Enhanced Jaya Algorithm for design optimization of planar steel

frames

S. O. Degertekin1 I. B. Ugur2,

Department of Civil Engineering, Dicle University, 21100, Diyarbakır,Turkey

1

2

Department of Civil Engineering, Dicle University, 21100, Diyarbakır,Turkey

Abstract. An efficient meta-heuristic optimization method called Jaya Algorithm (JA) has gained wide acceptance

among optimization researchers in various engineering problems. The characteristic feature of JA is that does not

use algorithm-specific parameters and has a very simple formulation based on the concept of approaching the best

solution and moving away from the worst solution. This study presents an enhanced JA formulation for design

optimization of planar steel frames under strength, displacement and geometric-size constraints. The enhanced

Jaya Algorithm (EJA) accelerates the convergence to global optima and obtains better designs by randomizing a

specific number of best and worst solutions in each iteration in order to strengthen the exploitation behavior of the

method. The validity of EJA for planar steel frames is investigated by solving well-known five benchmark

problems up to 32 design variables. The results demonstrate the superiority of EJA over standard JA and other

state-of-the-art metaheuristic optimization methods in terms of optimized weight, number of structural analyses

and several statistical indices like standard deviation.

Keywords:

algorithm

design optimization; planar steel frames; meta-heuristic optimization methods; enhanced Jaya

1. Introduction

The emergence of meta-heuristic optimization methods that mimic natural phenomena has

increased considerably over the past three decades. A meta-heuristic could be defined as the

process of an iterative generation which sheds light on a heuristic by incorporating smartly

different concepts for exploration and exploitation of the search space and achieving strategies

in order to find near-optimum solutions [1]. Exploration and exploitation are the most

significant concepts of finding the best solution in all metaheuristic optimization methods.

Exploration provides generating diverse solutions in order to explore search space on a global

scale whereas exploitation focuses on the search in a local region by exploiting the information.

The balance between these two concepts allows to identify regions containing high-quality

solutions and move away from previously explored regions that are far from global optimum.

In the last two decades, the bio-inspired approaches (Genetic Algorithm (GA) [2], Particle

Swarm (PSO) [3], Ant Colony (ACO) [4], Honey Bee Mating (HBMO) [5], Enhanced Honey

Bee Mating (EHBMO) [6], Whale Optimization Algorithm (WOA) [7], Enhanced Whale

Optimization Algorithm (EWOA) [8] etc.) and physic-inspired approaches (Simulating

Annealing (SA) [9], Harmony Search (HS) [10], Big-bang big-crunch [11], Colliding Bodies

(CBO) [12] etc.) have been proposed for the optimization problems and extended by enhancing

their capabilities in optimization procedures such as the convergence, time consumption and

achieving the near-global optima.

Constructions must be designed as safely bearing the specified design loads constrained to

the structural provisions as well as the least amount of material is to be used. Meanwhile,

resource and time management are some of the most challenging problems in structural

engineering, however, structural designers can overcome these problems using meta-heuristics

to obtain the best design in terms of cost and safety. Since frame structures constitute the vast

majority of the skeletal systems in structural engineering, the optimum design of planar steel

frames is a common selected issue as a benchmark problem to investigate the efficiency of

meta-heuristics. Hence, various optimization methods have been proposed for the minimization

weight of steel frames under strength and stability circumstances specified in design codes.

Just to overview the literature published in the past two decades, Camp et. al. [13] used the

Ant Colony algorithm (ACO) that is to simulate the ant behavior to structural optimization of

steel frames.

Degertekin [14] utilized the Harmony Search (HS) based on the concept of searching for the

best harmony in musical improvisation. The efficiency of HS was tested in the optimization of

planar steel frames using three steel frames in comparison to the genetic algorithm and ant

colony optimization methods.

In the study proposed by Saka [15], structural optimization algorithms including GA, SA

and HS were reviewed and assessed comparing the optimization results of a steel frame design

example for each method.

Hasancebi et. al. [16] applied these techniques genetic algorithms, simulated annealing,

evolution strategies, particle swarm optimizer, tabu search, ant colony optimization and

harmony search to the real size rigidly connected steel frames including a planar example.

Dogan and Saka [17] developed an optimum design algorithm based on particle swarm

optimizer for planar steel frames. The superiority of the proposed algorithm was verified by

optimizing three steel frames in comparison to SA and GA.

An enhanced honey bee mating optimization method (EHBMA) for the optimum design of

side sway steel frames was proposed by Maheri and Nerimani [6] in order to overcome trapping

local optima and extend the search space of HBMO. The performance of the new method was

evaluated with four design examples.

Kaveh and Gaazan [8] proposed a new method called EWOA aimed to enhance the

convergence speed and solution accuracy of the standard method by modifying the formulation

of WOA. The efficiency of the new method was tested with four benchmark skeletal structures

involved steel frames and the results were compared to WOA and other optimization methods.

Carrero et. al. [18] implemented a search group algorithm (SGA) to three steel frame

examples in order to investigate the efficiency of the method in the structural design field. The

method has worked on the feasible domain only that leads to avoiding numerous structural

analyses. The results demonstrated that the proposed method achieved competitive

performance.

Farshchin et. al. [19] applied a school-based optimization (SBO) algorithm that is an

extended version of teaching-learning based optimization (TLBO) including multiple

classrooms and multiple teachers for the optimum design of planar steel frames

Most evolutionary and swarm-based intelligence algorithms require algorithm-specific

parameters for tuning the optimization process. However, inappropriate tuning of these

parameters affects the computational cost or convergence rate of the method negatively. In

order to overcome these issues, Rao [20] proposed a parameter-less evolutionary algorithm that

has a powerful search engine and can be easily implemented for any optimization problem. The

JA and its enhanced versions with various strategies have been utilized in large-scale real-life

urban traffic light scheduling problems [21], parameter estimating of battery models [22], cost

minimization of underground cable systems [23], structural damage detection [24] and medical

imaging problems. Besides, the JA was used also for the optimum design of truss structures

with both discrete and continuous variables [25,26]. The satisfactory performance of the JA in

optimum sizing of truss structures encouraged the authors to use JA in the structural

optimization of planar steel frames.

The main objective of this study is to minimize the weight of planar steel frames with

limitations of LRFD-AISC [27] and ASD-AISC [28] provisions using the JA and enhance the

standard JA in terms of faster convergence and stronger search capability. For this purpose, JA

is applied to sizing optimization of the well-known planar frame structures include up to 32

design variables utilized as the benchmark problems in the literature. In particular, the 244member planar frame is selected as an optimization problem since it has multiple search spaces

that vary according to the element type.

The remaining parts of the study are organized as follows. Section 2 recalls the discrete

sizing optimization of planar steel frames according to LRFD-AISC [27] and ASD-AISC [28].

Section 3 outlines the main steps for the implementation of the JA and EJA. Section 4 describes

the test problems and discusses optimization results. Section 5 provides a brief conclusion of

the study.

2. Sizing optimization of planar steel frames

To design an economical structure, the weight should be minimized within feasible

conditions. The weight of a steel structure depends on the material density, lengths and crosssectional areas of the elements. Cross-sectional areas are selected as design variables in the

optimization problem since material density and lengths are constant.

The objective of the optimization problem is to minimize the weight of structures under

stress, displacement and geometrical constraints by searching best cross-sectional areas in a

pre-defined section list. It can be stated as;

Find

𝐴 ∈ 𝑆 = {𝐴1 , 𝐴2 , . . . . . , 𝐴𝑛𝑐𝑠 }

ng

nm

k 1

i 1

To minimize W ( A) Ak i Li

k=1,2,….,ng

i=1,2,...,nm

(1)

j=1,2….nc

Subject to gj(A) ≤ 0

where A is the vector including the design variables (i.e. member groups), S is a set of

discrete cross-sectional areas, W(A) is the total weight of structure defined as a object function,

γi and Li are the material density and the length of member I , Ai is the cross-sectional area

of the member i., gj(A) denotes the design constraints including stress, displacement and

geometric constraints, n is number of constraints, ng is number of member group (i.e. design

variables), nm is the number of members, nd is the number of degrees of freedom, ncs is the

number of discrete cross-sectional areas in the section list.

In order to convert a constrained optimization problem to an unconstrained one, a

penalty approach is utilized to take into account the constraint violations. Accordingly, the

objective function is redefined as:

𝑊𝑝 (𝐴) = (1 + 𝜀1 ∙ 𝜓)𝜀2 × 𝑊(𝐴)

(2)

𝜓 = ∑𝑛𝑗=1 max[0, 𝑔𝑗 (𝐴)]

(3)

where n is the number of constraints for each design, 𝜓 represents the sum of the violated

constraints. 𝜀1 is the penalty constant set to 1, 𝜀2 is the exponent of the penalty function taken

as 2. The penalty parameters allow the objective function to approach in a feasible direction.

2.1 Constraints of frame structures

The optimum design of steel frame structures is subjected to displacement, stress and

geometrical constraints specified in the design codes. In this study, LRFD-AISC [27]

requirements are utilized for the first four examples whereas ASD-AISC [28] limitations are

selected as design constraints for the last example.

Strength constraints are described as following equations indicated in ASD-AISC for

different cases of fa/Fa:

𝑓

𝑓

𝑓

𝑓

𝑔𝑠,𝑗 (𝐴) = [𝐹𝑎 + 𝐹𝑏𝑥 + 𝐹𝑏𝑦 ] − 1 ≤ 0𝑖𝑓 𝐹𝑎 ≤ 0.15𝑗 = 1,2 … 𝑛𝑚

𝑎

𝑓

𝑔𝑠,𝑗 (𝐴) = [𝐹𝑎 +

𝑎

𝑏𝑥

𝑎

𝑏𝑦

𝐶𝑚𝑥 𝑓𝑏𝑥

𝑓

(1− 𝑎 )𝐹𝑏𝑥

𝐹′𝑒𝑥

+

𝐶𝑚𝑦 𝑓𝑏𝑦

𝑓

(1− 𝑎 )𝐹𝑏𝑦

𝐹′𝑒𝑦

𝑓

] − 1 ≤ 0𝑖𝑓 𝐹𝑎 > 0.15

𝑎

(4)

(5)

𝑓

𝑓

𝑓

𝑎

𝑔𝑠,𝑗 (𝐴) = [0.6𝐹

+ 𝐹𝑏𝑥 + 𝐹𝑏𝑦 ] − 1 ≤ 0

𝑦

𝑏𝑥

(6)

𝑏𝑦

Fy is the yield stress of the material, fa is the required axial stress computed as P/A where A is

the cross-sectional area. Fa denotes the allowable axial stress depending on the elastic or

inelastic buckling behavior of the member. fbx and fby are required flexural stresses about the

major and minor axis. Fbx and Fby represent nominal flexural stress about the major and minor

axis. Fex and Fey stand for Euler stress on the -x and -y axis, respectively. Cmx and Cmy are

described as reduction factors that are used for the distribution of moments along the member

length depending on the sway behavior.

Strength constraints are described as following equations indicated in LRFD-AISC

against both bending and axial forces:

𝑃

8

𝑀𝑢𝑥

𝑔𝑠,𝑗 (𝐴) = 𝜙 𝑢𝑃 + 9 (𝜙

𝑏 𝑀𝑛𝑥

𝑐 𝑛

𝑃

𝑀𝑢𝑥

𝑔𝑠,𝑗 (𝐴) = 2𝜙 𝑢𝑃 + (𝜙

𝑏 𝑀𝑛𝑥

𝑐 𝑛

𝑀𝑢𝑦

+𝜙

𝑏 𝑀𝑛𝑦

𝑀𝑢𝑦

+𝜙

𝑃

) − 1 ≤ 0𝑖𝑓 𝜙 𝑢𝑃 ≥ 0.2

𝑏 𝑀𝑛𝑦

𝑐 𝑛

𝑃

) − 1 ≤ 0𝑖𝑓 𝜙 𝑢𝑃 < 0.2

𝑐 𝑛

(7)

(8)

Pu and Pn represent the required axial strength and the nominal axial strength for both

compression and tension; Mux and Mnx denote required flexural strength and nominal flexural

strength about the x-direction (major axis); Muy and Mny are the required flexural strength and

nominal flexural strength about the y-direction (minor axis). It should be noted that Mny=0 for

planar frame structures. 𝜙𝑐 is the axial resistance factor and taken as 0.90 for tension and 0.85

for compression; 𝜙𝑏 is the flexural resistance reduction factor and taken as 0.90.

Lateral displacement and inter-story drifts are considered as displacement constraints

and restricted to be less than the limit values described below:

𝑔𝑑 (𝐴) =

∆𝑇

𝐻

− 𝑅 ≤ 0

𝑑

𝑔𝑖𝑠,𝑛 (𝐴) = ℎ𝑛 − 𝑅𝐼 ≤ 0𝑛 = 1,2 … 𝑛𝑠

𝑛

(9)

(10)

where ∆ 𝑇 represents the lateral displacement of the top story, H is the total height of the frame

structure, R denotes the maximum displacement limit taken as 1/300, dn is the inter-story drift

of the n-th floor, hn is the story height of the n-th floor. Ns is the number of stories. Rı denotes

the inter-story limit value specified as 1/300.

Apart from strength and displacement constraints, geometrical constraints are

considered so as to restrict the flange width of the beam section at each beam-column

connection to be less than or equal to the flange width of the column section. The equations of

geometrical constraints are shown below:

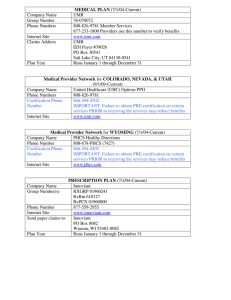

Figure 1. Beam-column connection

𝑔𝑔 (𝐴) =

𝑏𝑓𝑏

𝑏𝑓𝑐

𝑔𝑔 (𝐴) = (𝑑

− 1 ≤ 0

𝑏′𝑓𝑏

𝑐 −2𝑡𝑓 )

−1 ≤0

(11)

(12)

bf, 𝑏′𝑓𝑏 and bfc represent the flange width of the beam B1, the beam B2 and the column,

respectively, tf is the flange thickness of the column.

3. Enhanced Jaya Algorithm (EJA)

The JA quite recently developed optimization method is firstly proposed by Rao [20]. The

word “Jaya” originally means “victory” in Sanskrit. The algorithm is based on the concept that

the solution obtained for a given optimization problem should move toward the best solution

and must avoid the worst solution. The algorithm always tries to get closer to success (i.e.,

reaching the best design) and then tries to avoid failure (i.e., moving away from the worst

design) [20]. The most important feature of JA is that the JA has not any algorithm-specific

parameters whereas the other metaheuristic optimization algorithms have algorithm-specific

parameters. The JA only requires two standard control parameters which are the population size

(i.e., number of solutions in the population) and maximum iteration number.

The implementation of JA is very simple and has only one equation for modifying the designs.

Ak,l,it denotes the value of the k-th design variable for the l-th design during the it-th iteration, the JA

modifies the Ak,l,it as follows:

Aknew

,l ,it Ak ,l ,it r1, k ,it Ak ,best,it Ak ,l ,it r2, k ,it Ak , worst ,it Ak ,l ,it

(13)

where Aknew

,l ,it is the new design variable for the Ak ,l ,it , r1,k ,it and r2 ,k ,it are the randomly generated real

numbers in the range [0,1] for the k-th design variable at the it-th iteration. Ak ,best ,it is the k-th design

variable of the best design at the it-th iteration and Ak ,worst,it is the k-th design variable of the worst

design at the it-th iteration. The term r1,k ,it Ak ,best,it Ak ,l ,it indicates the tendency of the solution to

move closer to the best solution, and the term r2,k ,it Ak ,worst,it Ak ,l ,it indicates the tendency of the

solution to avoid the worst solution. It is worth pointing out that the random numbers r1 and r2 ensure

good exploration of the search space and the absolute value of the candidate solution (|Ak,l,it|)

considered in Eq (13) further enhances the exploration ability of the algorithm [20]. The flowchart

diagram of JA is shown in Fig.1.

There are many concepts are used in metaheuristic algorithms in order to strengthen the

searching process, converge the better global optima or accelerate the optimization. One of these

concepts is the elitism which is used during every generation in which elite (best) solutions replaced

with the worst solutions. In Enhanced Jaya Algorithm, unlike the elitism concept, worst solutions are

not duplicated by the elite ones. The specified number of best and worst solutions are identified.

Afterward, one of the identified solutions for each best and worst solutions is selected randomly then

used in the modification equation of JA. This process allows the algorithm to avoid the local trapping

and enhance the exploration capability.

As mentioned earlier, standard JA has no algorithm-specific parameter and only needs

common control parameters as population size (np) and maximum iteration number (itmax). The

optimization is terminated when the maximum iteration number is exceeded. However, each

optimization run could find the best solution for a different value of itmax. Instead, the following

formulation is implemented to terminate the search process when it is satisfied.

𝑆𝑇𝐷[𝑊𝑝 (𝐴1 ),𝑊𝑝 (𝐴2 ),…𝑊𝑝 (𝐴𝑛𝑠 )]

𝑛𝑠

∑

(

𝑖=1

1

≤ 𝜀𝑐𝑜𝑛

(14)

)

𝑊𝑝 (𝐴𝑖 )

In Eq. (14), 𝑊𝑝 (𝐴𝑖 ) represents the penalized objective function of i-th design in the population,

ns is the population size, 𝜀𝑐𝑜𝑛 is the coefficient of convergence tolerance taken as 10-4. As a

consequence of considering a dynamic itmax value, the needed common control parameters reduced to

only one which is population size.

4. Implementation of EJA for frame structures

In frame optimization, the EJA is initialized by randomly generated frame designs as the

population size np (number of frame designs) and the penalty functions for each design are

calculated by the results of structural analysis. The penalized functions are calculated at the rate

of constraint violation. After that, the frame design with a certain number of lower penalized

function values 𝑊𝑝 (𝐴𝑏𝑒𝑠𝑡

)

𝑖

and a certain number of higher penalized function values

𝑊𝑝 (𝐴𝑤𝑜𝑟𝑠𝑡

) are assigned to the best design and the worst design vectors, respectively. The

𝑖

size of the best and worst vectors is set to 3. In order to modify the design variables by using

Eq.(13), the best and worst design is randomly selected from the best and worst vectors. The

new frame design is generated with modified design variables. The new penalized objective

function 𝑊𝑝,𝑛𝑒𝑤 (𝐴) is calculated. If the new penalized objective function value is smaller than

the previous one, ( 𝑊𝑝,𝑛𝑒𝑤 (𝐴) < 𝑊𝑝,𝑝𝑟𝑒 (𝐴) ), the new design is replaced with the previous one.

Otherwise, the previous design remains unchanged. This process is repeated for each frame

design in the population then an iteration is completed. The optimization is terminated when

the Eq. (14) is satisfied which depends on the standard derivation of penalized objective

function values in the population The Eq. (14) was defined as a termination criterion depends

on the standard deviation of penalized objective function values in the population and when the

criterion is satisfied, the optimization process is terminated. The best design without constraint

violation is reported as the optimum design.

The implementation of enhanced JA for optimum design of frame structures is summarized

below.

Step 1: Generate the initial population (i.e., frame designs) using random integers

between 1 and the number of discrete values for each design variable. Calculate

the penalized objective function values 𝑊𝑝 (𝐴) for all frame designs in the

population using Eq. (1-12). Set the iteration counter as it=0.

Step 2: Increase the iteration counter, it=it+1

Step 3: Determine the best and worst three designs of the population. 𝐴𝑖𝑏𝑒𝑠𝑡 , 𝐴𝑖𝑤𝑜𝑟𝑠𝑡 𝑖 =

1,2,3. Select one of them as the best and worst design randomly.

Step 4: Modify discrete design variables by using Eq. (13) for each frame design in the

𝑛𝑒𝑤

population. Obtain the new designs with modified design variables𝐴

𝑛𝑒𝑤

the penalized function values 𝑊𝑝 (𝐴

and calculate

) with modified design variables.

Step 5: If 𝑊𝑝 (𝐴𝑛𝑒𝑤

)<𝑊𝑝 (𝐴𝑝𝑟𝑒

𝑖

𝑖 ) , replace the i-th new design with the previous one

otherwise; keep the previous design. Repeat this process for each frame designs

stored in the population.

Step 6: Terminate the optimization process if Eq. (14) is satisfied. Store the feasible

design corresponding to the lowest value of the objective function as the final

optimum design. Otherwise, go to Step 2

5. Design Examples

To demonstrate the performance the Enhanced Jaya Algorithm, five classical benchmark

frame examples as follows: Two-bay three-story steel frame, one-bay ten-story steel frame,

three-bay fifteen-story steel frame, a three-bay twenty four-story steel frame and 224-member

braced planar steel frame are optimized according to provisions of LRFD-AISC [27] and ASDAISC [28] specifications and the results are compared with standard Jaya Algorithm and other

metaheuristic methods in the literature.

The EJA and JA were executed ten times and the initial population of each run was

generated randomly. The population size was set to 20 for all examples.

The statistical performance and robustness of algorithms used in benchmark examples are

assessed and reported in related tables in terms of the best, mean, worst weighed designs, the

standard deviation of best designs obtained in each run and number of structural analyses. The

optimum design of each example reported in other studies was analyzed using the given

optimum sections in order to check constraint violation. If detected, the violation rates of both

strength and displacement constraints are reported in the tables.

EJA was coded in the MATLAB R2017a [29] programming language and automated to

interact with OPENSEES [30] structural analysis program for controlling design and

displacement constraints during the optimization process. The proposed program was executed

on a standard PC equipped with a single 2.2 GHz Intel® Pentium i7-4702MQ CPU.

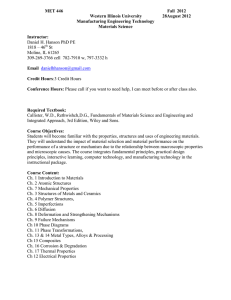

5.1. Two-bay three story frame

The first design example to test the validity of EJA is two-bay three story frame as

shown in Fig. 2. The frame example has 15 members divided into 2 groups: beams and

columns. The column members are restricted to be selected from W10 sections and beams are

selected from all W shaped standard sections. The Young modulus of steel E is 29000 ksi and

yield stress is Fy is 36 ksi. For each column, the effective length factor is calculated according

to equations proposed by Dumonteil [31] for sway-permitted frames. The effective length

factor of the out-of-plane columns (Ky) is considered as 1.0. The unbraced length ratio of beams

is set to 0.167. Displacement constraints are not taken into account for this design.

Figure 2. Two-bay three story frame

This frame example was optimized by Camp et al. [13] using ACO, Degertekin [14]

using HS, Carraro et al. [18] using SGA, by Maheri and Nerimani [6] using HBMO and

Farshchin et al. [19] using SBO, JA and EJA from this study. The best design obtained by each

algorithm is reported as well as the statistical performance of these methods in terms of average

weight and standard deviation in Table 1.

The JA and EJA obtained the same design weighing 18792 lb as ACO, SGA and SBO

methods. While other methods required at least 420 structural analyses to converge the

optimum, JA and EJA required 155 and 72 structural analyses, respectively. It is evident that

the enhanced Jaya Algorithm converges the best design in much less structural analysis than

the others as shown in Fig 2. In ten independent runs, the mean weight and standard deviation

values of EJA are 18814 lb and 32.34 lb less than other methods except SBO. The results

reported by HS and HBMO methods are not feasible due to the constraint violations as

demonstrated in Table 1.

Table 1. Comparison of optimum designs for two bay three story frame

Optimal cross section area (in2)

Design

variables

ACO

[13]

HS

[14]

SGA

[18]

HBMO

[6]

SBO

[19]

JA

This study

EJA

This study

Column

W24×62

W21×62

W24×62

W10×77

W24×62

W24×62

W24×62

Beam

W10×60

W10×54

W10×60

W10×77

W10×60

W10×60

W10×60

18792

18292

18792

18000

18792

18792

18792

3000

1853

420

463

502

155

75

19163

18784

19011

N/A

18792

18851

18814

1693

411

385.09

N/A

0

36.68

32.34

Max IR

0.946

1.02

0.946

1.39

0.946

0.946

0.946

IRlimit

Max CV

(%)

1

1

1

1

1

1

1

None

2

None

39

None

None

None

Best

weight

(lb)

NSA

Mean

weight

(lb)

SD

Convergence curves are compared by plotting the structural weight versus number of structural

analyses in Fig 2. It is obvious that the EJA has the most powerful convergence ability among

all methods shown in Fig 2.

Figure 3. Comparison of convergence curves for the one-bay three story frame

5.2 One-bay ten story frame

A further design example commonly used in literature is one bay ten story plane as given

in Fig 4. with configuration, member grouping and load conditions. The frame has 30 members

which are gathered in 9 design groups and grouped in a way that the columns of two consecutive

stories and the beams of three consecutive stories except roof beams form a group distinctively.

Beam groups are selected from any 267 standard W-sections, column groups are restricted to

W12 and W14 sections. The material density, yield stress and the effective length factor of

members are considered as in the previous example. The columns are considered unbraced

along their length and the unbraced length for each beam member is specified as 1/5 of the span

length.

Figure 4. Two-bay three story frame

Two different optimization cases are considered in terms of displacement limitations. In

case 1, the inter-story drift for all stories is limited to story height/300; while in case 2, only the

displacement of top story is limited to total frame height/300. Both optimization cases are

considered in this study and the results are compared with other related methods in the literature.

Table 2. Comparison of optimum designs for one bay ten storey frame

Optimal cross section (area. in2)

Case 1

Sizing

variables

Case 2

GA

[34 ]

SBO

[19]

HBMO

[6]

EHBMO

[6]

1

2

3

4

5

6

7

8

W14×233

W14×176

W14×159

W14×99

W12×79

W33×118

W30×90

W27×84

W14×233

W14×176

W14×159

W14×99

W14×61

W33×118

W30×90

W27×84

W14×159

W14×159

W14×159

W14×159

W14×145

W21×73

W21×73

W24×76

W14×159

W14×159

W14×132

W14×109

W14×90

W24×94

W24×94

W18×76

JA

This

Study

W14x233

W14x176

W14x159

W14x99

W14x68

W33x118

W30x90

W24x84

EJA

This

Study

W14x233

W14x176

W14x159

W14x99

W12x65

W33x118

W30x90

W24x84

ACO

[13]

HS

[14]

SGA

[18]

SBO

[19]

W14×233

W14×176

W14×145

W14×99

W14×61

W30×108

W30×90

W27×84

JA

This

Study

W14x233

W14x176

W14x145

W14x99

W12x65

W30x108

W30x90

W27x84

EJA

This

Study

W14x233

W14x176

W14x145

W14x99

W12x65

W30x108

W30x90

W24x84

W14×233

W14×176

W14×145

W14×99

W12×65

W30×108

W30×90

W27×84

W14×211

W14×176

W14×145

W14×90

W14×61

W33×118

W30×99

W24×76

W14×233

W14×176

W14×132

W14×99

W14×68

W30×108

W30×90

W27×84

9

W24×55

W18×46

W24×76

W24×62

W21x44

W21x44

W21×44

W18×46

W21×50

W18×46

W21x44

W21x44

Best weight

(lb)

65136

64002

61014

57714

64298

64151

62610

61864

62262

62430

62610

62579

NSA

N/A

12691

1823

1340

18541

11857

8300

3690

7980

11677

7688

6933

Mean

weight (lb)

N/A

65880

N/A

N/A

66992.8

64469.5

63308

62923

65257

63244

62943

62684

Worst

weight (lb)

N/A

N/A

N/A

N/A

68785

65027.08

N/A

N/A

N/A

N/A

63518

63150

SD

Max ISD

N/A

0.0033

832

0.0033

N/A

0.00851

N/A

0.00596

1614

0.0033

294

0.0033

684

4.23

1.74

4.125

7027

4.224

706.84

4.217

340

4.23

252

4.32

ISDlimit

0.00333

0.0033

0.00333

0.00333

0.00333

0.00333

4.92

4.92

4.92

4.92

4.92

4.92

Max IR

0.967

1

1.91

1.438

0.968

0.998

0.986

1.0502

1.0148

0.999

0.986

0.998

IRlimit

1

1

1

1

1

1

1

1

1

1

1

1

Max CV (%)

None

None

155.1

78.9

None

None

None

5.02

1.48

None

None

None

The optimization performance of GA [34], SBO [19], HBMO [6], EHBMO [6] for case 1 and

ACO [13], HS [14], SGA, [18], and SBO [19] for case 2 is summarized in Table 2. Although

the best design of EJA is % 0.23 heavier than the SBO, EJA requires 834 less structural analysis

than SBO in case 1. Besides, EJA has the least standard deviation value that indicates the

robustness of the method. As detailed in the Table 2, best designs of HBMO and EHBMO are

extremely violated both strength and displacement constraints while EJA, JA, GA [34] and

SBO [19] strictly satisfy the limitations. In case 2, SBO [19] has the best design with the

weighing of 62430 lb that is % 0.24 lighter than EJA. It is clear that the best results of both

methods are rather close. In terms of required analysis number and statistical values, EJA has

the most satisfying performance with a standard deviation of 252 lb, a mean weight of 62684

lb and structural analysis number of 6933.

Figure 5.a. Comparison of convergence curves for the two-bay three story frame (Case 1)

Figure 5.b. Comparison of convergence curves for the two-bay three story frame (Case 2)

The convergence history of EJA and JA is indicated and compared with other methods

for both cases in Fig. 5. The convergence rate of the EJA is significantly higher than the others

as seen in the figure. In comparison to JA, the trend of achieving the near-optimum region is

faster by far.

5.3. Three Bay Fifteen Story Frame

Three bay fifteen-story planar frame was optimized firstly by Saka [15] using SA and

GA according to both LRFD [27] and ASD [28] provisions. The geometry and load conditions

of the frame are shown in Figure 6. The frame consists of 105 members divided into 12 design

groups. Grouping is considered as consecutive three-story inner and outer columns form a

distinct group, roof and intermediate story beams constitute a distinct group. The frame is

subjected to gravity loading as well as wind loading which computed according to The British

Code considering 45 m/s wind speed and 6 m frame spacing [15]. The modulus of elasticity

is 200 kN/mm2. In this example, both inter-story drift and lateral displacement of the top story

are considered as displacement constraints and restricted to be smaller than 1.17 cm and 17. 67

cm, respectively. In this example, the strength capacities of members are calculated with the

formulations specified in LRFD-AISC [27].

Figure 6. Three bay fifteen story frame

The optimum design results of EJA and other methods are reported in Table 4. The EJA

obtained the best design weighing of 33896 kg which is %9.27 lighter than the best design

obtained using PSO [17], %13.7 lighter than the SA and %17.22 lighter than GA [15]. In

addition, EJA has found better a design with less structural analysis with less standard deviation

than standard JA. The design of PSO [17] violated displacement constraint at a high rate as seen

in Table 3.

Table 3. Comparison of optimum designs for three bay fifteen storey frame

Sizing

variables

GA

[15]

SA

[15]

PSO

[17]

JA

This Study

EJA

This Study

1

W21×50

W21×50

W6×9

W8×18

W8×18

2

W24×55

W21×57

W21×44

W21×44

W21×44

3

W10×39

W10×33

W10×33

W12×35

W10×54

4

W14×53

W10×39

W10×33

W16×40

W16×36

5

W14×53

W12×53

W14×53

W21×55

W21×48

6

W14×68

W16×67

W21×111

W24×84

W21×68

7

W24×117

W24×104

W21×111

W30×90

W30×90

8

W14×43

W10×39

W14×61

W12×35

W8×24

9

W14×48

W14×48

W14×61

W16×40

W16×40

10

W14×68

W14×61

W24×76

W21×55

W24×62

11

W14×109

W14×99

W27×94

W30×90

W30×90

12

W16×100

W14×99

W27×102

W33×118

W30×108

40949

39262

37360

34103

33896

Best

(kg)

weight

NSA

25000

15500

7000

7870

7165*

Mean weight

(lb)

N/A

N/A

N/A

35381

34664

Worst weight

(lb)

N/A

N/A

N/A

37395

36752

SD

N/A

N/A

N/A

1366

1199

Max ISD

1.12

1.17

1.07

1.16

1.16

ISDlimit

1.17

1.17

1.17

1.17

1.17

Max IR

0.95

0.91

0.87

0.99

0.99

1

1

1

1

1

None

None

116

None

None

IRlimit

Max CV (%)

The design history graph of optimization using PSO [17], JA and EJA is plotted in Fig.

8. The convergence of EJA is rather satisfying in comparison to PSO [17] by far. JA has similar

convergence behavior with EJA as illustrated in Fig 7.

Figure 7. Comparison of convergence curves for the three-bay fifteen story frame

5.4 Three-Bay Twenty-Four Story Frame

The fourth, commonly used benchmark example is three-bay twenty-four story frame

consisting of 168 members that are collected in 20 groups shown in Fig. 8. with configuration

and loading conditions. The frame was originally designed by Davison and Adams [32] later

optimized by Camp et. al using PSO [13] , Degertekin using HS [14], Carraro et. al. using SGA

[18], Mahari and Nerimani using HBMO and EHBMO [6], Kaveh and Ghazaan using WOA

and EWOA [8] and Farshchin et. al. using SBO [19].

The material modulus of elasticity is 29782 ksi and the yield stress is taken as 33.4 ksi.

All members are considered unbraced along their lengths. For each column, the effective length

factor is calculated according to equations proposed by Dumonteil [31] for sway-permitted

frames. The effective length factor of the out-of-plane columns (Ky) is considered as 1.0. The

beam member groups could be selected from W-shaped sections in AISC standard list while

the column members are limited to W14 sections. The grouping scheme is demonstrated in Fig.

8.

Figure 8. Three-bay twenty-four story frame

Table 4 lists results of optimum designs including EJA and other optimization methods. The

EJA has the best design weighing of 201193 lb in comparison to all techniques reported in the

table. It should be noted that the EJA is overall the most efficient optimizer with the lightest

feasible design and the lowest standard deviation value. Much as SGA [18] and EHBMO [6]

found lighter designs weighing of 194508 and 188640 lb respectively, these designs violate

constraints at high rates as %34 and %1766.

Table 4. Comparison of optimum designs for three bay twenty four story frame

Optimal cross section (area. in2)

Sizing

variables

W30×90

JA

This

Study

W30×90

EJA

This

Study

W30×90

W10×30

W8×18

W16×26

W12×19

W21×62

W24×55

W21×48

W24×55

W24×55

W14×26

W6×8.5

W6×8.5

W6×8.5

W6×8.5

ACO

[13]

HS

[14]

SGA

[18]

HBMO

[6]

EHBMO

[6]

WOA

[8]

EWOA

[8]

SBO

[19]

1

W30×90

W30×90

W24×68

W10×22

W10×15

W30×90

W30×90

2

W8×18

W10×22

W21×55

W27×539 W36×256

W10×17

3

W24×55

W18×40

W24×62

4

W8×21

W12×16

W12×87

W8×21

W6×16

W33×221 W27×146

5

W14×145 W14×176 W14×159 W14×145 W14×145 W14×109 W14×159 W14×152 W14×120 W14×159

6

W14×132 W14×176 W14×145 W14×145 W14×120 W14×145

7

W14×132 W14×132 W14×120

W14×68

W14×26

W14×109 W14×120 W14×109

W14×90

W14×109

8

W14×132 W14×109

W14×99

W14×22

W14×26

W14×99

W14×74

W14×74

W14×90

W14×74

9

W14×68

W14×82

W14×68

W14×48

W14×53

W14×53

W14×74

W14×82

W14×74

W14×61

10

W14×53

W14×74

W14×48

W14×68

W14×99

W14×43

W14×43

W14×43

W14×34

W14×38

11

W14×43

W14×34

W14×48

W14×132 W14×159

W14×34

W14×30

W14×34

W14×30

W14×34

12

W14×43

W14×22

W14×34

W14×342

W14×22

W14×22

W12×19

W14×22

W14×22

13

W14×145 W14×145 W14×109 W14×159 W14×145 W14×120

W14×90

W14×109

14×109

W14×90

14

W14×145 W14×132

14×109

W14×99

15

16

W14×30

W14×99

W14×120 W14×120 W14×132

W14×82

W14×109

W14×26

W14×99

W14×120 W14×109

W14×120 W14×109

W14×99

W14×99

W14×74

W14×109

W14×90

W14×99

W14×109

W14×90

W14×90

W14×82

W14×109

W14×48

W14×26

W14×82

W14×99

W14×99

W14×90

W14×90

17

W14×90

W14×61

W14×90

W14×43

W14×26

W14×90

W14×68

W14×68

W14×74

W14×74

18

W14×61

W14×48

W14×74

W14×53

W14×26

W14×61

W14×61

W14×61

W14×74

W14×61

19

W14×30

W14×30

W14×43

W14×176 W14×370

W14×38

W14×43

W14×34

W14×43

W14×34

20

W14×26

W14×22

W14×43

W14×211 W14×109

W14×22

W14×22

W14×22

W14×22

W14×22

220465

214860

194508

214848

188640

206520

203490

202422

203069

201193*

15500

13924

8010

2074

1826

19640

18820

14572

13097

16306

229555

222620

213545

N/A

N/A

216475

208648

209560

207949.2

203612.9

N/A

N/A

N/A

N/A

N/A

243143

226019

N/A

216308.9

207178.9

4561

N/A

7027

N/A

N/A

N/A

N/A

7052

4204

1966

0.00307

0.0329

0.00447

0.0331

0.0622

0.00332

0.00332

0.0032

0.00333

0.00333

0.00333

0.00333

0.00333

0.00333

0.00333

0.00333

0.00333

0.0033

0.00333

0.00333

Max IR

0.779

0.0774

0.949

4.69

10.75

0.974

0.817

0.998

0.991

0.952

IRlimit

Max CV

(%)

1

1

1

1

1

1

1

1

1

1

None

None

34

893

1766

None

None

None

None

None

Best

weight

(lb)

NSA

Mean

weight

(lb)

Worst

weight

(lb)

SD

Max

ISD

ISDlimit

Fig. 9 illustrates the convergence history of EJA and other algorithms to the optimum design.

In this example, number of structural analyses required by EJA in order to find the optimum

design is 16306. Despite the fact that the convergence rate of EJA is slightly slower than the

others, it reaches the best feasible design. It can be explained as comparing the convergence

behavior of the unfeasible designs with feasible ones is pointless.

Figure 9. Comparison of convergence curves for the three-bay twenty-four story frame

5.5. 224 Member Braced Frame

The last comparison example is 224 member braced frame which was firstly optimized

by Hasancebi et. al. [16] using seven different algorithms: SA, ESs, TS, ACO, PSO, SGA and

HS.

(a) Side view

(b) Plan view

Figure 10. 224 member braced frame

Fig 10. demonstrates side and plan views of the example which represents one of the interior

frameworks of the structure along the short side direction. The height is 276 ft and the frame

has three bays that each one has a span of 30 ft. The non-swaying concept is provided by bracing

the frame with X-type system placed within the middle bays. The further trusses are also placed

at the twelfth and the top story in order to increase lateral rigidity and hence the large

displacements are prevented. The members are collected in 32 groups that specified as interior

columns, exterior columns, beams and diagonals of successive three stories as shown in Fig

10.(a). The material properties of the steel are as follows: modulus of elasticity (E) is 29000 ksi

and yield strength (Fy) is 36 ksi. The column members are selected from the wide-flange profile

list consisting of 297 sections while beams and diagonals are restricted to be selected from

discrete sets of 171 and 147 economical sections classified according to the properties of area,

inertia and radii of gyration. The single loading condition is the combination of the gravity, live,

snow and wind load that are calculated as to ASCE7-05 [33]: a design dead load of 60.13 lb/ft2,

a design live load of lb/ft2 a ground snow load of 25 lb/ft2 and a basic wind speed of 91 mph

resulting in a uniformly distributed gravity load of 1001.62 lb/ft on top story beams, and of

1453.72 lb/ft on other story beams. Wind loads applying at each floor level on windward and

leeward faces of the frame are tabulated in Table 5. The strength, stability and displacement

constraints are considered according to the provisions of ASD-AISC [28].

Table 5. Wind loads acting on 224-member braced frame

Windward

Leeward

Floor

(kips)

(kips)

1

1.69

2.454

2

1.933

2.454

3

2.17

2.454

4

2.356

2.454

5

2.512

2.454

6

2.646

2.454

7

2.765

2.454

8

2.872

2.454

9

2.971

2.454

10

3.062

2.454

11

3.146

2.454

12

3.225

2.454

13

3.3

2.454

14

3.371

2.454

15

3.438

2.454

16

3.502

2.454

17

3.563

2.454

18

3.621

2.454

19

3.678

2.454

20

3.732

2.454

21

3.784

2.454

22

3.835

2.454

23

3.884

2.454

24

1.966

1.227

The optimum results of 224 member braced frame using JA, EJA and other methods are

tabulated in Table 6. The EJA obtained the best design weighing of 219845.9 lb that is %11

lighter than the SA which has the best design among seven methods in the study of Hasancebi

[16]. In addition, EJA obtained %7.2 lighter design with 1491 less number of structural analyses

and with 7206 less standard deviation value than JA.

Table 6. Comparison of optimum designs for 224 member braced frame

Sizing

variables

Optimal cross section (area. in2)

SA

[16]

ESs

[16]

TS

[16]

ACO

[16]

PSO

[16]

SGA

[16]

HS

[16]

JA

EJA

This Study This Study

1

W14×109

W14×109

W12×120

W14×120

W27×146

W18×143

W24×146

W14×145

W14×120

2

W40×277

W40×277

W36×280

W40×268

W36×260

W40×328

W14×233

W14×257

W36×280

3

W8×40

W10×39

W8×40

W10×45

W10×39

W10×39

W10×49

W10×33

W8×24

4

W16×40

W16×40

W16×45

W16×40

W16×40

W16×40

W16×40

W18×40

W16×36

5

W14×99

W30×108

W18×106

W33×118

W18×130

W18×119

W14×109

W18×119

W14×99

6

W12×190

W12×210

W30×191

W40×221

W14×176

W21×201

W21×201

W30×191

W24×192

7

W10×39

W8×35

W8×35

W8×35

W8×35

W8×35

W10×39

W8×24

W6×20

8

W16×45

W14×43

W16×45

W14×43

W16×40

W16×40

W16×40

W16×40

W21×44

9

W14×90

W27×94

W18×97

W14×90

W21×101

W14×99

W21×101

W10×100

W14×90

10

W14×145

W14×145

W40×167

W33×152

W21×182

W12×152

W14×132

W36×150

W36×150

11

W8×31

W8×35

W10×33

W14×43

W8×401

W10×39

W12×45

W6×20

W8×24

12

W16×45

W14×43

W16×45

W18×50

W16×45

W16×45

W16×50

W21×44

W18×40

13

W30×90

W30×90

W27×94

W30×90

W21×101

W30×99

W21×147

W24×104

W14×90

14

W27×114

W30×116

W10×112

W27×129

W10×112

W30×235

W21×147

W27×129

W10×112

15

W8×40

W8×40

W10×39

W8×35

W8×35

W8×31

W14×61

W8×24

W10×22

16

W18×50

W18×50

W16×50

W18×60

W18×50

W24×76

W24×68

W16×40

W21×44

17

W10×68

W21×73

W24×76

W21×83

W12×87

W16×67

W14×82

W14×82

W24×94

18

W24×104

W24×104

W18×97

W24×104

W18×86

W14×99

W14×109

W30×124

W27×102

19

W8×31

W8×31

W8×31

W8×31

W8×31

W10×33

W10×33

W5×19

W6×15

20

W16×45

W14×43

W16×50

W16×40

W16×40

W14×43

W16×40

W18×46

W21×44

21

W14×53

W24×76

W14×53

W21×62

W24×84

W10×60

W18×71

W10×68

W16×57

22

W12×72

W8×31

W14×68

W21×73

W12×53

W14×74

W14×90

W12×72

W12×65

23

W8×31

W8×31

W8×31

W8×31

W8×31

W8×35

W8×48

W8×21

W6×15

24

W16×40

W16×40

W16×40

W16×40

W24×68

W18×50

W16×45

W14×38

W18×40

25

W16×40

W16×40

W14×43

W16×67

W21×68

W16×45

W14×74

W16×57

W18×50

26

W10×54

W10×49

W12×45

W12×53

W10×39

W12×53

W27×129

W10×54

W16×57

27

W8×31

W8×31

W8×31

W10×33

W8×31

W8×40

W12×40

W6×20

W6×15

28

W16×40

W16×40

W16×40

W16×40

W16×40

W16×45

W16×40

W18×35

W18×35

29

W8×31

W8×31

W8×35

W14×53

W24×76

W10×60

W21×83

W8×40

W12×35

30

W8×35

W8×35

W10×33

W12×45

W14×61

W16×67

W14×61

W10×100

W8×28

31

W8×31

W8×31

W10×33

W10×33

W8×31

W8×31

W10×49

W6×20

W6×15

32

W14×43

W14×43

W18×55

W18×55

W24×68

W24×68

W18×65

W16×31

W18×35

247053.34

248226.5

255486.55

264471.82

270204.24

285261.62

300092.65

236959.5

219845.9

50000

50000

50000

50000

50000

50000

50000

29427

27932

Mean

weight (lb)

N/A

N/A

N/A

N/A

N/A

N/A

N/A

257403.46

236434.7

Worst

weight (lb)

N/A

N/A

N/A

N/A

N/A

N/A

N/A

286639.9

258593.1

SD

N/A

N/A

N/A

N/A

N/A

N/A

N/A

21222.31

14016.71

Max ISD

0.00166

0.001715

0.001625

0.001582

0.001556

0.001503

0.001436

0.001786

0.001831

ISDlimit

0.00333

0.00333

0.00333

0.00333

0.00333

0.00333

0.00333

0.00333

0.00333

Best

weight

(kg)

NSA

Max IR

0.9979

1.81

0.9885

0.9647

0.9982

0.9726

0.9887

0.9947

0.9986

IRlimit

Max CV

(%)

1

1

1

1

1

1

1

1

1

None

81

None

None

None

None

None

None

None

The convergence history curves of all algorithms are plotted in Fig. 9. It should be noted

that the number of structural analyses for the EJA is almost half of other methods and this is a

shred of strict evidence that EJA has a great convergence performance compared to all methods

given in Fig 9. Although JA does not converge as fast as ESs [16] and TS [16] methods, it

eventually obtains lighter designs than both.

Figure 11. Comparison of convergence curves for the 224-member braced frame

6. Conclusions

JA is one of the most efficient optimization algorithms using only one simple modification

equation without specific parameters based on approaching the best solution meanwhile getting

away from the worst ones. In this study, the standard formulation of JA was modified in order

to enhance the exploration capacity with less structural analyses and avoid trapping in local

optima also applying a dynamic termination criterion for preventing useless iterations which do

not affect the optimization process.

Frame structures are relatively more complex optimization problems since involving more

parameters and formulations unlike truss structures. In order to tackle the complexity and attain

better solutions, the enhanced Jaya algorithm (EJA) was proposed for the weight minimization

of planar steel frames by size tuning of structural members. To test the validity of the algorithm,

five planar steel frame structures were optimized and the results were compared with those of

optimization methods. Remarkably, EJA found the best design compared to all methods in

every single example and strictly satisfied the constraints. The statistical results indicate that

EJA has better performance than the standard JA and other algorithms in terms of robustness,

convergence speed and feasibility.

The competitive performance of EJA allows the researchers to apply the method to other

engineering problems. Further studies are currently conducted for using EJA in the optimization

of large-scale 3D steel frames with a large number of design variables.

REFERENCES

[1] Henderson, D., Jacobson, S. H., Johnson, A. W., Glover, F., & Kochenberger, G. A. (2003).

Handbook of metaheuristics. Chapter The Theory and Practice of Simulated Annealing, 57, 287-319.

[2] Holland JH . Adaptation in natural and artificial systems. Ann Arbor, MI: Uni- versity of Michigan

Press; 1975

[3] Kennedy J, Eberhart R (1995) Particle swarm optimization. In: Proceedings of IEEE international

conference on neural networks.Perth, Australia, pp 1942–1948

[4] Dorigo M , Maniezzo V , Colorni A . The ant system: optimization by a colony cooperating agents.

IEEE Trans Syst Man Cybern B 1996;1(26):29–41 .

[5] Bozorg Haddad O , Afshar A , Marino MA . Honey bees mating optimization algorithm (HBMO);

a new heuristic approach for engineering optimization. In: Proc. 1st int. conf. on modeling, simulation

and applied optimization (ICMSA0/05), Sharjah, UAE; 2005 February .

[6] Maheri, M. R., Shokrian, H., & Narimani, M. M. (2017). An enhanced honey bee mating

optimization algorithm for design of side sway steel frames. Advances in Engineering Software, 109,

62-72.

[7] Mirjalili, S., & Lewis, A. (2016). The whale optimization algorithm. Advances in engineering

software, 95, 51-67.

[8] Kaveh, A., & Ghazaan, M. I. (2017). Enhanced whale optimization algorithm for sizing optimization

of skeletal structures. Mechanics Based Design of Structures and Machines, 45(3), 345-362.

[9] Van Laarhoven, P. J., & Aarts, E. H. (1987). Simulated annealing. In Simulated annealing: Theory

and applications (pp. 7-15). Springer, Dordrecht.

[10] Geem, Z. W., Kim, J. H., & Loganathan, G. V. (2001). A new heuristic optimization algorithm:

harmony search. simulation, 76(2), 60-68.

[11] Erol, O. K., & Eksin, I. (2006). A new optimization method: big bang–big crunch. Advances in

Engineering Software, 37(2), 106-111.

[12] Kaveh, A., & Mahdavi, V. R. (2014). Colliding bodies optimization: a novel meta-heuristic method.

Computers & Structures, 139, 18-27.

[13] Camp, C. V., Bichon, B. J., & Stovall, S. P. (2005). Design of steel frames using ant colony

optimization. Journal of Structural Engineering, 131(3), 369-379.

[14] Degertekin, S. O. (2008). Optimum design of steel frames using harmony search

algorithm. Structural and multidisciplinary optimization, 36(4), 393-401.

[15] Saka, M. P. (2007). Optimum design of steel frames using stochastic search techniques based on

natural phenomena: a review. Civil computations: tools and techniques, Saxe-Coburg Publications,

Stirlingshire, UK, 105-147.

[16] Hasançebi, O., Çarbaş, S., Doğan, E., Erdal, F., & Saka, M. P. (2010). Comparison of nondeterministic search techniques in the optimum design of real size steel frames. Computers &

structures, 88(17-18), 1033-1048.2

[17] Doğan, E., & Saka, M. P. (2012). Optimum design of unbraced steel frames to LRFD–AISC using

particle swarm optimization. Advances in Engineering Software, 46(1), 27-34.

[18] Carraro, F., Lopez, R. H., & Miguel, L. F. F. (2017). Optimum design of planar steel frames using

the Search Group Algorithm. Journal of the Brazilian Society of Mechanical Sciences and

Engineering, 39(4), 1405-1418.

[19] Farshchin, M., Maniat, M., Camp, C. V., & Pezeshk, S. (2018). School based optimization

algorithm for design of steel frames. Engineering Structures, 171, 326-335.

[20] Rao, R. (2016). Jaya: A simple and new optimization algorithm for solving constrained and

unconstrained

optimization

problems. International

Journal

of

Industrial

Engineering

Computations, 7(1), 19-34.

[21] Gao, K., Zhang, Y., Sadollah, A., & Su, R. (2016). Jaya algorithm for solving urban traffic signal

control problem. In 2016 14th International Conference on Control, Automation, Robotics and Vision

(ICARCV) (pp. 1-6). IEEE.

[22] Wang, L., Zhang, Z., Huang, C., & Tsui, K. L. (2018). A GPU-accelerated parallel Jaya algorithm

for efficiently estimating Li-ion battery model parameters. Applied Soft Computing, 65, 12-20.

[23] Ocłoń, P., Cisek, P., Rerak, M., Taler, D., Rao, R. V., Vallati, A., & Pilarczyk, M. (2018). Thermal

performance optimization of the underground power cable system by using a modified Jaya

algorithm. International Journal of Thermal Sciences, 123, 162-180.

[24] Ding, Z., Li, J., & Hao, H. (2019). Structural damage identification using improved Jaya algorithm

based on sparse regularization and Bayesian inference. Mechanical Systems and Signal Processing, 132,

211-231.

[25] Degertekin, S. O., Lamberti, L., & Ugur, I. B. (2018). Sizing, layout and topology design

optimization of truss structures using the Jaya algorithm. Applied soft computing, 70, 903-928.

[26] Degertekin, S. O., Lamberti, L., & Ugur, I. B. (2019). Discrete sizing/layout/topology optimization

of truss structures with an advanced Jaya algorithm. Applied Soft Computing, 79, 363-390.

[27] LRFD–AISC, Manual of steel construction. Load and resistance factor design. Metric conversion

of the second edition, vol. I & II. AISC; 1999.

[28] ASD-AISC, Manual of steel construction-allowable stress design, 9th ed.,Chicago, Illinois, USA;

1989.

[29] The MathWorks, MATLAB®Version R2017a, 2017, Austin (TX) USA.

[30] Mazzoni, S., McKenna, F., Scott, M. H., & Fenves, G. L. (2006). OpenSees command language

manual. Pacific Earthquake Engineering Research (PEER) Center, 264.

[31] Dumonteil P, Moore, W. Simple Equations for Effective Length Factors-Discussion. Eng J-Am

Inst Steel Constr INC 1993; 30:37–37.

[32] Davison, J. H., & Adams, P. F. (1974). Stability of braced and unbraced frames. Journal of the

Structural Division, 100(2), 319-334.

[33] ASCE 7-05. Minimum design loads for building and other structures; 2005.

[34] Pezeshk S, Camp CV, Chen D. Design of nonlinear framed structures using genetic optimization.

J Struct Eng 2000;126:382–8.