SMT Magazine: New Technologies in Electronics Manufacturing

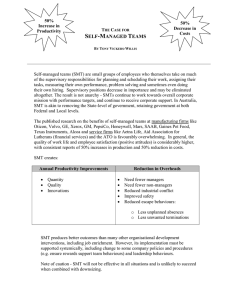

advertisement