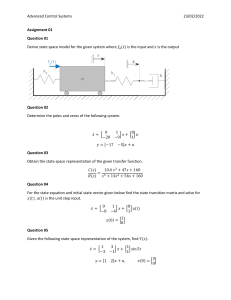

EXPERIMENT ONE DATE: 28/10/2021 TOPIC – Conductors AIM/OBJECTIVE: To familiarize students with different kinds of conductors used for power transmission and distribution APPARATUS/MATERIALS: Insulator used are (pin insulators, shackle and post insulator) THEORY: An electrical insulator is a material in which electric current does not flow freely. The atoms of the insulator have tightly bound electrons which cannot readily move. Other materials— semiconductors and conductors—conduct electric current more easily. The property that distinguishes an insulator is its resistivity; insulators have higher resistivity than semiconductors or conductors. The most common examples are non-metals. A perfect insulator does not exist because even insulators contain small numbers of mobile charges (charge carriers) which can carry current. In addition, all insulators become electrically conductive when a sufficiently large voltage is applied that the electric field tears electrons away from the atoms. This is known as the breakdown voltage of an insulator. Some materials such as glass, paper and PTFE, which have high resistivity, are very good electrical insulators. A much larger class of materials, even though they may have lower bulk resistivity, are still good enough to prevent significant current from flowing at normally used voltages, and thus are employed as insulation for electrical wiring and cables. Examples include rubber-like polymers and most plastics which can be thermoset or thermoplastic in nature. Insulators are used in electrical equipment to support and separate electrical conductors without allowing current through themselves. An insulating material used in bulk to wrap electrical cables or other equipment is called insulation. The term insulator is also used more specifically to refer to insulating supports used to attach electric power distribution or transmission lines to utility poles and transmission towers. They support the weight of the suspended wires without allowing the current to flow through the tower to ground.ductor DIAGRAM: PROCEDURE: Students should identify different kinds of insulator used for transmission and distribution of electric power PRECAUTION: Careful identification is done to distinguish between different types of insulators used for power transmission and distribution OBSERVATION insulators have higher resistivity than semiconductors or conductors. CONCLUSION: Insulators are used in electrical equipment to support and separate electrical conductors without allowing current through themselves. EXPERIMENT TWO DATE: 11/11/2021 TOPIC: Line Support AIM/OBJECTIVE: To demonstrate the use of line support for power transmission and distribution APPARATUS: Charts showing different line support THEORY: The supporting structures for overhead lines conductors are various types of poles and towers. In general the line supports should have the following properties I. II. III. IV. V. High mechanical strength to withstand the weight of conductors and wind load. Light in weight without the loss of mechanical strength. Cheap in cost and economical to maintain. Longer life. Easy accessibility of conductors for maintenance. The line support used for transmission and distribution of electric power are of various types including wooden poles, steel poles, R.C.C poles and lattice steel towers. WOODEN POLE These are made of seasoned wood (sal or chir) and are suitable for lines of moderate cross-sectional area and of relatively shorter spans, say up to 50 meters. Such supports are cheap, easily available, provide insulating properties and, therefore, are widely used for distribution purposes in rural areas. The wooden poles tend to rot below ground level causing foundation failure. In order to prevent this, the portion of the pole below the ground is impregnated with preservative like CREOSOTE OIL The main objections to wooden supports are: I. II. III. IV. V. Tendency to rot below the ground level. Comparatively smaller life (20-25 years). Cannot be used for voltages higher. Less mechanical strength. Require periodical inspection. STEEL POLE Steel pole possesses greater mechanical strength, than longer life and permit longer spans than wooden poles. Such poles are generally used for distribution purposes in the cities. This type of pole need to be galvanized or painted in order to prolong its life. The steel poles are of three types viz (i) rail poles (ii) tubular poles (iii) rolled steel poles. REINFORCED CONCRETE POLES (RCC) The reinforced concrete poles have greater mechanical strength, longer life and permit longer spans than steel poles. The holes in the poles facilitate the climbing of poles and at the same time reduce the weight of line supports. The main difficulty with the use of these poles is the high cost of transport owing to their heavy weight. Hence, such poles are manufactured at the site in order to avoid heavy cost of transportation. STEEL TOWERS In practice, wooden steel and reinforced concrete poles are used for distribution purposes at low voltages, say up to 11kv. For long distance transmission at higher voltage steel towers are used. Steel towers have greater mechanical strength, lager life, can withstand severe climatic conditions and permit the use of longer spans. The risk of interrupted service due to broken or punctured insulation is considerably reduced swing to longer span. Tower footings are usually grounded by driving rods into the earth. This minimizes the lightening troubles as each tower acts as lightening conduct. DIAGRAM: PROCEDURE: Pole stand identification should be done by the students PRECAUTION: Proper identification is done to avoid ambiguity in different types of line support OBSERVATION: Different line supports are used at different stages of electrical power transmission and distribution CONCLUSION: Pole stand serves a major purpose in power transmission and distribution EXPERIMENT THREE DATE: 18/11/2021 TOPIC: Underground Cables AIM/OBJECTIVE: To familiarize students with underground cables APPARTUS: Piece of underground cable (single core, 2-core, 3-core, 4-core) THEORY: An underground cable essentially consists of one or more conductors covered with suitable insulation and surrounded by a protecting cover. Although, several types of cables are available, the type of cable to be used will depend upon the working voltage and service requirements. In general, a cable must fulfill the following requirements: I. The conduct used in underground cable should be tinned stranded copper or aluminum of high conductivity. Stranding is done so that conductor may become flexible and carry more current. II. The conductor size should be such that the cable carries the desired load current without overheating and causes voltage drop within permissible limits. III. The cable must have proper thickness of insulation in order to give high degree of safety and reliability of voltage for which it is designed. IV. The cable must be provided with suitable mechanical protection so that it may withstand the rough use in laying it. V. The cable should have complete chemical and physical stability throughout. CONSTRUCTION a. CORE OR CONDUCTOTOR: a cable may one or more than one core (conductor) depending upon the type of service for which it is intended. The conductors are made of tinned copper or aluminum and are usually stranded in order to provide flexibility to the cable. b. INSULATION: each core or conductor is provided with a suitable thickness of insulation, the thickness of layer depending upon the voltage to be withstood by the cable. The commonly used materials for insulation are impregnated paper, varnished cambric or rubber mineral compound. c. METALLIC SHEATH: in order to protect the cable from moisture, gases or other damaging liquids (acids or alkaline) in the soil and atmosphere, a metallic sheath of lead or aluminum is provided over the insulation. d. BEDDING: over the metallic sheath is applied a layer of bedding which consists of a fibrous material like jute or hessian tape. The purpose is to protect the metallic sheath against corrosion and from other mechanical injury due to armouring. e. ARMOURING: over the bedding, armouring is provided which consists of one or two layers of galvanized steel wire or steel tape. Its purpose is to protect the cable from mechanical injury while laying it and during the course of handling. Armouring may not be done in the case of some cables. f. SERVING: in order to protect armouring from atmospheric conditions, layer of fibrous material (like jute) similar to bedding is provided over the armouring. In general bedding, armouring and serving are only applied to the cables for the protection of conductor insulation and to protect the metallic sheath from mechanical injury. DIAGRAM: PROCEDURE: Students are required to identify different layers of underground cables PRECAUTION: I ensured proper identification of different layers of underground cables OBSERVATION: Underground cables have several cores used for different purposes It has different layers that protects the conductor CONCLUSION: Electric power can be transmitted or distributed either by overhead system or underground cables