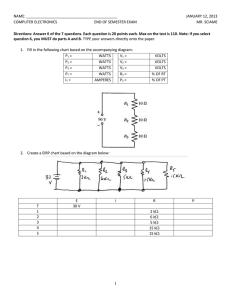

subzero.com 800.222.7820 CI Induction Cooktop Service Manual General Information Controls & Operation Component Access & Removal Troubleshooting Guide Wiring Diagrams 2 6 18 24 34 General Information Cooktop Induction (CI) Series INTRODUCTION This Technical Service Manual has been compiled to provide the most recent technical service information. This information enables the service technician to troubleshoot and diagnose malfunctions, perform necessary repairs and return the appliance to proper operational condition. The service technician should read the complete instructions contained in this service manual before initiating any repairs on a Wolf Appliance. For installation information see Induction and Electric Cooktops Installation Guide available at http://www.subzero-wolf.com/trade-resources/product-specifications. For Use and Care information see Use & Care Guide: Induction Cooktops available at http://www.subzerowolf.com/trade-resources/product-specifications. IMPORTANT SAFETY INFORMATION TECHNICAL ASSISTANCE Below are the Product Safety Labels used in this manual. The "Signal Words" used are WARNING and CAUTION. If you should have any questions regarding the appliance and/or this manual, please contact: Wolf Appliance, Inc. ATTN: Service Department P.O. Box 44988 Madison, WI 53744 - 4988 Please note that these safety labels are placed in areas where awareness of personal safety and product safety should be taken and lists the precautions to be taken when the signal word is observed. Customer Care Phone #: (800) 332 - 9513 Facsimile #: (608) 441 - 5887 INDICATES THAT HAZARDOUS OR UNSAFE PRACTICES COULD RESULT IN SEVERE PERSONAL INJURY OR DEATH. Technical Assistance (For Technicians in Customer’s Homes Only) Phone #: (800) 919 - 8324 Warranty Claims Phone #: (800) 404 - 7820 Facsimile #: (608) 441 - 5886 Indicates that hazardous or unsafe practices could result in minor personal injury or product and/or property damage Service Department e-mail Address: customerservice@wolfappliance.com In addition, please pay attention to the signal word “NOTE”, which highlights especially important information within each section. Main Office Hours: 8:00 AM to 5:00 PM Central Time Monday through Friday (24/7 Phone Coverage) This manual is designed to be used by Certified Service Personnel only. Wolf Appliance, Inc. assumes no responsibility for any repairs made to Wolf appliances by anyone other than Certified Service Technicians. The information and images are the copyright property of Wolf Appliance, Inc., an affiliate of Sub-Zero Group, Inc. Neither this manual nor any information or images contained herein may be copied or used in whole or in part without the express written permission of Wolf Appliance, Inc., an affiliate of Sub-Zero Group, Inc. © Wolf Appliance, Inc., all rights reserved. #826139 - Revision A - February, 2015 1-2 General Information Cooktop Induction (CI) Series WARRANTY INFORMATION This page contains a summary of the 2 & 5 Year Warranty that is supplied with every Wolf product, followed by a Non-Residential Warranty Summary and then notes about the warranties. 2 & 5 Year Warranty Summary: • 2 Year Total Product Warranty, parts and labor. • 3-5 Year Limited Parts Only Warranty. Details: • Warranty applies to products installed in United States or Canada, for residential use only. • Warranty begins at time of unit’s initial installation. • Warranty does not cover Wolf Appliances installed in a demonstration kitchen, test kitchen, culinary school kitchen, or similar installations. (See Special Warranty below) • Warranty and service information collected by Wolf Appliance, Inc. is arranged and stored under unit serial number and/or customer’s name. Wolf Appliance, Inc requests that you have model and serial number available whenever contacting factory or parts distributor. • 3-5 Year Limited Parts Only Warranty applies to the control board, generator(s), and coil assemblies. Special Warranty Summary 2 Year Total Product Warranty, parts and labor. Details: • This Warranty applies to products installed in United States or Canada, for use in a demonstration kitchen, test kitchen, culinary school kitchen, and similar installations that help promote Wolf Appliance brand and its products. • Warranty begins at time of unit’s initial installation. • Warranty and Service information collected by Wolf Appliance, Inc. is arranged and stored under unit serial number and/or customer’s name. Wolf Appliance, Inc. requests that you have model and serial number available whenever contacting factory or parts distributor. NOTE: “ICB” appliances carry no factory warranty. The product distributor or appliance dealer may offer their own warranty. Wolf Appliance, Inc. Fitchburg, WI INDUCTION COOKTOP FOR HOUSEHOLD USE ONLY VOLTS : 208 ~ 240 ~ Hz : 50/60 MODEL#: CI243C/B kW : 5.94 6.85 2 WIRE SERIAL#:176XXXXX “Do Not Immerse In Water” “Ne pas plonger dans l’eau” 825206 Figure 1-1. Typical Rating Plate Layout RATING PLATE Figure 1-2. The rating plate is located beneath the cooktop. 1-5 #826139 - Revision A - February, 2015 General Information Cooktop Induction (CI) Series CI SERIES CONFIGURATIONS Transitional Cooktops 15” Two Coil Assemblies - Transitional 30” Four Coil Assemblies - Transitional Model Number: CI152T/S Model Number: CI304T/S Description: Cooktop Induction, 15”, Two Coil Assemblies, Transitional / Stainless steel Description: Cooktop Induction, 30”, Four Coil Assemblies, Transitional / Stainless steel 36” Five Coil Assemblies - Transitional Model Number: CI365T/S Description: Cooktop Induction, 36”, Five Coil Assemblies, Transitional / Stainless steel 1-7 #826139 - Revision A - February, 2015 General Information Cooktop Induction (CI) Series Contemporary Cooktops 24” Three Coil Assemblies - Contemporary 30” Four Coil Assemblies - Contemporary Model Number: CI243C/B Model Number: CI304C/B Description: Cooktop Induction, 24”, Three Coil Assemblies, Contemporary / Black unframed Description: Cooktop Induction, 30”, Four Coil Assemblies, Contemporary / Black unframed 36” Five Coil Assemblies - Contemporary Model Number: CI365C/B Description: Cooktop Induction, 36”, Five Coil Assemblies, Contemporary / Black unframed #826139 - Revision A - February, 2015 1-8 Electronics Cooktop Induction (CI) Series ELECTRONICS This section describes the basic operation of the CI Series electronics and how the touch pad responds to input commands. The control board receives touch sensitive input and triggers a command in the generator(s). The generator(s) uses Insulated Gate Bipolar Transistors (IGBTs) to maintain the correct power at the coil assembly. Temperature is monitored at heat sinks and at the coil assemblies by a special type of thermistor called a Negative Temperature Coefficient (NTC) thermistor. Touch Pads Global Touch Pads • • • • • LOCK - Locks or unlocks the entire cooktop. Touch and hold for 3 seconds. Acceptance beep when state changes. Padlock is displayed when locked. ALL OFF - Disables entire cooktop. Red circle displayed when any coil assembly is energized. “+” - Adds time to the count down timer. Valid Selection beep to acknowledge touch. “-” - Decreases time to the count down timer. Valid Selection beep to acknowledge touch. TIMER - Activate and deactivate the timer. Valid Selection beep to acknowledge touch. Control Zone Pads: • • • • • • • • • ON/OFF - Enables or disables individual control zone. SIM - sets power to level 1. MLT - sets power to level 1. HI - sets power to level 10. BOOST - sets power to Boost and adjusts adjacent power levels as required by the induction power sharing scheme. Toggles Boost off if already engaged. BRIDGE - Activates vertically adjacent coil assemblies to same power level. BRG - Activates horizontally adjacent coil assemblies to same power level. ALL BRIDGE - Activates the four adjacent coil assemblies on the left side of the 36” model. ‘’ . . . .” - Sets power to levels 2 through 9. Annunciator: • • • • • Adjust annunciator volume and frequency in user options mode. See Frequency Duration and Selection Chart on the next page. Cooktop must be in idle mode to adjust annunciator. Factory default setting for volume is medium. Factory default setting for frequency is medium. Low frequency is 1.5 kHz. Medium frequency is 2.0 kHz. High Frequency is 2.5 kHz. HOT Surface Display: • • • LED is on when the cooktop glass temperature at any coil assembly (NTC reading) is greater than 149º F. LED turns off when the glass temperature is below 122º F. Independent of any control zone activation or the cooktop being in lock or showroom mode. #826139 - Revision A - February, 2015 2-2 Electronics Cooktop Induction (CI) Series Frequency Duration and Selection Chart Name Duration Type Occurrence Valid Selection 280 ms Beep Touch on valid pad Invalid Selection 750 ms Beep Touch on invalid pad Acceptance 280 ms Beep Twice with 250 ms delay on the successful receipt of a command Timer Complete 750 ms Beep Four times with 200 ms delay on the expiration of a timer Then every 8500 ms until acknowledge Failure 750 ms Beep Four times with 200 ms delay on priority 1 errors One Minute Remaining 750 ms Beep When there is one minute remaining on a timer or timed cook cycle. Note: ms = milliseconds. CI Series Coil Assembly Wattage and Layout Generator Board #1 2300 Watts B O O S T 1400 Watts ON OFF ALL OFF TIMER _ SIM LOCK + ....... . HI BOOST ON OFF MLT . . . . . . .. HI Figure 2-1 CI152 2-3 #826139 - Revision A - February, 2015 Electronics Cooktop Induction (CI) Series Generator Board #2 Generator Board #1 2100 Watts 2600 Watts B R I D G E B O O S T B O O S T 2100 Watts ON OFF ALL OFF TIMER _ LOCK SIM ....... . BRIDGE ON OFF + ON OFF HI SIM ....... . BOOST MLT . . . . . . .. HI BOOST HI Figure 2-2 CI243 Generator Board #2 Generator Board #1 2100 Watts B R I D G E 2600 Watts B O O S T 2100 Watts B O O S T 1400 Watts ON OFF ALL OFF TIMER Figure 2-3 CI304 #826139 - Revision A - February, 2015 2-4 _ LOCK + SIM BRIDGE ON OFF SIM ....... . HI ON OFF SIM BOOST ....... . HI ....... . HI BOOST ON OFF MLT . . . . . . .. HI Electronics Cooktop Induction (CI) Series Generator Board #2 Generator Board #1 2100 Watts B R I D G E BRG B O O S T 2100 Watts 2100 Watts B R I D G E BRG Generator Board #3 2600 Watts B O O S T B O O S T 2100 Watts ON OFF ALL BRIDGE ALL OFF LOCK SIM BRIDGE ON OFF SIM ....... . HI BRG BOOST ....... . ON OFF SIM BRIDGE HI BRG ON OFF MLT ....... . HI ON OFF SIM ....... . BOOST . . . . . . .. HI BOOST HI TIMER _ + Figure 2-4 CI365 Timer General Information: • • • • • • • • • • Available in any mode except Lock Mode. The 2-digit display is blank unless there is a fault, in Diagnostic Mode, or Showroom Mode. Shows minutes until the timer reaches 1 minute. Switches to seconds at 1 minute, and counts down from 60 seconds. Timer is paused until 3 seconds after the last change in value then countdown begins. Adjusting the time on a running timer resets the seconds to zero. If counting down seconds and the “-” pad is touched the timer stops without alarm. Maximum time allowed is 99 minutes. Minimum time allowed is 1 minute. Timer turns off after 10 seconds if no time is entered. Starting the Timer: 1. 2. 3. 4. 5. 6. Unlock the cooktop. Press and release the TIMER pad. Time increases and decreases with a touch of the “+” or “-” pad. If the “+” or “-” pad is held continuously for 3 intervals the count rate increases. If the “+” or “-” pad is held continuously for additional 3 intervals, the count rate increases again. A continuously held “+” or “-” increases in this manner: 00, 01, 02, 03, 04, 05, 10, 15, 20, 30, 40, 50, 60, 70, 80, 90, 99. 2-5 #826139 - Revision A - February, 2015 Electronics Cooktop Induction (CI) Series Ending the Timer: • • • • At 60 seconds the One Minute Remaining beep sounds. At 00 the Timer Complete beep sounds until acknowledged. Touch of the TIMER or “-” pad stops Timer Complete beep and clears the display. Touch of the “+” pad adds time to the timer as described above. Display States of the Timer: • • When active the 2-digit display and Timer are on. Other displays are as described in Idle Mode or Operational Mode. Fans • • • • • • Fan control is determined by the temperature on the heat sinks. Both fans of a three or four coil assembly generator start simultaneously on low speed. If one heatsink reaches the threshold temperature, only that fan speed is increased. A very high power request, such as two elements on 100% or one on boost switches the fans on independently of the heatsink temperature. After generator is off fan continues to run until heat sink temperature is below 113° F, or up to 600 seconds. Fan is limited to low speed when the generator is off. Temperature thresholds: • 113° F – start low speed • 131° F – start high speed Modes Power Up Mode: • • • • All LED indicators are on for two seconds. After LED power up sequence the annunciator sounds the Acceptance beep. During the Acceptance beep the cooktop enters Lock Mode. LOCK display is on. Lock Mode: No pad can function except for the LOCK pad or the pads associated with entering Diagnostic Mode. Entering Lock Mode: • • • • • • Engages after ten continuous minutes of Idle Mode. After power up sequence. Touch and hold LOCK pad for 3 seconds when in Idle Mode. Annunciator sounds Acceptance beep when Lock Mode is entered. LOCK LED is visible. Annunciator sounds Failure beep if any control zone is active when trying to enter Lock Mode. Exiting Lock Mode: • • • • Touch and hold the LOCK pad for 3 seconds. If LOCK pad is held for more than 10 seconds cooktop relocks. Annunciator sounds Acceptance beep to indicate Lock Mode has been exited. LOCK LED turns off and control zones enter Idle Mode. #826139 - Revision A.2 - February, 2016 2-6 Electronics Cooktop Induction (CI) Series Valid key presses in Lock Mode: • • LOCK pad for exiting Lock Mode. Touch and hold “+” and “-” pads for 5 seconds to enter Diagnostic Mode. Display states in Lock Mode: • • LOCK display is on. All other displays are off. Idle Mode: Cooktop is unlocked and control zones are inactive. Valid key presses in Idle Mode: • • • LOCK – Touch and hold LOCK pad to enter Lock Mode. ON/OFF – Touch any control zone ON/OFF pad places that control zone in Wake-Up Mode. TIMER – Touch TIMER pad activates the Timer. Display states in Idle Mode: All displays are off. Wake-Up Mode: Entering Wake-Up Mode: • • Touch ON/OFF pad on any inactive control zone. All LEDs for that control zone flash until a power level is set. Valid key presses in Wake-Up Mode: • • • • • • • SIM or MLT – Activates the control zone at power level 1. HI – Activates the control zone at power level 10. BOOST – Activates the control zone at power level Boost. “…” – Activates the control zone at a power level 2 through 9. ON/OFF – Touch any other control zone ON/OFF pad causes that control zone to enter Wake-Up Mode. ON/OFF – Retouch of same ON/OFF pad causes control zone to return to Idle Mode. ALL OFF – Causes all active control zones to return to Idle Mode. Notes and Restrictions in Wake-Up Mode: • • • • • A valid key press must be made within 10 seconds or control zone returns to Idle Mode. If a valid key press is made but no pan is sensed on the coil assembly in 30 seconds the control zone returns to Idle Mode. During the 30 second wait, the “…” LEDs for that control zone flash the power level selected. If a bridge is activated and a pan is detected on one control zone but not all control zones being bridged the “…” LEDs for the unsensed control zones flash the power level that has been selected. If after 2 minutes one or more of the control zones in the bridge still does not sense a pot, all control zones in the bridge return to Idle Mode, including the sensed control zone. Display states in Wake-Up Mode: • • • All displays for a given control zone are flashing on/off. ALL OFF display is turned on. All other displays are off. 2-7 #826139 - Revision A - February, 2015 Electronics Cooktop Induction (CI) Series Operational Mode When any control zone is active at any power level greater than 0. Entering Operational Mode from Wake-Up Mode: • • • • SIM or MLT – Activates the control zone at power level 1. HI – Activates the control zone at power level 10. BOOST – Activates the control zone at power level Boost. “…” – Activates the control zone at power level 2 through 9. Corresponding to the “.” which was pressed. Exiting Operational Mode: • • ON/OFF – Touch the same ON/OFF pad returns control zone to Idle Mode. ALL OFF – All active control zones return to Idle Mode. Valid Key Presses in Operational Mode: • • • • • • • SIM or MLT – Activates the control zone at power level 1. HI – Activates the control zone at power level 10. BOOST – Activates the control zone at power level Boost. “…” – Activates the control zone at a power level 2 through 9. BRIDGE or BRG activates adjacent coil(s) to same power level. Can be used to deactivate the bridge function leaving the individual zones active. ON/OFF – Retouch of same ON/OFF pad causes control zone to return to Idle Mode. ALL OFF – All active control zones return to Idle Mode. Bridge and Coil Assembly Operational Mode Notes (See Figures 2-2 to 2-4): • If two coil assemblies are powered by the same generator board and the power demand between front and rear coil assembly is greater than 3700 Watts, the power level of both coil assemblies are reduced an equal percentage to 3700 Watts combined output. • Turning off a coil assembly that is part of a bridge, turns off all coil assemblies in the bridge. • If the coil assembly is turned back on, the bridge has to be reset. • After a bridge is activated, any control zone part of the bridge can be used to adjust power levels. • If a horizontal or vertical bridge is activated while another bridge is active, the most recent command takes precedence, activating the new bridge and shutting off the old bridge. Boost Operational Mode Notes (See Figures 2-1 to 2-4): • During Boost coils assemblies on the same generator board have their power level adjusted. • If Boost is activated, a second touch of the BOOST pad deactivates Boost, returning the power level to Hi. • Boost can not be activated for control zones in a bridge. • Boost has an operational time limit of 15 minutes. • Boost on 15” model raise 2300 Watts coil assembly to 3150 Watts. Maximum power level on 1400 Watt coil assembly is approximately 50%, or 700 Watts. • Boost on 24” model raises rear 2100 Watt coil assembly to 3000 Watts. Maximum power level on front 2100 Watt coil assembly is approximately 50%, or 1050 Watts. Boost raises 2600 Watt coil assembly to 3150 Watts. • Boost on 30” model raises rear 2100 Watt coil assembly to 3000 Watts. Maximum power level on front 2100 Watt coil assembly is approximately 50%, or 1050 Watts. The 2600 Watt coil assembly is raised to 3150 Watts. Maximum power level on the front 1400 Watt coil assembly is approximately 50%, or 700 Watts. • Boost on 36” model raises either rear 2100 Watt coil assemblies to 3000 Watts. Maximum power level on either front 2100 Watt coil assemblies is approximately 50%, or 1050 Watts. The 2600 Watt coil assembly is raised to 3700 Watts. • Boost on the 2600 Watt coil assembly does not affect other coil assemblies on the 24” and 36” units. • Boost on the 2600 Watt coil assembly affects the 1400 Watt coil assembly on the 30” unit. #826139 - Revision A.1 - September, 2015 2-8 Electronics Cooktop Induction (CI) Series Display States in Operational Mode • ALL OFF is turned on. • SIM/MLT, “…”, HI, BOOST, and BRIDGE/BRG are on if they have been activated. • All other displays for the active control zone are off. • All other displays in Idle Mode are off. • Power level indicators (SIM/MLT or “…”) less than the power level selected are on. • Power levels greater than selected power level are off. • Adjusting the power level on any bridged coil assembly changes all power levels and displays in the bridge. ALL OFF: • • De-energizes the entire cooktop at any time. Does not turn off the TIMER. Error Mode: Note: For error codes see Section 4 - Troubleshooting. • • • • • • • • • • • System logs initial generation of an error into memory for later inspection. Up to 8 errors can be logged in memory. All detected errors logged regardless of priority. Errors may be canceled by the user or be self-correcting. Specific zones are not recorded in diagnostic mode if a cooking zone specific error is logged. If there are more than 8 error codes the error log displays the most recent and discards the oldest error. Errors are displayed using error codes. Error codes are also used in Diagnostic Mode. When an error is displayed it is accompanied by the Failure beep. Active error is one that is currently being displayed, other errors can be debounced and logged while another error is active. Some errors are only displayed when a pad in the affected control zone is touched. Showroom Mode Notes and Restrictions in Showroom Mode: • Full user functionality with no power being supplied to the coil assemblies. • Available on 120 VAC (without transformer) or 240 VAC power. • Connecting the unit to 120 VAC will cause error E6. This is normal. Proceed with the steps to place unit in Showroom mode. • Generator fan may not run. • Hot surface indicator is not visible. Entering Showroom Mode: Engaged from Diagnostic Mode. Exiting Showroom Mode Disengaged from Diagnostic Mode. Operation of Showroom Mode: • No power is supplied to the coil assemblies. • Control operates as if power was supplied to the coil assemblies. • All visual and audible feedback functions as if in Operational Mode, except pot detection. • When cooktop is in Showroom Mode the LOCK LED is visible. • SH is displayed at all times in the 2-digit display, unless the timer is activated. • SH is displayed in 2-digit display 5 minutes after last Timer pad touch. • On loss of power cooktop returns to Showroom mode. 2-9 #826139 - Revision A - February, 2015 Electronics Cooktop Induction (CI) Series Diagnostic Mode Used to test the cooktop systems, view stored error codes, view real-time readings from system sensors, and to enter/exit Showroom mode. Entering Diagnostic Mode: • Must be entered from Lock Mode. • Touch and hold the “+” pad and “-” pad for 5 seconds. • After 5 seconds enters LED test, alerting the user to remove their fingers. • If another key pad sensor detects a signal, Diagnostic Mode does not engage. • If either the “+” or “-” pad is not released after 7 seconds, Diagnostic Mode does not engage. • Power to all coil assemblies is disabled. • After 60 seconds if no input is detected the control returns to Lock Mode. • ALL OFF pad exits Diagnostic Mode and the control returns to Lock Mode. • There are no audible signals. • To step through the various tests touch the “+” and “-” pads. • Rear left “…” display advances one LED for each test to identify which test is being performed. Diagnostic Mode Procedures a. LED Test: • All LED indicators for all control zones are on. LOCK LED, all segments of the Timer display, HOT display and all BOOST LEDs are on. • Front left control zone SIM/MLT, “…” or HI pads cycles LEDs to on, dim, or off. • One “.” displayed on the left rear control zone indicates LED test is running. • “+” pad engages Generator Reconfiguration. b. Generator Reconfiguration: • Touch “+” pad during the LED test. • Two “.” are displayed on left rear control zone. • CF is displayed in the 2-digit display. • Press and hold “+” and “-” pads together for 3 seconds activates the generator reconfiguration. • Acceptance beep is sounded after the requisite press-and-hold and the cooktop resets. • “-” pad engages LED Test. • “+” pad engages Control Temperature Readout. NOTES: Left rear “.” remains at two and CF is displayed in the 2-digit display during the reconfiguration. After replacing a generator, the LOCK light does not illuminate. The unit is locked. c. Control Temperature Readout: • Touch “+” pad during Generator Reconfiguration. • Three “.” are displayed on left rear control zone. • 2-digit display shows the ambient control temperature in °C. • Over 99° C (210° F), the decimal point of the 2 digit display turns on to indicate the temperature is 100° C or higher. • “-” pad engages Generator Reconfiguration. • “+” pad engages Heat Sink Temperature. d. Heat Sink Temperature Test: • Touch “+” pad during the Control Temperature Readout. • Four “.” are displayed on left rear control zone. • 2-digit display shows the current heat sink state. • “0” – temperature is ≤ 176° F – unit works correctly. • “1” – temperature is > 176° F – boost is disabled for affected zones. • “2” – temperature is > 192° F and ≤ 201° F – affected zone limited to 60% power. • temperature is > 201° F and ≤ 210° F zones limited to 40% power. • “3” – temperature is > 210° F – all affected zones turned off #826139 - Revision A.3 - March, 2016 2-10 Cooktop Induction (CI) Series Electronics Heat Sink Performance notes: • • • • • Front left control zone SIM/MLT and HI LEDS are on. Touch the front left control zone SIM/MLT or HI pad cycles through the heat sink temperatures. Left front control zone displays dimmed 1, 2, or 3 “.” to indicate heat sink number, with one ‘.’ on to indicate which heat sink temperature is displayed. • First LED is generator board #1. • Second LED is generator board #2. • Third LED is generator board #3. A touch of the “-” pad engages the Control Temperature Readout. A touch of the “+” pad engages the Coil Temperature test. e. Coil Temperature Test • Touch “+” pad during the Heat Sink Temperature test. • Five “.” are displayed on left rear control zone. • 2-digit display shows the coil temperature in °C. • Over 99° C (210° F), the decimal point of the 2 digit display turns on to indicate the temperature is 100° C (210° F) or higher. • Front left SIM/MLT and HI are on. Touch the front left control zone SIM/MLT or HI pad cycles through the coil temperatures. • Front left control zone displays dimmed 1, 2, 3, 4, or 5 “.” to indicate coil number, with one “.” on to indicate which coil temperature is displayed (See figure 2-5 for coil locations). • First LED is coil assembly and NTC #1 • Second LED is coil assembly and NTC #2 • Third LED is coil assembly and NTC #3 • Fourth LED is coil assembly and NTC #4 • Fifth LED is coil assembly and NTC #5 • “-” pad engages the heat sink temperature test. • “+” pad engages the error code indicator. Coil Temperature Performance Impact: • 160° C (320° F) boost is disabled for affected zones. • 240° C (464° F) affected zones are limited to 60% power. • 260° C (500° F) affected zones are turned off. • 285° C (545° F) all zones are turned off. Figure 2-5. Coil Assembly Locations 2-11 #826139 - Revision A - February, 2015 Electronics Cooktop Induction (CI) Series f. Error Code Indicator • Touch “+” pad during the Coil Temperature test. • Six “.” are displayed on left rear control zone. • Front control zone shows 0-8 dimmed “.” based on how many error codes are logged. • Fully lit LED indicates which error is being displayed in the 2-digit display. • If only a single error has been logged, only a single fully lit LED is displayed. • If no errors are logged SIM/MLT, HI, and “.” are not displayed and “- -” is displayed in the 2-digit display. • 2-digit display shows the corresponding error code stored in memory. • Front left SIM/MLT and HI are dimmed. A touch of the front control zone SIM/MLT or HI pads cycles through the stored error codes. • Touch and hold TIMER pad for 5 seconds to clear error code history. • Clearing the error code history is only possible if at least one error was logged. • Clearing the error code history is confirmed by a double beep. • If an error is currently present when the log is cleared, it immediately regenerates an error code. • “-” pad engages the Coil Temperature test. • “+” pad engages Showroom Mode menu. g. Showroom Mode • Touch “+” pad during the Error Code Indicator. • Seven “.” displayed on left rear control zone. • Touch the left front control zone HI pad to engage showroom mode. • SH is displayed in the 2-digit display when in showroom mode. • Touch the left front control zone SIM/MLT pad to disengage showroom mode. • ”-” pad engages the Error Code indicator. • “+” pad engages the Software Version indicator. h. Software Version Indicator • Touch “+” pad during Showroom Mode. • Eight “.” are displayed on left rear control zone. • 2-digit display cycles to show the software version of the control. • “-” pad engages the Showroom Mode menu. #826139 - Revision A - February, 2015 2-12 Electronics Cooktop Induction (CI) Series User Options Mode User Options Mode is used to set certain functions of the cooktop to the user’s preference. Entering User Options Mode • Cooktop must be in Idle Mode. • Touch and hold ALL OFF pad for 5 seconds. • After 5 seconds a valid selection beep sounds alerting the user to remove their finger. • If any other key pad sensor detects a signal, User Option Mode does not engage. • If the ALL OFF pad is not released after 7 seconds, User Option Mode does not engage. • Power to all hobs is disabled in User Option Mode. • If after 60 seconds no inputs are detected while in User Option Mode, the control returns to Idle Mode. • If the ALL OFF pad is touched at any time while in User Option Mode, the control returns to Idle Mode. • Use the “+” and “-” pads to step through the settings. • Left rear “…” display advances one LED for each setting. The number of “...” on identifies which setting is being adjusted. User Options a. Annunciator Volume: • One “.” displayed on of the left rear control zone. • Uo displayed on the 2-digit display. • The “.” displayed on the front left control zone show the current volume level. • Power level 1 for low, power level 5 for medium, and power level 10 for high. • Touch the front left control zone MLT/SIM pad or HI pad to adjust the volume up or down. • As the volume is adjusted, the annunciator sounds a tone at the newly selected setting. • A touch of the “+” pad advances the user options mode to Annunciator Frequency. b. Annunciator Frequency: • Two “.” displayed on of the left rear control zone. • Fr displayed on the 2-digit display. • The “.” displayed on the front left control zone shows the current frequency level. • Power level 1 for low, power level 5 for medium, and power level 10 for high. • Touch the front left control zone MLT/SIM pad or HI pad to adjust the frequency up or down. • As the frequency is adjusted, the annunciator sounds a tone at the newly selected setting. • A touch of the “+” pad advances the user options mode to Auto-Lock. c. Auto-Lock: • Auto-lock function is enabled by default. • If disabled, the cooktop does not automatically enter lock mode after 10 minutes of continuous idle mode. • Three “.” displayed on of the left rear control zone. • Lo is displayed in the 2-digit display. • Touch the left front control zone MLT/SIM pad to disable the auto-lock function. The front left control zone power level changes to level one.. • Touch the left front control zone HI pad to enables the auto-lock feature. The front left control zone power level changes to level ten. 2-13 #826139 - Revision A - February, 2015 Component Removal Cooktop Induction (CI) Series COMPONENT REMOVAL This section explains how to remove components from a Wolf CI Series. Depending on which component you are going to remove, you may have to remove other components first. Refer to the appropriate section in this manual that explains how to remove those various components. When reassembling, just reverse the steps that were used to remove the components. NOTE: Before attempting to access or remove any components from a Wolf appliance, take note of the WARNINGS and CAUTIONS below. • TO AVOID ELECTRIC SHOCK, POWER TO THE UNIT MUST BE DISCONNECTED WHENEVER SERVICING AND/OR ACCESSING COMPONENTS. • KEEP IN MIND THAT COOKTOP SURFACES AND COMPONENTS GET HOT DURING USE OF THE APPLIANCE. • PULLING A UNIT FROM ITS INSTALLATION SHOULD ONLY BE PERFORMED BY AN CERTIFIED SERVICE TECHNICIAN OR INSTALLER. • When working on the cooktop and components, be careful when handling sheet metal parts. They may have sharp edges. Tools Needed • • • • • • • • 6-Lobe Torx type driver size T-15 6-Lobe Torx type driver size T-20 6-Lobe Torx type driver size T-25 7/16” open ended wrench Phillips screw driver Small flat blade screw driver Flat blade screw driver Needle nose pliers #826139 - Revision A - February, 2015 3-2 Cooktop Induction (CI) Series Component Removal Glass Top To remove the glass top, first remove the cooktop from its installation, then (See Figure 3-1): 1. Use a T-20 Torx bit to extract screws from front frame. 2. Use a T-20 Torx bit to extract screws from back frame. 3. Remove glass top. Control Board To remove the control board, first remove the glass top, then (See Figure 3-2): 1. Use a needle nose pliers to compress top of control board support and lift control board off of control board support. 2. Proceed to next control board support until control board is removed from all control board supports. 3. Disconnect comm cable from control board. 4. Remove control board. Figure 3-1. Glass Top Screws Control Board Support Figure 3-2. Control Board 3-3 #826139 - Revision A.4 - January, 2017 Component Removal Cooktop Induction (CI) Series Coil Assembly Position Pin To remove the coil assembly, first remove the glass top, then (See Figure 3-3): 1. Use a small flat blade screw driver to lift the coil assembly from the wire side of the coil assembly. 2. Lift coil assembly off hook and loop fastener tab opposite the wire side of the coil assembly. 3. Use a T-25, a large phillips screw driver, or a large flat blade screw driver to loosen screws holding coil assembly wires. 4. Disconnect Negative Temperature Coefficient (NTC) sensor cable from below generator plate. 5. Remove coil assembly. Note: Position Pin Hook and Loop Fastener Coil assembly wires are covered by insulation. The black insulation is on the solid black wire and should be connected to the coil assembly terminal nearest the front. Figure 3-3. Coil Assembly Generator Plate To remove the generator plate, first disconnect the comm harness and remove the coil assemblies, then (See Figure 3-4): Ground Screws 1. Use a phillips screw driver to extract ground screws. 2. Use a T-15 to extract screws holding the generator plate to the generator. 3. Feed comm harness through generator plate. 4. Remove generator plate. Figure 3-4. Generator plate #826139 - Revision A - February, 2015 3-4 Cooktop Induction (CI) Series Component Removal Comm Harness To remove the comm harness, first remove the generator plate, then (See Figure 3-5): 1. Push tab away from comm harness connector on the generator. 2. Remove comm harness. 3. New comm harness has a key in the connector for control board side. Fan Assembly To remove the fan assembly, first remove the generator plate, then (See Figure 3-6): 1. Press connector tab in and disconnect fan assembly connector. 2. Use a small flat blade screw driver to spread the fan assembly retainer tabs slightly to release fan assembly. 3. Remove the fan assembly. Figure 3-5. Comm Cable on Generator and Control Figure 3-6. Fan Assembly 3-5 #826139 - Revision A - February, 2015 Component Removal Cooktop Induction (CI) Series Generator Assembly (except 36” models) To remove the generator assembly first remove the generator plate, then (See Figure 3-7): 1. Turn generator over and use T-20 or large flat blade screw driver to disconnect power wire harness. 2. Disconnect comm cable. 3. Remove generator assembly. Generator Assembly (36” models) To remove the generator assembly first remove the generator plate, then (See Figure 3-8): 1. Use a T-15 to remove wire clamp from generator being replaced. 2. Disconnect connecting wire spade terminals from the generator being replaced. 3. Disconnect the connecting ribbon cable from the generator being replaced. 3. Disconnect comm cable from the generator being replaced. 4. On four coil generator, turn generator over and use a T-20 or a large flat blade screw driver to disconnect power wire harness. 5. Remove generator. Figure 3-7. Generator Assembly Figure 3-8. Generators 36” Models #826139 - Revision A - February, 2015 3-6 Cooktop Induction (CI) Series Component Removal Intake Gasket To remove the intake gasket first remove the generator, then (See Figure 3-9): 1. Turn generator over and remove any remaining pieces of old intake gasket. 2. Attach new intake gasket. Support Spring, Mounting Pin, or Washer To remove the support spring, mounting pin or washer, first remove the generator, then (See Figure 3-10): 1. Remove support spring from mounting pin. 2. Use a 7/16” open end wrench to remove the mounting pin. 3. Remove washer from clinch stud. Figure 3-9. Intake Gasket Figure 3-10. Mounting Pin, Support Spring and Washer 3-7 #826139 - Revision A - February, 2015 Troubleshooting Cooktop Induction (CI) Series TROUBLESHOOTING This section of the manual contains troubleshooting information which will help the Certified Service Technician troubleshoot a Wolf CI Series. The table of contents below shows how the troubleshooting section is laid out. INDUCTION Generator and control board share the software for controlling the cooktop. If a logic or programing issue is suspected then the control board should be replaced first as it is the less expensive part. On 36” models the left generator is the controlling generator and contains most of the software for the generators. Error E6 will occur whenever cooktop is connected to 120 VAC. If the cooktop is to be used in Showroom mode, then after the error occurs proceed with the steps to place the cooktop in Showroom mode. Measuring current on the coil assemblies will not give reliable results, and not recommend as a diagnostic tool. • TO AVOID ELECTRIC SHOCK, POWER TO THE UNIT MUST BE DISCONNECTED WHENEVER SERVICING AND/OR ACCESSING COMPONENTS. • COOKTOP SURFACES AND COMPONENTS GET HOT DURING USE OF THE APPLIANCE. • PULLING A UNIT FROM ITS INSTALLATION SHOULD ONLY BE PERFORMED BY AN CERTIFIED SERVICE TECHNICIAN OR INSTALLER. • When working on the cooktop and components, be careful handling sheet metal parts. They may have sharp edges. #826139 - Revision A - February, 2015 4-2 Troubleshooting Cooktop Induction (CI) Series Diagnostic Mode Used to test the cooktop systems, view stored error codes, view real-time readings from system sensors, and to enter/exit Showroom mode. Entering Diagnostic Mode: • Enter from Lock Mode. • Touch and hold the “+” pad and “-” pad for 5 seconds. • After 5 seconds enters LED test, alerting the user to remove their fingers. • If another key pad sensor detects a signal, Diagnostic Mode does not engage. • If either the “+” or “-” pad is not released after 7 seconds, Diagnostic Mode does not engage. • Power to all coil assemblies is disabled. • After 60 seconds if no input is detected the control returns to Lock Mode. • ALL OFF pad exits Diagnostic Mode and the control returns to Lock Mode. • There are no audible signals. • To step through the various tests touch the “+” and “-” pads. • Rear left “…” display advances one LED for each test to identify which test is being performed. Diagnostic Mode Procedures LED Test: • All LED indicators for all control zones are on. LOCK LED, all segments of the Timer display, HOT display and all BOOST LEDs are on. • Front left control zone SIM/MLT, “…” or HI pads cycles LEDs to on, dim, or off. • One “.” displayed on the left rear control zone indicates LED test is running. • “+” pad engages Generator Reconfiguration. Generator Reconfiguration: • Touch “+” pad during the LED test. • Two “.” are displayed on left rear control zone. • CF is displayed in the 2-digit display. • Press and hold “+” and “-” pads together for 3 seconds activates the generator reconfiguration. • Acceptance beep is sounded after the requisite press-and-hold and the cooktop resets. • “-” pad engages LED Test. • “+” pad engages Control Temperature Readout. NOTES: Left rear “.” remains at two and CF is displayed in the 2-digit display during the reconfiguration. After replacing a generator the LOCK light does not illuminate. The unit is locked. Control Temperature Readout: • Touch “+” pad during Generator Reconfiguration. • Three “.” displayed on left rear control zone. • 2-digit display shows the ambient control temperature in °C. • Over 99° C (210° F), the decimal point of the 2 digit display turns on to indicate the temperature is 100° C or higher. • “-” pad engages Generator Reconfiguration. • “+” pad engages Heat Sink Temperature. Heat Sink Temperature Test: • Touch “+” pad during the Control Temperature Readout. • Four “.” displayed on left rear control zone. • 2-digit display shows the current heat sink state. • State is temperature based and not the actual heat sink temperature. • “0” – temperature is ≤ 176° F – cooktop works correctly. • “1” – temperature is > 176° F – boost is disabled for affected zones. • “2” – temperature is > 192° F and ≤ 201° F – affected zone limited to 60% power. • temperature is > 201° F and ≤ 210° F zones limited to 40% power. • “3” – temperature is > 210° F – all affected zones turned off 4-3 #826139 - Revision A.3 - March, 2016 Troubleshooting Cooktop Induction (CI) Series Heat Sink Performance: • • • • • Front left control zone SIM/MLT and HI LEDS are on. Touch the front left control zone SIM/MLT or HI pad cycles through the heat sink temperatures. Left front control zone displays dimmed 1, 2, or 3 “.” to indicate heat sink number, with one ‘.’ on to indicate which heat sink temperature is displayed. • First LED is generator board #1. • Second LED is generator board #2. • Third LED is generator board #3. A touch of the “-” pad engages the Control Temperature Readout. A touch of the “+” pad engages the Coil Temperature test. Coil Temperature Test • Touch “+” pad during the Heat Sink Temperature test. • Five “.” are displayed on left rear control zone. • 2-digit display shows the coil temperature in °C. • Over 99° C (210° F), the decimal point of the 2 digit display turns on to indicate the temperature is 100° C (210° F) or higher. • Front left SIM/MLT and HI are on. Touch the front left control zone SIM/MLT or HI pad cycles through the coil temperatures. • Front left control zone displays dimmed 1, 2, 3, 4, or 5 “.” to indicate coil number, with one “.” on to indicate which coil temperature is displayed (See figure 2-5 for coil locations). • First LED is coil assembly and NTC #1 • Second LED is coil assembly and NTC #2 • Third LED is coil assembly and NTC #3 • Fourth LED is coil assembly and NTC #4 • Fifth LED is coil assembly and NTC #5 • “-” pad engages the heat sink temperature test. • “+” pad engages the error code indicator. Coil Temperature Performance Impact: • 160° C (320° F) boost is disabled for affected zones. • 240° C (464° F) affected zones are limited to 60% power. • 260° C (500° F) affected zones are turned off. • 285° C (545° F) all zones are turned off. Figure 4-1. Coil Assembly Locations #826139 - Revision A - February, 2015 4-4 Troubleshooting Cooktop Induction (CI) Series Error Code Indicator • Touch “+” pad during the Coil Temperature test. • Six “.” are displayed on left rear control zone. • Front control zone shows 0-8 dimmed “.” based on how many error codes are logged. • Fully lit LED indicates which error is being displayed in the 2-digit display. • If only a single error has been logged, only a single fully lit LED is displayed. • If no errors are logged SIM/MLT, HI, and “.” are not displayed and “- -” is displayed in the 2-digit display. • 2-digit display shows the corresponding error code stored in memory. • Front left SIM/MLT and HI are dimmed. A touch of the front control zone SIM/MLT or HI pads cycles through the stored error codes. • Touch and hold TIMER pad for 5 seconds to clear error code history. • Clearing the error code history is only possible if at least one error was logged. • Clearing the error code history is confirmed by a double beep. • If an error is currently present when the log is cleared, it immediately regenerates an error code. • “-” pad engages the Coil Temperature test. • “+” pad engages Showroom Mode menu. Showroom Mode • Touch “+” pad during the Error Code Indicator. • Seven “.” displayed on left rear control zone. • Touch the left front control zone HI pad to engage showroom mode. • SH is displayed in the 2-digit display when in showroom mode. • Touch the left front control zone SIM/MLT pad to disengage showroom mode. • ”-” pad engages the Error Code indicator. • “+” pad engages the Software Version indicator. Software Version Indicator • Touch “+” pad during Showroom Mode. • Eight “.” are displayed on left rear control zone. • 2-digit display cycles to show the software version of the control. • “-” pad engages the Showroom Mode menu. 4-5 #826139 - Revision A - February, 2015 Troubleshooting Cooktop Induction (CI) Series General Errors Table Code Description Test 22 Pad Error None 1. Cycle unit power. 2. Reseat comm cable(s). 3. Replace control board. 30 Data Flash Error (result of flashing software) None 1. Cycle unit power. 2. Replace control board. 31 Invalid Configuration None 1. Perform generator reconfiguration. 2. Replace generator. Action NOTE: After installing a new generator, the LOCK light does not illuminate. The unit is in LOCK and can be placed in Diagnostics. Control Temperature Readout 1. Test fan operation. 2. Ensure fan vent is not blocked. 3. No large pot or pan overlapping the control area. 4. Direct sunlight or heat lamps not shinning on controls. 5. Replace control board. 36 TC temperature too high 39 Controller Options Error None 1. Cycle unit power. 2. Inspect and reseat comm cables. 3. Replace control board. 47 LIN Communication Error None 1. Inspect control board. 2. Inspect and reseat comm cables. 3. Replace control board. U400 Over Voltage #826139 - Revision A.3 - March, 2016 1. Test L1 to Ground 2. Test L2 to Ground 3. Test L1 to L2 4-6 1. L1 to Ground and L2 to Ground ≤ 132 VAC. 2. L1 to L2 ≤ 265 VAC 3. Confirm single phase circuit. 4. If electrical problem report issue to consumer. 5. If no issue found replace generator. Cooktop Induction (CI) Series Troubleshooting Cooking Zone Specific Errors Test Code Description E2 Coil temperature too high E4 Configuration implausible (control board issue) E6 Power supply error E7 Unspecified error (usually accompanied by another error) None E8 Fan error Test fan - See page 4-8 E9 Temperature monitoring error None 1. Cycle unit power. 2. Replace generator. EA Controller error None 1. Cycle unit power. 2. Perform generator reconfigureation. 3. Replace control board. Coil temperature test None 1. 2. 3. 4. Action 1. Test fan operation. 2. Ensure fan vent is not blocked. 3. Replace coil assembly. 1. Cycle unit power. 2. Perform generator reconfiguration. 3. Replace control board. 1. L1 to Ground and L2 to Ground Test L1 to Ground between 90 VAC and 132 VAC. Test L2 to Ground 2. L1 to L2 between 180 VAC and Test L1 to L2 265 VAC. Test cooktop cabinet to adjacent ground receptacle 3. Resistance to ground should be close to zero ohms. 4. Report issue to consumer. 5. Check generators and replace as needed. 6. Perform generator reconfiguration. 4-7 Cycle unit power. 1. Test fan operation. 2. Ensure fan vent is not blocked. 3. Replace generator. #826139 - Revision A.3 - March, 2016 Troubleshooting Cooktop Induction (CI) Series Fan Test Each generator board has a 12 VDC fan. It is not possible to check the fan by measuring the resistance. Resistance is never consistant. Fan resistance is never constant so is not measurable. 1. 2. 3. 4. Turn the coil assembly on at Boost for each generator board. The fan will start as soon as in Boost. Use a 9 volt battery to energize the fan. Black wire to negative and red wire to positive. Assure the fan vent is not blocked. There is no minimum distance to non-combustible surfaces below the cooktop. However, a structure to close to the fan vents, or an appliance that is getting warm can affect the coil NTC sensors. If possible remove the structure from beneath the cooktop and test again. HOT Indicator Stays On One of the coil assembly NTC reading 50° C (122° F) or above will cause the HOT indicator to come on. 1. Check coil assembly NTC temperatures in Diagnostics. They should be consistant. A defective NTC reading higher than the actual temperature would require replacing that generator. 2. A warm coil temperature can be caused by heat on the coil assembly such as from direct sunlight or a hot pan sitting on the coil assembly. 3. Cycle unit power. 4. Assure fan is operating and fan vent is not blocked. 4. If no coil assembly NTC is reading 50° C (122° F) or above, replace the control board. A damaged control board or stuck HOT indicator may cause the issue. No Pan Detection The pan detection system is an integral part of the generator. Only magnet pans work with induction generators. 1. 2. 3. 4. Test pan for correct magnetic properties by stick a magnet to the bottom and side of the pan. Pan should be the same size as the coil assembly. Check for error codes in diagnostics. Check voltage to the cooktop. See error code E6 on page 4-7 #826139 - Revision A - February, 2015 4-8 Technical Data Cooktop Induction (CI) Series • THIS APPLIANCE MUST BE PROPERLY GROUNDED AT ALL TIMES WHEN ELECTRICAL POWER IS APPLIED. • DO NOT GROUND APPLIANCE WITH NEUTRAL (WHITE) HOUSE SUPPLY WIRE. A SEPARATE GROUND WIRE MUST BE UTILIZED. • IF ALUMINUM HOUSE SUPPLY WIRING IS UTILIZED, SPLICE APPLIANCE COPPER WIRE TO ALUMINUM HOUSE WIRING USING SPECIAL CONNECTORS DESIGNED AND CERTIFIED FOR JOINING COPPER AND ALUMINUM. FOLLOW THE CONNECTOR MANUFACTURES RECOMMENDED PROCEDURE CAREFULLY. IMPROPER CONNECTION CAN RESULT IN A FIRE HAZARD. Power Requirements: 180 VAC to 265 VAC, single phase, 60 Hz, dedicated circuit. Power Rating and Electrical Service: 15” Induction Models - 3.7 kW at 240 VAC 3.2 kW at 208 VAC Breaker - 20 Amp dedicated circuit 24” Induction Models - 6.85 kW at 240 VAC 5.9 kW at 208 VAC Breaker - 30 Amp dedicated circuit 30” Induction Models - 7.4 kW at 240 VAC 6.4 kW at 208 VAC Breaker - 40 Amp dedicated circuit 36” Induction Models - 11.1 kW at 240 VAC 9.6 kW at 208 VAC Breaker - 50 Amp dedicated circuit kW = kilowatts VAC = Volts A/C #826139 - Revision A.4 - January, 2017 5-2 Technical Data Cooktop Induction (CI) Series Induction Power Level Charts The power level charts list the percentage of total power, watts for each setting on the coil assembly, and the maximum operation time at that power level. Percentages and wattages are approximate. Medium (50% Power) is at power level 8. 15” Induction Power Level Level LEDs Displayed % of Power 1400 W Coil 2300 W Coil Operation Limit 0 0 0.00% 0.0 0.0 1 MLT/SIM 2.00% 28 Watts 46 Watts 8 Hours 2 2 5.50% 77 Watts 126.5 Watts 8 Hours 3 3 11.00% 154 Watts 253 Watts 6 Hours 4 4 16.50% 231 Watts 379.5 Watts 6 Hours 5 5 22.00% 308 Watts 506 Watts 6 Hours 6 6 26.50% 371 Watts 609.5 Watts 6 Hours 7 7 36.00% 504 Watts 828 Watts 6 Hours 8 8 50.00% 700 Watts 1150 Watts 2 Hours 9 9 75.00% 1050 Watts 1725 Watts 2 Hours 10 HI 100.00% 1400 Watts 2300 Watts 2 Hours Boost Boost N/A N/A 3150 Watts 30 minutes 24” Induction Power Level 0 LEDs Displayed 0 1 MLT/SIM 2.00% 42 Watts 42 Watts 52 Watts 8 Hours 2 2 5.50% 115.5 Watts 115.5 Watts 143 Watts 8 Hours 3 3 11.00% 231 Watts 231 Watts 286 Watts 6 Hours 4 4 16.50% 346.5 Watts 346.5 Watts 429 Watts 6 Hours 5 5 22.00% 462 Watts 462 Watts 572 Watts 6 Hours 6 6 26.50% 556.5 Watts 556.5 Watts 689 Watts 6 Hours 7 7 36.00% 756 Watts 756 Watts 936 Watts 6 Hours 8 8 50.00% 1050 Watts 1050 Watts 1300 Watts 2 Hours 9 9 75.00% 1575 Watts 1575 Watts 1950 Watts 2 Hours 10 HI 100.00% 2100 Watts 2100 Watts 2600 Watts 2 Hours Boost Boost N/A N/A 3000 Watts 3150 Watts 30 minutes Level % of Power 2100 W Coil 2100 W Coil 2600 W Coil 0.00% 0.0 0.0 0.0 Operation Limit Coil assemblies that Bridge 5-3 #826139 - Revision A - February, 2015 Technical Data Cooktop Induction (CI) Series 30” Induction Power Level 0 LEDs Displayed 0 1 Level % of Power 2100 W Coil 2100 W Coil 1400 W Coil 2600 W Coil Operation Limit 0.00% 0.0 0.0 0.0 0.0 MLT/SIM 2.00% 42 Watts 42 Watts 28 Watts 52 Watts 8 Hours 2 2 5.50% 115.5 Watts 115.5 Watts 77 Watts 143 Watts 8 Hours 3 3 11.00% 231 Watts 231 Watts 154 Watts 286 Watts 6 Hours 4 4 16.50% 346.5 Watts 346.5 Watts 231 Watts 429 Watts 6 Hours 5 5 22.00% 462 Watts 462 Watts 308 Watts 572 Watts 6 Hours 6 6 26.50% 556.5 Watts 556.5 Watts 371 Watts 689 Watts 6 Hours 7 7 36.00% 756 Watts 756 Watts 504 Watts 936 Watts 6 Hours 8 8 50.00% 1050 Watts 1050 Watts 700 Watts 1300 Watts 2 Hours 9 9 75.00% 1575 Watts 1575 Watts 1050 Watts 1950 Watts 2 Hours 10 HI 100.00% 2100 Watts 2100 Watts 1400 Watts 2600 Watts 2 Hours Boost Boost N/A N/A 3000 Watts N/A 3150 Watts 30 minutes 36” Induction Power Level Level LEDs Displayed 0 0 0.00% 0.0 0.0 0.0 0.0 0.0 1 MLT/SIM 2.00% 42 Watts 42 Watts 42 Watts 42 Watts 52 Watts 8 Hours 2 2 5.50% 115.5 Watts 115.5 Watts 115.5 Watts 115.5 Watts 143 Watts 8 Hours 3 3 11.00% 231 Watts 231 Watts 231 Watts 231 Watts 286 Watts 6 Hours 4 4 16.50% 346.5 Watts 346.5 Watts 346.5 Watts 346.5 Watts 429 Watts 6 Hours 5 5 22.00% 462 Watts 462 Watts 462 Watts 462 Watts 572 Watts 6 Hours 6 6 26.50% 556.5 Watts 556.5 Watts 556.5 Watts 556.5 Watts 689 Watts 6 Hours 7 7 36.00% 756 Watts 756 Watts 756 Watts 756 Watts 936 Watts 6 Hours 8 8 50.00% 1050 Watts 1050 Watts 1050 Watts 1050 Watts 1300 Watts 2 Hours 9 9 75.00% 1575 Watts 1575 Watts 1575 Watts 1575 Watts 1950 Watts 2 Hours 10 HI 100.00% 2100 Watts 2100 Watts 2100 Watts 2100 Watts 2600 Watts 2 Hours Boost Boost N/A N/A 3000 Watts N/A 3000 Watts 3700 Watts 30 minutes % of Power 2100 W Coil 2100 W Coil 2100 W Coil 2100 W Coil 2600 W Coil Coil assemblies that Bridge #826139 - Revision A - February, 2015 5-4 Operation Limit Wiring Cooktop Induction (CI) Series WIRING DIAGRAM MODEL: CI15 - This wiring information is provided for use by qualified service personnel only. - Disconnect appliance from electrical supply before begining service. - Be sure all grounding devices are connected when service is complete. - Failure to observe the above warnings may result in severe electrical shock. PART NUMBER 823961 Rev B GREEN/ YELLOW L2 GREEN/YELLOW BLUE BROWN 2300W COIL FAN BLACK/BLUE 2-PIN NTC BLACK BLACK/ORANGE 2-PIN NTC BLACK GENERATOR 1400W COIL 4-PIN COMM USER INTERFACE #826139 - Revision A - February, 2015 6-2 L1 Wiring Cooktop Induction (CI) Series WIRING DIAGRAM MODEL: CI24 - This wiring information is provided for use by qualified service personnel only. - Disconnect appliance from electrical supply before begining service. - Be sure all grounding devices are connected when service is complete. - Failure to observe the above warnings may result in severe electrical shock. PART NUMBER 823973 Rev A BROWN L1 BLACK BLUE L2 BLUE GREEN/YELLOW 2100W COIL 1 FAN 2 3 4 5 FAN 2600W COIL BLACK/YELLOW BLACK/ORANGE 2-PIN NTC 2-PIN NTC BLACK BLACK BLACK/YELLOW 2-PIN NTC BLACK 4-PIN COMM GENERATOR 2100W COIL USER INTERFACE 6-3 #826139 - Revision A - February, 2015 Wiring Cooktop Induction (CI) Series WIRING DIAGRAM MODEL: CI30 - This wiring information is provided for use by qualified service personnel only. - Disconnect appliance from electrical supply before begining service. - Be sure all grounding devices are connected when service is complete. - Failure to observe the above warnings may result in severe electrical shock. PART NUMBER 823962 Rev B BROWN L1 BLACK BLUE L2 BLUE GREEN/YELLOW 2100W COIL 1 FAN 2 3 4 5 FAN 2600W COIL BLACK/YELLOW BLACK/ORANGE 2-PIN NTC 2-PIN NTC BLACK BLACK BLACK/YELLOW BLACK/ORANGE 2-PIN NTC 2-PIN NTC BLACK BLACK 4-PIN COMM GENERATOR 1400W COIL 2100W COIL USER INTERFACE #826139 - Revision A - February, 2015 6-4 Wiring Cooktop Induction (CI) Series WIRING DIAGRAM MODEL: CI36 - This wiring information is provided for use by qualified service personnel only. - Disconnect appliance from electrical supply before begining service. - Be sure all grounding devices are connected when service is complete. - Failure to observe the above warnings may result in severe electrical shock. PART NUMBER 823963 Rev B GRAY BROWN BLACK 2100W COIL L1 BLUE 2100W COIL L2 BLUE TC N AC K N BL PI BL BLACK/YELLOW BLACK 2-PIN NTC FAN 2- AC K/ YE LL O W GREEN/YELLOW 1 2 3 4 5 GREEN/YELLOW BLUE BLACK 4-PIN RIBBON FAN BLACK/ORANGE FAN 2-PIN NTC GENERATOR BLACK/YELLOW BLACK 2-PIN NTC 4-PIN COMM BLACK/YELLOW BLACK 2-PIN NTC GENERATOR 2100W COIL BLACK 1-PIN COMM 2600W COIL 2100W COIL USER INTERFACE 6-5 #826139 - Revision A - February, 2015