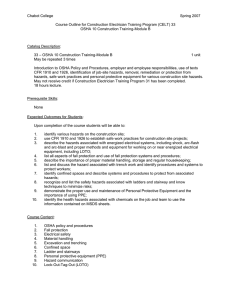

Handbook of OSHA Construction Safety and Health, Second Edition

advertisement