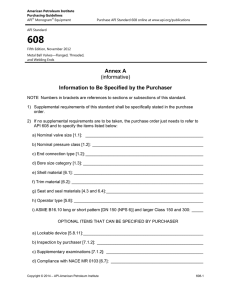

Petroleum Measurement Standards Addendum: Electronic Metering

advertisement