tools and Test Equipment Rev. 15 Page 918 Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR (4) Hardware Requirements for Downloading CVR Data The FA2100CVR must be removed from the aircraft prior to downloading voice data. Data Link messages, however, can be downloaded while the recorder is on the aircraft as this data is accessed in a similar manner to standard flight data. There are two methods to download audio and data link information from the Model FA2100CVR memory: (a) Directly download into either a ROC or RAU using the Computer Interface Control Cable Interface (CICCIfc) utility software in conjunction with the CICC/2 Interface Cable assembly; p/n: 17TES0070 & 17TES0072. (b) Using the Portable Interface (PI) Unit, p/n: 17TES0043 with Mod−Dot #6. This device is used to download the FA2100CVR voice and data link information to a PCMCIA memory card which then can be transferred into either a ROC or RAU that has the ADLP software installed for playback. For detailed operational instructions, refer to the Audio Data Link Player Software Operator’s Manual, P/N: 165E3596−00. D. CVR Download Cable Cable can be used to downloaded data while the recorder is on the aircraft using the Portable Interface Unit. The data in the CVR can not be erase while using the cable. Refer to the Installation and Operation Manual, Cockpit Voice Recorder, Model FA2100CVR, Part Number 165E1846-00.33 23–70–04 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. Special Tools and Test Equipment Rev. 15 Page 919 Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 60in."6 in. P1 J1 P1 J1 115 VAC HOT 2 2 115 VAC HOT AC COMMON COLD 3 3 AC COMMON COLD 5 5 6 6 7 7 8 8 9 9 +27.5 VDC INPUT +27.5 VDC INPUT 10 10 12 12 13 13 14 14 15 15 16 CHASSIS GND 17 16 57 57 CONNECTS TO FA2100 CVR 17 CHASSIS GND CONNECTS TO CVR TRAY Figure 913. FA2100CVR Download Cable, p/n 17TES0078, Wiring Diagram 23–70–04 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. Special Tools and Test Equipment Rev. 15 Page 920 Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version. AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR ILLUSTRATED PARTS LIST 1. GENERAL This section contains the following sections: introduction, equipment designator list, numerical index, and detailed parts list. The introduction of this section describes usage of the IPB, a listing of abbreviations, and a list of vendor names, addresses, and codes per the current issue of “Federal Supply Code for Manufacturers”, catalog handbook H4–1. The Equipment Designator Index provides a cross reference from manufacture reference designator to manufacturing part number. The Numerical Index provides a numerical listing of all manufacturing part numbers. 2. PURPOSE The purpose of this Illustrated Parts List is to assist maintenance and supply personnel in requisitioning, storing, issuing and identifying parts to maintain the FA2100 Cockpit Voice Recorder. This Illustrated Parts List is not to be taken as the authority for the procedure of assembly or disassembly. Overhaul or repair should be done by authorized personnel only. 3. ABBREVIATIONS The following abbreviations are used in this section: Abbreviation AR ASSY EFF FIG NHA NO RF Meaning As Required Assembly Effectivity Figure Next Higher Assembly Number Reference 4. EQUIPMENT DESIGNATOR INDEX The Equipment Designator Index is an index of designators assigned to electrical parts as shown in electrical wiring and schematic diagrams. Since Level 2 repair is the maintenance philosophy of the FA2100CVR, there are no Equipment designators listed. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Illustrated Parts List Rev. 15 Page 1001 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 5. NUMERICAL INDEX The Numerical Index is a complete listing of parts included in the Detail Parts List, cross– referenced to the applicable figure and item number, L-3’s part numbers, the manufacturer’s part numbers and total quantity required. Part numbers are arranged in a alphanumerical sequence beginning at the extreme left– hand position and continue from left to right, one position at a time. The order to precedence in beginning the part number arrangement is as follows: A. Letters A through Z (Alphabetical Os are considered as numerical zeros). B. Numerals 0 through 8. Part number entry is limited to a single line and does not exceed fifteen characters. The FIGURE number and ITEM number columns contain the figure and item number(s) for all parts listed. When more than one figure and item number are shown for the same part number, the part number is not repeated. 6. DETAIL PARTS LIST The Detail Parts List consists of illustrations and columnar parts breakdown of the component and all assemblies, subassemblies, and parts that can be disassembled, repaired and reassembled, or replaced. Items that are riveted, welded or spun over are not listed. Parts made of bulk stock such as wire, tape or bonding braid are also not listed. Illustrations are each assigned a figure number, commencing with Figure 1 and progressing in sequence. The FIGURE AND INDEX NUMBER column reflects the assigned figure number of the illustration in which the item is shown and the item number listed on the illustration. Figure numbers are shown for the first entry of each figure and at the top of each subsequent column. When there is more than one type of subassembly for the same function additional figures are included with the same number, but followed by an additional alpha designator (such as A, B, etc.). Each part number listed in the Detail Parts List is assigned an index number. Index numbers begin with number 1 for each illustration and in broken sequence to facilitate the insertion of new items which are not variants of existing items. Items listed but not illustrated are identified by a dash to the left of the index number. The PART NUMBER column contains the manufacturer’s part number when the part is purchased from a source other than Aviation Recorders, or the Aviation Recorders part number for those parts which must be purchased from Aviation Recorders Division. When the manufacturer’s part number is used for any parts, the Aviation Recorders num- Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Illustrated Parts List Rev. 15 Page 1002 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR ber is also shown enclosed in parentheses in the NOMENCLATURE column. When standard parts (such as MS, AN, RC, CP, etc.) are used, vendor codes are not assigned to these parts. However, for non–standard parts the vendor code is assigned in the NOMENCLATURE column and is preceded by the letter “V.” It corresponds to the Federal Supply Code for Manufacturers, (FSCM) now known as Commercial and Government Entity (CAGE) as listed in Cataloging Handbook H4/H8. When a part has multiple vendors, all part numbers are listed in the PART NUMBER column. The first vendor will be assigned an item number and each subsequent part number is assigned the same item number with an alpha variant. The NOMENCLATURE column describes the part or assembly. Nomenclature wording is arranged so that the identifying noun or key word is always the first part of the description; this is followed by modifying words. Standard abbreviations are used as necessary. Assemblies which are not broken down within a listing but which are covered by a separate figure will carry the notation “(SEE FIG. – FOR DETAIL BREAKDOWN).” The listing of the assembly in the breakdown figure will carry the reference “(SEE FIG. – FOR NHA)”. If the vendor is not L−3 Aviation Recorders, the manufacturer’s vendor code may be included in parentheses in this column. The indenture system, provided by the numbers “1” through “6” in the heading, shows the relationship of one part to another; for example, a part listed under indenture “3” is a component of the assembly listed under indenture “2” immediately above it. Items used to attach parts or assemblies to each other are designated “ATTACHING PARTS” and are listed immediately following the item or items they attach. The symbol “* * *” denotes the end of attaching parts. The EFFECTIVITY CODE column establishes parts’ relationship with units or assemblies which are essentially the same but have variations. These units or assemblies are the lead times on each figure. These units or assemblies are assigned reference letters such as A, B, C, D, etc. Parts which are not common to all configurations but are associated with one or more of the coded lead items carry the letter or letters assigned to the lead item with which it is associated. If a part is common to all lead items, the EFFECTIVITY CODE column is blank. The UNITS PER ASSY column lists the quantity of the item required in one assembly in which it is a component. It is, therefore, not necessarily the total quantity of the part required in the complete equipment; the equipment total can be found in the Numerical Index. The term “RF” denotes that the assembly has been previously listed in the parts breakdown. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Illustrated Parts List Rev. 15 Page 1003 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 7. PART NUMBERING L−3AR does not delineate its part numbers by special characters, such as the “−” dash character. L−3AR considers its part numbers with or without the use of special characters to be the same, for example, there is no difference between part number 266−E0305−00, 266E0305−00, or 266E030500. To be in compliance with ARINC Specifications 100 and 200 the part numbers listed in this manual use the following format: 266E0305−00. L−3AR typically identifies its part numbers on other documents such as internal engineering drawings, purchase orders, component labels, shipping orders, Form 8130’s, and certification documents with the format: 266−E0305−00. 8. MANUFACTURER’S CODE Due to the Level−2 maintenance philosophy used with the FA2100 CVR, all spare parts will be ordered through L−3 Communications. L3AR Vendor Code, manufacturer name and address, as listed in the “Federal Supply Codes for Manufacturers” Cataloging Handbook H4/H8, Commercial and Government Entity (CAGE) codes, (formerly FSCM), and/or the NATO Code as applicable (Ref. ATA Spec. 200), is listed below. The CAGE code is the vendor (V) code listed in parentheses in the NOMENCLATUE column of the Detailed Parts List. Code V06141 Manufacturer L-3 Aviation Recorders 100 Cattlemen Road Sarasota, FL 34232 9. L−3 AVIATION RECORDERS (L−3AR) AUTHORIZED PARTS L−3AR has performed additional environmental testing on the Stainless and Titanium Crash−Survivable Memory Units (CSMU) for all Models of recorders using the L−3AR 90−Day Underwater Locator Beacon, PN 266E5542−00, and mounting screws that make up the ULB Conversion Kit, p/n: 068E5542−00. These tests were conducted to ensure that the transition from the 30−day ULB to 90−Day ULB for CSMUs used on all Models of L−3AR Recorders meet the requirements of DO−160G Vibration and ED−112A Beacon Shear and Tensile Test. The results of these tests are contained in the following L−3AR Environmental Test Reports, Document Numbers: F ENV284 − MODELS FA2100 Style CSMUs: All Part Numbers: FA2100CVR, FDR, CVDR, MADRAS, DASU & APR2500. F ENV285 − Models FA5000 − Titanium CSMUs: All Part Numbers: FA5000CVR, FDR, CVDR & MADRAS F ENV286 − SRVIVR Style CSMUs: All Part Numbers: SRVIVRCVR, FDR & CVDR Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Illustrated Parts List Rev. 15 Page 1004 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR To ensure integrity of the locating device function and the FAA Manufacturing Inspection District Office (MIDO) approved installation and assembly of all L−3AR Recorder models, it is required that only the L-3AR ULB Conversion Kit, p/n: 068E5542−00 be used when converting from a 30−Day ULB to a 90−Day ULB. Also the four attaching ULB hex−screws (1−75) must be replaced when the 90−Day ULB is removed or replaced. Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Illustrated Parts List Rev. 15 Page 1005 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 10. CONFIGURATION MATRIX Listed below are the current configurations for the FA2100 Cockpit Voice Recorder (CVR). Part Number 2100-1010-( ) is capable of storing 30 minutes of voice data while p/n: 2100-1020-( ) is capable of storing 2 hours of voice data, p/n: 2100−1020−02 has FSK capability, p/n: 2100−1025/1026/1027−( ) has OMS capability. 2100−1010−00 ARINC 757, 30 MIN. CVR, 1/2 ATR SHORT 2100−1010−50 ARINC 757, 30 MIN. GA CVR, 1/2 ATR SHORT, 28 VDC ONLY 2100−1010−51 ARINC 757, 30 MIN. GA CVR, 1/2 ATR SHORT, TITANIUM CSMU W/ RTV, 28 VDC ONLY 2100−1020−00 ARINC 757, 2−HR. CVR, 1/2 ATR SHORT 2100−1020−02 ARINC 757, 2−HR. CVR W/ FSK 2100−1020−50 ARINC 757, 2−HR. GA CVR, 1/2 ATR SHORT, 28 VDC ONLY 2100−1020−51 ARINC 757, 2−HR. GA CVR, 1/2 ATR SHORT, TITANIUM CSMU W/ RTV, 28 VDC ONLY 2100−1025−02 ARINC 757, 2−HR. CVR W/ OMS, 4 CHANNEL HIGH QUALITY 2100−1025−12 ARINC 757, 2−HR. CVR W/ OMS, 4 CHANNEL HIGH QUALITY (CYRILLIC) 2100−1025−22 ARINC 757, 2−HR. CVR W/ OMS, 4 CHANNEL HIGH QUALITY W/ RIPS 2100−1025−24 ARINC 757, 2−HR. CVR W/ OMS, 4 CHANNEL HIGH QUALITY W/ RIPS S/W 2100−1026−02 ARINC 757, 2−HR. CVR W/ OMS, 4 CHANNEL HIGH QUALITY W/ RIPS 2100−1027−02 ARINC 757, 2−HR. CVR W/ OMS, 4 CHANNEL HIGH QUALITY W/ RIPS 2100−1220−00 ARINC 757, 2−HR. CVR, 1/2 ATR SHORT, 90−DAY BEACON 2100−1220−02 ARINC 757, 2−HR. CVR W/ FSK, 90−DAY BEACON 2100−1225−22 ARINC 757, 2−HR. CVR W/ OMS, 4 CHANNEL HIGH QUALITY W/ RIPS, 90−DAY BEACON 2100−1225−24 ARINC 757, 2−HR. CVR W/ OMS, 4 CHANNEL HIGH QUALITY W/ RIPS S/W, 90−DAY BEACON 2100−1226−02 ARINC 757, 2−HR. CVR W/ OMS, 4 CHANNEL HIGH QUALITY W/ RIPS, 90−DAY BEACON 2100−1227−02 ARINC 757, 2−HR. CVR W/ OMS, 4 CHANNEL HIGH QUALITY W/ RIPS, 90−DAY BEACON 2100−1925−22 ARINC 757, 2−HR. CVR W/ OMS, 4 CHANNEL HIGH QUALITY W/ RIPS 90−DAY BEACON Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Illustrated Parts List Rev. 15 Page 1006 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR NUMERICAL INDEX PART NUMBER BB1P061H05 BB1P141H16 MS15795−803 MS16995−52 MS16995*54 MS21044C04 MS24693−C26 MS24693−C4 MS24693−C4 MS24693−C6 MS24693−C7 MS51957−14 MS51957−14 MS51957−14 MS51957−14 MS51957*28 MS51957*45 279800024 2290200365 2529800107 2739800201 9030100047 9030100047 9030100049 9030100075 016E1589−00 016E4797*00 016E5352−00 024E1620−00 024E1620−01 024E2659*01 024E3424*00 024E3424*03 027E1590*00 042E1597*00 042E1597*01 075E1598*00 AIRLINE PART NO. FIG. ITEM TTL REQ 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 25B 190B 145 190A 75 150 95 130 140 141A 141B 160 180 125A 125B 25A 60 225 127 235 152 205 245 240A 240B 70 146A 146B 165A 170A 165B 170B 165C 35 5A 5B 20A 10 4 2 4 4 2 8 4 2 2 2 4 10 6 7 10 4 1 1 1 1 1 1 1 1 2 1 1 2 1 1 2 1 1 1 1 1 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Illustrated Parts List Rev. 15 Page 1007 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR PART NUMBER 075E1806*00 111*98*00097 1256 (DEL.) 140E4207*00 147E1679−00 166*98*00359 (DEL.) 166*98*00361 (DEL.) 166E1594*00 166E1595*00 166E1647*00 191E1603−00 191E1603−01 192E1599*00 197E1746−00 205E1591−00 205E1593−00 205E1596−00 205E1763−00 205E1763−01 205E1763−11 205E1849−00 205E1849−02 205E1849−03 205E1849−04 (DEL.) 205E1849−10 205E1849−13 205E1849−14 (DEL.) 205E1849−17 205E1931−00 205E2502−10 205E2502−11 205E2502*14 205E2502−21 205E2502*24 205E2502*34 205E2502−38 205E2502−52 205E2503−01 AIRLINE PART NO. FIG. ITEM TTL REQ 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 20B 55 45 151 210 65 66 10 15 50 90A 90B 30 220 175A 105A 155A 105B 105C 105F 155B 155D 155C 155E 155F 155G 155H 155J 175B 175C 175D 175E 175G 175J 175K 175H 175F 105D 1 2 1 1 1 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 23–70–04 Illustrated Parts List Rev. 15 Page 1008 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR PART NUMBER 205E2503−05 205E2503−08 205E3977*10 205E3977*12 205E3977*13 205E3977*14 (DEL.) 205E3977*17 205E3977*20 205E3977*22 205E3977*23 205E3977*24 (DEL.) 205E3977*29 205E3977*37 2100*1010*00 2100*1010*50 2100*1010*51 2100*1020*00 2100*1020*02 2100*1020*50 2100*1020*51 2100*1020*90 (DEL.) 2100*1020*91 (DEL.) 2100*1020*93 (DEL.) 2100*1025*02 2100*1025*12 2100*1025*22 2100*1025*24 2100*1026*02 2100*1027*02 2100*1220*00 2100*1220*02 2100*1225*22 2100*1225*24 2100*1226*02 2100*1227*02 2100*1925*22 229E0574*00 230E2520−00 AIRLINE PART NO. FIG. ITEM TTL REQ 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 105E 105G 155K 155L 155M 155N 155P 155R 155S 155T 155U 155V 155W 1A 1E 1F 1B 1C 1G 1H 1K 1D 1J 1L 1M 1N 1R 1P 1T 1U 1V 1W 1AA 1Y 1AB 1AC 40 200A 1 1 1 1 1 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 23–70–04 Illustrated Parts List Rev. 15 Page 1009 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR PART NUMBER 230E2521*00 230E5675*00 253E1568−00 253E1568−01 253E1568−06 253E1568−07 253E1568−33 253E1568−38 253E1568−39 253E1568−40 253E1568−41 253E4427-33 253E5675-00 253E5675-11 253E5675-20 266E0305−00 266E0305−01 266E0305−02 (DEL.) 266E5542−00 297−98−00087 297−98−00257 297−98−00283 297−98−00319 3M#7201 (DEL.) 742E1619−00 742E1619−03 9300−388 AIRLINE PART NO. FIG. ITEM TTL REQ 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 28 200B 185B 185A 185C 185D 185E 185F 185G 185H 185J 185K 185L 185M 185N 80A 80B 80C 80D 120A 115 110 120B 100 135A 135B 85 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 4 1 2 4 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 1 1 1 23–70–04 Illustrated Parts List Rev. 15 Page 1010 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 25 20 A B 80A 80B 80C 80D 185 A B 205 120 110 C 190 135 141 146 151 185 C 160 125 155 A B 115 200 165 (W2) 105 B A 170 (W1) 120 160 165 (W3) 180 5 175 10 15* (farside) Figure 1. (Sheet 1 of 2) Model FA2100 Cockpit Voice Recorder PN: 2100-1010-( ) & 2100-1X2X-( ) Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Illustrated Parts List Rev. 15 Page 1011 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR 125 151 141 146 141 141 90 130 B B View 95 80A/B/C REFERENCE ONLY 70 75 REPLACEMENT DATE 85 C 60 40 30 A 50 View View C 45 55 A Figure 1. (Sheet 2 of 2) Model FA2100 Cockpit Voice Recorder PN: 2100-1010-( ) & 2100-1X2X-( ) Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Illustrated Parts List Rev. 15 Page 1012 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR FIG. ITEM PART NUMBER UNITS PER EFF CODE ASSY AIRLINE NOMENCLATURE PART NO. 1234567 1 1A 2100−1010−00 COCKPIT VOICE RECORDER FA2100 CVR, ARINC 757, 30 MIN. CVR, 1/2 ATR SHORT (OBSOLETE) A RF 1B 2100−1020−00 COCKPIT VOICE RECORDER FA2100 CVR, ARINC 757, 2−HR. CVR, 1/2 ATR SHORT B RF 1C 2100−1020−02 COCKPIT VOICE RECORDER FA2100 CVR, ARINC 757, 2−HR. CVR W/ FSK, 1/2 ATR SHORT C RF 1D 2100−1020−91 DELETED 1E 2100−1010−50 COCKPIT VOICE RECORDER FA2100 CVR, ARINC 757, 30 MIN. GA CVR, 1/2 ATR SHORT, 28 VDC ONLY (OBSOLETE) E RF 1F 2100−1010−51 COCKPIT VOICE RECORDER FA2100 CVR, ARINC 757, 30 MIN. GA CVR, 1/2 ATR SHORT, 28 VDC ONLY, TITANIUM CSMU, W/ RTV F RF 1G 2100−1020−50 COCKPIT VOICE RECORDER FA2100 CVR, ARINC 757, 2−HR. GA CVR, 1/2 ATR SHORT, 28 VDC ONLY (OBSOLETE) G RF 1H 2100−1020−51 COCKPIT VOICE RECORDER FA2100 CVR, ARINC 757, 2−HR. GA CVR, 1/2 ATR SHORT, 28 VDC ONLY, TITANIUM CSMU, W/ RTV (OBSOLETE) H RF 1J 2100−1020−93 DELETED 1K 2100−1020−90 DELETED 1L 2100−1025−02 COCKPIT VOICE RECORDER FA2100 CVR, ARINC 757, 2−HR. CVR, 1/2 ATR SHORT, OMS L RF 1M 2100−1025−12 COCKPIT VOICE RECORDER FA2100 CVR, ARINC 757, 2−HR. CVR, 1/2 ATR SHORT, OMS (CYRILLIC) (RUSSIAN TEXT) M RF Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Illustrated Parts List Rev. 15 Page 1013 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR FIG. ITEM PART NUMBER UNITS PER EFF CODE ASSY AIRLINE NOMENCLATURE PART NO. 1234567 1 1N 2100−1025−22 COCKPIT VOICE RECORDER FA2100 CVR, ARINC 757, 2−HR. CVR, 1/2 ATR SHORT, OMS N RF 1P 2100−1026−02 COCKPIT VOICE RECORDER FA2100 CVR, ARINC 757, 2−HR. CVR, 1/2 ATR SHORT, OMS P RF 1R 2100−1025−24 COCKPIT VOICE RECORDER FA2100 CVR, ARINC 757, 2−HR. CVR, 1/2 ATR SHORT, OMS , RIPS S/W R RF 1T 2100−1027−02 COCKPIT VOICE RECORDER FA2100 CVR, ARINC 757A, 2−HR. CVR, 1/2 ATR SHORT, OMS T RF 1U 2100−1220−00 COCKPIT VOICE RECORDER FA2100 CVR, ARINC 757, 2−HR. CVR, 1/2 ATR SHORT, 90−DAY BEACON U RF 1V 2100−1220−02 COCKPIT VOICE RECORDER FA2100 CVR, ARINC 757, 2−HR. CVR W/ FSK, 1/2 ATR SHORT, 90−DAY BEACON V RF 1W 2100−1225−22 COCKPIT VOICE RECORDER FA2100 CVR, ARINC 757, 2−HR. CVR, 1/2 ATR SHORT, OMS, 90−DAY BEACON W RF 1Y 2100−1226−02 COCKPIT VOICE RECORDER FA2100 CVR, ARINC 757, 2−HR. CVR, 1/2 ATR SHORT, OMS, 90−DAY BEACON Y RF 1AA 2100−1225−24 COCKPIT VOICE RECORDER FA2100 CVR, ARINC 757, 2−HR. CVR, 1/2 ATR SHORT, OMS , RIPS S/W, 90−DAY BEACON AA RF 1AB 2100−1227−02 COCKPIT VOICE RECORDER FA2100 CVR, ARINC 757A, 2−HR. CVR, 1/2 ATR SHORT, OMS, 90−DAY BEACON AB RF 1AC 2100−1925−22 COCKPIT VOICE RECORDER FA2100 CVR, ARINC 757, 2−HR. CVR, 1/2 ATR SHORT, OMS, 90−DAY BEACON AC RF Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Illustrated Parts List Rev. 15 Page 1014 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR FIG. ITEM PART NUMBER UNITS PER EFF CODE ASSY AIRLINE NOMENCLATURE PART NO. 1234567 1 5A 042E1597−00 .CHASSIS, SHORT 1/2 ATR ARINC A, B, C, E, F, G, H, L, M, N, P, R, U, V, W, Y, AA, AC 1 5B 042E1597−01 .CHASSIS, SHORT 1/2 ATR ARINC, AP T, AB 1 10 166E1594−00 .TAPE, REFLECTIVE, ENGLISH FLIGHT RECORDER DO NOT OPEN 1 15 166E1595−00 .TAPE, REFLECTIVE, FRENCH ENREGISTREUR DE VOL NE PAS OUVRIR 1 20A 075E1598−00 .COVER, CHASSIS, SHORT A, B, C, L, M, N, P, R, T, U, V, W, Y, AA, AB, AC 1 20B 075E1806−00 .COVER, CHASSIS, SHORT, LIGHTWEIGHT E, F, G, H 1 ATTACHING PARTS − 25A MS51957−28 .SCREW, PAN HEAD, 6−32 x 3/8 (V06141) (2290200085) (SUPSD BY 25B PER SB004) 10 25B BB1P061H05 .SCREW, PAN HEAD, SEALING 6−32 x 5/16 (V06141) (2299800465) (SUPSDS 25A PER SB004) 10 28 230E2521−00 .SEAL, CHASSIS COVER, SHORT-BOX *** Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. A, B, C, L, M, N, P, R, T, U, V, W, Y, AA, AB, AC 23–70–04 Illustrated Parts List Rev. 15 Page 1015 Apr. 14/16 1 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR FIG. ITEM PART NUMBER UNITS PER EFF CODE ASSY AIRLINE NOMENCLATURE PART NO. 1234567 1 30 192E1599−00 .FRONT PANEL ASSEMBLY 1 35 027E1590−00 .CAP,PROTECTIVE METAL 1 ATTACHING PARTS 40 229E0574−00 .SCREW, JACK, KNURLED *** 1 − 45 1256 .DELETED 1 − 50 166E1647−00 .LABEL, IDENT, COCKPIT VOICE RECORDER 55 111−98−00097 .FASTENER, HOOK, NAS622 (V94867) (MFG. NO. HDH-4) 2 ATTACHING PARTS 60 MS51957−45 .SCREW, PAN HEAD, 8−32 X 1/2 (V06141) (2290200102) *** − 65 166−98−00359 .DELETED − 66 166−98−00361 .DELETED 70 016E1589-00 .BRACKET, BEACON, MOUNT 4 2 ATTACHING PARTS 75 MS16995−54 .SCREW, SCHCAP, 1/4−20 X 1−1/2 (V06141) (2290200424) *** 80A 266E0305-00 BEACON, ACOUSTIC, UNDERWATER (SUPSD BY 80D PER SB022) DUKANE (V94970) (DK-120) FOR BATTERY REPLACEMENT ORDER 30−DAY BATTERY KIT (147E0305−00) Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 4 A, B, C, E, F, G, H, L, M, N, P, R, T 23–70–04 Illustrated Parts List Rev. 15 Page 1016 Apr. 14/16 1 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR FIG. ITEM PART NUMBER UNITS PER EFF CODE ASSY AIRLINE NOMENCLATURE PART NO. 1234567 1 80B 266E0305-01 .BEACON, ACOUSTIC, UNDERWATER (SUPSD BY 80D PER SB022) DUKANE (V94970) (DK-120) FOR BATTERY REPLACEMENT ORDER 30−DAY BATTERY KIT (147E0305−00) A, B, C, E, F, G, H, L, M, N, P, R, T 1 80C 266E0305-02 .BEACON, ACOUSTIC, UNDERWATER, (SUPSD BY 80D PER SB022) DUKANE (V94970) (ELP−362D) FOR BATTERY REPLACEMENT ORDER 30−DAY BATTERY KIT (147E0305−00) A, B, C, E, F, G, H, L, M, N, P, R, T 1 80D 266E5542-00 .BEACON, LOCATOR, UNDERWATER, 90−DAY (SUPSDS ITEM 80A, 80B, 80C, PER SB022 (CODE F) (HAZMAT CLS9) 1 FOR BATTERY REPLACEMENT, ORDER 90−DAY ULB BATTERY KIT (147E5542−00) 85 9300-388 .PLUG 1 90A 191E1603-00 .REAR PANEL ASSEMBLY, ARINC 757 90B 191E1603-01 .REAR PANEL ASSEMBLY, ARINC 757A A, B, C, E, F, G, H, L, M, N, P, R, U, V, W, Y, AA, AC 1 T, AB 1 ATTACHING PARTS − 95 MS24693-C26 .SCREW, FLAT HEAD, 6−32 X 3/8 (V06141) (2290200361) *** 100 3M#7201 DELETED Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 8 23–70–04 Illustrated Parts List Rev. 15 Page 1017 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR FIG. ITEM PART NUMBER UNITS PER EFF CODE ASSY AIRLINE NOMENCLATURE PART NO. 1234567 1 105A 205E1593-00 .PWA, AIRCRAFT INTERFACE, ARINC 757 (SUPSD BY 105E, PER SB015) A, B, C 1 105B 205E1763-00 .PWA, AIRCRAFT INTERFACE, GA, ARINC 757 (OBS, SUPSD BY 105C, PER ECO 9432) E, F, G, H 1 105C 205E1763-01 .PWA, AIRCRAFT INTERFACE, GA, DC, ARINC 757 (SUPSDS ITEM 105B PER ECO 9432) (SUPSD BY 105F PER SB015) E, F, G, H 1 105D 205E2503-01 .PWA, AIRCRAFT INTERFACE, ARINC 757−4 L, M, N, P, R,W, Y, AA, AC 1 105E 205E2503-05 .PWA, AIRCRAFT INTERFACE, ARINC 757−4 (SUPSDS ITEM 105A, PER SB015) A, B, C, U, V 1 105F 205E1763-11 .PWA, AIRCRAFT INTERFACE, GA, DC, ARINC 757 (SUPSDS ITEM 105C, PER SB015) E, F, G, H 1 105G 205E2503-08 .PWA, AIRCRAFT INTERFACE T, AB 1 ATTACHING PARTS 4 110 297-98-00283 .STANDOFF, 3/16 HEX, M-F4-40 X 1.03 2 115 297-98-00257 .STANDOFF, 3/16 HEX, 4-40 X 1-1/32 1 120A 297-98-00087 .STANDOFF, 3/16 HEX, M-F4-40 X 3/4 SST (SUPSD BY 120B, PER SB 015) 4 120B 297-98-00319 .STANDOFF, 3/16 HEX, M-F4-40 X 7/8 (SUPSDS ITEM 120A, PER SB 015) 4 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Illustrated Parts List Rev. 15 Page 1018 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR FIG. ITEM PART NUMBER UNITS PER EFF CODE ASSY AIRLINE NOMENCLATURE PART NO. 1234567 1 125A MS51957-14 .SCREW, PAN HEAD, 4-40 X 5/16 (V06141) (2290200074) A, B, C, E, F, G, H, L, M, N, P, R, U, V, W, Y, AA, AC 6 125B MS51957-14 .SCREW, PAN HEAD, 4-40 X 5/16 (V06141) (2290200074) T, AB 7 127 2290200365 .SCR,FLH ,8−32 X1/4 T, AB 1 130 MS24693-C4 .SCREW, FLAT HEAD, 4-40 X 3/8 (V06141) (2290200356) 4 *** 135A 742E1619-00 .CAPACITOR ASSEMBLY, STORAGE (SUPSD BY 135B, PER SB017) 1 135B 742E1619-03 .CAPACITOR ASSEMBLY, STORAGE (SUPSDS ITEM 135A, PER SB 017) 1 ATTACHING PARTS 140 MS24693-C4 .SCREW, FLAT HEAD, 4-40 X 3/8 (V06141) (2290200356) (SUPSD BY 141A, PER SB016) 141A MS24693-C6 .SCREW, FLAT HEAD, 4−40 X 1/2 (V06141) (2290200357) (SUPSDS ITEM 140, PER SB016) A, B, C, E, F, G, H, L, M, N, P, R, U, V, W, Y, AA, AC 2 141B MS24693-C7 .SCREW, FLAT HEAD, 4−40 X 5/8 (V06141) (2290200357) (SUPSDS ITEM 140, PER SB016) T, AB 2 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 2 23–70–04 Illustrated Parts List Rev. 15 Page 1019 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR FIG. ITEM PART NUMBER UNITS PER EFF CODE ASSY AIRLINE NOMENCLATURE PART NO. 1234567 1 145 MS15795-803 .WASHER, #4, FLAT, STAINLESS STEEL (V06141) (2730200004) (SUPSD BY 146, PER SB016) 146A 016E4797−00 .BRACKET, CAPACITOR (SUPSDS ITEM 145, PER SB016) 146B 016E5352-00 .BRACKET, PLASTIC CAPACITOR 150 MS21044C04 .NUT, HEX, SELF-LOCKING, 4-40 (V06141) (2870200019) (SUPSD BY 151, PER SB016) 151 140E4207−00 .INSULATOR, LATCH, FC (SUPSDS ITEM 150, PER SB016) 152 2739800201 .WASHER,SHOULDER,.115ID *** 155A 205E1596-00 .PWA, AUDIO COMPRESSOR (SUPSD BY 155B, PER ECO 8824) 155B 205E1849-00 .PWA, AUDIO COMPRESSOR (SUPSDS 155A, SN377 PER ECO 8824) (SUPSD BY 155F, PER ECO 10320) A, B 1 155C 205E1849-03 .PWA, AUDIO COMPRESSOR w/ FSK (SUPSDS 155A, SN377 PER ECO 8893, (SUPSD BY 155G, PER ECO 10365) C 1 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 2 A, B, C, E, F, G, H, L, M, N, P, R, U, V, W, Y, AA, AC 1 T, AB 1 2 A, B, C, E, F, G, H, L, M, N, P, R, U, V, W, Y, AA, AC 1 T, AB 1 1 23–70–04 Illustrated Parts List Rev. 15 Page 1020 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR FIG. ITEM PART NUMBER UNITS PER EFF CODE ASSY AIRLINE NOMENCLATURE PART NO. 1234567 1 155D 205E1849-02 .PWA, AUDIO COMPRESSOR, w/ AGC (SUPSDS 155A, SN377 PER ECO 8893) (SUPSD BY 155L, PER SB009) E, F G, H 1 155E 205E1849-04 .Deleted 155F 205E1849-10 .PWA, AUDIO COMPRESSOR (SUPSDS 155B, SN377 PER ECO 10320) (SUPSD BY 155K, PER SB009) A, B 1 155G 205E1849-13 .PWA, AUDIO COMPRESSOR, W/ FSK (SUPSDS 155C, SN377 PER ECO 10365) (SUPSD BY 155M, PER SB009) C 1 155H 205E1849-14 .Deleted 155J 205E1849-17 .PWA, AUDIO COMPRESSOR, HIGH QUALITY ONLY (SUPSD BY 155P PER SB009) L 1 155K 205E3977−10 .PWA, AUDIO COMPRESSOR (SUPSDS 155F, PER SB009) (SUPSD BY ITEM 155R, PER SB015) A, B 1 155L 205E3977−12 .PWA, AUDIO COMPRESSOR, w/ AGC (SUPSDS 155D, PER SB009) (SUPSD BY ITEM 155S, PER SB015) E, F G, H 1 155M 205E3977−13 .PWA, AUDIO COMPRESSOR, W/ FSK (SUPSDS 155G, PER SB009) (SUPSD BY ITEM 155T, PER SB015) C 1 155N 205E3977−14 .Deleted 155P 205E3977−17 .PWA, AUDIO COMPRESSOR, HIGH QUALITY ONLY (SUPSDS 155J, PER SB009) L, M, N, R, W, AA, AC 1 155R 205E3977−20 .PWA, AUDIO COMPRESSOR (SUPSDS ITEM 155K, PER SB015) A, B, U 1 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Illustrated Parts List Rev. 15 Page 1021 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR FIG. ITEM PART NUMBER UNITS PER EFF CODE ASSY AIRLINE NOMENCLATURE PART NO. 1234567 1 155S 205E3977−22 .PWA, AUDIO COMPRESSOR, w/ AGC (SUPSDS 155L, PER SB015) E, F G, H 1 155T 205E3977−23 .PWA, AUDIO COMPRESSOR (SUPSDS ITEM 155M, PER SB015) C, V 1 155U 205E3977−24 .Deleted 155V 205E3977−29 .PWA, AUDIO COMPRESSOR, HIGH QUALITY ONLY P, Y 1 155W 205E3977−37 .PWA, AUDIO COMPRESSOR, HIGH QUALITY ONLY T, AB 1 160 MS51957-14 .SCREW, PAN HEAD, 4-40 X 5/16 (V06141) (2290200074) *** 4 165A 024E1620-00 .CABLE ASSEMBLY, FA2100, W001 & W003 (SUPSD BY ITEM 165B for W001 and 170B for W003, PER SB015) 2 165B 024E2659−01 .CABLE ASSEMBLY, FA2100, W001 (SUPSDS ITEM 165A (W001 only) (EFF A,B,C,L,M,N) PER SB015) A, B, C, L, M, N, P, R, T, U, V, W, Y, AA, AB, AC 1 165C 024E3424−03 .CABLE ASSEMBLY, FA2100, W001 (SUPSDS ITEM 165A (W001 only)(EFF E,F,G,H) PER SB015) E, F, G, H 1 170A 024E1620-01 .CABLE ASSEMBLY, FA2100, W002 (SUPSD BY ITEM 170B, PER SB015) 1 170B 024E3424−00 .CABLE ASSEMBLY, FA2100, W002 & W003 (SUPSDS ITEM 165A (W003 only) & 170A, PER SB015) 2 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 1 23–70–04 Illustrated Parts List Rev. 15 Page 1022 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR FIG. ITEM PART NUMBER UNITS PER EFF CODE ASSY AIRLINE NOMENCLATURE PART NO. 1234567 1 175A 205E1591-00 .PWA, ACQUISITION PROCESSOR (SUPSD BY 175B, PER SB002) 175B 205E1931-00 .PWA, ACQUISITION PROCESSOR (SUPSDS 175A, PER SB002) (SUPSD BY 175D, PER SB006) A, B, C, E, F, G, H 1 175C 205E2502-10 .PWA, ACQUISITION PROCESSOR (SUPSDS 175B, PER SB006) (SUPSD BY 175D PER SB006) A, B, C, E, F, G, H 1 175D 205E2502-11 .PWA, ACQUISITION PROCESSOR (SUPSDS 175B & 175C, PER SB006) (CONFIGS E, F, G, H SUPSD BY ITEM 175F, PER SB013) (CONFIGS A, B, C SUPSD BY ITEM 175G, PER SB015) A, B, C, E, F, G, H 1 175E 205E2502−14 .PWA, ADV ACQUISITION PROCESSOR W/ OMS L, M, N, R, W, AA, AC 1 175F 205E2502-52 .PWA, ACQUISITION PROCESSOR (SUPSDS 175D PER SB013) (SUPSD BY ITEM 175H, PER SB015) E, F, G, H 1 175G 205E2502-21 .PWA, ACQUISITION PROCESSOR (SUPSDS 175D PER SB015) A, B, C, U, V 1 175H 205E2502-38 .PWA, ACQUISITION PROCESSOR (SUPSDS 175F PER SB015) E, F, G, H 1 175J 205E2502−24 .PWA, ADV ACQUISITION PROCESSOR W/ OMS P, Y 1 175K 205E2502−34 .PWA, ADV ACQUISITION PROCESSOR W/ OMS T, AB 1 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 1 23–70–04 Illustrated Parts List Rev. 15 Page 1023 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR FIG. ITEM PART NUMBER UNITS PER EFF CODE ASSY AIRLINE NOMENCLATURE PART NO. 1234567 1 ATTACHING PARTS 180 MS51957-14 .SCREW, PAN HEAD, 4–40 X 5/16 (V06141) (2290200074) *** 185A 253E1568-01 .MEMORY (CSMU) ASSEMBLY, 7X32 MEG (SUPSD BY 185G PER SB008) A, E 1 185B 253E1568-00 .MEMORY(CSMU) ASSEMBLY, 15X32 MEG (SUPSD BY 185F PER SB008) B, C, G 1 185C 253E1568-06 .MEMORY (CSMU) ASSEMBLY, 7X32 MEG, TITANIUM (SUPSD BY 185H PER SB008) F 1 185D 253E1568-07 .MEMORY (CSMU) ASSEMBLY, 15X32 MEG, TITANIUM (SUPSD BY 185J PER SB008) H 1 185E 253E1568-33 .MEMORY (CSMU) ASSEMBLY, 9X128 MEG 3V STRATA FLASH (SUPSD BY 185L PER SB019) L, N, P, R, T 1 185F 253E1568-38 .MEMORY (CSMU) ASSEMBLY, 7X128 MEG 3V STRATA FLASH (SUPSDS 185B, PER SB008) (SUPSD BY 185L PER SB019) B, C, G 1 185G 253E1568-39 .MEMORY (CSMU) ASSEMBLY, 4X128 MEG 3V STRATA FLASH (SUPSDS 185A, PER SB008) (SUPSD BY 185L PER SB019) A, E 1 185H 253E1568-40 .MEMORY (CSMU) ASSEMBLY, 7X128 MEG 3V STRATA FLASH, TITANIUM (SUPSDS 185C, PER SB008) (SUPSD BY 185M PER SB019) F 1 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 10 23–70–04 Illustrated Parts List Rev. 15 Page 1024 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR FIG. ITEM PART NUMBER UNITS PER EFF CODE ASSY AIRLINE NOMENCLATURE PART NO. 1234567 1 185J 253E1568-41 .MEMORY (CSMU) ASSEMBLY, 7X128 MEG 3V STRATA FLASH, TITANIUM (SUPSDS 185D, PER SB008) (SUPSD BY 185M PER SB019) H 1 185K 253E4427-33 .MEMORY (CSMU) ASSEMBLY, 9X128 MEG 3V STRATA FLASH MEG, CYRILLIC (RUSSIAN TEXT) (SUPSD BY 185N PER SB019) M 1 185L 253E5675-00 .MEMORY (CSMU) ASSEMBLY, 2 GB NAND MEMORY MODULE (SUPSDS 185E-185G, PER SB019) (SUPSD BY 185P FOR B, C, N, U, V, W, AA, AC PER SB023) A, B, C, E, G, L, N, P, R, T, U, V, W, Y, AA, AB, AC 1 185M 253E5675-11 .MEMORY (CSMU) ASSEMBLY, 2 GB NAND MEMORY MODULE, TITANIUM (SUPSDS 185H & 185J, PER SB019) (SUPSD BY 185R FOR H PER SB023) F, H 1 185N 253E5675-20 .MEMORY (CSMU) 2GB NAND, CYRILLIC, NON EMI (SUPSDS 185K, PER SB019) M 1 185P 253E5675-02 .MEMORY (CSMU) 2GB NAND (SUPSDS 185L, PER SB023) B, C, N, U, V, W, AA, AC 1 185R 253E5675-13 .MEMORY (CSMU) 2GB NAND, TITANIUM (SUPSDS 185M, PER SB023) H 1 ATTACHING PARTS 190A MS16995-52 .SCREW, SCHCAP, 1/4-20 X 1 (V06141) (2290200325) (SUPSD BY 190B PER SB004) 4 190B BB1P141H16 .SCREW, SCHCAP, 1/4-20 X 1 (V06141) (2299800464) (SUPSDS 190A PER SB004) 4 200A 230E2520-00 .SEAL, CSMU COVER, SHORT-BOX (SUPSD BY 200B, PER SB019) 1 Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Illustrated Parts List Rev. 15 Page 1025 Apr. 14/16 AVIATION RECORDERS COMPONENT MAINTENANCE MANUAL FA2100CVR FIG. ITEM PART NUMBER UNITS PER EFF CODE ASSY AIRLINE NOMENCLATURE PART NO. 1234567 1 200B 230E5675−00 .SEAL, CSMU COVER, SHORT-BOX (SUPSDS 200A, PER SB019) *** 1 205 9030100047 .LABEL, ESD 1 − 210 147E1679-00 SHIPPING PACKAGE KIT 1 − 220 197E1746-00 .CONTAINER, SHIPPING, SHORT 1 − 225 0279800024 .CAP, DUST, DPX SERIES CONN, 1 1 − 235 2529800107 .TAPE, WATERPROOF, WOVEN BACKED 1 − 240A 9030100049 .BAG, PINK ZIPLOCK, 9 X 12 (SUPSD BY 240B) 1 − 240B 9030100075 .BAG, 14X24, TRANSPARENT PINK (SUPSDS 240A) 1 − 245 9030100047 .STATIC AWARENESS LABEL 1 − ITEM NOT ILLUSTRATED Use or disclosure of information on this sheet is subject to the restrictions on the cover page of this document. The document reference is online, please check the correspondence between the online documentation and the printed version. 23–70–04 Illustrated Parts List Rev. 15 Page 1026 Apr. 14/16 The document reference is online, please check the correspondence between the online documentation and the printed version.