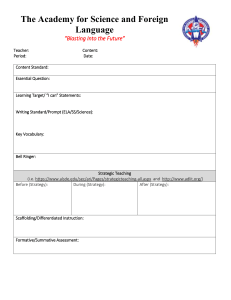

Materials and Design 30 (2009) 2895–2902

Contents lists available at ScienceDirect

Materials and Design

journal homepage: www.elsevier.com/locate/matdes

Effects of grit blasting on surface properties of steel substrates

K. Poorna Chander, M. Vashista, Kazi Sabiruddin, S. Paul, P.P. Bandyopadhyay *

Department of Mechanical Engineering, IIT Kharagpur, Kharagpur, West Bengal 721 302, India

a r t i c l e

i n f o

Article history:

Received 29 October 2008

Accepted 12 January 2009

Available online 20 January 2009

Keywords:

Surface treatments (C)

Scanning electron microscopy (G)

X-ray analysis (G)

Ferrous metals and alloys (A)

Plastic behaviour (F)

a b s t r a c t

Low carbon steel substrates have been grit blasted using alumina grits of various sizes under varying

pressure, time, angle and standoff distances and the corresponding effect on surface roughness and surface residual stress has been studied. The mechanism of material removal in grit blasting has been analyzed. The effect of blasting process parameters on substrate surface residual stress has been studied

using a statistically designed experiment. For this purpose the Barkhausen noise analysis (BNA) of the

blasted surface has been undertaken. Then the BNA results have been calibrated against and complemented using the residual stress values measured using X-ray diffraction. The correlation between BN

signal and the measured residual stress has been studied. The material removal in blasting takes place

by microcutting, indentation or by a mixed mode depending on the blasting angle. During blasting the

alumina grits themselves also undergo erosion. The analysis of the experimental results shows that

the surface roughness increases with grit size, blasting pressure and to an extent with blasting time

and blasting angle as well. The compressive residual stress of the surface and subsurface hardness

increases with blasting pressure and blasting angle. The Barkhausen noise signal has a strong correlation

with the magnitude of the compressive residual stress on the blasted surface.

Ó 2009 Elsevier Ltd. All rights reserved.

1. Introduction

Grit blasting is a process in which angular shaped metallic or

ceramic grits are carried by a pressurised air stream and hurled

against the surface of the work material. The sharp grits erode

the surface and a rough surface suitable for thermal spraying is created. Some of the common grits are alumina grits, silicon carbide

grits, chilled iron grits, etc. It is necessary to make the substrate

rough before thermal spraying so that the coating can stick to

the substrate by mechanical anchorage. Grit blasting is also undertaken to prepare a surface before dip coating the same, using light

metal alloys like Babbitt. It is also a routine procedure for cleaning

the surface of a green sand moulded product.The roughness obtained is dependent on the grit blasting parameters, e.g., blasting

pressure, angle, standoff distance, grit size and type, etc.

The effect of the process parameters of grit blasting on the

roughness of blasted surface has been discussed in the literature

[1–7]. It has been observed that the roughness increases with an

increase in grit blasting pressure and decreases with an increase

in standoff distance. However, below a critical standoff distance

the surface roughness is low. The surface roughness increases with

blasting angle till the angle is around 75°. Material removal in grit

blasting occurs by an erosion process, where mechanisms like

microcutting, ploughing and extrusion are active [2,8,9]. On grit

* Corresponding author. Tel.: +91 3222 282950; fax: +91 3222 282700.

E-mail address: ppb@mech.iitkgp.ernet.in (P.P. Bandyopadhyay).

0261-3069/$ - see front matter Ó 2009 Elsevier Ltd. All rights reserved.

doi:10.1016/j.matdes.2009.01.014

blasting, the surface undergoes work hardening and a nano-grain

region is said to develop on the top layer which has a typical thickness of a few lm. This low cost process is thus possibly capable of

providing a nano-structured top layer on the surface of a ductile

material, wherein the transformation from crystallites to nanocrystallites is not abrupt [10].

A grit blasted surface in general, is under compressive stress.

Mellali et al. [3] has used the curvature method to measure the

compressive residual stress on the grit blasted surface. It has been

found that the stress increases with blasting pressure and grit size.

Other methods suitable for measurement of residual stresses in

ferromagnetic material are X-ray diffraction and Barkhausen noise

analysis (BNA). BNA is a micromagnetic technique of stress measurement which is very suitable for industrial use [11,12]. The

measuring principal is based on the fact that the residual stress

influences the magnetic domains of ferromagnetic materials. A ferromagnetic body consists of ferromagnetic domains having different local magnetization directions. These domains are separated by

boundaries known as Bloch walls. An external magnetic field

causes a change in total magnetization of a ferromagnetic body

undergoing magnetic excitation and initiates the corresponding

Bloch wall movements. These movements can be detected using

a small conductive coil in the form an electric pulse, which is

known as Barkhausen noise (BN). The presence and distribution

of elastic stress in the material influences the Bloch walls to find

the direction of easiest orientation to the lines of magnetic flux.

In other words, residual stress present in a body influences the

2896

K. Poorna Chander et al. / Materials and Design 30 (2009) 2895–2902

Bloch wall movements and consequently, the BN. A tensile stress

registers an increase in BN and a compressive stress shows a decrease. Hence the surface residual stress of a ferromagnetic component can be measured using BNA technique. This is an on-site and

quick method of stress determination.

The objective of the present work has been to study the mechanism of material removal during grit blasting of low carbon steel

using alumina grits. The effect of various grit blasting parameters

on the material removal mechanism, roughness and residual stress

of the grit blasted surface has been investigated. The residual stress

measurement has been undertaken using both X-ray diffraction

and Barkhausen noise analysis. The fact that grit blasting creates

a nano-structured layer has been established.

2. Experimental procedure

The experimental conditions for grit blasting are listed in Table

1. Test coupons of size 25 25 5 mm are sliced from a low carbon steel plate. The samples are held in a vise inside the grit blasting cabinet and the required angle is obtained in the vise. The

nozzle is held in position by a stiffener of adjustable length, using

which the standoff distance between the job and the nozzle can be

set. Once the angle and the standoff distance are fixed, blasting of

the small sample is carried out without moving the nozzle. Blasting

is undertaken on a round area on the centre of the sample and further analysis of the surface, e.g., roughness, X-ray is done on that

area only. The roughness of the grit blasted surfaces has been measured using a Taylor Hobson surtronic 3+ surface roughness tester.

For each data point corresponding to the roughness of grit blasted

surface using a particular combination of process parameters, three

coupons have been grit blasted. Then the roughness measurements

have been taken at four to six places on each sample and an average of these readings taken from all the three samples is reported

in each case. The grit blasted sample has been cross sectioned and

polished metallographically for hardness measurement using a

Leco LM 700 microhardness tester. The hardness has been measured in a direction away from the blasted surface along the thickness of the sample starting from a depth of about 25 lm. A load of

10 gf has been used for each hardness measurement. An average of

six hardness data has been reported. The morphology of the

blasted surface and the grits has been observed using a JEOL JSM

5800 scanning electron microscope. X-ray diffraction of the samples, other than the samples used for stress measurement, has been

done using Co Ka radiation in a Phillips diffractometer (PW 1729

generator, and PW 1710 diffractometer controller). The grain size

of the grit blasted and deformed layer has been estimated using

peak broadening. For measurement of peak broadening two samples have been annealed at 500 °C for 2 h and furnace cooled. Both

of them have been polished again for cleaning the oxide layer and

subsequently only one of them has been grit blasted for 1 min

using grits of mesh 24. Both of these have been used for X-ray diffraction. The annealed and as polished sample has been tested so

that the peak width of the grit blasted sample can be compared

with it.

The Barkhausen noise (BN) measurement has been carried out

with a 100 Hz excitation frequency of the external magnetic field

and 3.5 V magnetizing voltage using commercially available sys-

tem, Rollscan 300 BN. The data acquisition during Barkhausen

noise measurement and the subsequent analysis of the BN signal

have been undertaken using commercially available l-scan software. Fig. 1 shows typical representation of BN superimposed with

external magnetic excitation field. Fig. 2 on the other hand shows

the rectified BN signals for positive and negative magnetization cycles. In the present investigation, rms and peak values of the BN

signals have been employed to characterize the change in the micromagnetic response of the work piece upon grit blasting.

The state of stress of the grit blasted surface has been measured

using X-ray diffraction technique. For this purpose a PW1710 Philips X-ray diffractometer with five tilt angles from 45° to +45° has

been used. Fe has served as the target material. Scan parameters

have been collected using Philips X’pert Data Collector software

with 2h values (2h is the angle between source and diffracted Xray beam) chosen to encompass the Fe Ka doublet for the {2 1 1}

planes, where, 110 6 2h 6 113. The resulting spectra have been

analyzed using Philips X’pert stress software to determine uniaxial

residual stress. The well known sin2 W technique has been used to

obtain absolute stress value, where W is the angle between the surface normal and the bisector of source and diffracted X-ray beam.

Pearson VII technique has been used to calculate the peak position

on the diffracted intensity plots. Young’s modulus and Poisson ratio used for stress calculation are 211.9 GPa and 0.29, respectively.

Effect of process parameters on surface residual stress upon grit

blasting of the substrate material has been studied using statistical

design of experiments. Design of experiment enables along with

regression analysis, development of empirical models relating the

responses with the process parameters with significantly less

number of experiments. In the present investigation blasting pressure, grit size and impingement angle have been chosen as independent controllable parameters as they have significant

contribution towards grit blasting process [13–15].

As an initial attempt a linear first order model has been aimed

with total 13 trials. The levels of independent factors are shown

in Table 2, whereas Table 3 lists the combination of process parameters. The independent variables are in coded form in the developed regression models. It is a case of linear coding. The

measured values of BN parameters (rms and peak value) and surface residual stress obtained from XRD are also listed in this table.

Trial numbers 9–13 indicate the central points which enable estimation of pure experimental error and lack of fit of the model

independently.

3. Results and discussion

Fig. 3a is a secondary electron image of the surface of a low carbon steel test coupon grit blasted for only 5 s using grits of size 24,

standoff distance of 100 mm and blasting angle 20°. This figure

clearly shows traces of microcutting. The sharp edges of the particles cut into the work material, creating a fresh surface, pushing

the metal and folding it at the edge of the microcutting track

[2,9]. This is indicated by superimposing a rectangle in Fig. 3a.

Microcutting continues with blasting time, filling the surface with

microcutting tracks. Fig. 3b, taken after 60 s of blasting time bears

testimony to this fact. In this figure the traces of microcutting have

been shown using arrows. At this low blasting angle as expected,

Table 1

Experimental conditions for grit blasting.

Substrate

Grit type and size

Blasting pressure

(bar)

Stand off distance (mm)

Blasting angle

(°)

Blasting time (s)

Mild steel composition C 0.2%, Mn 0.3%,

P 0.04%, S 0.05%

Alumina, grit size 24, 48

and 60

5, 7

50, 80, 100, 130, 160 and

200

20, 50, 70, 80,

90

15, 30, 60, 90, 120, 150,

180

2897

K. Poorna Chander et al. / Materials and Design 30 (2009) 2895–2902

Fig. 1. The Barkhausen effect signal with excitation field taken from l-scan software.

Fig. 2. Averaged and rectified (positive and negative) impulses.

Table 2

Level of independent variables.

Levels

Low

Centre

High

Coding

Blasting pressure (bar)

Grit size

Blasting angle (°)

1

5

24

40

0

6

40

60

1

7

60

80

the microcutting is the major mechanism of material removal. A

major change in the mechanism of material removal takes place

as the angle of blasting is changed to 90°. Fig. 4a and b is the secondary electron images of a surface grit blasted at 90°. In this case

the grits get embedded in the surface and displace material. This is

also known as material removal by indentation [2]. Fig. 4a is a close

up of a typical indentation mark left on the surface after 5 s of

blasting time. One indentation is immediately followed by others.

The indentations overlap and a rough surface is created. Fig. 4b

shows a large crater created by overlapping indentations. In both

Fig. 4a and b, the indent areas have been identified using letter

‘I’. This mechanism of material removal obviously brings about a

rougher surface as compared to that created using a blasting angle

of 20°.

The grits also undergo surface damage during blasting process.

As such the grit material is brittle. During collision with the substrate the sharp edges of the grits are broken. In addition, collisions

Table 3

Experimental conditions and results for BN measurement and measured residual stresses.

Trial numbers

Blasting pressure (bar)

Grit size

Angle (°)

1

2

3

4

5

6

7

8

9

10

11

12

13

5

7

5

7

5

7

5

7

6

6

6

6

6

24

24

60

60

24

24

60

60

40

40

40

40

40

40

40

40

40

80

80

80

80

60

60

60

60

60

Coding

x1

x2

x3

1

1

1

1

1

1

1

1

0

0

0

0

0

1

1

1

1

1

1

1

1

0

0

0

0

0

1

1

1

1

1

1

1

1

0

0

0

0

0

BN (rms)

BN (peak)

r (MPa)

108

72

90

57

77

55

75

47

59

61

71

75

66

152

97

126

79

104

75

104

67

84

85

96

80

90

282

342

289

350

297

371

328

370

357

350

335

347

353

2898

K. Poorna Chander et al. / Materials and Design 30 (2009) 2895–2902

Fig. 3. Secondary electron image of the surfaces grit blasted using 24 grit size alumina grits at a blasting angle of 20°, standoff distance 100 mm and blasting time: (a) 5 s, (b)

40 s.

Fig. 4. Secondary electron image of the surfaces grit blasted using 24 grit size alumina grits at a blasting angle of 90°, standoff distance 100 mm and blasting time: (a) 5 s, (b)

40 s.

occur between the impacting and ricocheting grits as well. With

each collision grits wear out from the surface by microbrittle fracture. The loss of grit volume is a function of grit usage time. Eventually the grits loose their effectiveness and needs replacement.

Fig. 5a and b is the secondary electron images of a fresh grit and

a grit used for 40 s, respectively. The used grit shows pitting on

the surface as a result of removal of tiny particles from the surface

of the grit owing to microfracturing.

Fig. 6 is the plot showing the variation of surface roughness

against a wide range of blasting time (Fig. 6a), standoff distance

(Fig. 6b) and angle of impact (Fig. 6c), respectively. The roughness

is found to increase as the blasting time (Fig. 6a) is increased from

30 to 60 s and thereafter no significant variation in roughness with

increase in blasting time is recorded. The roughness value is found

to decrease a little when the blasting time approaches 3 min. The

initial increase in roughness is owing to the attack of grits on previously unaffected areas. After some time the surface layer is work

hardened and significant increase in roughness by plastic deformation is not possible. Beyond this point of saturation, with over

blasting, some of the plastically deformed parts and folded over attached chip material (Fig. 3a) are removed, flat areas are created

and there is a decrease in overall surface roughness. All subsequent

blasting trials have been conducted for 1 min only. The roughness

is found to increase initially with standoff distance (Fig. 6b) up to

Fig. 5. Secondary electron images of (a) fresh alumina grit of size 24 and (b) the same grit after 40 s of blasting time.

2899

K. Poorna Chander et al. / Materials and Design 30 (2009) 2895–2902

Ra in microns

Angle of impact 90 degree

SOD 100 mm

Time of blasting 1 min

Grit Alumina

Grit size 24, 48 and 60

5 bar

6

7 bar

4

2

0

10

30

50

70

grit size in mesh no

Fig. 7. Variation of roughness in grit blasted surface with grit size and blasting

pressure.

Fig. 8. Variation of cross sectional hardness of the grit blasted surface along the

thickness of the sample and away from the grit blasted surface.

Fig. 6. Variation of surface roughness of grit blasted mild steel surfaces under a

wide range of variation in (a) blasting time, (b) standoff distance, (c) angle of

impact.

100 mm for this experiment, and no further increase in roughness

has followed a further increase in standoff distance. Below 100 mm

the impacting particles collide with the ricocheting particles

resulting low blasting efficiency [3]. At 130 mm of standoff distance, the kinetic energy of the grits is reduced owing to entrainment of air and flaring of the jet and hence, the corresponding

blasted surface roughness is lower than that that at 100 mm. Beyond 130 mm the roughness value does not show a major change

with a further increase in standoff distance up to 200 mm. It can be

speculated that an increase beyond this standoff distance is likely

to cause a reduction in the roughness value since this standoff distance will correspond to a still lower kinetic energy of the particles

during impact. In subsequent trials a standoff distance of 100 mm

has been used. The roughness is found to increase with blasting angle (Fig. 5c) up to 80°. A further increase in blasting angle to 90° has

caused a decrease in roughness. Blasting at a lower angle causes

material removal mainly by microcutting where in the blasting

particle grazes on the blasted surface keeping the roughness low.

With increase in angle of impact the indentation effect becomes

more predominant. The roughness of an indented surface tends

to be higher. The roughness attains the highest value when the

blasting angle is around 80°. In this regime, a limited microcutting

and mainly indentation mechanisms are active and these two together brings about a change in the geometry of the asperities

keeping the roughness high. The asperities are more hook shaped

when blasted using blasting angle near 80°.

Fig. 7 shows the variation of surface roughness with blasting

pressure and grit size. Blasting has been done under two pressures

5 bar and 7 bar. At a higher blasting pressure the grit velocity is always higher and as a result a higher surface roughness is obtained.

A larger grit on the other hand can bring about more damage and

create larger craters on the blasted surface and hence the roughness is higher with larger grit.

Fig. 8 shows the variation of cross sectional hardness of the grit

blasted surface along the thickness of the sample and away from

the grit blasted surface. The hardness is highest at a point nearest

to the surface and hardness decreases with distance from the surface. Grit blasting involves considerable work hardening of the surface and the high hardness value near the surface is attributed to

this work hardening. The effect of work hardening gradually reduces with distance from the affected surface and hence the hardness also decreases. Under orthogonal impact the degree of

indentation (i.e., plastic deformation) is more than that of the surface blasted using a blasting angle of 60°. As a result the degree of

2900

K. Poorna Chander et al. / Materials and Design 30 (2009) 2895–2902

ð1Þ

peak ¼ 95:5 21:0p 6:75n 12:8h;

ð2Þ

where p is blasting pressure, n is the grit size and h is the blasting

angle.

Tables 4 and 5 provide the ANOVAs for rms and peak values of

BN, respectively. For the purpose of analysis, a confidence level of

95% has been chosen, which means the associated a-error is 0.05. It

is the low probability of finding a significant association amongst

the BN signal and blasting parameters when one does not really exist. F-ratios (Fisher test ratios) of all factors (regression, lack of fit

and process parameters) as obtained have been compared with

the statistical values of F-ratio for 95% level of confidence.

Both the ANOVAs clearly indicate that the blasting pressure and

impingement angles have significant effects on BN parameters as

the F-ratio of corresponding coefficients is significant. On the other

hand, the effect of grit size seems to be statistically insignificant

within the present experimental domain. Earlier investigators have

indicated in case of solid impact erosion significant effect of blasting pressure and angle of impingement on erosion rate [1–3]. Tables 4 and 5 also reveal the insignificance of lack of fit with

respect to pure experimental error.

Fig. 9a and b shows the effect of blasting pressure and impingement angle on rms and peak of BN signal. As the blasting pressure

and impingement angle are increased, there is an associated decrease in the BN parameters. An increase in either pressure or angle

of impingement (towards 90°) increases the momentum of the

individual impacting particle in a direction orthogonal to the

Total

Regression

b1(blasting

pressure)

b2 (grit size)

b3 (blasting

angle)

Error

Lack of fit

Pure error

a

Degree of

freedom

Sum of

square

Mean of

square

F-ratio

(calc.)

F-ratio

(table)

12

3

1

6298.4

5206.4

3507

5249

1735.5

3507

44.4794

89.8847

6.59

7.71

1

1

355.1

1344.2

355.1

1344.2

9.1014

34.4519

7.71

7.71

10

5

4

1092.1

936

156.1

109.2

187.2

39

4.7979

6.26

120

40 degree

60 degree

80 degree

80

rms

rms ¼ 70:2 14:9p 5:37n 9:13h;

Table 5

Summary of ANOVA results for BN (peak).

40

Grit: alumina, 24 mesh

Blasting time 1 min

SOD 100mm

0

4.5

5.5

6.5

7.5

pressure in bar

b

160

40 degree

60 degree

120

Peak

work hardening of the surface under orthogonal impact is higher

and this is reflected in its higher hardness value.

Surface integrity is a term that collectively reflects the state of

stress on surface and subsurface of a component along with information on microhardness, microstructure and presence of other

damages like cracks, etc. Micromagnetic techniques like Barkhausen noise analysis (BNA) can estimate the surface integrity, particularly state of stress and change in hardness and microstructure of

a component [11,12]. Table 3 shows the peak and rms (root mean

square) values of Barkhausen noise (BN) for different combinations

of process parameters used in this experiment. Trial numbers 9–13

are the repeated trials at the central point and they reflect the

repeatability and robustness of the experimental technique. Analysis of variance (ANOVA) has been undertaken to quantitatively

analyze the adequacy of model and significance of each regression

coefficients of the linear models.

Eqs. (1) and (2) are the linear models obtained through regression analysis of the data presented in Table 3. These models exhibit

the effect of process parameters, namely, the blasting pressure, the

grit size in mesh number and the impingement angle on the two

BN parameters under study, namely rms and peak values of BN

signal:

80 degree

80

Grit Alumina, 24 mesh

40

Blasting time 1 min

SOD 100mm

0

4.5

5.5

6.5

7.5

Pressure in bar

Fig. 9. The plot showing the effect of blasting pressure and impingement angle on

(a) rms and (b) peak of BN signal.

Table 4

Summary of ANOVA results for BN (rms).

Total

Regression

b1 (blasting

pressure)

b2 (grit size)

b3 (blasting

angle)

Error

Lack of fit

Pure error

Degree of

freedom

Sum of

square

Mean of

square

F-ratio

(calc.)

F-ratio

(table)

12

3

1

3088.3

2667.4

1770.1

257.4

889.1

1770.1

19.8465

39.511

6.59

7.71

1

1

231.1

666.1

231.1

666.1

5.159

14.868

7.71

7.71

10

5

4

420.9

241.7

179.2

42.1

48.3

44.8

1.0792

6.26

blasted surface. This is expected to provide a larger crater size

and a greater degree of plastic deformation of the blasted surface.

Such plastic deformation of the work material in turn, results compressive residual stress. Compressive residual stresses diminish the

level of BN parameters as shown in Fig. 9a and b.

Further, as stated earlier, a lower angle of impact tends to provide microcutting or scratching actions (Fig. 3). Similar observations have also been reported earlier in solid impact erosion [13–

15] and abrasive water jet machining [16]. Such microcutting action expectedly introduces less compressive stresses than near

orthogonal impacts. This observation is also corroborated from

2901

K. Poorna Chander et al. / Materials and Design 30 (2009) 2895–2902

r ¼ 336:23 þ 29:625p þ 5:625n þ 12:875h;

ð3Þ

where p is pressure, n is grit size and h is the blasting angle.

F-ratio for the coefficient of blasting pressure and impingement

angle indicate their significant association with residual stress.

Also the regression equation is significant in explaining the relationship between process parameters with residual stress. Table

6 also indicates the adequacy of the model by revealing insignificance of lack of fit with respect to pure experimental error. Eqs.

(1)–(3) also show the existence of similarity between significant

coefficients of process parameters on their respective responses.

Fig. 10 demonstrates that the compressive residual stress increases

with an increase in blasting pressure and impingement angle. As

stated before, an increase in these two parameters indicates a rise

in momentum of the impacting particles in a direction orthogonal

to the substrate. This explains a rise in plastic deformation and

residual compressive stress of the substrates. Figs. 11 and 12 exhibit the correlation between BN parameters (rms and peak) and the

induced residual stress. A close almost linear relation between BN

parameters and XRD residual stress measurement has been

established.

Measurement of grit size has been done using Scherer’s

formula:

dg ¼ 0:9 k=ððD2hÞ cos hÞ;

where dg = grain (crystallite) size, k = wavelength of the X-ray in

use, for Co Ka it is 0.161 nm, h = diffraction angle, D2h = full width

half maxima.

Fig. 13 shows the peaks from both the as annealed and the annealed and grit blasted surfaces. The peak corresponding to the grit

blasted surface shows a broadening and a shift. The factors affecting this broadening and shift are grain size, residual stress and

125

100

BN (rms)

Fig. 8, where it is found that a near orthogonal impact brings about

more plastic deformation on a surface and hence a surface with a

greater degree of work hardening and corresponding higher hardness results.

Grit blasted samples have also been characterized using X-ray

diffraction complementing Barkhausen noise analysis. The measured stress values are compressive throughout the experimental

domain. Table 6 presents the ANOVA for residual stress.

Eq. (3) represents the linear model for compressive residual

stress obtained through regression analysis to capture the effect

of process parameters on residual stress:

75

50

Table 6

Anova for residual stress.

Degree of

freedom

Total

Regression

Blasting

pressure

Grit size

Angle

Error

Lack of fit

Pure error

Sum of

square

Mean of

square

12

3

1

370

8600

7021.1

864

2867

7021.1

1

1

10

5

4

253.1

1326.1

1770

1491

279

253.1

1326.1

177

298

70

F-ratio

(calc.)

25

-400

F-ratio

(table)

-350

-300

-250

residual stress (MPa)

41.0715

100.5892

6.59

7.71

3.6264

18.9989

7.71

7.71

4.2714

6.26

Fig. 11. Variation of BN (peak) with residual stress.

175

150

BN (peak)

Compressive residual stress in

MPa

400

370

340

125

100

310

75

80 degree

280

60 degree

40 degree

250

4.5

5.5

6.5

7.5

Pressure in bar

Fig. 10. Variation of residual stress with blasting pressure and impingement angle.

50

-400

-350

-300

residual stress (MPa)

Fig. 12. Variation of BN (rms) with residual stress.

-250

2902

K. Poorna Chander et al. / Materials and Design 30 (2009) 2895–2902

owing to collisions with the target and with other grits. The surface

residual stress of the grit blasted surface has been measured using

both X-ray diffraction and Barkhausen noise analysis techniques.

There is an almost linear correlation between the Barkhausen noise

signal and the measured compressive residual stress of grit blasted

low carbon steel surfaces. Grit blasting has been found to produce a

surface with a compressive residual stress. This stress increases

with both blasting pressure and blasting angle, since these two

parameters brings about a greater degree of plastic deformation

on the surface. Also, upon grit blasting a nano-structured surface

is produced.

10000

as annealed

Intensity (arbitrary units)

annealed and grit blasted

8000

Co K alpha

6000

4000

References

2000

0

50

51

52

53

54

55

Diffraction angle (degree)

Fig. 13. Selective peaks from XRD patterns showing peak broadening of as annealed

and grit blasted low carbon steel surfaces.

instrumental broadening. The as annealed peak also shows a

broadening which is attributed to instrumental broadening only.

The measured grain size of the as annealed sample is found to be

20 lm and that of the grit blasted surface as calculated using

Scherer’s formula after background correction and correction for

instrumental broadening is 80 nm. Hence, it is observed that grit

blasting in this case produces a nano-structured surface [10].

4. Conclusions

In this paper, the mechanism of material removal during grit

blasting of low carbon steel surface using alumina grits of different

sizes has been discussed thoroughly. Two mechanisms, namely,

microcutting and indentation, were identified. The effect of varying

the grit blasting parameters like blasting pressure, blasting angle,

grit size, standoff distance, etc. on the blasted surface roughness

has been addressed. Grit erosion during blasting has been detected.

This attributed to microfracturing of the brittle grit at the surface

[1] Wigren J. Technical note: grit blasting as surface preparation before plasma

spraying. Surf Coat Technol 1988;34(1):101–8.

[2] Griffiths BJ, Gawne DT, Dong G. The erosion of steel surfaces by grit-blasting as

a preparation for plasma spraying. Wear 1996;194(1):95–102.

[3] Mellali M, Grimaud A, Leger AC, Fauchais P, Lu J. Alumina grit blasting

parameters for surface preparation in the plasma spraying operation. Therm

Spray Technol 1997;6(2):217–27.

[4] Amada S, Hirose T. Influence of grit blasting pre-treatment on the adhesion

strength of plasma sprayed coatings: fractal analysis of roughness. Surf

Coatings Technol 1998;102:132–7.

[5] Day J, Huang X, Richards NL. Examination of a grit-blasting process for thermal

spraying using statistical methods. J Therm Spray Technol 2005;14(4):471–9.

[6] Varacalle DJ, Guillen DP, Deason DM, Rhodaberger W, Sampson E. Effect of gritblasting on substrate roughness and coating adhesion. J Therm Spray Technol

2006;15(3):348–55.

[7] Mohammadi Z, Ziaei-Moayyed AA, Sheikh-Mehdi Mesgar A. Grit blasting of Ti–

6Al–4V alloy: optimization and its effect on adhesion strength of plasmasprayed hydroxyapatite coatings. J Mater Process Technol 2007;194:15–23.

[8] Bellman Jr R, Levy A. Erosion mechanism in ductile metals. Wear

1981;70:1–27.

[9] Momber AW, Wong YC, Budidharm RIJE. Hydrodynamic profiling and grit

blasting of low-carbon steel surfaces. Trib Int 2002;35:271–81.

[10] Guan XS, Dong ZF, Li DY. Surface nanocrystallization by sandblasting and

annealing for improved mechanical and tribological properties.

Nanotechnology 2005;16:2963–71.

[11] Tonshoff HK, Friemuth T, Becker JC. Process monitoring in grinding. Ann CIRP

2002;51:551–71.

[12] Brinksmeier E, Schneider E, Theiner WA, Tonshoff HK. Nondestructive testing

for evaluating surface integrity. Ann CIRP 1984;32:489–509.

[13] Bitter JGA. A study of erosion phenomena: Part I. Wear 1963;6:5–21.

[14] Hutchings IM. Deformation of metal-surfaces by oblique impact of square

plates. Int J Mech Sci 1977;19:45–52.

[15] Finnie I. Some observations on the erosion of ductile metals. Wear

1972;19:81–90.

[16] Paul S, Hoogstrate AM, Van Praag R. Abrasive water jet machining of glass fibre

metal laminates. Proc Inst Mech Eng – Part B: J Eng Manuf 2002;216:1459–69.