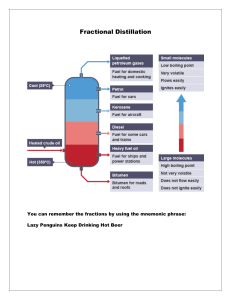

University of Science and Technology of Southern Philippines 1st Cagayan de Oro City Semester SY 2021 - 2022 TOPIC 7 Liquid FUELS 2 3 Liquid Fuel – Petroleum Petroleum or crude oil is a naturally occurring brown to black colored viscous oil formed under the crust of earth, on shore or off shore. Chemically it is a mixture of various hydrocarbons with small amounts of N, O, S compounds. The approximate composition of petroleum: • • • • C = 80 - 84% H = 10 - 14 % S = 0.1 - 0.5 % N+ O = Negligible 3 4 Classification of Petroleum 1. Paraffinic-base type crude oil • Contains saturated hydrocarbons from CH4 to C35H72 and a little amount of naphthalenes and aromatics. • (e.g. : Pennsylvanian and gulf coast oil) 2. Asphaltic-base type crude oil • Contains mainly cycloparaffins or naphthalenes with smaller amounts of paraffins and aromatic hydrocarbons. • (e.g.: Californian oil) 3. Mixed-base type crude oil • Contains both paraffinic and asphaltic hydrocarbons and are generally in the form of semi-solid waxes. • (e.g. : Mexican oil) 4 5 Processing of Crude Petroleum • Petroleum is found deep below the earth crust. • The oil is found floating over salt water or brine. • Generally, accumulation of natural gas occurs above the oil. 5 6 Refining of Petroleum The process of removing impurities and separating out the oil into various fractions having different boiling points is known as refining of petroleum. Refining plants are called oil refineries. The process of refining involves 3 steps: • • • Separation of water Removal of impurities Fractional distillation. 6 7 Refining Step 1: Separation of Water The crude oil from the well is an extremely stable emulsion of oil and salt water. The crude oil is allowed to flow between 2 highly charged electrodes, where colloidal water droplets coalesce to form large drops, which is then separated out from the oil. 7 8 Refining Step 2: Removal of Impurities The presence of NaCl and MgCl2 in the crude oil can corrode the refining equipment, hence these salts are removed by electrical desalting and dehydration methods. The sulfur compounds present in the crude oil is removed by treating the oil with copper(II) oxide, which results in the formation of copper sulfide, which is then removed by filtration. 8 9 Refining Step 3: Fractional Distillation The crude oil is heated to about 400°C, whereby all volatile substances are evaporated. The hot vapors are then passed up a fractionating column, which is a tall cylindrical tower containing a number of horizontal stainless steel trays at short distances. When the vapors of the oil go up the fractionating column, they gradually cool and condense at different heights of the column. The fractions having higher boiling point condense at lower trays whereas the fractions having lower boiling points condense at higher trays. 9 10 Refining Step 3: Fractional Distillation 10 11 Some Important Fractions of Petroleum: 1. Petrol or Gasoline (C5-C9) • • • • • • It is a low boiling fraction of petroleum obtained between 40 – 120oC. It is a mixture of hydrocarbons pentane to nonane (in terms of carbon atoms C5 - C9). Its calorific value is about 11,250 kcals/kg. It is used as fuel in ICE of automobiles and aero planes. Its antiknock value can be improved by the addition of Tetra Ethyl Lead (TEL). It is used as a fuel in IC engine and also used in dry cleaning and as a solvent. 11 12 Some Important Fractions of Petroleum: 2. Naphtha (C9-C10) • It is a colorless, light fraction obtained between 1200C to 1800C during fractional distillation of petroleum. It is a mixture of hydrocarbons such as nonane and decane. • Naphtha is also called as white spirit, which is generally used in dry cleaning and as thinner for varnish, floor and furniture polishes etc. The lightest portion of the distillate is used as solvent for fats and rubbers, whereas the heaviest portion of the same is used as a fuel. 12 13 Some Important Fractions of Petroleum: 3. Kerosene( C10-C16) • It is relatively a high boiling fraction obtained between 180-250oC during fractional distillation of petroleum. It is a mixture of hydrocarbons such as decane to hexadecane approximate composition is C = 84%, H = 16%, > 0.1% S. Its calorific value is about 11,100 kcal/kg. • It is mainly used as a domestic fuel in stoves and lamps. • It is also used as jet engine fuel and for making oil gas. 13 14 Some Important Fractions of Petroleum: 4. Diesel (C15-C18) • It is also a high boiling fraction obtained between 250-320oC during fractional distillation of petroleum. It is a mixture of hydrocarbons such as C15H32 to C18H38. Its calorific value is about 11,000 kcal/kg. • It is used as a very good diesel engine fuel. 14 Some Important Fractions of Petroleum: 5. Heavy oil or Residual fuel oil (C17 – C30) • • • • The left over portion of petroleum after distilling off all the lighter fractions are called Fuel Oil. • The approximate composition of fuel oil is C = 86%, H = 12%, S = 1%, H2O = 0.6%; sediments = 0.4%. • Its calorific value is about 9200 kcal/kg. The following fractions are obtained on further vacuum distillation of the fuel oil. i) Light fuel oil = 350 -420oC ii) Heavy neutral oil = 420-500oC It is used as fuel for ships and also used in metallurgical furnaces. Gasoline is also obtained from oil by cracking process. 15 16 Some Important Fractions of Petroleum: 6. Asphalt • Asphalts are obtained by: i) The oxidation of residual heavy oil in presence of air at higher temperature. ii) The deep vacuum distillation of residual heavy oil. • Asphalts are available in the market in liquid, semi-solid and solid forms. • • It is used for road making and making water-proofing roofs. It is also used for the manufacture of water proofing concrete and water proofing paints. 16 17 Standard Ignition Temperature and Flash Point Standard Ignition Temperature (SIT) • It is the lowest temperature that a fuel will ignite without the help of any external flame or ignition source. Flash Point • • • It is the lowest temperature at which a fuel can be heated so that the vapor gives off flashes when an open flame is passed over it. This gives an indication of the flammability of the fuel. Its significance is in the safety aspects of storing and handling the fuel. 17 18 Fire Point and Smoke Point Fire Point • It is the temperature to which the oil must be heated so that the vapor pressure is sufficient to maintain the flame after the flame source is removed. Smoke Point • It is an arbitrary scale related to the height of the flame of the fuel burning in a standard lamp without smoking. 18 19 Cracking Cracking is defined as the decomposition of high boiling hydrocarbons of high molecular weight into smaller, low boiling hydrocarbons of low molecular weight. The crude oil on fractional distillation yields only about 15 - 20 % gasoline. This is known as Straight Run Gasoline. 19 20 Cracking During cracking: • Straight chain alkanes are converted into branched chain hydrocarbons. • Saturated hydrocarbons are converted into mixture of Saturated and Unsaturated hydrocarbons. • Aliphatic alkanes are converted into cyclic alkanes. • All hydrocarbons obtained by cracking have lower boiling point than the parent hydrocarbons. 20 21 TypesTwo of Cracking in Use Types of Cracking in Use: 1. Thermal Cracking • In this process, the heavy oil is subjected in high temperature and pressure, when the bigger hydrocarbon molecules break down to give smaller molecules of the paraffins, olefins, and hydrogen. • The cracked products are then separated by fractional distillation. 21 22 Types of Cracking in Use 2. Catalytic Cracking • In this process, cracking is carried out in the presence of a catalyst at a lower temperatures and pressures. The catalysts like aluminum silicate, Al2SiO3, or alumina Al2O3, used in cracking gives higher yield and better quality of gasoline 22 23 Knocking The rate of ignition of the fuel gradually increases and the final portion of the fuel-air mixture gets ignited instantaneously producing an explosive sound known as knocking. Knocking property of the fuel reduces the efficiency of engine. So a good gasoline should resist knocking. 23 24 Octane Number or Octane Rating It is introduced to express the knocking characteristics of petrol. It has been found that n-heptane knocks very badly and hence, its anti-knock value has been given zero (0). On the other hand, iso-octane gives very little knocking and so, its anti-knock value has been given 100. Octane number is defined as the percentage of iso-octane present in a mixture of iso-octane and n-heptane. 24 25 Cetane Number or Cetane Rating It is introduced to express the knocking characteristics of diesel. Cetane has a very short ignition lag and hence its cetane number is taken as 100. On the other hand, 2-methyl naphthalene has a long ignition lag and its cetane number is taken as zero (0). Cetane number is defined as the percentage of hexadecane (n-cetane) present in a mixture of hexadecane and 2-methyl naphthalene, which has the same ignition lag as the fuel under test. 25 26 Improvement of Antiknock Characteristics The octane number of fuel can be improved by: 1. Blending petrol of high octane number with petrol of low octane number, so that the octane number of the latter can be improved 2. The addition of anti-knock agents 26 27 TOPIC 7 Gaseous FUELS 28 Gaseous Fuels 28 Gaseous Fuel – Natural Gas 29 Natural gas is always found above the oil in the oil wells. It is also called Marsh gas. It consists of methane and other saturated hydrocarbons. The average composition of natural gas is as follows : • • • • • Methane = 88.5 % Ethane = 5.5 % Propane = 4 % Butane = 1.5% Pentane = 0.5% If natural gas contains lower hydrocarbons like methane and ethane it is called lean or dry gas. In the natural gas contains higher hydrocarbons like propane, butane along with methane it is called rich or wet gas. 29 29 30 Gaseous Fuel – Water or Blue Gas Water gas essentially a mixture of combustible gases like CO, H2 with a little non combustible gases like CO2 and N2. 30 31 Gaseous Fuel – Producer Gas It is prepared by passing air mixed with a little steam over a red hot coal (or) a coke bed maintained at above 1100° C in a special reactor called ‘‘ Gas Producer’’. 31 32 Gaseous Fuel – Liquified Petroleum Gas (LPG) It is a mixture of propane and butane. It is obtained as one of the top fractions in the fractional distillation of petroleum. It is easily liquefied and so can be economically stored and transported in cylinders. The approximate composition is as follows: • • • • N-Butane = 70 % Isobutane = 17 % N-Propane = 11 % Butylene and Ethane = 2 % 32 33 Biofuels Biogas: from animal manure, other organic wastes, energy crops Bioethanol/Ethanol: from sugar/starch Biodiesel: from vegetable oils, animal fats 33 34 TOPIC 7 BIOFUELS 35 Bioethanol vs Biodiesel 35 36 Power Alcohol When ethyl alcohol is used as fuel in an internal combustion engine, it is called power alcohol. Generally, ethyl alcohol is used as a 5-25% mixture with petrol. 36 37 Philippines: Biofuels Act of 2006 • Develop and utilize indigenous renewable and sustainablysourced clean energy to reduce dependence on imported oil. • Mitigate toxic and greenhouse gas emissions. • Increase rural employment and income. • Ensure the availability of alternative and renewable clean energy without any detriment to the natural ecosystem, biodiversity and food reserves of the country. 37 38 Philippines: Biofuels Act of 2006 • At present, 5% ethanol and 2.5% biodiesel. 38 REFERENCES REFERENCES R. Mukhopadhyay & S. Datta. Engineering Chemistry. Syed Shabudeen P.S. Fuels and Combustion. Retrieved from https://www.researchgate.net/publication/265602602 K. Sesha Maheswaramma. Engineering Chemistry. J. A. Moulijn, M. Makkee, A.E. Van Diepen. Chemical Process Technology. H. Schobert. Chemistry of Fossil Fuels and Biofuels. Wiley Critical Content. Petroleum Technology. Volume 1-2 . J.G. Speight. The Chemistry and Technology of Petroleum. C.S. Hsu & P.R. Robinson. Springer Handbook of Petroleum Technology. L.J. Gonzaga. Lectures 5-9 Fuels. [Powerpoint Slides]. 39