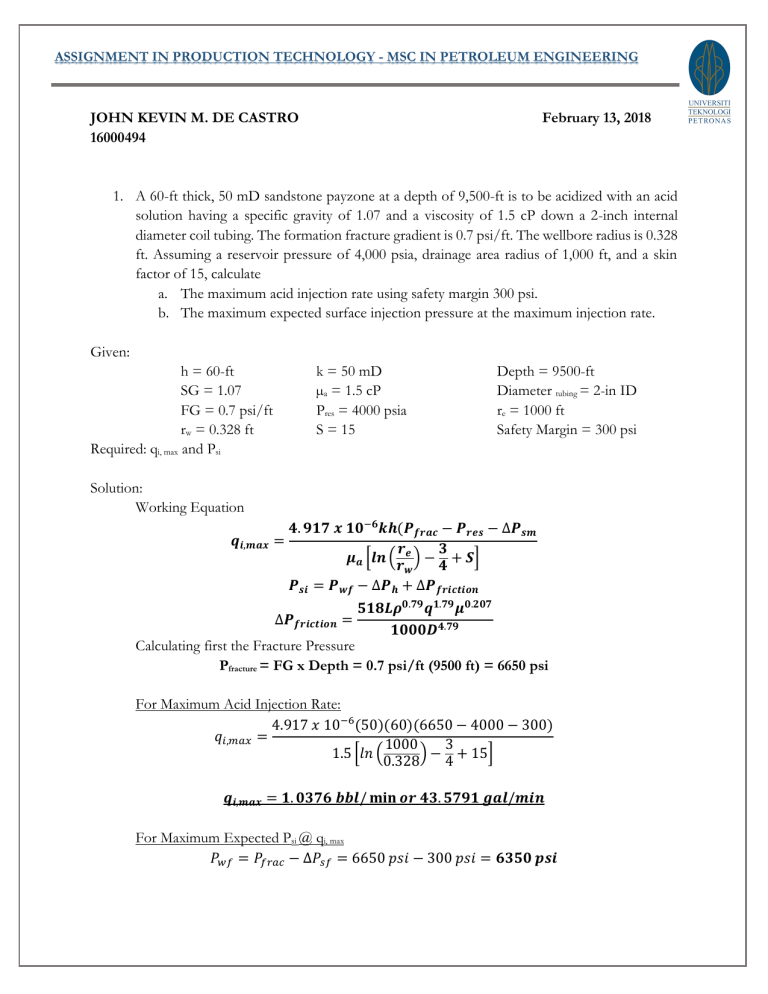

ASSIGNMENT IN PRODUCTION TECHNOLOGY - MSC IN PETROLEUM ENGINEERING JOHN KEVIN M. DE CASTRO 16000494 February 13, 2018 1. A 60-ft thick, 50 mD sandstone payzone at a depth of 9,500-ft is to be acidized with an acid solution having a specific gravity of 1.07 and a viscosity of 1.5 cP down a 2-inch internal diameter coil tubing. The formation fracture gradient is 0.7 psi/ft. The wellbore radius is 0.328 ft. Assuming a reservoir pressure of 4,000 psia, drainage area radius of 1,000 ft, and a skin factor of 15, calculate a. The maximum acid injection rate using safety margin 300 psi. b. The maximum expected surface injection pressure at the maximum injection rate. Given: h = 60-ft SG = 1.07 FG = 0.7 psi/ft rw = 0.328 ft Required: qi, max and Psi k = 50 mD µa = 1.5 cP Pres = 4000 psia S = 15 Depth = 9500-ft Diameter tubing = 2-in ID re = 1000 ft Safety Margin = 300 psi Solution: Working Equation 𝒒𝒊,𝒎𝒂𝒙 = 𝟒. 𝟗𝟏𝟕 𝒙 𝟏𝟎−𝟔 𝒌𝒉(𝑷𝒇𝒓𝒂𝒄 − 𝑷𝒓𝒆𝒔 − ∆𝑷𝒔𝒎 𝒓 𝟑 𝝁𝒂 [𝒍𝒏 (𝒓 𝒆 ) − 𝟒 + 𝑺] 𝒘 𝑷𝒔𝒊 = 𝑷𝒘𝒇 − ∆𝑷𝒉 + ∆𝑷𝒇𝒓𝒊𝒄𝒕𝒊𝒐𝒏 ∆𝑷𝒇𝒓𝒊𝒄𝒕𝒊𝒐𝒏 = 𝟓𝟏𝟖𝑳𝝆𝟎.𝟕𝟗 𝒒𝟏.𝟕𝟗 𝝁𝟎.𝟐𝟎𝟕 𝟏𝟎𝟎𝟎𝑫𝟒.𝟕𝟗 Calculating first the Fracture Pressure Pfracture = FG x Depth = 0.7 psi/ft (9500 ft) = 6650 psi For Maximum Acid Injection Rate: 4.917 𝑥 10−6 (50)(60)(6650 − 4000 − 300) 𝑞𝑖,𝑚𝑎𝑥 = 1000 3 1.5 [𝑙𝑛 (0.328) − 4 + 15] 𝒒𝒊,𝒎𝒂𝒙 = 𝟏. 𝟎𝟑𝟕𝟔 𝒃𝒃𝒍/ 𝐦𝐢𝐧 𝒐𝒓 𝟒𝟑. 𝟓𝟕𝟗𝟏 𝒈𝒂𝒍/𝒎𝒊𝒏 For Maximum Expected Psi @ qi, max 𝑃𝑤𝑓 = 𝑃𝑓𝑟𝑎𝑐 − ∆𝑃𝑠𝑓 = 6650 𝑝𝑠𝑖 − 300 𝑝𝑠𝑖 = 𝟔𝟑𝟓𝟎 𝒑𝒔𝒊 ASSIGNMENT IN PRODUCTION TECHNOLOGY - MSC IN PETROLEUM ENGINEERING 𝑝𝑠𝑖 (1.07)(9500 𝑓𝑡) = 𝟒𝟒𝟎𝟏. 𝟒𝟒𝟓 𝒑𝒔𝒊 𝑓𝑡 𝑔 𝑔 𝑔 𝜌 𝑖𝑛 = 1.07 (1 ) = 1.07 𝑐𝑐 𝑐𝑐 𝑐𝑐 0.79 518(9500)(1.07) (1.0376)1.79 (1.5)0.207 = 1000(2)4.79 ∆𝑷𝒇𝒓𝒊𝒄𝒕𝒊𝒐𝒏 = 𝟐𝟏𝟖. 𝟎𝟏𝟎𝟓 𝒑𝒔𝒊 ∆𝑃ℎ = 0.433 ∆𝑃𝑓𝑟𝑖𝑐𝑡𝑖𝑜𝑛 𝑃𝑠𝑖 = 6350 − 4401.445 + 218.0105 𝑷𝒔𝒊 = 𝟐𝟏𝟔𝟔. 𝟓𝟔𝟓𝟓 2. Calculate the gravimetric dissolving power of a. 3 wt% HF reacting with i. Orthoclase feldspar ii. Kaolinite iii. Montmorillonite Working Equation 𝒙 𝒏𝒎𝒊𝒏𝒆𝒓𝒂𝒍 𝑴𝒎𝒊𝒏𝒆𝒓𝒂𝒍 𝜷𝒙 = [ ] 𝟏𝟎𝟎 𝒏𝒂𝒄𝒊𝒅 𝑴𝒂𝒄𝒊𝒅 i. Chemical reaction – Orthoclase Feldspar with Hydrofluoric acid 𝑲𝑨𝒍𝑺𝒊𝟑 𝑶𝟖 + 𝟏𝟒𝑯𝑭 + 𝟐𝑯+ → 𝑲+ + 𝑨𝒍𝑭+ 𝟐 + 𝟑𝑺𝒊𝑭𝟒 + 𝟖𝑯𝟐 𝑶 nm = 1 Mm = (39.1 + 27 + (3x28.09) + (8x16) = 278.37 lb/lb-mol 𝜷𝒙 = ii. na = 14 Ma = 1+19 = 20 lb/lb-mol 3 1(278.37) 𝒍𝒃𝒎 𝒐𝒇 𝑶𝒓𝒕𝒉𝒐𝒄𝒍𝒂𝒔𝒆 𝑭𝒆𝒍𝒅𝒔𝒑𝒂𝒓 [ ] = 𝟎. 𝟎𝟐𝟗𝟖 100 14(20) 𝒍𝒃𝒎 𝒐𝒇 𝟑% 𝑯𝑭 Chemical reaction – Kaolinite with Hydrofluoric acid 𝑨𝒍𝟒 𝑺𝒊𝟒 𝑶𝟏𝟎 (𝑶𝑯)𝟖 + 𝟐𝟒𝑯𝑭 + 𝟒𝑯+ → 𝟒𝑨𝒍𝑭+ 𝟐 + 𝟒𝑺𝒊𝑭𝟒 + 𝟏𝟖𝑯𝟐 𝑶 nm = 1 na = 40 Mm = ((27x4) + (28.09x4) + (16x18)+8) = 516.36 lb/lb-mol Ma = 1+19 = 20 lb/lb-mol 𝜷𝒙 = iii. 3 1(516.36) 𝒍𝒃𝒎 𝒐𝒇 𝑲𝒂𝒐𝒍𝒊𝒏𝒊𝒕𝒆 [ ] = 𝟎. 𝟎𝟑𝟐𝟑 100 24(20) 𝒍𝒃𝒎 𝒐𝒇 𝟑% 𝑯𝑭 Chemical reaction – Montmorillonite with Hydrofluoric acid 𝑨𝒍𝟒 𝑺𝒊𝟖 𝑶𝟐𝟎 (𝑶𝑯)𝟒 + 𝟒𝟎𝑯𝑭 + 𝟒𝑯+ → 𝟒𝑨𝒍𝑭+ 𝟐 + 𝟖𝑺𝒊𝑭𝟒 + 𝟐𝟒𝑯𝟐 𝑶 ASSIGNMENT IN PRODUCTION TECHNOLOGY - MSC IN PETROLEUM ENGINEERING nm = 1 na = 40 Mm = ((27x4) + (28.09x8) + (16x24)+4) = 720.72 lb/lb-mol Ma = 1+19 = 20 lb/lb-mol 𝜷𝒙 = 3 1(720.72) 𝒍𝒃𝒎 𝒐𝒇 𝑴𝒐𝒏𝒕𝒎𝒐𝒓𝒊𝒍𝒍𝒐𝒏𝒊𝒕𝒆 [ ] = 𝟎. 𝟎𝟐𝟕𝟎 100 40(20) 𝒍𝒃𝒎 𝒐𝒇 𝟑% 𝑯𝑭 3. Calculate the volumetric dissolving power of a. 3 wt% HF reacting with i. Orthoclase feldspar ii. Kaolinite iii. Montmorillonite Working Equation 𝝆𝒂𝒄𝒊𝒅 𝒔𝒐𝒍𝒖𝒕𝒊𝒐𝒏 𝑿𝒙% = 𝜷𝒙% ( ) 𝝆𝒎𝒊𝒏𝒆𝒓𝒂𝒍 Assumption: The following assumptions are made for specific gravity of each mineral and the acid. SGortho feld = 2.55 SGKao = 2.6 SGMont = 2.01 SGacid = 1.15 i. 𝜷𝒙 = 𝟎. 𝟎𝟐𝟗𝟖 𝒍𝒃𝒎 𝒐𝒇 𝑶𝒓𝒕𝒉𝒐𝒄𝒍𝒂𝒔𝒆 𝑭𝒆𝒍𝒅𝒔𝒑𝒂𝒓 𝒍𝒃𝒎 𝒐𝒇 𝟑% 𝑯𝑭 1.15 𝑥 62.4 𝒇𝒕𝟑 𝒐𝒇 𝑶𝒓𝒕𝒉𝒐𝒄𝒍𝒂𝒔𝒆 𝑭𝒆𝒍𝒅𝒔𝒑𝒂𝒓 𝑋𝑥% = 0.0298 ( ) =. 𝟎𝟏𝟑𝟒 2.55 𝑥 62.4 𝒇𝒕𝟑 𝒐𝒇 𝟑% 𝑯𝑭 ii. 𝜷𝒙 = 𝟎. 𝟎𝟑𝟐𝟑 𝑋𝑥% iii. 𝒍𝒃𝒎 𝒐𝒇 𝑲𝒂𝒐𝒍𝒊𝒏𝒊𝒕𝒆 𝒍𝒃𝒎 𝒐𝒇 𝟑% 𝑯𝑭 1.15 𝑥 62.4 𝒇𝒕𝟑 𝒐𝒇 𝑲𝒂𝒐𝒍𝒊𝒏𝒊𝒕𝒆 = 0.0323 ( ) =. 𝟎𝟏𝟒𝟑 2.6 𝑥 62.4 𝒇𝒕𝟑 𝒐𝒇 𝟑% 𝑯𝑭 𝜷𝒙 = 𝟎. 𝟎𝟐𝟕𝟎 𝒍𝒃𝒎 𝒐𝒇 𝑴𝒐𝒏𝒕𝒎𝒐𝒓𝒊𝒍𝒍𝒐𝒏𝒊𝒕𝒆 𝒍𝒃𝒎 𝒐𝒇 𝟑% 𝑯𝑭 1.15 𝑥 62.4 𝒇𝒕𝟑 𝒐𝒇 𝑴𝒐𝒏𝒕𝒎𝒐𝒓𝒊𝒍𝒍𝒐𝒏𝒊𝒕𝒆 𝑋𝑥% = 0.0270 ( ) =. 𝟎𝟏𝟓𝟒 2.01 𝑥 62.4 𝒇𝒕𝟑 𝒐𝒇 𝟑% 𝑯𝑭 ASSIGNMENT IN PRODUCTION TECHNOLOGY - MSC IN PETROLEUM ENGINEERING 4. Problem 16.1 For the reaction between 20 wt% HCl solution and calcite, calculate the gravimetric and volumetric dissolving power of the acid solution. Working Equation 𝜷𝒙 = 𝒙 𝒏𝒎𝒊𝒏𝒆𝒓𝒂𝒍 𝑴𝒎𝒊𝒏𝒆𝒓𝒂𝒍 [ ] 𝟏𝟎𝟎 𝒏𝒂𝒄𝒊𝒅 𝑴𝒂𝒄𝒊𝒅 𝑿𝒙% = 𝜷𝒙% ( 𝝆𝒂𝒄𝒊𝒅 𝒔𝒐𝒍𝒖𝒕𝒊𝒐𝒏 ) 𝝆𝒎𝒊𝒏𝒆𝒓𝒂𝒍 Assumption: SGmineral = 2.71 SGacid = 1.07 Chemical Reaction: 𝑪𝒂𝑪𝑶𝟑 + 𝟐𝑯𝑪𝒍 → 𝑪𝒂𝑪𝒍𝟐 + 𝑯𝟐 𝑶 + 𝑪𝑶𝟐 nm = 1 na = 2 Mm = (40.08 + 12 + (16x3)) = 100.08 lb/lb-mol Ma = 1+35.5 = 36.5 lb/lb-mol For Gravimetric dissolving power 20 1(100.08) 𝒍𝒃𝒎 𝒐𝒇 𝑪𝒂𝒍𝒄𝒊𝒕𝒆 𝜷𝒙 = [ ] = 𝟎. 𝟐𝟕𝟒𝟐 100 2(36.5) 𝒍𝒃𝒎 𝒐𝒇 𝟐𝟎% 𝑯𝑪𝒍 For Volumetric dissolving power 1.07 𝑥 62.4 𝒇𝒕𝟑 𝒐𝒇 𝑪𝒂𝒍𝒄𝒊𝒕𝒆 𝑿𝒙% = 0.2742 ( ) =. 𝟏𝟎𝟖𝟑 𝟑 2.71 𝑥 62.4 𝒇𝒕 𝒐𝒇 𝟐𝟎% 𝑯𝑪𝒍 5. Problem 16.3 A sandstone with a porosity of 0.18 containing 8 v% calcite is to be acidized with HF/HCl mixture solution. A preflush of 15 wt% HCl solution is to be injected ahead of the mixture to dissolve the carbonate minerals and establish a low-pH environment. If the HCl preflush is to remove all carbonates in a region within 1.5 ft beyond 0.328-ft radius wellbore before the HCl the HF/HCl stage enters the formation, what minimum preflush volume is required in terms of gallon per foot of pay zone? Given: Lithology = Sandstone formation [HCl]preflush = 15 wt% Working Equation: Ø = 0.18 ra = 1.5+0.328 = 1.828 ft 𝟏 ) + 𝑽𝒑 𝑿𝒎 𝑽𝒑 = ∅𝝅(𝒓𝟐𝒂 − 𝒓𝟐𝒘 ) 𝑽𝒎 = 𝝅(𝟏 − ∅)𝑿𝒎 (𝒓𝟐𝒂 − 𝒓𝟐𝒘 ) 𝑽𝒂 = 𝑽𝒎 (𝟏 + Xm = 0.08 rw = 0.328 ft ASSIGNMENT IN PRODUCTION TECHNOLOGY - MSC IN PETROLEUM ENGINEERING 𝜷𝒙 = 𝒙 𝒏𝒎𝒊𝒏𝒆𝒓𝒂𝒍 𝑴𝒎𝒊𝒏𝒆𝒓𝒂𝒍 [ ] 𝟏𝟎𝟎 𝒏𝒂𝒄𝒊𝒅 𝑴𝒂𝒄𝒊𝒅 𝑿𝒙% = 𝜷𝒙% ( 𝝆𝒂𝒄𝒊𝒅 𝒔𝒐𝒍𝒖𝒕𝒊𝒐𝒏 ) 𝝆𝒎𝒊𝒏𝒆𝒓𝒂𝒍 Solution: 𝑉𝑝 = 𝜋(0.18)(1.8282 − 0.3282 ) 𝑉𝑝 = 1.8288 𝑓𝑡 3 𝑓𝑡 𝑜𝑓 𝑝𝑎𝑦 𝑧𝑜𝑛𝑒 = 𝑉𝑚 = 𝜋(1 − 0.18)(0.08)(1.8282 − 0.3282 ) 𝑓𝑡 3 𝑉𝑚 = 0.6665 𝑓𝑡 𝑜𝑓 𝑝𝑎𝑦 𝑧𝑜𝑛𝑒 𝐶𝑎𝐶𝑂3 + 2𝐻𝐶𝑙 → 𝐶𝑎𝐶𝑙2 + 𝐶𝑂2 + 𝐻2 𝑂 nm = 1 na = 2 Mm = (40.08 + 12 + (16x3)) = 100.08 lb/lb-mol Ma = 1+35.5 = 36.5 lb/lb-mol 15 1(100.08) 𝑙𝑏𝑚 𝑜𝑓 𝐶𝑎𝑙𝑐𝑖𝑡𝑒 𝛽𝑥 = [ ] = 0.2056 100 2(36.5) 𝑙𝑏𝑚 𝑜𝑓 15% 𝐻𝐶𝑙 1.07 𝑥 62.4 𝑓𝑡 3 𝑜𝑓 𝐶𝑎𝑙𝑐𝑖𝑡𝑒 𝑋𝑥% = 0.2056 ( ) = 0.0812 3 2.71 𝑥 62.4 𝑓𝑡 𝑜𝑓 15% 𝐻𝐶𝑙 𝑉𝑎 = 0.6665 (1 + 𝑽𝒂 = 𝟏𝟎. 𝟕𝟎𝟑𝟒 1 ) + 1.8288 0.0812 𝒇𝒕𝟑 𝒐𝒇 𝟏𝟓 𝒘𝒕% 𝑯𝑪𝒍 𝒇𝒕 𝒐𝒇 𝒑𝒂𝒚 𝒛𝒐𝒏𝒆 𝑽𝒂 = 𝟖𝟎. 𝟎𝟔𝟏𝟔 since 1 ft3 = 7.48 gal 𝒈𝒂𝒍 𝒐𝒇 𝟏𝟓 𝒘𝒕% 𝑯𝑪𝒍 𝒇𝒕 𝒐𝒇 𝒑𝒂𝒚 𝒛𝒐𝒏𝒆 6. Problem 16.5 A 30-ft thick, 40-mD sandstone pay zone at a depth of 9,000 ft is to be acidized with an acid solution having a specific gravity of 1.07 and a viscosity of 1.2 cP down a 2-inch ID coil tubing. The formation fracture gradient is 0.7 psi/ft. The wellbore radius is 0.328 ft. Assuming a reservoir pressure is 4000 psia, drainage area radius is 1,500 ft and skin factor of 10, calculate (a) The maximum acid injection rate using safety margin 200 psi. (b) The maximum expected surface injection pressure at the maximum injection rate. Given: h = 30-ft k = 40 mD Depth = 9000-ft ASSIGNMENT IN PRODUCTION TECHNOLOGY - MSC IN PETROLEUM ENGINEERING SG = 1.07 FG = 0.7 psi/ft rw = 0.328 ft Required: qi, max and Psi µa = 1.2 cP Pres = 4000 psia S = 10 Diameter tubing = 2-in ID re = 1500 ft Safety Margin = 200 psi Solution: Working Equation 𝒒𝒊,𝒎𝒂𝒙 𝟒. 𝟗𝟏𝟕 𝒙 𝟏𝟎−𝟔 𝒌𝒉(𝑷𝒇𝒓𝒂𝒄 − 𝑷𝒓𝒆𝒔 − ∆𝑷𝒔𝒎 = 𝒓 𝟑 𝝁𝒂 [𝒍𝒏 (𝒓 𝒆 ) − 𝟒 + 𝑺] 𝒘 𝑷𝒔𝒊 = 𝑷𝒘𝒇 − ∆𝑷𝒉 + ∆𝑷𝒇𝒓𝒊𝒄𝒕𝒊𝒐𝒏 𝟓𝟏𝟖𝑳𝝆𝟎.𝟕𝟗 𝒒𝟏.𝟕𝟗 𝝁𝟎.𝟐𝟎𝟕 ∆𝑷𝒇𝒓𝒊𝒄𝒕𝒊𝒐𝒏 = 𝟏𝟎𝟎𝟎𝑫𝟒.𝟕𝟗 Calculating first the Fracture Pressure Pfracture = FG x Depth = 0.7 psi/ft (9000 ft) = 6300 psi For Maximum Acid Injection Rate: 4.917 𝑥 10−6 (40)(30)(6300 − 4000 − 200) 𝑞𝑖,𝑚𝑎𝑥 = 1500 3 1.2 [𝑙𝑛 (0.328) − 4 + 10] 𝒒𝒊,𝒎𝒂𝒙 = 𝟎. 𝟓𝟖𝟒𝟏 𝒃𝒃𝒍/ 𝐦𝐢𝐧 𝒐𝒓 𝟐𝟒. 𝟓𝟑𝟐𝟐 𝒈𝒂𝒍/𝒎𝒊𝒏 For Maximum Expected Psi @ qi, max 𝑃𝑤𝑓 = 𝑃𝑓𝑟𝑎𝑐 − ∆𝑃𝑠𝑓 = 6300 𝑝𝑠𝑖 − 200 𝑝𝑠𝑖 = 𝟔𝟏𝟎𝟎 𝒑𝒔𝒊 𝑝𝑠𝑖 (1.07)(9500 𝑓𝑡) = 𝟒𝟏𝟔𝟗. 𝟕𝟗 𝒑𝒔𝒊 ∆𝑃ℎ = 0.433 𝑓𝑡 𝑔 𝑔 𝑔 𝜌 𝑖𝑛 = 1.07 (1 ) = 1.07 𝑐𝑐 𝑐𝑐 𝑐𝑐 518(9000)(1.07)0.79 (0.5841)1.79 (1.2)0.207 ∆𝑃𝑓𝑟𝑖𝑐𝑡𝑖𝑜𝑛 = 1000(2)4.79 ∆𝑷𝒇𝒓𝒊𝒄𝒕𝒊𝒐𝒏 = 𝟕𝟎. 𝟓𝟏𝟎𝟔 𝒑𝒔𝒊 𝑃𝑠𝑖 = 6100 − 4169.79 + 65.3343 𝑷𝒔𝒊 = 𝟐𝟎𝟎𝟎. 𝟕𝟐𝟎𝟔 𝒑𝒔𝒊 7. Problem 16.7 A 20 wt% HCl is needed to propagate wormholes 2 ft from 0.328-ft radius wellbore in a limestone formation (specific gravity = 2.71) with a porosity of 0.12. The designed injection rate is 0.12 bbl/min-ft, diffusion coefficient is 10-9 m2/sec. In linear core floods, 1.2 pore ASSIGNMENT IN PRODUCTION TECHNOLOGY - MSC IN PETROLEUM ENGINEERING volume is needed for wormhole breakthrough at the end of the core. Calculate the acid volume requirement using the volumetric model Given: Ø = 0.12 Working Equation: rwh = 2 +328 =2.328 ft rw = 0.328 ft (PV)bt = 1.2 𝑽𝒉 = 𝝅∅(𝒓𝟐𝒘𝒉 − 𝒓𝟐𝒘 )(𝑷𝑽)𝒃𝒕 Solution: 𝑉ℎ = 𝜋(0.12)(2.3282 − 0.3282 )(1.2) 𝑽𝒉 = 𝟐. 𝟒𝟎𝟑𝟏 𝒇𝒕𝟑 𝒐𝒇 𝟐𝟎 𝒘𝒕% 𝑯𝑪𝒍 𝒇𝒕 𝒐𝒇 𝒑𝒂𝒚 𝒛𝒐𝒏𝒆 𝑽𝒉 = 𝟏𝟕. 𝟗𝟕𝟓𝟏 ; since 1 ft3 = 7.48 gal 𝒈𝒂𝒍 𝒐𝒇 𝟐𝟎 𝒘𝒕% 𝑯𝑪𝒍 𝒇𝒕 𝒐𝒇 𝒑𝒂𝒚 𝒛𝒐𝒏𝒆 8. Use the data provided in Table 1 to estimate the fracture toughness for each of the lithologies shown. Calculate the Young’s modulus that would give the same fracture toughness as calculated in the example problem (For sand, KIC=553 psi√𝑖𝑛 and for shale, KIC=784 psi√𝑖𝑛). Table 1: Typical Range of Values for Young’s Modulus Lithology Young’s Modulus (GPa) Poisson’s Ratio Soft Sandstone 0.6893 – 6.8929 0.20 to 0.35 Medium Sandstone 13.7857 – 34.4643 0.15 to 0.25 Hard Sandstone 41.3571 – 68.9286 0.10 to 0.15 Limestone 55.1429 – 82.7143 0.30 to 0.35 Coal 0.6893 – 6.8929 0.35 to 0.45 Shale 6.8929– 68.9286 0.28 to 0.43 Solution: a. Fracture toughness for each lithology, given the following data based on table 1 can be calculate using Equation 7 of Whittaker et al, 1992. 𝑲𝑰𝑪 = 𝟎. 𝟑𝟑𝟔 + 𝟎. 𝟎𝟐𝟔𝑬 where E is the Young’s Modulus in GPa For Soft Sandstone: average E = 3.7911 GPa 𝐾𝐼𝐶 = 0.336 + 0.026(0.6893) = 𝟎. 𝟑𝟓𝟑𝟗 𝑴𝑷𝒂 √𝒊𝒏 (minimum) 𝐾𝐼𝐶 = 0.336 + 0.026(6.8929) = 𝟎. 𝟓𝟏𝟓𝟐 𝑴𝑷𝒂 √𝒊𝒏 (maximum) 6) 𝐾𝐼𝐶 = 0.336 + 0.026(0. 55𝑥10 = 𝟎. 𝟒𝟑𝟒𝟔 𝑴𝑷𝒂 √𝒊𝒏 (average) For Medium Sandstone: average E = 24.1250 GPa 𝐾𝐼𝐶 = 0.336 + 0.026(13.7857) = 𝟎. 𝟔𝟗𝟒𝟒 𝑴𝑷𝒂 √𝒊𝒏 (minimum) 𝐾𝐼𝐶 = 0.336 + 0.026(34.4643) = 𝟏. 𝟐𝟑𝟐𝟏 𝑴𝑷𝒂 √𝒊𝒏 (maximum) ASSIGNMENT IN PRODUCTION TECHNOLOGY - MSC IN PETROLEUM ENGINEERING 𝐾𝐼𝐶 = 0.336 + 0.026(024.1250) = 𝟎. 𝟗𝟔𝟑𝟑 𝑴𝑷𝒂 √𝒊𝒏 (average) For Hard Sandstone: average E = 55.1429 GPa 𝐾𝐼𝐶 = 0.336 + 0.026(41.3571) = 𝟏. 𝟒𝟏𝟏𝟑 𝑴𝑷𝒂 √𝒊𝒏 (minimum) 𝐾𝐼𝐶 = 0.336 + 0.026(68.9286) = 𝟐. 𝟏𝟐𝟖𝟏 𝑴𝑷𝒂 √𝒊𝒏 (maximum) 𝐾𝐼𝐶 = 0.336 + 0.026(55.1429) = 𝟏. 𝟕𝟔𝟗𝟕 𝑴𝑷𝒂 √𝒊𝒏 (average) For Limestone: average E = 68.9286 GPa 𝐾𝐼𝐶 = 0.336 + 0.026(55.1429) = 𝟏. 𝟕𝟔𝟗𝟕 𝑴𝑷𝒂 √𝒊𝒏 (minimum) 𝐾𝐼𝐶 = 0.336 + 0.026(82.7143) = 𝟐. 𝟒𝟖𝟔𝟔 𝑴𝑷𝒂 √𝒊𝒏 (maximum) 𝐾𝐼𝐶 = 0.336 + 0.026(68.9286) = 𝟐. 𝟏𝟐𝟖𝟏 𝑴𝑷𝒂 √𝒊𝒏 (average) For Coal: average E = 3.7911 GPa 𝐾𝐼𝐶 = 0.336 + 0.026(0.6893) = 𝟎. 𝟑𝟓𝟑𝟗 𝑴𝑷𝒂 √𝒊𝒏 (minimum) 𝐾𝐼𝐶 = 0.336 + 0.026(6.8929) = 𝟎. 𝟓𝟏𝟓𝟐 𝑴𝑷𝒂 √𝒊𝒏 (maximum) 𝐾𝐼𝐶 = 0.336 + 0.026(3.7911) = 𝟎. 𝟒𝟑𝟒𝟔 𝑴𝑷𝒂 √𝒊𝒏 (average) For Shale: average E = 37.9108 GPa 𝐾𝐼𝐶 = 0.336 + 0.026(6.8929) = 𝟎. 𝟓𝟏𝟓𝟐 𝑴𝑷𝒂 √𝒊𝒏 (minimum) 𝐾𝐼𝐶 = 0.336 + 0.026(68.9286) = 𝟐. 𝟏𝟐𝟖𝟏 𝑴𝑷𝒂 √𝒊𝒏 (maximum) 𝐾𝐼𝐶 = 0.336 + 0.026(37.9108) = 𝟏. 𝟑𝟐𝟏𝟕 𝑴𝑷𝒂 √𝒊𝒏 (average) b. Young’s Modulus based on the following fracture toughness, (For sand, KIC=553 psi√𝑖𝑛 and for shale, KIC=784 psi√𝑖𝑛). 𝑬= For Sand 𝑲𝑰𝑪 − 𝟎. 𝟑𝟑𝟔 𝟎. 𝟎𝟐𝟔 101325 𝑃𝑎 1 𝑀𝑃𝑎 )𝑥( ) = 3.8118 𝑀𝑃𝑎 √𝑖𝑛 14.7 𝑝𝑠𝑖 1𝑥106 𝑃𝑎 3.8118 − 0.336 𝑬= = 𝟏𝟑𝟑. 𝟔𝟖𝟒𝟔 𝑮𝑷𝒂 0.026 553 𝑝𝑠𝑖 √𝑖𝑛 ( For Shale 101325 𝑃𝑎 1 𝑀𝑃𝑎 784 𝑝𝑠𝑖 √𝑖𝑛 ( )𝑥( ) = 5.404 𝑀𝑃𝑎 √𝑖𝑛 14.7 𝑝𝑠𝑖 1𝑥106 𝑃𝑎 5.404 − 0.336 𝑬= = 𝟏𝟗𝟒. 𝟗𝟐𝟑𝟏 𝑮𝑷𝒂 0.026 9. Table A shows selected values of fracture toughness that were determined experimentally for chalk, limestone and sandstone samples. Analyze in detail, the difficulty of matching fracture pressure on the basis of fracture toughness measured under confined conditions. Table A: Selected Values of Fracture Toughness ASSIGNMENT IN PRODUCTION TECHNOLOGY - MSC IN PETROLEUM ENGINEERING Rock Type Confining Pressure (MPa) Chalk Chalk Chalk Limestone Limestone Limestone Sandstone Sandstone Sandstone 0.00 24.13 48.26 0.00 24.13 48.26 0.00 24.13 48.26 Experimental KIC (MPa √𝑖𝑛) 0.73 2.22 2.33 1.44 2.12 4.92 1.36 2.62 4.96 Solution: By using Eq. 9 - KIC(Pconf) = (1+(0.037Pconf))*KIC(Pconf=0), we can estimate the fracture toughness based on the equation. Confining Experimental Fracture Calculated KIC Lithology Pressure (MPa) KIC (MPa √in) (MPa √in) Chalk 0 0.73 0.73 2.22 1.3818 Chalk 24.13 2.33 2.0335 Chalk 48.26 1.44 1.44 Limestone 0 2.12 2.7256 Limestone 24.13 4.92 4.0113 Limestone 48.26 1.36 1.36 Sandstone 0 2.62 2.5742 Sandstone 24.13 4.96 3.7884 Sandstone 48.26 From the data above, we can see that as the confining pressure increases, fracture toughness increases both for experimental and calculated value. But we can also notice that there is a discrepancy between the experimental and calculated fracture toughness. In the case of chalk, the experimental value is higher than the calculated one and also we can notice that as the confining pressure increases, the difference between the experimental and calculated fracture toughness decreases. For limestone, the difference in experimental and calculated doesn’t change (almost 0.6 to 0.9 difference) from 24.13 to 48.26 MPa. There is no trend as to which is greater in terms of increasing confining pressure unlike for chalk. For sandstone, experimental value is higher compare to calculated fracture toughness and the difference between the two increases as the confining pressure increases. In short, the difficulty in matching the fracture toughness and confining pressure to fracture pressure can be due to the change in the testing environment and due to the nature, composition and ASSIGNMENT IN PRODUCTION TECHNOLOGY - MSC IN PETROLEUM ENGINEERING properties of the rock being subject to testing. Maybe the hardness, maybe moisture content, temperature and other factors may affect its result. Fracture Toughness (Mpa √in) Confining Pressure vs Frcature Toughness 6 5 4 3 2 1 0 0 24.13 48.26 Confining Pressure (MPa) Experimental Value (Chalk) Calculated Value (Chalk) Experimental Value (Limestone) Calculated Value (Limestone) Experimental Value (Sandstone) Calculated Value (Sandstone) The graph above shows the proximity between the two values in terms of graph. Confining Pressure (Mpa) Fracture Toughness vs Confining Pressure for Chalk 60 50 40 30 20 10 0 0 0.5 1 1.5 2 2.5 Faracture Toughness (Mpa √in) Calculated Value (Chalk) Experimental Value (Chalk) ASSIGNMENT IN PRODUCTION TECHNOLOGY - MSC IN PETROLEUM ENGINEERING Confining Pressure (Mpa) Fracture Toughness vs Confining Pressure for Limestone 60 50 40 30 20 10 0 0 1 2 3 4 5 6 Faracture Toughness (Mpa √in) Calculated Value (Limestone) Experimental Value (Limestone) Confining Pressure (Mpa) Fracture Toughness vs Confining Pressure for Sandstone 60 40 20 0 0 1 2 3 4 Faracture Toughness (Mpa √in) Calculated Value (Sandstone) Experimental Value (Sandstone) 5 6 ASSIGNMENT IN PRODUCTION TECHNOLOGY - MSC IN PETROLEUM ENGINEERING