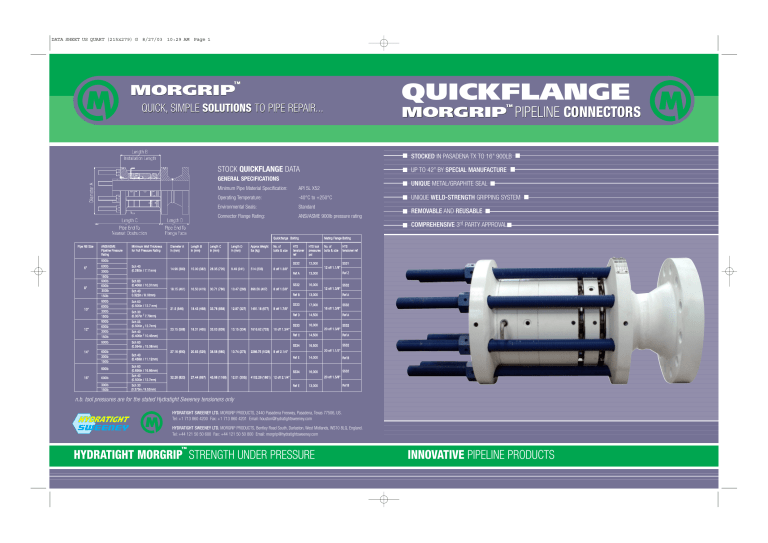

DATA SHEET US QUART (215x279) G 8/27/03 10:29 AM Page 1 ™ QUICKFLANGE MORGRIP QUICK, SIMPLE SOLUTIONS TO PIPE REPAIR... ™ MORGRIP PIPELINE CONNECTORS STOCKED IN PASADENA TX TO 16” 900LB STOCK QUICKFLANGE DATA UP TO 42” BY SPECIAL MANUFACTURE GENERAL SPECIFICATIONS UNIQUE METAL/GRAPHITE SEAL Minimum Pipe Material Specification: API 5L X52 Operating Temperature: -40°C to +250°C Environmental Seals: Standard Connector Flange Rating: ANSI/ASME 900lb pressure rating UNIQUE WELD-STRENGTH GRIPPING SYSTEM REMOVABLE AND REUSABLE COMPREHENSIVE 3rd PARTY APPROVAL Quickflange Quick lange Bolting Pipe NB Size ANSI/ASME Pipeline Pressure Rating Ra ting Minimum Wall all Thickness for or Full Pressure Ra Rating ting Diameter A in (mm) Length B in (mm) Length C in (mm) Length D in (mm) Approx Weight eight lbs (kg) No. of bolts & size Sch 40 (0.280in / 7.11mm) 14.96 (380) 15.00 (382) 28.35 (720) 9.49 (241) 514 (233) 8 of off 1.3/8" 900lb 6" 600lb 300lb 8" 150lb 900lb 600lb 300lb 150lb 900lb 10" 600lb 300lb 150lb 900lb 12" 600lb 300lb 150lb 900lb 14" 16" Sch 60 (0.406in / 10.31mm) Sch 40 0.322in / 8.18mm) Sch 60 (0.500in / 12.7 mm) 18.15 (461) 21.5 (546) 16.50 (419) 18.43 (468) 30.71 (780) 33.78 (858) 10.47 (266) 12.87 (327) 896.56 (407) 1491.18 (677) Sch 40 (0.406in / 10.46mm) 23.15 (588) 18.31 (465) 33.03 (839) 13.15 (334) 1616.62 (733) Sch 40 (0.438in / 11.12mm) 900lb Sch 60 (0.656in / 16.66mm) 600lb Sch 40 (0.500in / 12.7mm) 300lb 150lb Sch 30 (0.375in / 9.52mm) 27.16 (690) 32.28 (820) 20.83 (529) 27.44 (697) 38.58 (980) 45.98 (1168) 10.74 (273) 12.01 (305)) 2266.75 (1028) HTS tool No. of pressures bolts & size psi HTS tensioner ref SS32 12,000 SS31 12 of off 1.1/8" Ref A 13,000 SS32 16,000 Ref B 13,000 SS33 17,000 Ref Z SS32 12 of off 1.3/8" Ref A SS32 16 of off 1.3/8" 8 of off 1.7/8" Ref D 14,500 SS33 16,000 Ref A SS32 20 of off 1.3/8" 10 of off 1.3/4" Sch 60 (0.594in / 15.08mm) 600lb 300lb 150lb HTS tensioner ref 8 of off 1.5/8" Sch 30 (0.307in / 7.79mm) Sch XS (0.500in / 12.7mm) Mating Ma ting Flange Bolting Ref C 14,500 SS34 16,500 Ref A SS32 20 of off 1.1/2" 8 of off 2.1/4" Ref E 14,000 SS34 16,000 Ref B SS32 20 of off 1.5/8" 4102.29 (1861) 12 of off 2.1/4" Ref E 13,000 Ref B n.b. tool pressures are for the stated Hydratight Sweeney tensioners only HYDRATIGHT SWEENEY LTD. MORGRIP PRODUCTS, 2440 Pasadena Freeway, Pasadena, Texas 77506, US. Tel: +1 713 860 4200 Fax: +1 713 860 4201 Email: houston@hydratightsweeney.com HYDRATIGHT SWEENEY LTD. MORGRIP PRODUCTS, Bentley Road South, Darlaston, West Midlands, WS10 8LQ, England. Tel: +44 121 50 50 600 Fax: +44 121 50 50 800 Email: morgrip@hydratightsweeney.com ™ HYDRATIGHT MORGRIP STRENGTH UNDER PRESSURE INNOVATIVE PIPELINE PRODUCTS DATA SHEET US QUART (215x279) G 8/27/03 10:29 AM Page 3 QUICKFLANGE TECHNICAL DATA... ™ MORGRIP PIPELINE CONNECTORS Quickflange from MORGRIP™ is the high specification pipeline connector used for permanent subsea repair and tie-in applications around the world. As the connector bolts are tightened, the components move together, simultaneously compressing the seals and activating the ball gripping mechanism. Pre-set gap spacers have been replaced by simple shear pins and other mechanisms simplified With its successful MORGRIP™ supply history of over to ensure as few subsea tasks as possible. The external pressure test is all that 1100 connectors Hydratight Sweeney now offers remains to prove a successful activation. Quickflange - which provides the benefits of MORGRIP™ at a competitive price. Quickflange employs patented and unique weld-strength grip and metal/graphite sealing systems in a connector simplified for easy Environmental Seal installation. External Test Port Metal/Graphite Twin Seal System There is no similar product that has more comprehensive third party approvals than MORGRIP™ which offers as standard: Compliance with API 6H DNV Type Approval up to 42” and 2500lb (in accordance with RP-F104) Lloyds Register Approval -all sizes and pressure ratings APPLICATIONS Standard Quickflange is terminated by a 900lb RTJ flange and is installed by customer personnel through simple Hydratight Sweeney bolt tightening. The product is also simple to remove and to re-set ready for use in other typical applications such as: Pipeline spool repair (with and without misalignment flanges). Riser Repair (above and below waterline). Quickflange metal seals compliment those of ball flanges and RTJ flanges. Quickflange out-performs 9/10 welds in terms of fatigue. Quickflange has a design life of 30 years. Quickflange is easily installed by customer personnel. Gripping Segments Ball Cage Locking Pin Shear Pin Preset Gap Spacers ASME 900lb RTJ Flange Pipeline tie-in. OVATIVE PIPELINE PRODUCTS INNOVATIVE PIPELINE PRODUCTS INNOVATIVE PIPELINE PRODUCTS INNOVATIVE PIPELINE PRODUCTS INNOVATIVE PIPELINE PRO DATA SHEET US QUART (215x279) G 8/27/03 10:29 AM Page 3 QUICKFLANGE TECHNICAL DATA... ™ MORGRIP PIPELINE CONNECTORS Quickflange from MORGRIP™ is the high specification pipeline connector used for permanent subsea repair and tie-in applications around the world. As the connector bolts are tightened, the components move together, simultaneously compressing the seals and activating the ball gripping mechanism. Pre-set gap spacers have been replaced by simple shear pins and other mechanisms simplified With its successful MORGRIP™ supply history of over to ensure as few subsea tasks as possible. The external pressure test is all that 1100 connectors Hydratight Sweeney now offers remains to prove a successful activation. Quickflange - which provides the benefits of MORGRIP™ at a competitive price. Quickflange employs patented and unique weld-strength grip and metal/graphite sealing systems in a connector simplified for easy Environmental Seal installation. External Test Port Metal/Graphite Twin Seal System There is no similar product that has more comprehensive third party approvals than MORGRIP™ which offers as standard: Compliance with API 6H DNV Type Approval up to 42” and 2500lb (in accordance with RP-F104) Lloyds Register Approval -all sizes and pressure ratings APPLICATIONS Standard Quickflange is terminated by a 900lb RTJ flange and is installed by customer personnel through simple Hydratight Sweeney bolt tightening. The product is also simple to remove and to re-set ready for use in other typical applications such as: Pipeline spool repair (with and without misalignment flanges). Riser Repair (above and below waterline). Quickflange metal seals compliment those of ball flanges and RTJ flanges. Quickflange out-performs 9/10 welds in terms of fatigue. Quickflange has a design life of 30 years. Quickflange is easily installed by customer personnel. Gripping Segments Ball Cage Locking Pin Shear Pin Preset Gap Spacers ASME 900lb RTJ Flange Pipeline tie-in. OVATIVE PIPELINE PRODUCTS INNOVATIVE PIPELINE PRODUCTS INNOVATIVE PIPELINE PRODUCTS INNOVATIVE PIPELINE PRODUCTS INNOVATIVE PIPELINE PRO DATA SHEET US QUART (215x279) G 8/27/03 10:29 AM Page 1 ™ QUICKFLANGE MORGRIP QUICK, SIMPLE SOLUTIONS TO PIPE REPAIR... ™ MORGRIP PIPELINE CONNECTORS STOCKED IN PASADENA TX TO 16” 900LB STOCK QUICKFLANGE DATA UP TO 42” BY SPECIAL MANUFACTURE GENERAL SPECIFICATIONS UNIQUE METAL/GRAPHITE SEAL Minimum Pipe Material Specification: API 5L X52 Operating Temperature: -40°C to +250°C Environmental Seals: Standard Connector Flange Rating: ANSI/ASME 900lb pressure rating UNIQUE WELD-STRENGTH GRIPPING SYSTEM REMOVABLE AND REUSABLE COMPREHENSIVE 3rd PARTY APPROVAL Quickflange Quick lange Bolting Pipe NB Size ANSI/ASME Pipeline Pressure Rating Ra ting Minimum Wall all Thickness for or Full Pressure Ra Rating ting Diameter A in (mm) Length B in (mm) Length C in (mm) Length D in (mm) Approx Weight eight lbs (kg) No. of bolts & size Sch 40 (0.280in / 7.11mm) 14.96 (380) 15.00 (382) 28.35 (720) 9.49 (241) 514 (233) 8 of off 1.3/8" 900lb 6" 600lb 300lb 8" 150lb 900lb 600lb 300lb 150lb 900lb 10" 600lb 300lb 150lb 900lb 12" 600lb 300lb 150lb 900lb 14" 16" Sch 60 (0.406in / 10.31mm) Sch 40 0.322in / 8.18mm) Sch 60 (0.500in / 12.7 mm) 18.15 (461) 21.5 (546) 16.50 (419) 18.43 (468) 30.71 (780) 33.78 (858) 10.47 (266) 12.87 (327) 896.56 (407) 1491.18 (677) Sch 40 (0.406in / 10.46mm) 23.15 (588) 18.31 (465) 33.03 (839) 13.15 (334) 1616.62 (733) Sch 40 (0.438in / 11.12mm) 900lb Sch 60 (0.656in / 16.66mm) 600lb Sch 40 (0.500in / 12.7mm) 300lb 150lb Sch 30 (0.375in / 9.52mm) 27.16 (690) 32.28 (820) 20.83 (529) 27.44 (697) 38.58 (980) 45.98 (1168) 10.74 (273) 12.01 (305)) 2266.75 (1028) HTS tool No. of pressures bolts & size psi HTS tensioner ref SS32 12,000 SS31 12 of off 1.1/8" Ref A 13,000 SS32 16,000 Ref B 13,000 SS33 17,000 Ref Z SS32 12 of off 1.3/8" Ref A SS32 16 of off 1.3/8" 8 of off 1.7/8" Ref D 14,500 SS33 16,000 Ref A SS32 20 of off 1.3/8" 10 of off 1.3/4" Sch 60 (0.594in / 15.08mm) 600lb 300lb 150lb HTS tensioner ref 8 of off 1.5/8" Sch 30 (0.307in / 7.79mm) Sch XS (0.500in / 12.7mm) Mating Ma ting Flange Bolting Ref C 14,500 SS34 16,500 Ref A SS32 20 of off 1.1/2" 8 of off 2.1/4" Ref E 14,000 SS34 16,000 Ref B SS32 20 of off 1.5/8" 4102.29 (1861) 12 of off 2.1/4" Ref E 13,000 Ref B n.b. tool pressures are for the stated Hydratight Sweeney tensioners only HYDRATIGHT SWEENEY LTD. MORGRIP PRODUCTS, 2440 Pasadena Freeway, Pasadena, Texas 77506, US. Tel: +1 713 860 4200 Fax: +1 713 860 4201 Email: houston@hydratightsweeney.com HYDRATIGHT SWEENEY LTD. MORGRIP PRODUCTS, Bentley Road South, Darlaston, West Midlands, WS10 8LQ, England. Tel: +44 121 50 50 600 Fax: +44 121 50 50 800 Email: morgrip@hydratightsweeney.com ™ HYDRATIGHT MORGRIP STRENGTH UNDER PRESSURE INNOVATIVE PIPELINE PRODUCTS Who We Are Hydratight Mechanical Connectors One Company, Total Support, Complete Solutions Hydratight Mechanical Connectors are equal in strength and performance to that of a welded connection. They are suitable for any application where a weld would be a traditional solution, providing the same safety, strength and reliability. Hydratight’s Mechanical Connectors have a 100% leak-free in-service record. Our global network means you can rely on the right people, products and services wherever you are in the world. Mechanical Connector Installation Step 1 Mechanical Connectors from Hydratight are available in a variety of formats, including standard flange termination and the unique pipe-to-pipe direct coupling connector. All formats suit specific applications, whether for use on carbon steel, stainless steel or duplex pipes. The following illustrates the steps to follow for a pipe-to-pipe installation. Leak located and isolated, damaged section of pipeline is cut and removed. Mechanical Connectors Email us at: solutions@hydratight.com Or find your local representative at: hydratight.com/contact Over many years, Hydratight has provided world-class bolted joint solutions and continues to set international standards in joint integrity for its customers on a global scale. Hydratight works in partnership with the world’s leading OEMs using the latest computer technology and market leading development facilities. We continue to push back the boundaries of technology to provide fast, accurate and reliable solutions to critical assembly problems. Our people are the key to our success: qualified, competent and innovative people, working closely with our customers ensuring a total understanding of their requirements. One Company - Meets Standards Totally committed to safety and quality, all Hydratight products and services are designed, manufactured and carried out within a management system in accordance with ISO 9001: 2008 (Quality Management), ISO 14001: 2004 (Environmental Management) and OHSAS 18001:2007 (Occupational Health and Safety). Scan to view demo video. Our extensive bolting and machining services include: Step 2 Step 3 Connectors deployed and stabbed onto pipeline(s). Connectors activated. • Torque and tension bolting equipment • Portable machining equipment • Product sales, rental and technical support • Product service and training • Special designs and alternative sizes are available upon request Hydratight’s Mechanical Connectors Our range of Mechanical Connectors provides high integrity connections for all types of metal pipe work, onshore, offshore and subsea. Used to replace the need for welding, they are based upon a unique pipe gripping and sealing system which allows the connectors to withstand high internal pressure and external load conditions. Step 4 Step 5 New spool piece positioned. Spool piece connected to Mechanical Connectors. For additional specifications on our products for sale or rental, videos of our products in action, or information about our on-site services, please visit us on the web at hydratight.com. Engineering Driven Safety Focused Solutions hydratight.com 3 Material sourced from fully sustainable, managed forests using Elemental Chlorine Free fibre. HT/MC/US/02-13 2 hydratight.com hydratight.com 7 Who We Are Hydratight Mechanical Connectors One Company, Total Support, Complete Solutions Hydratight Mechanical Connectors are equal in strength and performance to that of a welded connection. They are suitable for any application where a weld would be a traditional solution, providing the same safety, strength and reliability. Hydratight’s Mechanical Connectors have a 100% leak-free in-service record. Our global network means you can rely on the right people, products and services wherever you are in the world. Mechanical Connector Installation Step 1 Mechanical Connectors from Hydratight are available in a variety of formats, including standard flange termination and the unique pipe-to-pipe direct coupling connector. All formats suit specific applications, whether for use on carbon steel, stainless steel or duplex pipes. The following illustrates the steps to follow for a pipe-to-pipe installation. Leak located and isolated, damaged section of pipeline is cut and removed. Mechanical Connectors Email us at: solutions@hydratight.com Or find your local representative at: hydratight.com/contact Over many years, Hydratight has provided world-class bolted joint solutions and continues to set international standards in joint integrity for its customers on a global scale. Hydratight works in partnership with the world’s leading OEMs using the latest computer technology and market leading development facilities. We continue to push back the boundaries of technology to provide fast, accurate and reliable solutions to critical assembly problems. Our people are the key to our success: qualified, competent and innovative people, working closely with our customers ensuring a total understanding of their requirements. One Company - Meets Standards Totally committed to safety and quality, all Hydratight products and services are designed, manufactured and carried out within a management system in accordance with ISO 9001: 2008 (Quality Management), ISO 14001: 2004 (Environmental Management) and OHSAS 18001:2007 (Occupational Health and Safety). Scan to view demo video. Our extensive bolting and machining services include: Step 2 Step 3 Connectors deployed and stabbed onto pipeline(s). Connectors activated. • Torque and tension bolting equipment • Portable machining equipment • Product sales, rental and technical support • Product service and training • Special designs and alternative sizes are available upon request Hydratight’s Mechanical Connectors Our range of Mechanical Connectors provides high integrity connections for all types of metal pipe work, onshore, offshore and subsea. Used to replace the need for welding, they are based upon a unique pipe gripping and sealing system which allows the connectors to withstand high internal pressure and external load conditions. Step 4 Step 5 New spool piece positioned. Spool piece connected to Mechanical Connectors. For additional specifications on our products for sale or rental, videos of our products in action, or information about our on-site services, please visit us on the web at hydratight.com. Engineering Driven Safety Focused Solutions hydratight.com 3 Material sourced from fully sustainable, managed forests using Elemental Chlorine Free fibre. HT/MC/US/02-13 2 hydratight.com hydratight.com 7 Who We Are Hydratight Mechanical Connectors One Company, Total Support, Complete Solutions Hydratight Mechanical Connectors are equal in strength and performance to that of a welded connection. They are suitable for any application where a weld would be a traditional solution, providing the same safety, strength and reliability. Hydratight’s Mechanical Connectors have a 100% leak-free in-service record. Our global network means you can rely on the right people, products and services wherever you are in the world. Mechanical Connector Installation Step 1 Mechanical Connectors from Hydratight are available in a variety of formats, including standard flange termination and the unique pipe-to-pipe direct coupling connector. All formats suit specific applications, whether for use on carbon steel, stainless steel or duplex pipes. The following illustrates the steps to follow for a pipe-to-pipe installation. Leak located and isolated, damaged section of pipeline is cut and removed. Mechanical Connectors Email us at: solutions@hydratight.com Or find your local representative at: hydratight.com/contact Over many years, Hydratight has provided world-class bolted joint solutions and continues to set international standards in joint integrity for its customers on a global scale. Hydratight works in partnership with the world’s leading OEMs using the latest computer technology and market leading development facilities. We continue to push back the boundaries of technology to provide fast, accurate and reliable solutions to critical assembly problems. Our people are the key to our success: qualified, competent and innovative people, working closely with our customers ensuring a total understanding of their requirements. One Company - Meets Standards Totally committed to safety and quality, all Hydratight products and services are designed, manufactured and carried out within a management system in accordance with ISO 9001: 2008 (Quality Management), ISO 14001: 2004 (Environmental Management) and OHSAS 18001:2007 (Occupational Health and Safety). Scan to view demo video. Our extensive bolting and machining services include: Step 2 Step 3 Connectors deployed and stabbed onto pipeline(s). Connectors activated. • Torque and tension bolting equipment • Portable machining equipment • Product sales, rental and technical support • Product service and training • Special designs and alternative sizes are available upon request Hydratight’s Mechanical Connectors Our range of Mechanical Connectors provides high integrity connections for all types of metal pipe work, onshore, offshore and subsea. Used to replace the need for welding, they are based upon a unique pipe gripping and sealing system which allows the connectors to withstand high internal pressure and external load conditions. Step 4 Step 5 New spool piece positioned. Spool piece connected to Mechanical Connectors. For additional specifications on our products for sale or rental, videos of our products in action, or information about our on-site services, please visit us on the web at hydratight.com. Engineering Driven Safety Focused Solutions hydratight.com 3 Material sourced from fully sustainable, managed forests using Elemental Chlorine Free fibre. HT/MC/US/02-13 2 hydratight.com hydratight.com 7 Construction Capability Repair The continued development of Mechanical Connector technology has enabled Hydratight to expand its product range to include Riser Hang-off Systems, Remote Bolting Systems and Repair Sleeve Clamps. Hydratight’s innovative designs have produced a pipe connection which is equivalent in strength and sealing performance to that of a welded joint. This can be reliably achieved without hot work and far more safely, simply and quickly than a welded joint. 5 1 Subsea Flange Adaptor 1 2 10 6 4 3 10 Steel Catenary Riser Clamp Topside Flange Adaptor 6 7 2 12 Turret based Riser Hang-off Clamp 7 11 Riser Systems Repairs Hydratight’s range of Riser Hang-off Systems provide hang off solutions for pre-stressed, retrofit, turret based and steel catenery applications. Although Hydratight’s Mechanical Connectors are used extensively on new construction projects, the connector was initially developed for, and is still widely used, for pipeline repairs. The pre-stressed hang-off allows high temperature, high load risers to be locked in position at the hang-off point to minimize load transfer effects. The retrofit system has the ability to lock rigid risers in position as they are pulled through existing or pre-installed j-tubes on a fixed platform. Steel Catenary Riser Clamp Topside Flange Adaptor 3 9 11 Hydratight’s Mechanical Connectors Retrofit Riser Hang-off Clamp 4 Topside Flange Adaptor 4 hydratight.com 12 Remote Technology Subsea Coupling 9 Hydratight’s range of Mechanical Connectors offer versatile solutions to the problem of bare pipe connections. Their design is adapted to suit applications ranging from high temperature, high pressure hydrocarbon service lines fitted on the topside of offshore platforms, through to the supply of connectors capable of being remotely installed in over 3,280ft of water. The system provides a connection that is equal in strength to a weld and has DNV and Lloyds Type approvals, stating that the Couplings may be used as a permanent or temporary substitute for welded connections. As well as providing Mechanical Connectors for permanent pipeline repairs, Hydratight has also supplied temporary repair clamps, capable of sealing minor pipeline leaks or restoring the structural integrity of damaged or corroded pipes. Hydratight is now the accepted and preferred repair system for many oil & gas operators world-wide. The industry’s confidence in Hydratight’s products and capability has led to the organization establishing an Emergency Pipeline Repair System (EPRS) Club initially for the North Sea, but now covering other key oil and gas locations around the world. The increased use of steel catenery risers for deepwater applications has led to Hydratight developing a rotary hang-off system. 5 Hydratight has gained an enviable track record having been used by the majority of major energy companies for both pipeline tie-ins and emergency repairs for thousands of critical topside and subsea applications. Misalignment flange For turret based FPSOs, Hydratight offers a hang-off which enables the flexible riser to be pulled into and locked in the turret before the riser is released and pulled through to its upper connection. 8 The versatility of the Mechanical Connector design enables it to be used in many different scenarios, whether making a bare pipe repair or inserting flanged spools. 8 The oil and gas industry’s requirement to develop deepwater fields has enabled Hydratight to further develop its remote technology. This generation of remote Mechanical Connectors has led to the development of remote bolting systems, which allow both Connectors and Clamps to be bolted securely without the need for diver intervention. These diverless repairs have been performed on pipelines with a diameter of up to 30", however the technology has full approval for up to 42" diameter. Subsea Flange Adaptor Riser Pull-in Head 13 Remove Connector Installation Frame hydratight.com 5 6 hydratight.com 13 Construction Capability Repair The continued development of Mechanical Connector technology has enabled Hydratight to expand its product range to include Riser Hang-off Systems, Remote Bolting Systems and Repair Sleeve Clamps. Hydratight’s innovative designs have produced a pipe connection which is equivalent in strength and sealing performance to that of a welded joint. This can be reliably achieved without hot work and far more safely, simply and quickly than a welded joint. 5 1 Subsea Flange Adaptor 1 2 10 6 4 3 10 Steel Catenary Riser Clamp Topside Flange Adaptor 6 7 2 12 Turret based Riser Hang-off Clamp 7 11 Riser Systems Repairs Hydratight’s range of Riser Hang-off Systems provide hang off solutions for pre-stressed, retrofit, turret based and steel catenery applications. Although Hydratight’s Mechanical Connectors are used extensively on new construction projects, the connector was initially developed for, and is still widely used, for pipeline repairs. The pre-stressed hang-off allows high temperature, high load risers to be locked in position at the hang-off point to minimize load transfer effects. The retrofit system has the ability to lock rigid risers in position as they are pulled through existing or pre-installed j-tubes on a fixed platform. Steel Catenary Riser Clamp Topside Flange Adaptor 3 9 11 Hydratight’s Mechanical Connectors Retrofit Riser Hang-off Clamp 4 Topside Flange Adaptor 4 hydratight.com 12 Remote Technology Subsea Coupling 9 Hydratight’s range of Mechanical Connectors offer versatile solutions to the problem of bare pipe connections. Their design is adapted to suit applications ranging from high temperature, high pressure hydrocarbon service lines fitted on the topside of offshore platforms, through to the supply of connectors capable of being remotely installed in over 3,280ft of water. The system provides a connection that is equal in strength to a weld and has DNV and Lloyds Type approvals, stating that the Couplings may be used as a permanent or temporary substitute for welded connections. As well as providing Mechanical Connectors for permanent pipeline repairs, Hydratight has also supplied temporary repair clamps, capable of sealing minor pipeline leaks or restoring the structural integrity of damaged or corroded pipes. Hydratight is now the accepted and preferred repair system for many oil & gas operators world-wide. The industry’s confidence in Hydratight’s products and capability has led to the organization establishing an Emergency Pipeline Repair System (EPRS) Club initially for the North Sea, but now covering other key oil and gas locations around the world. The increased use of steel catenery risers for deepwater applications has led to Hydratight developing a rotary hang-off system. 5 Hydratight has gained an enviable track record having been used by the majority of major energy companies for both pipeline tie-ins and emergency repairs for thousands of critical topside and subsea applications. Misalignment flange For turret based FPSOs, Hydratight offers a hang-off which enables the flexible riser to be pulled into and locked in the turret before the riser is released and pulled through to its upper connection. 8 The versatility of the Mechanical Connector design enables it to be used in many different scenarios, whether making a bare pipe repair or inserting flanged spools. 8 The oil and gas industry’s requirement to develop deepwater fields has enabled Hydratight to further develop its remote technology. This generation of remote Mechanical Connectors has led to the development of remote bolting systems, which allow both Connectors and Clamps to be bolted securely without the need for diver intervention. These diverless repairs have been performed on pipelines with a diameter of up to 30", however the technology has full approval for up to 42" diameter. Subsea Flange Adaptor Riser Pull-in Head 13 Remove Connector Installation Frame hydratight.com 5 6 hydratight.com 13 Construction Capability Repair The continued development of Mechanical Connector technology has enabled Hydratight to expand its product range to include Riser Hang-off Systems, Remote Bolting Systems and Repair Sleeve Clamps. Hydratight’s innovative designs have produced a pipe connection which is equivalent in strength and sealing performance to that of a welded joint. This can be reliably achieved without hot work and far more safely, simply and quickly than a welded joint. 5 1 Subsea Flange Adaptor 1 2 10 6 4 3 10 Steel Catenary Riser Clamp Topside Flange Adaptor 6 7 2 12 Turret based Riser Hang-off Clamp 7 11 Riser Systems Repairs Hydratight’s range of Riser Hang-off Systems provide hang off solutions for pre-stressed, retrofit, turret based and steel catenery applications. Although Hydratight’s Mechanical Connectors are used extensively on new construction projects, the connector was initially developed for, and is still widely used, for pipeline repairs. The pre-stressed hang-off allows high temperature, high load risers to be locked in position at the hang-off point to minimize load transfer effects. The retrofit system has the ability to lock rigid risers in position as they are pulled through existing or pre-installed j-tubes on a fixed platform. Steel Catenary Riser Clamp Topside Flange Adaptor 3 9 11 Hydratight’s Mechanical Connectors Retrofit Riser Hang-off Clamp 4 Topside Flange Adaptor 4 hydratight.com 12 Remote Technology Subsea Coupling 9 Hydratight’s range of Mechanical Connectors offer versatile solutions to the problem of bare pipe connections. Their design is adapted to suit applications ranging from high temperature, high pressure hydrocarbon service lines fitted on the topside of offshore platforms, through to the supply of connectors capable of being remotely installed in over 3,280ft of water. The system provides a connection that is equal in strength to a weld and has DNV and Lloyds Type approvals, stating that the Couplings may be used as a permanent or temporary substitute for welded connections. As well as providing Mechanical Connectors for permanent pipeline repairs, Hydratight has also supplied temporary repair clamps, capable of sealing minor pipeline leaks or restoring the structural integrity of damaged or corroded pipes. Hydratight is now the accepted and preferred repair system for many oil & gas operators world-wide. The industry’s confidence in Hydratight’s products and capability has led to the organization establishing an Emergency Pipeline Repair System (EPRS) Club initially for the North Sea, but now covering other key oil and gas locations around the world. The increased use of steel catenery risers for deepwater applications has led to Hydratight developing a rotary hang-off system. 5 Hydratight has gained an enviable track record having been used by the majority of major energy companies for both pipeline tie-ins and emergency repairs for thousands of critical topside and subsea applications. Misalignment flange For turret based FPSOs, Hydratight offers a hang-off which enables the flexible riser to be pulled into and locked in the turret before the riser is released and pulled through to its upper connection. 8 The versatility of the Mechanical Connector design enables it to be used in many different scenarios, whether making a bare pipe repair or inserting flanged spools. 8 The oil and gas industry’s requirement to develop deepwater fields has enabled Hydratight to further develop its remote technology. This generation of remote Mechanical Connectors has led to the development of remote bolting systems, which allow both Connectors and Clamps to be bolted securely without the need for diver intervention. These diverless repairs have been performed on pipelines with a diameter of up to 30", however the technology has full approval for up to 42" diameter. Subsea Flange Adaptor Riser Pull-in Head 13 Remove Connector Installation Frame hydratight.com 5 6 hydratight.com 13 Who We Are Hydratight Mechanical Connectors One Company, Total Support, Complete Solutions Hydratight Mechanical Connectors are equal in strength and performance to that of a welded connection. They are suitable for any application where a weld would be a traditional solution, providing the same safety, strength and reliability. Hydratight’s Mechanical Connectors have a 100% leak-free in-service record. Our global network means you can rely on the right people, products and services wherever you are in the world. Mechanical Connector Installation Step 1 Mechanical Connectors from Hydratight are available in a variety of formats, including standard flange termination and the unique pipe-to-pipe direct coupling connector. All formats suit specific applications, whether for use on carbon steel, stainless steel or duplex pipes. The following illustrates the steps to follow for a pipe-to-pipe installation. Leak located and isolated, damaged section of pipeline is cut and removed. Mechanical Connectors Email us at: solutions@hydratight.com Or find your local representative at: hydratight.com/contact Over many years, Hydratight has provided world-class bolted joint solutions and continues to set international standards in joint integrity for its customers on a global scale. Hydratight works in partnership with the world’s leading OEMs using the latest computer technology and market leading development facilities. We continue to push back the boundaries of technology to provide fast, accurate and reliable solutions to critical assembly problems. Our people are the key to our success: qualified, competent and innovative people, working closely with our customers ensuring a total understanding of their requirements. One Company - Meets Standards Totally committed to safety and quality, all Hydratight products and services are designed, manufactured and carried out within a management system in accordance with ISO 9001: 2008 (Quality Management), ISO 14001: 2004 (Environmental Management) and OHSAS 18001:2007 (Occupational Health and Safety). Scan to view demo video. Our extensive bolting and machining services include: Step 2 Step 3 Connectors deployed and stabbed onto pipeline(s). Connectors activated. • Torque and tension bolting equipment • Portable machining equipment • Product sales, rental and technical support • Product service and training • Special designs and alternative sizes are available upon request Hydratight’s Mechanical Connectors Our range of Mechanical Connectors provides high integrity connections for all types of metal pipe work, onshore, offshore and subsea. Used to replace the need for welding, they are based upon a unique pipe gripping and sealing system which allows the connectors to withstand high internal pressure and external load conditions. Step 4 Step 5 New spool piece positioned. Spool piece connected to Mechanical Connectors. For additional specifications on our products for sale or rental, videos of our products in action, or information about our on-site services, please visit us on the web at hydratight.com. Engineering Driven Safety Focused Solutions hydratight.com 3 Material sourced from fully sustainable, managed forests using Elemental Chlorine Free fibre. HT/MC/US/02-13 2 hydratight.com hydratight.com 7 Product ID: 20502-0124-01 // Page: 1/2 MORGRIP CLIP CONNECTORS PRODUCT GROUP MORGRIP CLAMPS & CONNECTORS PRODUCT DESCRIPTION The MORGRIP Clad & Lined Pipe (CLiP) Connector is the only DNV-GL Type Approved method to permanently repair pipelines which are clad or lined with corrosion resistant alloy (CRA). These pipeline systems cannot be repaired in the conventional manner as the pipe media, if allowed to bypass the CRA, will penetrate the base metal leading to failure. Developed under a joint industry project with 2 major operators and witnessed throughout by DNV-GL in accordance with RP-A203 Technology Qualification, MORGRIP CLiP provides a reliable, repeatable, permanent repair that does not prevent pigging operations or other long term inspection and maintenance programs. Deploying an End Seal Module that is fitted to conventional MORGRIP designs, including onshore, topside, subsea and remote deepwater connectors, the technology uses graphite seals that engage onto the pipe inner diameter, ensuring continuation of the CRA lining. MORGRIP CLiP Connectors, ideal for emergency repair, planned shutdown or contingency stock, are based on over 30 years of MORGRIP technology and application. Quicker, easier, safer and significantly cheaper than complex hyperbaric welding or pipeline replacement. CAPACITIES Pipeline size 10” to 26” Material Carbon steel pipeline clad or lined with corrosion resistant alloy Temperature -40degC to 149degC Working Pressure Up to 364Bar For applications outside of this scope, bespoke engineered solutions are available. CONNECTOR SUBSEA SOLUTIONS Head office: Kokstadflaten 17, 5257 Kokstad, Norway Locations in: Brazil, UK, Croatia & Bosnia www.connectorsubsea.com // mail@connectorsubsea.com +47 99 70 11 11 // connector-subsea-solutions Product ID: 20502-0124-01 // Page: 2/2 MORGRIP CLIP CONNECTORS MORGRIP CLAMPS & CONNECTORS INTERFACES Activation Bolt Tensioners Gripping Technology Ball & Taper Seal Material Dual Graphite End Seal Module featured in standard MORGRIP Subsea Flange Adaptor Back Seal Pressure Test Yes Diver Installation Rigging with buoyancy subsea or subsea lifting frames Remote Installation Connector installation frame ADDITIONAL INFORMATION Design code DNVGL-ST-F101/ F113 Pipeline Repair ASME BPVC VIII Div.1 ASME B31.3 API 5L Linepipe specification ASME BPVC VIII Div.2 on request Coating Jotamastik 87 or Interzone 954 as standard Maintenance Not required post installation Packing Steel shipping frames 01 // 16in MORGRIP CLiP Connector CONNECTOR SUBSEA SOLUTIONS Head office: Kokstadflaten 17, 5257 Kokstad, Norway Locations in: Brazil, UK, Croatia & Bosnia End Seal Module that enables graphite seal activation on pipe end 02 // End Seal Module mounted in Adaptor Plate www.connectorsubsea.com // mail@connectorsubsea.com +47 99 70 11 11 // connector-subsea-solutions Product ID: 20502-0120-01 // Page: 1/2 SUBSEA DIVER INSTALLED CONNECTORS PRODUCT GROUP MORGRIP CLAMPS & CONNECTORS PRODUCT DESCRIPTION MORGRIP Subsea Diver Installed Connectors enable subsea pipelines to be joined or terminated in a flange or end cap, without the need for hyperbaric welding or hot work. With a choice of gripping and sealing technologies available, we are able to meet a wide criteria of customer needs that balance the specific application requirements with quality, cost and delivery schedule options. For DNV-GL Type Approved products, the MORGRIP is supplied with our unique gripping and graphite sealing technology to ensure a connection that is at least as strong as the pipe itself, outperforming quality welds in fatigue loading. With over 3000 supplied since the 1980’s MORGRIP retains a 100% in-service leak free record. These products are quick and easy to install significantly reducing shutdown windows and associated operational costs. CAPACITIES Pipeline size 1/2in to 42in Material Carbon steels, stainless steels, duplex steels Temperature -40degC to 250degC Working Pressure Up to and including ANSI 2500 rating (638bar test pressure) For applications outside of this scope, bespoke engineered solutions are available. 6 5 4 3 2 1 1 2 3 4 5 D 7 6 8 9 10 11 12 D C A A B B C C Connector Specification Table: Description Value Class ASME B16.5 CLASS 1500 FLANGE ADAPTOR CONFIGURATION NOMINAL SIZE 18 B YOKE M24 SWIVEL HOIST RING 17 ISO 7089 - 10 16 ISO 4017 - M10 x 1.5 x 25 15 ANODE in mm 406.4 REFER TO SPECIFICATION SHEET -20 to 120 255 barg 384 barg WEIGHT (design) 2503 kg SUBMERGED WEIGHT 2169 kg Steel PN00032073 4 EN 898-2 GRADE 8 C70891014 4 EN 898-1 GRADE 8.8 C401710254 2 DNVGL-RP-B401 Zn-based PN00034557 RESPONSIBLE Work In Progress STATE S0212P1800DK BS EN 10270-3 1.4310 016AA0077186 CLEAR PERSPEX 011AM0077190 BS EN 10025 S355JR OR EQUIV 011AK0077192 8 BS EN 10025 S355JR OR EQUIV 011AK0077191 27 SPRING GUIDE FEMALE 100 ACETAL (BLACK) 011AJ0077188 26 SPRING GUIDE MALE 100 NYLON (BLACK) 011AJ0077187 25 BALL CAGE INDICATOR PIN 24 BALL CAGE LOCKING PIN 10 23 BALL BEARING 35MM 100 22 16" STAB ON GRAPHITE SEAL 2 GRAPHITE 21 16" 3000S - ANTI EXTRUSION RING 1 4 ASTM A350 LF2 SILVER STEEL 011AH0049151 011AC0077184 EN24T 011AG0077189 EN31 011AF0072167 PN00020616 20 16" ENVIRONMENTAL SEAL 1 SILICONE (60 SHORE) 011AB0049146 PN00020615 19 16" 3000S - ENVIRONMENTAL SEAL PLATE 1 BS EN 10025 S355JR 011AA0077185 12 ISO 4017 - M10 x 1.5 x 20 3 EN 898-1 GRADE 8.8 C401710204 18 16" 3000S - TAPER HOUSING SPACER 1 ASTM A694 F60 009CA0077177 11 ISO 4762 - M12 x 1.75 x 65 6 EN 898-1 GRADE 8.8 C476212654 17 16" 3000S - BALL CAGE RETRACT RING 1 ASTM A350 LF2 009AU0077183 10 16in MORSMART- PSG SPACER ASSEMBLY 3 Carbon Steel PN00033953 9 STUD ASSY 2 1/2in in x 800LG C/W 2 NUTS 8 ASTM A193 GRADE B7M BOLTS - PTFE COATED PN00033946 8 16in MORSMART- COLLET GRIPPER 16 1 ASTM A788/A29 GRADE 4140 16" 3000S - BALL CAGE OUTER 15 009AK0077181 ASTM A694 F60 1 16" 3000S - TAPER HOUSING INTER 009AN0077182 ASTM A350 LF2 1 16" 3000S - TAPER HOUSING OUTER 12 ASTM A350 LF2 1 16" 3000S - ADAPTOR PLATE 13 PN00033440 4 16" 3000S - BALL CAGE INNER 14 ASTM A194 GR. 2HM NUTS - PTFE COATED F 009AJ0077173 34CrNiMo6 2 009AG0077174 34CrNiMo6 16in MORSMART- GRIPPER BUSHING 1 ASTM A788/A29 GRADE 4140 PN00033439 11 16" 3000S - TAPER HOUSING INNER 2 34CrNiMo6 009AE0077176 16in MORSMART- ANTI-EXTRUSION RING 02 4 ASTM A240 Grade 316 PN00033949 10 16" 3000S - SEAL HOUSING 1 ASTM A694 F60 009AD0077178 5 16in MORSMART- ANTI-EXTRUSION RING 01 4 ASTM A240 Grade 316 PN00033948 9 16" 3000S - TWIN SEAL HOUSING 1 ASTM A694 F60 4 16in MORSMART- SEAL 2 Elast-O-Lion 101 PN00033950 8 16" 3000S - TRANSITION FLANGE 1 ASTM A694 F60 009AA0077180 3 16in MORSMART- SEAL PUSHER RING 2 ASTM A694 GRADE F52 PN00033436 7 BONDED SEAL 1/4" BSP 2 ST-NITRILE 002JA0026574 6 END PLUG 1/4" BSP 2 PD970 PT3 817M40 002GF0027347 5 MET HEX HEAD BOLT M12 x 130 LONG 8 4 MET HEX HEAD BOLT M10 x 20 LONG 3 SKT HD CAPSCREW M12 x 90 LONG 2 SKT HD CAPSCREW M10 x 20 LONG 1 SKT HD CAPSCREW M6 x 15 LONG 2 16in MORSMART- BODY 16in MORSMART- BACK FLANGE G TITLE 1 ASTM A694 GRADE F52 1 ASTM A694 GRADE F52 QTY PN00033438 PN00033435 MATERIAL PART NUMBER PART NUMBER / DRAWING NUMBER: 16in MORSMART Connector PN00033441 General Arrangement PROJECTION: 1:7 3 FORMAT: A3 H A ITEM DESCRIPTION UNLESS STATED OTHERWISE ALL DIMENSIONS IN MILLIMETERS SN-19100 - L&T Hydrocarbon Engineering SHEET: WEIGHT: 1 of 2 DRAWING TYPE: 2502.8 kg GA CREATED BY: GENERAL / GEOMETRIC TOLERANCES DWG REV: DRAWN BY: JUV ECN NO. DESCRIPTION CONNECTOR SUBSEA SOLUTIONS Head office: Kokstadflaten 17, 5257 Kokstad, Norway Locations in: Brazil, UK, Croatia & Bosnia 1 SUBMERGED WEIGHT 2169 kg 2 3 4 Gr 8.8 001CN0045863 4 Gr 8.8 001CN0025687 28 Gr 8.8 001AA0000215 8 Gr 8.8 001AA0000174 4 Gr 8.8 001AA0000112 QTY MATL PART NUMBER MATERIAL: S.ANTILL DATE: 04/10/18 PROTECTIVE TREATMENT: CHECKED: D.HARDIE DATE: 08/10/18 PROJECTION: SALES QUOTE NO. DRAWN: DATE 5 REV BY 6 CHK'D 7 TITLE: SCALE: CORNER RADII: 8 3RD ANGLE SALES ORDER NO. 9 G WALSALL THIS DRAWING AND THE DESIGN IS THE PROPERTY OF HYDRATIGHT AND MUST NOT BE COPIED OR DISCLOSED IN WHOLE OR IN PART TO ANY THIRD PARTY WITHOUT WRITTEN CONSENT SURFACE FINISH: BREAK SHARP EDGES: 009AC0077179 © COPYRIGHT 3474.2 kg HEAT TREATMENT: 1 REV WEIGHT: SEE BOM 1 JUV 2 IF IN DOUBT ASK F 009AF0077175 7 6 1 E 011AE0049158 Steel Steel, Mild This drawing is the property of CONNECTOR SUBSEA SOLUTIONS. It must not be copied, altered or distribued in any way without prior consent from the company! 4 A320-L43 - A194-G7 (3.2 Certs) 4 PRESET GAP SPACER 2 SCALE: JUV COMMENT 1 PRESET GAP REMOVAL HANDLE (131-135mm) 28 2 PROJECT: DATE 100 INDICATOR PIN COVER 29 BONDED SEAL 1/4" BSP DESCRIPTION: 1 12 COMPRESSION SPRING 30 END PLUG 1/4" BSP Max work pressure 450bar TITLE: REV STUD ASSY 2-3/4" UN8 x 1800mm 2 x NUTS 31 13 ITEM 5 B 32 14 A 6 D °C DESIGNED PRESSURE HYDROTEST PRESSURE 2 E 16 ODnominal PIPE WALL THICKNESS DESIGN TEMPERATURE D C Unit SIZE 1011031143 10 A1 GENERAL ARRANGEMENT 16" 120bar 3000S FLANGE ADAPTOR 0.25 CAD SOURCE: PRO E SHEET: HXSAC0077164 11 H 1 OF 2 REV. DRAWING NO. A 12 www.connectorsubsea.com // mail@connectorsubsea.com +47 99 70 11 11 // connector-subsea-solutions Product ID: 20502-0120-01 // Page: 2/2 SUBSEA DIVER INSTALLED CONNECTORS MORGRIP CLAMPS & CONNECTORS INTERFACES Activation Option for single or dual activation with bolt tensioners Gripping Technology Collet or ball & taper Seal Material Dual elastomeric or dual graphite Back Seal Pressure Test Yes Installation Rigging with buoyancy or subsea lifting frames 02 // Mounted on transport frames ADDITIONAL INFO Design code DNVGL-ST-F101/ F113 Pipeline Repair ASME BPVC VIII Div.1 ASME B31.3 API 5L Linepipe specification ASME BPVC VIII Div.2 on request Coating Jotamastic 87, Interzone 954 or NORSOK M-501 System 7C & 7B Compliant Maintenance Not required post installation Packing Wooden shipping crates or steel shipping frames Design Life 40 years 03 // Factory acceptance testing 04 // Subsea Installation 01 // Offshore mobilisation CONNECTOR SUBSEA SOLUTIONS Head office: Kokstadflaten 17, 5257 Kokstad, Norway Locations in: Brazil, UK, Croatia & Bosnia 05 // Subsea Installation www.connectorsubsea.com // mail@connectorsubsea.com +47 99 70 11 11 // connector-subsea-solutions